Abstract

Electrochemical energy storage is one of the primary technologies for energy storage, making batteries essential in applications such as electric vehicles and energy storage stations. For the battery itself, achieving resistance to extreme temperatures is a critical objective. However, there are no battery materials or systems that can be deemed absolutely safe or performance-temperature-independent. In this Perspective, we discuss battery safety from a thermal point of view and emphasize the importance of battery thermal management. Battery thermal management ensures that electrochemical reactions occur within an optimal temperature range, suppressing side reactions and delaying or even preventing thermal runaway. This equilibrium is essential for improving battery efficiency and extending its operational lifespan. When absolute safety cannot be assured in battery materials and systems, thermal management becomes the primary barrier to battery thermal risks. However, owing to the extremely rapid rate of exothermic side reactions, the importance of fire suppression becomes evident when thermal runaway cannot be contained, leading to fire accidents. The control of heat generation, effective thermal management and robust fire suppression strategies are key to ensure battery thermal safety and will have a crucial role in the development and large-scale application of batteries.

Key points

-

Thermal issues are a critical challenge in battery safety, directly determining the prevention efficacy of thermal runaway-induced hazards.

-

Effective thermal runaway mitigation requires dual approaches: internally suppressing heat generation through electrochemical optimization and externally enhancing heat dissipation via thermal management.

-

Thermal management serves as the fundamental prerequisite for normal battery operation and proactive prevention of thermal hazards.

-

Fire suppression acts as the ultimate safeguard against battery thermal accidents, limiting fire propagation through physical or chemical intervention.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Guerra, O. J. Beyond short-duration energy storage. Nat. Energy 6, 460–461 (2021).

Deng, J., Bae, C., Denlinger, A. & Miller, T. Electric vehicles batteries: requirements and challenges. Joule 4, 511–515 (2020).

Chen, S. et al. All-temperature area battery application mechanism, performance, and strategies. Innovation 4, 100465 (2023).

Guo, Y. et al. Solid-state lithium batteries: safety and prospects. eScience 2, 138–163 (2022).

Ali, H., Khan, H. A., Khalid, M. & Pecht, M. A review and analysis of the safety labeling of lithium-ion batteries. J. Energy Storage 120, 116461 (2025).

Jia, Z. et al. Advances and perspectives in fire safety of lithium-ion battery energy storage systems. eTransportation 24, 100390 (2025).

Feng, X. et al. Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater. 10, 246–267 (2018).

Wang, Q. et al. Multidimensional fire propagation of lithium-ion phosphate batteries for energy storage. eTransportation 20, 100328 (2024).

Feng, X., Ren, D., He, X. & Ouyang, M. Mitigating thermal runaway of lithium-ion batteries. Joule 4, 743–770 (2020).

Yuan, M. Q. & Liu, K. Rational design on separators and liquid electrolytes for safer lithium-ion batteries. J. Energy Chem. 43, 58–70 (2020).

Lai, Y. X., Wu, W. X., Chen, K., Wang, S. F. & Xin, C. A compact and lightweight liquid-cooled thermal management solution for cylindrical lithium-ion power battery pack. Int. J. Heat Mass Transf. 144, 118581 (2019).

Rodrigues, M.-T. F. et al. A materials perspective on Li-ion batteries at extreme temperatures. Nat. Energy 2, 17108 (2017).

Wang, Y., Zhang, X., Li, K., Zhao, G. & Chen, Z. Perspectives and challenges for future lithium-ion battery control and management. eTransportation 18, 100260 (2023).

Meng, X. et al. Enhancing extinguishing efficiency for lithium-ion battery fire: investigating the extinguishing mechanism and surface/interfacial activity of F-500 microcapsule extinguishing agent. eTransportation 22, 100357 (2024).

Weng, J. et al. Safety issue on PCM-based battery thermal management: material thermal stability and system hazard mitigation. Energy Storage Mater. 53, 580–612 (2022).

Lyu, P. et al. Recent advances of thermal safety of lithium ion battery for energy storage. Energy Storage Mater. 31, 195–220 (2020).

Liu, X. et al. Thermal runaway of lithium-ion batteries without internal short circuit. Joule 2, 2047–2064 (2018).

E, J., Xiao, H., Tian, S. & Huang, Y. A comprehensive review on thermal runaway model of a lithium-ion battery: mechanism, thermal, mechanical, propagation, gas venting and combustion. Renew. Energy 229, 120762 (2024).

Kong, D., Wang, G., Ping, P. & Wen, J. A coupled conjugate heat transfer and CFD model for the thermal runaway evolution and jet fire of 18650 lithium-ion battery under thermal abuse. eTransportation 12, 100157 (2022).

Feng, X. et al. Propagation dynamics of the thermal runaway front in large-scale lithium-ion batteries: theoretical and experiment validation. Int. J. Heat Mass Transf. 225, 125393 (2024).

