Abstract

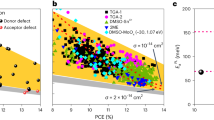

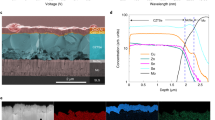

Solar cells based on kesterite materials, Cu2ZnSn(S,Se)4 (CZTSSe), offer a non-toxic, Earth-abundant solution for energy generation. However, they have historically struggled to achieve power conversion efficiencies comparable to those of other thin-film photovoltaic technologies. Here we highlight the critical role of the synthesis and formation pathway of these multinary semiconductors, discussing the challenges associated with kesterite layer fabrication and their impact on device performance. In particular, we discuss how the design of molecular inks in kesterite synthesis is key to overcoming these limitations, unveiling the connections between precursor chemistry, synthesis pathways and the formation of point and extended defects. We discuss how precise control over these factors has enabled kesterite solar cells to exceed 15% efficiency. Building on these advances, we propose strategies to further improve device performance. Finally, the insights presented here provide a framework for the exploration and development of other multinary semiconductor materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Chen, J. et al. Navigating phase diagram complexity to guide robotic inorganic materials synthesis. Nat. Synth. 3, 606–614 (2024).

Bennett, J. A. & Abolhasani, M. Robotic synthesis decoded through phase diagram mastery. Nat. Synth. 3, 565–567 (2024).

Katagiri, H. et al. Preparation and evaluation of Cu2ZnSnS4 thin films by sulfurization of EB evaporated precursors. Sol. Energy Mater. Sol. Cells 49, 407–414 (1997).

Giraldo, S. et al. Progress and perspectives of thin film kesterite photovoltaic technology: a critical review. Adv. Mater. 31, 1806692 (2019).

Keller, J. et al. High-concentration silver alloying and steep back-contact gallium grading enabling copper indium gallium selenide solar cell with 23.6% efficiency. Nat. Energy 9, 467–478 (2024).

He, M. et al. Kesterite solar cells: insights into current strategies and challenges. Adv. Sci. 8, 2004313 (2021).

Wang, L. et al. Defects in kesterite materials towards high-efficiency solar cells: origin, impact, characterization, and engineering. J. Mater. Chem. A 12, 25643–25677 (2024).

Schorr, S. et al. Point defects, compositional fluctuations, and secondary phases in non-stoichiometric kesterites. J. Phys. Energy 2, 012002 (2020).

Grenet, L., Suzon, M. A. A., Emieux, F. & Roux, F. Analysis of failure modes in kesterite solar cells. ACS Appl. Energy Mater. 1, 2103–2113 (2018).

Li, J. et al. Defect control for 12.5% efficiency Cu2ZnSnSe4 kesterite thin-film solar cells by engineering of local chemical environment. Adv. Mater. 32, 2005268 (2020). Demonstrates 12.5% CZTSe by engineering the local chemical environment controlling the reaction pathway, directly linking processing chemistry to defect control and device efficiency.

Ye, K. et al. Tuning electrical, optical, and thermal properties through cation disorder in Cu2ZnSnS4. Chem. Mater. 31, 8402–8412 (2019).

Fonoll-Rubio, R. et al. Insights into interface and bulk defects in a high efficiency kesterite-based device. Energy Environ. Sci. 14, 507–523 (2021).

Kim, S. Y. et al. Void and secondary phase formation mechanisms of CZTSSe using Sn/Cu/Zn/Mo stacked elemental precursors. Nano Energy 59, 399–411 (2019).

Wang, W., et al. Device characteristics of CZTSSe thin-film solar cells with 12.6% efficiency. Adv. Energy Mater. 4, 1301465 (2014). Reports the long-standing 12.6% pure solution hydrazine-processed CZTSSe benchmark.

Yang, K. J. et al. A band-gap-graded CZTSSe solar cell with 12.3% efficiency. J. Mater. Chem. A 4, 10151–10158 (2016).

Kim, S., Kim, K. M., Tampo, H., Shibata, H. & Niki, S. Improvement of voltage deficit of Ge-incorporated kesterite solar cell with 12.3% conversion efficiency. Appl. Phys. Express 9, 102301 (2016).

Son, D. H. et al. Effect of solid-H2S gas reactions on CZTSSe thin film growth and photovoltaic properties of a 12.62% efficiency device. J. Mater. Chem. A 7, 25279–25289 (2019).

Green, M. A. et al. Solar cell efficiency tables (Version 64). Prog. Photovolt. Res. Appl. 32, 425–441 (2024).

Qi, Y. et al. Enhancing grain growth for efficient solution-processed (Cu,Ag)2ZnSn(S,Se)4 solar cells based on acetate precursor. ACS Appl. Mater. Interfaces 12, 14213–14223 (2020).

Ki, W. & Hillhouse, H. W. Earth-abundant element photovoltaics directly from soluble precursors with high yield using a non-toxic solvent. Adv. Energy Mater. 1, 732–735 (2011). Introduces the DMSO–thiourea molecular ink route for kesterite materials, establishing Lewis acid–base complexation as a scalable, non-toxic pathway for solution-processed kesterite.

