Abstract

The depletion of natural resources has created an urgent need to identify alternative, sustainable materials for construction. Simultaneously, the rapid global accumulation and improper disposal of electronic waste (E-waste), particularly in developing countries, have raised significant environmental and public health concerns. This study investigates the use of electronic plastic waste (E-PW) as a partial replacement for fine aggregate in concrete, with replacement levels of 5%, 10%, 15%, and 20% evaluated at different curing ages. While the inclusion of E-PW led to reductions in mechanical and durability performance compared to conventional concrete, these effects were mitigated by replacing 10% of the cement with silica fume (SF). The enhancement provided by SF demonstrated improved strength and performance in the E-PW concrete mixtures. According to SEM results, SF highlights the interfacial transition zone (ITZ) associated with E-PW in the OPC matrix. The best performing mix for blends containing E-PW and SF were M7 (5% E-PW + 10% SF), achieved a compressive strength of 37.69 MPa, a flexural strength of 5.36 MPa, and a splitting tensile strength of 3.91 MPa at 56 days, surpassing those of the reference concrete. An environmental perspective, life cycle assessment demonstrated that a 20% replacement of fine aggregates with E-PW reduced the overall environmental burden by 5.3% and lowered the global warming potential by 1.43%, equivalent to saving approximately 4–5 kg CO₂-eq per cubic meter of concrete. Hence, the findings support the potential for producing eco-efficient concrete by partially replacing natural sand with E-waste, contributing to resource conservation and environmental sustainability.

Similar content being viewed by others

Data availability

Data availability: The datasets generated and analyzed during this study are available from the corresponding author upon request.

Abbreviations

- E-waste:

-

Electronic Waste

- E-PW:

-

Electronic Plastic Waste

- SF:

-

Silica Fume

- SCM:

-

Supplementary Cementitious Materials

- FA:

-

Fine Aggregate

- CA:

-

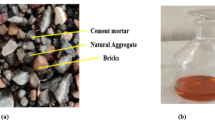

Coarse Aggregate

- SCM:

-

Supplementary Cementitious Materials

- FA:

-

Fine Aggregate

- CA:

-

Coarse Aggregate

- ABS:

-

Acrylonitrile Butadiene Styrene

- FTIR:

-

Fourier-Transform Infrared Spectroscopy

- HIPS:

-

High-Impact Polystyrene

- PC:

-

Polycarbonate

- PVC:

-

Polyvinyl chloride

- UPV:

-

Ultrasonic Pulse Velocity

- RH:

-

Rebound hammer

- RCPT:

-

Rapid Chloride Permeability

- SEM:

-

Scanning Electron Microscopy

- LCA:

-

Life Cycle Assessment

- CH:

-

Calcium Hydroxide

- C-S-H:

-

Calcium Silicate Hydrate

- ITZ:

-

Interfacial Transition Zone

- GPW:

-

Global Warming Potential

- XRD:

-

X-Ray Diffraction

- TGA:

-

Thermogravimetric Analysis

References

Sobuz, M. H. R. et al. Combined influence of modified recycled concrete aggregate and Metakaolin on high-strength concrete production: experimental assessment and machine learning quantifications with advanced SHAP and PDP analyses. Constr. Build. Mater. 461, 139897 (2025).

Kumar, V. Experimental study on concrete incorporating partial replacement of aggregates with coconut shell and cement with rice husk Ash. Int. J. Res. Appl. Sci. Eng. Technol. 12, 1967–1971 (2024).

Patel, J. S. Study on concrete using fly Ash, rise husk Ash and egg shell powder. Int. J. Res. Appl. Sci. Eng. Technol. V, 566–570 (2017).

Demirboga, R. & Farhan, K. Z. Palm oil fuel ash (POFA). in Sustainable Concrete Made with Ashes and Dust from Different Sources 279–330 (Elsevier, 2022). https://doi.org/10.1016/B978-0-12-824050-2.00006-1

Pradhan, S., Kumar, S. & Barai, S. V. Particle packing method of mix proportioning and modified mixing approach. in Particle Packing Method for Recycled Aggregate Concrete 37–47 (Springer Nature Singapore, Singapore, doi:https://doi.org/10.1007/978-981-99-7516-7_4. (2024).

