Abstract

Egyptian blue (EB) is a heterogeneous multi-phase blue pigment originating in Egypt ≈5000 years ago. While cuprorivaite (CaCuSi4O10) is the primary chromophore, color of the powdered pigment depends upon multiple factors, including other phases and particle size. In this study, we synthesized EB using differing raw materials and heating times and investigated the phases and microstructure of the particles via X-ray diffraction, electron beam X-ray microanalysis, and X-ray nano-computed tomography. We measured color by reflectance visible/near-infrared spectrometry and color coordinate extraction and obtained comparative measurements on modern pigments, two Egyptian artifacts (≈2300–3400 years old), and synthesized Cu-doped glasses. Photoluminescence mapping of the artifacts confirmed intergrowth of cuprorivaite encased within colorless particles which otherwise appear as a single phase. This accurate determination of color coupled with correlation to phase distribution provides a series of recipes for obtaining given colors, knowledge which is useful for archeologists and conservation scientists working with EB materials.

Similar content being viewed by others

Introduction

Egyptian blue (EB), the world’s oldest synthetic pigment, first evidenced about 3100 BCE, was highly valued throughout the ancient world1,2. Primary production of EB, at least in ancient Egyptian and Roman times, was likely conducted at distinct sites separate from those evidencing secondary use of the material2. Archeological evidence of production has been found in only a few sites, while portable ‘chunks’ of EB in various shapes (e.g., “loaves”, ingots, balls) have been found in many contexts, suggesting the formalized trade of EB. This specialization is similar to what is known about the trade in colored glass from Egyptian sites such as Amarna and Qantir, where glass ingots were produced and transported to secondary sites3,4. Like glass, raw Egyptian blue was likely subsequently processed in workshops for use as a pigment, which may or may not have been located near primary production centers.

EB provided an alternative to cost-prohibitive blue stones like turquoise and lapis-lazuli, the latter a highly prized stone imported over several thousand kilometers from modern Afghanistan5. These stones could only be fashioned into objects or inlays, whereas makers could put EB to a much wider range of uses. The creation of a human-made alternative for these precious stones made the manufacturing of blue objects more accessible throughout the Mediterranean basin6. As early as the fourth millennium BCE, Egyptian societies produced the pigment using a series of precursors that include a silica source, lime, an alkaline flux, and a copper source5,7.

Throughout Egyptian history, most local copper was extracted at sites in the Eastern Desert and Sinai8. Expedition workers often melted it into ingots before transporting it to secondary metalworking sites located in major urban centers along the Nile. These secondary sites would have been a great source for bronze scale shavings that can be used to produce EB8. During the later Iron Age, local populations within the Arabah valley mined copper at Timna and Arabah, adding additional copper resources9. The copper source for EB likely varied over time, with accounts given for roasted copper sulfide ores, copper carbonate ores such as malachite or azurite, and copper metal or recycled bronze alloys, which may have included corrosion products1,2,10.

The source of lime has been debated, some suggesting that it was part of a calcareous sand source2, and others suggesting that it was a deliberate adulteration of the soda mineral natron11. Either way, the Roman author Vitruvius does not mention lime being a deliberately added component of EB, despite its necessity as a component of cuprorivaite (CaCuSi4O10), the mineral equivalent of the synthetic primary chromophore of EB. The soda source named by Vitruvius was the material natron (mostly consisting of the mineral trona, Na2CO3·NaHCO3·2H2O), which was added during synthesis, presumably as a flux7,12. From measured Na2O/K2O ratios, flux for EB from Egypt appears to be made rather using ash of salt-loving plants as the soda source, though the composition of some contemporaneous green frits does suggest use of natron7. Plant ash was used as flux in glassmaking in Late Bronze Age Mesopotamia and ancient Egypt, while natron was used in glassmaking during the Roman period4. Though there is no direct evidence that EB and glassmaking were practiced together, it is well established that faience (glazed ceramic ware) and glass were produced in the same workshops using the same materials2, so it is at least possible that there was technology transfer between EB and glassmaking.

It is important to consider that the raw materials used to make EB may have changed over time. Over the millennia, the technology for producing EB dispersed throughout the Mediterranean, Mesopotamia, and later European polities. The ancient Egyptians used it as a pigment, which they ground, mixed with a simple binder, and applied to wood, stone, and cartonnage (a layered material made with linen, like papier-mâché). Other Egyptian uses include refired EB powder into bulk beads and amulets2. In later periods, the Romans used it as bulk tesserae within mosaics13, on frescos, and on buildings1. Use became much less widespread after c. 600 CE but continued until at least the Renaissance. Modern rediscovery of EB in the 19th and 20th centuries has shown cuprorivaite to be one of an important class of intensely colorful and stoichiometrically-similar minerals and synthetic copper silicates, (MCuSi4O10), where M = (Ca, Sr, Ba, etc.)1, with interesting optical, magnetic, and biological properties. These properties have given rise to potential new technological applications for EB, and hence interest has been renewed in this ancient material1,14. Note that hereinafter mineral names with the same stoichiometry as synthesized materials will be used for readability, and the term EB will be used exclusively to refer to the mixed phase assemblage which results from most synthesis procedures, both ancient and modern.

The Si-O bond topology of cuprorivaite is a corrugated infinite sheet, built from double-stacked tetrahedra along z. Each SiO4 tetrahedron is coordinated at three of its apices to next-neighbor SiO4 tetrahedra (each tetrahedron shares 3 of its O to neighboring Si). The fourth O atom in each SiO4 tetrahedron forms a bond with square planar Cu, forming a box-like intersheet three-dimensional framework. The Si-O-Cu sheets are further connected through bonds with [8]-coordinated, irregularly shaped Ca polyhedra, completing the overall framework structure of cuprorivaite. Despite being termed as such in the literature15, cuprorivaite and related compounds are not properly two-dimensional silicates, but are considered phyllosilicates.

The source of the color and interesting properties is Cu2+ coordinated equatorially by four oxide anions, forming essentially ideal square-planar [CuO₄]⁶⁻ units. In most other copper oxysalt minerals, d⁹ Cu2+ centers occurring in octahedral environments often display Jahn-Teller (JT) distortions due to an electronic degeneracy in the eg orbitals, resulting in compressed “2 + 4” (2 long and 4 short Cu–O bonds) and elongated “4 + 2” (4 long, 2 short) geometries16. The square planar geometry of Cu2+ in cuprorivaite does not arise from a JT (or pseudo-JT) distortion of an octahedral [CuO₆] configuration, because its structure lacks any proximal oxide sites in the axial direction. Instead, the crystal structure itself enforces the strong anisotropy around each Cu²⁺ site, stabilizing the high-energy d(x²-y²) orbital. This crystal-field splitting determines the energy of the d–d transitions responsible for the intense blue color.

Modern applications for cuprorivaite include biomedical analysis, telecommunications, security inks, and lasers, as well as applications taking advantage of the material’s high quantum efficiency emission in the near infrared region1,17. The unique corrugated sheet in cuprorivaite, containing square planar Cu2+, absorbs broadly in the visible and near infrared (VNIR) spectrum between 430-800 nm and emits a luminescence band at ~910 nm18. The lowest electronic transition is responsible for this characteristic luminescence17,18. These qualities allow Egyptian blue to produce electromagnetic radiation in the NIR, leading to the pigment’s use within the modern applications listed. This property also allows modern art conservators and scientists to identify Egyptian blue even when the color is obscured or degraded19.

EB objects have a considerable diversity of color. Even ancient makers recognized that EB can be multiple colors. In his book On Stones (De Lapidus) written in 315 BCE, Greek natural philosopher Theophrastus indicates that there were four possible colors of EB20,21. Skovmøller et al. 22 suggest that these hues are: saturated almost black blue, light blue, bluish green, and purple. Later ca. 77–79 CE, in Natural History, Pliny the Elder describes several named varieties of EB, which may indicate sources of production or quality, though he also describes a grade of EB produced by washing and grinding, and evidence from late Hellenistic Kos suggests that separated EB grains were sometimes even mixed with other blue pigments20. These color variations are recognizable even in the oldest known Egyptian names for the pigment, which include words relating to natural stones of different hues: lapis lazuli and turquoise. This same variation of blue hues is observed in the coeval technology of faience, and the slightly later glassmaking23,24.

In this definition, hue is the principal constituent that causes the eye to separate the color, saturation defines the relative amount of gray, tone describes the relative white (pale) and black (dark) admixture, and brightness describes the level of reflectivity22,25. These definitions are qualitative, however, and scientific measurements can define color more rigorously using spectroscopy26,27, as described herein.