Xin, H., Katahara, J. K., Braly, I. L. & Hillhouse, H. W. 8% efficient Cu2ZnSn(S,Se)4 solar cells from redox equilibrated simple precursors in DMSO. Adv. Energy Mater. 4, 1301823 (2014). Shows that redox-equilibrated DMSO precursors and controlled mixing order govern Cu/Sn oxidation states, material quality and device performance.

Guo, Q. et al. Fabrication of 7.2% efficient CZTSSe solar cells using CZTS nanocrystals. J. Am. Chem. Soc. 132, 17384–17386 (2010).

Miskin, C. K. et al. 9.0% efficient Cu2ZnSn(S,Se)4 solar cells from selenized nanoparticle inks. Prog. Photovolt. Res. Appl. 23, 654–659 (2015).

Gong, Y. et al. Ag incorporation with controlled grain growth enables 12.5% efficient kesterite solar cell with open circuit voltage reached 64.2% Shockley–Queisser limit. Adv. Funct. Mater. 31, 2101927 (2021). Introduces Ag alloying with ink-controlled grain growth and device performance, evidencing alloy-assisted pathway engineering.

Gong, Y. et al. Elemental de-mixing-induced epitaxial kesterite/CdS interface enabling 13%-efficiency kesterite solar cells. Nat. Energy 7, 966–977 (2022). Highlights the role of a soft thermal treatment on solution-processed CZTSSe/CdS interface to enable a champion device with 13% efficiency.

Zhou, J. et al. Control of the phase evolution of kesterite by tuning of the selenium partial pressure for solar cells with 13.8% certified efficiency. Nat. Energy 8, 526–535 (2023). Shows that controlled selenization conditions further suppress intermediate phases and drive uniform crystallization, delivering a certified 13.8% CZTSSe.

Shi, J. et al. Multinary alloying for facilitated cation exchange and suppressed defect formation in kesterite solar cells with above 14% certified efficiency. Nat. Energy 9, 1095–1104 (2024). Shows that multinary alloying further suppresses intermediate phases and drives uniform crystallization, delivering a certified 14.2% CZTSSe.

Yin, K. et al. A high-efficiency (12.5%) kesterite solar cell realized by crystallization growth kinetics control over aqueous solution based Cu2ZnSn(S,Se)4. J. Mater. Chem. A 10, 779–788 (2022).

Su, Z. et al. Device postannealing enabling over 12% efficient solution-processed Cu2ZnSnS4 solar cells with Cd2+ substitution. Adv. Mater. 32, 2000121 (2020).

Yan, C. et al. Cu2ZnSnS4 solar cells with over 10% power conversion efficiency enabled by heterojunction heat treatment. Nat. Energy 3, 764–772 (2018).

Zhao, Y. et al. Controllable double gradient bandgap strategy enables high efficiency solution-processed kesterite solar cells. Adv. Funct. Mater. 34, 2311992 (2024).

Zhou, J. et al. Regulating crystal growth via organic lithium salt additive for efficient kesterite solar cells. Nano Energy 89, 106405 (2021).

Gong, Y. et al. Li-doping and Ag-alloying interplay shows the pathway for kesterite solar cells with efficiency over 14%. Adv. Funct. Mater. 34, 2404669 (2024).

Wang, J. et al. Pd(II)/Pd(IV) redox shuttle to suppress vacancy defects at grain boundaries for efficient kesterite solar cells. Nat. Commun. 15, 4344 (2024).

Li, Y. et al. Suppressing element inhomogeneity enables 14.9% efficiency CZTSSe solar cells. Adv. Mater. 34, 2400138 (2024).

Otgontamir, N. et al. High efficiency kesterite solar cells through a dual treatment approach: improving the quality of both absorber bulk and heterojunction interface. Adv. Energy Mater. 13, 2302941 (2023).

Xin, H. et al. Lithium-doping inverts the nanoscale electric field at the grain boundaries in Cu2ZnSn(S,Se)4 and increases photovoltaic efficiency. Phys. Chem. Chem. Phys. 17, 23859–23866 (2015).

Giraldo, S. et al. How small amounts of Ge modify the formation pathways and crystallization of kesterites. Energy Environ. Sci. 11, 582–593 (2018). Identifies the role of Ge doping in formation pathway and device performance.

Katagiri, H., Ishigaki, N., Ishida, T. & Saito, K. Characterization of Cu2ZnSnS4 thin films prepared by vapor phase sulfurization. Jpn J. Appl. Phys. 40, 500 (2001).

Guo, Q., Hillhouse, H. W. & Agrawal, R. Synthesis of Cu2ZnSnS4 nanocrystal ink and its use for solar cells. J. Am. Chem. Soc. 131, 11672–11673 (2009).

Hsu, W. et al. Growth mechanisms of co-evaporated kesterite: a comparison of Cu-rich and Zn-rich composition paths. Prog. Photovolt. Res. Appl. 22, 35–43 (2014).

Lee, Y. S. et al. Cu2ZnSnSe4 thin-film solar cells by thermal co-evaporation with 11.6% efficiency and improved minority carrier diffusion length. Adv. Energy Mater. 5, 1401372 (2015).

Kim, S. et al. Ge-incorporated Cu2ZnSnSe4 thin-film solar cells with efficiency greater than 10%. Sol. Energy Mater. Sol. Cells 144, 488–492 (2016).