Lai, X., Wang, S., Wang, H., Zheng, Y. & Feng, X. Investigation of thermal runaway propagation characteristics of lithium-ion battery modules under different trigger modes. Int. J. Heat Mass Transf. 171, 121080 (2021).

Schaeffler, S. & Jossen, A. In situ measurement and modeling of internal thermal runaway propagation within lithium-ion cells under local overheating conditions. J. Power Sources 614, 234968 (2024).

Feng, X. et al. Mechanism of internal thermal runaway propagation in blade batteries. J. Energy Chem. 89, 184–194 (2024).

Finegan, D. P. et al. In-operando high-speed tomography of lithium-ion batteries during thermal runaway. Nat. Commun. 6, 6924 (2015).

Lyu, P., Liu, X., Liu, C. & Rao, Z. The influence of tab overheating on thermal runaway propagation of pouch-type lithium-ion battery module with different tab connections. Int. J. Heat Mass Transf. 211, 124279 (2023).

Peng, R. et al. Experimental investigation of the influence of venting gases on thermal runaway propagation in lithium-ion batteries with enclosed packaging. eTransportation 23, 100388 (2025).

Wang, H. et al. Fire and explosion characteristics of vent gas from lithium-ion batteries after thermal runaway: a comparative study. eTransportation 13, 100190 (2022).

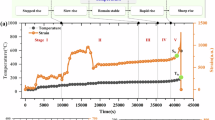

Feng, X. et al. Time sequence map for interpreting the thermal runaway mechanism of lithium-ion batteries with LiNixCoyMnzO2 cathode. Front. Energy Res. 6, 126 (2018).

Janek, J. & Zeier, W. G. A solid future for battery development. Nat. Energy 1, 16141 (2016).

Hou, D. et al. Effect of the grain arrangements on the thermal stability of polycrystalline nickel-rich lithium-based battery cathodes. Nat. Commun. 13, 3437 (2022).

Hou, J. et al. Thermal runaway of lithium-ion batteries employing LiN(SO2F)2-based concentrated electrolytes. Nat. Commun. 11, 5100 (2020).

Wang, Y. et al. Reductive gas manipulation at early self-heating stage enables controllable battery thermal failure. Joule 6, 2810–2820 (2022).

Mei, W. et al. Operando monitoring of thermal runaway in commercial lithium-ion cells via advanced lab-on-fiber technologies. Nat. Commun. 14, 5251 (2023).

Jin, Y. et al. Detection of micro-scale Li dendrite via H2 gas capture for early safety warning. Joule 4, 1714–1729 (2020).

Liu, T. et al. Investigation on fine water mist battery thermal management system for thermal runaway control. Appl. Therm. Eng. 211, 118474 (2022).

Lyu, P. et al. Artificial intelligence algorithms optimize immersion boiling heat transfer strategies to mitigate thermal runaway of lithium-ion batteries. eTransportation 24, 100395 (2025).

Deng, J., Bae, C., Marcicki, J., Masias, A. & Miller, T. Safety modelling and testing of lithium-ion batteries in electrified vehicles. Nat. Energy 3, 261–266 (2018).

Li, W., Zhu, J., Xia, Y., Gorji, M. B. & Wierzbicki, T. Data-driven safety envelope of lithium-ion batteries for electric vehicles. Joule 3, 2703–2715 (2019).

Hao, M. L., Li, J., Park, S., Moura, S. & Dames, C. Efficient thermal management of Li-ion batteries with a passive interfacial thermal regulator based on a shape memory alloy. Nat. Energy 3, 899–906 (2018).

Chombo, P. V. & Laoonual, Y. A review of safety strategies of a Li-ion battery. J. Power Sources 478, 228649 (2020).

Hwang, F. S. et al. Review of battery thermal management systems in electric vehicles. Renew. Sustain. Energy Rev. 192, 114171 (2024).

Hu, X. et al. Battery warm-up methodologies at subzero temperatures for automotive applications: recent advances and perspectives. Prog. Energy Combust. Sci. 77, 100806 (2020).

Shao, D. et al. Advanced low-temperature preheating strategies for power lithium-ion batteries applied in electric vehicles: a review. Int. J. Electrochem. Sci. 19, 24 (2024).

Wu, S., Xiong, R., Li, H., Nian, V. & Ma, S. The state of the art on preheating lithium-ion batteries in cold weather. J. Energy Storage 27, 101059 (2020).

Wang, Y. B. et al. Evaluating the performance of liquid immersing preheating system for lithium-ion battery pack. Appl. Thermal Eng. 190, 116811 (2021).

Liu, Z. Y., Liu, X., Meng, H., Guo, L. K. & Zhang, Z. Numerical analysis of the thermal performance of a liquid cooling battery module based on the gradient ratio flow velocity and gradient increment tube diameter. Int. J. Heat Mass Transf. 175, 121338 (2021).

Ling, Z. Y., Wang, F. X., Fang, X. M., Gao, X. N. & Zhang, Z. G. A hybrid thermal management system for lithium ion batteries combining phase change materials with forced-air cooling. Appl. Energy 148, 403–409 (2015).

