Abstract

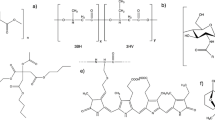

This study is about the fabrication and evaluation of a new green composite made from the tree bark of the Yakushima Jisugi tree and polybutylene succinate (PBS) polymer. The tensile properties and biodegradability of the composite were evaluated, including a 6-month-long soil burial test. The tensile strength of the composite was not as high as that of neat PBS since the bark content was high at 60 wt.%. In compost, the composite degraded by about 13% in 8 weeks. The composite also displayed biodegradability in outdoor soil, which was evaluated by measuring changes in tensile and thermal properties. The tensile modulus, strength, and elongation at break deteriorated, and the melting point decreased as soil burial progressed, eventually reaching a melting point 2 °C lower than the as-fabricated specimen after 30 weeks of burial. Furthermore, by combining the tensile data from the biodegradation experiments in compost and soil, it was estimated that the composite degraded by about 5% during 30 weeks of soil burial. A theoretical framework based on random chain-scission kinetics was introduced to rationalize the experimentally observed exponential relationship between increased degree of biodegradation and decrease in tensile strength, providing a description of tensile strength deterioration as a function of material degradation. Due to the material’s excellent biodegradability, it has potential applications in agriculture and as a component in time-programmed devices that self-disintegrate after being discarded. In addition, partial discharge testing revealed that the composite exhibited sufficient initial dielectric strength, further supporting its potential for transient applications such as biodegradable sensors or disposable electronic packaging.

Similar content being viewed by others

Data availability

The datasets generated and analysed during the current study are available from the corresponding author upon reasonable request.

References

Naderi Kalali, E. et al. A critical review of the current progress of plastic waste recycling technology in structural materials. Curr. Opin. Green. Sustain. Chem. 40, 100763 (2023).

Ziani, K. et al. Microplastics: a real global threat for environment and food safety: a state of the art review. Nutrients 15, 617 (2023).

Omura, T. et al. Microbial decomposition of biodegradable plastics on the deep-sea floor. Nat. Commun. 15, 568 (2024).

Xu, J. & Guo, B.-H. Poly(butylene succinate) and its copolymers: research, development and industrialization. Biotechnol. J. 5, 1149–1163 (2010).

Zini, E. & Scandola, M. Green composites: an overview. Polym. Compos. 32, 1905–1915 (2011).

Lettner, M., Schöggl, J.-P. & Stern, T. Factors influencing the market diffusion of bio-based plastics: results of four comparative scenario analyses. J. Clean. Product. 157, 289–298 (2017).

Platnieks, O., Gaidukovs, S., Thakur, K. V., Barkane, A. & Beluns, S. Bio-based poly (butylene succinate): recent progress, challenges and future opportunities. Eur. Polym. J. 161, 110855 (2021).

Alkandary, A. & Netravali, N. A. Hybrid green composites using rice straw and jute fabric as reinforcement for soy protein-based resin. Compos. B 256, 110626 (2023).

Guangul, A. H., Prabhakar, N. M., Lee, W. D. & Song, J.-I. Development of hybrid green composites by dual natural fibers (jute/bamboo) reinforcement and investigation of their mechanical behavior. Polym. Compos. 45, 8225–8235 (2024).

Elbasiouny, H. et al. Agricultural waste management for climate change mitigation: some implications to Egypt. In Waste Management in MENA Regions. Springer Water (eds Negm, A., Shareef, N.) 149–169 (Springer, Cham, 2020).

Totaro, G. et al. A. Formulation of green particulate composites from PLA and PBS matrix and wastes deriving from the coffee production. J. Polym. Environ. 27, 1488–1496 (2019).

Sangilimuthukumar, J. et al. The use of pineapple fiber composites for automotive applications: a short review. J. Mater. Sci. Res. Rev. 3, 367–373 (2020).

Sirichalarmkul, A. & Kaewpirom, S. Enhanced biodegradation and processability of biodegradable package from poly(lactic acid)/poly(butylene succinate)/rice-husk green composites. J. Appl. Polym. Sci. 138, 50652 (2021).

Aliotta, L., Seggiani, M., Lazzeri, A., Gigante, V. & Cinelli, P. A brief review of poly (butylene succinate) (PBS) and its main copolymers: synthesis, blends, composites, biodegradability, and applications. Polymers 14, 844 (2022).

