Abstract

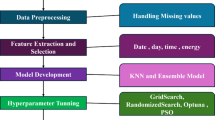

To overcome the efficiency degradation caused by independently designing transmission ratios and evaluating mechanical losses in hybrid electric vehicle drivetrains, this study proposes a unified transmission ratio–efficiency coupled modeling and optimization framework for multi-row planetary gear transmissions. An improved kinematic model based on topological analysis is integrated with a refined multi-source loss model for meshing, bearing, churning, and windage losses. The resulting nonlinear coupled system is solved using a Newton–Raphson method with adaptive step-size regulation. This approach enables the prediction of speed distribution, torque balance, and transmission efficiency under varying operating conditions. An enhanced multi-objective particle swarm optimization (MOPSO) algorithm is then employed to identify high-efficiency zones and to optimize key structural and lubrication parameters. Bench-test verification is conducted through efficiency MAP measurements, thermal endurance tests, and dynamic response evaluations. The results indicate a mean efficiency prediction error of 1.38% and stable thermal and transient behavior. After optimization, the high-efficiency zone coverage increases from 68.5% to 78.6%, and the comprehensive efficiency rises from 92.8% to 95.6%. Overall, the proposed framework provides a computationally efficient and engineering-applicable approach for the systematic design and optimization of planetary gear transmissions.

Similar content being viewed by others

Data availability

The data are available from the corresponding author on reasonable request.

References

Pei, H. et al. Designing multi-mode power split hybrid electric vehicles using the hierarchical topological graph theory. IEEE Trans. Veh. Technol. 69, 7159–7171 (2020).

Gu, J., Zhao, Z., Chen, Y., He, L. & Zhan, X. Integrated optimal design of configuration and parameter of multimode hybrid powertrain system with two planetary gears. Mech. Mach. Theory. 143, 103619 (2020).

Habermehl, C., Jacobs, G. & Neumann, S. A modeling method for gear transmission efficiency in transient operating conditions. Mech. Mach. Theory. 153, 103996 (2020).

Yue, K. et al. Study on gear meshing power loss calculation considering the coupling effect of friction and dynamic characteristics. Tribol Int. 183, 108378 (2023).

Dai, Y., Zhang, Y. Y. & Zhu, X. Generalized analytical model for evaluating the gear power losses transition from windage to churning behavior. Tribol Int. 185, 108565 (2023).

Quiban, R., Changenet, C., Marchesse, Y. & Ville, F. Experimental investigations about the power loss transition between churning and windage for spur gears. J. Tribol. 143, 024501 (2021).

Kim, S. & Choi, S. B. Cooperative control of drive motor and clutch for gear shift of hybrid electric vehicles with dual-clutch transmission. IEEE/ASME Trans. Mechatron. 25, 1578–1588 (2020).

Huang, K., Wang, W., Cheng, J., Yang, C. & Xiang, C. Multi-dynamic torque coordination control strategy for a power-split hybrid electric vehicle during mode shift. Chin. J. Mech. Eng. 35, 103 (2022).

Ehsani, M., Singh, K. V., Bansal, H. O. & Mehrjardi, R. T. State of the art and trends in electric and hybrid electric vehicles. Proc. IEEE 109, 967–984 (2021).

Li, Q., Zhang, Z., Bai, J., Zhang, T. & Gai, F. Development of a compound power-split hybrid power system for commercial vehicles. Int. J. Automot. Technol. 23, 135–147 (2022).

Zanasi, R. & Tebaldi, D. Modeling of complex planetary gear sets using power-oriented graphs. IEEE Trans. Veh. Technol. 69, 14470–14483 (2020).

Gao, B., Wang, Y. & Yu, G. Research progress on the dynamic characteristics of planetary gear transmission in a non-inertial system. Machines 11, 751 (2023).

Du, Q. et al. A 3K planetary gear train with a flexure-based anti-backlash carrier for collaborative robots. Mech. Mach. Theory. 191, 105495 (2024).

Tong, S., Yan, X., Yang, L. & Yang, X. A novel multi-objective dynamic reliability optimization approach for a planetary gear transmission mechanism. Axioms 13, 560 (2024).

B Younes, E., Changenet, C., Bruyère, J., Rigaud, E. & Perret-Liaudet, J. Multi-objective optimization of gear unit design to improve efficiency and transmission error. Mech. Mach. Theory. 167, 104499 (2022).

Huang, W. K. et al. An iterative model for mesh stiffness of spur gears considering slice coupling under elastohydrodynamic lubrication. J. Cent. South. Univ. 30, 3414–3434 (2023).

