Abstract

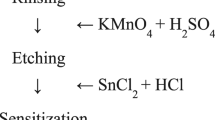

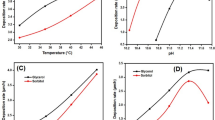

This work explores the deposition of nanoscale copper utilizing five different electroless bath formulations based on xylitol. Good complexation, reduction, and pH control were demonstrated in the first bath using xylitol, glyoxylic acid, and potassium hydroxide. A modified version included 1,2,4-triazole (Tz), which served as a stabilizing agent and a strong inhibitor. To enhance environmental compatibility and regulate deposition behavior, later formulations included chitosan (CS), triazole dithiocarbamate (TzDTC), and methanesulfonic acid (MSA) at a concentration of one part per million. Copper deposition was effectively accomplished at pH 12.75 and 45 °C. The optimized additive combination improved corrosion resistance, as evidenced by a drop in icorr from 58.3 to 41.8 mA/cm2, reduced surface roughness from 155.8 nm (plain bath) to 19.0 nm (brightener bath), and reduced the amount of deposit from 3.46 per hour to 2.68 µm/h. The specific surface area increased in conjunction with the crystallite size falling from 24.07 to 20.17 nm. TzDTC significantly changed the electrochemical and physical characteristics of the bath. In contrast, CS improved the smoothness and homogeneity of the copper layer that was deposited by acting as a brightener and leveling agent. The article describes the resulting shiny copper coatings and methodically assesses the additives’ inhibitory and accelerating effects. Surface texture was assessed using XRD and atomic force microscopy (AFM), and corrosion behavior was evaluated using cyclic voltammetry and Tafel polarization.

Similar content being viewed by others

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Varzaru, G., Savu, M., Mihailescu, B., Ionescu, C. & Branzei, M. Investigating the use of solderless assembly for electronics of some electrically conductive composite materials. Recent Pro. Sci. Tech. 8, 153–175. https://doi.org/10.9734/bpi/rpst/v8/18843D (2023).

Giurlani, W. et al. Electroplating for decorative applications: Recent trends in research and development. Coatings 8, 260. https://doi.org/10.3390/coatings8080260 (2018).

Zhou, Q. et al. Effect of Ni2+ concentration on microstructure and bonding capacity of electroless copper plating on carbon fibers. J. Alloys Compd. 863, 158467. https://doi.org/10.1016/j.jallcom.2020.158467 (2021).

Barshilia, H. C. Surface modification technologies for aerospace and engineering applications: current trends, challenges and future prospects. Trans Indian Natl. Acad. Eng. 6, 173–188. https://doi.org/10.1007/s41403-021-00208-z (2021).

Kostrada, A. Effectiveness of metal coating using electroplating electroless plating, and hot dipping in the manufacture of weapons. Int. J. Soc. Serv. Res. 3, 1494–1498. https://doi.org/10.46799/ijssr.v3i6.399 (2023).

Tian, J. et al. Printable and filament-drawable PDMS-based adhesive assisted manufacturing of highly conductive copper micro-patterns. J. Colloid Interface Sci. 677, 130–139. https://doi.org/10.1016/j.jcis.2024.08.068 (2025).

Gugua, E. C., Ujah, C. O., Asadu, C. O., Von Kallon, D. V. & Ekwueme, B. N. Electroplating in the modern era, improvements and challenges: A review. Hybrid Adv. 7, 100286. https://doi.org/10.1016/j.hybadv.2024.100286 (2024).

Melentiev, R., Yudhanto, A., Tao, R., Vuchkov, T. & Lubineau, G. Metallization of polymers and composites: State-of-the-art approaches. Mater. Des. 221, 110958. https://doi.org/10.1016/j.matdes.2022.110958 (2022).

Balaramesh, P., Jayalakshmi, S., Fdo, S. A., Anitha, V. & Venkatesh, P. Thin film to nano copper deposition by special additives on an eco-friendly electroless bath. Mater. Today Proc. 47, 1862–1867. https://doi.org/10.1016/j.matpr.2021.03.513 (2021).

