Abstract

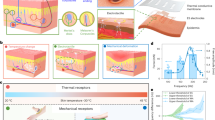

Haptic technology reproduces the human sense of touch, playing a critical role in enhancing immersions in virtual and augmented reality, medical training and human–machine interface. With the rapid development of these fields, haptic devices are transitioning from rigid, bulky systems to flexible, wearable formats that are lightweight, stretchable and skin conforming, greatly improving user comfort and tactile fidelity. The ultimate goal of next-generation haptic interface is to achieve precise, high-resolution tactile feedback that closely mimics natural skin sensations through direct mechanical interaction. However, current technologies remain limited in delivering diverse feedback modalities and fine spatial resolution, mainly owing to the underexplored potential of deformable materials and adaptive structural designs. This Review highlights recent progress in deformable materials and structural innovations for wearable haptic feedback. Systematic evaluation metrics are proposed based on key haptic perception mechanisms to assess performance across multiple indicators, including amplitude, frequency, spatial resolution and energy efficiency. Key achievements in material science, structural engineering and system integration are analysed, along with discussion of current challenges and future research directions of next-generation flexible and wearable haptic interfaces. With these proposed metrics, we aim to guide researchers in selecting appropriate materials and design strategies for future haptic systems.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Hansen, J. R. & Loftin, L. K. Quest for performance: the evolution of modern aircraft. Technol. Cult. 28, 734 (1987).

Frisoli, A. & Leonardis, D. Wearable haptics for virtual reality and beyond. Nat. Rev. Electr. Eng. 1, 666–679 (2024).

Bach-Y-Rita, P., Collins, C. C., Saunders, F. A., White, B. & Scadden, L. Vision substitution by tactile image projection. Nature 221, 963–964 (1969).

Huang, Y. et al. Recent advances in multi-mode haptic feedback technologies towards wearable interfaces. Mater. Today Phys. 22, 100602 (2022).

Yu, X. et al. Skin-integrated wireless haptic interfaces for virtual and augmented reality. Nature 575, 473–479 (2019).

Gerald, A. & Russo, S. Soft sensing and haptics for medical procedures. Nat. Rev. Mater. 9, 86–88 (2024).

Yin, J., Hinchet, R., Shea, H. & Majidi, C. Wearable soft technologies for haptic sensing and feedback. Adv. Funct. Mater. 31, 2007428 (2021).

Kim, H. J., Koo, J. H., Lee, S., Hyeon, T. & Kim, D.-H. Materials design and integration strategies for soft bioelectronics in digital healthcare. Nat. Rev. Mater. https://doi.org/10.1038/s41578-025-00819-w (2025).

Fleck, J. J. et al. Wearable multi-sensory haptic devices. Nat. Rev. Bioeng. 3, 288–302 (2025).

Ankit et al. Soft actuator materials for electrically driven haptic interfaces. Adv. Intell. Syst. 4, 2100061 (2022).

Shi, Y. & Shen, G. Haptic sensing and feedback techniques toward virtual reality. Research 7, 0333 (2024).

Oh, S. et al. Easy-to-wear auxetic SMA knot-architecture for spatiotemporal and multimodal haptic feedbacks. Adv. Mater. 35, 2304442 (2023).

Abad, S.-A., Herzig, N., Raitt, D., Koltzenburg, M. & Wurdemann, H. Bioinspired adaptable multiplanar mechano-vibrotactile haptic system. Nat. Commun. 15, 7631 (2024).

Tan, M. W. M., Wang, H., Gao, D., Huang, P. & Lee, P. S. Towards high performance and durable soft tactile actuators. Chem. Soc. Rev. 53, 3485–3535 (2024).

Lederman, S. J. & Klatzky, R. L. Haptic perception: a tutorial. Atten. Percept. Psychophys. 71, 1439–1459 (2009).

Kappers, A. M. L. & Bergmann Tiest, W. M. Haptic perception. WIREs Cognit. Sci. 4, 357–374 (2013).

Dahiya, R. S., Metta, G., Valle, M. & Sandini, G. Tactile sensing — from humans to humanoids. IEEE Trans. Robot. 26, 1–20 (2010).

LaMotte, R. H. & Srinivasan, M. A. Tactile discrimination of shape: responses of rapidly adapting mechanoreceptive afferents to a step stroked across the monkey fingerpad. J. Neurosci. 7, 1672–1681 (1987).

Grunwald, M. (ed.) Human Haptic Perception: Basics and Applications https://doi.org/10.1007/978-3-7643-7612-3 (Birkhäuser, 2008).

Johnson, K. O., Yoshioka, T. & Vega-Bermudez, F. Tactile functions of mechanoreceptive afferents innervating the hand. J. Clin. Neurophysiol. 17, 539 (2000).

Kern, T. A. (ed.) Engineering Haptic Devices: A Beginner’s Guide for Engineers https://doi.org/10.1007/978-3-540-88248-0 (Springer, 2009).

Jenmalm, P., Birznieks, I., Goodwin, A. W. & Johansson, R. S. Influence of object shape on responses of human tactile afferents under conditions characteristic of manipulation. Eur. J. Neurosci. 18, 164–176 (2003).

Mancini, F. et al. Whole-body mapping of spatial acuity for pain and touch. Ann. Neurol. 75, 917–924 (2014).

Craig, J. C. & Lyle, K. B. A comparison of tactile spatial sensitivity on the palm and fingerpad. Percept. Psychophys. 63, 337–347 (2001).

Gentaz, E., Baud-Bovy, G. & Luyat, M. The haptic perception of spatial orientations. Exp. Brain Res. 187, 331–348 (2008).

