Abstract

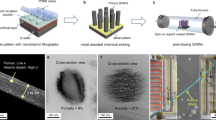

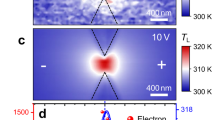

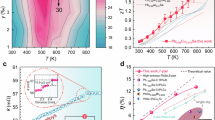

Thermoelectric materials interconvert thermal gradients and electric fields for power generation or for refrigeration1,2. Thermoelectrics currently find only niche applications because of their limited efficiency, which is measured by the dimensionless parameter ZT—a function of the Seebeck coefficient or thermoelectric power, and of the electrical and thermal conductivities. Maximizing ZT is challenging because optimizing one physical parameter often adversely affects another3. Several groups have achieved significant improvements in ZT through multi-component nanostructured thermoelectrics4,5,6, such as Bi2Te3/Sb2Te3 thin-film superlattices, or embedded PbSeTe quantum dot superlattices. Here we report efficient thermoelectric performance from the single-component system of silicon nanowires for cross-sectional areas of 10 nm × 20 nm and 20 nm × 20 nm. By varying the nanowire size and impurity doping levels, ZT values representing an approximately 100-fold improvement over bulk Si are achieved over a broad temperature range, including ZT ≈ 1 at 200 K. Independent measurements of the Seebeck coefficient, the electrical conductivity and the thermal conductivity, combined with theory, indicate that the improved efficiency originates from phonon effects. These results are expected to apply to other classes of semiconductor nanomaterials.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

MacDonald, D. K. C. Thermoelectricity: An Introduction to the Principles (Wiley, New York, 1962)

Mahan, G., Sales, B. & Sharp, J. Thermoelectric materials: New approaches to an old problem. Phys. Today 50, 42–47 (1997)

Chen, G. et al. Recent developments in thermoelectric materials. Int. Mater. Rev. 48, 45–66 (2003)

Venkatasubramanian, R. et al. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 413, 597–602 (2001)

Harman, T. C. et al. Quantum dot superlattice thermoelectric materials and devices. Science 297, 2229–2232 (2002)

Hsu, K. F. et al. Cubic AgPbmSbTe2+m: Bulk thermoelectric materials with high figure of merit. Science 303, 818–821 (2004)

Hicks, L. D. & Dresselhaus, M. S. Thermoelectric figure of merit of a one-dimensional conductor. Phys. Rev. B 47, 16631–16634 (1993)

Mahan, G. D. & Sofo, J. O. The best thermoelectric. Proc. Natl Acad. Sci. USA 93, 7436–7439 (1996)

Humphrey, T. E. & Linke, H. Reversible thermoelectric nanomaterials. Phys. Rev. Lett. 94, 096601 (2005)

Boukai, A., Xu, K. & Heath, J. R. Size-dependent transport and thermoelectric properties of individual polycrystalline bismuth nanowires. Adv. Mater. 18, 864–869 (2006)

Yu-Ming, L. et al. Semimetal-semiconductor transition in Bi1-xSbx alloy nanowires and their thermoelectric properties. Appl. Phys. Lett. 81, 2403–2405 (2002)

Majumdar, A. Enhanced thermoelectricity in semiconductor nanostructures. Science 303, 777–778 (2004)

Weber, L. & Gmelin, E. Transport properties of silicon. Appl. Phys. A 53, 136–140 (1991)

Small, J. P., Perez, K. M. & Kim, P. Modulation of thermoelectric power of individual carbon nanotubes. Phys. Rev. Lett. 91, 256801 (2003)

Li, S. et al. Measuring thermal and thermoelectric properties of one-dimensional nanostructures using a microfabricated device. J. Heat Transf. 125, 881–888 (2003)

Li, D. et al. Thermal conductivity of individual silicon nanowires. Appl. Phys. Lett. 83, 2934–2936 (2003)

Morales, A. M. & Lieber, C. M. A laser ablation method for the synthesis of semiconductor crystalline nanowires. Science 279, 208–211 (1998)