Shamnaz, P. T. M., Bal, D. K. & Sahoo, B. B. A technical review on controlling the Li-ion battery temperature through composite phase change materials and hybrid cooling techniques. J. Energy Storage 112, 115584 (2025).

Ping, P. et al. Experimental study on nano-encapsulated inorganic phase change material for lithium-ion battery thermal management and thermal runaway suppression. Chem. Eng. J. 463, 142401 (2023).

Piao, N. et al. Challenges and development of lithium-ion batteries for low temperature environments. eTransportation 11, 100145 (2022).

Dizaji, H. S., Jafarmadar, S., Khalilarya, S. & Pourhedayat, S. A comprehensive exergy analysis of a prototype Peltier air-cooler; experimental investigation. Renew. Energy 131, 308–317 (2019).

Lei, Z. G., Zhang, C. N., Li, J. Q., Fan, G. C. & Lin, Z. W. Preheating method of lithium-ion batteries in an electric vehicle. J. Mod. Power Syst. Clean Energy 3, 289–296 (2015).

Alaoui, C. & Salameh, Z. M. A novel thermal management for electric and hybrid vehicles. IEEE Trans. Veh. Technol. 54, 468–476 (2005).

Fang Wang, J. X. Design and Manufacturing Technology of Battery Pack for Electric Vehicle (China Science, 2017).

Sadighi Dizaji, H. et al. Enhanced Peltier refrigerator using an innovative hot-side heat-rejection mechanism; experimental study under both transient and steady-state conditions. Energy 309, 133132 (2024).

Seo, J. H., Patil, M. S., Cho, C. P. & Lee, M. Y. Heat transfer characteristics of the integrated heating system for cabin and battery of an electric vehicle under cold weather conditions. Int. J. Heat Mass Transf. 117, 80–94 (2018).

Tang, A. H. et al. Orthogonal design based pulse preheating strategy for cold lithium-ion batteries. Appl. Energy 355, 122277 (2024).

Wang, C.-Y. et al. A fast rechargeable lithium-ion battery at subfreezing temperatures. J. Electrochem. Soc. 163, A1944 (2016).

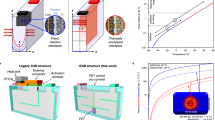

Longchamps, R. S., Ge, S., Trdinich, Z. J., Liao, J. & Wang, C.-Y. Battery electronification: intracell actuation and thermal management. Nat. Commun. 15, 5373 (2024).

Zhang, G. S. et al. Rapid self-heating and internal temperature sensing of lithium-ion batteries at low temperatures. Electrochim. Acta 218, 149–155 (2016).

Wang, C. Y. et al. Lithium-ion battery structure that self-heats at low temperatures. Nature 529, 515–518 (2016).

Ruan, H. J. et al. An optimal internal-heating strategy for lithium-ion batteries at low temperature considering both heating time and lifetime reduction. Appl. Energy 256, 113797 (2019).

Petzl, M., Kasper, M. & Danzer, M. A. Lithium plating in a commercial lithium-ion battery a low-temperature aging study. J. Power Sources 275, 799–807 (2015).

Guo, S. S., Yang, R. X., Shen, W. X., Liu, Y. S. & Guo, S. G. DC–AC hybrid rapid heating method for lithium-ion batteries at high state of charge operated from low temperatures. Energy 238, 121809 (2022).

Xie, Y. et al. A health-aware AC heating strategy with lithium plating criterion for batteries at low temperatures. IEEE Trans. Ind. Inform. 20, 2295–2306 (2024).

Wang, Y. J., Zhang, X. C. & Chen, Z. H. Low temperature preheating techniques for lithium-ion batteries: recent advances and future challenges. Appl. Energy 313, 118832 (2022).

Hu, Z. X. B. et al. Experimental study on the mechanism of frequency-dependent heat in AC preheating of lithium-ion battery at low temperature. Appl. Therm. Eng. 214, 118860 (2022).

Qu, Z. G., Jiang, Z. Y. & Wang, Q. Experimental study on pulse self-heating of lithium-ion battery at low temperature. Int. J. Heat Mass Transf. 135, 696–705 (2019).

Qin, Y. D. et al. A rapid lithium-ion battery heating method based on bidirectional pulsed current: heating effect and impact on battery life. Appl. Energy 280, 115957 (2020).

Wu, X. G., Cui, Z. H., Chen, E. S. & Du, J. Y. Capacity degradation minimization oriented optimization for the pulse preheating of lithium-ion batteries under low temperature. J. Energy Storage 31, 101746 (2020).

Ruan, H. J. et al. A rapid low-temperature internal heating strategy with optimal frequency based on constant polarization voltage for lithium-ion batteries. Appl. Energy 177, 771–782 (2016).