Recreation of cuprorivaite-bearing material by modern techniques has shown that the color can also depend on synthesis route, which has been accomplished via hydrothermal, sol–gel, or the more primitive solid-state or melt-flux methods1. Resultant colors change due to variations in process (such as temperature and time) as well as differences in raw materials. Many studies have focused on the recreation of Egyptian blue7,28,29,30,31,32,33,34. EB is sometimes considered a frit, meaning that is bound by a glassy phase. The main coloring agent is cuprorivaite, though other strongly coloring phases may be formed, including Cu-rich glass10,35, tenorite (CuO), Cu-doped wollastonite, and other complex Cu phases like liebauite (Ca3Cu5Si9O26)36 or potentially alkali copper silicates (Hubert’s blue, Na2CuSi4O1011 or litidionite CuNaKSi4O1037). Materials produced in ancient times, as well as modern melt-flux synthesized analogs, do not consist of isolated particles of individual phases (e.g., cuprorivaite, SiO2 polymorphs (quartz, cristobalite, tridymite), and tenorite). Rather, the frit consists of intergrown cuprorivaite, silicate glass, and silica polymorph blebs, with and without wollastonite (CaSiO3) and rarely other phases, depending on the source materials and conditions used6,7,18,31,33,34,35,38,39,40,41,42,43.

Herein, we describe a thorough examination of the process variability and effect of precursor selection to obtain insight into the procedures that early cultures may have followed to manufacture Egyptian blue. Using a variety of raw materials and heat treatment conditions, our focus was to produce and deduce causes of esthetic variability, particularly the resulting color of the obtained powders. In our study, we chose to vary the raw materials and fix the firing temperature at 1000 °C. This temperature is higher than the nominal temperature most researchers believed that practitioners used throughout antiquity (850–950 °C), but our temperature choice is within the range of temperatures hypothesized by various authors (742–1100 °C). The use of a slightly higher temperature and longer reaction time also promoted the solid-state formation of cuprorivaite, even in the absence of a flux, as detailed below. We then characterized the synthesized materials using modern microscopy and microanalytical techniques, including X-ray diffraction and Raman spectroscopy for phase identification, and correlated these results to our quantitative color measurements. We also compare these experimentally derived materials to commercially available pigments and ancient Egyptian artifacts. We were particularly interested in correlations between process, chemistry, phase assemblage, and their combined effect on perceived color.

The synthetic samples produced in this work are currently on display at the Carnegie Museum of Natural History (CMNH) in Pittsburgh, PA, USA, as part of the Stories We Keep Exhibition, which highlights how modern science reveals hidden stories in ancient Egyptian objects, their conservation, and the connection Egyptians formed with minerals and materials in the Nile Valley. In late 2026, these samples will be placed into a permanent display as part of the long-term exhibition Egypt on the Nile.

Our main findings indicate that experimentally reproduced Egyptian blue pigment, as well as ancient pigments on artifacts, owe their color to both macroscopic as well as microscopic phase intermixing. Blue color primarily originates from cuprorivaite content, though in most cases, as little as 50 wt.% of this phase imparts a deep blue. Particle size of the pigment results in measurable spectroscopic color differences, and the presence of a copper-doped glass phase, only produced when soda is present in the recipe, imparts a green component to the hue, as confirmed by measurements on synthesized glasses. The white balance of the substrate, such as textile, gypsum underlayer, or stone, for example, changes the perceived color. This work provides recipes and quantitative colors such that art and heritage science researchers can better match colors and reproduce a wide range of colors encountered in ancient objects containing Egyptian blue pigment.

Methods

Materials

In this study, 12 different EB “recipes” were developed and synthesized, and additionally, 11 other materials were investigated, including commercial pigments, Cu-doped glasses, and two ancient Egyptian artifacts with variably-colored coatings of EB. The 12 synthetic samples were produced from crystalline silicon dioxide (SiO2), various copper sources including copper oxide (CuO), natural secondary copper carbonate minerals azurite (Cu3(CO3)2(OH)2) or malachite (Cu₂CO₃(OH)₂), a calcium source (CaCO3 or CaO), and several recipes include additional sodium carbonate (soda, Na2CO3). We conducted all EB syntheses at 1000 °C for 1–11 h. We synthesized three families of samples, indicating the copper source, denoted LC (laboratory chemicals), A or AR (azurite), and M or MR (malachite); R indicates a repeat sample, and we designate samples by this prefix followed by a number. In each series, one recipe contained soda while one did not.

Laboratory-prepared samples

The precursors used for sample production include copper oxide (CuO), basic copper carbonate (Cu3(CO3)2(OH)2 or Cu₂CO₃(OH)₂), calcium carbonate (CaCO3), sodium carbonate (Na2CO3), and crystalline silicon oxide (SiO2). Details on the manufacturers and purity (all >98%) of the chemicals are shown in Table S1. All compounds were selected as laboratory chemicals, apart from Cu3(CO3)2(OH)2 and Cu₂CO₃(OH)₂. Both basic copper carbonate sources were mineral samples, used in the form of nearly phase-pure azurite (Cu3(CO3)2(OH)2) and malachite (Cu₂CO₃(OH)₂), provided by CMNH.

It is acknowledged that the particle size of reagents will influence the kinetics and even the ultimate phase fractions. For example, Nicola et al. 44 showed that with nano-sized silica, high fractions of cuprorivaite can be formed without any flux. It is well-known in glassmaking that smaller silica particles will alter batch kinetics, causing more bubbles and influencing the viscosity of early melt45. Thus, presumably, particle size will influence the diffusion of copper and calcium and the nucleation and growth of cuprorivaite in the silicate liquid46. However, these differences were not explored in the current study.

Two sets of samples were prepared. The first set contained only SiO2, CaCO3, and one source of copper; the second set replicated the first with the further addition of Na2CO3, to observe the effects of flux in the production of Egyptian blue. Derived from previous literature and ancient Egyptian blue synthesis, the most effective molar ratio predicted by the cuprorivaite stoichiometry is 4:1:1 for SiO2: CaCO3: CuO18,47,48. Each set of samples followed approximately a 4:1:1 ratio as seen in Table 1. All precursors were combined as finely ground powders and subsequently batched to yield about 18 g of mixture. A tungsten carbide mill was used to pulverize the azurite and malachite precursors. All batches were mixed by hand using a stainless-steel mortar and pestle.

Each sample mixture received a heat treatment at 1000°C in air in a high-temperature box furnace (Sentro Tech) or muffle furnace (Thermolyne). Powders were placed in shallow glazed porcelain dishes and ramped at 13 °C/min from room temperature. We do not see evidence of substantial reactions between the glaze and powders, but rather observe a “loaf” of sintered EB (similar to that observed archeologically2) that is readily separated from the crucible. Heat treatment of the individual samples ranged from 1 to 11 h once the mixtures reached 1000 °C, followed by immediate unregulated cooling in ambient air to room temperature. Infrared thermometer measurements showed that the sample surface dropped from 1000 °C to 400 °C in about one minute, and down to 200 °C at four minutes. Initial experiments had dwell times of only 1 h, but some samples were cooled, examined for color, then reheated for an additional 10 h. Detailed recipes are shown in Table 1. Select reactions were studied by thermal analysis, as shown in Fig. S23.

To determine the effect of cooling rate, two experiments were conducted with the AR2 composition, where a 10-h hold at 1000 °C was followed by an immediate removal of the sample (air cooled), and one that was slow cooled in the furnace (DelTech, drop bottom). For the air-cooled experiment, the sample temperature was monitored below 400 °C periodically with an infrared pyrometer and logarithmically fitted with a point fixed at 1000 °C. For the furnace-cooled sample, the temperature was recorded from an external furnace monitoring thermocouple, previously reported49.

Archeological samples

Samples obtained from the following ancient Egyptian objects in the care of CMNH were used for comparison during characterization: 1) a recarved cartouche dating to the reign of Akhenaten (CMNH 7043-7) and 2) a fragment of Ptolemaic cartonnage (CMNH 4209-12). Both objects come from excavated contexts, giving them a secure date and provenience. The cartouche comes from Amarna and dates to ca. 1349-1336 BCE; the cartonnage is from Sedment and dates to 332-30 BCE.

Commercial pigments and reference colors

Reference pigments (Egyptian Blue, Egyptian Green, Han Blue, and Han Purple6,28,50,51) were purchased from Kremer Pigmente Inc. (Aichstetten, Germany). Two size fractions of the Egyptian Blue samples (passing and failing a 38 μm sieve) and Han Blue (“0–40 μm” and “40–80 μm”, per the supplier) were acquired for comparison of particle size on color measurement.