Liu, Z., Dave, S. & Rinderknecht, S. Energy loss and efficiency investigations of a dual-clutch transmission based on adaptive experiment and analytical simulation. Forsch. Ingenieurwes. 88, 32 (2024).

Mantriota, G. & Reina, G. Dual-motor planetary transmission to improve efficiency in electric vehicles. Machines 9, 58 (2021).

Hong, X., Wu, J., Zhang, N. & Wang, B. Energy efficiency optimization of Simpson planetary gearset–based dual-motor powertrains for electric vehicles. Energy 259, 124908 (2022).

Xu, X. et al. Optimization design for the planetary gear train of an electric vehicle under uncertainties. Actuators 11, 49 (2022).

Sedak, I., Rosić, B. & M., & Multi-objective optimization of planetary gearbox with adaptive hybrid particle swarm differential evolution algorithm. Appl. Sci. 11, 1107 (2021).

Kim, B. S., Chung, W. J., Kim, S. & Park, Y. J. Optimum design of planetary gear set using multi-objective optimization considering mass, power loss and transmission error. Mech. Based Des. Struct. Mach. 52, 7325–7348 (2024).

Kwon, K., Lee, J. H. & Lim, S. K. Optimization of multi-speed transmission for electric vehicles based on electrical and mechanical efficiency analysis. Appl. Energy. 342, 121203 (2023).

Georgiev, N. Efficiency estimation and optimization of multistage compound planetary gearboxes and application to the design of the active skin propulsion of EELS. In Proc. IEEE/RSJ Int. Conf. Intell. Robots Syst. 6458–6465 (2023).

Paschold, C., Lohner, T. & Stahl, K. Local calculation of load-dependent gear power losses of cylindrical gears. J. Tribol. 147, 112201 (2025).

Li, Y., Han, J. & Tang, X. Predictive energy management for dual motor-driven electric vehicles. SAE Technical Paper 2022-01-7006 (2022).

Ke, T., Nie, L. & Kecskeméthy, A. Powertrain configuration design for two-mode power split hybrid electric vehicle. Sci. Rep. 15, 3676 (2025).

Ren, W. et al. Shifting process optimization of dedicated hybrid transmission. IEEE Access. 10, 61892–61904 (2022).

Chen, H., Li, L. & Küçükay, F. Study of series-parallel and power-split DHT for hybrid powertrains. Automot. Innov. 3, 342–355 (2020).

Nguyen, A. T. et al. Fuzzy control systems: past, present and future. IEEE Comput. Intell. Mag. 14, 56–68 (2019).

Jing, J., Zhang, J., Liu, Y. et al. Research on the control systems for hybrid and electric powertrains[R]. SAE Technical Paper (2024).

Li, P., Jiao, X. & Li, Y. Adaptive real-time energy management control strategy based on fuzzy inference system for plug-in hybrid electric vehicles. Control Eng. Pract. 107, 104703 (2021).

Furuta, H. & Yoshida, J. Hybrid electric two-wheeled vehicle fitted with an EVT system (electrical variable transmission system). SAE Int. J. Adv. Curr. Pract. Mobil. 6, 2243–2258 (2024).

Handschuh, M., Guner, A. & Kahraman, A. An experimental investigation of windage and oil churning power losses of gears and discs. Proc. Inst. Mech. Eng. J 237, (2023).

Zschippang, H. A., Weikert, S. & Wegener, K. Face-gear drive: meshing efficiency assessment. Mech. Mach. Theory. 171, 104765 (2022).

Quiban, R., Changenet, C., Marchesse, Y., Ville, F. & Belmonte, J. Churning losses of spiral Bevel gears at high rotational speed. Proc. Inst. Mech. Eng. J. 234, 172–182 (2020).

Funding

This work is also supported by the Anhui Provincial Key Project of Natural Science—Research and Application of High-Efficiency Hybrid Vehicle Transmission Technology (2025AHGXZK31129).

Author information

Authors and Affiliations

Contributions

Qiong Zhang: Writing-original draft, review and editing. Cuifeng Ren: Formal analysis, Methodology, Validation. Haixia Niu: Review, supervision. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Q., Ren, C. & Niu, H. Transmission ratio-efficiency coupled modeling and high-efficiency zone design for multi-row planetary gear transmission of hybrid electric vehicles. Sci Rep (2026). https://doi.org/10.1038/s41598-026-37023-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-37023-x