Guo, S. S., Xiong, R., Wang, K. & Sun, F. C. A novel echelon internal heating strategy of cold batteries for all-climate electric vehicles application. Appl. Energy 219, 256–263 (2018).

Zhang, J. B., Ge, H., Li, Z. & Ding, Z. M. Internal heating of lithium-ion batteries using alternating current based on the heat generation model in frequency domain. J. Power Sources 273, 1030–1037 (2015).

Li, J. Q., Sun, D. N., Chai, Z. X., Jiang, H. F. & Sun, C. Sinusoidal alternating current heating strategy and optimization of lithium-ion batteries with a thermo-electric coupled model. Energy 186, 115798 (2019).

Mohan, S., Kim, Y. & Stefanopoulou, A. G. Energy-conscious warm-up of Li-ion cells from subzero temperatures. IEEE Trans. Ind. Electron. 63, 2954–2964 (2016).

Zhu, C. et al. Modeling and control of an integrated self-heater for automotive batteries based on traction motor drive reconfiguration. IEEE J. Emerg. Sel. Top. Power Electron. 11, 384–395 (2023).

Ouyang, T., Liu, B., Xu, P., Wang, C. & Ye, J. Electrochemical–thermal coupled modelling and multi-measure prevention strategy for Li-ion battery thermal runaway. Int. J. Heat Mass Transf. 194, 123082 (2022).

Suresh Patil, M., Seo, J.-H. & Lee, M.-Y. A novel dielectric fluid immersion cooling technology for Li-ion battery thermal management. Energy Convers. Manag. 229, 113715 (2021).

Zhao, G., Wang, X. L., Negnevitsky, M. & Zhang, H. Y. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 501, 230001 (2021).

Ma, Y., Ma, Q., Liu, Y., Gao, J. & Chen, H. Two-level optimization strategy for vehicle speed and battery thermal management in connected and automated EVs. Appl. Energy 361, 122928 (2024).

Zhou, H., Zhou, F., Xu, L., Kong, J. & QingxinYang Thermal performance of cylindrical lithium-ion battery thermal management system based on air distribution pipe. Int. J. Heat Mass Transf. 131, 984–998 (2019).

Wang, T., Tseng, K. J. & Zhao, J. Development of efficient air-cooling strategies for lithium-ion battery module based on empirical heat source model. Appl. Therm. Eng. 90, 521–529 (2015).

Zichen, W. & Changqing, D. A comprehensive review on thermal management systems for power lithium-ion batteries. Renew. Sustain. Energy Rev. 139, 110685 (2021).

Luo, J., Zou, D., Wang, Y., Wang, S. & Huang, L. Battery thermal management systems (BTMs) based on phase change material (PCM): a comprehensive review. Chem. Eng. J. 430, 132741 (2022).

Jouhara, H. et al. Heat pipe based systems — advances and applications. Energy 128, 729–754 (2017).

Lin, X., Zhang, X., Liu, L., Liang, J. & Liu, W. Polymer/expanded graphite-based flexible phase change material with high thermal conductivity for battery thermal management. J. Clean. Prod. 331, 130014 (2022).

Dwivedi, A. et al. A comprehensive review on heat pipe-assisted hybrid battery thermal management strategies: opportunities, challenges and its future aspects. J. Energy Storage 112, 115475 (2025).

Faiza Mohamed, N., Mohd Zulkifly, A. & Mohd Azmi, I. Effect of heat pipe’s configuration in managing the temperature of EV battery. CFD Lett. 15, 22–34 (2023).

Parthasarathi, S., Nagarajan, S., Desai, S., Reddy, S. U. & Narasimham, G. S. V. L. Effect of bend radius and insulation on adiabatic section on the performance of a single closed loop pulsating heat pipe: experimental study and heat transfer correlation. Heat Mass Transf. 57, 1871–1892 (2021).

Lian, Y. B., Ling, H. P., Song, G., Ma, Q. C. & He, B. Experimental investigation on a heating-and-cooling difunctional battery thermal management system based on refrigerant. Appl. Therm. Eng. 225, 120138 (2023).

Dai, H. S., Yang, C. X., Zhang, F., Liao, G. L. & Zhang, B. L. Transient heat dissipation performance investigation on the battery thermal management system based on S-CO2 immersion cooling. Energy 318, 134656 (2025).

Li, Y. et al. Experimental investigations of liquid immersion cooling for 18650 lithium-ion battery pack under fast charging conditions. Appl. Therm. Eng. 227, 120287 (2023).

Wang, Q., Jiang, B., Li, B. & Yan, Y. Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 64, 106–128 (2016).

Lin, X. W. et al. A comparative investigation of two-phase immersion thermal management system for lithium-ion battery pack. J. Clean. Prod. 434, 140472 (2024).

Roe, C. et al. Immersion cooling for lithium-ion batteries — a review. J. Power Sources 525, 231094 (2022).

Chakraborty, S., Shukla, D. & Panigrahi, P. K. A review on coolant selection for thermal management of electronics and implementation of multiple-criteria decision-making approach. Appl. Therm. Eng. 245, 122807 (2024).