Bensmaïa, S. J. & Hollins, M. The vibrations of texture. Somatosens. Mot. Res. 20, 33–43 (2003).

Delhaye, B., Hayward, V., Lefèvre, P. & Thonnard, J.-L. Texture-induced vibrations in the forearm during tactile exploration. Front. Behav. Neurosci. 6, 37 (2012).

Harrington, G. S. & Hunter Downs, J. III FMRI mapping of the somatosensory cortex with vibratory stimuli: is there a dependency on stimulus frequency? Brain Res. 897, 188–192 (2001).

Purves, D. et al. (eds) Neuroscience 3rd edn (Sinauer Associates, 2004).

Pyun, K. R., Rogers, J. A. & Ko, S. H. Materials and devices for immersive virtual reality. Nat. Rev. Mater. 7, 841–843 (2022).

Li, M., Pal, A., Aghakhani, A., Pena-Francesch, A. & Sitti, M. Soft actuators for real-world applications. Nat. Rev. Mater. 7, 235–249 (2022).

International Electrotechnical Commission. Audio/video, information and communication technology equipment - Part 1: Safety requirements. IEC 62368-1 (2023).

International Organization for Standardization. Ergonomics of the thermal environment — Methods for the assessment of human responses to contact with surfaces. ISO 13732-1:2006 (2006).

Liang, X. & Boppart, S. A. Biomechanical properties of in vivo human skin from dynamic optical coherence elastography. IEEE Trans. Biomed. Eng. 57, 953–959 (2010).

Yeh, C.-H. et al. Application of piezoelectric actuator to simplified haptic feedback system. Sens. Actuators A Phys. 303, 111820 (2020).

Sorgini, F. et al. Encapsulation of piezoelectric transducers for sensory augmentation and substitution with wearable haptic devices. Micromachines 8, 270 (2017).

Uchino, K. Advanced Piezoelectric Materials: Science and Technology (Woodhead Publishing, 2017).

Liao, W.-Q. et al. A molecular perovskite solid solution with piezoelectricity stronger than lead zirconate titanate. Science 363, 1206–1210 (2019).

Stadlober, B., Zirkl, M. & Irimia-Vladu, M. Route towards sustainable smart sensors: ferroelectric polyvinylidene fluoride-based materials and their integration in flexible electronics. Chem. Soc. Rev. 48, 1787–1825 (2019).

Maeder, M. D., Damjanovic, D. & Setter, N. Lead free piezoelectric materials. J. Electroceram. 13, 385–392 (2004).

Jin, H. et al. Review on piezoelectric actuators based on high-performance piezoelectric materials. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 69, 3057–3069 (2022).

Zhou, X. et al. Review on piezoelectric actuators: materials, classifications, applications, and recent trends. Front. Mech. Eng. 19, 6 (2024).

Baik, S., Han, I., Park, J.-M. & Park, J. Multi-fingertip vibrotactile array interface for 3D virtual interaction. In 2020 IEEE Haptics Symposium 898–903 https://doi.org/10.1109/HAPTICS45997.2020.ras.HAP20.5.08241ef4 (IEEE, 2020).

Dagdeviren, C. et al. Conformal piezoelectric systems for clinical and experimental characterization of soft tissue biomechanics. Nat. Mater. 14, 728–736 (2015).

Jin, H. et al. Highly pixelated, untethered tactile interfaces for an ultra-flexible on-skin telehaptic system. npj Flex. Electron. 6, 82 (2022).

Sekhar, M. C. et al. A review on piezoelectric materials and their applications. Cryst. Res. Technol. 58, 2200130 (2023).

Chen, C.-T., Lin, S.-C., Trstenjak, U., Spreitzer, M. & Wu, W.-J. Comparison of metal-based PZT and PMN–PT energy harvesters fabricated by aerosol deposition method. Sensors 21, 4747 (2021).

Mohith, S., Upadhya, A. R., Navin, K. P., Kulkarni, S. M. & Rao, M. Recent trends in piezoelectric actuators for precision motion and their applications: a review. Smart Mater. Struct. 30, 013002 (2020).

Wu, J., Xiao, D. & Zhu, J. Potassium–sodium niobate lead-free piezoelectric materials: past, present, and future of phase boundaries. Chem. Rev. 115, 2559–2595 (2015).

Chorsi, M. T. et al. Piezoelectric biomaterials for sensors and actuators. Adv. Mater. 31, 1802084 (2019).

Watanabe, J., Ishikawa, H., Arouette, X., Matsumoto, Y. & Miki, N. Artificial tactile feeling displayed by large displacement MEMS actuator arrays. In 2012 IEEE 25th Int. Conf. Micro Electro Mech. Syst. 1129–1132 (IEEE, 2012).

Ninomiya, T. et al. MEMS-based hydraulic displacement amplification mechanism with completely encapsulated liquid. Sens. Actuators A Phys. 166, 277–282 (2011).

Zhang, L. et al. Recent progress on structure manipulation of poly(vinylidene fluoride)-based ferroelectric polymers for enhanced piezoelectricity and applications. Adv. Funct. Mater. 33, 2301302 (2023).

Van Duong, Q., Nguyen, V. P., Domingues Dos Santos, F. & Choi, S. T. Localized fretting-vibrotactile sensations for large-area displays. ACS Appl. Mater. Interfaces 11, 33292–33301 (2019).

Seo, D. G. & Cho, Y.-H. Resonating tactile stimulators based on piezoelectric polymer films. J. Mech. Sci. Technol. 32, 631–636 (2018).

Shouji, Y. et al. Fast response, high-power tunable ultrathin soft actuator by functional piezoelectric material composite for haptic device application. Adv. Electron. Mater. 9, 2201040 (2023).

