Abstract

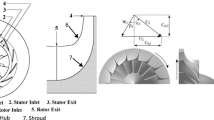

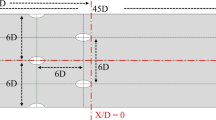

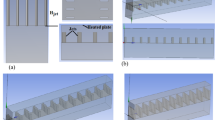

Due to the demand of unmanned helicopters for drag reduction and rain-proof, the helicopter nacelle must be sealed. It will lead to a decrease in the heat transfer efficiency of the radiator, and the output power of the engine will drop dramatically. The helicopter’s flight safety will be seriously jeopardized, especially when the helicopter is hovering (maximum engine power is needed). Currently, active cooling by equipping the radiator with a fan is the only solution, and the heat transfer efficiency of the radiator could be controlled by fan. Therefore, the performance of the fan directly affects the flight safety of the whole system. In this study, the Airfoils 30, suitable for low Reynolds number flows, is adopted to design the fan blade considering the characteristics of helicopter heat sink miniaturization and high integration. Then, a three-dimensional CFD (computational fluid dynamics) k-omega SST model is developed to investigate the effects of fan blade torsion angle, chord length, mounting angle and the number of blades on the performance of the fan. Furthermore, the constraints of radiator dimension, air flow resistance on the performance of the fan are considered comprehensively to finalize the new fan configuration. The optimised parameters of fan suitable for high flow rate (above 1.17 kg/s) are chord length is 55 mm, torsion angle is 26°, mounting angle is 39° and the blade number is 7. The fan efficiency increases about 13.6%. The power consumption decreases about 9.5% (about 73 W). The fan rotational speed decreases 10.5%. The improvement of fan efficiency is a key measure for energy conservation and carbon reduction in unmanned helicopter systems. The 73 W power consumption of the fan decrease indicates that 1.2 kg green-house gas emission reduces per day. The lower power consumption will result in a 0.14% cruising endurance increase. The fan is then manufactured by additive manufacturing based on CFD optimization results. This deep integration between CFD and additive manufacturing reduces trial and error costs and energy consumption. It also shows the promising future of UAV components autonomous manufacturing. Finally, the experiment is conducted in lab under 40℃. The experimental results indicate that the maximum output power of the engine is over than 90 kW. Based on the helicopter main rotor performance curve, the helicopter could hover indefinitely with 500 kg loading under 40 °C. It is a criterion to identify the designing success.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Shuhong, L. I. U., Yulin, W. U. & Zhigang, Z. U. O. Applied Fluid Mechanics (Tsinghua University Press, 2012) ((In Chinese)).

Moreau, S. Improvement of fan design using CFD. SAE Technical Paper 970934, (2002).

Henner M. Kessaci S. Moreau S. Latest improvements of CFD Models of engine cooling axial fan systems. SAE Technical Paper Series.

Yi-You, W., Min, W. U., Dun-Lu. L. Noise Calculation of engine cooling fan based on CFD. Mechan. Eng. (2009).

Wang, A., Hui, X. Z. & Ghazialam, H. Evaluation of the Multiple Reference Frame (MRF) Model in a Truck Fan Simulation (SAE Paper, 2005).

Ota, H. et al. Development of High Efficient Radiator Cooling Fan for Automotive Application (SAE Technical Paper, 2013).

Kobayashi, Y., Kohri, I. & Matsushima, Y. Study of Influence of MRF Method on the Prediction of the Engine Cooling Fan Performance (SAE Technical Paper, 2011).

Kohri, I., Kobayashi, Y. & Matsushima, Y. Prediction of the performance of the engine cooling fan with CFD simulation. SAE Int. J. Passenger Cars-Mechan. Syst. 3, 508–522 (2010).

Yuntao, C. CFD Analysis and Low Noise Optimization Design of Engine Cooling Fan for Sedan (Jilin University, 2007) ((In Chinese)).

Xingrong, W. CFD Analysis and Simulation Process Optimization of Engine Cooling Fan Aerodynamic Performance (South China University of Technology, 2013) ((In Chinese)).

Shengfu, Li. & Xinxin, W. Optimization design analysis of automotive cooling fan blade parameters. Mechan. Design Manuf. 07, 48–52 (2019) ((In Chinese)).

Yaozhen, Z. CFD Analysis and Low Noise Optimization Design of Car Engine Cooling Fan (Jilin University, 2007) ((In Chinese)).

Wang, Z,N., Wang, H. Design of automobile cooling fan based on computational fluid dynamics. Optimized design of automobile cooling fan based on computational fluid dynamics. Mechanical Design and Manufacturing, 2016 (10): 182–186

Wang, Y., Lu J., Jiang, B., et al. Study on the effect of blade inclination on the performance of cross-flow wind turbine using CFD technology. Journal of Hefei University of Technology: Natural Science Edition, (2012). (In Chinese)

Li, Y. E., Feng, X. U., Yan, S. H. I., Haibo, L. I. N. & Chao, S. U. N. Research and optimization of aerodynamic performance of automobile engine cooling fan. Pract. Energy Saving Technol. 5, 76–80 (2018) ((In Chinese)).