To obtain a more complete understanding of the color of individual phases identified in the synthesized EB, we used additional targeted syntheses to obtain single-phase materials for study. We synthesized four Cu-rich glasses (with CuO concentrations >20 wt.%) corresponding to the residual glasses (RG) observed in AR2 and MR2, with one set containing all the measured elements (including Al, Fe, Mg, K, P), denoted AR2-RG and MR2-RG, and the other set containing only Ca, Na, Si, Cu, and O, denoted AR2-RG-S and MR2-RG-S (where S represents a simplified composition). Complete compositions in Supplementary Table S8, Table S10. Glasses were produced with a standard melt-quench method (1 h, 1000 °C isothermal melt in 90%Pt 10%Rh crucibles, quenched by placing crucible bottom in water). X-ray diffraction (XRD), Fig. S2, showed only tridymite and quartz for the AR2 and MR2 glasses and a broad background expected from glass.

Cu-doped wollastonite, with 2.5% of Ca replaced by Cu (per the energy dispersive spectroscopy (EDS) measured compositions of Cu in wollastonite from MR1, MR2, AR1, and AR2) was synthesized through an aqueous route, and XRD noted only a wollastonite phase, Fig. S3. We also attempted synthesis of a sample having the composition of the unidentified Cu-rich silicate (CRS) phase from AR1. The attempted synthesis of the CRS phase produced only cuprorivaite and tenorite plus secondary cristobalite and wollastonite, and not exotic phases e.g., liebauite Ca3Cu5Si9O2636.

Crystalline phase purity/assemblages of all pigments, glasses, and wollastonite were verified with XRD, details shown in Fig. S5. Tables S2–S4 show a summary of the supplementary color references.

Analytical methods

We performed material characterization on various subsamples of the corpus, including thermal analysis, powder XRD with Rietveld refinement, laser Raman and photoluminescence measurements, visible-induced luminescence imaging (VIL), visible absorption spectroscopy, reflectance visible near-infrared (VNIR) spectrometry, quantitative electron beam X-ray microanalysis performed on cross-sectioned powders, and nano-scale volumetric X-ray tomography. A brief description of the analytical methods used is described below, with some additional details in the Supplementary.

Powder X-ray diffraction

X-ray diffraction patterns were collected on a Panalytical X’Pert Pro diffractometer, utilizing Ni-filtered Cu Kα radiation. A variable counting time routine was employed, with a data collection time of one hour for the range 10–70° 2θ, and three hours for 70–130° 2θ; data were normalized with respect to collection time prior to analysis. The crystalline phases present were identified by matching the observed reflections to phases in the Inorganic Crystal Structure Database (ICSD). Rietveld method refinements were performed in the GSAS-II software package52. An internal standard method using ZnO (NIST SRM 674b) was used to examine the amorphous content of select compositions (MR1, MR2, AR1, AR2). Significant preferred orientation of cuprorivaite was observed in all materials studied here in the (002) direction; during refinements, this was modeled with a one-axis March-Dollase function.

Raman spectroscopy

Fragments from ancient artifacts (CMNH 4209-12 and CMNH 7043-7) containing Egyptian Blue as well as selected synthesized materials were measured with a Thermo Scientific DXR2xi Raman imaging microscope using three different excitation wavelengths: 455 nm, 532 nm, and 785 nm. The laser power and exposure times were adjusted depending on the wavelength to prevent saturation of the detector and ranged from 0.5 to 20 mW and from 0.0025 to 2 s. Each spectrum shown is an average of at least 60 scans per location and 3–5 locations per sample. Maps were collected through a 10× objective and 25 μm pinhole aperture. Because each wavelength resulted in some fluorescence, it was difficult to extract Raman spectra from individual grains on all the Egyptian Blue artifacts.

Visible-induced luminescence

Multispectral imaging was performed with a modified Nikon D5600 (internal infrared (IR) filter removed) and a series of ultraviolet (UV), IR, and visible (VIS) bandpass filters in a dark room. The samples were illuminated with different light sources ranging from IR to UV A (365 nm). The images capture distinct differences in visible-induced luminescence and reflectance amongst the samples. Photoshop was used to process “raw” .dng images. Color was corrected using standard gray swatches, and “spectralon,” a material with high diffuse reflectance, was used to compare relative reflectance along with other color, scale, and UV-indicating fiducials.

Microchemical analysis

Scanning electron and X-ray imagery were collected with an Hitachi S3700N scanning electron microscopy (SEM) equipped with a Bruker XFlash 6-60 X-ray detector. Images and data were collected under both variable pressure using 80 Pa of ambient atmosphere and high vacuum conditions. Compositional data was obtained using matrix corrections used within the Bruker Esprit v2.5 software platform. Bulk compositions of the experimental rough powders were roughly estimated by standardless analysis of sum spectra obtained by scanning an area 0.84 mm × 0.63 mm and taking the mean of five scanned regions. Quantitative point analyses for a subset of four experimental powders (AR1, AR2, MR1, and MR2) were performed by extracting X-ray spectra from spectral images of mounted and carbon coated polished cross sections using a standards-based φ(ρz) method.

X-ray nano-computed tomography

X-ray nano-Computed Tomography (nano-CT) on MR1, MR2, AR1, AR2, commercial Egyptian Blue Pigment, and a cartonnage fragment (CMNH 4209-12) was conducted with a Zeiss Xradia 810 Ultra. Pseudo-monochromatic 5.4 keV X-rays (from a Cr-anode) probed pigment particles, with a 65 μm (in both diameter and height) field of view, 300 nm resolution (binned from 150 nm resolution), and a Zernike phase contrast filter. During a 180° rotation, 901 images with 90 s exposure time were collected (except for the cartonnage fragment, where 721 images with 50 s exposure time were used). XRM reconstructor (Zeiss) and Dragonfly software (Object Research Systems) were used for reconstruction and 3D visualization, respectively. For visualization of phase differences, X-ray attenuations were thresholded and false-color adjusted. For phase assignment, attenuation modeling was performed in Hephaestus53 utilizing chemical microanalysis compositions and XRD identifications for density determination (except for the glass phase, where the density was measured using the Archimedes’ method on the residual AR2 and MR2 glasses), then compared with morphologies identified with 2D microanalysis. Further procedural details can be found in ref. 54.

Reflectance VNIR spectrometry

A Foster and Freeman Video Spectral Comparator (VSC8000/HS), was used to determine quantitative color. Visible and near-infrared reflectance spectra were collected between 400 nm and 1000 nm at a spectral resolution of 3 nm using a multi-LED light source (see Fig. S11). In characterizing the color of synthesized experimental powders and commercially manufactured synthetic reference pigments, powders were packed into 3.25 mm diameter wells drilled into a plastic substrate. For each sample, color measurements were measured by collecting reflected light from a circular region of interest 55 µm in diameter. White balancing was performed using a vendor-supplied high reflectance white solid with near uniform spectral intensity over the wavelength range of interest. For color measurements of the artifact containing Egyptian blue pigment, a circular region of interest of 200 µm was used to estimate the bulk color, while a 50 µm spot was used to localize and estimate the color of individual blue grains. For these artifact measurements, the exposed substrate of the object was used to perform the white reference. Both reflectance spectra and the calculated International Commission on Illumination (CIE) L*, a* and b* color space measurements were exported and analyzed (further details in Supplementary)55.

Results

Phase development and heterogeneity

Figure 1a depicts white light photographs of the synthesized EB samples. Visual comparison of the color references can be seen in Figs. S1–S4. Figure 1b and Table S5 show phase distributions of synthesized EB as obtained by powder XRD, with full Rietveld refinements in Figs. S5, S6. XRD established the presence of cuprorivaite (Egyptian blue chromophore) as the dominant crystalline component, as well as the presence of unreacted or thermally altered SiO2 polymorphs, including quartz, cristobalite, and tridymite. Most of the samples also contain wollastonite (CaSiO3), with the notable exceptions of M2, LC3, MR2, and MR3. XRD indicated tenorite (CuO) in only a few samples, either as unreacted CuO precursor (significant in LC3, minor in LC4 and LC1), or as a reaction product (M1 having a few percent, with traces in A2, AR1, and MR1). Cuprorivaite was the most prevalent phase within the laboratory chemical samples that contained Na2CO3 (LC2, LC3). A few recipes contained only a small fraction of cuprorivaite (A2, AR2, AR4) despite being qualitatively indistinguishable visually from the other azurite-precursor samples (Fig. 1a).

All LC samples initially received one hour of heat treatment prior to XRD measurement. At this point, XRD observed only SiO2 polymorphs, including cristobalite and tridymite. Interestingly, in related syntheses, other researchers report that these phases form only when heated at or above 950 °C40,50. We then applied an additional 10 h heat treatment and obtained the phase assemblage in Fig. 1b. These samples were visually gray or grayish green before additional heat treatment, becoming increasingly blue with further heating.