Wu, C. X. et al. A review on the liquid cooling thermal management system of lithium-ion batteries. Appl. Energy 375, 124173 (2024).

Zhu, T., Cruden, A., Peng, Q. & Liu, K. L. Enabling extreme fast charging. Joule 7, 2660–2662 (2023).

Liu, Q. et al. The electro-thermal equalization behaviors of battery modules with immersion cooling. Appl. Energy 351, 121826 (2023).

Fu, W. C. et al. High power and energy density dynamic phase change materials using pressure-enhanced close contact melting. Nat. Energy 7, 270–280 (2022).

Liu, K. L. et al. Adaptive battery thermal management systems in unsteady thermal application contexts. J. Energy Chem. 97, 650–668 (2024).

Adhikari, N., Bhandari, R. & Joshi, P. Thermal analysis of lithium-ion battery of electric vehicle using different cooling medium. Appl. Energy 360, 122781 (2024).

Xiao, Y. Y. et al. High-temperature resistant, super elastic aerogel sheet prepared based on in-situ supercritical separation method for thermal runaway prohibition of lithium-ion batteries. Energy Storage Mater. 61, 102871 (2023).

Feng, J. B. et al. Fire-safe aerogels and foams for thermal insulation: from materials to properties. Adv. Mater. 37, e2411856 (2025).

Li, C. D. et al. A review of silicon-based aerogel thermal insulation materials: performance optimization through composition and microstructure. J. Non Cryst. Solids 553, 120517 (2021).

Wang, A. et al. Research progress of aerogel used in lithium-ion power batteries. J. Loss Prevent. Process Indus. 92, 105433 (2024).

Zhang, Z. et al. Thermal interface materials with low modulus and high thermal conductivity by manipulating multi-branched PDMS network: the disentanglement and entanglement effect of dangling chain. Chem. Eng. J. 495, 153352 (2024).

Xu, X. et al. Double-negative-index ceramic aerogels for thermal superinsulation. Science 363, 723–727 (2019).

Li, P., Zou, Q., Liu, X. & Yang, R. A heat transfer model for liquid film boiling on micro-structured surfaces. Natl Sci. Rev. 11, nwae090 (2024).

Može, M. et al. Laser-engineered microcavity surfaces with a nanoscale superhydrophobic coating for extreme boiling performance. ACS Appl. Mater. Interfaces 12, 24419–24431 (2020).

Cho, H. J., Preston, D. J., Zhu, Y. Y. & Wang, E. N. Nanoengineered materials for liquid–vapour phase-change heat transfer. Nat. Rev. Mater. 2, 16092 (2017).

Vakarelski, I. U., Patankar, N. A., Marston, J. O., Chan, D. Y. C. & Thoroddsen, S. T. Stabilization of Leidenfrost vapour layer by textured superhydrophobic surfaces. Nature 489, 274–277 (2012).

Kim, J., Oh, J. & Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 149, 192–212 (2019).

Jiang, W., Lyu, P., Liu, X. J. & Rao, Z. H. An immersion flow boiling heat dissipation strategy for efficient battery thermal management in non-steady conditions. Appl. Therm. Eng. 245, 122783 (2024).

Sun, S. L., Ma, C. Y., Wang, X. Y., Yang, Y. & Mei, J. Design and optimisation of a novel serpentine flow channel with branch structure. Energy 293, 130494 (2024).

Schöberl, J., Ank, M., Schreiber, M., Wassiliadis, N. & Lienkamp, M. Thermal runaway propagation in automotive lithium-ion batteries with NMC-811 and LFP cathodes: safety requirements and impact on system integration. eTransportation 19, 100305 (2024).

Nishijima, M. et al. Accelerated discovery of cathode materials with prolonged cycle life for lithium-ion battery. Nat. Commun. 5, 4553 (2014).

Feng, X. N. et al. Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database. Appl. Energy 246, 53–64 (2019).

Song, Y. Z. et al. Simultaneously blocking chemical crosstalk and internal short circuit via gel-stretching derived nanoporous non-shrinkage separator for safe lithium-ion batteries. Adv. Mater. 34, e2106335 (2022).

Liu, X. H., Ai, W. L., Marlow, M. N., Patel, Y. & Wu, B. The effect of cell-to-cell variations and thermal gradients on the performance and degradation of lithium-ion battery packs. Appl. Energy 248, 489–499 (2019).

Song, W. J. et al. Non-uniform effect on the thermal/aging performance of lithium-ion pouch battery. Appl. Therm. Eng. 128, 1165–1174 (2018).

Xia, G., Cao, L. & Bi, G. A review on battery thermal management in electric vehicle application. J. Power Sources 367, 90–105 (2017).

Liu, Q. Q., Petibon, R., Du, C. Y. & Dahn, J. R. Effects of electrolyte additives and solvents on unwanted lithium plating in lithium-ion cells. J. Electrochem. Soc. 164, A1173–A1183 (2017).

