Abstract

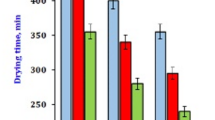

Efficient dehydration of heat-sensitive crops remains a major challenge due to the trade-off between drying time, energy demand, and product quality. This study investigated the hybrid infrared–hot air drying of Moringa oleifera leaves in a continuous conveyor-belt dryer, focusing on the joint effects of air temperature (35–55 °C), airflow velocity (0.3–1.0 m/s), and infrared intensity (0.08–0.15 W/cm2). Experimental results demonstrated that higher air temperatures and infrared intensities significantly reduced drying time (from 210 min at 35 °C, 0.08 W/cm2, and 1.0 m/s to 95 min at 55 °C, 0.15 W/cm2, and 0.3 m/s) and lowered specific energy consumption (SEC) from 5.2 to 3.9 MJ/kg. In contrast, increasing airflow velocity extended the drying period and higher SEC by up to 18%. The maximum thermal and drying efficiencies reached 42.96% and 27.0%, respectively, under optimized conditions. Among eleven thin-layer drying models evaluated, the Midilli–Kucuk model achieved the best performance (R2 > 0.999; RMSE < 0.0003). Artificial intelligence (ANN, PCA, and SOM) further enhanced process interpretation, confirming that high infrared intensity and air temperature minimized SEC while maximizing energy efficiency. An environmental assessment revealed that optimized hybrid drying reduced CO₂ emissions by approximately 20% compared to conventional hot-air drying, corresponding to a carbon mitigation potential of 0.45–0.52 kg CO₂ per kg dried product. These findings establish a predictive and sustainable framework for intelligent hybrid drying, offering industrial relevance for energy-efficient processing of moringa and other heat-sensitive crops.

Similar content being viewed by others

Data availability

The original contributions presented in the study are included in the article; further inquiries can be directed to the first author (Hany S. El-Mesery, elmesiry@ujs.edu.cn) and the corresponding author.

References

Fakayode, O. A., Akpan, D. E. & Ojoawo, O. O. Size characterization of moringa (Moringa oleifera) seeds and optimization of the dehulling process. J. Food Process Eng. 42, e13182 (2019).

Puspantari, W. & Laily, N. Evaluation of physical properties and tannin levels in Moringa leaves using various drying methods (IOP Publ, 2025).

Adekanye, T., Alhassan, E., Amodu, M., Olanrewaju, T. & Iyanda, M. Kinetics of heat and mass transfer in moringa leaves drying in a cabinet dryer. Results Eng. 26, 104763 (2025).

Kusuma, H. S. et al. Experimental investigation in the drying process of moringa leaves using microwave drying: drying kinetics, energy consumption, and CO2 emission. Appl. Food Res. 4, 100401 (2024).

Mardiana, T., Hayati, R. & Hafsah, D. S. Optimization of the physicochemical quality of Moringa oleifera leaf powder with variations in drying temperature and duration (IOP Publ, 2025).

Bao, Y. et al. A phenolic glycoside from Moringa oleifera Lam. improves the carbohydrate and lipid metabolisms through AMPK in db/db mice. Food Chem. 311, 125948 (2020).

El-Mesery, H. S., ElMesiry, A. H., Quaye, E. K., Hu, Z. & Salem, A. Machine learning algorithm for estimating and optimizing the phytochemical content and physicochemical properties of okra slices in an infrared heating system. Food Chem. X 25, 102248 (2025).

Wu, B., Guo, Y., Wang, J., Pan, Z. & Ma, H. Effect of thickness on non-fried potato chips subjected to infrared radiation blanching and drying. J. Food Eng. 237, 249–255 (2018).

Daliran, A., Taki, M., Marzban, A., Rahnema, M. & Farhadi, R. Experimental evaluation and modeling the mass and temperature of dried mint in greenhouse solar dryer; Application of machine learning method. Case Stud. Therm. Eng. 47, 103048 (2023).