Yoon, S. H. et al. HapSense: a soft haptic I/O device with uninterrupted dual functionalities of force sensing and vibrotactile actuation. In Proc. 32nd Annual ACM Symposium on User Interface Software and Technology (UIST '19) 949–961 (2019).

Chen, X. et al. Relaxor ferroelectric polymer exhibits ultrahigh electromechanical coupling at low electric field. Science 375, 1418–1422 (2022).

Liu, Q., Ghodrat, S., Huisman, G. & Jansen, K. M. B. Shape memory alloy actuators for haptic wearables: a review. Mater. Des. 233, 112264 (2023).

Kim, M.-S. et al. Shape memory alloy (SMA) actuators: the role of material, form, and scaling effects. Adv. Mater. 35, 2208517 (2023).

Kim, D. et al. Actuating compact wearable augmented reality devices by multifunctional artificial muscle. Nat. Commun. 13, 4155 (2022).

Hwang, D., Lee, J. & Kim, K. On the design of a miniature haptic ring for cutaneous force feedback using shape memory alloy actuators. Smart Mater. Struct. 26, 105002 (2017).

Matsunaga, T., Totsu, K., Esashi, M. & Haga, Y. Tactile display using shape memory alloy micro-coil actuator and magnetic latch mechanism. Displays 34, 89–94 (2013).

Knoop, E. & Rossiter, J. The tickler: a compliant wearable tactile display for stroking and tickling. In Proc. 33rd Annual ACM Conference Extended Abstracts on Human Factors in Computing Systems 1133–1138 (Association for Computing Machinery, 2015).

Liu, Q., Ghodrat, S. & Jansen, K. M. B. Modelling and mechanical design of a flexible tube-guided SMA actuator. Mater. Des. 216, 110571 (2022).

Lim, B., Lee, C. & Hwang, D. Development of embedded sensor system for 5-DOF finger-wearable tactile interface. IEEE/ASME Trans. Mechatron. 26, 1728–1736 (2021).

Tong, Y., Shuitcev, A. & Zheng, Y. Recent development of TiNi-based shape memory alloys with high cycle stability and high transformation temperature. Adv. Eng. Mater. 22, 1900496 (2020).

Mohd Jani, J., Leary, M., Subic, A. & Gibson, M. A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 56, 1078–1113 (2014).

Rodinò, S., Rota, G., Chiodo, M., Corigliano, A. & Maletta, C. Artificial intelligence control methodologies for shape memory alloy actuators: a systematic review and performance analysis. Micromachines 16, 780 (2025).

Dayyoub, T., Maksimkin, A. V., Filippova, O. V., Tcherdyntsev, V. V. & Telyshev, D. V. Shape memory polymers as smart materials: a review. Polymers 14, 3511 (2022).

Xia, Y., He, Y., Zhang, F., Liu, Y. & Leng, J. A review of shape memory polymers and composites: mechanisms, materials, and applications. Adv. Mater. 33, 2000713 (2021).

Ren, Z. et al. Phase-changing bistable electroactive polymer exhibiting sharp rigid-to-rubbery transition. Macromolecules 49, 134–140 (2016).

Hwang, I. et al. Height-renderable morphable tactile display enabled by programmable modulation of local stiffness in photothermally active polymer. Nat. Commun. 15, 2554 (2024).

Besse, N., Rosset, S., Zarate, J. J. & Shea, H. Flexible active skin: large reconfigurable arrays of individually addressed shape memory polymer actuators. Adv. Mater. Technol. 2, 1700102 (2017).

Aksoy, B. & Shea, H. Reconfigurable and latchable shape-morphing dielectric elastomers based on local stiffness modulation. Adv. Funct. Mater. 30, 2001597 (2020).

Peng, Q. et al. Shape-memory polymer nanocomposites with a 3D conductive network for bidirectional actuation and locomotion application. Nanoscale 8, 18042–18049 (2016).

Mirvakili, S. M. & Hunter, I. W. Multidirectional artificial muscles from nylon. Adv. Mater. 29, 1604734 (2017).

Oh, S. et al. Cooling-accelerated nanowire-nitinol hybrid muscle for versatile prosthetic hand and biomimetic retractable claw. Adv. Funct. Mater. 32, 2111145 (2022).

Kalairaj, M. S., Banerjee, H., Lim, C. M., Chen, P.-Y. & Ren, H. Hydrogel-matrix encapsulated nitinol actuation with self-cooling mechanism. RSC Adv. 9, 34244–34255 (2019).

Lee, H.-T., Kim, M.-S., Lee, G.-Y., Kim, C.-S. & Ahn, S.-H. Shape memory alloy (SMA)-based microscale actuators with 60% deformation rate and 1.6 kHz actuation speed. Small 14, 1801023 (2018).

Frenzel, J. et al. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 58, 3444–3458 (2010).

Koerner, H., Price, G., Pearce, N. A., Alexander, M. & Vaia, R. A. Remotely actuated polymer nanocomposites — stress-recovery of carbon-nanotube-filled thermoplastic elastomers. Nat. Mater. 3, 115–120 (2004).

Leng, J. S., Huang, W. M., Lan, X., Liu, Y. J. & Du, S. Y. Significantly reducing electrical resistivity by forming conductive Ni chains in a polyurethane shape-memory polymer/carbon-black composite. Appl. Phys. Lett. 92, 204101 (2008).

Zhang, F. et al. Conductive shape memory microfiber membranes with core–shell structures and electroactive performance. ACS Appl. Mater. Interfaces 10, 35526–35532 (2018).