Wang, C. Y. et al. Fast charging of energy-dense lithium-ion batteries. Nature 611, 485–490 (2022).

Khan, S. A. et al. Advancements in battery thermal management system for fast charging/discharging applications. Energy Storage Mater. 65, 103144 (2024).

Talele, V., Patil, M. S., Panchal, S., Fraser, R. & Fowler, M. Battery thermal runaway propagation time delay strategy using phase change material integrated with pyro block lining: dual functionality battery thermal design. J. Energy Storage 65, 107253 (2023).

Ma, J., Sun, Y. F. & Zhang, S. Experimental investigation on energy consumption of power battery integrated thermal management system. Energy 270, 126860 (2023).

Ebbs-Picken, T., Da Silva, C. M. & Amon, C. H. Design optimization methodologies applied to battery thermal management systems: a review. J. Energy Storage 67, 107460 (2023).

García, A., Monsalve-Serrano, J., Micó, C. & Guaraco-Figueira, C. Detailed characterisation of particle emissions from the thermal runaway of nickel–manganese–cobalt 811 lithium-ion batteries at different states of charge. J. Energy Storage 96, 112695 (2024).

Mathieu, O., Keesee, C., Gregoire, C. & Petersen, E. L. Experimental and chemical kinetics study of the effects of halon 1211 (CF2BrCl) on the laminar flame speed and ignition of light hydrocarbons. J. Phys. Chem. A 119, 7611–7626 (2015).

Wang, Q. S. et al. The efficiency of heptafluoropropane fire extinguishing agent on suppressing the lithium titanate battery fire. Fire Technol. 52, 387–396 (2016).

Zhao, J. et al. Preparation of hydrophobic and oleophobic fine sodium bicarbonate by gel–sol–gel method and enhanced fire extinguishing performance. Mater. Des. 186, 108331 (2020).

Meng, X. et al. Experimental study on combustion behavior and fire extinguishing of lithium iron phosphate battery. J. Energy Storage 30, 101532 (2020).

Ubaldi, S. et al. Suppression capacity and environmental impact of three extinguishing agents for lithium-ion battery fires. Case Stud. Chem. Environ. Eng. 10, 100810 (2024).

Rohilla, M., Saxena, A., Dixit, P. K., Mishra, G. K. & Narang, R. Aerosol forming compositions for fire fighting applications: a review. Fire Technol. 55, 2515–2545 (2019).

Zhang, L., Jin, K. Q., Sun, J. H. & Wang, Q. S. A review of fire-extinguishing agents and fire suppression strategies for lithium-ion batteries fire. Fire Technol. 60, 817–858 (2024).

Xu, C. et al. Preparation and characterization of fire-extinguishing efficiency of novel gel foam for lithium-ion battery fires. Process Saf. Environ. Prot. 197, 106999 (2025).

Zhou, G. et al. Preparation of environment-friendly gel–protein foam and its fire suppression performance for lithium-ion batteries. Fuel 384, 133979 (2025).

Zhang, L. et al. Experimental investigation of water spray on suppressing lithium-ion battery fires. Fire Saf. J. 120, 103117 (2021).

Ma, Y. F. et al. Thermal runaway propagation behavior and cooling effect of water mist within a 18650-type LiFePO4 battery module under different conditions. Process Saf. Environ. Prot. 185, 1362–1372 (2024).

Lu, J. Z. et al. Experimental evaluation of protecting high-voltage electrical transformers using water mist with and without additives. Fire Technol. 55, 1671–1690 (2019).

Li, L. X. et al. Efficient and environmentally friendly composite additive fine water mist for suppressing thermal runaway of lithium-ion batteries. J. Energy Storage 114, 115780 (2025).

Jia, H. L., Shen, H. D., Xiang, H. J., Li, D. H. & Zhai, R. P. Analysis of the fire-extinguishing effect and the weakening of flame intensification of nonionic liquid water mist. Combust. Sci. Technol. 192, 902–914 (2020).

Yuan, S., Chang, C., Zhang, J., Liu, Y. & Qian, X. Experimental investigation of a micelle encapsulator F-500 on suppressing lithium ion phosphate batteries fire and rapid cooling. J. Loss Prev. Process Ind. 79, 104816 (2022).

Yuan, S. et al. The extinguishment mechanisms of a micelle encapsulator F-500 on lithium-ion battery fires. J. Energy Storage 55, 105186 (2022).

Zhang, T., Han, Z., Du, Z., Zhang, Z. & Liu, K. Application of thermal mechanism to evaluate the effectiveness of the extinguishment of CH4/air cup-burner flame by water mist with additives. Int. J. Hydrog. Energy 41, 15078–15088 (2016).

Joseph, P., Nichols, E. & Noyozhilov, V. A comparative study of the effects of chemical additives on the suppression efficiency of water mist. Fire Saf. J. 58, 221–225 (2013).

