Abstract

As transistor scaling approaches nanometre and even atomic scales, 3D stacking has become a critical enabler for advancement in the semiconductor industry, especially in high-performance computing and artificial intelligence (AI) applications. However, 3D integration introduces substantial thermal management challenges related to the increased power density and constrained heat dissipation pathways, particularly through low thermal conductivity interlayer dielectrics and complex interfaces. In this Review, we discuss state-of-the-art thermal management materials, covering their process compatibility, the critical integration challenges and the need for improved methods to enhance heat transport across interfaces. Advanced thermal characterization metrologies are introduced to highlight the need for non-destructive in-line metrologies. Finally, we provide a road map that outlines future research directions for material growth, integration and characterization methodologies to enable viable thermal solutions for 3D integration and beyond.

Key points

-

The shrinking dimensions, increased structural complexity and 3D stacking of silicon-based semiconductor devices are intensifying challenges in thermal dissipation.

-

Breakthroughs are needed to address maximum temperatures near hot spots in 3D-stacked devices, requiring innovation in material growth, processing and integration.

-

Advancements are necessary in the characterization of the thermal properties of the materials and in the methods to enhance heat transport across interfaces.

-

The development of non-destructive in-line metrologies compatible with semiconductor processing flows is highly desirable for the characterization of thermal management film stacks and the monitoring of thermal dissipation performance within chips.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Mii, Y. J. Semiconductor industry outlook and new technology frontiers. In Intenaional Electron Devices Meeting 1.1.1–1.1.6 (IEEE, 2024). This work points out a technology road map and outlook for the semiconductor industry.

Cao, W. et al. The future transistors. Nature 620, 501–515 (2023). This work describes the directions for transistor evolution and needs for new materials.

Yeap, G. et al. 2 nm platform technology featuring energy-efficient nanosheet transistors and interconnects co-optimized with 3DIC for AI, HPC and mobile SoC applications. In Internationa Electron Devices Meeting 2.1.1–2.1.4 (IEEE, 2024).

Liao. S. S. et al. Complementary field-effect transistor (CFET) demonstration at 48 nm gate pitch for future logic technology scaling. In International Electron Devices Meeting 29.6.1–29.6.4 (IEEE, 2023).

Liao. S. S. et al. First demonstration of monolithic CFET inverter at 48 nm gate pitch toward future logic technology scaling. In International Electron Devices Meeting 2.5.1–2.5.4 (IEEE, 2024). This work showcases a state-of-the-art BSPDN-implemented CFET inverter at an industry-relevant scale.

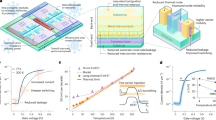

Woon. W. Y. et al. Integration and characterization of high thermal conductivity materials for heat dissipation in stacked devices. In Symposium VLSI Technology and Circuits JFS3.4 (IEEE, 2024). This work illustrates the progress and development directions for integration and characterization of high thermal conductivity materials for heat dissipation in stacked devices and demonstrates SSTR as an effective thermal characterization metrology for a complex film stack.

Tung, C. H. & Yu, D. C. H. An integrated system scaling solution for future high performance computing. In Symposium VLSI Technology and Circuits JSF4.2 (IEEE, 2023). This work presents the technology road map, especially 3D stacking, in system integration for high-performance computing.

Chen. R. et al. Power, performance, area and thermal analysis of 2D and 3D ICs at A14 node designed with back-side power delivery network. In International Electron Devices Meeting 23.4.1–23.4.4 (IEEE, 2022).

Tatum, L. P., Sikder, U. & Liu, T.-J. K. Design technology co-optimization for back-end-of-line nonvolatile NEM switch arrays. IEEE Trans. Electron. Dev. 68, 1471–1477 (2021).

Woon. W. Y. et al. Thermal dissipation in stacked devices. In International Electron Devices Meeting 19.3.1–19.3.3 (IEEE, 2023). This work discusses diamond and AlN as thermal management material candidates and the mitigation of TBR, and demonstrates SSTR as an effective thermal characterization metrology for thermal management films.

Lau, J. H. et al. Thermal management of 3D IC integration with TSV (through silicon via). In Electronic Components and Technology Conference 635 (IEEE, 2009).

Prasad, C., Ramey, S. & Jiang, L. Self-heating in advanced CMOS technologies. In International Reliability Physics Symposium 6A-4.1–6A-4.7 (IEEE, 2017). This work describes the electrical impacts on CMOS devices by self-heating.

Park, K. et al. Development of an advanced TDDB analysis model for temperature dependency. Electronics 8, 942 (2019).

Chang, X. et al. Calibrated fast thermal calculation and experimental characterization of advanced BEOL stacks. In Electronic Components and Technology Conference 1485–1492 (IEEE, 2024).

Minnich, A. J. Advances in the measurement and computation of thermal phonon transport properties. J. Phys. Condens. Matter 27, 053202 (2015). This work describes the fundamentals of thermal phonon transport properties.

Nomura, M. et al. Review of thermal transport in phononic crystals. Mater. Today Phys. 22, 100613 (2022).

Jeong, C., Datta, S. & Lundstrom, M. Thermal conductivity of bulk and thin-film silicon: a Landauer approach. J. Appl. Phys. 111, 093708 (2012).

Kuryliuk, V., Nepochatyi, O., Chantrenee, P., Lacroix, D. & Isaiev, M. Thermal conductivity of strained silicon: molecular dynamics insight and kinetic theory approach. J. Appl. Phys. 126, 055109 (2019).

Hanus, R. et al. Thermal transport in defective and disordered materials. Appl. Phys. Rev. 8, 031311 (2021). This work describes the effect of defects and disorder on thermal transport in thermal management materials.