Lendlein, A. & Gould, O. E. C. Reprogrammable recovery and actuation behaviour of shape-memory polymers. Nat. Rev. Mater. 4, 116–133 (2019).

Ware, T. et al. Thiol-ene/acrylate substrates for softening intracortical electrodes. J. Biomed. Mater. Res. Part B Appl. Biomater. 102, 1–11 (2014).

Liu, Y. et al. Water-induced shape-memory poly(D,L-lactide)/microcrystalline cellulose composites. Carbohydr. Polym. 104, 101–108 (2014).

Ince, J., Prasad, K., Subhani, K., Duffy, A. & Salim, N. Liquid crystalline elastomers as artificial muscles and flexible actuators for robotics/hybrid engineered machinery. Adv. Compos. Hybrid. Mater. 7, 186 (2024).

Feng, W., He, Q. & Zhang, L. Embedded physical intelligence in liquid crystalline polymer actuators and robots. Adv. Mater. 37, 2312313 (2025).

Sun, J., Wang, C., Liu, Y., Liang, X. & Wang, Z. Liquid crystal elastomer composites for soft actuators. Int. J. Smart Nano Mater. 14, 440–459 (2023).

Camargo, C. J. et al. Localised actuation in composites containing carbon nanotubes and liquid crystalline elastomers. Macromol. Rapid Commun. 32, 1953–1959 (2011).

Torras, N., Zinoviev, K. E., Esteve, J. & Sánchez-Ferrer, A. Liquid-crystalline elastomer micropillar array for haptic actuation. J. Mater. Chem. C 1, 5183–5190 (2013).

Torras, N. et al. Tactile device based on opto-mechanical actuation of liquid crystal elastomers. Sens. Actuators A Phys. 208, 104–112 (2014).

Camargo, C. J. et al. Batch fabrication of optical actuators using nanotube–elastomer composites towards refreshable Braille displays. J. Micromech. Microeng. 22, 075009 (2012).

He, Q. et al. Electrospun liquid crystal elastomer microfiber actuator. Sci. Robot. 6, eabi9704 (2021).

White, T. J. & Broer, D. J. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nat. Mater. 14, 1087–1098 (2015).

Lancia, F., Ryabchun, A., Nguindjel, A.-D., Kwangmettatam, S. & Katsonis, N. Mechanical adaptability of artificial muscles from nanoscale molecular action. Nat. Commun. 10, 4819 (2019).

Ishizuka, H. & Miki, N. Development of a tactile display with 5 mm resolution using an array of magnetorheological fluid. Jpn. J. Appl. Phys. 56, 06GN19 (2017).

Guo, Y. et al. MRS-Tex: a magnetically responsive soft tactile device for texture display. IEEE Trans. Ind. Electron. 69, 11531–11540 (2022).

Biswas, S. & Visell, Y. Emerging material technologies for haptics. Adv. Mater. Technol. 4, 1900042 (2019).

Shokrollahi, H. & Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 189, 1–12 (2007).

Chen, X. et al. Direct-write printed magnetic-controlled soft robots for non-contact applications. AIP Adv. 13, 125129 (2023).

Yamada, S. et al. Magnetic haptic device using miniature SmFeN powder magnets in PCB-on-MEMS system. Sens. Actuators A Phys. 364, 114792 (2023).

Vural, M. et al. Soft electromagnetic vibrotactile actuators with integrated vibration amplitude sensing. ACS Appl. Mater. Interfaces 15, 30653–30662 (2023).

Chen, S. et al. Multimodal 5-DOF stretchable electromagnetic actuators toward haptic information delivery. Adv. Funct. Mater. 34, 2314515 (2024).

Mao, G. et al. Soft electromagnetic actuators. Sci. Adv. 6, eabc0251 (2020).

Xavier, M. S. et al. Soft pneumatic actuators: a review of design, fabrication, modeling, sensing, control and applications. IEEE Access 10, 59442–59485 (2022).

Mihai, L. A. & Goriely, A. How to characterize a nonlinear elastic material? A review on nonlinear constitutive parameters in isotropic finite elasticity. Proc. R. Soc. A Math. Phys. Eng. Sci. 473, 20170607 (2017).

Martins, P. A. L. S., Natal Jorge, R. M. & Ferreira, A. J. M. A comparative study of several material models for prediction of hyperelastic properties: application to silicone-rubber and soft tissues. Strain 42, 135–147 (2006).

El Hami, A. & Radi, B. in Fluid–Structure Interactions and Uncertainties Ch. 1, 1–34 (Wiley, 2017).

Maruthavanan, D., Seibel, A. & Schlattmann, J. Fluid–structure interaction modelling of a soft pneumatic actuator. Actuators 10, 163 (2021).

Robinson, S. S. et al. Integrated soft sensors and elastomeric actuators for tactile machines with kinesthetic sense. Extreme Mech. Lett. 5, 47–53 (2015).

Kanjanapas, S., Nunez, C. M., Williams, S. R., Okamura, A. M. & Luo, M. Design and analysis of pneumatic 2-DoF soft haptic devices for shear display. IEEE Robot. Autom. Lett. 4, 1365–1371 (2019).

Jumet, B. et al. Fluidically programmed wearable haptic textiles. Device 1, 100059 (2023).

Russomanno, A., Xu, Z., O’Modhrain, S. & Gillespie, B. A pneu shape display: physical buttons with programmable touch response. In 2017 IEEE World Haptics Conf. 641–646 (IEEE, 2017).

Qi, J., Gao, F., Sun, G., Yeo, J. C. & Lim, C. T. HaptGlove — untethered pneumatic glove for multimode haptic feedback in reality–virtuality continuum. Adv. Sci. 10, 2301044 (2023).