Banerjee, D. & Nanda, R. P. Waste materials as concrete aggregate - A systematic review. IOP Conf. Ser. Earth Environ. Sci. 1326, 012149 (2024).

Jeyanth, B., Sudharsanan, R., Thillai Backiam, M. & Vijay, M. Sustainability of Natural Aggregates by Utilising CDW in Concrete. in Integrated Approaches Towards Solid Waste Management 121–131Springer International Publishing, Cham, (2021). https://doi.org/10.1007/978-3-030-70463-6_12

Omran, S. & Sisupalan, S. Effect of replacing natural aggregate with plastic aggregate on the mechanical properties of Concrete-Review. Civil Environ. Eng. Rep. 34, 462–482 (2024).

Alex Tullo. The plastics industry will confront its carbon footprint. C&EN Global Enterp. 100, 30–30 (2022).

Kumar, P., Kumar, P. & Singh Thakur, S. E. -Waste and hazardous elements: A comprehensive study of chemical components and environmental threats. Int. J. Innovative Sci. Res. Technol. (IJISRT). 1074–1085. https://doi.org/10.38124/ijisrt/IJISRT24OCT1008 (2024).

The Global E-waste Monitor. 2024 - E-Waste Monitor. https://ewastemonitor.info/the-global-e-waste-monitor-2024/

Nithya, R., Sivasankari, C. & Thirunavukkarasu, A. Electronic waste generation, regulation and metal recovery: a review. Environ. Chem. Lett. 19, 1347–1368 (2021).

Priyashantha, A. K. H., Pratheesh, N. & Pretheeba, P. E-waste scenario in South-Asia: an emerging risk to environment and public health. Environ. Anal. Health Toxicol. 37, e2022022 (2022).

Biranagi, P. K. et al. An experimental study on concrete by using E-Waste as partial replacement of coarse aggregate. Int. J. Res. Appl. Sci. Eng. Technol. 12, 250–255 (2024).

Shinu, M. T., Needhidasan, S. & N. M. & An experimental study of replacing conventional coarse aggregate with E-waste plastic for M40 grade concrete using river sand. Mater. Today Proc. 22, 633–638 (2020).

Basha, S., Reddy Ch, M., K, V. & B. & Strength behaviour of geopolymer concrete replacing fine aggregates by M- sand and E-waste. Int. J. Eng. Trends Technol. 40, 401–407 (2016).

Hinge, P. et al. An assessment of workability, mechanical and durability properties of high-strength concrete incorporating nano-silica and recycled E-waste materials. Beni Suef Univ. J. Basic. Appl. Sci. 13, 65 (2024).

Altawaiha, H. A review on the utilization of E-plastic waste in concrete production: a step towards sustainability. J. Building Pathol. Rehabilitation. 9, 131 (2024).

Li, H. et al. Effect of fine aggregate particle characteristics on mechanical properties of fly Ash-Based geopolymer mortar. Minerals 11, 897 (2021).

Alyaseen, A. et al. Influence of silica fume and Bacillus subtilis combination on concrete made with recycled concrete aggregate: experimental investigation, economic analysis, and machine learning modeling. Case Stud. Constr. Mater. 19, e02638 (2023).

Garg, R. et al. Mechanical strength and durability analysis of mortars prepared with fly Ash and nano-metakaolin. Case Stud. Constr. Mater. 18, e01796 (2023).

Paruthi, S., Rahman, I., Khan, A. H., Sharma, N. & Alyaseen, A. Strength, durability, and economic analysis of GGBS-based geopolymer concrete with silica fume under harsh conditions. Sci. Rep. 14, 31572 (2024).

Akram, A., Sasidhar, C. & Pasha, K. M. E-waste management by utilization of E-plastics in concrete mixture as coarse aggregate replacement. Pp Int. J. Innov. Res. Sci. Eng. Technol. 4 (7), 4, 5087–5095 (2015).

Manjunath, B. T. A. Partial replacement of E-plastic waste as Coarse-Aggregate in concrete. Procedia Environ. Sci. 35, 731–739 (2016).

