Abstract

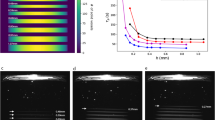

In tomographic Volumetric Additive Manufacturing (VAM), light is projected into a rotating vial of photosensitive resin, enabling printing of polymer structures around pre-existing inserts (‘overprinting’). However, printing around complex, heavily occluding inserts remains unexplored. In this study, the capabilities and challenges of the tomographic VAM process when printing around such inserts are examined, and an occlusion-based orientation optimization is proposed to address these challenges. A cost function based on light occlusion is introduced to predict optical dose quality and optimize insert and print model orientation. By maximizing the number of directions from which the print model voxels receive light, dose quality and print fidelity are increased. Simulations showed that although the conventional tomographic VAM overprinting works well for simple convex inserts, it struggles for complex ones, and the proposed orientation optimization method improves print quality and reduces unprinted regions. A commercial resin wase used for volumetric overprinting of complex structures. Physical prints closely matched simulation results; micro-CT imagery confirmed that orientation optimization significantly improves tomographic volumetric printing around complex and occluding inserts and increases the possible depth of printing within insert recesses. This approach has enabled printing complex geometries around complex inserts, often unfeasible using conventional manufacturing methods.

Similar content being viewed by others

Data availability

All data regarding this study are included in the manuscript, Supplementary Information, and online (benchmark files, orientation optimization code, micro-CT imagery, and a sample print video) at the link below: https://doi.org/10.5281/zenodo.15421104.

References

Vasconcelos, R. L., Oliveira, G. H. M., Amancio-Filho, S. T. & Canto, L. B. Injection overmolding of polymer-metal hybrid structures: A review. Polym. Eng. Sci. 63, 691–722. https://doi.org/10.1002/pen.26244 (2023).

Aliyeva, N., Sas, H. S. & Saner Okan, B. Recent developments on the overmolding process for the fabrication of thermoset and thermoplastic composites by the integration of nano/micron-scale reinforcements. Compos. - A: Appl. Sci. Manuf. 149, 106525. https://doi.org/10.1016/j.compositesa.2021.106525 (2021).

Cheng, B. et al. In situ chemical bonding at the 30 wt.% GF/PA6-A2024 aluminium alloy interface via ultrasonic-assisted injection moulding. Thin-Walled Struct. 210, 112983. https://doi.org/10.1016/j.tws.2025.112983 (2025).

Wang, J., Mao, Q., Jiang, N. & Chen, J. Effects of Injection Molding Parameters on Properties of Insert-Injection Molded Polypropylene Single-Polymer Composites. Polymers, 14, 23. (2022). https://doi.org/10.3390/polym14010023

Kulkarni, R. et al. An assessment of thermoset injection molding for Thin-Walled conformal encapsulation of Board-Level electronic packages. J. Manuf. Mater. Process. 3, 18. https://doi.org/10.3390/jmmp3010018 (2019).

Rajamani, P. K., Ageyeva, T. & Kovács, J. G. Personalized mass production by hybridization of additive manufacturing and injection molding. Polymers 13, 309. https://doi.org/10.3390/polym13020309 (2021).

Islam, M. A. et al. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 132, 108364. https://doi.org/10.1016/j.polymertesting.2024.108364 (2024).

Kataria, A. & Rosen, D. W. Building around inserts: methods for fabricating complex devices in stereolithography. Rapid Prototyp. J. 7, 253–262. https://doi.org/10.1108/13552540110410459 (2001).

Glasschroeder, J., Prager, E. & Zaeh, M. F. Powder-bed-based 3D-printing of function integrated parts. Rapid Prototyp. J. 21, 207–215. https://doi.org/10.1108/RPJ-12-2014-0172 (2015).

Ahlers, D. et al. Automated in situ placing of metal components into 3-D printed FFF objects. IEEE ASME Trans. Mechatron. 26, 1886–1894. https://doi.org/10.1109/TMECH.2021.3078409 (2021).

Meisel, N. A., Elliott, A. M. & Williams, C. B. A procedure for creating actuated joints via embedding shape memory alloys in polyjet 3D printing. J. Intell. Mater. Syst. Struct. 26, 1498–1512. https://doi.org/10.1177/1045389X14544144 (2015).

Delmans, M. & Haseloff, J. µCube: a framework for 3D printable optomechanics. J. Open. Hardw. 2, 1–9. https://doi.org/10.5334/joh.8 (2018).

Kelly, B. E. et al. Volumetric additive manufacturing via tomographic reconstruction. Science 363, 1075–1079. https://doi.org/10.1126/science.aau7114 (2019).