Fairbrother, A. et al. On the formation mechanisms of Zn-rich Cu2ZnSnS4 films prepared by sulfurization of metallic stacks. Sol. Energy Mater. Sol. Cells 112, 97–105 (2013).

López-Marino, S. et al. Inhibiting the absorber/Mo-back contact decomposition reaction in Cu2ZnSnSe4 solar cells: the role of a ZnO intermediate nanolayer. J. Mater. Chem. A 1, 8338–8343 (2013).

López-Marino, S. et al. ZnSe etching of Zn-rich Cu2ZnSnSe4: an oxidation route for improved solar-cell efficiency. Chem. A Eur. J. 19, 14814–14822 (2013).

Brammertz, G. et al. Characterization of defects in 9.7% efficient Cu2ZnSnSe4–CdS–ZnO solar cells. Appl. Phys. Lett. 103, 163904 (2013).

Scragg, J. J. et al. Effects of back contact instability on Cu2ZnSnS4 devices and processes. Chem. Mater. 25, 3162–3171 (2013).

Yang, K. et al. Effects of the compositional ratio distribution with sulfurization temperatures in the absorber layer on the defect and surface electrical characteristics of Cu2ZnSnS4 solar cells. Prog. Photovolt. Res. Appl. 23, 1771–1784 (2015).

Sun, K. et al. Over 9% efficient kesterite Cu2ZnSnS4 solar cell fabricated by using Zn1–xCdxS buffer layer. Adv. Energy Mater. 6, 1600046 (2016).

Katagiri, H. et al. Enhanced conversion efficiencies of Cu2ZnSnS4-based thin film solar cells by using preferential etching technique. Appl. Phys. Express 1, 041201 (2008).

Lopez-Marino, S. et al. The importance of back contact modification in Cu2ZnSnSe4 solar cells: the role of a thin MoO2 layer. Nano Energy 26, 708–721 (2016).

Larsen, J. K. et al. Surface modification through air annealing Cu2ZnSn(S,Se)4 absorbers. Thin Solid Films 633, 118–121 (2017).

Taskesen, T. et al. Resilient and reproducible processing for CZTSe solar cells in the range of 10%. Prog. Photovolt. Res. Appl. 26, 1003–1006 (2018).

Sun, R. et al. Beyond 11% efficient Cu2ZnSn(Se,S)4 thin film solar cells by cadmium alloying. Sol. Energy Mater. Sol. Cells 174, 494–498 (2018).

Taskesen, T. et al. Device characteristics of an 11.4% CZTSe solar cell fabricated from sputtered precursors. Adv. Energy Mater. 8, 1703295 (2018).

He, M. et al. High efficiency Cu2ZnSn(S,Se)4 solar cells with shallow LiZn acceptor defects enabled by solution-based Li post-deposition treatment. Adv. Energy Mater. 11, 2003783 (2021).

Gang, M. G. et al. A facile process for partial Ag substitution in kesterite Cu2ZnSn(S,Se)4 solar cells enabling a device efficiency of over 12%. ACS Appl. Mater. Interfaces 13, 3959–3968 (2021).

Larramona, G. et al. Fine-tuning the Sn content in CZTSSe thin films to achieve 10.8% solar cell efficiency from spray-deposited water–ethanol-based colloidal inks. Adv. Energy Mater. 5, 1501404 (2015).

Guo, Q. et al. Enhancing the performance of CZTSSe solar cells with Ge alloying. Sol. Energy Mater. Sol. Cells 105, 132–136 (2012).

Todorov, T. K., Reuter, K. B. & Mitzi, D. B. High-efficiency solar cell with Earth-abundant liquid-processed absorber. Adv. Mater. 22, E156–E159 (2010).

Barkhouse, D. A. R., Gunawan, O., Gokmen, T., Todorov, T. K. & Mitzi, D. B. Device characteristics of a 10.1% hydrazine-processed Cu2ZnSn(Se,S)4 solar cell. Prog. Photovolt. Res. Appl. 20, 6–11 (2012).

Todorov, T. K. et al. Beyond 11% efficiency: characteristics of state-of-the-art Cu2ZnSn(S,Se)4 solar cells. Adv. Energy Mater. 3, 34–38 (2013).

Winkler, M. T. et al. Optical designs that improve the efficiency of Cu2ZnSn(S,Se)4 solar cells. Energy Environ. Sci. 7, 1029–1036 (2014).

Shin, B. et al. Thin film solar cell with 8.4% power conversion efficiency using an Earth-abundant Cu2ZnSnS4 absorber. Prog. Photovolt. Res. Appl. 21, 72–76 (2013).

Hiroi, H., Sakai, N., Kato, T. & Sugimoto, H. High voltage Cu2ZnSnS4 submodules by hybrid buffer layer. In Proc. 39th Photovoltaic Specialists Conference 0863–0866 (IEEE, 2013).

Schnabel, T., Abzieher, T., Friedlmeier, T. M. & Ahlswede, E. Solution-based preparation of Cu2ZnSn(S,Se)4 for solar cells—comparison of SnSe2 and elemental Se as chalcogen source. IEEE J. Photovolt. 5, 670–675 (2015).

