Abstract

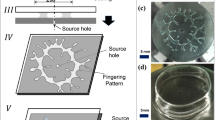

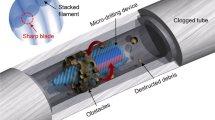

This study employed the Eulerian multiphase flow model to investigate the influence of single-head interrupted helical blades on the solid–liquid separation performance of a screw extrusion device. Numerical simulations were conducted on cylindrical shafts with interruption distances of 30 mm, 40 mm, and 50 mm, and conical shafts with interruption distances of 20 mm, 30 mm, and 40 mm. The working performance, particle volume fraction, solid phase velocity, and pressure distribution in the dewatering zone were analyzed. The results indicated that the variation in particle volume fraction could be divided into three stages: the cylindrical shaft exhibited an oscillatory large-amplitude increase, while the conical shaft showed a stable small-amplitude increase. The dewatering performance of the conical shaft was significantly better than that of the cylindrical shaft, reaching the best effect at an interruption distance of 40 mm—the solid phase volume fraction reached 48% (cylindrical) and 55% (conical) respectively. The interruption distance had a significant impact on performance by controlling the material residence time. In the cylindrical shaft, the pressure in the extrusion zone decreased with the increase in the interruption distance; while in the conical shaft, both short and long distances maintain high pressure. These findings support the design of single-head interrupted helical screw extrusion devices.

Similar content being viewed by others

Data availability

The data supporting the conclusions of this study are detailed in the main text of the paper and its supplementary information files. Due to the large size of the numerical simulation files, they may be provided by the corresponding author upon reasonable request.

References

Chen, Y. S. et al. Examples of Agricultural Waste Fertilization Utilization and Equipment Selection (China Agriculture Press, 2019).

Zhao, X. H. & Yang, W. J. Exploration on the treatment and comprehensive utilization of livestock and poultry breeding manure. Livestock Poultry Ind. 35(3), 42–44 (2024).

Yan, C. et al. Screw extrusion process used in the polymer modified asphalt field: A review. J. Clean. Prod. 448, 141592 (2024).

Zhang, G. Q., Jiang, X. M. & Zhang, B. L. Research on solid - liquid separation technologies and equipment for livestock and poultry manure. China South. Agric. Mach. 54(9), 7–10 (2023).

Zhang, Z. et al. Design and experiment of spiral squeeze dewatering machine for paint slag. J. Hebei Univ. Water Resour. Electr. Eng. 34(3), 73–77 (2024).

Qin, Z. X., Lu, Y. Z. & Chen, H. W. Structural simulation analysis and optimal design of a new type of screw extruder. China Biogas 42(6), 65–70 (2024).

Xu, W. et al. Optimization design of screw extrusion solid-liquid separator for Livestock and poultry waste. Light Ind. Mach. 41(5), 96–104 (2023).

Shen, J. T. et al. Research and design of KP-250 screw press separator. Agric. Mech. Res. 36(8), 210–213 (2014).

Guan, Z. J. et al. Optimal design and experiment of screw extrusion solid-liquid separation for cow manure. Trans. Chin. Soc. Agric. Mach. 47(11), 192–197 (2016).

Kapre V, Barocio E, Pipes R B. Single screw extrusion of long discontinuous fiber‐reinforced polymers: Pellet motion and heat transfer. Polymer Composites. (2025).

Zhu, D. W. et al. Numerical simulation analysis of flow field in flow channel of internal interrupted-whorl screw separator. Trans. Chin. Soc. Agric. Mach. 48(10), 92–100 (2017).

Xu, W. et al. Numerical simulation study on spiral extrusion dehydration process of animal waste. Light Ind. Mach. 41(4), 42–51 (2023).

Feng, S. et al. Study on performance of kitchen waste spiral extrusion device based on discrete element method. Food Mach. 38(4), 109–113 (2022).

Hu, X. Y. Optimization design and experiment of spiral extrusion equipment for solid-liquid separation of biogas slurry. Agric. Mach. Mainten. 2, 32–35 (2024).

Huang, Z. D. Design of a new type of cow dung solid-liquid separator. Agric. Mach. Mainten. 10, 19–21 (2022).

Zhao, W. S. Organization design and experiments of screw separator. Chin. Acad. Agric. Sci. https://doi.org/10.21203/rs.3.rs-7873162/v1 (2017).

Wu, S. Z. & Ren, C. Y. Numerical simulation of wind blown sand based on the Eulerian model. J. Lanzhou Univ. (Nat. Sci.) 48(1), 104–107112 (2012).

Wang, F. J. Computational Fluid Dynamics Analysis: Principles and Applications of CFD Software (Tsinghua University Press, 2015).

Li, L. C., Xu, B. & Yang, J. Sinking/Floating particles solid suspension characteristics in stirred tank based on CFD simulation. J. Mech. Eng. 50(12), 185–191 (2014).

Zhang, G. et al. Study on the characteristics of columnar particle beds in tubular fixed-bed reactors based on CFD-DEM method and porous media model. Pet. Process. Petrochem. 55(11), 90–99 (2024).

Xu, D. L. et al. Simulation and optimal design of RPB based on modified porous medium model. CIESC J. 76(4), 1569–1582 (2025).

Anderson, J. D. Fundamentals of Computational Fluid Dynamics and their Applications (China Machine Press, 2007).

Gao, X. F. et al. Solid-liquid two-phase flow of mixed particles in vortex pump based on CFD-DEM. Trans. Chin. Soc. Agric. Mach. 54(8), 163–170 (2023).

Song, Y. W. Design and Research on Regeneration System of Cow Mattress Material (Inner Mongolia University of Technology, 2022).

Zhang, S. C. Design and Test of Manure Water Separation Device for Large-Scale Livestock and Poultry Breeding (Hebei Normal University Of Science & Technology, 2024).

Weisong, Z. et al. Mechanical properties and construction of constitutive model for compression and stress relaxation of cattle manure. Inmateh Agric. Eng. https://doi.org/10.35633/inmateh-71-62 (2023).

Funding

This research was supported by the Key R&D and Achievement Transformation Program of Inner Mongolia Autonomous Region (Science and Technology Support for Northeast Revitalization) (2023YFDZ0061).

Author information

Authors and Affiliations

Contributions

Methodology, Formal Analysis and Research: Risu NA; Writing—Initial Draft Preparation, Analysis and Research: Nan WANG; Writing—Commentary and Editing: Silu Ma; Supervision: Haoran Sun.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Na, R., Wang, N., Ma, S. et al. Numerical simulation of flow field in single-head broken-tooth spiral extrusion dewatering channel. Sci Rep (2026). https://doi.org/10.1038/s41598-026-36029-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-36029-9