Schwartz, J. J. Additive manufacturing: frameworks for chemical Understanding and advancement in vat photopolymerization. MRS Bull. 47, 628–641. https://doi.org/10.1557/s43577-022-00343-0 (2022).

Madrid-Wolff, J. et al. A review of materials used in tomographic volumetric additive manufacturing. MRS Commun. 13, 764–785. https://doi.org/10.1557/s43579-023-00447-x (2023).

Waddell, T. et al. Use of volumetric additive manufacturing as an in-space manufacturing technology. Acta Astronaut. 211, 474–482. https://doi.org/10.1016/j.actaastro.2023.06.048 (2023).

de Beer, M. P. et al. Rapid, continuous additive manufacturing by volumetric polymerization Inhibition patterning. Sci. Adv. 5, eaau8723. https://doi.org/10.1126/sciadv.aau8723 (2019).

Loterie, D., Delrot, P. & Moser, C. High-resolution tomographic volumetric additive manufacturing. Nat. Commun. 11, 852. https://doi.org/10.1038/s41467-020-14630-4 (2020).

Falandt, M. et al. Spatial-Selective volumetric 4D printing and Single-Photon grafting of biomolecules within Centimeter-Scale hydrogels via tomographic manufacturing. Adv. Mater. Technol. 8, 2370071. https://doi.org/10.1002/admt.202370071 (2023).

Qiu, W. et al. A synthetic dynamic Polyvinyl alcohol Photoresin for fast volumetric Bioprinting of functional ultrasoft hydrogel constructs. Adv. Funct. Mater. 33, 2214393. https://doi.org/10.1002/adfm.202214393 (2023).

Cook, C. C. et al. Highly tunable Thiol-Ene photoresins for volumetric additive manufacturing. Adv. Mater. 32, 2003376. https://doi.org/10.1002/adma.202003376 (2020).

Schwartz, J. J., Porcincula, D. H., Cook, C. C., Fong, E. J. & Shusteff, M. Volumetric additive manufacturing of shape memory polymers. Polym. Chem. 13, 1813–1817. https://doi.org/10.1039/D1PY01723C (2022).

Kollep, M. et al. Tomographic volumetric additive manufacturing of silicon oxycarbide ceramics. Adv. Eng. Mater. 24, 2101345. https://doi.org/10.1002/adem.202101345 (2022).

Toombs, J. T. et al. Volumetric additive manufacturing of silica glass with microscale computed axial lithography. Science 376, 308–312. https://doi.org/10.1126/science.abm6459 (2022).

Pazhamannil, R. V., Hadidi, H. M. & Puthumana, G. Development of a low-cost volumetric additive manufacturing printer using less viscous commercial resins. Polym. Eng. Sci. 63, 65–77. https://doi.org/10.1002/pen.26186 (2023).

Chansoria, P. et al. Synergizing algorithmic Design, photoclick chemistry and Multi-Material volumetric printing for accelerating complex shape engineering. Adv. Sci. 10, 2300912. https://doi.org/10.1002/advs.202300912 (2023).

Bernal, P. N. et al. Volumetric Bioprinting of complex Living-Tissue constructs within seconds. Adv. Mater. 31, 1904209. https://doi.org/10.1002/adma.201904209 (2019).

Madrid-Wolff, J., Boniface, A., Loterie, D., Delrot, P. & Moser, C. Controlling light in scattering materials for volumetric additive manufacturing. Adv. Sci. 9, 2105144. https://doi.org/10.1002/advs.202105144 (2022).

Bhattacharya, I., Toombs, J. & Taylor, H. High fidelity volumetric additive manufacturing. Addit. Manuf. 47, 102299. https://doi.org/10.1016/j.addma.2021.102299 (2021).

Rackson, C. M. et al. Object-space optimization of tomographic reconstructions for additive manufacturing. Addit. Manuf. 48, 102367. https://doi.org/10.1016/j.addma.2021.102367 (2021).

Toombs, J. T., Shan, I. K. & Taylor, H. K. Ethyl Cellulose-Based thermoreversible organogel photoresist for Sedimentation-Free volumetric additive manufacturing. Macromol. Rapid Commun. 44, 2200872. https://doi.org/10.1002/marc.202200872 (2023).

Darkes-Burkey, C. & Shepherd, R. F. Volumetric 3D printing of endoskeletal soft robots. Adv. Mater. 36, 2402217. https://doi.org/10.1002/adma.202402217 (2024).

Bagheri, A., Zakerzadeh, M. R. & Sadigh, M. J. Weighting Method to Increase Print Fidelity of Filtered Back Projection Volumetric Additive Manufacturing Around Complex Inserts. 11th RSI Int. Conf. Robot. Mechatron. (ICRoM). 682–686. (2023). https://doi.org/10.1109/ICRoM60803.2023.10412496 (2023).