Botchway, D. N. L., Bentil, J. & Henaku, C. Y. Effect of partial replacement of coarse aggregate with electronic waste plastic in light weight concrete. J. Manage. Sci. Eng. Res. 5, 38–44 (2022).

Kumar, K. S. & Baskar, K. Effect of temperature and thermal shock on concrete containing hazardous electronic waste. J. Hazard. Toxic. Radioact Waste. 22, 04017028 (2017).

Ejiogu, I. K. The effect of elevated temperature on the mechanical properties of waste plastics polyethylene trephthalate (PET) and low density polyethylene (LDPE) filled normal concrete blocks. Int. J. Res. Appl. Sci. Eng. Technol. 6, 1510–1520 (2018).

Farah, E., Yaacoub, S. & Dgheim, J. El Hajj, N. Assessing the impact of shredded polyethylene terephthalate (PET) Post-Consumer plastic as a partial replacement for coarse aggregates in unreinforced concrete. Materials 17, 5208 (2024).

Abu-Saleem, M. et al. Evaluation of concrete performance with different types of recycled plastic waste for Kerb application. Constr. Build. Mater. 293, 123477 (2021).

Pešić, N., Živanović, S., Garcia, R. & Papastergiou, P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr. Build. Mater. 115, 362–370 (2016).

Islam, M. J. et al. Strength, durability, and impact behavior of recycled aggregate concrete with polypropylene aggregate. Constr. Build. Mater. 408, 133646 (2023).

Hamah Sor, N. et al. The behavior of sustainable self-compacting concrete reinforced with low-density waste polyethylene fiber. Mater. Res. Express. 9, 035501 (2022).

Wang, L. et al. Experimental investigation on physical properties of concrete containing polypropylene fiber and Water-Borne epoxy for pavement. Coat. 2023. 13, 452 (2023).

Sabău, M. & Vargas, J. R. Use of e-plastic waste in concrete as a partial replacement of coarse mineral aggregate. Computers Concrete. 21, 377–384 (2018).

Pothinathan, S. K. M., Muthukannan, M. & Ganaraj, S. C. Examination of strength and durability properties of E-Concrete using PCB as coarse aggregate. Int. J. Eng. Adv. Technol. 9, 411–415 (2019).

Goh, P. G., Maghfouri, M., Onn, C. C. & Loo, S. C. Life cycle assessment on recycled e-waste concrete. Case Stud. Constr. Mater. 17, e01412 (2022).

Kang, H. Y. & Schoenung, J. M. Economic analysis of electronic waste recycling: modeling the cost and revenue of a materials recovery facility in California. Environ. Sci. Technol. 40, 1672–1680 (2006).

Kumar, A., Devi, K., Singh, M. & Soni, D. K. Significance of stone waste in strength improvement of soil. J. Building Mater. Sci. 1, 32–36 (2019).

Awasthi, M., Vaibhav, K., Choudhary, A. K., Gautam, A. K. & Chandra, A. E-Waste management. Global Waste Manage. 85–114. https://doi.org/10.1002/9781394318414.CH5 (2025).

Aytekin, B., Mardani-Aghabaglou, A. & Sustainable Materials A review of recycled concrete aggregate utilization as pavement material. Transp. Res. Rec. 2676, 468–491 (2022).

Danish, A. et al. A compendious review on the influence of e-waste aggregates on the properties of concrete. Case Stud. Constr. Mater. 18, e01740 (2023).

Bulut, H. A. & Şahin, R. A study on mechanical properties of polymer concrete containing electronic plastic waste. Compos. Struct. 178, 50–62 (2017).

IS 269. Specification for Ordinary Portland Cement, 33 Grade: Bureau of Indian Standards : Free Download, Borrow, and Streaming : Internet Archive. https://archive.org/details/gov.in.is.269.1989

IS 383. Coarse and Fine Aggregate for Concrete - Specification: Bureau of Indian Standards : Free Download, Borrow, and Streaming : Internet Archive. https://archive.org/details/gov.in.is.383.2016/is.383.2016/

Charitopoulou, M. A., Lappas, A. A. & Achilias, D. S. Thermo-chemical recycling of plastics retrieved from waste electric and electronic equipment (WEEE) by pyrolysis: identification of the polymer type, removal of bromine compounds from plastics based on an environmentally-friendly process and characterization of the pyrolysates. Sustain. Chem. Pharm. 35, 101210 (2023).

