Abstract

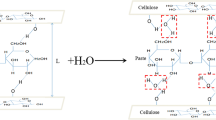

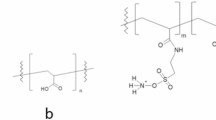

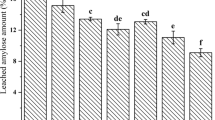

Acrylic acid (AA)/methyl acrylate (MA)-modified starch was prepared via a catalytic process involving horseradish peroxidase (HRP)/acetylacetone (ACAC) as an initiation system. The structural analysis results demonstrated that the grafting of AA and MA onto starch was successful. Furthermore, the impact of the grafting reaction conditions on the grafting effect and the characteristics of the resulting grafted products were also examined. The results demonstrated that AA and MA were successfully grafted onto starch. The optimal conditions for starch grafting with AA/MA were identified as a reaction time of 4 h, an HRP enzyme concentration of 12 U/mL, a total monomer/starch ratio of 4:6, and a molar ratio of AA/MA feeding of 3:7. The viscosity and viscoelasticity of the modified starch slurry increased, and the film-forming property was enhanced. Compared with the original starch film, the modified film markedly increased the flexibility and tensile strength. Furthermore, an increased acrylic acid content maintained the original hydrophilicity of the modified starch film.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lee H, Choi S, Kim J, Lee K. An experimental investigation on mechanical fatigue property of chemical starch-based ER fluids. J Intel Mat Syst Str. 2002;13:629 https://doi.org/10.1177/1045389X02013010004.

Chen ND. Soochow University. TS103.846, SuZhou, 2012, https://doi.org/10.7666/d.y2122174.

Cheng DS, Yu W, Wang S. Manufacture and property of Co60 Co-radiation grafted starch. Cotton Textile Technol. 2010; 4. https://doi.org/10.3969/j.issn.1001-7415.2010.02.001.

Tan M, Xie J, Yang W, Xu D. Study of starch graft copolymerization initiation system. Ind Catal. 2005; 3. https://doi.org/10.3969/j.issn.1008-1143.2005.z1.088.

Mostafa KM. Graft polymerization of acrylic acid onto starch using potassium permanganate acid (redox system). J Appl Polym Sci. 1995;56:263 https://doi.org/10.1002/app.1995.070560217.

Wang S, Cheng D, Yu W. Analysis of the effect of Co-60 radiation modification on starch. China Textile Leader. 2008; 109. https://doi.org/10.3969/j.issn.1003-3025.2008.10.024.

Yu F, Yao S. Ultraviolet photoinitiation of starch grafted with acrylonitrile (I). Polym Mater Sci Eng. 1998;02:32. https://doi.org/10.16865/j.cnki.1000-7555.1998.02.009.

Shen S, Zhu Z, Liu F. Introduction of poly[(2-acryloyloxyethyl trimethyl ammonium chloride)-co-(acrylic acid)] branches onto starch for cotton warp sizing. Carbohydr Polym. 2016;138:280–9. https://doi.org/10.1016/j.carbpol.2015.11.058.

Xu L, Yang C, Duan B, Jiang C. Lipase-catalyzed synthesis of starch/polycaprolactone graft copolymers. Polym Mater Sci Eng. 2009;25:34. https://doi.org/10.3321/j.issn:1000-7555.2009.07.010.

Chen FD. Jiangnan University. O636.12, 2009, https://doi.org/10.7666/d.y1584271.

Lv S, Ma Y, Liu G, Hou M, Yan X, Gong R. pH control method for HRP-catalysed polymerization of sodium p-hydroxybenzenesulphonate and its applications. China Leather. 2011;40:5. https://doi.org/10.13536/j.cnki.issn1001-6813.2011.05.013.

Lv S, Sun T, Zhou Q, Liu J, Ding H. Synthesis of starch-gp (DMDAAC) using HRP initiation and the correlation of its structure and sludge dewaterability. Carbohyd Polym. 2014;103:285. https://doi.org/10.1016/j.carbpol.2013.12.036.

Wang S, Wang Q, Xu J, Fan X, Wang P. Preparation and its sizing properties of starch-poly(methyl acrylate) size catalyzed by horseradish peroxidase. J Text Res. 2017;38:6 https://doi.org/10.13475/j.fzxb.20160703006.

Liu G, Lv S, Ma Y. Preparation and properties of HRP-catalysed starch-acrylamide graft copolymers. China Leather. 2010; 5. https://doi.org/10.13536/j.cnki.issn1001-6813.2010.05.002.