Werner, M. et al. Enhanced carrier collection from CdS passivated grains in solution-processed Cu2ZnSn(S,Se)4 solar cells. ACS Appl. Mater. Interfaces 7, 12141–12146 (2015).

Haass, S. G. et al. 11.2% efficient solution processed kesterite solar cell with a low voltage deficit. Adv. Energy Mater. 5, 1500712 (2015).

Liu, F. et al. Kesterite Cu2ZnSn(S,Se)4 solar cells with beyond 8% efficiency by a sol–gel and selenization process. ACS Appl. Mater. Interfaces 7, 14376–14383 (2015).

Collord, A. D. & Hillhouse, H. W. Germanium alloyed kesterite solar cells with low voltage deficits. Chem. Mater. 28, 2067–2073 (2016).

Haass, S. G. et al. Complex interplay between absorber composition and alkali doping in high-efficiency kesterite solar cells. Adv. Energy Mater. 8, 1701760 (2018).

Cabas-Vidani, A. et al. High-efficiency (LixCu1−x)2ZnSn(S,Se)4 kesterite solar cells with lithium alloying. Adv. Energy Mater. 8, 1801191 (2018).

Qi, Y. et al. Synergistic effect of Mn on bandgap fluctuations and surface electrical characteristics in Ag-based Cu2ZnSn(S,Se)4 solar cells. J. Mater. Chem. A 9, 2292–2300 (2021).

Guo, J. et al. Enhancing the photovoltaic performance of Cu2ZnSn(S,Se)4 solar cells with Ba trace doping: large chemical mismatch cation incorporation. Sol. RRL 5, 2100607 (2021).

Deng, Y. et al. Adjusting the SnZn defects in Cu2ZnSn(S,Se)4 absorber layer via Ge4+ implanting for efficient kesterite solar cells. J. Energy Chem. 61, 1–7 (2021).

Chang, X. et al. Synergistic incorporation of NaF and CsF PDT for high efficiency kesterite solar cells: unveiling of grain interior and grain boundary effects. J. Mater. Chem. A 9, 413–422 (2021).

Du, Y. et al. Defect engineering in Earth-abundant Cu2ZnSn(S,Se)4 photovoltaic materials via Ga3+-doping for over 12% efficient solar cells. Adv. Funct. Mater. 31, 2010325 (2021).

Cui, C. et al. Surface defect ordered Cu2ZnSn(S,Se)4 solar cells with efficiency over 12% via manipulating local substitution. J. Energy Chem. 67, 555–562 (2022).

Zhao, Y. et al. Local Cu component engineering to achieve continuous carrier transport for enhanced kesterite solar cells. ACS Appl. Mater. Interfaces 13, 795–805 (2021).

Duan, B. et al. Two-step annealing CZTSSe/CdS heterojunction to improve interface properties of kesterite solar cells. ACS Appl. Mater. Interfaces 13, 55243–55253 (2021).

Sun, Y. et al. N-type surface design for p-type CZTSSe thin film to attain high efficiency. Adv. Mater. 33, 2104330 (2021).

Xu, X. et al. Efficient and composition-tolerant kesterite Cu2ZnSn(S,Se)4 solar cells derived from an in situ formed multifunctional carbon framework. Adv. Energy Mater. 11, 2102298 (2021).

Guo, J. et al. Microenvironment created by SnSe2 vapor and pre-selenization to stabilize the surface and back contact in kesterite solar cells. Small 18, 2203354 (2022).

Liang, G. X. et al. Optimizing the ratio of Sn4+ and Sn2+ in Cu2ZnSn(S,Se)4 precursor solution via air environment for highly efficient solar cells. Sol. RRL 5, 2100574 (2021).

Zhao, X. et al. Precursor solution chemistry via water additive enabling CZTSSe solar cells with over 12% efficiency. Sci. China Mater. 66, 895–902 (2023).

Zhao, Y. et al. Over 12% efficient kesterite solar cell via back interface engineering. J. Energy Chem. 75, 321–329 (2022).

Guo, Y. et al. Plasmonic local electric field-enhanced interface toward high-efficiency Cu2ZnSn(S,Se)4 thin-film solar cells. ACS Appl. Mater. Interfaces 14, 26690–26698 (2022).

Fu, J. et al. Rational design of heterojunction interface for Cu2ZnSn(S,Se)4 solar cells to exceed 12% efficiency. Sol. RRL 6, 2101032 (2022).

Liu, Y. et al. Li/Ag co-doping synergistically boosts the efficiency of kesterite solar cells through effective SnZn defect passivation. Adv. Mater. Interfaces 9, 2201677 (2022).

Guo, H. et al. Band-gap-graded Cu2ZnSn(S,Se)4 drives highly efficient solar cells. Energy Environ. Sci. 15, 693–704 (2022).

Wang, J. et al. Ge bidirectional diffusion to simultaneously engineer back interface and bulk defects in the absorber for efficient CZTSSe solar cells. Adv. Mater. 34, 2202858 (2022).

Lou, L. et al. A feasible and effective solution-processed PCBM electron extraction layer enabling the high VOC and efficient Cu2ZnSn(S,Se)4 devices. J. Energy Chem. 70, 154–161 (2022).