Shams, S., Idris, P. R. & Yusof, I. Toxicity characterization and environmental impact of E-Waste processing. Manage. Electron. Waste: Resource Recovery Technol. Regul. 73–87. https://doi.org/10.1002/9781119894360.CH4 (2024).

Das, P. & Singh, S. Global Challenges of E-Waste: Its Management and Future Scenarios. Sustainable Management of Electronic Waste 277–292 (2024). https://doi.org/10.1002/9781394166923CH14;JOURNAL:JOURNAL:BOOKS;WGROUP:STRING:PUBLICATION.

IS: 456. Plain and Reinforced Concrete - Code of Practice. (2000).

Pahari, A. K. & Dubey, B. K. Waste From Electrical and Electronics Equipment. Plastics to Energy: Fuel, Chemicals, and Sustainability Implications 443–468 (2019). https://doi.org/10.1016/B978-0-12-813140-4.00018-2

Mourshed, M. et al. Composition, Collection, and treatment of E-Waste. Manage. Electron. Waste: Resource Recovery Technol. Regul. 39–72. https://doi.org/10.1002/9781119894360.CH3 (2024).

Bernstein, M. P., Sandford, S. A. & Allamandola, L. J. The infrared spectra of nitriles and related compounds frozen in ar and H 2 O. Astrophys. J. 476, 932–942 (1997).

Halonen, M., Halonen, L. & Nesbitt, D. J. Structural issues in conjugated hydrocarbons: High-Resolution infrared Slit-Jet spectroscopy of trans-1,3-Butadiene. J. Phys. Chem. A. 108, 3367–3372 (2004).

Sears, W. M., Hunt, J. L. & Stevens, J. R. Raman spectra at low temperatures and depolarization ratios for styrene and polystyrene. J. Chem. Phys. 77, 1639–1644 (1982).

Ali, K., Qureshi, M. I., Saleem, S. & Khan, S. U. Effect of waste electronic plastic and silica fume on mechanical properties and thermal performance of concrete. Constr. Build. Mater. 285, 122952 (2021).

Balasubramanian, B., Krishna, G., Saraswathy, G. V. T., Srinivasan, K. & V. & Experimental investigation on concrete partially replaced with waste glass powder and waste E-plastic. Constr. Build. Mater. 278, 122400 (2021).

Anand & Hamdan, A. Impact of partial replacement of coarse aggregate with electronic plastic waste on compressive strength of concrete. Mater. Today Proc. 56, 143–149 (2022).

Raj Kumar, P. & Harikrishna, D. Strength and microstructural characterization of silica fume blended concrete with increased curing period. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2024.05.102 (2024).

Rashidi, A., Mohammad Zain, M. I. S. & Ahmadi, R. Mix proportion for medium grade concrete with silica fume as cement replacement for general purpose construction. IOP Conf. Ser. Mater. Sci. Eng. 1101, 012013 (2021).

Alhajiri, A. M. & Akhtar, M. N. Enhancing sustainability and economics of concrete production through silica fume: A systematic review. Civil Eng. J. 9, 2612–2629 (2023).

Khan, M., Rehman, A. & Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 244, 118382 (2020).

IS: 456. Plain and Reinforced Concrete - Code of Practice, New Delhi, (2000).

Indian Standards, B. IS 516 (Method of Tests for Strength of Concrete, 1959).

Indian Standards, B. & IS 5816. : Method of Test Splitting Tensile Strength of Concrete. doi: (1999). https://law.resource.org/pub/in/bis/S03/is.5816.1999.pdf

Indian Standards, B. & IS 13311-1. : Method of Non-destructive testing of concret, Part 1: Ultrasonic pulse velocity. doi: (1992). https://law.resource.org/pub/in/bis/S03/is.13311.1.1992.pdf

Indian Standards, B. & IS 13311-2. Method of non-destructive Testing of concret-methods of test, Part Vol. 2 (Rebound hammer, 1992).