To test the effect of cooling rate, we performed a pair of experiments with the AR2 composition, where immediate removal from the furnace after ten hours at 1000 °C was compared with a slow “furnace cool” where the power was shut off and the thermal mass of the furnace was allowed to naturally cool. In both cases, the reacted material formed a “loaf” which easily detached from the porcelain dish upon cooling. On grinding, the color of the air-cooled sample was a pale gray-green, whereas the slow cooled sample was noticeably bluer (Fig. 2). Additionally, quantitative XRD results indicate that the cuprorivaite phase fraction was significantly higher, +70% in the slower cooled sample, the amorphous fraction decreased −30%, and the total silica fraction decreased −20% (Fig. 2). This is consistent with the observation that 11 total hours of high temperature treatment produced bluer samples than 1 h. In addition, it is consistent with the claim of Hatton et al. 7 that cuprorivaite nucleates and grows from the melt, as the longer cooling time would enable this. Overall, this pair of experiments suggests that longer treatment at high temperature and slower cooling produces bluer pigments. Note that for all the rest of the experiments described herein, the air cooling was performed after each heat treatment.

a Photos of synthesis process showing ground precursors, the reacted pigment, the “loaves” after they easily separate from the porcelain crucibles (indicating minimal interaction), and the resulting ground pigments for samples cooled in air versus slowly cooled in a furnace. b XRD with ZnO external standard demonstrating increase in cuprorivaite fraction (+70% per Rietveld refinement) at the expense of amorphous Si-O and SiO2 when cooled slowly. Three dominant reflections of cuprorivaite are marked by asterisks. c Comparison of generalized cooling rates is demonstrated here.

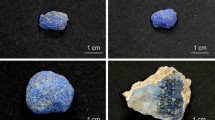

Close inspection of the archeological samples confirms they are also multi-phase materials (Fig. 3). Here we observe dark blue, light blue, and colorless sub-millimeter grains fused together in samples of both the cartonnage and the cartouche (Fig. 3c, e, f).

Cartonnage (CMNH 4209-12); a large piece of cartonnage; b higher resolution image of fragment; c even smaller fragment of the EB section used for Raman and nano-computed tomography; cartouche (CMNH 7043-7); d overview of cartouche; e fragment of EB from cartouche; f higher resolution image of (e) showing individual grains with different colors.

Raman spectroscopy and luminescence measurements further support the phase assemblages identified by powder XRD. Modern confocal Raman spectrometers use monochromatic laser sources to probe surface sizes as small as 1 µm in diameter, and although internal reflection can create a deeper sampling volume depending on transparency, the technique allows for accurate surface mapping of the vibrational modes for heterogeneous samples. Further, use of different excitation wavelengths can “fingerprint” distinct behavior in some materials56,57.

Figure 4a includes a magnified portion of the cartouche EB with corresponding Raman map in Fig. 4b. We created the map by considering the threshold intensity of the 5000–6000 cm−1 Raman shift (532 nm excitation) region (Fig. 4c), corresponding to 725–781 nm. This is the beginning of the near-infrared luminescence characteristic of cuprorivaite17, observed during 785 nm excitation. The luminescence extends from 817–1027 nm, peaking near ~908–915 nm, Fig. 4d, and originates due to the 2B2g → 2B1g electronic transition of Cu2+ in square planar configuration58. The red and green areas of the map in Fig. 4b correspond to regions of cuprorivaite, or where internal reflections from underlying cuprorivaite present at the surface of the grain (Fig. 4a). By using other excitation wavelengths (see Figs. S7–S10), such as 455 nm, the characteristic luminescence of the silica phases such as cristobalite or quartz59 can be mapped as well.

EB cartonnage artifact CMNH 4209-12: a optical image, ~1 mm field of view; b Raman map using 532 nm excitation, with map colored according to spectral window highlighted in (c) as the shaded region (5000–6000 cm−1); higher intensity (red), versus lower intensity (blue), areas shown in (b) corresponds with the rising luminescence signature seen in (d) when excited with 785 nm laser light. Raman spectra under 455 nm excitation conditions for (e) cartouche artifact CMNH 7043-7 and f lab synthesized powder MR1. Comparison of all synthesized powders using visible-induced luminescence (VIL) imaging: g white light source and h VIL obtained by exciting with red light.

The characteristic luminescence of EB and other blue pigments examined here are dominated by their corresponding chromophore, including: Egyptian Blue [cuprorivaite (CaCuSi4O10)], Han Blue, [effenbergerite60 (BaCuSi4O10)], and Han Purple [colinowensite61 (BaCuSi2O6)], and are strongly excited by visible light in the red portion of the spectrum. Conversely, Egyptian green (nominally Cu-doped glass) does not exhibit this spectral feature19. Researchers in art and cultural heritage use this so-called visible-induced luminescence (VIL) to identify EB in ancient paintings and sculptures17,62. Figure 4g shows a white light image of the synthesized EB pigments, while Fig. 4h shows the near-infrared luminescence when excited with red light (other light conditions shown in Fig. S11). In this figure, MR1 and MR4 (and possibly LC1) are the brightest emitters, followed by similar behavior for MR2, MR3, M1, M2, LC2, LC3, LC4, A1, and AR3. Several pigments gave no VIL: AR1, AR2, AR4, A2. Most of these showed very small cuprorivaite fractions: 2% (AR2), 8% (AR4), 17% (A2). AR1 has 32% cuprorivaite, which should have produced strong luminescence, but the relative lack of VIL may be related to limited sample, the incidence angle of illumination, or some other factors. It has been shown that cuprorivaite created without a glass phase, from simple solid state synthesis using silica nanoparticles, results in much brighter VIL44. This cannot be the explanation in the case of AR1, however, as it has no Na added and thus should have no glass phase.

Given favorable conditions, spectrometers can obtain genuine Raman shift vibrational spectra without significant interference from luminescence. Using 455 nm excitation, we recorded Raman spectra for the CMNH cartouche fragment (CMNM 7043-7) (Fig. 4e), showing a characteristic band for cuprorivaite around 450 cm−1. Data collected for the cartonnage fragment were inconclusive, owing to an overwhelmingly strong fluorescence signal. We also investigated lab-synthesized sample MR1 using 455 nm excitation in several regions (Fig. 3f). These spectra contained characteristic bands attributable to quartz as well as cuprorivaite, as observed by other investigations18,40,63. Previous Raman studies have additionally identified minerals that may help determine raw material provenance10,43.

Previous studies suggested that Egyptian blue should contain an amorphous glass phase along with a crystalline cuprorivaite. Researchers find both phases within a wide variety of bulk compositions from materials originating from the Old Kingdom and Roman Period. Intergrowth occurs between dendritic or quadratic platelets of cuprorivaite crystals and a glassy matrix that has been found to contain wollastonite crystals64. These observations suggest that Egyptian blue mixtures are not only sintered and densified but have also been heated above the solidus and have undergone partial melt formation. This can only be accomplished in the presence of a flux agent38. Whereas cuprorivaite can be formed in a pure solid-state process44, it is more readily produced in the presence of the flux, which causes the formation of a liquid or amorphous alkali silicate phase at temperatures <1000 °C, thereby allowing the nucleation and growth of microcrystalline cuprorivaite, wollastonite, and high temperature silica polymorphs46.

It has been observed by many others6,7,50,65 that “blue,” “turquoise,” and “green” glass phases can be found in ancient EB samples. This glass phase is normally observed as a separate Raman active band corresponding to the stretching of bonds in the Si-O network10,18. To assess the presence of a glassy phase, we subjected selected synthesized samples (AR1, AR2, MR1, MR2) to additional powder XRD using a ZnO internal standard, to enable quantification of the amorphous fraction. Only experiments containing Na2CO3 (AR2, MR2) contained quantifiable glass, 15–40% by mass (Table S5). These samples showed weak (MR2) to no (AR2) VIL response (Fig. 4h), while MR1, containing no glass, showed strong VIL due to its high, ~49 wt%, cuprorivaite content. In section Perceived Color below, we further assess the glass phase, its composition, and coloration.

Microstructure and chemical analysis

To investigate the nature of the synthesized pigment particles, we used a suite of microscopy and microanalysis techniques. Quantitative chemical information is available in Tables S6–S11. For all synthesized pigments, we used a standards-based SEM-EDS technique to determine composition. For initial estimates of the bulk composition, we performed quantification on rough powders. The main constituents, as expected, were SiO2, CaO, CuO, and Na2O. For LC# samples based on laboratory chemicals, we detected impurities of K, Al, and Mg. For samples with an azurite precursor, A# and AR#, we quantified the above oxides along with Fe2O3 and P2O5, where detected Fe2O3 is likely to be from the azurite mineral precursor or its matrix, though a small fraction of Fe could be from the SiO2 source (see Table S1). Comparable results were obtained for samples with a malachite precursor, M# and MR#. The results from two experiments using Cu minerals (azurite or malachite) with flux are shown in Table 2.