Lee, T. et al. Defect passivation for kesterite CZTSSe solar cells via in situ Al2O3 incorporation into the bulk CZTSSe absorber. Sol. RRL 6, 2100862 (2022).

Ji, Y. et al. CuSCN modified back contacts for high performance CZTSSe solar cells. Adv. Funct. Mater. 33, 2211421 (2023).

Farooq, U. et al. Defects passivation by solution-processed titanium doping strategy towards high efficiency kesterite solar cells. Chem. Eng. J. 451, 139109 (2023).

Yin, K. et al. Lanthanum-induced synergetic carrier doping of heterojunction to achieve high-efficiency kesterite solar cells. J. Mater. Chem. A 11, 9646–9653 (2023).

Jian, Y. et al. Grain growth mechanism of CZTSSe films controlled by the evaporation area of Se. Sol. RRL 7, 2300006 (2023).

Chen, X. Y. et al. Ag, Ti dual-cation substitution in Cu2ZnSn(S,Se)4 induced growth promotion and defect suppression for high-efficiency solar cells. J. Mater. Chem. A 10, 22791–22802 (2022).

Zhao, X. et al. Regulating charge carrier recombination in Cu2ZnSn(S,Se)4 solar cells via cesium treatment: bulk and interface effects. J. Mater. Chem. A 11, 11454–11462 (2023).

Geng, H. et al. Two-step cooling strategy for synergistic control of CuZn and SnZn defects enabling 12.87% efficiency (Ag,Cu)2ZnSn(S,Se)4 solar cells. Adv. Funct. Mater. 33, 2210551 (2023).

Yu, Z. et al. Unveiling the selenization reaction mechanisms in ambient air-processed highly efficient kesterite solar cells. Adv. Energy Mater. 13, 2300521 (2023).

Qi, Y. et al. Passivating SnZn defect and optimizing energy level alignment via organic silicon salt incorporation toward efficient solution-processed CZTSSe solar cells. Adv. Funct. Mater. 34, 2308333 (2024).

Ma, Q. et al. 2D Ti3C2-MXene serving as intermediate layer between absorber and back contact for efficient CZTSSe solar cells. ACS Appl. Mater. Interfaces 15, 55652–55658 (2023).

Zhao, Y. et al. Suppressing surface and bulk effect enables high efficiency solution-processed kesterite solar cells. Chem. Eng. J. 479, 147739 (2024).

Wei, H. et al. Regulating hetero-nucleation enabling over 14% efficient kesterite solar cells. Small 20, 2308266 (2023).

Lou, L. et al. Crown ether-assisted colloidal ZnO window layer engineering for efficient kesterite (Ag,Cu)2ZnSn(S,Se)4 solar cells. ACS Energy Lett. 8, 3775–3783 (2023).

Green, M. A. et al. Solar cell efficiency tables (Version 63). Prog. Photovolt. Res. Appl. 32, 3–13 (2024).

Zhang, X. et al. Suppressed interface defects by GeSe2 post-deposition treatment enables high-efficiency kesterite solar cells. Adv. Funct. Mater. 33, 2211315 (2023).

Fu, J. et al. Defect engineering enabling p-type Mo(S,Se)2:TM (TM = V, Nb, Ta) towards high-efficiency kesterite solar cells. Chem. Eng. J. 457, 141348 (2023).

Jian, Y. et al. Modification of back interfacial contact with MoO3 layer in situ introduced by Na2S aqueous solution for efficient kesterite CZTSSe solar cells. J. Mater. Chem. C 11, 4634–4644 (2023).

Xu, X. et al. 12.84% efficiency flexible kesterite solar cells by heterojunction interface regulation. Adv. Energy Mater. 13, 2301701 (2023).

Cao, L. et al. Passivating grain boundaries via graphene additive for efficient kesterite solar cells. Small 20, 2304866 (2024).

Xiao, Q. et al. Defect engineering of solution-processed ZnO:Li window layers towards high-efficiency and low-cost kesterite photovoltaics. J. Mater. Chem. A 11, 11161–11169 (2023).

Wang, M. et al. Hyperactive selenium source yields kesterite solar cells with 12.86% efficiency. Adv. Funct. Mater. 33, 2307389 (2023).

Wang, Z. et al. Toward high efficient Cu2ZnSn(Sx,Se1−x)4 solar cells: break the limitations of VOC and FF. Small 19, 2300634 (2023).

Li, Y. et al. Suppressing deep-level trap toward over 13% efficient solution-processed kesterite solar cell. Small 20, 2401330 (2024).

Jian, Y. et al. Segmented control of selenization environment for high-quality Cu2ZnSn(S,Se)4 films toward efficient kesterite solar cells. Small Methods 8, 2400041 (2024).

Wang, L. et al. Synergistic crystallization modulation and defects passivation in kesterite via anion-coordinate precursor engineering for efficient solar cells. Adv. Sci. 11, 2405016 (2024).

Cao, L. et al. Modifying surface termination by bidentate chelating strategy enables 13.77% efficient kesterite solar cells. Adv. Mater. 36, 2311918 (2024).