Test Method for Electrical Indication of Concretes Ability to Resist Chloride Ion Penetration. Preprint at (2019). https://doi.org/10.1520/C1202-19

Test Method for. Density, Absorption, and Voids in Hardened Concrete. Preprint at (2021). https://doi.org/10.1520/C0642-21

Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. Preprint at (2020). https://doi.org/10.1520/C1585-20

Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy. Preprint at (2022). https://doi.org/10.1520/C1723-16R22

LCA Consequential. The ISO 14040 standards for consequential LCA. (2015). https://consequential-lca.org

Ekvall, T. Attributional and Consequential Life Cycle Assessment. in Sustainability Assessment at the 21st centuryIntechOpen, (2020). https://doi.org/10.5772/intechopen.89202

ISO 14040 standards. Environmental Management-Life Cycle Assessment-Requirements and Guidelines. (2006).

Muralikrishna, I. V. & Manickam, V. Life cycle assessment. in Environmental Management 57–75 (Elsevier, doi:https://doi.org/10.1016/B978-0-12-811989-1.00005-1. (2017).

Zhang, Y. et al. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 209, 115–125 (2019).

Dong, Y. H. & Ng, S. T. Comparing the midpoint and endpoint approaches based on ReCiPe—a study of commercial buildings in Hong Kong. Int. J. Life Cycle Assess. 19, 1409–1423 (2014).

Kim, K. M. & Cho, Y. K. Effect of surface hydrophilized plastic waste aggregates made by mixing various kinds of plastic on mechanical properties of mortar. Mater. 2024. 17, 247 (2024).

Oddo, M. C., Cavaleri, L., La Mendola, L. & Bilal, H. Integrating plastic waste into concrete: sustainable solutions for the environment. Mater. 2024. 17, 3408 (2024).

Farooq, A. et al. Impact on concrete properties using e-plastic waste fine aggregates and silica fume. Gospodarka Surowcami Mineralnymi - Mineral. Resour. Manage. https://doi.org/10.24425/gsm.2019.128516 (2023).

Cuesta, A. et al. Local structure and Ca/Si ratio in C-S-H gels from hydration of blends of tricalcium silicate and silica fume. Cem. Concr Res. 143, 106405 (2021).

Lavagna, L., Suarez-Riera, D., Mangani, N. & Pavese, M. Mechanical properties of mortars with waste plastic as replacement of natural aggregate. (2024). https://doi.org/10.1680/jmacr.23.00102 76, 515–522

Ramakrishnan, A. & Jegan, J. Surface modified synthetic plastic aggregate for Concrete – Experimental and analytical studies. Mater. Sci. 29, 104–110 (2023).

Ahmad, J. et al. A review on sustainable concrete with the partially substitutions of silica fume as a cementitious material. Sustainability 14, 12075 (2022).

Mukharjee, B. B. & Barai, S. V. Influence of incorporation of colloidal Nano-Silica on behaviour of concrete. Iran. J. Sci. Technol. Trans. Civil Eng. 44, 657–668 (2020).

Radwan, A. A. et al. The use of plastic waste as replacement of coarse aggregate in concrete industry. Sustain. 2024. 16, 10522 (2024).

Alqahtani, F. K. & Zafar, I. Construction of green concrete incorporating fabricated plastic aggregate from waste processing. Sustain. 2023. 15, 4114 (2023).

Hossain, M. B., Bhowmik, P. & Shaad, K. M. Use of waste plastic aggregation in concrete as a constituent material. Progressive Agric. 27, 383–391 (2016).

Ullah, Z., Qureshi, M. I., Ahmad, A., Khan, S. U. & Javaid, M. F. An experimental study on the mechanical and durability properties assessment of E-waste concrete. J. Building Eng. 38, 102177 (2021).

Xie, Y., Far, H., Mortazavi, M. & El-Sherbeeny, A. M. Improving the mechanical properties of concrete mixtures by shape memory alloy fibers and silica fume. Build. 2024. 14, 1709 (2024).

Hamed, Y. R., Elshikh, Y., Elshami, M. M., Matthana, A. A., Youssf, O. & M. H. S. & Mechanical properties of fly Ash and silica fume based geopolymer concrete made with magnetized water activator. Constr. Build. Mater. 411, 134376 (2024).

Almeshal, I., Tayeh, B. A., Alyousef, R., Alabduljabbar, H. & Mohamed, A. M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 9, 4631–4643 (2020).