Windischmann. H. in Properties, Growth and Applications of Diamond (eds. Nazare, M. H. & Neves, A. J.) 410–416 (INSPEC, 2001).

Wort, C. J. H. & Balmer, R. S. Diamond as an electronic material. Mater. Today 11, 22–28 (2008).

Isberg, J. et al. High carrier mobility in single-crystal plasma-deposited diamond. Science 297, 1670–1672 (2002).

Ward, A., Broido, D. A., Stewart, D. A. & Deinzer, G. Ab intio theory of the lattice thermal conductivity in diamond. Phys. Rev. B 80, 125203 (2009).

Onn, D. G., Witek, A., Qiu, Y. Z., Anthony, T. R. & Banholzer, W. F. Some aspects of the thermal conductivity of isotopically enriched diamond single crystals. Phys. Rev. Lett. 68, 2806 (1992).

Inyushkin, A. V. et al. Thermal conductivity of high purity synthetic single cristal diamonds. Phys. Rev. B 97, 144305 (2018).

Olson, J. R. et al. Thermal conductivity of diamond between 170 and 1200 K and the isotope effect. Phys. Rev. B 47, 14850 (1993).

Katcho, N. A., Carrete, J. & Mingo, N. Effect of nitrogen and vacancy defects on the thermal conductivity of diamond: an ab initio Green’s function approach. Phys. Rev. B 90, 094117 (2014).

Sukhadolau, A. V. et al. Thermal conductivity of CVD diamond at elevated temperatures. Diam. Relat. Mater. 14, 589–593 (2005).

Wang, T., Carrete, J., van Roekeghem, A., Mingo, N. & Madsen, G. K. H. Ab initio phonon scattering by dislocations. Phys. Rev. B 95, 245304 (2017).

Cheng, Y., Nomura, M., Volz, S. & Xiong, S. Phonon–dislocation interaction and its impact on thermal conductivity. J. Appl. Phys. 130, 040902 (2021).

Fischer, M., Gsell, S., Schreck, M. & Bergmaier, A. Growth sector dependence and mechanism of stress formation in epitaxial diamond growth. Appl. Phs. Lett. 100, 041906 (2012).

Stehl, C. et al. Efficiency of dislocation density reducation during heteroepitaxial growth of diamond for detector applications. Appl. Phys. Lett. 103, 151905 (2013).

Wang, W.-H. et al. Recent progress on controlling dislocation density and behavior during heteroepitaxial single crystal diamond growth. N. Carbon Mater. 36, 1034–1045 (2021).

Schreck, M. et al. Multiple role of dislocations in the heteroepitaxial growth of diamond: a brief review. Phys. Status Solidi A 213, 2028–2035 (2016).

Schreck, M., Gsell, S., Brescia, R. & Fischer, M. Ion bombardment induced buried lateral growth: the key mechanism for the synthesis of single crystal diamond wafers. Sci. Rep. 7, 44462 (2017).

Chae, K.-W., Baik, Y.-J., Park, J.-K. & Lee, W.-S. The 8-inch free-standing CVD diamond wafer fabricated by DC-PACVD. Diam. Relat. Mater. 19, 1168–1171 (2010).

Shu, G. et al. Coessential-connection by microwave plasma chemical vapor deposition: a common process towards wafer scale single crystal diamond. Funct. Diam. 1, 47–62 (2021).

Janssen, G. & Giling, L. J. “Mosaic” growth of diamond. Diam. Relat. Mater. 4, 1025–1031 (1995).

Yamada, H. et al. Fabrication and fundamental characterizations of tiled clones of single-crystal diamond with 1-inch size. Diam. Relat. Mater. 24, 29–33 (2012).

Yamada, H., Chayahara, A., Mokuna, Y., Kato, Y. & Shikata, S. A 2-in. mosaic wafer made of a single-crystal diamond. Appl. Phys. Lett. 104, 102110 (2014).

Shu, G. et al. Epitaxial growth of mosaic diamond: mapping of stress and defects in crystal junction with a confocal Raman spectroscopy. J. Cryst. Growth 463, 19–26 (2017).

Ralchenko, V. G. et al. Thermal conductivity of diamond mosaic crystals grown by chemical vapor deposition: thermal resistance of junctions. Phys. Rev. Appl. 16, 014049 (2021).

Matsushita, A. et al. Evaluation of diamond mosaic wafer crystallinity by electron backscatter diffraction. Diam. Relat. Mater. 101, 107558 (2020).

Vaissere, N. et al. Heteroepitaxial diamond on iridium: new insights on domain formation. Diam. Relat. Mater. 36, 16–25 (2013).

Wang, W. et al. Heteroepitaxy of diamond semiconductor on iridium: a review. Funct. Diam. 2, 215–235 (2022). This work reviews heteroepitaxy of SCD.

Wang, Y. et al. Virtues of Ir(100) substrate on diamond epitaxial growth: first-principle calculation and XPS study. J. Cryst. Growth 560-561, 126047 (2021).

Kimura, Y., Oshima, R., Sawabe, A. & Aida, H. Analysis of the correlation between in-situ and ex-situ observations of the initial stages of growth of heteroepitaxial diamond on Ir(001)/MgO(001). J. Cryst. Growth 595, 126807 (2022).

Kasu, M., Takaya, R. & Kim, S.-W. Growth of high-quality inch-diameter heteroepitaxial diamond layers on sapphire substrates in comparison to MgO substrates. Diam. Relat. Mater. 126, 109086 (2022).

Aida, H., Ihara, T., Oshima, R., Kimura, Y. & Sawabe, A. Analysis of external surface and internal lattice curvatures of freestanding heteroepitaxial diamond grown on an Ir(001)/MgO(001) substrate. Diam. Relat. Mater. 136, 110026 (2023).