Melosh, N. A. et al. Ultra-high density nanowire lattices and circuits. Science 300, 112–115 (2003)

Wang, D., Sheriff, B. A. & Heath, J. R. Complementary symmetry silicon nanowire logic: Power-efficient inverters with gain. Small 2, 1153–1158 (2006)

Cahill, D. G., Watson, S. K. & Pohl, R. O. Lower limit to the thermal conductivity of disordered crystals. Phys. Rev. B 46, 6131–6140 (1992)

Landau, L. D. & Lifshitz, E. M. in Theory of Elasticity 3rd edn 138 (Butterworth Heinemann, Oxford, 1986)

Pearson, W. B. Survey of thermoelectric studies of the Group 1 metals at low temperatures carried out at the National Research Laboratories, Ottawa. Sov. Phys. Solid State 3, 1024–1033 (1961)

Herring, C. Theory of the thermoelectric power of semiconductors. Phys. Rev. 96, 1163–1187 (1954)

Geballe, T. H. & Hull, G. W. Seebeck effect in silicon. Phys. Rev. 98, 940–947 (1955)

Behnen, E. Quantitative examination of the thermoelectric power of n-type Si in the phonon drag regime. J. Appl. Phys. 67, 287–292 (1990)

Trzcinksi, R., Gmelin, E. & Queisser, H. J. Quenched phonon drag in silicon microcontacts. Phys. Rev. Lett. 56, 1086–1089 (1986)

Maranganti, R. & Sharma, P. Length scales at which classical elasticity breaks down for various materials. Phys. Rev. Lett. 98, 195504 (2007)

Lifshitz, R. & Roukes, M. L. Thermoelastic damping in micro- and nanomechanical systems. Phys. Rev. B 61, 5600–5609 (2000)

Zener, C. Internal friction in solids. I. Theory of internal friction in reeds. Phys. Rev. 52, 230–235 (1937)

Gurevich, L. The thermoelectric properties of conductors. Zhurnal Eksperimentalnoi I Teoreticheskoi Fiziki 16, 193–228 (1946)

Acknowledgements

We thank D. Wang for discussions and J. Dionne, M. Roy, K. Kan and T. Lee for fabrication assistance. This work was supported by the Office of Naval Research, the Department of Energy, the National Science Foundation, the Defense Advanced Research Projects Agency, and a subcontract from the MITRE Corporation.

Author Contributions A.I.B., Y.B., J.-K.Y. and J.R.H. contributed primarily to the design and execution of the experiments. J.T.-K. and W.A.G. contributed primarily to the theory.

Author information

Authors and Affiliations

Corresponding author

Supplementary information

Supplementary Information

The file contains Supplementary Methods and Discussion with Supplementary Figures S1-S8. This file contains information about the materials processing and thermoelectric measurements. Also, a more detailed discussion of the results and theory is included. (PDF 1155 kb)

Rights and permissions

About this article

Cite this article

Boukai, A., Bunimovich, Y., Tahir-Kheli, J. et al. Silicon nanowires as efficient thermoelectric materials. Nature 451, 168–171 (2008). https://doi.org/10.1038/nature06458

Received:

Accepted:

Issue date:

DOI: https://doi.org/10.1038/nature06458

This article is cited by

-

Flexible thermoelectrics in crossed graphene/hBN composites

Scientific Reports (2024)

-

Mechanical properties of fullerene embedded silicon nanowires

Archive of Applied Mechanics (2023)

-

Atomistic simulation of low-dimensional nanostructures toward extreme-scale supercomputing

CCF Transactions on High Performance Computing (2023)

-

Investigation of Quantum Conductance in Silicon Nanowire Doped with Boron in the Presence and Absence of (3-Aminopropyl) Triethoxysilane Molecule

Iranian Journal of Science (2023)

-

Quantifying spectral thermal transport properties in framework of molecular dynamics simulations: a comprehensive review

Rare Metals (2023)