Abstract

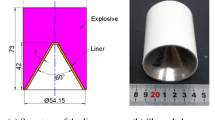

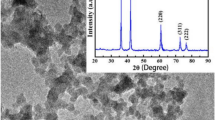

This study develops a theoretical model to predict the formation mechanism of non-cohesive jets from Zr-based amorphous alloy liners by integrating compressible circular flow theory with the JH-2 material model. Through a combination of theoretical analysis, experimental verification, and numerical simulation, the formation characteristics of Zr-based amorphous alloy jets were systematically investigated. Jet formation experiments were conducted, and X-ray image results showed that the morphology of Zr-based amorphous alloy (Zr41.2Ti13.8Cu12.5Ni10Be22.5, Vit1) jets exhibited typical discrete characteristics. The results from numerical simulations aligned well with the experimental data, validating the applicability of the JH-2 model for Zr-based amorphous alloy materials. The predictive model proposes the existence of a maximum collapse angle \(\:{\beta\:}_{\text{m}\text{a}\text{x}}\) during the collapse process of Zr-based amorphous alloy liners, explaining why these jets exhibit non-cohesive characteristics despite not satisfying the sound velocity criterion. Additionally, a correction was applied to the dimensionless ratio \(\:{x}_{0}/{x}_{1}\), reducing the model’s prediction error to within 0.56%. The model developed in this study can accurately predict the dynamic forming process of zirconium-based amorphous alloy jets, including the formation states (cohesive or non-cohesive) of each element of the liner during the collapse process.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article and its supplementary information files.

References

Tang, H. et al. Research on Jet Incoherence of Depleted Uranium Liner[C]//Journal of Physics: Conference Series. IOP Publishing 2174(1), 012064 (2022).

DU, Y. et al. Research on the radial crater growth theoretical model of energetic jet penetrating concrete[J]. Journal of Projectiles, Rockets, Missiles and Guidance. 44(2), 21–29 (2024).

Tian, L., Li, M. & Peng, Y. Study on jet formation characteristics of PTFE/Al composite energetic liner[C]//Journal of Physics: Conference Series. IOP Publishing 2891(3), 032012 (2024).

Sun, T. et al. Formation behaviors of rod-like reactive shaped charge penetrator and their effects on damage capability[J]. Defence Technology 32, 242–253 (2024).

Guo, H. G. et al. Reaction characteristic of PTFE/Al/Cu/Pb composites and application in shaped charge liner[J]. Defence Technology 18(9), 1578–1588 (2022).

Han, J. et al. Design and penetration of a new W-particle/Zr-based amorphous alloy composite liner[J]. J. Braz. Soc. Mech. Sci. Eng. 42, 1–13 (2020).

Zhao, Z. et al. Effect of Zn and Ni added in W-Cu alloy on penetration performance and penetration mechanism of shaped charge liner[J]. Int. J. Refract Metal Hard Mater. 54, 90–97 (2016).

Baker, E. L. et al. Barnie: A unitary demolition warhead[C]//Proceedings of the 19th International Symposium on Ballistics, Interlaken, Switzerland. 7–11 (2001).

Hu, F. et al. Impact resistance of concrete targets pre-damaged by explosively formed projectile (EFP) against rigid projectile[J]. Int. J. Impact Eng 122, 251–264 (2018).

Sohn, D. & Han, J. An empirical approach for penetration of tandem warheads into concrete targets[J]. Eng. Fail. Anal. 120, 105043 (2021).

Walters, W. P. & Zukas, J. A. Fundamentals of shaped charges[J]. (No Title), (1989).

Walsh, J. M., Shreffler, R. G. & Willig, F. J. Limiting conditions for jet formation in high velocity collisions[J]. J. Appl. Phys. 24(3), 349–359 (1953).

Chou, P. C., Carleone, J. & Karpp, R. R. Criteria for jet formation from impinging shells and plates[J]. J. Appl. Phys. 47(7), 2975–2981 (1976).

Chou, P. C. The stability of shaped-charge jets. Journal Applied Physics 48, 4187–4195 (1977).

Harrison, J. T. BASC, an analytical code for calculating shaped charge properties[C]//Proc. 6th Int. Symp. on Ballistics. 19–27 (1981).

Baker, E. L. Modeling and optimization of shaped charge liner collapse and jet formation[R]. Army armament research development and engineering center picatinny arsenal nj armament engineering directorate. (1993).

Hirsch, E. & Mayseless, M. The maximum mach number of coherent copper jet [J].

Miller, S., Konfino, S. & Peretz, D. Extension of the criterion on the cohesiveness of jets formed by collapsing shells[J]. 1989.

Wang, F. et al. Investigation on shaped charge jet density gradient for metal matrix composites: Experimental design and execution[J]. Int. J. Impact Eng 109, 311–320 (2017).

Liu, X. et al. Moderating jet coherency to enhance the aftereffect damage while retaining desired penetration capability of shaped charge liners with Ti-Zr-Nb-Al energetic high-entropy alloys[J]. Journal of Alloys and Compounds. 181585 (2025).

Baker, E. L. et al. Glass as a shaped charge liner material[C]//Proceedings of the 26th International Symposium on Ballistics. 340–347 (2011).

Gao, D. et al. Penetration and cratering of steel target by jets from titanium alloy shaped charge liners[J]. Materials 15(14), 5000 (2022).

Guo, M. et al. The effect of aluminum particle size on the formation of reactive jet[J]. Crystals 12(11), 1560 (2022).