Kimura, Y. et al. Physical bending of heteroepitaxial diamond grown on an Ir/MgO substrate. Diam. Relat. Mater. 137, 110055 (2023).

Li, L. et al. Simulation of diamond synthesis by microwave plasma chemical vapor deposition with multiple substrates in a substrate holder. J. Cryst. Growth 579, 126457 (2022).

Sang, L. Diamond as the heat spreader for the thermal dissipation of GaN-based electronic devices. Funct. Diam. 1, 174–188 (2021).

Tijent, F. Z., Faqir, M., Chouiyakh, H. & Essadiqi, E. H. Review—integration methods of GaN and diamond for thermal management optimization. ECS J. Solid. State Sci. Technol. 10, 074003 (2021).

Chao, P.-C. et al. Low-temperature bonded GaN-on-diamond HEMTs with 11 W/mm output power at 10 GHz. IEEE Trans. Electron. Dev. 62, 3658–3664 (2015).

Mendes, J. C., Lieher, M. & Li, C. Diamond/GaN HEMTs: where from and where to? Materials 15, 415 (2022).

Du, L. & Hu, W. An overview of heat transfer enhancement methods in microchannel heat sinks. Chem. Eng. Sci. 280, 119081 (2023).

Fu, J. et al. Investigation of the cooling enhancement of a single crystal diamond heat sink with embedded microfluidic channels. Diam. Relat. Mater. 130, 109470 (2022).

Hartmann, J., Voigt, P. & Reichling, M. Measuring local thermal conductivity in polycrystalline diamond with a high resolution photothermal microscope. J. Appl. Phys. 81, 2966–2972 (1997).

Anaya, J. et al. Control of the in-plane thermal conductivity of ultra-thin nanocrystalline diamond films through the grain and grain boundary properties. Acta Mater. 103, 141–152 (2016).

Sood, A. in Thermal Management of Gallium Nitride Electronics (ed. Tadjer, M. J. & Anderson, T. J.) 45–67 (Woodhead, 2022).

Malakoutian, M. et al. Cooling future system-on-chips with diamond inter-tiers. Cell Rep. Phys. Sci. 4, 101686 (2023). This work showcases application of CVD-grown PCD as thermal management materials in semiconductor chips.

Dong, H., Wen, B. & Melnik, R. Relative importance of grain boundaries and size effects in thermal conductivity of nanocrystalline materials. Sci. Rep. 4, 7037 (2014).

Malakoutian, M., Soman, R., Woo, K. & Chowdhury, S. Development of 300–400 °C grown diamond for semiconductor devices thermal management. MRS Adv. 9, 7–11 (2024).

Malakoutian, M. et al. Record-low thermal boundary resistance between diamond and GaN-on-SiC for enabling radiofrequency device cooling. ACS Appl. Mater. Interfaces 13, 60553–60560 (2021).

Dumka, D. C. et al. Electrical and thermal performance of AlGaN/GaN HEMTs on diamond substrate for RF applications. In Compound Semiconductor Integrated Circuit Symposium 1–4 (IEEE, 2013).

Soman, R. et al. Novel all-around diamond integration with GaN HEMTs demonstrating highly efficient device cooling. In International Electron Devices Meeting 30.8.1–30.8.4 (IEEE, 2022).

Woo, K. et al. Interlayer engineering to achieve <1 m2 K/GW thermal boundary resistances to diamond for effective device cooling. In International Electron Devices Meeting 1–4 (IEEE, 2023).

Zhong et al. Low-temperature bonding of Si and polycrystalline diamond with ultra-low thermal boundary resistance by reactive nanolayers. J. Mater. Sci. Technol. 188, 37–43 (2024).

Cheng, Z., Mu, F., Yates, L., Suga, T. & Graham, S. Interfacial thermal conductance across room-temperature-bonded GaN/diamond interfaces for GaN-on-diamond devices. ACS Appl. Mater. Interfaces 12, 8376–8384 (2020).

Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R. Rep. 37, 129–281 (2002).

Marks, N. A., McKenzie, D. R., Pailthrope, B. A., Bernasconi, M. & Parrinello, M. Microscopic structure of tetrahedral amorphous carbon. Phys. Rev. Lett. 76, 768 (1996).

Vetter, J. 60 years of DLC coatings: historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for industrial applications. Surf. Coat. Tech. 257, 213–240 (2014).

Shamsa, M. et al. Thermal conductivity of diamond-like carbon films. App. Phys. Lett. 89, 161921 (2006).

Giri, A., Dionne, C. J. & Hopkins, P. E. Atomic coordination dictates vibrational characteristics and thermal conductivity in amorphous carbon. NPJ Comput. Mater. 8, 55 (2022).

Baranov, A. M. et al. Development of DLC film technology for electronic application. Diam. Relat. Mater. 9, 649–653 (2000).

Xu, R. L. et al. Thermal conductivity of crystalline AlN and the influence of atomic-scale defects. J. Appl. Phys. 126, 185105 (2019).

Slack, G. A., Tanzilli, R. A., Pohl, R. O. & Vandersande, J. W. The intrinsic thermal conductivity of AIN. J. Phys. Chem. Solids 48, 641–647 (1987).

Cheng, Z. et al. Experimental observation of high intrinsic thermal conductivity of AlN. Phys. Rev. Mater. B 4, 044602 (2020).

Li, J., Nam, K., Nakarmi, M., Lin, J. & Jiang, H. Band structure and fundamental optical transitions in wurtzite AlN. Appl. Phys. Lett. 83, 5163–5165 (2003).

Feneberg, M., Leute, R. A. R., Neuschl, B., Thonke, K. & Bickermann, M. High-excitation and high-resolution photoluminescence spectra of bulk AlN. Phys. Rev. B 82, 1–8 (2010).