Thai, M. T. et al. Soft microtubule muscle-driven 3-axis skin-stretch haptic devices. IEEE Access 8, 157878–157891 (2020).

Carpenter, C. W. et al. Electropneumotactile stimulation: multimodal haptic actuators enabled by a stretchable conductive polymer on inflatable pockets. Adv. Mater. Technol. 5, 1901119 (2020).

Zhakypov, Z. & Okamura, A. M. FingerPrint: a 3-D printed soft monolithic 4-degree-of-freedom fingertip haptic device with embedded actuation. In 2022 IEEE 5th Int. Conf. Soft Robot. 938–944 (IEEE, 2022).

Joshi, S. & Paik, J. Pneumatic supply system parameter optimization for soft actuators. Soft Robot. 8, 152–163 (2021).

Cacucciolo, V. et al. Stretchable pumps for soft machines. Nature 572, 516–519 (2019).

Smith, M., Cacucciolo, V. & Shea, H. Fiber pumps for wearable fluidic systems. Science 379, 1327–1332 (2023).

Qiu, Y., Lu, Z. & Pei, Q. Refreshable tactile display based on a bistable electroactive polymer and a stretchable serpentine joule heating electrode. ACS Appl. Mater. Interfaces 10, 24807–24815 (2018).

Russomanno, A., Gillespie, R. B., O’Modhrain, S. & Burns, M. The design of pressure-controlled valves for a refreshable tactile display. In 2015 IEEE World Haptics Conf. 177–182 (IEEE, 2015).

Raitor, M., Walker, J. M., Okamura, A. M. & Culbertson, H. WRAP: wearable, restricted-aperture pneumatics for haptic guidance. In 2017 IEEE International Conference on Robotics and Automation (ICRA) 427–432 (IEEE, 2017).

Wu, X., Kim, S.-H., Zhu, H., Ji, C.-H. & Allen, M. G. A refreshable braille cell based on pneumatic microbubble actuators. J. Microelectromech. Syst. 21, 908–916 (2012).

Zárate, J. J., Tosolini, G., Petroni, S., De Vittorio, M. & Shea, H. Optimization of the force and power consumption of a microfabricated magnetic actuator. Sens. Actuators A Phys. 234, 57–64 (2015).

Ozioko, O., Karipoth, P., Hersh, M. & Dahiya, R. Wearable assistive tactile communication interface based on integrated touch sensors and actuators. IEEE Trans. Neural Syst. Rehabilitat. Eng. 28, 1344–1352 (2020).

Jung, Y. H., Kim, J.-H. & Rogers, J. A. Skin-integrated vibrohaptic interfaces for virtual and augmented reality. Adv. Funct. Mater. 31, 2008805 (2021).

Ha, K.-H. et al. Full freedom-of-motion actuators as advanced haptic interfaces. Science 387, 1383–1390 (2025).

Huang, Y. et al. A skin-integrated multimodal haptic interface for immersive tactile feedback. Nat. Electron. 6, 1020–1031 (2023).

Gallo, S., Son, C., Lee, H. J., Bleuler, H. & Cho, I.-J. A flexible multimodal tactile display for delivering shape and material information. Sens. Actuators A Phys. 236, 180–189 (2015).

Jung, Y. H. et al. A wireless haptic interface for programmable patterns of touch across large areas of the skin. Nat. Electron. 5, 374–385 (2022).

Flavin, M. T. et al. Bioelastic state recovery for haptic sensory substitution. Nature 635, 345–352 (2024).

Li, D. et al. Miniaturization of mechanical actuators in skin-integrated electronics for haptic interfaces. Microsyst. Nanoeng. 7, 85 (2021).

Li, D. et al. Bioinspired ultrathin piecewise controllable soft robots. Adv. Mater. Technol. 6, 2001095 (2021).

Li, D., Yao, K., Gao, Z., Liu, Y. & Yu, X. Recent progress of skin-integrated electronics for intelligent sensing.Light Adv. Manuf. 2, 39–58 (2021).

Kim, J. et al. Braille display for portable device using flip-latch structured electromagnetic actuator. IEEE Trans. Haptics 13, 59–65 (2020).

Johnstone, R. W. & Parameswaran, M. in An Introduction to Surface-Micromachining (eds Johnstone, R. W. & Parameswaran, M.) 135–152 (Springer US, 2004).

Ariano, P. et al. Polymeric materials as artificial muscles: an overview. J. Appl. Biomater. Funct. Mater. 13, 1–9 (2015).

Tang, C. et al. A review on high-frequency dielectric elastomer actuators: materials, dynamics, and applications. Adv. Intell. Syst. 6, 2300047 (2024).

Yang, L., Wang, H., Zhang, D., Yang, Y. & Leng, D. Large deformation, high energy density dielectric elastomer actuators: principles, factors, optimization, applications, and prospects. Chem. Eng. J. 489, 151402 (2024).

Pelrine, R. E., Kornbluh, R. D. & Joseph, J. P. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 64, 77–85 (1998).

Pelrine, R., Kornbluh, R., Pei, Q. & Joseph, J. High-speed electrically actuated elastomers with strain greater than 100%. Science 287, 836–839 (2000).

Keplinger, C., Li, T., Baumgartner, R., Suo, Z. & Bauer, S. Harnessing snap-through instability in soft dielectrics to achieve giant voltage-triggered deformation. Soft Matter 8, 285–288 (2011).

Lee, H. S. et al. Design analysis and fabrication of arrayed tactile display based on dielectric elastomer actuator. Sens. Actuators A Phys. 205, 191–198 (2014).

Yuan, W. et al. Fault-tolerant dielectric elastomer actuators using single-walled carbon nanotube electrodes. Adv. Mater. 20, 621–625 (2008).

