Abstract

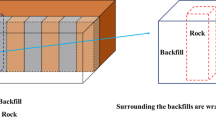

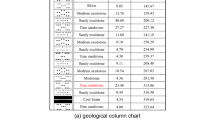

Economic investment and mechanical characteristics represent primary limitations to the widespread adoption of cemented tailings backfill. This study introduces an approach of using quarry waste to generate rock powder, which is subsequently mixed with tailings to produce cemented tailings-rock powder backfill (CTRPB). This method achieves cost efficiency while facilitating synergistic waste management. Through uniaxial compression testing, the influences of rock powder type and content on the mechanical behavior, failure modes, and energy transformation of CTRPB were examined. A piecewise damage constitutive model was developed to explore damage progression mechanisms. Findings demonstrate that the incorporation of rock powder markedly improves the deformation resistance of CTRPB. Both uniaxial compressive strength (UCS) and elastic modulus exhibit an initial increase followed by a decline as content rises, with optimal levels and enhancement effects differing across various rock powders. The failure process of CTRPB encompassed four distinct phases, where rock powder amplified post-peak energy release and fragmentation behaviors. Energy assessment indicated that rock powder significantly boosted energy storage and dissipation capacities, elevating total energy density, elastic energy density, and dissipated energy density by 252.17%, 213.87%, and 478.99%, respectively. The formulated piecewise damage constitutive model correlated well with experimental data in the pre-peak regime. Damage evolution may be categorized into four stages, and damage values can act as indicators for assessing failure conditions in the resource utilization of mining waste and rock powder-tailings backfill technology. This research offers a theoretical foundation for the resource-oriented use of mine waste and rock powder-tailings backfill technology.

Similar content being viewed by others

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Sun, W., Wang, H. J. & Hou, K. P. Control of waste rock-tailings paste backfill for active mining subsidence areas. J. Clean. Prod. 171, 567–579 (2018).

Pan, M., Jafari, L., Guo, M. & Grabinsky Hybrid failure of cemented paste backfill. Minerals 11 (10), 1141 (2021).

Liu, L. et al. An experimental study on the early-age hydration kinetics of cemented paste backfill. Constr. Build. Mater. 212, 283–294 (2019).

Xue, G. L., Yilmaz, E., Feng, G. & Cao, S. Bending behavior and failure mode of cemented tailings backfill composites incorporating different fibers for sustainable construction. Constr. Build. Mater. 289, 123163 (2021).

Sari, M., Yilmaz, E., Kasap, T. & Guner, N. U. Strength and microstructure evolution in cemented mine backfill with low and high pH pyritic tailings: effect of mineral admixtures. Constr. Build. Mater. 328, 127109 (2022).

Cao, S. et al. Loading rate effect on uniaxial compressive strength behavior and acoustic emission properties of cemented tailings backfill. Constr. Build. Mater. 213, 313–324 (2019).

Zheng, K. R. et al. Influences of phosphate tailings on hydration and properties of Portland cement. Constr. Build. Mater. 98, 593–601 (2015).

Lu, G. D. et al. A multiphysics-viscoplastic cap model for simulating blast response of cemented tailings backfill. J. Rock. Mech. Geotech. 9 (3), 551–564 (2017).

Li, M. et al. Effects of soaking durations and dry-wet cycles on the mechanical properties of coal slime-based grouting backfill materials. Case Stud. Constr. Mat. 22, 04908 (2025).

Benzaazoua, M., Fall, M. & Belem, T. A contribution to Understanding the hardening process of cemented pastefill. Min. Eng. 17 (2), 141–152 (2004).

Ng, C. et al. A review on microstructural study and compressive strength of geopolymer mortar, paste and concrete. Constr. Build. Mater. 186, 550–576 (2018).

Yilmaz, E. et al. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents. Constr. Build. Mater. 75, 99–111 (2015).

Zhang, C. et al. Simulation of hydration reactions and microstructural characteristics of cemented tailings backfill under temperature effects. Constr. Build. Mater. 470, 140573 (2025).

Zhao, Y. H. et al. Solid waste binder cemented dihydrate phosphogypsum aggregate to prepare backfill material. Min. Eng. 226, 109249 (2025).

Hou, C. et al. Influence of binder content on temperature and internal strain evolution of early age cemented tailings backfill. Constr. Build. Mater. 189, 585–593 (2018).

Chen, W., Chen, L. & Yin, S. H. Effect of bacteria on cemented fly-ash backfill: mechanical strength, hydration mechanism and leaching behavior. Constr. Build. Mater. 472, 140791 (2025).

Cao, S., Song, W. D. & Yilmaz, E. Influence of structural factors on uniaxial compressive strength of cemented tailings backfill. Constr. Build. Mater. 174, 190–201 (2018).