Kepeniene, V., Stagniunaite, R., Stalnioniene, I. & Norkus, E. Influence of temperature on electroless copper deposition from formaldehyde-containing solutions using 2-hydroxy-1,2,3-propanetricarboxylic acid as Cu (II) ligand. ECS Trans. 64, 25–34. https://doi.org/10.1149/06430.0025ecst (2015).

Jayalakshmi, S. et al. The effect of chelators on additives in the surface characterization and electrochemical properties of an eco-friendly electroless copper nano deposition. Sci. Rep. 13, 11062. https://doi.org/10.1038/s41598-023-38115-8 (2023).

Jiang, T. et al. Electroless copper plating on a cotton surface: Effect of metal ion ligand stability constant on reduction deposition. Langmuir 40, 16283–16290. https://doi.org/10.1021/acs.langmuir.4c01455 (2024).

Bragaglia, M., Paleari, L., Mariani, M. & Nanni, F. Sustainable formaldehyde-free copper electroless plating on carbon-epoxy substrates. J. Mater. Sci. Mater. Electron. 35, 707. https://doi.org/10.1007/s10854-024-12493-9 (2024).

Qin, W. & Guo, R. Metallization of polyester fabric by autocatalytic copper plating process using glyoxylic acid as a reducing agent. Fibers Polym. 16, 1671–1675. https://doi.org/10.1007/s12221-015-4943-4 (2015).

Guo, R. Preparation of copper-coated polyester fabric via electroless plating using glyoxylic acid as reducing agent. J. Fiber Bioeng. Inform. 8, 321–327. https://doi.org/10.3993/jfbim00100 (2015).

Balaramesh, P. et al. Influence of conventional and sustainable electroless baths on autocatalytic copper deposition. Sci. Rep. 15, 33338. https://doi.org/10.1038/s41598-025-19231-z (2025).

Qin, W. F. Development of metallised polyester fabric by electroless copper for aircraft application using glyoxylic acid as reductant. Trans. IMF 94, 246–249. https://doi.org/10.1080/00202967.2016.1163064 (2016).

Gwon, Y. R., Lee, J.-Y., Kim, Y. & Choe, S. Electrodeposition of compact silver from ligand-free methanesulfonic acid-based electrolyte containing copper ions. Mater. Chem. Phys. 326, 129832. https://doi.org/10.1016/j.matchemphys.2024.129832 (2024).

Fdo, S. A., Venkatesh, P. & BalaRamesh, P. Electroless copper deposition using 3-mercaptopropionic acid as an additive. Mater. Today Proc. 47, 1883–1886. https://doi.org/10.1016/j.matpr.2021.03.583 (2021).

Balaramesh, P., Jayalakshmi, S., Fdo, S. A., Anitha, V. & Venkatesh, P. Influence of organosulphur additives on autocatalytic copper thin film deposition. Mater. Today Proc. 47, 2020–2024. https://doi.org/10.1016/j.matpr.2021.04.212 (2021).

Abbadi, A., Rácz, A. & Bokányi, L. Exploring the comminution process of waste printed circuit boards in recycling: A review. J. Mater. Cycles Waste Manag. 26, 1326–1348. https://doi.org/10.1007/s10163-024-01945-3 (2024).

Hong, Y. et al. Air-plasma surface modification of epoxy resin substrate to improve electroless copper plating of printed circuit board. Vacuum 170, 108967. https://doi.org/10.1016/j.vacuum.2019.108967 (2019).

Ghosh, S. Electroless copper deposition: A critical review. Thin Solid Films 669, 641–658. https://doi.org/10.1016/j.tsf.2018.11.016 (2019).

Zhang, J. et al. Discovery and optimization of 1,2,4-triazole derivatives as novel ferroptosis inhibitors. Eur. J. Med. Chem. 284, 117192. https://doi.org/10.1016/j.ejmech.2024.117192 (2025).