Yuan, W., Brochu, P., Ha, S. M. & Pei, Q. Dielectric oil coated single-walled carbon nanotube electrodes for stable, large-strain actuation with dielectric elastomers. Sens. Actuators A Phys. 155, 278–284 (2009).

Stoyanov, H. et al. Long lifetime, fault-tolerant freestanding actuators based on a silicone dielectric elastomer and self-clearing carbon nanotube compliant electrodes. RSC Adv. 3, 2272–2278 (2013).

Ji, X. et al. Untethered feel-through haptics using 18-µm thick dielectric elastomer actuators. Adv. Funct. Mater. 31, 2006639 (2021).

Ankit, Tiwari, N., Rajput, M., Chien, N. A. & Mathews, N. Highly transparent and integrable surface texture change device for localized tactile feedback. Small 14, 1702312 (2018).

Mun, S. et al. Electro-active polymer based soft tactile interface for wearable devices. IEEE Trans. Haptics 11, 15–21 (2018).

Marette, A. et al. Flexible zinc–tin oxide thin film transistors operating at 1 kV for integrated switching of dielectric elastomer actuators arrays. Adv. Mater. 29, 1700880 (2017).

Guo, Y. et al. Haptic artificial muscle skin for extended reality. Sci. Adv. 10, eadr1765 (2024).

Youn, J.-H. et al. Skin-attached haptic patch for versatile and augmented tactile interaction. Sci. Adv. 11, eadt4839 (2025).

Ji, X. et al. An autonomous untethered fast soft robotic insect driven by low-voltage dielectric elastomer actuators. Sci. Robot. 4, eaaz6451 (2019).

Zhao, H. et al. A wearable soft haptic communicator based on dielectric elastomer actuators. Soft Robot. 7, 451–461 (2020).

Chen, Y. et al. Controlled flight of a microrobot powered by soft artificial muscles. Nature 575, 324–329 (2019).

Carpi, F. & De Rossi, D. Dielectric elastomer cylindrical actuators: electromechanical modelling and experimental evaluation. Mater. Sci. Eng. C 24, 555–562 (2004).

Dünki, S. J., Ko, Y. S., Nüesch, F. A. & Opris, D. M. Self-repairable, high permittivity dielectric elastomers with large actuation strains at low electric fields. Adv. Funct. Mater. 25, 2467–2475 (2015).

Zhang, Y. et al. Electrical and mechanical self-healing in high-performance dielectric elastomer actuator materials. Adv. Funct. Mater. 29, 1808431 (2019).

Yin, L.-J. et al. Soft, tough, and fast polyacrylate dielectric elastomer for non-magnetic motor. Nat. Commun. 12, 4517 (2021).

Youn, J.-H., Mun, H. & Kyung, K.-U. A wearable soft tactile actuator with high output force for fingertip interaction. IEEE Access 9, 30206–30215 (2021).

Phung, H. et al. Interactive haptic display based on soft actuator and soft sensor. In 2017 IEEE/RSJ Int. Conf. Intell. Robot. Syst. 886–891 (IEEE, 2017).

Chen, S., Chen, Y., Yang, J., Han, T. & Yao, S. Skin-integrated stretchable actuators toward skin-compatible haptic feedback and closed-loop human–machine interactions. npj Flex. Electron. 7, 1 (2023).

Han, A. K., Ji, S., Wang, D. & Cutkosky, M. R. Haptic surface display based on miniature dielectric fluid transducers. IEEE Robot. Autom. Lett. 5, 4021–4027 (2020).

Leroy, E. & Shea, H. Hydraulically amplified electrostatic taxels (HAXELs) for full body haptics. Adv. Mater. Technol. 8, 2300242 (2023).

Grasso, G., Rosset, S. & Shea, H. Fully 3D-printed, stretchable, and conformable haptic interfaces. Adv. Funct. Mater. 33, 2213821 (2023).

Shao, Y., Shagan Shomron, A., Javot, B., Keplinger, C. & Kuchenbecker, K. J. Wearable electrohydraulic actuation for salient full-fingertip haptic feedback. Adv. Mater. Technol. 10, 2401525 (2025).

Rothemund, P., Kellaris, N., Mitchell, S. K., Acome, E. & Keplinger, C. HASEL artificial muscles for a new generation of lifelike robots — recent progress and future opportunities. Adv. Mater. 33, 2003375 (2021).

Taghavi, M., Helps, T. & Rossiter, J. Electro-ribbon actuators and electro-origami robots. Sci. Robot. 3, eaau9795 (2018).

Kellaris, N., Gopaluni Venkata, V., Smith, G. M., Mitchell, S. K. & Keplinger, C. Peano-HASEL actuators: muscle-mimetic, electrohydraulic transducers that linearly contract on activation. Sci. Robot. 3, eaar3276 (2018).

Acome, E. et al. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science 359, 61–65 (2018).

Leroy, E., Hinchet, R. & Shea, H. Multimode hydraulically amplified electrostatic actuators for wearable haptics. Adv. Mater. 32, 2002564 (2020).

Sîrbu, I.-D. et al. Electrostatic actuators with constant force at low power loss using matched dielectrics. Nat. Electron. 6, 888–899 (2023).

Rothemund, P., Kirkman, S. & Keplinger, C. Dynamics of electrohydraulic soft actuators. Proc. Natl Acad. Sci. USA117, 16207–16213 (2020).

Zhao, X. & Wang, Q. Harnessing large deformation and instabilities of soft dielectrics: theory, experiment, and application. Appl. Phys. Rev. 1, 021304 (2014).