Tang Zhao. Research and optimization of engine cooling fan blade parameters. Guangzhou: South China University of Technology, (2012). (In Chinese)

Jung, Y. S., Lee, B. & Baeder, J. Prediction of Coaxial rotor hub flow using mercury framework. J. Am. Helicopter Soc. 69(2), 1–4 (2024).

Renaud, T., Pape, A. L. & Péron, S. Numerical analysis of hub and fuselage drag breakdown of a helicopter configuration. CEAS Aeronaut. J. 4(4), 409–419 (2013).

Zaharia, S. M. et al. Material extrusion additive manufacturing of the composite UAV Used for search-and-rescue missions. Drones 7, 602 (2023).

Helge, K. et al. Additive manufacturing of porous structures for unmanned aerial vehicles applications. Adv. Eng. Mater. 20, 1800290 (2018).

Bozkurttas, M. et al. CFD-Based Analysis and Design of Biomimetic Flexible Propulsor for Autonomous Underwater Vehicles (AIAA, 2007).

Zhao, J. et al. CFD analysis of Ducted-Fan UAV Based on Magnus Effect (IEEE, 2012).

Yin, S. et al. Electric Scissors for precise generation of organic droplets in microfluidics: a universal approach that goes beyond surface wettability. J. Phys. Chem. C 123, 25643 (2019).

Yin, S. et al. Triple-layered encapsulation through direct droplet impact. J. Colloid Interface Sci. 615, 887 (2023).

VA113-BBL504P fan performance experiment report.

Subramanya, R. Modelling and Simulation of Fan Performance Using CFD Group (Linkopings University, 2020).

Zhang, S., et al. Intelligent simulation and optimization of axial flow fan based on CFD. (2023).

Low Reynolds Number, Low drag, high lift airfoil. Michael S. Selig, William Holmes, Frank Stauder. Patent.

Ding, D., Ng, B. F., Liu, H., Lu, X. & Wan, M. P. The characteristics and formation mechanism of emissions from thermal decomposition of 3D printer polymer filaments. Sci. Total Environ. 20, 984–994 (2019).

Zhang, H. & Moon, S. K. Hybrid machine learning method to determine the optimal operating process window in aerosol jet 3D printing. ACS Appl. Mater. Interface 11, 17994–18003 (2019).

Zhang, H., Moon, S. K. & Ngo, T. H. 3D printed electronics of non-contact ink writing techniques: status and promise. Int. J. Precis. Eng. Manuf. Green Technol. 7, 511–524 (2020).

Yang, X. et al. Active fabrics with controllable stiffness for robotic assistive interface. Adv. Mater. 36, 2404502 (2024).

Zhang H, Moon SK, Ngo TH, Tou J, Mohamed AB. A hybrid machine learning approach for the quality optimization of a 3D printed sensor. In 2018 International Conference on Intelligent Rail Transportation (ICIRT). IEEE.

Li, M., Yin, S., Liu, Z. & Zhang, H. Machine learning enables electrical resistivity modeling of printed lines in aerosol jet 3D printing. Sci. Rep. 14, 14614 (2024).

Wang, B. et al. A post-treatment method to enhance the property of aerosol jet printed electric circuit on 3D printed substrate. Materials 13, 5602 (2020).

Zhang, H., Huang, J., Zhang, X. & Wong, C. N. Autonomous optimization of process parameters and in-situ anomaly detection in aerosol jet printing by an integrated machine learning approach. Additive Manuf 86, 104208 (2024).

Acknowledgements

This research was supported by the Anhui HAERY Aviation Power Co., Ltd. This work was also supported by the Technology development Program (No.RS-2025-25443487) funded by the Ministry of SMEs and Startups (MSS, Korea).

Funding

This research was supported by the Anhui province fundamental research funding (No. 2024AH051814). Valuable support from Anhui HAERY Aviation Power Co., Ltd. This work was also supported by the Technology development Program (No.RS-2025-25443487) funded by the Ministry of SMEs and Startups (MSS, Korea).

Author information

Authors and Affiliations

Contributions

Liang Si: Conceptualization, Methodology, Investigation, Writing original draft. Zhixin Liu: Conceptualization, Methodology, Investigation, Writing original draft. Nannan Xiao: Methodology, Investigation, Writing original draft. Yuwen Zhang: Methodology, Investigation, Writing original draft. Yebao Liu: Methodology, Writing original draft, Writing. Shuai Deng: Methodology, Writing original draft. Yuchuan Li: Methodology, Writing original draft. Haisheng Yang: Validation, Writing original draft. Xiongjian Zhang: Validation, Writing original draft. Guoqiang Fu; - review & Editing draft. Joon Phil Choi: Methodology, Writing—review & editing.

Corresponding authors

Ethics declarations

Competing intertests

The authors declare that they have no competing interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Si, L., Liu, Z., Xiao, N. et al. CFD-enabled sustainable design and manufacturing of cooling fan for unmanned helicopter. Sci Rep (2026). https://doi.org/10.1038/s41598-026-35901-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-35901-y