Cao, S., Yilmaz, E. & Song, W. D. Dynamic response of cement-tailings matrix composites under SHPB compression load. Constr. Build. Mater. 186, 892–903 (2018).

Cao, S., Yilmaz, E. & Song, W. D. Evaluation of Viscosity, strength and microstructural properties of cemented tailings backfill. Minerals-Basel 8 (8), 352 (2018).

Guo, B. et al. The study on the damage evolution and size characteristics of gangue cemented backfill. Case Stud. Constr. Mat. 22, 04871 (2025).

Xue, G. L. et al. Influence of fiber reinforcement on mechanical behavior and microstructural properties of cemented tailings backfill. Constr. Build. Mater. 213, 275–285 (2019).

Chen, X. et al. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced cemented paste backfill. Constr. Build. Mater. 190, 211–221 (2018).

Wu, J. Y. et al. Microscopic mechanism of cellulose nanofibers modified cemented gangue backfill materials. Adv. Compos. Hybrid. Ma. 8, 177 (2025).

Manohar, M. et al. A performance evaluation of fly Ash–Plastic aggregate in hydraulic backfilling: A comparative study. Materials 18, 2751 (2025).

Yin, H. et al. Multiscale study on the compressive performance of diverse solid waste backfill bodies. Geomech. Geophys. Geo-energ. Geo-resour. 11 9. (2025).

An, S. H. et al. Rheological and mechanical properties of full-tailings backfill material prepared by ultrafine-iron-tailings-powder-based consolidation agent. Constr. Build. Mater. 417, 135286 (2024).

Wang, Z. Q. et al. Utilization of alkaline additives for backfilling performance improvement of sulphide-rich tailings. Environ. Res. 283, 122188 (2025).

Ouattara, D. et al. Effect of superplasticizers on the consistency and unconfined compressive strength of cemented paste backfills. Constr. Build. Mater. 181, 59–72 (2018).

Tan, Y. Y. et al. Long-term mechanical behavior and characteristics of cemented tailings backfill through impact loading. Int. J. Min. Met. Mater. 27 (2), 140–151 (2020).

Zheng, D. et al. Investigation on dynamical mechanics, energy dissipation, and microstructural characteristics of cemented tailings backfill under Shpb tests. Minerals 11 (5), 542 (2021).

Zheng, D. et al. Fractal and microscopic quantitative characterization of unclassified tailings Flocs. Int. J. Min. Met. Mater. 28 (9), 1429–1439 (2021).

Shao, X. et al. Enhancing Mid-Term strength and microstructure of fly Ash–Cement paste backfill with silica fume for continuous mining and backfilling operations. Materials 17 (24), 6037 (2024).

Xu, B. et al. Nonlinear stress growth and failure characteristics of gangue-cemented backfill. Constr. Build. Mater. 424, 135938 (2024).

Zhao, K. et al. Mechanical properties of glass fiber-reinforced backfills under different proportion conditions. Arch. Civ. Mech. Eng. 24, 196 (2024).

Song, B. et al. Experimental study on the strength and damage characteristics of Cement–Fly Ash–Slag–Gangue cemented backfill. Buildings 14, 1411 (2024).

Sun, Y. et al. Bending properties and damage evolution of fiber-reinforced aeolian sand backfill materials. Sci. Rep. 14, 23670 (2024).

Li, H., Wang, H. J. & Bai, L. J. Effect of coal gangue grading characteristics on cemented paste backfill rheology. Case Stud. Constr. Mat. 21, 03694 (2024).

Hefni, M. A. Investigating the basic properties of basalt fiber reinforced cemented paste backfill as a sustainable material for mine backfilling. Sci. Rep. 15, 10073 (2025).

Yang, J. et al. Mechanical and microstructural enhancement of coal gangue backfill using polypropylene fiber and silica fume. Environ. Res. 285, 122547 (2025).

He, W. et al. Study on mechanical properties and toughness characteristics of fiber reinforced storage backfill after carbonation curing. Structures 77, 108996 (2025).

Xue, G. L. et al. Fiber length effect on strength properties of polypropylene fiber reinforced cemented tailings backfill specimens with different sizes. Constr. Build. Mater. 241, 118113 (2020).

Cao, S., Yilmaz, E. & Song, W. D. Fiber type effect on strength, toughness and microstructure of early age cemented tailings backfill. Constr. Build. Mater. 223, 44–54 (2019).

Hu, Y. F. et al. Preparation of high-performance and environmentally friendly superfine tailings cemented paste backfill using cellulose nanofibers. Process. Saf. Environ. 196, 106901 (2025).

Zhang, X. et al. Study on the mechanical properties and failure mechanism of polypropylene fiber-rubber-modified solid waste-based backfill. J. Mater. Sci. 60, 4053–4077 (2025).

Wu, J., Wang, N. & Peng Effect of grain composition on coarse aggregate filling slurry segregation. J. Cent. South. Univ. (Sci Technol). 47 (9), 3201–3207 (2016).