Frollini, E., Bartolucci, N., Sisti, L. & Celli, A. Biocomposites based on poly(butylene succinate) and curaua: Mechanical and morphological properties. Polym. Test. 45, 168–173 (2015).

Vorawongsagul, S., Pratumpong, P. & Pechyen, C. Preparation and foaming behavior of poly (lactic acid)/poly (butylene succinate)/cellulose fiber composite for hot cups packaging application. Food Packag. Shelf Life 27, 100608 (2021).

Rova, L., Kokubo, J., Wang, Z., Kurita, H. & Narita, F. Transforming tree bark waste into a green composite: tensile properties and biodegradability. J. Compos. Sci. 8, 465 (2024).

Giannotas, G., Kamperidou, V. & Barboutis, I. Tree bark utilization in insulating bio-aggregates: a review. Biofuels Bioprod. Bioref. 15, 1989–1999 (2021).

ISO 14855-2: Determination of the Ultimate Aerobic Biodegradability of Plastic Materials Under Controlled Composting Conditions—Method by Analysis of Evolved Carbon Dioxide. Part 2: Gravimetric Measurement of Carbon Dioxide Evolved in a Laboratory-Scale Test (International Organization for Standardization: Geneva, Switzerland, 2018).

ASTM D5338-15: Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials Under Controlled Composting Conditions, Incorporating Thermophilic Temperature (ASTM International: West Conshohocken, United States of America, 2021).

ISO 17556: Plastics — Determination of the Ultimate Aerobic Biodegradability of Plastic Materials in Soil by Measuring the Oxygen Demand in a Respirometer or the Amount of Carbon Dioxide Evolved (International Organization for Standardization: Geneva, Switzerland, 2019).

Ibrahim, H., Mehanny, S., Darwish, L. & Farag, M. A comparative study on the mechanical and biodegradation characteristics of starch-based composites reinforced with different lignocellulosic fibers. J. Polym. Environ. 26, 2434–2447 (2018).

Wang, H., Wei, D., Zheng, A. & Xiao, H. Soil burial biodegradation of antimicrobial biodegradable PBAT films. Polym. Degrad. Stabil. 116, 14–22 (2015).

Schirp, A., Deetz, R., Kopitzky, R. & Schirp, C. Composite sheets based on polylactic acid and sugar beet pulp: a solution to accelerate biological degradation of PLA on soil under outdoor exposure. Polym. Compos. 45, 15318–15339 (2024).

Rova, L., Gallet-Pandellé, A., Wang, Z., Kurita, H. & Narita, F. Japanese washi-paper-based green composites: Fabrication, mechanical characterization, and evaluation of biodegradability. Compos. A 184, 108261 (2024).

Barczewski, M., Sałasińska, K. & Szulc, J. Application of sunflower husk, hazelnut shell and walnut shell as waste agricultural fillers for epoxy-based composites: a study into mechanical behavior related to structural and rheological properties. Polym. Test. 75, 1–11 (2019).

Andrzejewski, J., Barczewski, M. & Szostak, M. Injection molding of highly filled polypropylene-based biocomposites. buckwheat husk and wood flour filler: a comparison of agricultural and wood industry waste utilization. Polymers 11, 1881 (2019).

Zhang, Q. et al. Biochar filled high-density polyethylene composites with excellent properties: towards maximizing the utilization of agricultural wastes. Ind. Crops Products 146, 112185 (2020).

Zhao, J.-H. et al. Biodegradation of poly(butylene succinate) in compost. J. Appl. Polym. Sci. 97, 2273–2278 (2005).

Kim, J. et al. Comparative degradation behavior of polybutylene succinate (PBS), used PBS, and PBS/Polyhydroxyalkanoates (PHA) blend fibers in compost and marine–sediment interfaces. Sustain. Mater. Technol. 41, e01065 (2024).

McCoy, J. B. & Madras, G. Degradation kinetics of polymers in solution: dynamics of molecular weight distributions. AIChE J. 43, 802–810 (1997).

Flory, J. P. Tensile strength in relation to molecular weight of high polymers. J. Am. Chem. Soc. 67, 2048 (1945).

Berry, P. J. Fracture processes in polymeric materials. V. Dependence of the ultimate properties of poly(methyl methacrylate) on molecular weight. J. Polym. Sci. A 2, 4069–4076 (1964).

Ward, M. I. & Sweeney, J. Tensile Properties of Solid Polymers 3rd edn (John Wiley & Sons: Chichester, UK, 2013).