Since the powders were heterogeneous, as confirmed by X-ray mapping (Fig. S12) and scanning electron imaging (Figs. S13–15), a subset of powders (AR1, AR2, MR1, MR2) was potted and cross-section polished for detailed investigation. Figure 5 shows a montage of results for AR2 and MR2, while we also obtained comparable results for AR1 and MR1 (Figs. S16, S17). Additionally, we obtained standards-based EDS compositions for each chemical phase in the experimental run assemblage (Tables S6-S10), including: cuprorivaite (AR1, AR2), wollastonite (AR1, AR2), silica (AR1, AR2), tenorite (AR1 only), a Cu-rich silicate (AR1 only), and a silicate glass (AR2 only). The Cu-rich silicate phase has chemistry similar to liebauite Ca3Cu5Si9O2636, with a stoichiometry of Ca2.3Cu5.37Si8.16Al0.92O26 (calculated cations per 26 O); however, XRD did not identify a distinct Cu-rich silicate phase in AR1.

AR2 is depicted above in (a–c) and MR2 below in (d–f). a, d represent SEM-EDS compositional images superimposed on BSE images of a polished particle cross-section where Ca, Cu, and Na are represented by red, green, and blue pixels, respectively. B and E are comprised of single element images for Ca, Si, Cu, and Na shown using a rainbow intensity color scale (blue to green to red for increasing intensity), and c, f show virtual slices extracted from a nano-CT 3D volume. Label notation: SiO2 – silica polymorph, Cuv – cuprorivaite, Wo – wollastonite, and gl – silicate glass.

Figure 5a shows cross-sections of AR2 using SEM-BSE, with overlaid colors showing areas enriched in Ca, Cu, and Na as obtained by SEM-EDS. Figure 5b shows single-element color-intensity maps according to concentration for Ca, Si, Cu, or Na that more readily highlight enriched regions in phases that incorporate two or more elements. The microstructure within each particle is clearly composed of multiple intergrown phases: 1) cuprorivaite (labeled Cuv and represented by light blue/green in Fig. 5a and highlighted in Fig. 5b “Cu”); 2) SiO2 (shown as gray in Fig. 5a and highlighted in Fig. 5b “Si”); 3) silicate glass (shown as blue/green in Fig. 5a and highlighted in Fig. 5b “Na”); and 4) wollastonite (represented by red/pink in Fig. 5a and labeled as Wo in Fig. 5b “Ca”). Cuprorivaite, crystalline SiO2 (cristobalite/tridymite), wollastonite, and glass were all detected by XRD (Table S5).

An equivalent microtexture is seen in reconstructed slices obtained using X-ray nano-computed tomography (nano-CT). We utilize nano-CT to provide a 3D visualization of phase assemblages. We assign the phases observed based upon X-ray attenuation modeling, phase morphology, and inverted nano-CT contrast correlated with SEM-EDS mapping. Figure 5c shows the AR2 cross-section image of a larger composite particle. The particle shows contrast between lower X-ray absorptivity phases, yielding darker regions of lower mean atomic number and/or lower density, and higher X-ray absorptivity phases, yielding lighter regions of higher mean atomic number and/or higher density.

Figure 5d shows an SEM micrograph with overlaid compositional analysis for MR2, and Fig. 5e shows the equivalent single element images. We do not detect wollastonite quantitatively in XRD, as the quantity must be below the threshold of detection, but it is visible in some micrographs. Figure 5f shows a nano-CT virtual slice of an MR2 particle, showing remarkably similar morphologies to those obtained from polished mechanical cross-sections using SEM, including dark rounded particles corresponding to partly dissolved silica (quartz) incompletely converted to tridymite or cristobalite. In-situ XRD experiments have previously shown the conversion of quartz to cristobalite near 1000 °C, along with the creation of wollastonite46. We obtained compositional data (Tables S9, S10) for the cuprorivaite phase (MR1, MR2), the silica phase (MR1, MR2), the wollastonite phase (MR1 only), and a silicate glass phase (MR2 only).

Additionally, we measured a fragment of the cartonnage (CMNH 4209-12) by nano-CT (Fig. 6). Needle-shaped crystals appear to be cuprorivaite46,66 with minor tenorite present as bright particles with the greatest X-ray absorptivity. The complex structure is evident both in virtual tomograph slices and in the surface 3-D rendering. Comparison with a high magnification halogen light photograph of the same artifact (Fig. 4a) shows that even the seemingly single grain crystallites of the same color are in fact multiphasic. Additional nano-CT results are shown in Figs. S18–20.

Perceived coloration

The precursor Cu source has a large effect on the overall color obtained (Fig. 1a). For instance, samples containing malachite produce a bright blue color after only one hour of heat treatment, whereas samples containing azurite display a gray-green color when processed under the same conditions. This can best be described as the production of a metastable green frit phase (Cu-bearing glass)40. A subsequent heat treatment of an additional 10 h was required to produce the same qualitative color results provided by malachite-containing samples. When we duplicated the procedure using the 10 h heat treatment using azurite, the powders displayed an undesirable coloration. (Note, however, this is an effect of time and cooling rate as indicated in Fig. 2). This difference in behavior between the azurite and malachite sources is potentially due to impurities from the natural source35. Ores of primary azurite typically contain minor amounts of malachite, hematite, goethite and other commonly occurring first row transition metal oxide minerals, such as cuprite, rutile and anatase67. According to the bulk compositions (Table S6) and the glass compositions (Table 2, Tables S8–S10), the malachite source contains lower concentrations of iron relative to the azurite source.

We obtained reflectance VNIR measurements on all synthesized EB pigments as well as commercial references, synthesized residual glasses, and the cartonnage artifact (Fig. 7). Minima in most reflectance spectra occur near 620 nm and 785 nm and correspond to minima in the transmission spectra (Figs. S21, 22) which arise due to the 2B1g → 2Eg, and 2B1g → 2B2g, transitions, respectively, of the of the Cu2+ ion with crystal-field splitting due to square planar (D4h) coordination58,68. These data show strong reflectance features in both the blue and near-infrared regions.

a Experimental EB powders, b Color reference powders, including from top: EB (Kremer) as received, EB (Kremer) large >38 µm, EB (Kremer) small <38 µm, MR2 experimental powder (same as A), Egyptian green (Kremer), MR2 residual glasses (RG and RG-S) synthesized from experimental compositions, and EB cartonnage artifact spectra collected at differing spot sizes. Note: one sigma uncertainties are shown by light gray error bars about the mean values represented by a solid black line.

We compared the reflectance peaks of the commercial references with those of the synthesized materials. A peak ≈445 nm for the Egyptian blue from Kremer (EBK) coincides with a feature in the Egyptian green Kremer (EGK) near the maxima for all the synthesized EB pigments at ≈425 nm and ≈470 nm. The data shows a peak centered near ≈465 nm in spectra taken on the cartonnage as well as the synthesized pigments. The main reflectance peak for the synthesized residual glasses MR2-RG occurs near ≈510 nm, which does not directly correspond to any other features measured, other than perhaps the EGK which peaks ≈490 nm. In the near infrared, all spectra obtained for synthesized pigments show sharp reflection intensities at ≈800 nm and another ≈880 nm, the latter feature compares favorably to the dominant reflectance evident for the cartonnage ≈880 nm, as well as the EBK ≈ 890 nm.

From the same spectroscopic data, we calculated the International Commission on Illumination (CIE) color perception values – L*, a* and b*. In this scheme, qualitatively, larger (smaller) L* is white (black), positive (negative) a* is red (green), and positive (negative) b* is yellow (blue). Table 3 shows the resulting color coordinates for all materials examined. Figure 8 shows the b* versus a* and b* versus L* plots for all materials, including: MR2 synthesized pigment, its residual glass as a bulk sample (MR2-RG), EGK commercial pigment (green glass), EBK commercial pigment as received along with sieved large and small size fractions, large and small spot size measurements of the cartonnage fragment (CMNH 4209-12), and our other color references. Other researchers obtained similar color coordinates in previous works6,50. We make several immediate observations.

First, the size fraction of the powder directly affects the color perception values. We exemplify this by comparing the as-received EBK with the <38 µm (EBK-sm) and >38 µm (EBK-lg) fractions. For b*, EBK-sm > EBK > EBK-lg; in other words, the larger particle fraction appears both blue shifted (relative to yellow) and red shifted (relative to green) giving the overall appearance of more blue/red coloration. Additionally, for L*, EBK-sm > EBK > EBK-lg; in other words, the large particle fraction appears ‘more black/less white.’ These particle size effects on color have been observed qualitatively before1,30 but not quantitatively; here the effect is revealed by the linear relationship displayed among the two EB size fractions that straddle the as-received powders. The same color perception shift observed for EB with particle size was also noted for Han blue “coarse” (40–80 μm) relative to Han blue fine (<40 μm) powders, which were sold as different sieve sizes.