El-Mesery, H. S., Hu, Z., Ashiagbor, K. & Rostom, M. A study into how thickness, infrared intensity, and airflow affect drying kinetics, modeling, activation energy, and quality attributes of apple slices using infrared dryer. J. Food Sci. 89, 2895–2908 (2024).

El-Mesery, H. S. et al. Optimization of dried garlic physicochemical properties using a self-organizing map and the development of an artificial intelligence prediction model. Sci. Rep. 15, 3105 (2025).

Ren, Z. et al. Combinative effect of cutting orientation and drying techniques (hot air, vacuum, freeze and catalytic infrared drying) on the physicochemical properties of ginger (Zingiber officinale Roscoe). LWT 111238 https://doi.org/10.1016/j.lwt.2021.111238. (2021)

Torki-Harchegani, M., Ghanbarian, D., Maghsoodi, V. & Moheb, A. Infrared thin layer drying of saffron (Crocus sativus L.) stigmas.: Mass transfer parameters and quality assessment. Chinese J. Chem. Eng. 25, 426–432 (2017).

Krishnamurthy, K., Khurana, H. K., Soojin, J., Irudayaraj, J. & Demirci, A. Infrared heating in food processing: An overview. Compr. Rev. Food Sci. Food Saf. 7, 2–13 (2008).

Boateng, I. D., Yang, X. M. & Li, Y. Y. Optimization of infrared-drying parameters for Ginkgo biloba L. seed and evaluation of product quality and bioactivity. Ind. Crops Prod. 160, 113108 (2021).

Guo, Y. et al. Effects of power ultrasound enhancement on infrared drying of carrot slices: Moisture migration and quality characterizations. Lwt 126, 109312 (2020).

Wu, B., Guo, X., Guo, Y., Ma, H. & Zhou, C. Enhancing jackfruit infrared drying by combining ultrasound treatments: Effect on drying characteristics, quality properties and microstructure. Food Chem. 358, 129845 (2021).

Boateng, I. D. et al. Effect of pulsed-vacuum, hot-air, infrared, and freeze-drying on drying kinetics, energy efficiency, and physicochemical properties of Ginkgo biloba L. seed. J. Food Process Eng. 44, e13655 (2021).

Rashid, M. T. et al. Effect of infrared drying with multifrequency ultrasound pretreatments on the stability of phytochemical properties, antioxidant potential, and textural quality of dried sweet potatoes. J. Food Biochem. 43, e12809 (2019).

Chabane, F., Moummi, N. & Brima, A.. An experimental study and mathematical modeling of solar drying of moisture content of the mint, apricot, and green pepper. Energy Sources,Recover. Util. Environ. Eff. https://doi.org/10.1080/15567036.2019.1670755.(2019)

Rashid, M. T. et al. Multi-frequency ultrasound and sequential infrared drying on drying kinetics, thermodynamic properties, and quality assessment of sweet potatoes. J. Food Process Eng. 42, e13127 (2019).

Salehi, F. Recent Applications and Potential of Infrared Dryer Systems for Drying Various Agricultural Products: A Review. Int. J. Fruit Sci. 20, 586–602 (2020).

Moradi, M., Fallahi, M. A. & Mousavi Khaneghah, A. Kinetics and mathematical modeling of thin layer drying of mint leaves by a hot water recirculating solar dryer. J. Food Process Eng. 43, 1–10 (2020).

Boateng, I. D. et al. Effect of pulsed-vacuum, hot-air, infrared, and freeze-drying on drying kinetics, energy efficiency, and physicochemical properties of Ginkgo biloba L. seed. J. Food Process Eng. 44, 1–14 (2021).

Wu, B. et al. Drying performance and product quality of sliced carrots by infrared blanching followed by different drying methods. Int. J. Food Eng. 14, 20170384 (2018).

Gu, C. et al. Effects of catalytic infrared drying in combination with hot air drying and freeze drying on the drying characteristics and product quality of chives. Lwt 161, 113363 (2022).