Bagheri, A., Zakerzadeh, M. R. & Sadigh, M. J. Occlusion-based model weighting for volumetric additive manufacturing around inserts. Virtual Phys. Prototyp. 19, e2407473. https://doi.org/10.1080/17452759.2024.2407473 (2024).

Birosz, M. T., Safranyik, F. & Andó, M. Build orientation optimization of additive manufactured parts for better mechanical performance by utilizing the principal stress directions. J. Manuf. Process. 84, 1094–1102. https://doi.org/10.1016/j.jmapro.2022.10.038 (2022).

Shi, P. et al. Learn to rotate: part orientation for reducing support volume via generalizable reinforcement learning. IEEE Trans. Industr Inf. 19, 11687–11700. https://doi.org/10.1109/TII.2023.3249751 (2023).

Pereira, S., Vaz, A. I. F. & Vicente, L. N. On the optimal object orientation in additive manufacturing. J. Adv. Manuf. Technol. 98, 1685–1694. https://doi.org/10.1007/s00170-018-2218-0 (2018).

Fritz, K. & Kim, I. Y. Simultaneous topology and build orientation optimization for minimization of additive manufacturing cost and time. Int. J. Numer. Methods Eng. 121, 3442–3481. https://doi.org/10.1002/nme.6366 (2020).

Golmohammadi, A. H., Khodaygan, S. & and A framework for multi-objective optimisation of 3D part-build orientation with a desired angular resolution in additive manufacturing processes. Virtual Phys. Prototyp. 14, 19–36. https://doi.org/10.1080/17452759.2018.1526622 (2019).

Jinlong, L., Zhiping, Z., Zhuqing, W. & Xiong, Y. The effect of build orientation on tensile properties and corrosion resistance of 316L stainless steel fabricated by laser powder bed fusion. J. Manuf. Process. 106, 363–369. https://doi.org/10.1016/j.jmapro.2023.10.010 (2023).

Qin, Y., Qunfen, Q., Peizhi, S., Jiang, X. & J., S. P. & and Automatic determination of part build orientation for laser powder bed fusion. Virtual Phys. Prototyp. 16, 29–49. https://doi.org/10.1080/17452759.2020.1832793 (2021).

Qin, Y. et al. Optimisation of process parameters for improving surface quality in laser powder bed fusion. J. Adv. Manuf. Technol. 130, 2833–2845. https://doi.org/10.1007/s00170-023-12826-8 (2024).

Li, Y. & Teng, Z. Effect of printing orientation on mechanical properties of SLA 3D-printed photopolymer. Fatigue Fract. Eng. Mater. Struct. 47, 1531–1545. https://doi.org/10.1111/ffe.14265 (2024).

Wechsler, F. et al. Overprinting with Tomographic Volumetric Additive Manufacturing. arXiv:2507.13842. (2025).

Florczak, S. et al. Adaptive and context-aware volumetric printing. Nature 645, 108–114. https://doi.org/10.1038/s41586-025-09436-7 (2025).

Kelly, B. E. et al. Volumetric additive manufacturing via tomographic reconstruction [suppl]. Science 363, 1075–1079. https://doi.org/10.1126/science.aau7114 (2019).

Storn, R. & Price, K. Differential Evolution – A simple and efficient heuristic for global optimization over continuous spaces. J. Glob Optim. 11, 341–359. https://doi.org/10.1023/A:1008202821328 (1997).

Virtanen, P. et al. SciPy 1.0: fundamental algorithms for scientific computing in python. Nat. Methods. 17, 261–272. https://doi.org/10.1038/s41592-019-0686-2 (2020).

Toombs, J. computed-axial-lithography/VAMToolbox: v0.1.4b for Zenodo only. Zenodo https://doi.org/10.5281/zenodo.6630437 (2022).

Tisato, S., Vera, G., Mani, A., Chase, T. & Helmer, D. An easy-to-build, accessible volumetric 3D printer based on a liquid crystal display for rapid resin development. Addit. Manuf. 87, 104232. https://doi.org/10.1016/j.addma.2024.104232 (2024).

Author information

Authors and Affiliations

Contributions

AB, RS and MRZ contributed to the study conception. AB designed the models, prepared the figures and the initial draft of the manuscript. AB and RS conducted the simulations, and designed and carried out the experiments. AB, MRZ and MJS provided the materials for the study. MRZ and MJS supervised the study. All authors have read and approved the final manuscript and agree to be responsible for its integrity and accuracy.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary Material 2

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bagheri, A., Zakerzadeh, M.R., Sadigh, M.J. et al. Volumetric additive manufacturing of complex geometries around complex inserts. Sci Rep (2026). https://doi.org/10.1038/s41598-026-35258-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-35258-2