Vaziri, S. et al. AlN: an engineered thermal material for 3D integrated circuits. Adv. Func. Mat. 35, 2402662 (2024). This work describes and reviews the status of low temperature deposited AlN as a thermal management material.

Koh, Y. R. et al. Bulk-like intrinsic phonon thermal conductivity of micrometer-thick AlN films. ACS Appl. Mater. Interfaces 12, 29443–29450 (2020).

Hoque, M. S. B. et al. High in-plane thermal conductivity of aluminum nitride thin films. ACS Nano 15, 9588–9599 (2021).

Aissa, K. A. et al. Achieving high thermal conductivity from AlN films deposited by high-power impulse magnetron sputtering. J. Phys. Appl. Phys. 47, 355303 (2014).

Perez, C. et al. High thermal conductivity of submicrometer aluminum nitride thin films sputter-deposited at low temperature. ACS Nano 17, 21240–21250 (2023).

Duquenne, C. et al. Thermal conductivity of aluminium nitride thin films prepared by reactive magnetron sputtering. J. Phys. Appl. Phys. 45, 015301 (2011).

Zhao, Y. et al. Pulsed photothermal reflectance measurement of the thermal conductivity of sputtered aluminum nitride thin films. J. Appl. Phys. 96, 4563–4568 (2004).

Choi, S. R., Kim, D., Choa, S.-H., Lee, S.-H. & Kim, J.-K. Thermal conductivity of AlN and SiC thin films. Int. J. Thermophys. 27, 896–905 (2006).

Jacquot, A. et al. Optical and thermal characterization of AlN thin films deposited by pulsed laser deposition. Appl. Surf. Sci. 186, 507–512 (2002).

Belkerk, B. E., Soussou, A., Carette, M., Djouadi, M. A. & Scudeller, Y. Structural-dependent thermal conductivity of aluminium nitride produced by reactive direct current magnetron sputtering. Appl. Phys. Lett. 101, 151908 (2012).

Belkerk, B. E. et al. Substrate-dependent thermal conductivity of aluminum nitride thin-films processed at low temperature. Appl. Phys. Lett. 105, 221905 (2014).

Lee, P. C. et al. Achieving a high thermally conductive one micron AlN deposition by high power impulse magnetron sputtering plus kick. ACS Appl. Mater. Interfaces 16, 26664 (2024).

Jarrige, J., Lecompte, J. P., Mullot, J. & Müller, G. Effect of oxygen on the thermal conductivity of aluminium nitride ceramics. J. Eur. Ceram. Soc. 17, 1891–1895 (1997).

Kobayashi, R., Moriya, Y., Imamura, M., Oosawa, K. & Oh-Ishi, K. Relation between oxygen concentration in AlN lattice and thermal conductivity of AlN ceramics sintered with various sintering additives. J. Ceram. Soc. Jpn. 119, 291–294 (2011).

Kim, J. et al. Direct evidence on effect of oxygen dissolution on thermal and electrical conductivity of AlN ceramics using Al solid-state NMR analysis. Materials 15, 8125 (2022).

Ueda, S. T. et al. Tris(dimethylamido) aluminum(III) and N2H4: ideal precursors for the low-temperature deposition of large grain, oriented c-axis AlN on Si via atomic layer annealing. Appl. Surf. Sci. 554, 149656 (2021).

Ozgit, C., Donmez, I., Alevli, M. & Biyikli, N. Self-limiting low-temperature growth of crystalline AlN thin films by plasma-enhanced atomic layer deposition. Thin Solid. Films 520, 2750–2755 (2012).

Iqbal, A. & Mohd-Yasin, F. Reactive sputtering of aluminum nitride (002) thin films for piezoelectric applications: a review. Sensors 18, 1797 (2018).

Umeda, K., Takeuchi, M., Yamada, H., Kubo, R. & Yoshino, Y. Improvement of thickness uniformity and crystallinity of AlN films prepared by off-axis sputtering. Vacuum 80, 658–661 (2006).

Deng, R., Muralt, P. & Gall, D. Biaxial texture development in aluminum nitride layers during off-axis sputter deposition. J. Vac. Sci. Technol. A 30, 051501 (2012).

Lee, P.-C. et al. Achieving a high thermally conductive one micron AlN deposition by high power impulse magnetron sputtering plus kick. ACS Appl. Mater. Interfaces 16, 26664–26673 (2024).

Jaramillo-Fernandez, J., Ordonez-Miranda, J., Ollier, E. & Volz, S. Tunable thermal conductivity of thin films of polycrystalline AlN by structural inhomogeneity and interfacial oxidation. Phys. Chem. Chem. Phys. 17, 8125–8137 (2015).

Pan, T. S. et al. Enhanced thermal conductivity of polycrystalline aluminum nitride thin films by optimizing the interface structure. J. Appl. Phys. 112, 044905 (2012).

Biswas, A. et al. Structural, optical, and thermal properties of BN thin films grown on diamond via pulsed laser deposition. Phys. Rev. Mater. 7, 094602 (2023).

Monteiro, S. N. et al. Cubic boron nitride competing with diamond as a superhard engineering material—an overview. J. Mater. Res. Technol. 2, 68 (2013).

Fukamachi, S. et al. Large-area synthesis and transfer of multilayer hexagonal boron nitride for enhanced graphene device arrays. Nat. Electron. 6, 126–136 (2023).

Cai, Q. et al. High thermal conductivity of high-quality monolayer boron nitride and its thermal expansion. Sci. Adv. 5, eaav0129 (2019). This work discusses the thermal conductivity of intrinsic monolayer BN.