Clark, J. A. et al. Complexation chemistry in N,N-dimethylformamide-based molecular inks for chalcogenide semiconductors and photovoltaic devices. J. Am. Chem. Soc. 141, 298–308 (2019). Maps solvent–ligand complexation and Cu redox/disproportionation in aprotic polar inks, providing mechanistic insights to stabilize oxidation states in kesterite molecular inks.

Saidaminov, M. I. et al. Conventional solvent oxidizes Sn(II) in perovskite inks. ACS Energy Lett. 5, 1153–1155 (2020).

Lundberg, D. & Persson, I. On solvated tin(iv) ions and the coordination chemistry of high-valent d10 metal ions. Dalt. Trans. 48, 9089–9093 (2019).

Yang, M. et al. Self-stabilizing molecular solution for Cu2SnS3 thin film: an insight into the oxidation inhibitor of bivalent tin ion. J. Power Sources 494, 229699 (2021).

Hages, C. J., Koeper, M. J., Miskin, C. K., Brew, K. W. & Agrawal, R. Controlled grain growth for high performance nanoparticle-based kesterite solar cells. Chem. Mater. 28, 7703–7714 (2016).

Mainz, R. et al. Real-time observation of Cu2ZnSn(S,Se)4 solar cell absorber layer formation from nanoparticle precursors. Phys. Chem. Chem. Phys. 15, 18281 (2013).

Chernomordik, B. D. et al. Microstructure evolution during selenization of Cu2ZnSnS4 colloidal nanocrystal coatings. Chem. Mater. 28, 1266–1276 (2016).

Gong, Y. et al. Sn4+ precursor enables 12.4% efficient kesterite solar cell from DMSO solution with open circuit voltage deficit below 0.30 V. Sci. China Mater. 64, 52–60 (2021). Shows that Sn4+-based DMSO molecular inks yield high-quality CZTSSe through oxidation state control.

Gong, Y. et al. Identifying the origin of the VOC deficit of kesterite solar cells from the two grain growth mechanisms induced by Sn2+ and Sn4+ precursors in DMSO solution. Energy Environ. Sci. 14, 2369–2380 (2021). Links molecular ink composition and Sn oxidation state to distinct grain-growth mechanisms and VOC loss.

Trifiletti, V. et al. Study of precursor-inks designed for high-quality Cu2ZnSnS4 films for low-cost PV application. ChemistrySelect 4, 4905–4912 (2019).

Willett, R. D. & Chang, K. The crystal structure of copper(II) chloride bis(dimethylsulphoxide). Inorg. Chim. Acta 4, 447–451 (1970).

Watt, G. W. & Thompson, J. S. The interaction of liquid ammonia and urea and thiourea complexes of copper(I) and (II), silver(I), zinc(II), nickel(II) and palladium(II). J. Inorg. Nucl. Chem. 33, 1319–1323 (1971).

Cassidy, J. E., Moser, W., Donaldson, J. D., Jelen, A. & Nicholson, D. G. Thiourea complexes of tin(II) compounds. J. Chem. Soc. A 1970, 173–175 (1970).

Abdel-Shakour, M. et al. High-efficiency tin halide perovskite solar cells: the chemistry of tin (II) compounds and their interaction with Lewis base additives during perovskite film formation. Sol. RRL 5, 2000606 (2021).

Semenov, V. N. & Ovechkina, N. M. Formation of SnS, SnS2, and PbS films from thiourea coordination compounds. Russ. J. Appl. Chem. 84, 2033–2039 (2011).

Kumari, R. G. et al. Raman spectral investigation of thiourea complexes. Spectrochim. Acta A 73, 263–267 (2009).

Dunstan, P. O. Thermochemistry of adducts of tin(IV) chloride with amides and thioamides. Thermochim. Acta 345, 117–123 (2000).

Su, Z. et al. Fabrication of Cu2ZnSnS4 solar cells with 5.1% efficiency via thermal decomposition and reaction using a non-toxic sol–gel route. J. Mater. Chem. A 2, 500–509 (2014).

Liang, A. et al. An effective precursor-solutioned strategy for developing Cu2ZnSn(S, Se)4 thin film toward high efficiency solar cell. Adv. Energy Mater. 15, 2403950 (2025).

Mangan, T. C., McCandless, B. E., Dobson, K. D. & Birkmire, R. W. Thermochemical and kinetic aspects of Cu2ZnSn(S,Se)4 thin film growth by reacting Cu–Zn–Sn precursors in H2S and H2Se. J. Appl. Phys. 118, 065303 (2015).

Xu, X. et al. Controlling selenization equilibrium enables high-quality kesterite absorbers for efficient solar cells. Nat. Commun. 14, 6650 (2023).

Martinho, F. et al. Persistent double-layer formation in kesterite solar cells: a critical review. ACS Appl. Mater. Interfaces 12, 39405–39424 (2020).

Pan, X. et al. 12.3% efficient low VOC loss pure sulfide kesterite solar cells from DMSO solution via cadmium alloying. Adv. Energy Mater. 13, 2301780 (2023).

Scragg, J. J., Ericson, T., Kubart, T., Edoff, M. & Platzer-Björkman, C. Chemical insights into the instability of Cu2ZnSnS4 films during annealing. Chem. Mater. 23, 4625–4633 (2011).

Scragg, J. J., Dale, P. J., Colombara, D. & Peter, L. M. Thermodynamic aspects of the synthesis of thin-film materials for solar cells. ChemPhysChem 13, 3035–3046 (2012).

