Abstract

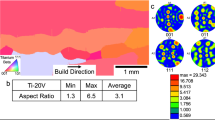

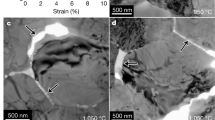

Titanium alloys are high-performance materials critical for demanding applications in aerospace, defense, and energy sectors. Basal twist grain boundaries were recently identified as key microstructure configurations leading to failures under different conditions. In the present study, we examined deformation and fracture in these specific locations to shed light on the mechanical behavior in relation to grain boundary characteristics. In situ characterization using high resolution digital image correlation was employed, and revealed both unexpectedly low stress deformation and early cleavage-like fracture. The collected dataset enabled the identification of influential grain boundary parameters, including their twist and tilt components. Molecular dynamics simulations of bicrystals subjected to shear loadings properly replicated experimental observations, and unveiled underlying mechanisms. The clarified influence of grain boundary characteristics on the mechanical response offers a new understanding of the detrimental role of basal twist grain boundaries on the performance of titanium alloys.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author, Samuel Hemery (samuel.hemery@ensma.fr), on reasonable request.

References

Gerd Lütjering, James C. Williams. Titanium. (Springer, 2007).

Peters, M., Kumpfert, J., Ward, C. H. & Leyens, C. Titanium Alloys for Aerospace Applications. in Titanium and Titanium Alloys 333–350 (John Wiley & Sons, 2005).

Williams, J. C. & Starke, E. A. Progress in structural materials for aerospace systems1. Acta Mater. 51, 5775–5799 (2003).

Peters, M., Hemptenmacher, J., Kumpfert, J. & Leyens, C. Structure and Properties of Titanium and Titanium Alloys. in Titanium and Titanium Alloys 1–36 (John Wiley & Sons, 2005).

Williams, J. C. & Boyer, R. R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 10, 705 (2020).

McDowell, D. L. & Dunne, F. P. E. Microstructure-sensitive computational modeling of fatigue crack formation. Int. J. Fatigue 32, 1521–1542 (2010).

Ozturk, D., Pilchak, A. L. & Ghosh, S. Experimentally validated dwell and cyclic fatigue crack nucleation model for α–titanium alloys. Scr. Mater. 127, 15–18 (2017).

Xu, Y. et al. Predicting dwell fatigue life in titanium alloys using modelling and experiment. Nat. Commun. 11, 5868 (2020).

Christ, H.-J., Fritzen, C.-P. & Köster, P. Micromechanical modeling of short fatigue cracks. Curr. Opin. Solid State Mater. Sci. 18, 205–211 (2014).

Lütjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 243, 32–45 (1998).

Briffod, F., Shiraiwa, T., Enoki, M. & Emura, S. Effect of macrozones on fatigue crack initiation and propagation mechanisms in a forged Ti-6Al-4V alloy under fully-reversed condition. Materialia 22, 101401 (2022).

Bridier, F., Villechaise, P. & Mendez, J. Slip and fatigue crack formation processes in an α/β titanium alloy in relation to crystallographic texture on different scales. Acta Mater. 56, 3951–3962 (2008).

Pilchak, A. L. & Williams, J. C. Observations of facet formation in near-α titanium and comments on the role of hydrogen. Met. Mater. Trans. A 42, 1000–1027 (2011).

Pilchak, A. L., Williams, R. E. A. & Williams, J. C. Crystallography of fatigue crack initiation and growth in fully lamellar Ti-6Al-4V. Met. Mater. Trans. A 41, 106 (2009).

Bantounas, I., Dye, D. & Lindley, T. C. The effect of grain orientation on fracture morphology during high-cycle fatigue of Ti–6Al–4V. Acta Mater. 57, 3584–3595 (2009).

Tympel, P. O., Lindley, T. C., Saunders, E. A., Dixon, M. & Dye, D. Influence of complex LCF and dwell load regimes on fatigue of Ti–6Al–4V. Acta Mater. 103, 77–88 (2016).

Sinha, V. et al. Correlating scatter in fatigue life with fracture mechanisms in forged Ti-6242Si alloy. Met. Mater. Trans. A 49, 1061–1078 (2018).

Lavogiez, C., Hémery, S. & Villechaise, P. On the mechanism of fatigue and dwell-fatigue crack initiation in Ti-6Al-4V. Scr. Mater. 183, 117–121 (2020).

Hémery, S. et al. Strain localization and fatigue crack formation at (0001) twist boundaries in titanium alloys. Acta Mater. 219, 117227 (2021).

Lavogiez, C., Dureau, C., Nadot, Y., Villechaise, P. & Hémery, S. Crack initiation mechanisms in Ti-6Al-4V subjected to cold dwell-fatigue, low-cycle fatigue and high-cycle fatigue loadings. Acta Mater. 244, 118560 (2023).

Hémery, S., Bertheau, D. & Hamon, F. Microtexture effects on fatigue and dwell-fatigue lifetimes of Ti-6Al-4V. Int. J. Fatigue 179, 108068 (2024).