Yuan, C. et al. Modulating the thermal conductivity in hexagonal boron nitride via controlled boron isotope concentration. Commun. Phys. 2, 43 (2019).

Jiang, P. Q., Qian, X., Yang, R. G. & Lindsay, L. Anisotropic thermal transport in bulk hexagonal boron nitride. Phys. Rev. Mater. 2, 064005 (2018).

Sichel, E. K., Miller, R. E., Abrahams, M. S. & Buiocchi, C. J. Heat capacity and thermal conductivity of hexagonal pyrolytic boron nitride. Phys. Rev. B. 13, 4607 (1976).

Alvarez, G. A. et al. Cross-plane thermal conductivity of h-BN thin films grown by pulsed laser deposition. Appl. Phys. Lett. 122, 232101 (2023).

Jiang, H. et al. Recent research advances in hexagonal boron nitride/polymer nanocomposites with isotropic thermal conductivity. Adv. Nanocomposites 1, 144 (2024).

Jo, I. et al. Thermal conductivity and phonon transport in suspended few-layer hexagonal boron nitride. Nano Lett. 13, 550 (2013).

Ying, H. et al. Tailoring the thermal transport properties of monolayer hexagonal boron nitride by grain size engineering. 2D Mater. 7, 015031 (2019).

Wang, C. et al. Superior thermal conductivity in suspended bilayer hexagonal boron nitride. Sci. Rep. 6, 25334 (2016).

Zhou, H. et al. High thermal conductivity of suspended few-layer hexagonal boron nitride sheets. Nano Res. 7, 1232 (2014).

Lindsay, L. & Broido, D. A. Enhanced thermal conductivity and isotope effect in single-layer hexagonal boron nitride. Phys. Rev. B. 84, 155421 (2011).

Cai, Q. et al. Outstanding thermal conductivity of single atomic layer isotope-modified boron nitride. Phys. Rev. Lett. 125, 085902 (2020).

Mercado, E. et al. Isotopically enhanced thermal conductivity in few-layer hexagonal boron nitride: implications for thermal management. ACS Appl. Nano Mater. 3, 12148 (2020).

Choi, D. et al. Large reduction of hot spot temperature in graphene electronic devices with heat-spreading hexagonal boron nitride. ACS Appl. Mater. Interfaces 10, 11101 (2018).

Zhang, H. et al. Implementation of high thermal conductivity and synaptic metaplasticity in vertically-aligned hexagonal boron nitride-based memristor. Sci. China Mater. 67, 1907–1914 (2024).

Koroglu, C. & Pop, E. High thermal conductivity insulators for thermal management in 3D integrated circuits. IEEE Electron. Dev. Lett. 44, 496 (2023).

Vaziri, S. et al. Ultrahigh thermal isolation across heterogeneously layered two-dimensional materials. Sci. Adv. 5, eeax1325 (2019).

Kimoto, T. & Cooper, J. A. Fundamentals of Silicon Carbide Technology: Growth, Characterization, Devices, and Applications 11–38 (Wiley, 2014).

Zheng, Q. et al. Thermal conductivity of GaN, 71GaN, and SiC from 150 K to 850 K. Phys. Rev. Mater. 3, 014601 (2019).

Qian, X., Jiang, P. & Yang, R. Anisotropic thermal conductivity of 4H and 6H silicon carbide measured using time-domain thermoreflectance. Mater. Today Phys. 3, 70–75 (2017).

Cheng, Z. et al. High thermal conductivity in wafer-scale cubic silicon carbide crystals. Nat. Commun. 13, 7201 (2022). This work discusses the thermal conductivity of wafer-scale cubic SiC.

Goela, J. S., Brese, N. E., Burns, L. E. & Pickering, M. A. in High Thermal Conductivity Materials (ed. Shinde, S. L. & Goela, J. S.) 167–198 (Springer, 2006).

Tairov, Y. M. & Tsvetkov, V. F. Investigation of growth processes of ingots of silicon carbide single crystals. J. Cryst. Growth 43, 209–212 (1978).

Chaussende, D. et al. Prospects for 3C-SiC bulk crystal growth. J. Cryst. Growth 310, 976–981 (2008).

Wang, G. et al. High-quality and wafer-scale cubic silicon carbide single crystals. Energy Environ. Mater. 7, e12678 (2023).

La Via, F. et al. New approaches and understandings in the growth of cubic silicon carbide. Materials 14, 5348 (2021).

Wellman, P. J. et al. Review of sublimation growth of SiC bulk crystals. Mater. Sci. Forum 1062, 104–112 (2022).

Portail, M., Zielinski, M., Chassagne, M., Roy, S. & Nemoz, M. Comparative study of the role of the nucleation stage on the final crystalline quality of (111) and (100) silicon carbide films deposited on silicon substrates. J. Appl. Phys. 105, 083505 (2009).

Kong, H. S., Glass, J. T. & Davis, R. F. Chemical vapor deposition and characterization of 6H‐SiC thin films on off‐axis 6H‐SiC substrates. J. Appl. Phys. 64, 2672–2679 (1988).

Powell, J. A. et al. Controlled growth of 3C‐SiC and 6H‐SiC films on low‐tilt‐angle vicinal (0001) 6H‐SiC wafers. Appl. Phys. Lett. 59, 333–335 (1991).

Leone, S. et al. Growth of smooth 4H-SiC epilayers on 4° off-axis substrates with chloride-based CVD at very high growth rate. Mater. Res. Bull. 46, 1272–1275 (2011).

Xin, B. et al. A step-by-step experiment of 3C-SiC hetero-epitaxial growth on 4H-SiC by CVD. Appl. Surf. Sci. 357A, 985–993 (2015).