In the commentaries on Theophrastus’ On Stones (section 55, commentary, p. 184)69 Caley notes that “blue frit apparently was always prepared and used in the form of relatively coarse particles, as the examination of ancient specimens has shown. The color that actually results on grinding it to a very fine powder is a dull bluish-gray, as was determined by an experiment on a specimen of the material found in the excavations at Athens. All other ancient pigments were available and useful only in the form of fine powders, and because of the great difference in the size of its particles, blue frit could not properly be mixed with other pigments.” Thus at least some authors note that EB would only be used as larger particles, and that the other blue colors of kyanos may be some of the other blue pigments, like lapis lazuli (Scythian) and azurite (Cyprian)69 (commentary on section 55, pp. 183, 186).

When comparing the synthesized MR2, the color coordinates are statistically indistinguishable from the EBK-sm. While the EBK contains ~100% cuprorivaite by powder XRD (potentially with a small fraction of residual amorphous flux), MR2 is only 42 wt.% cuprorivaite, with 41 wt.% tridymite and 15 wt.% glass. This suggests that the pigmentation effect of cuprorivaite is sufficiently strong that smaller volume fractions impart an equivalent ‘saturated’ blue (red) color. By extension, the values obtained for the cartonnage are progressively higher L* (whiter), lower a* (greener), and higher b* (less blue) than the ‘pure’ blue endmember of EBK cuprorivaite.

Two important factors should be noted in comparing the ancient EB and modern EB powders, namely: 1) while the commercial and experimental powders are reasonably well-packed materials, the cartonnage contains larger grains that are poorly packed together, thus impacting the degree of visible light translucency, and resulting in the large heterogeneity observed in the a* values of the ancient EB (Fig. 8); 2) importantly, ancient EB was white balanced against the pigment substrate comprised of gypsum (calcium sulfate), not a uniform highly reflective white reference (see Supplementary for details regarding the influence of the substrate on color determination).

We hypothesize that the residual Cu-containing glass from pigments containing Na2O (and hence a significant glassy phase, such as within MR2) might shift the perceived color, if slightly, toward green, in agreement with other observations6,7,50. The coordinates for this glass (MR2-RG) are statistically more green (low a*) and yellow (high b*) and are in fact close to the synthetic EGK, modern green glass pigment. Similarly, the Cu-doped wollastonite contributes a minor non-blue color component with a lower a* (less green/more red) and much higher b* (less blue/more yellow) than MR2 (see Table 3).

The comparison of data from Bianchetti et al. 50 is presented as the average of six reported points termed “blue” or “pale blue” (A850, C850, A960b, B950a, B960b, B950c; here A is high malachite/low calcite, B is high calcite/low malachite, C is low cuprite/low limestone; number is the firing temperature in degrees Celsius). Though the absolute values of the color coordinates reported are quite different than what we observed here, particularly in a* and b*, perhaps due to combined instrumental, white reference, and calculation methods, we can still make some comparisons. The average of ‘light green’ and ‘pale green’ (A1050c, A1050, A1050Hem, B950r) has a significantly higher b* than the ‘blue average’ above, meaning it is more yellow, and a significantly lower (more negative) a*, meaning it is greener. These trends match the results presented here as well.

Other standards are also presented in Fig. 8. Han blue, where Ba is substituted for Ca in the M site of the structure, samples both have more negative b* (bluer) than all EB samples, as well as larger a* samples (more red). As noted above, the larger particle fraction of Han blue is both bluer and redder than the smaller particle fraction. Han purple, on the other hand, has a similar b* to the synthetic EB (EBK) unsieved, but has a much higher a*, thus is redder (i.e., “purple”). The Cu-doped wollastonite has a positive b* (i.e., very yellow) and a fairly low a* value (more green than red), consistent with its appearance. On the L* axis, Cu-wollastonite has a large L* (whiter) than all other samples shown, while Han purple, and to a lesser extent large particle Han blue, have a small L* (blacker) than other samples.

We also plotted the measured colors on the CIE 1976 chromaticity projection on the v’ versus u’ scale (Fig. 9). For the synthesized pigments, MR2, MR3, and LC2 fall in the ‘bluest’ section, with the group LC1, MR1, MR4, and M2 being less blue. Figure 9b shows the color references, again indicating that the large particle pure cuprorivaite (EBK-lg) can be considered ‘bluer’ than MR2, while the color difference between MR2 and the small particle fraction (EBK-sm) is minimal at ΔE2000 = 0.8, well below the “just noticeable difference” threshold27 (see Supplementary for details). Here we see that the MR2 residual glasses are remarkably similar in color to synthetic Egyptian green frit (EGK).

Finally, it is worth re-emphasizing the heterogeneous nature of the pigments in the artifacts themselves. Figure 10 shows a fragment of the cartonnage where compositional imaging is correlated to a color image and the site of VNIR color measurements collected at the sub-millimeter scale. The non-uniform distribution of the cuprorivaite phase, noted by the measured Cu, correlates well with the visibly observed blue grains within the cartonnage and lower b* color perception values (bluer) for the 50 μm spots relative to the 200 µm data (Table 2). Finally, the cartonnage paint rests upon a gypsum substrate, as identified by sulfur in EDS (Fig. 10a), and this base has a color coordinate near white although yellower relative to bright white (Fig. S23b). To obtain the closest equivalent measurement representative of the pigment powders, we used the gypsum substrate as the “white reference”; otherwise the substrate would influence the perceived color (details further provided in the Supplementary). Note that the cartonnage measurements are from pigment layers of powder adhered to a substrate, and not a densely packed powder, which differs from the experimental pigments. In such cases, the low density of particle packing introduces more translucency within the powder grains, and that contributes to the larger standard deviations of the color measurements observed in Fig. 8a and Fig. 8b.

a Composite SEM-EDS X-ray image comprised of Ca (red), Cu (green), Si (blue), and S (orange) pixels. Higher resolution subregions i and ii are highlighted in white rectangles and shown below. b RGB image showing the location of color measurements for two × 200 µm spot line traces (unfilled white dashed circles), and 50 µm measurement spot sizes (thick unfilled white circles).

Discussion

In this study, we synthesized Egyptian blue pigments in a laboratory environment varying the copper source (CuO, azurite, or malachite), with or without the addition of Na2CO3 flux. We then extensively characterized these materials for their chemical composition, phase assemblage, and microstructure. Luminescence used for identification of the ancient pigment correlated to the presence of cuprorivaite, which is usually not present in distinct particles in EB pigments but rather is intermixed with one or more SiO2 polymorphs, wollastonite, tenorite, and/or silicate glass. Comparison with ancient EB pigments both here and in the literature confirmed that this multiphase mixture defining EB is the rule rather than the exception.

Accurate color measurements indicated significant variability in pigments synthesized through the basic process used for making EB. Deep blue coloration required a high fraction of cuprorivaite (i.e., >35 wt.%), but fractions higher than 50 wt.% did not necessarily change the color perception values. The presence of other phases, such as Cu-bearing wollastonite and Cu-bearing glass, tended to shift the average color more towards green-yellow and away from blue-red. Proof-of-concept experiments have shown the effect of longer heating times and slower cooling on increasing the cuprorivaite concentration and blue color at the expense of glass phase and silica. Given the diversity of colors easily obtainable within a narrow range of precursor concentrations and process parameters, it was likely that the ancient producers were able to control the color through raw materials and thermal environment, such that the four colors indicated by Theophrastus could be reproduced at will. From textual evidence, Theophrastus suggested that the different Egyptian kyanos (blue) colors were produced by grinding of different particle sizes21; however, there may have been other factors influencing the color as well. In this modern replication, we showed the conditions whereby it is possible to obtain specific colors.

A summary of the overall connections between phase composition and color is shown in Fig. 11. The figure shows trends of the a*, b*, and L* with additions of crystalline phases, and swatches indicating simulated colors along the changes in phase proportion. The most abundant phases in EB, cuprorivaite and the silica (sum of all polymorphs), are well correlated with color perception. Though trends for minor phases are not as highly correlated, especially since the phase fraction trends obtained from Rietveld do not include the contribution from the amorphous colored glass phase, a few generalizations can be made. Figure 11a shows that the addition of cuprorivaite beyond a threshold level (~40–50 wt.%) decreases the b* value. At least within the comparative data of this study, the b* (blueness) saturates about 50 wt.% cuprorivaite, giving the same value of b* as 100% cuprorivaite standard sieved to the smaller particle size (Fig. 8). At the same time, higher cuprorivaite concentrations weakly increase a*, making them appear overall less green. Increase in total silica shows a strong trend with decreasing a* (greener), as seen in Fig. 11c. In the few samples that contain tenorite (CuO), a large amount results in a lower L* value, hence darker/ blacker (Fig. 11d). Increasing fraction of wollastonite (presumably Cu-doped wollastonite) results in an increase of b* (yellower), or alternatively, samples with less wollastonite are bluer (Fig. 11e). Additionally, increased wollastonite has a very weak trend to samples which have lower a* (greener). This is consistent in reference to the color coordinates of pure Cu-wollastonite, which is yellow-green (Fig. 8). We can make an estimate of the effect of the Cu-doped residual glass phase in the samples containing Na flux by comparing the overall measured color of MR2 with the color of MR2-RG which is the glass made from the composition determined from MR2, where the glass is 15 wt.% of the overall sample (Fig. 11f). Clearly, the glass is less blue/more yellow (larger b*) and less red/more green (smaller a*). So, the less glass, the bluer the pigment is perceived, as was shown in the differential cooling experiment (Fig. 2), partially because the cuprorivaite competes with the glass and silica phases.

