Abstract

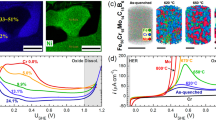

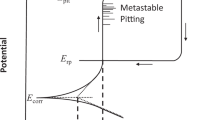

In this work, a flow-through electrochemical–ICP-AES platform for operando monitoring of pitting corrosion on the CoCrFeMnNi high-entropy alloy is introduced. This setup combines localized chloride injection, potentiostatic control, and online, element-resolved dissolution analysis, thereby addressing a long-standing gap in mechanistic studies of early pit initiation and repassivation. Experiments in 0.5 M H2SO4 with Cl- injection enabled the continuous transfer of dissolved species from the electrode surface to the ICP-AES detector, achieving sub-ppb sensitivity and allowing quantification of Co, Cr, Fe, Mn, and Ni dissolution rates during the pitting process. The results reveal four characteristic stages, namely, incubation, initiation, propagation, and repassivation, with subtle but systematic differences between alloying elements. Co and Fe contribute slightly more during initiation, while Cr plays a dominant role during repassivation, reflecting its critical involvement in passive film regeneration. Charge analysis demonstrates that repassivation consumes a quantity of charge far greater than expected for compact passive films, pointing instead to a slow, iterative re-formation and partial dissolution of hydrated oxides. This methodology provides new mechanistic insight into the dynamic sequence of film breakdown, localized dissolution, and film repair in multicomponent alloys, and establishes a versatile framework for studying localized corrosion processes with element-specific resolution.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during this study are not publicly available due to their use in an ongoing work, but are available from the corresponding authors on reasonable request.

References

George, E. P., Raabe, D. & Ritchie, R. O. High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019).

Tsai, M.-H. & Yeh, J.-W. High-entropy alloys: A critical review. Mater. Res. Lett. 2, 107–123 (2014).

Ye, Y. F., Wang, Q., Lu, J., Liu, C. T. & Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 19, 349–362 (2016).

Miracle, D. B. & Senkov, O. N. A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017).

Hsu, W.-L., Tsai, C.-W., Yeh, A.-C. & Yeh, J.-W. Clarifying the four core effects of high-entropy materials. Nat. Rev. Chem. 8, 471–485 (2024).

Luo, H., Li, Z., Mingers, A. M. & Raabe, D. Corrosion behavior of an equiatomic CoCrFeMnNi high-entropy alloy compared with 304 stainless steel in sulfuric acid solution. Corros. Sci. 134, 131–139 (2018).

Hou, Y. et al. On the corrosion resistance of the CoCrFeMnNi high entropy alloys in chloride-containing sulfuric acid solutions. Appl. Surf. Sci., 681. https://doi.org/10.1016/j.apsusc.2024.161487 (2025).

Fu, Y., Li, J., Luo, H., Du, C. & Li, X. Recent advances on environmental corrosion behavior and mechanism of high-entropy alloys. J. Mater. Sci. Technol. 80, 217–233 (2021).

Y. Shi, Yang, B. & Liaw, P. Corrosion-resistant high-entropy alloys: A review, Metals, 7 (2017). https://doi.org/10.3390/met7020043.

Qiu Y., Thomas, S., Gibson, M. A., Fraser, H. L. & Birbilis N. Corrosion of high entropy alloys. npj Mater. Degradation, 1 https://doi.org/10.1038/s41529-017-0009-y (2017).

Liang, J. et al. Corrosion resistance and mechanism of high-entropy alloys: A review. Mater. Corros. 75, 424–432 (2024).

Song, G., Fu, D., Lin, Y., Ma, L. & Zhang, D. Corrosion resistance prediction of high-entropy alloys: framework and knowledge graph-driven method integrating composition, processing, and crystal structure, npj Mater. Degradation, 9. https://doi.org/10.1038/s41529-025-00632-4 (2025).

Wang, X. et al. Effects of chloride ions on passive oxide films formed on Cr-Fe-Co-Ni(-Mo) multi-principal element alloy surfaces. J. Electrochem. Soc. 170, 041506 (2023).

Wang, X. et al. Enhanced passivity of Cr-Fe-Co-Ni-Mo multi-component single-phase face-centred cubic alloys: Design, production and corrosion behaviour. Corros. Sci. 200. https://doi.org/10.1016/j.corsci.2022.110233 (2022).

Hou, Y. et al. Generation of pits on CoCrFeMnNi high entropy alloy: an electrochemical impedance study of a single event. Electrochim. Acta, 526. https://doi.org/10.1016/j.electacta.2025.146193 (2025).