Yin, S., Cao, Y. & Wu, A. Mechanical and flow properties of glass fiber reinforced cemented filler with sulfur-containing tailings. Mater. Her. 37, 246–252 (2023).

Meng, Q. B. et al. Experimental research on rock energy evolution under uniaxial Cyclic loading and unloading compression. Geotech. Test. J. 41, 717–729 (2018).

Chen, Z. Q. et al. Energy damage evolution mechanism of rock and its application to brittleness evaluation. Rock. Mech. Rock. Eng. 52, 1265–1274 (2019).

Wen, T. et al. Energy evolution: a new perspective on the failure mechanism of purplish-red mudstones from the three Gorges reservoir area. China Eng. Geol. 264, 105350 (2020).

Peng, K. et al. Quantitative characteristics of energy evolution of gas-bearing coal under Cyclic loading and its action mechanisms on coal and gas outburst. Rock. Mech. Rock. Eng. 54, 3115–3133 (2021).

Zhang, Y. et al. Strain energy evolution characteristics and mechanisms of hard rocks under true triaxial compression. Eng. Geol. 260, 105222 (2019).

Liu, W. Z. & Niu, S. W. Energy evolution properties and strength failure criterion of coal-fired slag concrete based on energy dissipation. Case Stud. Constr. Mat. 17, 01369 (2022).

Aslani, F. & Nejadi, S. Self-compacting concrete incorporating steel and polypropylene fibers: compressive and tensile strengths, moduli of elasticity and rupture, compressive stress-strain curve, and energy dissipated under compression. Compos. Part. B: Eng. 53, 121–133 (2013).

Wang, Y. et al. On anisotropic fracture evolution and energy mechanism during marble failure under uniaxial deformation. Rock. Mech. Rock. Eng. 52, 3567–3583 (2019).

Wisniewska, S. et al. Effective properties of composite material based on total strain energy equivalence. Compos. Part. B: Eng. 166, 213–220 (2019).

Han, W. Q. et al. Damage evolution analysis of open-hole tensile laminated composites using a progress damage model verified by AE and DIC. Compos. Struct. 247, 112452 (2020).

Li, P. & Cai, M. F. Energy evolution mechanism and failure criteria of jointed surrounding rock under uniaxial compression. J. Cent. South. Univ. 28, 1857–1874 (2021).

Li, P. et al. Mechanical properties and energy evolution of jointed rock specimens containing an opening under uniaxial loading. Int. J. Min. Metall. Mater. 28, 1875–1886 (2021).

Liang, C. Y. et al. Experimental investigations on rate-dependent stress-strain characteristics and energy mechanism of rock under uniaixal compression. Chin. J. Rock. Mech. Eng. 09, 1830–1838 (2012). (in Chinese).

Huang, Z., Yilmaz, E. & Cao, S. Analysis of strength and microstructural characteristics of mine backfills containing fly Ash and desulfurized gypsum. Minerals 11 (4), 409 (2021).

Liu, Z. X. et al. On damage model of cemented tailings backfill and its match with rock mass. Rock. Soil. Mech. 27, 1442–1446 (2006). (in Chinese).

Liu, W. Z. et al. Mechanical properties and damage evolution of cemented coal gangue-fly Ash backfill under uniaxial compression: effects of different curing temperatures. Constr. Build. Mater. 305 (25), 124820 (2021).

Huang, S. et al. A statistical damage constitutive model under freeze-thaw and loading for rock and its engineering application. Cold Reg. Sci. Technol. 145, 142–150 (2018).

Lemaitre, J. A continuous damage mechanics model for ductile fracture. J. Eng. Mater. T. 107, 83–89 (1985).

Lemaitre, J. How to use damage mechanics. Nucl. Eng. Des. 80 (2), 233–245 (1984).

Gao, F., Xie, H. & Zhao, P. Fractal properties of the Weibull modulus and the strength of rock. Chin. Sci. Bull. 19, 1636–1640 (1993).

Funding

This study was supported by the National Key Research and Development Program of China under the 14th Five-Year Plan (2023YFC3012200).

Author information

Authors and Affiliations

Contributions

Jiyong Zhang: Conceptualization, Writing - original draft, Methodology, Investigation, Data curation. Qianjin Zou: Writing - original draft, Methodology, Investigation, Formal analysis, Conceptualization. Wentao Cai: Investigation, Data curation. Longyue Zhang: Investigation, Data curation. Haoran Ge: Investigation, Data curation. Haigang Li: Supervision, Validation, Methodology, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, J., Zou, Q., Cai, W. et al. Mechanical properties and energy evolution of cemented tailings-rock powder backfill under uniaxial compression: effect of rock powder type and content. Sci Rep (2026). https://doi.org/10.1038/s41598-026-36436-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-36436-y