Tkach, E. EDP Sciences,. Improvement of the modified heavy concrete properties based on the use of activated silica fume. in E3S Web of Conferences vol. 135 03028 (2019).

Ali, K. et al. Influence of recycled plastic incorporation as coarse aggregates on concrete properties. Sustain. 2023. 15, 5937 (2023).

Chaudhary, S. K. & Sinha, A. K. Effect of silica fume on permeability and microstructure of high strength concrete. Civil Eng. J. 6, 1697–1703 (2020).

Hamada, H. M. et al. Effect of silica fume on the properties of sustainable cement concrete. J. Mater. Res. Technol. 24, 8887–8908 (2023).

Mohammed, H., Sadique, M., Shaw, A. & Bras, A. The influence of incorporating plastic within concrete and the potential use of microwave curing; A review. J. Building Eng. 32, 101824 (2020).

Khan, M. I., Abbas, Y. M. & Fares, G. Enhancing cementitious concrete durability and mechanical properties through silica fume and Micro-Quartz. Sustain. 2023. 15, 15913 (2023).

Sutrisno, W., Ghewa, G., Suprobo, P., SORPTIVITY AND CHLORIDE PENETRABILITY & EVALUATION OF CONCRETE INCORPORATING FLY ASH AND SILICA FUME. J. Civil Eng. 34, 68–73 (2019).

Hanumanthu, K. & Sarkar, K. Improved sorptivity models for mortar and concrete based on significant process parameters. J. Building Eng. 47, 103912 (2022).

Renuka, V., Rao, S. V. & Tadepalli, T. Influence of particle packing on the properties of multi-component cementitious systems. J. Sustain. Cem. Based Mater. 14, 837–858 (2025).

Shinde, S. N. et al. Optimization of waste plastic fiber concrete with recycled coarse aggregate using RSM and ANN. Sci. Rep. 15, 7798 (2025).

Jain, B. & Sancheti, G. Influence of silica fume and iron dust on mechanical properties of concrete. Constr. Build. Mater. 409, 133910 (2023).

Jain, A. et al. Fresh, Strength, durability and microstructural properties of shredded waste plastic concrete. Iran. J. Sci. Technol. - Trans. Civil Eng. 43, 455–465 (2019).

Chung, S. Y. et al. Pore and solid characterizations of interfacial transition zone of mortar using microcomputed tomography images. J. Mater. Civ. Eng. 33, 04021348 (2021).

Islam, M. J., Meherier, M. S. & Islam, A. K. M. R. Effects of waste PET as coarse aggregate on the fresh and Harden properties of concrete. Constr. Build. Mater. 125, 946–951 (2016).

Xu, D. et al. Reactivity assessment of silica fume and its competitive reaction in binary blended SCMs paste. Constr. Build. Mater. 467, 140442 (2025).

Yavuz, D., Akbulut, Z. F. & Guler, S. Porous concrete modification with silica fume and ground granulated blast furnace slag: hydraulic and mechanical properties before and after freeze-thaw exposure. Constr. Build. Mater. 447, 138099 (2024).

Srivastava, A., Singh, S. K. & Sharma, C. S. Correlation between ultrasonic pulse velocity (UPV) and compressive strength of coal bottom Ash mortar. J. Institution Eng. (India): Ser. A. 102, 421–433 (2021).

Atici, U. Prediction of the strength of mineral-addition concrete using regression analysis. (2015). https://doi.org/10.1680/macr.2010.62.8.585 62, 585–592.

Su Kim, K. & Tayfur, S. Signal-Centric framework based on probability of detection for Real-Time reliability of concrete damage inspection. Appl. Sci. 2025. 15, 18 (2024).

Filonchyk, M., Peterson, M. P., Zhang, L., Hurynovich, V. & He, Y. Greenhouse gases emissions and global climate change: examining the influence of CO2, CH4, and N2O. Sci. Total Environ. 935, 173359 (2024).

Hamad, M. A. et al. Production of Ultra-High-Performance concrete with low energy consumption and carbon footprint using supplementary cementitious materials instead of silica fume: A review. Energies (Basel). 14, 8291 (2021).