X-axes in the plots are wt.% from XRD Rietveld analysis. a addition of cuprorivaite on b* and a*. b Visible light image of EB cartonnage artifact, and SEM-EDS false color composite image, where red represents- Ca, green- Cu, and blue- Si. c The sum of all polymorphs of silica on a*. d addition of tenorite on L*. e addition of wollastonite on b* and a*. f simulated color swatches for MR2 (as measured) and experimental residual glass (which was 15 wt.% of the overall MR2 phase assemblage). Note: The qualitative nature of the color shift with addition of a phase is indicated by one or more blue or green arrows (except d) where L* values are a measure of light and dark intensities within the plots. Additionally, selected simulated color swatches from Table 3 are displayed for reference along first or second order regressions of the data.

Secondary effects beyond the chromophore concentration cannot be ignored, as already discussed. The effect of particle size on measured and perceived color is significant. Larger particles are a deeper blue. However, as seen in actual archeological objects (Fig. 11b and Fig. 10b), EB on objects is very heterogeneous on a microscale if not a macroscale. Blue grains and clear grains are evident (see also Fig. 3 and Fig. 4), even though these particles themselves are not homogeneous phases, but rather highly structured with multiple phases in each particle (Fig. 5 and Fig. 6). Finally, the translucency (powder packing) and the substrate (e.g., gypsum, white tile, etc.) influence the perceived color.

These findings enrich previous scientific, archeological, and historical efforts to understand the uses and chemical properties of Egyptian blue and further define the technological variables early artisans would have needed to control to create the desired multicomponent synthetic pigment. Furthermore, these recipes may be useful for conservators and heritage scientists seeking to closely match colors from a diverse set of ancient objects. We must re-emphasize, however, that the coloration of the substrate (e.g., wrapping, parchment, paint binder) can also influence the perceived color of the final pigment, and conservation science requires further work to quantify this effect for the range of Egyptian blues encountered in heritage objects.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its supplementary information files.

References

Nicola, M., Gobetto, R. & Masic, A. Egyptian blue, Chinese blue, and related two-dimensional silicates: from antiquity to future technologies. Part A: general properties and historical uses. Ren. Lin. Sci. Fisic. Natur. 34, 369–413 (2023).

Kovalev, I., Rodler, A. S., Brøns, C. & Rehren, T. Making and working Egyptian blue—a review of the archaeological evidence. J. Arch. Sci. 153, 105772 (2023).

Smirniou, M. & Rehren, T. H. Direct evidence of primary glass production in late Bronze Age Amarna, Egypt. Archaeometry 53, 58–80 (2011).

Rehren, T. & Freestone, I. C. Ancient glass: from kaleidoscope to crystal ball. J. Arch. Sci. 56, 233–241 (2015).

Corcoran, L. The color blue as an ‘Animator’ in Ancient Egyptian Art. in Essays in Global Color History, Interpreting the Ancient Spectrum (ed. R. B. Goldman) 41–63 (Gorgias Press, 2016).

Pagès-Camagna, S. & Colinart, S. The Egyptian green pigment: Its manufacturing process and links to Egyptian blue. Archaeometry. 45, 637–658 (2003).

Hatton, G. D., Shortland, A. J. & Tite, M. S. The production technology of Egyptian blue and green frits from second millennium BC Egypt and Mesopotamia. J. Arch. Sci. 35, 1591–1604 (2008).

Ogden, J. Metals (Ancient Egyptian). in Ancient Egyptian Materials and Technology eds. P. T. Nicholson and I. Shaw) 148–176 (Cambridge University Press, 2000).

Ben-Yosef, E., Shaar, R., Tauxe, L. & Ron, H. A new chronological framework for Iron Age copper production at Timna (Israel). Bull. Am. Sch. Or. Res. 367, 31–71 (2012).

Dariz, P. & Schmid, T. Raman focal point on Roman Egyptian blue elucidates disordered cuprorivaite, green glass phase and trace compounds. Sci. Rep. 12, 15596 (2022).

Davidovits, F. In Proceedings of the Ninth International Congress of Egyptologists - Neuvième congrès international des égyptologues), 367–371, Grenoble, 2004).

Bredal-Jørgensen, J., Sanyova, J., Rask, V., Sargent, M. L. & Therkildsen, R. H. Striking presence of Egyptian blue identified in a painting by Giovanni Battista Benvenuto from 1524. Anal. Bioanal. Chem. 401, 1433 (2011).

Boschetti, C. Vitreous materials in early mosaics in Italy: Faience, Egyptian Blue, and Glass. J. Glass Stud. 53, 59–91 (2011).

Sgamellotti, A. & Anselmi, C. An evergreen blue. Spectroscopic properties of Egyptian blue from pyramids to Raphael, and beyond. Inorg. Chim. Acta. 530, 120699 (2022).

Johnson-McDaniel, D. Barrett, C. A. Sharafi, A. & Salguero, T. T. Nanoscience of an ancient pigment. 135, 1677–1679 (2013).

Burns, P. C. & Hawthorne, F. C. Static and dynamic Jahn-Teller effects in Cu (super 2+) oxysalt minerals. 34, 1089–1105 (1996).

Accorsi, G. et al. The exceptional near-infrared luminescence properties of cuprorivaite (Egyptian blue). Chem. Comm. 2009, 3392–3394 (2009).

Seymour, L. M. et al. On the production of ancient Egyptian blue: multi-modal characterization and micron-scale luminescence mapping. PLoS ONE 15, e0242549 (2020).

Verri, G. The spatially resolved characterisation of Egyptian blue, Han blue and Han purple by photo-induced luminescence digital imaging. Analy. Bioanaly. Chem. 394, 1011–1021 (2009).

Kostomitsopoulou Marketou, A. The materialisation of colour: reconstructing Egyptian blue manufacture on late Hellenistic Kos. Norw. Arch. Rev. 55, 21–37 (2022).

Katsaros, T., Liritzis, I. & Laskaris, N. Identification of Theophrastus’ pigments egyptios kyanos and psimythion from archaeological excavations: a case study. ArcheoSciences 34, 69–80 (2010).

Skovmøller, A., Brøns, C. & Sargent, M. L. Egyptian blue: modern myths, ancient realities. J. Roman. Arch. 29, 371–387 (2016).

Rehren, T. A review of factors affecting the composition of early Egyptian glasses and faience: alkali and alkali earth oxides. J. Arch. Sci. 35, 1345–1354 (2008).

Tite, M. S., Manti, P. & Shortland, A. J. A technological study of ancient faience from Egypt. J. Arch. Sci. 34, 1568–1583 (2007).

Biggam, C. P. What is color? The Semantics of Color: A Historical Approach 1–8 (Cambridge University Press, 2012).

Luo, M. R., Cui, G. & Rigg, B. The development of the CIE 2000 colour-difference formula: CIEDE2000. Color Res. Applic. 26, 340–350 (2001).

Yang, Y., Ming, J. & Yu, N. Color image quality assessment based on CIEDE2000. Adv. Multimedia. 2012, 273723 (2012).

Wiedemann, H.-G. & Berke, H. Chemical and physical investigations of Egyptian and Chinese blue and purple. Mon. Sites. 3, 154–171 (2001).

Berke, H. The invention of blue and purple pigments in ancient times. Chem. Soc. Rev. 36, 15–30 (2007).

Berke, H. Chemistry in ancient times: the development of blue and purple pigments. Angew. Chem. Int. Ed. 41, 2483–2487 (2002).

Grifa, C. et al. Beyond vitruvius: new insight in the technology of Egyptian Blue and Green Frits. J. Am. Ceram. Soc. 99, 3467–3475 (2016).

Kiss, A., Stretz, H. A., Ueda, A. & Mu, R. Synthesis of Egyptian Blue and mechanisms. J. Phys. Chem. Solids. 167, 110738 (2022).

Tite, M. et al. The production technology of, and trade in, Egyptian blue pigment in the Roman world. in Communities and Connections: Essays in Honour of Barry Cunliffe) 75-92 (Oxford University Press, 2007).

