Abstract

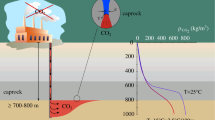

CO2 geological storage is widely regarded as one of the most technically mature and large-scale options for emissions reduction within CCUS (Carbon Capture, Utilization and Storage) technologies. However, CO2 corrosion and long-term injection/storage operations pose significant threats to the sealing integrity of cement sheaths in wellbores. Existing studies predominantly rely on numerical simulations to analyze the mechanical response on cement sheath under temperature–pressure conditions, neglecting the corrosion of cement sheath. However, there is a notable lack of theoretical computation models specifically for cement sheaths containing the coupled effects of corrosion and stress. This study establishes a mechanical model of the casing-CCS (corroded cement sheath)-formation assembly based on elastoplastic theory, incorporating thick-walled cylinder theory and the Mohr–Coulomb criterion. The model is solved using MATLAB to quantify the stress-displacement response of CCS during injection and storage. Results indicate that CO2 corrosion significantly increases the complexity of the stress state in the cement sheath and the risk of sealing failure. For a representative injection pressure of 60 MPa, introducing a 5 mm corroded layer increases the predicted micro-annulus aperture at the primary casing-cement interface from 0.0238 mm to 0.0519 mm after unloading (an increase of 118%). When the injection pressure varies from 40 to 100 MPa, the micro-annulus aperture grows from 0.0211 mm to 0.1113 mm, whereas increasing the CSCL thickness from 5 to 30 mm only enlarges it from 0.0519 mm to 0.0579 mm (11.5%). In contrast, increasing casing wall thickness from 7.5 mm to 17.5 mm reduces the maximum radial stress in the cement sheath from -28.88 MPa to -18.68 MPa and decreases the micro-annulus aperture from 0.1829 mm to 0.0413 mm. This study provides a theoretical foundation for optimizing wellbore design in CCUS projects.

Similar content being viewed by others

Data availability

Data available on request from the corresponding author.

Abbreviations

- CCUS:

-

Carbon capture, utilization and storage

- CCS:

-

Corroded cement sheath

- CSCL:

-

Cement sheath corroded layer

- CSIL:

-

Cement sheath intact layer

References

Dai, S., Liao, T. & Wu, Y. Progress of CO2 geological storage research, policy development and suggestions in China. Carbon Manag. 16, 14. https://doi.org/10.1080/17583004.2025.2485104 (2025).

Li, X. & Fang, Z. Status quo of connection technologies of CO2 geological storage in China. Rock Soil Mech. 28, 2229 (2007).

Du, J., Zhou, A., Zhong, Y. & Shen, S. Molecular simulation on CO2 adsorption heterogeneity in montmorillonite nanopores with different surface charges in presence of water. Chem. Eng. J. 482, 14. https://doi.org/10.1016/j.cej.2024.148958 (2024).

Leung, D., Caramanna, G. & Maroto-Valer, M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sust. Energ. Rev. 39, 426–443. https://doi.org/10.1016/j.rser.2014.07.093 (2014).

Bachu, S. Sequestration of CO2 in geological media: criteria and approach for site selection in response to climate change. Energy Convers. Manage. 41, 953–970. https://doi.org/10.1016/s0196-8904(99)00149-1 (2000).

White, C., Strazisar, B., Granite, E., Hoffman, J. & Pennline, H. Separation and capture of CO2 from large stationary sources and sequestration in geological formations -: Coalbeds and deep saline aquifers. J. Air Waste Manage. Assoc. 53, 645–715. https://doi.org/10.1080/10473289.2003.10466206 (2003).

Hong, Z. et al. A quick method for appraising pore connectivity and ultimate imbibed porosity in shale reservoirs. J. Marine Sci. Eng. 13, 174 (2025).

Meng, M. et al. Rock Fabric of Lacustrine Shale and Its Influence on Residual Oil Distribution in the Upper Cretaceous Qingshankou Formation Songliao Basin. Energy Fuels 37, 7151–7160. https://doi.org/10.1021/acs.energyfuels.3c00527 (2023).

Loizzo, M. et al. in 10th International Conference on Greenhouse Gas Control Technologies. 5203–5210 (Elsevier Science Bv, 2011).

Wang, D. et al. CO2 sequestration wells sealing evaluation model: Jimusar depression, China as an example. Geoenergy Sci. Eng https://doi.org/10.1016/j.geoen.2024.213439 (2025).

Bai, M., Sun, J., Song, K., Reinicke, K. & Teodoriu, C. Evaluation of mechanical well integrity during CO2 underground storage. Environ. Earth Sci. 73, 6815–6825. https://doi.org/10.1007/s12665-015-4157-5 (2015).

Li, C. et al. A new method to protect the cementing sealing integrity of carbon dioxide geological storage well: An experiment and mechanism study. Eng. Fracture Mech. https://doi.org/10.1016/j.engfracmech.2020.107213 (2020).

Li, J., Chen, Y., Liang, W., Zhang, S. & Qiu, Y. Experimental investigation on permeability and mechanical properties of cement-salt rock interface subjected to cyclic loading. Rock Mech. Rock Eng. 56, 7281–7299. https://doi.org/10.1007/s00603-023-03434-9 (2023).

Zhou, S. et al. Mechanical characteristics of well cement under cyclic loading and its influence on the integrity of shale gas wellbores. Fuel 250, 132–143. https://doi.org/10.1016/j.fuel.2019.03.131 (2019).