Yang, K. H., Jung, Y. B., Cho, M. S. & Tae, S. H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 103, 774–783 (2015).

Samad, S. & Shah, A. Role of binary cement including supplementary cementitious material (SCM), in production of environmentally sustainable concrete: A critical review. Int. J. Sustainable Built Environ. 6, 663–674 (2017).

Garlapati, V. K. E-waste in India and developed countries: Management, recycling, business and biotechnological initiatives. Renew. Sustain. Energy Rev. 54, 874–881 (2016).

Ghosh, S. K., Ghosh, S. K. & Baidya, R. Circular Economy in India: Reduce, Reuse, and Recycle Through Policy Framework. in Circular Economy: Recent Trends in Global Perspective 183–217Springer Nature Singapore, Singapore, (2021). https://doi.org/10.1007/978-981-16-0913-8_6

DPCC. DPCC Cracks the Whip on E-Waste Violations. (2024).

Dahiya, S., Katakojwala, R., Ramakrishna, S. & Mohan, S. V. Biobased products and life cycle assessment in the context of circular economy and sustainability. Mater. Circular Econ. 2, 7 (2020).

Wäger, P. A., Hischier, R. & Eugster, M. Environmental impacts of the Swiss collection and recovery systems for waste electrical and electronic equipment (WEEE): A follow-up. Sci. Total Environ. 409, 1746–1756 (2011).

Mishra, N. & Mancheri, N. Critical Rare Metal and Collaboration of India and Japan. in India, Japan and Beyond 65–87Springer Nature Singapore, Singapore, (2024). https://doi.org/10.1007/978-981-97-3282-1_5

Mudali, U. K., Patil, M., Saravanabhavan, R. & Saraswat, V. K. Review on E-Waste recycling: part I—A prospective urban mining opportunity and challenges. Trans. Indian Natl. Acad. Eng. 6, 547–568 (2021).

Pulicherla, K. K., Adapa, V., Ghosh, M. & Ingle, P. Current efforts on sustainable green growth in the manufacturing sector to complement make in India for making self-reliant India. Environ. Res. 206, 112263 (2022).

Chenoy, D., Ghosh, S. M. & Shukla, S. K. Skill development for accelerating the manufacturing sector: the role of ‘new-age’ skills for ‘Make in india’. Int. J. Train. Res. 17, 112–130 (2019).

International Olympic Committee. Designs of Tokyo 2020’s Recycled Medals Unveiled. (2021). https://olympics.com/en/news/designs-of-tokyo-2020-s-recycled-medals-unveiled

Timm, J. F. G., Morales, M. F. D. & Passuello, A. Sensitivity analysis of life cycle impacts distribution methods choice applied to silica fume production. IOP Conf. Ser. Earth Environ. Sci. 323, 012131 (2019).

ACI 318 – 14. Building Code Requirements for Structural Concrete (). (2014).

ACI 318 – 19 & ACI 318R-19, A. (American C. I. Building Code Requirements for Structural Concrete and Commentary. (2019).

CEN – European Committee for Standardization, E. 206. Concrete – Specification, Performance, Production and Conformity. (2013).

Acknowledgements

Acknowledgements: The authors gratefully acknowledge the funding of the Deanship of Graduate Studies and Scientific Research, Jazan University, Saudi Arabia, through project number: (JU-202505352-DGSSR-ORA-2025).

Funding

This research was funded by the Deanship of Graduate Studies and Scientific Research, Jazan University, Saudi Arabia, through project number: (JU-202505352-DGSSR-ORA-2025).

Author information

Authors and Affiliations

Contributions

S.O., S.S.: Conceptualization, Methodology, Formal analysis, Resources, Writing - review & editing the original draft, work administration. S.S., A.A., A.H.K.: Methodology, Formal analysis, Resources, Visualization, Validation, Writing - review & editing the original draft. The authors confirm that all individuals involved in the research have thoroughly read and given their consent to the final version of the manuscript that is to be published.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Omran, S., Sisupalan, S., Alyaseen, A. et al. Utilization of electronic plastic waste as fine aggregate with and without silica fume in concrete: experimentation and life cycle assessment. Sci Rep (2026). https://doi.org/10.1038/s41598-026-35491-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-35491-9