Daliran, A., Taki, M., Marzban, A., Rahnama, M. & Farhadi, R. Kinetic analysis, mathematical modeling and quality evaluation of mint drying in greenhouse solar dryer. Therm. Sci. Eng. Prog. 46, 102252 (2023).

de Souza, J. V. B., Perazzini, H., Lima-Corrêa, R. A. B. & Borel, L. D. M. S. Combined infrared-convective drying of banana: Energy and quality considerations. Therm. Sci. Eng. Prog. 48, 102393 (2024).

El‐Mesery, H. S., Ashiagbor, K., Hu, Z. & Rostom, M. Mathematical modeling of thin‐layer drying kinetics and moisture diffusivity study of apple slices using infrared conveyor‐belt dryer. J. Food Sci. (2024).

Sun, Q., Chen, L., Zhou, C., Okonkwo, C. E. & Tang, Y. Effects of cutting and drying method (vacuum freezing, catalytic infrared, and hot air drying) on rehydration kinetics and physicochemical characteristics of ginger (Zingiber officinale Roscoe). J. Food Sci. 87, 3797–3808 (2022).

Yu, J. et al. Drying kinetics of camellia oleifera seeds under hot air drying with ultrasonic pretreatment. Ind. Crops Prod. 222, 119467 (2024).

EL-Mesery, H. S., Sarpong, F. & Atress, A. S. H. Statistical interpretation of shelf-life indicators of tomato (Lycopersicon esculentum) in correlation to storage packaging materials and temperature. J. Food Meas. Charact. 1–11 (2022).

El-Mesery, H. S., ElMesiry, A. H., Husein, M., Hu, Z. & Salem, A. Artificial intelligence and machine learning models for predicting and evaluating the influence of shelf-life environments and packaging materials on garlic (Allium Sativum L) physicochemical and phytochemical compositions. Food Chem. X 29, 102731 (2025).

Zadhossein, S., Abbaspour-Gilandeh, Y., Kaveh, M., Nadimi, M. & Paliwal, J. Comparison of the energy and exergy parameters in cantaloupe (Cucurbita maxima) drying using hot air. Smart Agric. Technol. 4, 100198 (2023).

Zhang, W., Wang, K. & Chen, C. Artificial Neural Network Assisted Multiobjective Optimization of Postharvest Blanching and Drying of Blueberries. Foods 11, 1–18 (2022).

Aghababaei, A., Aghababaei, F., Pignitter, M. & Hadidi, M. Artificial Intelligence in Agro-Food Systems: From Farm to Fork. Foods (2025).

Zhong, L. et al. Improving of the drying characteristics, moisture migration and quality attributes by ultrasound pretreatment for convective dried Stropharia rugosoannulata slices. Food Res. Int. 211, 116465 (2025).

AOAC. Official methods of analysis of Official Analytical Chemistry. 16th ed., 3 rev. Gaitherburg: Published by AOAC International (1997).

El-Mesery, H. S., Qenawy, M., Hu, Z. & Alshaer, W. G. Evaluation of infrared drying for okra: Mathematical modelling, moisture diffusivity, energy activity and quality attributes. Case Stud. Therm. Eng. 50, 103451 (2023).

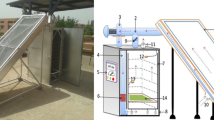

El-Mesery, H. S., ElMesiry, A. H., Adelusi, O. A., Hu, Z. & Elhadad, S. Computational simulation and mathematical modelling of thermal performance and energy enhancement of integrated infrared with hot air heated system. Alexandria Eng. J. 127, 920–942 (2025).

Aghbashlo, M. & kianmehrSamimi-Akhijahani, M. H. H. Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers. Manag. 49, 2865–2871 (2008).

El-Mesery, H. S., Ali, M., Qenawy, M. & Adelusi, O. A. Application of artificial intelligence to predict energy consumption and thermal efficiency of hybrid convection-radiation dryer for garlic slices. Eng. Appl. Artif. Intell. 138, 109338 (2024).

Castro, A. M., Mayorga, E. Y. & Moreno, F. L. Mathematical modelling of convective drying of feijoa (Acca sellowiana Berg) slices. J. Food Eng. 252, 44–52 (2019).