IOM3. Chapter 4: C-M-P – Deformation behaviour. Research 13, 1189 (2024).

Wu, Z. et al. Crack initiation mechanism in a high-strength Ti-5Al-7.5V alloy subjected to high cycle fatigue loading. Eng. Fail. Anal. 148, 107201 (2023).

Liu, C. et al. Microstructural effects on fatigue crack initiation mechanisms in a near-alpha titanium alloy. Acta Mater. 253, 118957 (2023).

Jia, R. et al. Crack nucleation and dislocation activities in titanium alloys with the strong transverse texture: Insights for enhancing dwell fatigue resistance. Int. J. Plast. 175, 103938 (2024).

Bean, C. et al. Microstructural statistics for low-cycle fatigue crack initiation in α+β titanium alloys: a microstructure based RVE assessment. Int. J. Fatigue 176, 107854 (2023).

Hémery, S., Naït-Ali, A., Smerdova, O. & Tromas, C. Deformation mechanisms in the α phase of the Ti-6Al-2Sn-4Zr-2Mo titanium alloy: in situ experiments and simulations. Int. J. Plast. 175, 103947 (2024).

Pagan, D. C. et al. Modeling slip system strength evolution in Ti-7Al informed by in-situ grain stress measurements. Acta Mater. 128, 406–417 (2017).

Williams, J. C., Baggerly, R. G. & Paton, N. E. Deformation behavior of HCP Ti-Al alloy single crystals. Met. Mater. Trans. A 33, 837–850 (2002).

Jones, I. P. & Hutchinson, W. B. Stress-state dependence of slip in Titanium-6Al-4V and other H.C.P. metals. Acta Metall. 29, 951–968 (1981).

Dawson, P. R., Boyce, D. E., Park, J.-S., Wielewski, E. & Miller, M. P. Determining the strengths of HCP slip systems using harmonic analyses of lattice strain distributions. Acta Mater. 144, 92–106 (2018).

Zhang, Z., Jun, T.-S., Britton, T. B. & Dunne, F. P. E. Determination of Ti-6242 α and β slip properties using micro-pillar test and computational crystal plasticity. J. Mech. Phys. Solids 95, 393–410 (2016).

Hasija, V., Ghosh, S., Mills, M. J. & Joseph, D. S. Deformation and creep modeling in polycrystalline Ti–6Al alloys. Acta Mater. 51, 4533–4549 (2003).

Liu, Y. et al. Discovery via integration of experimentation and modeling: three examples for titanium alloys. JOM 67, 164–178 (2015).

Echlin, M. P., Stinville, J. C., Miller, V. M., Lenthe, W. C. & Pollock, T. M. Incipient slip and long range plastic strain localization in microtextured Ti-6Al-4V titanium. Acta Mater. 114, 164–175 (2016).

Hémery, S., Dang, T., Signor, L. & Villechaise, P. Influence of microtexture on early plastic slip activity in Ti-6Al-4V polycrystals. Met. Mater. Trans. A 49, 2048–2056 (2018).

Hémery, S., Villechaise, P. & Banerjee, D. Microplasticity at room temperature in α/β titanium alloys. Met. Mater. Trans. A 51, 4931–4969 (2020).

Chen, Z. & Daly, S. H. Active slip system identification in polycrystalline metals by digital image correlation (DIC). Exp. Mech. 57, 115–127 (2017).

Xu, X. et al. Identification of active slip mode in a hexagonal material by correlative scanning electron microscopy. Acta Mater. 175, 376–393 (2019).

Sperry, R. et al. Slip band characteristics in the presence of grain boundaries in nickel-based superalloy. Acta Mater. 193, 229–238 (2020).

Lee, T. C., Robertson, I. M. & Birnbaum, H. K. TEM in situ deformation study of the interaction of lattice dislocations with grain boundaries in metals. Philos. Mag. A 62, 131–153 (1990).

Joseph, S., Lindley, T. C. & Dye, D. Dislocation interactions and crack nucleation in a fatigued near-alpha titanium alloy. Int. J. Plast. 110, 38–56 (2018).

Murr, L. E. Strain-induced dislocation emission from grain boundaries in stainless steel. Mater. Sci. Eng. 51, 71–79 (1981).

Koehler, J. S. & deWit, G. Influence of Elastic anisotropy on the dislocation contribution to the elastic constants. Phys. Rev. 116, 1121–1125 (1959).

Dokkum, J. S. V., Bos, C., Offerman, S. E. & Sietsma, J. Influence of dislocations on the apparent elastic constants in single metallic crystallites: an analytical approach. Materialia 20, 101178 (2021).

Stapleton, A. M. et al. Evolution of lattice strain in Ti–6Al–4V during tensile loading at room temperature. Acta Mater. 56, 6186–6196 (2008).

Luster, J. & Morris, M. A. Compatibility of deformation in two-phase Ti-Al alloys: dependence on microstructure and orientation relationships. Met. Mater. Trans. A 26, 1745–1756 (1995).