Ramazanov, S. M. & Ramazanov, G. M. Relaxing layers of silicon carbide grown on a silicon substrate by magnetron sputtering. Tech. Phys. Lett. 40, 44–47 (2014).

Wang, L. et al. Growth of 3C–SiC on 150-mm Si(100) substrates by alternating supply epitaxy at 1000 °C. Thin Solid. Films 519, 6443–6446 (2011).

Wang, L. et al. Demonstration of p-type 3C–SiC grown on 150 mm Si(100) substrates by atomic-layer epitaxy at 1000 °C. J. Cryst. Growth 329, 67–70 (2011).

Wu, Y.-F. et al. Very-high power density AlGaN/GaN HEMTs. IEEE Trans. Electron. Dev. 48, 586–590 (2001).

Gaska, R. et al. High-temperature performance of AlGaN/GaN HFETs on SiC substrates. IEEE Electron. Dev. Lett. 18, 492–494 (1997).

Torvik, J. T., Leksono, M., Pankove, J. I. & Van Zeghbroeck, B. A GaN/4H-SiC heterojunction bipolar transistor with operation up to 300 °C. MRS Internet J. Nitride Semicond. Res. 4, 3 (1999).

Keshmiri, N., Wang, D., Agrawal, B., Hou, R. & Emadi, A. Current status and future trends of GaN HEMTs in electrified transportation. IEEE Access. 8, 70553–70571 (2020).

Sengupta, A. & Islam, A. Performance comparison of AlGaN/GaN HFET with sapphire and 4H-SiC substrate. In Devices for Integrated Circuit 190–195 (IEEE, 2017).

Song, Y. et al. Ga2O3-on-SiC composite wafer for thermal management of ultrawide bandgap electronics. ACS Appl. Mater. Interfaces 13, 40817–40829 (2021).

Song, Y. et al. Ultra-wide band gap Ga2O3-on-SiC MOSFETs. ACS Appl. Mater. Interfaces 15, 7137–7147 (2023).

Leone, A. et al. Epitaxial growth optimization of AlGaN/GaN high electron mobility transistor structures on 3C-SiC/Si. J. Appl. Phys. 125, 235701 (2019).

Meier, F. et al. Selective area growth of cubic gallium nitride on silicon (001) and 3C-silicon carbide (001). AIP Adv. 11, 075013 (2021).

Minoura, Y. et al. Surface activated bonding of SiC/diamond for thermal management of high-output power GaN HEMTs. Jpn. J. Appl. Phys. 59, SGGD03 (2020).

Ziabe, E. et al. Thermal transport through GaN–SiC interfaces from 300 to 600 K. Appl. Phys. Lett. 107, 091605 (2015).

Mu, F. et al. High thermal boundary conductance across bonded heterogeneous GaN–SiC interfaces. ACS Appl. Mater. Interfaces 11, 33428–33434 (2019).

Field, D. E. et al. Thermal characterization of direct wafer bonded Si-on-SiC. Appl. Phys. Lett. 120, 113503 (2022).

Kuzmik, J. et al. Investigation of the thermal boundary resistance at the III-nitride/substrate interface using optical methods. J. Appl. Phys. 101, 054508 (2007).

Zhan, T. et al. Effects of thermal boundary resistance on thermal management of gallium-nitride-based semiconductor devices: a review. Micromachines 14, 2076 (2023).

Komiyama, J., Abe, Y., Suzuki, S. & Nakanishi, H. Suppression of crack generation in GaN epitaxy on Si using cubic SiC as intermediate layers. Appl. Phys. Lett. 88, 091901 (2006).

Komiyama, J., Abe, Y., Suzuki, S. & Nakanishi, H. Stress reduction in epitaxial GaN films on Si using cubic SiC as intermediate layers. J. Appl. Phys. 100, 033519 (2006).

Bae, D. G. et al. Embedded two-phase cooling of high heat flux electronics on silicon carbide (SiC) using thin-film evaporation and an enhanced delivery system (FEEDS) manifold-microchannel cooler. In Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems 466–472 (IEEE, 2017).

Cho, H. et al. Ultradeep, low-damage dry etching of SiC. Appl. Phys. Lett. 76, 739–741 (2000).

Liu, R. et al. A dry etching method for 4H-SiC via using photoresist mask. J. Cryst. Growth 531, 125351 (2020).

Racka-Szmidt, K., Stonio, B., Zelazko, J., Filipiak, M. & Sochacki, M. A review: inductively coupled plasma reactive ion etching of silicon carbide. Materials 15, 123 (2022).

Shen, D. et al. Enhanced thermal conductivity of epoxy composites filled with silicon carbide nanowires. Sci. Rep. 7, 2606 (2017).

Vu, M. C. et al. High thermal conductivity enhancement of polymer composites with vertically aligned silicon carbide sheet scaffolds. ACS Appl. Mater. Interfaces 12, 23388–23398 (2020).

Dai, W. et al. Enhanced thermal conductivity for polyimide composites with a three-dimensional silicon carbide nanowire@graphene sheets filler. J. Mater. Chem. A 3, 4884–4891 (2015).

Dai, W. et al. Enhanced thermal conductivity and retained electrical insulation for polyimide composites with SiC nanowires grown on graphene hybrid fillers. Compos. A Appl. Sci. Manuf. 76, 73–81 (2015).

Song, J. & Zhang, S. Vertically aligned silicon carbide nanowires/reduced graphene oxide networks for enhancing the thermal conductivity of silicone rubber composites. Compos. A Appl. Sci. Manuf. 133, 105873 (2020).

Li, S. et al. High thermal conductivity in cubic boron arsenide crystals. Science 361, 579–581 (2018). This work reports high thermal conductivity observed in boron arsenide.