Cao, X. Y., Bi, M. S., Ren, J. J. & Chen, B. Experimental research on explosion suppression affected by ultrafine water mist containing different additives. J. Hazard. Mater. 368, 613–620 (2019).

Liu, Y. et al. Experimental study on a novel safety strategy of lithium-ion battery integrating fire suppression and rapid cooling. J. Energy Storage 28, 101185 (2020).

Bai, Z. J. et al. Overview of anti-fire technology for suppressing thermal runaway of lithium battery: material, performance, and applications. J. Power Sources 640, 236767 (2025).

Liu, Y. J. et al. The efficiency and toxicity of dodecafluoro-2-methylpentan-3-one in suppressing lithium-ion battery fire. J. Energy Chem. 65, 532–540 (2022).

Huang, Z., Liu, P., Duan, Q., Zhao, C. & Wang, Q. Experimental investigation on the cooling and suppression effects of liquid nitrogen on the thermal runaway of lithium ion battery. J. Power Sources 495, 229795 (2021).

Wang, Z. et al. Revealing suppression effects of injection location and dose of liquid nitrogen on thermal runaway in lithium iron phosphate battery packs. Int. J. Heat Mass Transf. 219, 124866 (2024).

Wang, Z. et al. Effects of injection methods and occasions of liquid nitrogen on thermal runaway characteristics in 65 Ah LiFePO4 batteries. Appl. Therm. Eng. 239, 122126 (2024).

Ping, P. et al. Experimental study on the synergistic strategy of liquid nitrogen and water mist for fire extinguishing and cooling of lithium-ion batteries. Process Saf. Environ. Prot. 188, 713–725 (2024).

Shi, B. et al. Experimental study on suppressing thermal runaway propagation of lithium-ion battery modules by using liquid nitrogen: influence of injection pipe diameter and position. Therm. Sci. Eng. Prog. 50, 102580 (2024).

Yuan, S. et al. A review of fire-extinguishing agent on suppressing lithium-ion batteries fire. J. Energy Chem. 62, 262–280 (2021).

Meng, X. et al. Experimental study of intermittent spray cooling on suppression for lithium iron phosphate battery fires. eTransportation 11, 100142 (2022).

Hong, Y. et al. Experimental study of the suppressing effect of the primary fire and thermal runaway propagation for electric bicycle batteries using flood cooling. J. Clean. Prod. 435, 140392 (2024).

Wahab, A. et al. Immersion cooling innovations and critical hurdles in Li-ion battery cooling for future electric vehicles. Renew. Sustain. Energy Rev. 211, 115268 (2025).

Zhang, W. et al. Fabrication of a microcapsule extinguishing agent with a core–shell structure for lithium-ion battery fire safety. Mater. Adv. 2, 4634–4642 (2021).

Li, L. et al. Thermal-responsive, super-strong, ultrathin firewalls for quenching thermal runaway in high-energy battery modules. Energy Storage Mater. 40, 329–336 (2021).

Mao, Y., Ye, Y., Zhao, L., Chen, Y. & Chen, M. Suppression of lithium-ion battery thermal runaway propagation by zirconia ceramics and aerogel felt in confined space. Process Saf. Environ. Prot. 189, 1258–1273 (2024).

Yang, C., Sunderlin, N., Wang, W., Churchill, C. & Keyser, M. Compressible battery foams to prevent cascading thermal runaway in Li-ion pouch batteries. J. Power Sources 541, 231666 (2022).

Ma, H. H. et al. High-energy laser protection performance of fibrous felt-reinforced aerogels with hierarchical porous architectures. ACS Appl. Mater. Int. 16, 25568–25580 (2024).

Ge, S. K. et al. A passive fire protection method for main cables and slings of suspension bridges utilizing fiber felt/aerogel composites. Constr. Build. Mater. 408, 133822 (2023).

Luo, Y. et al. Lightweight, compressible, and stretchable composite foams for ultra-efficient and high-stable electromagnetic interference shielding materials. Carbon 215, 118480 (2023).

Hodlur, R. M. & Rabinal, M. K. Self assembled graphene layers on polyurethane foam as a highly pressure sensitive conducting composite. Compos. Sci. Technol. 90, 160–165 (2014).

Nambisan, P. et al. Characterization of commercial thermal barrier materials to prevent thermal runaway propagation in large format lithium-ion cells. J. Energy Storage 74, 109414 (2023).

Dhuchakallaya, I. & Saechan, P. Enhancing the cooling efficiency of the air cooling system for electric vehicle battery modules through liquid spray integration. J. Energy Storage 72, 108751 (2023).

Zou, K., Xu, J., Zhao, M. & Lu, S. Effects and mechanism of thermal insulation materials on thermal runaway propagation in large-format pouch lithium-ion batteries. Process Saf. Environ. Prot. 185, 1352–1361 (2024).

Han, D., Wang, J., Yin, C. & Zhao, Y. Advances in early warning of thermal runaway in lithium‐ion battery energy storage systems. Adv. Sensor Res. 4, 2400165 (2025).