Ren, Y. et al. Evolution of Cu2ZnSnS4 during non-equilibrium annealing with quasi-in situ monitoring of sulfur partial pressure. Chem. Mater. 29, 3713–3722 (2017).

Xie, H. et al. Impact of Na dynamics at the Cu2ZnSn(S,Se)4/CdS interface during post low temperature treatment of absorbers. ACS Appl. Mater. Interfaces 8, 5017–5024 (2016).

Neuschitzer, M. et al. Complex surface chemistry of kesterites: Cu/Zn reordering after low temperature postdeposition annealing and its role in high performance devices. Chem. Mater. 27, 5279–5287 (2015).

Jimenez-Arguijo, A. et al. Gradient doping in Cu2ZnSnSe4 by temperature and potential induced defect steering. Sol. Energy 262, 111883 (2023).

Mendis, B. G. et al. The role of secondary phase precipitation on grain boundary electrical activity in Cu2ZnSnS4 (CZTS) photovoltaic absorber layer material. J. Appl. Phys. 112, 124508 (2012).

He, M., Sun, K., Suryawanshi, M. P., Li, J. & Hao, X. Interface engineering of p–n heterojunction for kesterite photovoltaics: a progress review. J. Energy Chem. 60, 1–8 (2021).

Li, J. et al. Unveiling microscopic carrier loss mechanisms in 12% efficient Cu2ZnSnSe4 solar cells. Nat. Energy 7, 754–764 (2022).

Romanyuk, Y. E. et al. Doping and alloying of kesterites. J. Phys. Energy 1, 044004 (2019).

Platzer-Björkman, C. et al. Back and front contacts in kesterite solar cells: state-of-the-art and open questions. J. Phys. Energy 1, 044005 (2019).

Jimenez-Arguijo, A. et al. Small atom doping: a synergistic strategy to reduce SnZn recombination center concentration in Cu2ZnSnSe4. Sol. RRL 6, 2200580 (2022).

El Khouja, O. et al. Exploring the synthesis of Cu2(Zn,Cd)SnS4 at high temperatures as a route for high-efficiency solar cells. Prog. Photovolt. Res. Appl. 33, 628–643 (2025).

Scaffidi, R. et al. Ge-alloyed kesterite thin-film solar cells: previous investigations and current status—a comprehensive review. J. Mater. Chem. A 11, 13174–13194 (2023).

Zhao, Y. et al. Energy band alignment and defect synergistic regulation enable air-solution-processed kesterite solar cells with the lowest VOC deficit. Adv. Mater. 37, 2409327 (2025).

Jimenez-Arguijo, A. et al. Setting the baseline for the modelling of Kesterite solar cells: the case study of tandem application. Sol. Energy Mater. Sol. Cells 251, 112109 (2023).

Abou-Ras, D. et al. A comprehensive analysis of recombination at grain boundaries in high-efficiency kesterite-type solar cells. Energy Environ. Mater. 8, e70048 (2025).

Scaffidi, R. et al. Temperature- and light intensity-dependent current–voltage analysis applied to high-efficiency solution-processed kesterite solar cells. Newton 1, 100198 (2025).

Isab, A. A. & Wazeer, M. I. M. Complexation of Zn(II), Cd(II) and Hg(II) with thiourea and selenourea: a 1H, 13C, 15N, 77Se and 113Cd solution and solid-state NMR study. J. Coord. Chem. 58, 529–537 (2005).

Dimitrievska, M., Fairbrother, A., Saucedo, E., Pérez-Rodríguez, A. & Izquierdo-Roca, V. Secondary phase and Cu substitutional defect dynamics in kesterite solar cells: impact on optoelectronic properties. Sol. Energy Mater. Sol. Cells 149, 304–309 (2016).

Sardashti, K. et al. Impact of nanoscale elemental distribution in high-performance kesterite solar cells. Adv. Energy Mater. 5, 1402180 (2015).

Yin, W. J. et al. Engineering grain boundaries in Cu2ZnSnSe4 for better cell performance: a first-principle study. Adv. Energy Mater. 4, 1300712 (2014).

Thersleff, T. et al. Chemically and morphologically distinct grain boundaries in Ge-doped Cu2ZnSnSe4 solar cells revealed with STEM-EELS. Mater. Des. 122, 102–109 (2017).

Schwarz, T. et al. Atom probe tomography study of internal interfaces in Cu2ZnSnSe4 thin-films. J. Appl. Phys. 118, 095302 (2015).

Park, J. S., Kim, S. & Walsh, A. Opposing effects of stacking faults and antisite domain boundaries on the conduction band edge in kesterite quaternary semiconductors. Phys. Rev. Mater. 2, 014602 (2018).

Kim, S., Márquez, J. A., Unold, T. & Walsh, A. Upper limit to the photovoltaic efficiency of imperfect crystals from first principles. Energy Environ. Sci. 13, 1481–1491 (2020).

Chen, W., Dahliah, D., Rignanese, G. M. & Hautier, G. Origin of the low conversion efficiency in Cu2ZnSnS4 kesterite solar cells: the actual role of cation disorder. Energy Environ. Sci. 14, 3567–3578 (2021).