Pawar, K. & Dixit, P. A critical review of copper electroless deposition on glass substrates for microsystems packaging applications. Surf. Eng. 38, 576–617. https://doi.org/10.1080/02670844.2022.2142002 (2022).

Nagireddi, S., Golder, A. K. & Uppaluri, R. Role of EDTA on the Pd(II) adsorption characteristics of chitosan cross-linked 3-amino-1,2,4-triazole-5-thiol derivative from synthetic electroless plating solutions. Int. J. Biol. Macromol. 127, 320–329. https://doi.org/10.1016/j.ijbiomac.2019.01.033 (2019).

Cordonier, C. E. J. et al. Formation of micrometer-scale metal structures on glass by selective electroless plating on photopatterned titanium and copper-containing films. Langmuir 33, 14571–14579. https://doi.org/10.1021/acs.langmuir.7b03329 (2017).

Ajiboye, T. O., Ajiboye, T. T., Marzouki, R. & Onwudiwe, D. C. The versatility in the applications of dithiocarbamates. Int. J. Mol. Sci. 23, 1317. https://doi.org/10.3390/ijms23031317 (2022).

Seidi, F., Saeb, M. R., Huang, Y., Akbari, A. & Xiao, H. Thiomers of chitosan and cellulose: Effective biosorbents for detection, removal, and recovery of metal ions from aqueous medium. Chem. Rec. 21, 1876–1896. https://doi.org/10.1002/tcr.202100068 (2021).

Pustovalov, V. K., Astafyeva, L. G. & Fritzsche, W. Optical properties of core-shell nanoparticles and their application for effective absorption, scattering, extinction, and filtering solar and optical radiation. Phot. Nano. Fund. Appl. 62, 101312. https://doi.org/10.1016/j.photonics.2024.101312 (2024).

He, D., Qin, H., Qian, L., Sun, L. & Li, J. Conductive chitosan nonwoven fabrics by electroless plating with excellent laundering durability for wearable electronics. J. Nat. Fibers 19, 14855–14865. https://doi.org/10.1080/15440478.2022.2069190 (2022).

Wei, C. et al. Electroless deposition of automatically shedded thin copper foils. ACS Appl. Mater. Interfaces 12, 28831–28839. https://doi.org/10.1021/acsami.0c05987 (2020).

Langford, J. I. & Wilson, A. J. C. Scherrer after sixty years: A survey and some new results in the determination of crystallite size. J. Appl. Crystallogr. 11, 102–113. https://doi.org/10.1107/s0021889878012844 (1978).

Williamson, G. K. & Hall, W. H. X-ray line broadening from field aluminium and wolfram. Acta Metall. 1, 22–31. https://doi.org/10.1016/0001-6160(53)90006-6 (1953).

Ungár, T. Dislocation densities, arrangements and character from X-ray diffraction experiments. Mater. Sci. Eng. A. 309–310, 14–22. https://doi.org/10.1016/S0921-5093(00)01685-3 (2001).

Skold, R. V. & Larson, T. E. Measurement of the instantaneous corrosion rate by means of polarization data. Corrosion 13, 69–72. https://doi.org/10.5006/0010-9312-13.2.69 (1957).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (RS-2025-22222973).

Author information

Authors and Affiliations

Contributions

Palanivelu Balaramesh: formal analysis, writing—original draft. Raja Venkatesan: methodology, investigation, writing—original draft. Suseela Jayalakshmi: investigation, data curation. Shanmugam Kotteswaran: resources, software. Eswaran Kamaraj: conceptualization, data curation, writing—review and editing. Alexandre A. Vetcher: investigation, writing—original draft. Seong-Cheol Kim: supervision, project administration, funding acquisition, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent to participate

All person named as author in this manuscript have participated in the planning, design and performance of the research and in the interpretation of the result.

Consent for publication

All authors have indorsed the publication of this research.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Balaramesh, P., Venkatesan, R., Jayalakshmi, S. et al. Enhancement of electroless copper coatings by triazole dithiocarbamate and green additives. Sci Rep (2026). https://doi.org/10.1038/s41598-026-35680-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-35680-6