Chase, W. T. Egyptian blue as a pigment and ceramic material. in Science and Archaeology (ed. R. H. Brill) 80–90 (MIT Press, 1971).

Kostomitsopoulou Marketou, A. et al. Synchrotron radiation-based Micro-XANES and micro-XRF study of unsuccessfully produced Egyptian Blue from the late Hellenistic production site of Kos (Dodecanese, Greece). Anal. Chem. 93, 11557–11567 (2021).

Zöller, H. Tillmanns, Ε. & Hentschel, G. Liebauite, Ca3Cu5Si9O26· A new silicate mineral with 14er single chain. Z. Krist. 200, 115–126 (1992).

Kawamura, K. & Iiyama, J. T. Crystallochemistry and thermochemistry of sodi-potassic copper silicate Na2-2xK2xCuSi4O10. Bull. Minéral. 104, 387–395 (1981).

Jaksch, H., Seipel, W., Weiner, K. L. & Goresy, A. E. Egyptian blue—cuprorivaite a window to ancient Egyptian technology. Naturwissensch 70, 525–535 (1983).

Kakoulli, I. Egyptian blue in Greek painting between 2500 and 50 BC. in From Mine to Microscope: Advances in the Study of Ancient Technology eds. A. J. Shortland, I. Freestone and T. Rehren) 101-112 (2009).

Ingo, G. M. et al. Egyptian Blue cakes from the Ayanis fortress (Eastern Anatolia, Turkey): micro-chemical and -structural investigations for the identification of manufacturing process and provenance. J. Arch. Sci. 40, 4283–4290 (2013).

Kostomitsopoulou Marketou, A., Andriulo, F., Steindal, C. & Handberg, S. Egyptian blue pellets from the first century BCE workshop of Kos (Greece): microanalytical investigation by optical microscopy, Scanning electron microscopy-X-ray energy dispersive spectroscopy and micro-Raman spectroscopy. Minerals 10, 1063 (2020).

Oudbashi, O. & Hessari, M. A “Western” imported technology: an analytical study of the Achaemenid Egyptian blue objects. J. Cult. Herit. 47, 246–256 (2021).

Dariz, P. & Schmid, T. Trace compounds in Early Medieval Egyptian blue carry information on provenance, manufacture, application, and ageing. Sci. Rep. 11, 11296 (2021).

Nicola, M. et al. Increased NIR photoluminescence of Egyptian blue via matrix effect optimization. Mater. Chem. Phys. 313, 128710 (2024).

Schweiger, M. J. et al. Cluster formation of silica particles in glass batches during melting. J. Non-cryst. Solids. 356, 1359–1367 (2010).

Pradell, T., Salvado, N., Hatton, G. D. & Tite, M. S. Physical Processes Involved in Production of the Ancient Pigment, Egyptian Blue. J. Am. Ceram. Soc. 89, 1426–1431 (2006).

Bruni, S., Cariati, F., Casadio, F. & Toniolo, L. Spectrochemical characterization by micro-FTIR spectroscopy of blue pigments in different polychrome works of art. Vibr. Spectr. 20, 15–25 (1999).

Mazzocchin, G. A., Rudello, D., Bragato, C. & Agnoli, F. A short note on Egyptian blue. J. Cult. Herit. 5, 129–133 (2004).

Bussey, J. M., Wells, I. A., Smith-Gray, N. J. & McCloy, J. S. In-line detection of salt formation during vitrification using millimeter wave radiometry and interferometry. Measurement. 242, 116266 (2025).

Bianchetti, P., Talarico, F., Vigliano, M. G. & Ali, M. F. Production and characterization of Egyptian blue and Egyptian green frit. J. Cult. Herit. 1, 179–188 (2000).

Pozza, G., Ajò, D., Chiari, G., De Zuane, F. & Favaro, M. Photoluminescence of the inorganic pigments Egyptian blue, Han blue and Han purple. J. Cult. Herit. 1, 393–398 (2000).

Toby, B. H. & Von Dreele, R. B. GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J. Appl. Cryst. 46, 544–549 (2013).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchr. Rad. 12, 537–541 (2005).

Bussey, J. M., Weber, M. H., Smith-Gray, N. J., Sly, J. J. & McCloy, J. S. Examining phase separation and crystallization in glasses with X-ray nano-computed tomography. J. Non-cryst. Solids. 600, 121987 (2023).

Robertson, A. R. The CIE 1976 color-difference formulae. Color Res. Appl. 2, 7–11 (1977).

Downing, B., Karcher, S. & McCloy, J. Laser-induced luminescence imaging: microstructural-chemical analysis for nuclear materials. MRS Adv. 9, 473–478 (2024).

Karcher, S. et al. Benefits of using multiple Raman laser wavelengths for characterizing defects in a UO2 matrix. J. Raman Spectros. 53, 988–1002 (2022).

Binet, L., Lizion, J., Bertaina, S. & Gourier, D. Magnetic and new optical properties in the UV–Visible range of the Egyptian Blue pigment cuprorivaite CaCuSi4O10. J. Phys. Chem. C 125, 25189–25196 (2021).

Götze, J. et al. The 450 nm (2.8 eV) cathodoluminescence emission in quartz and its relation to structural defects and Ti contents. Amer. Min 109, 122–134 (2024).

Giester, G. & Rieck, B. Effenbergerite, BaCu[Si4O10], a new mineral from the Kalahari Manganese Field, South Africa: description and crystal structure. Miner. Mag. 58, 663–670 (1994).

Giester, G., Pristacz, H. & Rieck, B. Colinowensite, BaCuSi2O6, a new mineral from the Kalahari Manganese Field, South Africa and new data on wesselsite, SrCuSi4O10. Miner. Mag. 79, 1769–1778 (2015).

Verri, G. et al. The goddess’ new clothes: the carving and polychromy of the Parthenon Sculptures. Antiquity 97, 1173–1192 (2023).

Coimbra, M. M. et al. Shedding light on cuprorivaite, the egyptian blue pigment: joining neutrons and photons for a computational spectroscopy study. Cryst. Growth Design. 23, 4961–4969 (2023).

Wiedemann, H.-G. & Bayer, G. Trends and applications of thermogravimetry. in Inorganic and Physical Chemistry 67–140 (1978).

Pagès-Camagna, S. et al. New insights into the colour origin of archaeological Egyptian blue and green by XAFS at the Cu K-edge. X-Ray Spectr. 35, 141–145 (2006).

Tite, M. S., Bimson, M. & Cowell, M. R. Technological Examination of Egyptian Blue. in Archaeological Chemistry—III) 215-242 (American Chemical Society, 1984).

Aru, M., Burgio, L. & Rumsey, M. S. Mineral impurities in azurite pigments: artistic or natural selection? J. Raman Spectrosc. 45, 1013–1018 (2014).

García-Fernández, P., Moreno, M. & Aramburu, J. A. Origin of the anomalous color of Egyptian and Han Blue Historical Pigments: Going beyond the Complex Approximation in Ligand Field Theory. J. Chem. Ed. 93, 111–117 (2016).

Theophrastus, Caley, E.R. & translated Richards, J. F. C. Theophrastus. (On Stones, 1956).

Acknowledgements

E.P.V. and T.L. thank Dr. Susan Smith and the Smithsonian’s National Postal Museum for access to their VNIR spectrometer. The authors also wish to acknowledge Kate Smith of the Harvard Art Museums for assistance in capturing VIL images. The authors thank Ciara Cryst for helpful conversations and Arumala Josiah Lere-Adams for early XRD work. No direct funding was received for the completion of this project. The Joint Center for Research in Earth Abundant Materials (JCDREAM) and the Murdock Charitable Trust are acknowledged for funding the nano-CT instrument used in the Institute of Materials Research at Washington State University. TAO was supported by the Henry L. Hillman Foundation.

Author information

Authors and Affiliations

Contributions

Conceptualization: J.S.M., T.A.O., L.S.H. Methodology: J.S.M., E.V., J.E. Investigation: E.V., T.L., M.C.M.W., J.B., S.K., J.E., M.S. Visualization: T.A.O., E.V. Supervision: J.S.M. Writing—original draft: J.S.M., J.E. Writing—review & editing: J.S.M., E.V., T.L., J.E., T.A.O., L.S.H., J.B., M.C.M.W., and S.K.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

McCloy, J.S., Vicenzi, E.P., Lam, T. et al. Assessment of process variability and color in synthesized and ancient Egyptian blue pigments. npj Herit. Sci. 13, 202 (2025). https://doi.org/10.1038/s40494-025-01699-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s40494-025-01699-7

This article is cited by

-

Unexpected Egyptian blue in Renaissance paintings: identification in works by Perugino and “Lo Spagna” in the Louvre collection

Rendiconti Lincei. Scienze Fisiche e Naturali (2025)