Udebhulu, O., Aladeitan, Y., Azevedo, R. & De Tomi, G. A review of cement sheath integrity evaluation techniques for carbon dioxide storage. J. Petroleum Explor. Product. Technol. 14, 1–23. https://doi.org/10.1007/s13202-023-01697-0 (2024).

Deng, K. et al. Failure mechanism and influencing factors of cement sheath integrity under alternating pressure. Pet. Sci. 20, 2413–2427. https://doi.org/10.1016/j.petsci.2023.03.004 (2023).

Chu, W., Shen, J., Yang, Y., Li, Y. & Gao, D. Calculation of micro-annulus size in casing-cement sheath-formation system under continuous internal casing pressure change. Pet. Explor. Dev. 42, 414–421. https://doi.org/10.1016/s1876-3804(15)30033-1 (2015).

Zhang, X. et al. Study on the sealing integrity of cement sheath under cyclic internal pressure considering temperature effects. Geoenergy Sci. Eng. https://doi.org/10.1016/j.geoen.2025.213761 (2025).

Zhang, H., Shen, R., Yuan, G., Ba, Z. & Hu, Y. Cement sheath integrity analysis of underground gas storage well based on elastoplastic theory. J. Petrol. Sci. Eng. 159, 818–829. https://doi.org/10.1016/j.petrol.2017.10.012 (2017).

Xi, Y., Lian, W., Fan, L., Tao, Q. & Guo, X. Research and engineering application of pre-stressed cementing technology for preventing micro-annulus caused by cyclic loading-unloading in deep shale gas horizontal wells. J. Petroleum Sci. Eng. https://doi.org/10.1016/j.petrol.2021.108359 (2021).

Zhou, S. et al. Study on the mechanism and controlling method for annulus pressure buildup problems in shale gas wells. Geoenergy Sci. Eng. https://doi.org/10.1016/j.geoen.2023.212065 (2023).

Su, D. et al. Mechanical property design method of cement sheath in a horizontal shale oil well under fracturing conditions. Pet. Explor. Dev. 49, 919–928. https://doi.org/10.1016/s1876-3804(22)60321-5 (2022).

Su, D. et al. Sealing integrity evaluation and optimization of cement sheath-formation interface under different formation conditions during fracturing. J. Earth Sci. 36, 223–232. https://doi.org/10.1007/s12583-023-1837-z (2025).

Zhou, N. et al. Damage behavior and constitutive model of cement sheath under alternating temperature. Geoenergy Sci. Eng. https://doi.org/10.1016/j.geoen.2025.213945 (2025).

Yuan, B., Luo, W., Xu, B. & Fan, H. A prediction model for carbonation depth of cement sheath of carbon capture utilization and storage (CCUS) wells. J. Nat. Gas Sci. Eng. https://doi.org/10.1016/j.jngse.2022.104842 (2022).

Kutchko, B., Strazisar, B., Lowry, G., Dzombak, D. & Thaulow, N. Rate of CO2 attack on hydrated Class H well cement under geologic sequestration conditions. Environ. Sci. Technol. 42, 6237–6242. https://doi.org/10.1021/es800049r (2008).

Wu, Z., Wu, G. & Xing, X. Sealing integrity of cement sheath under the condition of CO2 corrosion-stress coupling. Drilling Fluid Completion Fluid. 41, 220–230 (2024).

Gu, T. et al. Coupled effect of CO2 attack and tensile stress on well cement under CO2 storage conditions. Constr. Build. Mater. 130, 92–102. https://doi.org/10.1016/j.conbuildmat.2016.10.117 (2017).

Mei, K. et al. Effectiveness and microstructure change of alkali-activated materials during accelerated carbonation curing. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2020.122063 (2021).

Li, Y., Tang, H., Wu, P. & Song, Y. Micro mechanical behavior and strain localization of oil well cement corroded by CO2. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2024.138371 (2024).

Zhang, H. et al. Application of ABAQUS Flow-Solid coupling model to evaluate sealing capability of sandstone formation interface based on the cracking behavior of cohesive force units. Constr. Build. Mater. 409, 19. https://doi.org/10.1016/j.conbuildmat.2023.133863 (2023).

Bu, Y. et al. Stress concentration of perforated cement sheath and the effect of cement sheath elastic parameters on its integrity failure during shale gas fracturing. Front. Mater. 9, 14. https://doi.org/10.3389/fmats.2022.980920 (2022).

He, Y., Song, Y., Hu, S., Liu, H. & Ge, X. Mechanical evaluation of casing in multiple thermal recovery cycles for offshore heavy oil wells. J. Marine Sci. Eng. https://doi.org/10.3390/jmse13030597 (2025).

Funding

This work is supported by National Natural Science Foundation of China (Grant No. 52404002), Open Fund of Hubei Key Laboratory of Oil and Gas Drilling and Production Engineering (Yangtze University) (Grant No. YQZC202411).

Author information

Authors and Affiliations

Contributions

K.Z. and H.M analyzed most of the data and wrote the main manuscript text. S.Z. contributed the central idea, revised the first draft, and provided financial support. Z.R. and Y.Z assisted with the analysis of the model and results. D.F. prepared all figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, K., Zheng, S., Meng, H. et al. Analysis of the long-term sealing integrity of cement sheath in CO2 storage wells. Sci Rep (2026). https://doi.org/10.1038/s41598-026-38242-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-38242-y