EL-Mesery, H. S. Improving the thermal efficiency and energy consumption of convective dryer using various energy sources for tomato drying. Alexandria Eng. J. 61, 10245–10261 (2022).

Kaveh, M., Zomorodi, S., Mariusz, S. & Dziwulska-Hunek, A. Determination of Drying Characteristics and Physicochemical Properties of Mint (Mentha spicata L). Leaves Dried in Refractance Window. Foods 13, 2867 (2024).

Kumar, L. & Prakash, O. Optimal simulation approach for tomato flakes drying in hybrid solar dryer. Energy Sources. Part A Recover. Util. Environ. Eff. 46, 5867–5887 (2024).

Kumar, L. & Prakash, O. Efficient simulation of bitter gourd drying in active solar dryer: A state-of-the-art model. Renew. Energy 227, 120434 (2024).

EL-Mesery, H. S., Kamel, R. M. & Emara, R. Z. Influence of infrared intensity and air temperature on energy consumption and physical quality of dried apple using hybrid dryer. Case Stud. Therm. Eng. 27, 101365 (2021)

Jahanbakhshi, A., Kaveh, M. & Sharabiani, V. R. Assessment of kinetics, effective moisture diffusivity, specific energy consumption, shrinkage, and color in the pistachio kernel drying process in microwave drying with ultrasonic pretreatment. J. Food. Processing Preservation. https://doi.org/10.1111/jfpp.14449 (2020).

Yagcioglu, A. Drying techniques of agricultural products (Ege Univ. Fac. Agric, 1999).

Page, G. E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin layers. (1949).

Ayensu, A. Dehydration of food crops using a solar dryer with convective heat flow. Sol. Energy 59, 121–126 (1997).

Midilli, A., Kucuk, H. & Yapar, Z. A new model for single-layer drying. Dry. Technol. 20, 1503–1513 (2002).

Wang, G. Y. & Singh, R. P. SINGLE LAYER DRYING EQUATION FOR ROUGH RICE. in Paper - American Society of Agricultural Engineers ASAE (1978).

Verma, L. R., Bucklin, R. A., Endan, J. B. & Wratten, F. T. Effects of drying air parameters on rice drying models. Trans. ASAE 28, 296–301 (1985).

Özdemir, M. & Devres, Y. O. The thin layer drying characteristics of hazelnuts during roasting. J. Food Eng. 42, 225–233 (1999).

Karathanos, V. T. Determination of water content of dried fruits by drying kinetics. J. Food Eng. 39, 337–344 (1999).

Henderson, S. M. & Pabis, S. Grain drying theory I. Temperature effect on drying coefficient. J. Agric. Eng. Res. 6, 169–174 (1961).

Madamba, P. S., Driscoll, R. H. & Buckle, K. A. The thin-layer drying characteristics of garlic slices. J. Food Eng. 29, 75–97 (1996).

Thompson, T. L., Peart, R. M. & Foster, G. H. Matllematical simulation of corn drying a new model. Trans. ASAE 11, 582–586 (1968).

El-Mesery, H. S. et al. Application of experimental, numerical, and machine learning techniques to improve drying performance and decrease energy consumption infrared continuous dryer. Case Stud. Therm. Eng. 69, 106025 (2025).

El-Mesery, H. S. et al. Artificial intelligence as a tool for predicting the quality attributes of garlic (Allium sativum L.) slices during continuous infrared-assisted hot air drying. J. Food Sci. 89, 7693–7712 (2024).

Bei, X. et al. Heat source replacement strategy using catalytic infrared: A future for energy saving drying of fruits and vegetables. J. Food Sci. 88, 13 (2023).

Wu, B. et al. Research progress in the application of catalytic infrared technology in fruit and vegetable processing. Compr. Rev. Food Sci. Food Saf. 23, e13291 (2024).

Bei, X., Yu, X., Zhou, C. & Yagoub, A. E. A. Improvement of the drying quality of blueberries by catalytic infrared blanching combined with ultrasound pretreatment. Food Chem. 447, 138983 (2024).