Mirvakili, S. M. & Hunter, I. W. Artificial muscles: mechanisms, applications, and challenges. Adv. Mater. 30, 1704407 (2018).

Ma, S. et al. High-performance ionic-polymer–metal composite: toward large-deformation fast-response artificial muscles. Adv. Funct. Mater. 30, 1908508 (2020).

Lu, C. et al. High-performance graphdiyne-based electrochemical actuators. Nat. Commun. 9, 752 (2018).

Correia, D. M. et al. Ionic liquid cation size-dependent electromechanical response of ionic liquid/poly(vinylidene fluoride)-based soft actuators. J. Phys. Chem. C 123, 12744–12752 (2019).

Zhang, H. et al. Low-voltage driven ionic polymer–metal composite actuators: structures, materials, and applications. Adv. Sci. 10, 2206135 (2023).

Wang, H., Yang, L., Yang, Y., Zhang, D. & Tian, A. Highly flexible, large-deformation ionic polymer metal composites for artificial muscles: fabrication, properties, applications, and prospects. Chem. Eng. J. 469, 143976 (2023).

Mahato, M. et al. CTF-based soft touch actuator for playing electronic piano. Nat. Commun. 11, 5358 (2020).

Yang, L. et al. Fabrication of Cu/nafion-based ionic polymer metal composites by electroless plating method. Integr. Ferroelectr. 209, 48–57 (2020).

Kim, S. Y. et al. Deformable ionic polymer artificial mechanotransducer with an interpenetrating nanofibrillar network. ACS Appl. Mater. Interfaces 11, 29350–29359 (2019).

Wang, G. et al. Review on the research progress and application of IPMC sensors. J. Bionic Eng. 21, 2687–2716 (2024).

Feng, G.-H. & Hou, S.-Y. Investigation of tactile bump array actuated with ionic polymer–metal composite cantilever beams for refreshable braille display application. Sens. Actuators A Phys. 275, 137–147 (2018).

Mazursky, A., Koo, J.-H., Mason, T., Woo, S.-Y. & Yang, T.-H. Design and experimental evaluation of an electrorheological haptic module with embedded sensing. Appl. Sci. 11, 7723 (2021).

Kato, Y. et al. Sheet-type braille displays by integrating organic field-effect transistors and polymeric actuators. IEEE Trans. Electron. Devices 54, 202–209 (2007).

Kong, L. & Chen, W. Carbon nanotube and graphene-based bioinspired electrochemical actuators. Adv. Mater. 26, 1025–1043 (2014).

Bang, J. et al. Bioinspired electronics for intelligent soft robots. Nat. Rev. Electr. Eng. 1, 597–613 (2024).

Chen, Z. et al. Bioinspired and biohybrid soft robots: principles and emerging technologies. Matter 8, 102045 (2025).

Kang, B. B., Choi, H., Lee, H. & Cho, K.-J. Exo-glove poly II: a polymer-based soft wearable robot for the hand with a tendon-driven actuation system. Soft Robot. 6, 214–227 (2019).

Lee, H. et al. 3D-printed programmable tensegrity for soft robotics. Sci. Robot. 5, eaay9024 (2020).

Mu, J. et al. Sheath-run artificial muscles. Science 365, 150–155 (2019).

Lima, M. D. et al. Electrically, chemically, and photonically powered torsional and tensile actuation of hybrid carbon nanotube yarn muscles. Science 338, 928–932 (2012).

Ze, Q. et al. Soft robotic origami crawler. Sci. Adv. 8, eabm7834 (2022).

Zhang, Z. et al. Active mechanical haptics with high-fidelity perceptions for immersive virtual reality. Nat. Mach. Intell. 5, 643–655 (2023).

Ko, J. et al. High-performance electrified hydrogel actuators based on wrinkled nanomembrane electrodes for untethered insect-scale soft aquabots. Sci. Robot. 7, eabo6463 (2022).

Patel, R. V., Atashzar, S. F. & Tavakoli, M. Haptic feedback and force-based teleoperation in surgical robotics. Proc. IEEE 110, 1012–1027 (2022).

Brown, N. C., Ames, D. C. & Mueller, J. Multimaterial extrusion 3D printing printheads. Nat. Rev. Mater. https://doi.org/10.1038/s41578-025-00809-y (2025).

Abbel, R., Galagan, Y. & Groen, P. Roll-to-roll fabrication of solution processed electronics. Adv. Eng. Mater. 20, 1701190 (2018).

Su, M. & Song, Y. Printable smart materials and devices: strategies and applications. Chem. Rev. 122, 5144–5164 (2022).

Ho, H.-N. Material recognition based on thermal cues: mechanisms and applications. Temperature 5, 36–55 (2018).

Oh, J. et al. A liquid metal based multimodal sensor and haptic feedback device for thermal and tactile sensation generation in virtual reality. Adv. Funct. Mater. 31, 2007772 (2021).

Hsu, P.-C. et al. Personal thermal management by metallic nanowire-coated textile. Nano Lett. 15, 365–371 (2015).

Lee, J. et al. Stretchable skin-like cooling/heating device for reconstruction of artificial thermal sensation in virtual reality. Adv. Funct. Mater. 30, 1909171 (2020).

Hong, S. et al. Wearable thermoelectrics for personalized thermoregulation. Sci. Adv. 5, eaaw0536 (2019).

Kotagama, P., Phadnis, A., Manning, K. C. & Rykaczewski, K. Rational design of soft, thermally conductive composite liquid-cooled tubes for enhanced personal, robotics, wearable electron. cooling. Adv. Mater. Technol. 4, 1800690 (2019).

