Abstract

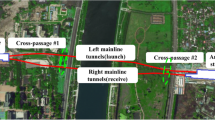

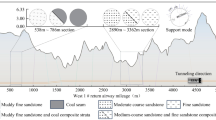

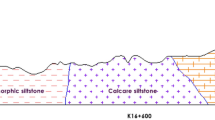

The tunnel boring machine (TBM) is a core equipment for mountain tunnel engineering, but it often faces problems such as surrounding rock deformation, collapse, and TBM entrapment when crossing fault fracture zones. Taking the TBM crossing of F1 fault in the Pilot Tunnel of Daliangshan No.1 Tunnel as the engineering case, this study adopted a combined method of laboratory tests, numerical simulation, and field monitoring to clarify the deformation characteristics of surrounding rock during TBM’s passage through the fault fracture zone, and proposed and verified effective reinforcement measures. The results show that the tunnel deformation in the F1 fault zone presents a "larger in the middle and smaller at both ends" pattern. When tunneling reached the fault core area, the maximum vertical vault settlement was 92 mm and the maximum ground settlement was 42 mm, with the vault settlement response occurring earlier than the sidewall springline deformation. Away from the fault zone, the stress release of surrounding rock stabilized, with a settlement increment of less than 5 mm. The comprehensive reinforcement system proposed for problems such as fractured surrounding rock in the fault zone and insufficient gripper shoe bearing capacity achieved remarkable effects. After reinforcement, the maximum vertical vault settlement and ground settlement of all monitored sections were reduced to approximately 17 mm and 7 mm, respectively, decreasing by 79.3% and 83.3% compared with those before reinforcement. This effectively mitigated construction risks and ensured continuous TBM advancement. The research findings can provide data support and technical reference for TBM construction in mountain tunnels under similar "weathered rock + fault fracture zone" conditions.

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed in the current study are available from the corresponding author on reasonable request.

References

Ozcelik, M. Criteria for the selection of construction method at the Ovit Mountain Tunnel (Turkey ). KSCE J. Civ. Eng. 20(4), 1323–1328 (2016).

Goodarzi, S. et al. (2021). Predicting TBM performance in soft sedimentary rocks, case study of Zagros mountains water tunnel projects. Tunn. Undergr. Space Technol. 109 (2025).

Ai, X. et al. Experimental investigation of mechanical behavior of horseshoe-shaped segmental tunnel linings. Sci. Rep. 14 (1) (2024).

Yang, G. et al. Response characteristics of surrounding rock and segment structure of large longitudinal slope tunnel. Electr. J. Struct. Eng. 24(1), 39–44 (2024).

Zhao, Z. et al. Construction methods and application of tbm in shengli tunnel of tianshan mountain under poor geological conditions. Civ. Eng. J. Staveb. Obz. 33(2), 168–180 (2024).

Liu, J. et al. Characterization of particle size distribution of rock chips and evaluation of rock breaking efficiency of TBM based on multifractal theory: A case study. Tunn. Undergr. Space Technol. 158 (2025).

Ji, F. et al. Mechanical response of surrounding rock of tunnels constructed with the TBM and drill-blasting method. Nat. Hazard. 66(2), 545–556 (2013).

Yang, J. et al. Comparative study of the excavation damage and rockburst of the deeply buried Jinping II diversion tunnels using a TBM and the drilling-blasting method. Adv. Civil Eng. (2020).

Man, K. et al. A new excavation technology of blasting combined with TBM. Geomat. Nat. Hazard. Risk 12(1), 3205–3223 (2021).

Zhang, Q. et al. Comparison of spatio-temporal characteristic of microseismic events in deep-buried tunnels with two excavation methods. Bull. Eng. Geol. Environ. 83 (3) (2024).

Dalgi莽, S. Tunneling in fault zones, Tuzla tunnel, Turkey. Tunn. Undergr. Sp. Technol. 18(5), 453–465 (2003).

Lu, W. et al. Study on mechanical properties of composite support structures in TBM tunnel under squeezing soft rock conditions. Tunn. Undergr. Space Technol. 144 (2021).

Wang, M. et al. Study on the information evolution law of water-resistant rock mass during fault water and mud inrush in TBM tunnels. KSCE J. Civ. Eng. 28(9), 4088–4099 (2024).

Wang, J. et al. Numerical response of advance support structures in TBM tunneling through altered zones: A case study. Buildings 15 (4) (2025).

Hamidi, J. K. et al. Risk assessment based selection of rock TBM for adverse geological conditions using Fuzzy-AHP. Bull. Eng. Geol. Environ. 69(4), 523–532 (2010).

Zhang, Y. et al. Failure characteristics and development mechanism of fault rockburst in a deep TBM tunnel: A case study. Acta Geotech. 18(10), 5575–5596 (2023).

Lin, P. et al. A new optimization method of initial support for TBM tunnel crossing fault zone based on deformation control contribution. Bull. Eng. Geol. Environ. 84 (2) (2025).