Chen, S., Walsh, A., Gong, X. & Wei, S. Classification of lattice defects in the kesterite Cu2ZnSnS4 and Cu2ZnSnSe4 Earth-abundant solar cell absorbers. Adv. Mater. 25, 1522–1539 (2013).

Kumar, M., Dubey, A., Adhikari, N., Venkatesan, S. & Qiao, Q. Strategic review of secondary phases, defects and defect-complexes in kesterite CZTS–Se solar cells. Energy Environ. Sci. 8, 3134–3159 (2015).

Crovetto, A. et al. Assessing the defect tolerance of kesterite-inspired solar absorbers. Energy Environ. Sci. 13, 3489–3503 (2020).

Hsu, W. C., Bob, B., Yang, W., Chung, C. H. & Yang, Y. Reaction pathways for the formation of Cu2ZnSn(Se,S)4 absorber materials from liquid-phase hydrazine-based precursor inks. Energy Environ. Sci. 5, 8564–8571 (2012).

Mitzi, D. B. N4H9Cu7S4: a hydrazinium-based salt with a layered Cu7S4-framework. Inorg. Chem. 46, 926–931 (2007).

Mitzi, D. B. Synthesis, structure, and thermal properties of soluble hydrazinium germanium(IV) and Tin(IV) selenide salts. Inorg. Chem. 44, 3755–3761 (2005).

Todorov, T., Sugimoto, H., Gunawan, O., Gokmen, T. & Mitzi, D. B. High-efficiency devices with pure solution-processed Cu2ZnSn(Se,S)4 absorbers. IEEE J. Photovolt. 4, 483–485 (2014).

Redinger, A., Berg, D. M., Dale, P. J. & Siebentritt, S. The consequences of kesterite equilibria for efficient solar cells. J. Am. Chem. Soc. 133, 3320–3323 (2011).

Xie, H. et al. Impact of Sn(S,Se) secondary phases in Cu2ZnSn(S,Se)4 solar cells: a chemical route for their selective removal and absorber surface passivation. ACS Appl. Mater. Interfaces 6, 12744–12751 (2014).

Kim, S. Y. et al. Effect of Cu–Sn–Se liquid phase on grain growth and efficiency of CZTSSe solar cells. Adv. Energy Mater. 10, 1903173 (2020).

Li, J. et al. Growth of Cu2ZnSnSe4 film under controllable Se vapor composition and impact of low Cu content on solar cell efficiency. ACS Appl. Mater. Interfaces 8, 10283–10292 (2016).

Cong, J. et al. Unveiling the role of Ge in CZTSSe solar cells by advanced micro-to-atom scale characterizations. Adv. Sci. 11, 2305938 (2024).

Acknowledgements

This project received funding from: the European Union’s Horizon research and innovation programme under grant agreements 866018 (SENSATE) and 101151487 (LEKPV); Spanish Ministry of Science and Innovation projects PCI2023-145971-2 (ACT-FAST; from Clean Energy Transition Partnership Programme 2022), PID2022-140226OB-C31 and -C32 (INNO-PV) and PID2023-148976OB-C41 (CURIO-CITY); the National Key Research and Development Program of China (project 2019YFE0118100); the National Natural Science Foundation of China (project 22075150); and COST Association project CA-21148 (Renew-PV). This work is also part of the Maria de Maeztu Units of Excellence Programme (CEX2023-001300-M, funded by MICIU/AEI/10.13039/501100011033). The authors from the Universitat Politècnica de Catalunya and Catalonia Institute for Energy Research belong to the Micro and Nanotechnologies for Solar Energy Group (MNTSolar) Consolidated Research Group of the Generalitat de Catalunya (2021 SGR 01286). K.S. acknowledges the Australian Research Council Discovery Early Career Researcher Award (DE230100021) and support from the Australian Centre of Advanced Photovoltaics as a recipient of the ACAP Fellowship (RG172864-B). Z.J.L.-K. acknowledges the Spanish Ministry of Science and Innovation for the Ramón y Cajal Fellowship (RYC2021-033239-I). S.G. thanks the Serra Húnter Programme. X.H. acknowledges financial support from the Australian Research Council Future Fellowships scheme (FT190100756). E.S. acknowledges the ICREA Academia programme.

Author information

Authors and Affiliations

Contributions

A.J.-A., Y.G., J.L., H.X., X.H. and E.S. conceived of the article idea. A.J.-A. and Y.G. performed the literature search and curated the data. A.J.-A. wrote the original draft of the manuscript. A.J.-A., Y.G., I.C., O.E.K., J.L., K.S., Z.J.L.-K., S.G., H.X., A.P.-R., H.X. and E.S. reviewed and edited the manuscript. A.J.-A., Y.G., I.C., O.E.K. and S.G. visualized the results. J.L., K.S., Z.J.L.-K., S.G., X.H. and E.S. supervised the project. A.P.-R. and E.S. acquired funding. E.S. managed the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jimenez-Arguijo, A., Gong, Y., Caño, I. et al. Formation pathway of high-efficiency kesterite solar cells fabricated through molecular ink chemistry. Nat Energy (2026). https://doi.org/10.1038/s41560-025-01900-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41560-025-01900-y