Hémery, S., Nizou, P. & Villechaise, P. In situ SEM investigation of slip transfer in Ti-6Al-4V: effect of applied stress. Mater. Sci. Eng. A 709, 277–284 (2018).

Han, S. & Crimp, M. A. ECCI analysis of shear accommodations at grain boundaries in commercially pure alpha titanium. Int. J. Plast. 131, 102731 (2020).

Wang, L. et al. Direct measurement of critical resolved shear stress of prismatic and basal slip in polycrystalline Ti using high energy X-ray diffraction microscopy. Acta Mater. 132, 598–610 (2017).

Wu, Z. et al. Preferential fatigue cracking at basal twist grain boundary (BTGB) in bimodal Ti-5Al-4V alloy: Dislocation activities and crack initiation. J. Mater. Sci. Technol. 217, 281–295 (2025).

Przybyla, C. P. & McDowell, D. L. Microstructure-sensitive extreme-value probabilities of high-cycle fatigue for surface vs. subsurface crack formation in duplex Ti–6Al–4V. Acta Mater. 60, 293–305 (2012).

Bachmann, F., Hielscher, R. & Schaeben, H. Texture analysis with MTEX – free and open source software toolbox. Solid State Phenom. 160, 63–68 (2010).

Stinville, J. C. et al. Sub-grain scale digital image correlation by electron microscopy for polycrystalline materials during elastic and plastic deformation. Exp. Mech. 56, 197–216 (2016).

Kammers, A. D. & Daly, S. Digital image correlation under scanning electron microscopy: methodology and validation. Exp. Mech. 53, 1743–1761 (2013).

Schindelin, J. et al. Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012).

Preibisch, S., Saalfeld, S. & Tomancak, P. Globally optimal stitching of tiled 3D microscopic image acquisitions. Bioinformatics 25, 1463–1465 (2009).

Bourdin, F. et al. Measurements of plastic localization by heaviside-digital image correlation. Acta Mater. 157, 307–325 (2018).

Valle, V., Hedan, S., Cosenza, P., Fauchille, A. L. & Berdjane, M. Digital image correlation development for the study of materials including multiple crossing cracks. Exp. Mech. 55, 379–391 (2015).

Hirel, P. Atomsk: a tool for manipulating and converting atomic data files. Comput. Phys. Commun. 197, 212–219 (2015).

Warrington, D. H. the coincidence site lattice (csl) and grain boundary (dsc) dislocations for the hexagonal lattice. J. Phys. Colloq. 36, C4–C95 (1975).

Bitzek, E., Koskinen, P., Gähler, F., Moseler, M. & Gumbsch, P. Structural relaxation made simple. Phys. Rev. Lett. 97, 170201 (2006).

Guénolé, J. et al. Assessment and optimization of the fast inertial relaxation engine (fire) for energy minimization in atomistic simulations and its implementation in LAMMPS. Comput. Mater. Sci. 175, 109584 (2020).

Thompson, A. P. et al. LAMMPS - a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 271, 108171 (2022).

Kim, Y.-K., Kim, H.-K., Jung, W.-S. & Lee, B.-J. Atomistic modeling of the Ti–Al binary system. Comput. Mater. Sci. 119, 1–8 (2016).

Tschopp, M. A., Coleman, S. P. & McDowell, D. L. Symmetric and asymmetric tilt grain boundary structure and energy in Cu and Al (and transferability to other fcc metals). Integr. Mater. Manuf. Innov. 4, 176–189 (2015).

Wang, J. & Beyerlein, I. J. Atomic structures of symmetric tilt grain boundaries in hexagonal close packed (hcp) crystals. Model. Simul. Mater. Sci. Eng. 20, 024002 (2012).

Wang, H., Guénolé, J., Korte-Kerzel, S., Al-Samman, T. & Xie, Z. Defects in magnesium and its alloys by atomistic simulation: Assessment of semi-empirical potentials. Comput. Mater. Sci. 240, 113025 (2024).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2009).

Acknowledgements

The ANR (Agence Nationale de la Recherche) is gratefully acknowledged for funding this study: ANR-20-CE08-0006 (PLASLOTI) and ANR-21-CE08-0001 (ATOUUM). High Performance Computing resources were provided by the EXPLOR center of the Université de Lorraine and by GENCI at TGCC (Grants 2023-A0150914654 and 2024-A0170914654).

Author information

Authors and Affiliations

Contributions

Conceptualization: J.G. and S.H., Methodology: T.Y., D.I., F.H., J.G., V.V., and S.H., Investigation: T.Y., D.I., J.G., and S.H., Visualization: T.Y., D.I., J.G., S.H., Supervision: V.V., J.G., and S.H., Writing—original draft: T.Y. and S.H., Writing—review and editing: T.Y., D.I., F.H., V.V., J.G., and S.H.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Zixu Guo and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yvinec, T., Iabbaden, D., Hamon, F. et al. Low stress grain boundary mediated plasticity and early fracture at basal twist grain boundaries in a titanium alloy. Commun Mater (2026). https://doi.org/10.1038/s43246-026-01102-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-026-01102-3