Schmidt, K. S., Simkins, S. & Alexander, M. Models for the Kinetics of Biodegradation of organic compounds not supporting growth. Appl Environ. Microbiol. 50, 323–331 (1985).

Rakesh, S. et al. Carbon mineralization rates and kinetics of surface-applied and incorporated rice and maize residues in entisol and inceptisol soil types. Sustainability 13, 7212 (2021).

Callister, D. W. & Rethwisch, G. D. Materials Science and Engineering: An Introduction 9th edn (Wiley: Hoboken, NJ, USA, 2014).

Dilkes-Hoffman, S. L., Lant, A. P., Laycock, B. & Pratt, S. The rate of biodegradation of PHA bioplastics in the marine environment: a meta-study,. Mar. Pollut. Bull. 142, 15–24 (2019). ISSN 0025-326X.

Wang, G. X., Huang, D., Ji, J. H., Völker, C. & Wurm, F. R. Seawater-degradable polymers—fighting the marine plastic pollution. Adv. Sci. 8, 2001121 (2021).

Eckel, F., Opdenbosch, V. D., Schandl, S. K. & Zollfrank, C. Dependency of tensile properties and biodegradation on molecular mass during hydrolysis of poly(butylene succinate). npj Mater. Degrad. 8, 97 (2024).

Barletta, M. et al. Poly(butylene Succinate) (PBS): materials, processing, and industrial applications. Prog. Polym. Sci. 132, 101579 (2022).

Vasile, C. et al. Study of the soil burial degradation of some PLA/CS biocomposites. Compos. B 142, 251–262 (2018).

Odusanya, S. A. et al. Preliminary studies on microbial degradation of plastics used in packaging potable water in Nigeria. Niger. Food J. 31, 63–72 (2013).

Schulte, M. P., Podrabsky, E. J., Stillman, H. J. & Tomanek, L. The effects of temperature on aerobic metabolism: towards a mechanistic understanding of the responses of ectotherms to a changing environment. J. Exp. Biol. 218, 1856–1866 (2015).

Pischedda, A., Tosin, M. & Degli-Innocenti, F. Biodegradation of plastics in soil: the effect of temperature,. Polym. Deg. Stab. 170, 109017 (2019).

Merijs-Meri, R. et al. Melt-processed polybutylene-succinate biocomposites with chitosan: development and characterization of rheological, thermal, mechanical and antimicrobial properties. Polymers 16, 2808 (2024).

Signori, F., Pelagaggi, M., Bronco, S. & Righetti, C. M. Amorphous/crystal and polymer/filler interphases in biocomposites from poly(butylene succinate). Thermochim. Acta 543, 74–81 (2012).

Rova, L. et al. Designed to disintegrate: a mechanical framework for bio-based biodegradable polymer composites. Mech. Eng. 1, 010802 (2026).

Eckert, M. & Pihera, J. Partial discharge measurement at pulse voltage: design of a measurement circuit and its components. In Proc. 2024 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic. 01–05 https://doi.org/10.1109/Diagnostika61830.2024.10693904. (2024).

Lee, H.-G., Park, D., An B. & Kim, J. Characteristics of partial discharge under AC and DC using artificial defects. In Proc. 2024 10th International Conference on Condition Monitoring and Diagnosis (CMD), Gangneung, Korea, Republic of. 633–636 (Institute of Electrical and Electronics Engineers, 2024).

Acknowledgements

This work was supported by JSPS KAKENHI Grant Number 25KJ0588 (Grant-in-Aid for JSPS Fellows). The authors would like to thank Mr. Hidenobu Ieyama of Channel Original Co., Ltd. who provided the bark which was used in this study.

Author information

Authors and Affiliations

Contributions

Lovisa Rova (L.R.), Zhenjin Wang (Z.W.), Hiroki Kurita (H.K.), Fumio Narita (F.N.). Conceptualization: H.K., F.N.; Data curation: L.R.; Formal analysis: L.R.; Funding acquisition: L.R.; Investigation: L.R., Z.W.; Methodology: Z.W., H.K., F.N.; Project administration: F.N.; Resources: L.R.; Supervision: F.N.; Validation: Z.W., H.K.; Visualization: L.R.; Writing – original draft: L.R.; Writing – review and editing: Z.W., H.K., F.N.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rova, L., Wang, Z., Kurita, H. et al. Evaluating and interpreting biodegradability of a tree bark–based green composite through tensile properties. npj Mater Degrad (2026). https://doi.org/10.1038/s41529-026-00740-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-026-00740-9