Wang S, Xu J, Wang Q, Fan X, Yu Y, Wang P, et al. Preparation and rheological properties of starch-g-poly (butyl acrylate) catalyzed by horseradish peroxidase. Process Biochem. 2017;59:104 https://doi.org/10.1016/j.procbio.2017.01.014.

Shogren RL, Willett JL, Biswas A. HRP-mediated synthesis of starch–polyacrylamide graft copolymers. Carbohyd Polym. 2009;75:189 https://doi.org/10.1016/j.carbpol.2008.07.004.

Xu S, Fan X, Wang Q, Xu J. Preparation and properties of binary grafted starch modified by horseradish peroxidase. N Chem Mater. 2019;47:5. https://doi.org/CNKI:SUN:HGXC.0.2019-08-049.

Liu Z, Jiang H. Synthesis of water-soluble sodium and methyl acrylate copolymers and study of their dispersion properties. Appl Chem Ind. 2009;38:4. https://doi.org/10.16581/j.cnki.issn1671-3206.2009.03.010.

Biller P, Ross A. Pyrolysis GC–MS as a novel analysis technique to determine the biochemical composition of microalgae. Algal Res. 2014;6:91. https://doi.org/10.1016/j.algal.2014.09.009.

Zhang Y, Gu Z, Hong Y, Li Z, Cheng L. Pasting and rheologic properties of potato starch and maize starch mixtures. Starch-Starke. 2011;63:11 https://doi.org/10.1002/star.200900255.

Angles MN, Dufresne A. Plasticized starch/tunicin whiskers nanocomposites. 1. Structural analysis. Macromolecules. 2000;33:8344. https://doi.org/10.1021/MA0008701.

Liu M, Wu J, Xie Y. Study on the pattern of graft copolymerization reaction between butyl acrylate and potato starch. Polym Mater Sci Eng. 1993;9:5. https://doi.org/10.1007/BF02943552.

Hu C, Lv T, Zhang Y. Synthesis of polymeric chelating agents by starch-grafted methyl acrylate and ethylenediamine. Chin J Chem. 2007;24:716. https://doi.org/10.3969/j.issn.1000-0518.2007.06.025.

Fan H, Chen Z. Synthesis and characterization of starch/DMDAAC-AM graft copolymers. Polym Mater Sci Eng. 2002;18:62. https://doi.org/10.16865/j.cnki.1000-7555.2002.05.014.

Braun D, Czerwinski W, Disselhoff G, Tüdős F, Kelen T, Turcsányi B. Analysis of the linear methods for determining copolymerization reactivity ratios, VII. A critical reexamination of radical copolymerizations of styrene. Angew Makromol Chem. 1984;125:161. https://doi.org/10.1002/apmc.1984.051250112.

Gao Y, Wang L. Cracking chromatography/mass spectrometry study of acrylic emulsion polymers. Paint Coat Ind. 1993; 4. CNKI:SUN:TLGY.0.1993-06-013.

Tang D, Wang W. Cracking gas chromatography-mass spectrometry study of acrylic resins. China Coat. 2013; 5. https://doi.org/10.13531/j.cnki.china.coatings.2013.04.007.

Wu J, Zhang G, Xue S, Jiang L. Pyrolysis mechanism of acrylate polymers by cracking-gas chromatography-mass spectrometry technique. Polym Mater Sci Eng. 1987; 80. https://doi.org/10.16865/j.cnki.1000-7555.1987.05.014.

Li H, Li M, Wang X. Synthesis and application of starch/BA-VAc graft copolymer. Polym Mater Sci Eng. 1997;13:4. https://doi.org/10.16865/j.cnki.1000-7555.1997.01.031.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (2021YFC2104000). We are grateful for the support from the International Joint Research Laboratory for Eco-Textile Technology at Jiangnan University.

Author information

Authors and Affiliations

Contributions

Wenda Wang: Conceptualization, methodology, software, formal analysis, investigation, and writing—original draft. Qiang Wang: Conceptualization, methodology, validation, resources, supervision, and writing—review & editing. Ping Wang: Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Wang, Q. & Wang, P. Research on the preparation and performance of acrylic acid/methyl acrylate-modified starch catalyzed by an HRP binary initiation system. Polym J 57, 189–201 (2025). https://doi.org/10.1038/s41428-024-00982-x

Received:

Revised:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41428-024-00982-x