Murphy, M. J. Examination of coherency coherence criteria for calculating shaped charge properties[A]. 6th ISB, San Antonio. 308–316 (1990).

Walker, J. D. Incoherence of shaped charge jets[C]//AIP Conference Proceedings. AIP 309(1), 1869–1872 (1994).

Curtis, J. P., Kelly, R. J. & Cowan, K. G. Variational approach to the calculation of the radii in the stagnant core model of shaped charge jet formation[J]. J. Appl. Phys. 76(12), 7731–7740 (1994).

Curtis, J. P. & Kelly, R. J. Circular streamline model of shaped-charge jet and slug formation with asymmetry[J]. J. Appl. Phys. 75(12), 7700–7709 (1994).

Kelly, R. J., Curtis, J. P. & Cowan, K. G. An analytic model for the prediction of incoherent shaped charge jets[J]. J. Appl. Phys. 86(3), 1255–1265 (1999).

Trishin, Y. A. & Kinelovskii, S. A. Effect of porosity on shaped-charge flow[J]. Combustion, Explosion, and Shock Waves 36(2), 272–281 (2000).

Baker, E. L. et al. Glass as a shaped charge liner material[C]. 26th International Symposium on Ballistics, Miami, Florida, USA, 340–347 (2011).

Shi, J. et al. Experimental and numerical investigation of jet performance based on Johnson-Cook model of liner material[J]. Int. J. Impact Eng 170, 104343 (2022).

Shi, J. et al. Cohesiveness and penetration performance of jet: Theoretical, numerical, and experimental studies[J]. Int. J. Impact Eng 175, 104543 (2023).

Su, C. et al. Formation behavior and reaction characteristic of a PTFE/Al reactive jet[J]. Materials 15(3), 1268 (2022).

Martin, M., Kecskes, L. & Thadhani, N. N. Dynamic compression of a zirconium-based bulk metallic glass confined by a stainless steel sleeve[J]. Scripta Mater. 59(7), 688–691 (2008).

Tao, P. et al. Thermodynamics and corrosion properties of nitrogen doped zirconium-based bulk metallic glasses. Intermetallics 159, 107913 (2023).

Jiang, L. et al. Processing, production and anticorrosion behavior of metallic glasses: A critical review[J]. J. Non-Cryst. Solids 612, 122355 (2023).

Gilbert, C. J. et al. Light emission during fracture of a Zr–Ti–Ni–Cu–Be bulk metallic glass[J]. Appl. Phys. Lett. 74(25), 3809–3811 (1999).

Walters, W. P., Kecskes, L. J. & Pritchett, J. E. Investigation of a bulk metallic glass as a shaped charge liner material[M]. Army Research Laboratory. (2006).

Cui, P. et al. Investigation of penetration performance of Zr-based amorphous alloy liner compared with copper[J]. Materials 13(4), 912 (2020).

Cui, P. et al. Numerical Simulation and Experimental Study on Jet Forming and Penetration Performance of Zr-based Amorphous Alloy Liner[J]. Engineering Letters. 29(1) (2021).

Cui, P. et al. Numerical simulation on jet forming and penetration performance of several amorphous energetic alloy liner with typical structures[C]//Journal of Physics: Conference Series. IOP Publishing 1948(1), 012186 (2021).

Cui, P. et al. Simulation and experimental study on jet velocity of Zr-based amorphous alloy liner[J]. Metals 12(6), 978 (2022).

Shi, J. et al. Research on non-cohesive jet formed by zr-based amorphous alloys[J]. Sci. Rep. 13(1), 4149 (2023).

Pugh, E. M., Eichelberger, R. J. & Rostoker, N. Theory of jet formation by charges with lined conical cavities[J]. J. Appl. Phys. 23(5), 532–536 (1952).

Curtis, J. P. & Kelly, R. J. A limit of validity of the straight line hypothesis in shaped charge jet formation modeling[J]. J. Appl. Phys. 82(1), 107–111 (1997).

Johnson, G. R. & Holmquist, T. J. An improved computational constitutive model for brittle materials[C]//AIP conference proceedings. American Institute of Physics 309(1), 981–984 (1994).

Cronin, D. S. et al. Implementation and validation of the Johnson-Holmquist ceramic material model in LS-Dyna[C]//Proc. 4th Eur. LS-DYNA Users Conf. 1: 47–60 (2003).

Yongxiang, S. et al. Study on JH-2 model of the ZrCuNiAlAg bulk amorphous alloy[J]. Explosion and Shock Waves. 39(9), 093104–1–093104–8 (2019).

Yunfeng Z. et al. Construction and application of the JH-2 model for a Zr-based bulk metallic glass alloy[J]. Explosion and Shock Waves. 40(7), 073101–1–073101–13 (2020).

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 12372360).

Author information

Authors and Affiliations

Contributions

Y.Q.N.: Conceptualization, Methodology, Data Curation, Validation, Writing-Original Draft, Formal analysis. L.J.: Project administration, Validation. X.J.: Conceptualization, Methodology, Validation, Funding acquisition. Z.X.H.: Conceptualization, Project administration. X.D.Z.: Methodology, Writing-Review & Editing. J.S.: Methodology, Validation. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Niu, Y., Ji, L., Jia, X. et al. Non-cohesive jet formation of Zr-based amorphous alloy shaped charge liners: a predictive model. Sci Rep (2026). https://doi.org/10.1038/s41598-026-35608-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-35608-0