Yang, S. et al. Comparing different battery thermal management systems for suppressing thermal runaway propagation. J. Energy Storage 101, 114005 (2024).

Zhang, X., Li, Z., Luo, L., Fan, Y. & Du, Z. A review on thermal management of lithium-ion batteries for electric vehicles. Energy 238, 121652 (2022).

Li, L. et al. Comparative study of thermal management systems with different cooling structures for cylindrical battery modules: side-cooling vs. terminal-cooling. Energy 274, 127414 (2023).

Huang, J. Q. et al. Operando decoding of chemical and thermal events in commercial Na(Li)-ion cells via optical sensors. Nat. Energy 5, 674–683 (2020).

Qin, Y. et al. Grid-plainification enables medium-temperature PbSe thermoelectrics to cool better than Bi2Te3. Science 383, 1204–1209 (2024).

Xiao, Y. & Zhao, L.-D. Seeking new, highly effective thermoelectrics. Science 367, 1196–1197 (2020).

Jiang, Z. Y., Li, J. Y., Qu, Z. G., Wang, L. & Miao, J. Y. Theoretical analysis on thermal grease dry-out degradation in space environment. Int. J. Therm. Sci. 179, 107694 (2022).

Lee, S., Lee, H., Jun, Y. J. & Lee, H. Hybrid battery thermal management system coupled with paraffin/copper foam composite phase change material. Appl. Energy 353, 122043 (2024).

Sheng, P. et al. Enhanced curing behavior, mechanical and thermal properties of 3D printed aluminum nitride ceramics using a powder coating strategy. Addit. Manuf. 74, 103732 (2023).

Wang, J. X. F. Design and Manufacturing Technology of Battery Pack for Electric Vehicle (China Science, 2017).

Zhai, R. et al. Effect of flame retardant R134a on the flammability characteristics of R1234yf. Energy 313, 134092 (2024).

Lu, L., Han, X., Li, J., Hua, J. & Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 226, 272–288 (2013).

Zeng, S. et al. A review of research on immersion cooling technology for lithium-ion batteries. Energy Storage Sci. Technol. 12, 2888–2903 (2023).

Chen, K., Wu, W. X., Yuan, F., Chen, L. & Wang, S. F. Cooling efficiency improvement of air-cooled battery thermal management system through designing the flow pattern. Energy 167, 781–790 (2019).

Lv, Y. F., Yang, X. Q., Zhang, G. Q. & Li, X. X. Experimental research on the effective heating strategies for a phase change material based power battery module. Int. J. Heat Mass Transf. 128, 392–400 (2019).

Rezgar, H., Taher, A., Ali, D. & Richard, E. L. Thermal conductivity of low density polyethylene foams part I: comprehensive study of theoretical models. J. Therm. Sci. 28, 745–754 (2019).

Zhou, W. Y., Qi, S. H., Tu, C. C. & Zhao, H. Z. Novel heat-conductive composite silicone rubber. J. Appl. Polym. Sci. 104, 2478–2483 (2007).

Coman, P. T., Darcy, E. C., Veje, C. T. & White, R. E. Numerical analysis of heat propagation in a battery pack using a novel technology for triggering thermal runaway. Appl. Energy 203, 189–200 (2017).

Wang, H. Y. et al. Study on the fire suppression efficiency of common extinguishing agents for lithium iron phosphate battery fires. Fire Technol. https://doi.org/10.1007/s10694-024-01687-6 (2025).

Hazard Control Technologies. Safety data sheet: F-500 multi-purpose encapsulator agent. https://firerover.com/wp-content/uploads/2024/06/f500-sds-french-canadian.pdf (HCT, 2024).

Yan, Z. et al. Experimental research on heat insulation performance of assembled thermal insulation materials in cryogenic tank. Manned Spacefl. 23, 56–60 (2017).

Acknowledgements

The authors thank the National Natural Science Foundation of China (Nos 52176092 and 52311530086), the Ministry of Science and Technology of the People’s Republic of China (No. 2022YFE0207900), the Science Fund for Distinguished Young Scholars of Hebei Province (No. E2024202056), the S&T Program of Hebei (No. E2024202293) and the Science Research Project of Hebei Education Department (No. JZX2024003).

Author information

Authors and Affiliations

Contributions

The authors contributed equally to all aspects of the article. All authors contributed substantially to discussion of the content, wrote the article and reviewed and/or edited the manuscript before submission.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Clean Technology thanks Yikai Jia and Chuanbo Yang for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rao, Z., Lyu, P., Li, M. et al. A thermal perspective on battery safety. Nat. Rev. Clean Technol. 1, 511–524 (2025). https://doi.org/10.1038/s44359-025-00073-x

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44359-025-00073-x

This article is cited by

-

Stacked temporal deep learning for early-stage degradation forecasting in lithium-metal batteries

Discover Artificial Intelligence (2025)