Kang, J. S., Li, M., Wu, H., Nguyen, H. & Hu, Y. Experimental observation of high thermal conductivity in boron arsenide. Science 361, 575–578 (2018).

Tian, F. et al. Unusual high thermal conductivity in boron arsenide bulk crystals. Science 361, 582–585 (2018).

Kang, J. S. et al. Integration of boron arsenide cooling substrates into gallium nitride devices. Nat. Electron. 4, 416–423 (2021).

Tian, F. & Ren, Z. High thermal conductivity in boron arsenide: from prediction to reality. Angew. Chem. Int. Ed. 58, 5824 (2019).

Singh, S. G. & Tan, C. S. Thermal mitigation using thermal through silicon via (TTSV) in 3-D ICs. In 4th International Microsystems, Packaging, Assembly and Circuits Technology Conference 182–185 (IEEE, 2009).

Kuang, Y., Lindsay, L., Shi, S., Wang, X. & Huang, B. Thermal conductivity of graphene mediated by strain and size. Int. J. Heat. Mass. Transf. 101, 772–778 (2016).

Singh, D., Murthy, J. Y. & Fisher, T. S. Mechanism of thermal conductivity reduction in few-layer graphene. J. Appl. Phys. 110, 044317 (2017).

Ghosh, S. et al. Extremely high thermal conductivity of graphene: prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 92, 151911 (2008).

Guo, Z., Zhang, D. & Gong, X.-G. Thermal conductivity of graphene nanoribbons. Appl. Phys. Lett. 95, 163103 (2009).

Fugallo, G. et al. Thermal conductivity of graphene and graphite: collective excitations and mean free paths. Nano Lett. 14, 6109–61104 (2014).

Han, Z. & Ruan, X. Thermal conductivity of monolayer graphene: convergent and lower than diamond. Phys. Rev. B 108, L121412 (2023). This work reviews and discusses the debates around thermal conductivity in graphene.

Balandin, A. A. et al. Superior thermal conductivity of single-layer graphene. Nano Lett. 8, 903–907 (2008).

Chen, S. et al. Raman measurements of thermal transport in suspended monolayer graphene of variable sizes in vacuum and gaseous environments. ACS Nano 5, 321–328 (2011).

Lee, J. U., Yoon, D., Kim, H., Lee, S. W. & Cheong, H. Thermal conductivity of suspended pristine graphene measured by Raman spectroscopy. Phys. Rev. B 83, 081419(R) (2011).

Jang, W., Chen, Z., Bao, W., Lau, C. N. & Dames, C. Thickness-dependent thermal conductivity of encased graphene and ultrathin graphite. Nano Lett. 10, 3909–3913 (2010).

Shtein, M., Nadiv, R., Buzaglo, M. & Regev, O. Graphene-based hybrid composites for efficient thermal management of electronic devices. ACS Appl. Mater. Interfaces 7, 23725–23730 (2015).

Zhang, K. & Yuen, M. M. F. Heat spreader with aligned CNTs designed for thermal management of HB-LED packaging and microelectronic packaging. In 7th International Conference on Electronics Packaging 1–4 (IEEE, 2006).

Xin, G. et al. Large-area freestanding graphene paper for superior thermal management. Adv. Mater. 26, 4521–4526 (2014).

Luo, H., Ajmal, K. M., Liu, W., Yamamura, K. & Deng, H. Polishing and planarization of single crystal diamonds: state-of-the-art and perspectives. Int. J. Extrem. Manuf. 3, 022003 (2021).

Xiao, C., Hsia, F.-C., Sutton-Cook, A., Weber, B. & Franklin, S. Polishing of polycrystalline diamond using synergies between chemical and mechanical inputs: a review of mechanisms and processes. Carbon 196, 29–48 (2022).

Eon, D. Diamonds in the current: navigating challenges for the integration of diamond in power electronics. Phys. Status Solidi A 221, 2400085 (2024).

Zheng, Y., Muehle, M., Lai, J., Albrecht, J. D. & Seo, J.-H. Bilayer metal etch mask strategy for deep diamond etching. J. Vac. Sci. Technol. B 40, 022210 (2022).

Baldwin, C. G., Downes, J. E. & Mildren, R. P. Enhanced etch rate of deep-UV laser induced etching of diamond in low pressure conditions. Appl. Phys. Lett. 117, 111601 (2020).

Zheng, Y. et al. Fast smoothing on diamond surface by inductively coupled plasma reactive ion etching. J. Mater. Res. 35, 462–472 (2020).

Toros, A. et al. Precision micro-mechanical components in single crystal diamond by deep reactive ion etching. Microsyst. Nanoeng. 4, 12 (2018).

Tang, Y. & Aslam, D. M. Technology of polycrystalline diamond thin films for microsystems applications. J. Vac. Sci. Technol. B 23, 1088–1095 (2005).

Whiteley, S. et al. Dopant selective photoelectrochemical etching of SiC. J. Electrochem. Soc. 170, 036508 (2023).

Hochreiter, A., Groß, F., Möller, M. N., Krieger, M. & Weber, H. B. Electrochemical etching strategy for shaping monolithic 3D structures from 4H-SiC wafers. Sci. Rep. 13, 19086 (2023).

Minowa, Y., Matsumae, T., Hayase, M., Kurashima, Y. & Takagi, H. Direct bonding of germanium and diamond substrates by reduction process. In International Conference on Electronics Packaging 119–120 (IEEE, 2024).

Kobayashi, A. et al. Room-temperature bonding of GaN and diamond via a SiC layer. Funct. Diam. 2, 142–150 (2022).

Matsumae, T., Takigawa, R., Kurashuma, Y., Takagi, H. & Higurashi, E. Low-temperature direct bonding of InP and diamond substrates under atmospheric conditions. Sci. Rep. 11, 11109 (2021).