Kudra, T. & Mujumdar, A. S. Advanced Drying Technologies. Advanced Drying Technologies https://doi.org/10.1201/9781420073898 (2009).

El-Mesery, H. S. et al. Evaluation of infrared radiation combined with hot air convection for energy-efficient drying of biomass. Energies 12, 2818 (2019).

Shen, C. et al. Drying kinetics and moisture migration mechanism of yam slices by cold plasma pretreatment combined with far-infrared drying. Innov. Food Sci. Emerg. Technol. 95, 103730 (2024).

Djebli, A., Hanini, S., Badaoui, O., Haddad, B. & Benhamou, A. Modeling and comparative analysis of solar drying behavior of potatoes. Renew. Energy 145, 1494–1506 (2020).

Lemus-Mondaca, R., Vega-Gálvez, A., Moraga, N. O. & Astudillo, S. Dehydration of S tevia rebaudiana B ertoni Leaves: Kinetics, Modeling and Energy Features. J. Food Process. Preserv. 39, 508–520 (2015).

El-Mesery, H. S. & El-khawaga, S. E. Drying process on biomass: Evaluation of the drying performance and energy analysis of different dryers. Case Stud. Therm. Eng. 33, 101953 (2022).

Kaveh, M., Abbaspour-Gilandeh, Y. & Nowacka, M. Comparison of different drying techniques and their carbon emissions in green peas. Chem. Eng. Process. - Process Intensif. 160, 108274 (2021).

Osae, R. et al. Drying of ginger slices—Evaluation of quality attributes, energy consumption, and kinetics study. J. Food Process Eng. 43, e13348 (2020).

Minaei, S., Chenarbon, H. A., Motevali, A. & Hosseini, A. A. Energy consumption, thermal utilization efficiency and hypericin content in drying leaves of St John ’ s Wort ( Hypericum Perforatum ). J. Energy. Southern Africa. 25, 27–35 (2014).

Suo, K. et al. Comparative Evaluation of Quality Attributes of the Dried Cherry Blossom Subjected to Different Drying Techniques. Foods. 13, 104 (2024).

An, N. N. et al. Effect of different drying techniques on drying kinetics, nutritional components, antioxidant capacity, physical properties and microstructure of edamame. Food Chem. 373, 131412 (2022).

Wu, B. et al. Catalytic infrared blanching and drying of carrot slices with different thicknesses: Effects on surface dynamic crusting and quality characterization. Innov. Food Sci. Emerg. Technol. 88, 103444 (2023).

Wang, Y., Li, T., Pan, Z., Ye, X. & Ma, H. Effectiveness of combined catalytic infrared radiation and holding time for decontamination Aspergillus niger on dried shiitake mushrooms (Lentinus edodes) with different moisture contents. LWT 176, 114503 (2023).

Motevali, A. et al. Comparison of environmental pollution and social cost analyses in different drying technologies. Int. J. Glob. Warm. 22, 1–29 (2020).

Kaveh, M., Çetin, N., Gilandeh, Y. A., Sharifian, F. & Szymanek, M. Comparative evaluation of greenhouse gas emissions and specific energy consumption of different drying techniques in pear slices. Eur. Food Res. Technol. 249, 3027–3041 (2023).

Motevali, A. & Tabatabaee Koloor, R. Acomparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J. Clean. Prod. 154, 445–461 (2017).

Author information

Authors and Affiliations

Contributions

Author contributions Statement Hany S. El-Mesery: supervision, investigation, formal analysis, writing–original draft, writing–review and editing, visualization, funding acquisition. Ahmed H. ElMesiry: investigation, Software, Formal analysis, Methodology, Data curation. Mansuur Husein: investigation. Writing, reviewing, and editing. Fangfang Liu: investigation, conceptualization. Amer Ali Mahdi: investigation, formal analysis, funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

El-Mesery, H.S., ElMesiry, A.H., Husein, M. et al. Computational intelligence applications in predicting energy consumption, greenhouse gas emissions, and drying performance of hybrid infrared dryer. Sci Rep (2026). https://doi.org/10.1038/s41598-026-35355-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-35355-2