Zhang, Q. et al. Investigation into the collapse height of TBM jamming machinery induced by fault fracture zones and the verification of applicability. Tunn. Undergr. Space Technol. 155 (2025).

Liu, B. et al. Comprehensive ahead prospecting for hard rock TBM tunneling in complex limestone geology: A case study in Jilin, China. Tunn. Undergr. Space Technol. 93 (2019).

Ji, M. et al. (2023). Stability analysis of tunnel surrounding rock when TBM passes through fracture zones with different deterioration levels and dip angles. Sustainability 15 (6) (2025).

Zhang, Q. et al. Microseismic characteristic and development mechanism of fault-slip rockburst in a deep-buried TBM excavated tunnel: A case study. Tunn. Undergr. Space Technol. 142 (2025).

Lin, P. et al. Risk assessment of TBM jamming based on Bayesian networks. Bull. Eng. Geol. Environ. 81 (1) (2022).

Liu, Z. et al. Multi-source seismic geological ahead-prospecting for TBM tunneling in fractured strata: Improved strategies and case studies in a water conveyance project, China. Bull. Eng. Geol. Environ. 83 (9) (2024).

Huang, X. et al. Application and prospect of hard rock TBM for deep roadway construction in coal mines. Tunn. Undergr. Sp. Technol. 73, 105–126 (2018).

Cui, G. & Ke, X. Rescue technology of the jamming accident for the double-shield TBM in complex geological conditions: A case study. Alex. Eng. J. 79, 374–389 (2023).

Kang, M. et al. Laboratory simulations on hybrid non-destructive survey of electrical resistivity and induced polarization to predict geological risks ahead of a TBM tunnel. Tunn Undergr Space Technol. 135 (2023).

Bayati, M. & Hamidi, J. K. A case study on TBM tunnelling in fault zones and lessons learned from ground improvement. Tunn. Undergr. Sp. Technol. 63, 162–170 (2017).

Wang, L. et al. Model test of TBM tunnel crossing large dip angle fault zone under high in situ stress. Geofluids (2022).

Abdollahi, M. S. et al. A 3D numerical model to determine suitable reinforcement strategies for passing TBM through a fault zone, a case study: Safaroud water transmission tunnel, Iran. Tunn. Undergr. Sp. Technol. 88, 186–199 (2019).

Li, Y. et al. Determining a suitable reinforcement strategy for TBM advance in a gully fault zone without jamming—A numerical analysis. Appl. Sci.-Basel 15 (5) (2025).

Zhao, K. et al. 3D simulation of TBM excavation in brittle rock associated with fault zones: The brenner exploratory tunnel case. Eng. Geol. 181, 93–111 (2014).

Lin, P. et al. Geochemical, mineralogical, and microstructural characteristics of fault rocks and their impact on TBM jamming: a case study. Bull. Eng. Geol. Environ. 81 (1) (2022).

Xu, Z. H. et al. Integrated geochemical, mineralogical, and microstructural identification of faults in tunnels and its application to TBM jamming analysis. Tunn. Undergr. Space Technol. 128 (2023).

Wu, F. et al. Study on tunnelling performance of dual-mode shield TBM by Cutterhead working performance and tunnelling difference comparison: A case in shenzhen metro Line 12. Rock Mech. Rock Eng. 56(7), 5315–5333 (2023).

Kang, J. et al. An integrated determination method of optimal supporting time against TBM jamming. Eng. Fail. Anal. 162 (2024).

Chen, A. et al. Deformation identification and treatment measures for a TBM tunnel crossing a fault zone: A case study. Tunn. Undergr. Space Technol. 162 (2025).

Fu, J. et al. Formation mechanism and prediction of rockbursts in tuff tunnels in shallow buried sections of gullies: A case study. Tunn. Undergr. Space Technol 156 (2025).

Fu, J. et al. Mechanical properties of basalt fibre reinforced polymer (BFRP) bars reinforced concrete-filled BFRP circular tubes and their application in adjacent tunnel construction. Int. J. Numer. Anal. Meth. Geomech. (2025).

Xue, X. et al. Prediction of fractured zones in deep roadway of coal mine excavated via TBM based on measurement while drilling method. Bull. Eng. Geol. Environ. 82 (8) (2023).

Acknowledgements

We sincerely acknowledge the financial support from the National Key R&D Program of China (2024YFF050790201) and the National Natural Science Foundation of China (52178397, 52478420).

Funding

This work was financially supported by the National Key R&D Program of China(2024YFF050790201), and the National Natural Science Foundation of China(52178397, 52478420).

Author information

Authors and Affiliations

Contributions

Fuan Lan : Writing – original draft, Visualization, Conceptualization, Investigation. Wenrui Du : Data curation. Ruihan Li : Methodology. Chuan He : Supervision, Funding acquisition. Junyang He : Investigation. Jian Yan : Visualization, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lan, F., Du, W., Li, R. et al. Research on surrounding rock deformation characteristics and support optimization measures for tunnel TBM crossing through fault fracture zones. Sci Rep (2026). https://doi.org/10.1038/s41598-026-35748-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-35748-3