Aouina, N. et al. Initiation and growth of a single pit on 316L stainless steel: Influence of SO4 2- and ClO4- anions. Electrochim. Acta 104, 274–281 (2013).

Aouina, N. et al. A flow microdevice for studying the initiation and propagation of a single pit. Corros. Sci. 62, 1–4 (2012).

Heurtault, S., Robin, R., Rouillard, F. & Vivier, V. On the propagation of open and covered pit in 316l Stainless Steel. Electrochim. Acta 203, 316–325 (2016).

Heurtault, S., Robin, R., Rouillard, F. & Vivier, V. Initiation and propagation of a single pit on stainless steel using a local probe technique. Faraday Discuss 180, 267–282 (2015).

Ogle, K. & Weber, S. Anodic dissolution of 304 stainless steel using atomic emission spectroelectrochemistry. J. Electrochem. Soc. 147, 1770 (2000).

Ogle, K., Tomandl, A., Meddahi, N. & Wolpers, M. The alkaline stability of phosphate coatings I: ICP atomic emission spectroelectrochemistry. Corros. Sci. 46, 979–995 (2004).

Ogle, K. Atomic emission spectroelectrochemistry: Real-time rate measurements of dissolution, corrosion, and passivation. Corrosion 75, 1398–1419 (2019).

Nishimoto, M., Kollender, J. P., Muto, I. & Hassel, A. W. In situ ICP-MS analysis of passivation process and selective dissolution of Fe-15Cr alloy in sulfuric acid. Corros. Sci. 249. https://doi.org/10.1016/j.corsci.2025.112846 (2025).

Gharbi, O. et al. On the corrosion of additively manufactured aluminium alloy AA2024 prepared by selective laser melting. Corros. Sci. 143, 93–106 (2018).

Mukhametzianova, G. et al. Mapping elemental solutes at sub-picogram levels during aqueous corrosion of Al alloys using diffusive gradients in thin films (DGT) with LA-ICP-MS. Anal. Bioanal. Chem. 416, 3373–3388 (2024).

Wiesener, M., Schinkinger, B. & Grundmeier, G. Complementary in-situ electrochemical ICP-OES and corrosion studies of hot-formed zinc alloy coated steel. Mater. Corros. 66, 1198–1205 (2015).

Qiu, Y. et al. Real-time dissolution of a compositionally complex alloy using inline ICP and correlation with XPS npj Mater. Degradation 4. https://doi.org/10.1038/s41529-020-0112-3 (2020).

Lebouil, S., Gharbi, O., Volovitch, P. & Ogle, K. Mg dissolution in phosphate and chloride electrolytes: Insight into the mechanism of the negative difference effect. Corrosion 71, 234–241 (2015).

Sur, D. et al. Investigating the synergistic benefits of Al on Cr(III) in the passive films of FeCoNi-Cr-Al CCAs in sulfuric acid. Electrochim. Acta 513. https://doi.org/10.1016/j.electacta.2024.145523 (2025).

Xie, C., Han, J., Sun, F. & Ogle, K. Deciphering the role of alloying elements in spontaneous passivation by element-resolved electrochemistry: From pure metals to equiatomic CoCrFeNi. Electrochim. Acta 526. https://doi.org/10.1016/j.electacta.2025.146177 (2025).

Acknowledgements

The authors acknowledge the support of the Center National de la Recherche Scientifique (CNRS) and the funding from the ANR (ANR-20-CE08-0031) – project TAPAS.

Author information

Authors and Affiliations

Contributions

**Y.H.**: Methodology, Investigation, Conceptualization, Data curation, Validation, Formal analysis, Writing—original draft, Writing—review & editing.**C.X., D.S.R.R.:** Investigation, Data curation, Writing—review & editing.**F.S., O.G., M.T., K.O., V.V.:** Supervision, Project administration, Conceptualization, Methodology, Data curation, Validation, Formal analysis, Writing—original draft, Writing—review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests. O.G. and V.V. are guest editors for npj Materials Degradation. None of them were involved in the journal’s review of this manuscript.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hou, Y., Gharbi, O., Xie, C. et al. Tracking element-specific dissolution during pitting corrosion: an operando ICP-AES–electrochemical study of the CoCrFeMnNi Cantor alloy. npj Mater Degrad (2026). https://doi.org/10.1038/s41529-026-00747-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-026-00747-2