Warkusz, F. The size effect and the temperature coefficient of resistance in thin films. J. Phys. D Appl. Phys. 11, 689–694 (1978).

Oliva, A. I. & Lugo, J. M. Measurement of the temperature coefficient of resistance in metallic films and nano-thickness. Int. J. Thermophys. 37, 35 (2016).

Belser, R. B. & Hicklin, W. H. Temperature coefficients of resistance of metallic films in the temperature range 25° to 600 °C. J. Appl. Phys. 30, 313–322 (1959).

Warzoha, R. J., Smith, A. N. & Harris, M. Maximum resolution of a probe-based, steady-state thermal interface material characterization instrument. J. Electron. Packag. 139, 011004 (2017).

Warzoha, R. J., Smith, A. N., Boteler, L. & Bajwa, A. Design considerations for miniaturized steady-state thermal characterization instruments. IEEE Trans. Comp. Pack. Manuf. 8, 1401–1410 (2018).

Wojciechowski, K. T., Zybala, R. & Mania, R. Application of DLC layers in 3-omega thermal conductivity method. J. Achiev. Mater. Manuf. Eng. 37, 512–517 (2009).

Ramu, A. T. & Bowers, J. E. Analysis of the “3-Omega” method for substrates and thick films of anisotropic thermal conductivity. J. Appl. Phys. 112, 043516 (2012). This work introduces 3ω methods for thermal characterization in general.

Chernodoubov, D. A. & Inyushkin, A. V. Automatic thermal conductivity measurements with 3-omega technique. Rev. Sci. Instrum. 90, 024904 (2019).

Kommandur, S. & Yee, S. A suspended 3-omega technique to measure the anisotropic thermal conductivity of semiconducting polymers. Rev. Sci. Instrum. 89, 114905 (2018).

Landry, D., Flores, R. & Goodman, R. B. Estimating the thermal conductivity of thin films: a novel approach using the transient plane source method. J. Heat. Mass. Transf. 146, 031004 (2023).

Zhang, Q., Zhu, W., Zhou, J. & Deng, Y. Realizing the accurate measurements of thermal conductivity over a wide range by scanning thermal microscopy combined with quantitative prediction of thermal contact resistance. Small 19, 2300968 (2023).

Juszczyk, J., Kazmierczak-Balata, A., Firek, P. & Bodzenta, J. Measuring thermal conductivity of thin films by scanning thermal microscopy combined with thermal spreading resistance analysis. Ultramicroscopy 175, 81–86 (2017).

Bodzenta, J. & Kazmierczak-Balata, A. Scanning thermal microscopy and its applications for quantitative thermal measurements. J. Appl. Phys. 132, 140902 (2022).

Jiang, P., Xin, Q. & Yang, R. Tutorial: time-domain thermoreflectance (TDTR) for thermal property characterization of bulk and thin film materials. J. Appl. Phys. 124, 161103 (2018). This work introduces TDTR methods for thermal characterization of bulk and thin films.

Schmidt, J., Cheaito, R. & Chiesa, M. A frequency-domain thermoreflectance method for the characterization of thermal properties. Rev. Sci. Instrum. 80, 094901 (2009). This work introduces FDTR methods for thermal characterization.

Braun, J. L., Olson, D. H., Gaskins, J. T. & Hopkins, P. E. A steady-state thermoreflectance method to measure thermal conductivity. Rev. Sci. Instrum. 90, 024905 (2019). This work introduces SSTR methods for thermal characterization.

Minnich, A. J. Multidimensional quasiballistic thermal transport in transient grating spectroscopy. Phys. Rev. B 92, 085203 (2015).

Sood, A. et al. Quasi-ballistic thermal transport across MoS2 thin films. Nano Lett. 19, 2434–2442 (2019).

Carslaw, H. & Jaeger, J. C. Conduction of Heat in Solids 109–112 (Oxford Univ. Press, 1959).

Schmidt, A. J., Chen, X. & Chen, G. Pulse accumulation, radial heat conduction, and anisotropic thermal conductivity in pump–probe transient thermoreflectance. Rev. Sci. Instrum. 79, 114902 (2008).

Braun, J. L. & Hopkins, P. E. Upper limit to the thermal penetration depth during modulated heating of multilayer thin films with pulsed and continuous wave lasers: a numerical study. J. Appl. Phys. 121, 175107 (2017).

Ruoho, M., Valset, K., Finstad, T. & Tittonen, I. Measurement of thin film thermal conductivity using the laser flash method. Nanotechnology 26, 195706 (2015).

Reparaz, J. S. et al. A novel contactless technique for thermal field mapping and thermal conductivity determination: two-laser Raman thermometry. Rev. Sci. Instrum. 85, 034901 (2014).

Author information

Authors and Affiliations

Contributions

W.-Y.W., A.K., J.-R.W., K.K.H., M.M., J.-H.J., S.V., I.D., C.C.S., J.F.H. and Y.W. researched data for the article. W.-Y.W., A.K., J.-R.W., K.K.H., M.M., J.-H.J., S.V., I.D., C.C.S., J.F.H., M.N. and S.S.L. substantially contributed to the discussion of the content. W.-Y.W., A.K., J.-R.W., K.K.H., S.V., J.F.H., M.N. and S.S.L. wrote the manuscript. W.-Y.W., X.-Y. B., S.C. and S.S.L. reviewed and edited the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Electrical Engineering thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Woon, WY., Kasperovich, A., Wen, JR. et al. Thermal management materials for 3D-stacked integrated circuits. Nat Rev Electr Eng 2, 598–613 (2025). https://doi.org/10.1038/s44287-025-00196-0

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44287-025-00196-0