Cai, S., Ke, P., Narumi, T. & Zhu, K. ThermAirGlove: a pneumatic glove for thermal perception and material identification in virtual reality. In 2020 IEEE Conference on Virtual Reality and 3D User Interfaces (VR) 248–257 (IEEE, 2020).

Lee, J., Kim, D., Sul, H. & Ko, S. H. Thermo-haptic materials and devices for wearable virtual and augmented reality. Adv. Funct. Mater. 31, 2007376 (2021).

Bensmaїa, S. J. & Hollins, M. Complex tactile waveform discrimination. J. Acoustic. Soc. Am. 108, 1236–1245 (2000).

Birznieks, I. et al. Tactile sensory channels over-ruled by frequency decoding system that utilizes spike pattern regardless of receptor type. eLife 8, e46510 (2019).

Ju, W.-E., Moon, Y.-J., Park, C.-H. & Choi, S. T. A flexible tactile-feedback touch screen using transparent ferroelectric polymer film vibrators. Smart Mater. Struct. 23, 074004 (2014).

Haynes, A., Simons, M. F., Helps, T., Nakamura, Y. & Rossiter, J. A Wearable skin-stretching tactile interface for human–robot and human–human communication. IEEE Robot. Autom. Lett. 4, 1641–1646 (2019).

Kang, B. et al. A flexible skin-mounted haptic interface for multimodal cutaneous feedback. Nat. Electron. 8, 818–830 (2025).

Sanchez-Tamayo, N. et al. Cutaneous electrohydraulic (CUTE) wearable devices for pleasant broad-bandwidth haptic cues. Adv. Sci. 11, 2402461 (2024).

Delmas, P., Hao, J. & Rodat-Despoix, L. Molecular mechanisms of mechanotransduction in mammalian sensory neurons. Nat. Rev. Neurosci. 12, 139–153 (2011).

Zimmerman, A., Bai, L. & Ginty, D. D. The gentle touch receptors of mammalian skin. Science 346, 950–954 (2014).

Pacchierotti, C. et al. Wearable haptic systems for the fingertip and the hand: taxonomy, review, and perspectives. IEEE Trans. Haptics 10, 580–600 (2017).

Rongala, U. B., Seyfarth, A., Hayward, V. & Jörntell, H. The import of skin tissue dynamics in tactile sensing. Cell Rep. Phys. Sci. 5, 101943 (2024).

Scheibert, J., Leurent, S., Prevost, A. & Debrégeas, G. The role of fingerprints in the coding of tactile information probed with a biomimetic sensor. Science 323, 1503–1506 (2009).

Jacquemoud, C., Bruyere-Garnier, K. & Coret, M. Methodology to determine failure characteristics of planar soft tissues using a dynamic tensile test. J. Biomech. 40, 468–475 (2007).

Bader, D. L. & Bowker, P. Mechanical characteristics of skin and underlying tissues in vivo. Biomaterials 4, 305–308 (1983).

Joodaki, H. & Panzer, M. B. Skin mechanical properties and modeling: a review. Proc. Instn Mech. Eng. H 232, 323–343 (2018).

Sakaguchi, S., Saito, K., Arakawa, N. & Konyo, M. The dynamic behavior of skin in response to vibrating touch stimuli affects tactile perception. Skin. Res. Technol. 29, e13295 (2023).

Boyer, G., Laquièze, L., Le Bot, A., Laquièze, S. & Zahouani, H. Dynamic indentation on human skin in vivo: ageing effects. Skin Res. Technol. 15, 55–67 (2009).

Hale, K. S. & Stanney, K. M. Deriving haptic design guidelines from human physiological, psychophysical, and neurological foundations. IEEE Computer Graph. Appl. 24, 33–39 (2004).

Deflorio, D., Di Luca, M. & Wing, A. M. Skin and mechanoreceptor contribution to tactile input for perception: a review of simulation models. Front. Hum. Neurosci. 16, 862344 (2022).

Pasluosta, C., Kiele, P. & Stieglitz, T. Paradigms for restoration of somatosensory feedback via stimulation of the peripheral nervous system. Clin. Neurophysiol. 129, 851–862 (2018).

Johansson, R. S. & Vallbo, ÅB. Tactile sensory coding in the glabrous skin of the human hand. Trends Neurosci. 6, 27–32 (1983).

Li, B. & Gerling, G. J. An individual’s skin stiffness predicts their tactile discrimination of compliance. J. Physiol. 601, 5777–5794 (2023).

Acknowledgements

This work was supported by the Research Grants Council of the Hong Kong Special Administrative Region (Grant Nos RFS2324-1S03, R1017-24F, C7005-23Y, T43-518/24-N, 11215722 and 11211523), City University of Hong Kong (Grant Nos 9200138 and 9200143), National Natural Science Foundation of China (Grant No. 52503311), the Nano and Material Technology Development Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (No. RS-2024-00411904), in part by the InnoHK Project on Project 2.2 — AI-based 3D ultrasound imaging algorithm at the Hong Kong Centre for Cerebro-Cardiovascular Health Engineering (COCHE).

Author information

Authors and Affiliations

Contributions

Z.C. and Y.H. contributed equally to this work. X.Y. and Y.H. conceived the ideas. Z.C., Y.H., B.Z., D.S. and X.Y. wrote and revised the manuscript. All authors contributed to discussing and commenting on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interest.

Peer review

Peer review information

Nature Reviews Materials thanks Seung Hwan Ko, Chengkuo Lee and Chwee Teck Lim for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Z., Huang, Y., Zhang, B. et al. Deformable materials and structures in wearable haptic interfaces. Nat Rev Mater (2026). https://doi.org/10.1038/s41578-025-00877-0

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41578-025-00877-0