Abstract

High-resolution 3D printing, particularly electrohydrodynamic (EHD) printing, represents a transformative approach for advanced manufacturing applications, including wearable electronics, bioelectronics, and soft robotics. Despite its potential, EHD printing faces challenges such as complex waveform control, limited material compatibility, satellite droplet formation, and continuous charge accumulation. To address these issues, the use of pulse-width modulation (PWM) control is proposed to enhance EHD printing performance. The influence of duty cycles and pulse subdivisions on EHD printing was systematically investigated through experiments and simulations, analyzing their effects on jetting dynamics, droplet formation, charge accumulation, and line quality. The results demonstrate that PWM modulation significantly improves jetting stability, reduces droplet diameter by up to 25%, minimizes satellite droplet formation, and effectively mitigates charge accumulation. Furthermore, PWM control was shown to facilitate the production of high-quality patterns. Notably, the proposed PWM approach is compatible with existing waveform control setups, offering enhanced precision and stability without requiring substantial modifications. These findings underscore the potential of PWM-controlled EHD printing for achieving high-resolution, versatile manufacturing in electronics and functional device production.

Similar content being viewed by others

Introduction

High-resolution 3D printing, also known as additive manufacturing (AM), has emerged as a transformative technology in advanced manufacturing, providing the ability to create complex, freeform electronic structures essential for wearable electronics, bioelectronics, soft robotics, and more. Recent developments have focused on various high-resolution 3D printing techniques, such as material jetting, extrusion, and polymerization, to fabricate functional electronic components like interconnects, batteries, and sensors1,2,3. These techniques enable miniaturization, high-aspect-ratio structures, and integration of multiple materials, which are key to addressing the needs of next-generation electronics4,5,6. The ability to form conductive and insulating patterns at nano-scales using novel printable inks has further expanded the potential applications of 3D printing, including wearable devices and complex electronic architectures7,8,9. As a result, these advancements have significantly enhanced the integration, performance, and scalability of electronic devices, enabling the development of high-precision, functional electronic structures10,11,12.

Electrohydrodynamic (EHD) printing offers unique advantages in resolution and material versatility. By applying an electric field to draw droplets or jets from the nozzle, EHD printing can create features significantly smaller than the nozzle diameter, achieving precision down to the micro and submicron scale. This capability extends its applicability to a wide range of challenging materials, including high-viscosity polymer melts and low-melting-point metals, expanding the potential applications for advanced electronic and biomedical devices13,14,15. By applying a high voltage, EHD printing forms a Taylor cone, from which fine droplets or jets of ink are emitted, allowing the deposition of intricate patterns on various substrates16,17,18. This technology is advantageous for its high resolution, material versatility, and its ability to avoid traditional mask-based lithography, making it highly suitable for applications in flexible electronics, biomedical sensors, and other demanding micro/nano devices19,20,21,22.

Printing precision, stability, and efficiency are core challenges that need to be addressed for advancing electrohydrodynamic (EHD) printing. Researchers have devoted significant efforts to tackle these issues. Studies have focused on optimizing the electric field control, nozzle design, and ink properties to achieve finer feature sizes and improve resolution15,23,24. For instance, precise modulation of the applied voltage and careful control over droplet formation at the nozzle tip are crucial in minimizing deviations in feature size and positioning.

In terms of electric field control, especially with regard to voltage waveform modulation, researchers have proposed various strategies to enhance printing precision. One significant approach involves replacing a continuous DC voltage with pulsed voltage, allowing for drop-on-demand (DOD) a technique where droplets are generated only when needed25,26,27. This method achieves controlled droplet formation by synchronizing droplet ejection with the pulsed voltage, ensuring that only a single droplet is released per pulse, which improves placement accuracy and material efficiency28,29.

Gong et al. achieved high-frequency EHD drop-on-demand (DOD) printing by adjusting the voltage waveform, successfully controlling droplet size to approximately 6 μm30,31,32,33. Li et al., through numerical simulations, segmented the pulsed waveform into two phases, ensuring the consistency of the Taylor cone and enabling stable printing34. Chen et al. employed an alternating current (AC) voltage to control jetting, effectively reducing the formation of satellite droplets35. Yang et al. categorized the jetting process into four distinct stages and modulated the voltage at each stage to control the Taylor cone’s morphology during ejection36. This approach enabled the successful printing of 3μm silver lines on a glass substrate.

Despite the variety of voltage waveforms currently designed for EHD printing, two common challenges remain. First, the complexity of waveform design often limits its applicability; many waveforms are tailored for specific ink or substrate materials, and researchers frequently do not provide clarity on the broader applicability of these waveforms. Second, in EHD drop-on-demand (DOD) printing, single-jet ejections or individual droplet prints are typically treated as the smallest operational unit, with adjustments to frequency or voltage made to control the printing process. While this approach is generally effective, the amplitude of each voltage pulse is constrained, as both increases and decreases in voltage can lead to undesirable jetting behaviors.

Building on these challenges, we propose a novel solution using pulse-width modulation (PWM) waveform control to enhance the jetting process. This approach is inspired by traditional motor control, where PWM has been widely adopted. In PWM control, a continuous signal is modulated by adjusting the pulse duration (or duty cycle) within a fixed period, allowing precise control over power delivery without continuously varying the voltage. This provides a series of rapid on-off pulses, where the effective voltage perceived by the system is determined by the ratio of pulse width to the overall cycle duration.

The voltage application method is illustrated in Fig. 1a. The conventional voltage application, as shown in the upper part of Fig. 1b, involves continuous voltage loading, which leads to continuous charge accumulation. In contrast, the PWM waveform, depicted in the lower part of Fig. 1b, applies voltage intermittently, thereby reducing charge accumulation. By splitting the pulse into smaller sub-pulses, PWM voltage control achieves higher effective frequencies. This allows for more precise modulation of the electric field and better control of the droplet ejection process. PWM control enables fine-tuning of the duty cycle and subdivision number, providing additional control parameters to adapt to various liquid properties and operational conditions. As shown in Fig. 1c, the growth rate of the Taylor cone decreases when voltage is not applied under PWM control. This leads to a reduction in droplet size under the same time conditions.

For EHD printing, PWM control offers distinct advantages. PWM’s adjustable duty cycle enables precise control over jetting dynamics, reducing unnecessary energy input and helping to minimize issues like satellite droplet formation. Additionally, PWM allows for fine-tuning the jetting process without drastically altering voltage amplitude, overcoming limitations related to single-pulse amplitude constraints in conventional EHD DOD approaches. This flexibility can improve adaptability to various ink viscosities and substrate properties, broadening the scope of materials and conditions suitable for high-precision EHD printing.

Specifically, this study will focus on the following key objectives:

-

1.

To develop and validate numerical simulations that model the fluid dynamics during the jetting process, including meniscus formation, jet elongation, charge density and droplet ejection under different PWM waveforms.

-

2.

To compare the experimental and simulation results to identify the optimal PWM parameters that yield stable, high-quality conductive lines with minimal deviation in line width and droplet formation.

-

3.

To assess the electrical performance of the printed nano-silver patterns, particularly in terms of their conductivity and reliability under mechanical deformation, such as bending, which is a critical requirement for flexible and wearable electronic applications.

The insights gained from this study will not only contribute to a deeper understanding of the PWM-controlled EHD printing process but also provide practical recommendations for improving the fabrication of flexible electronics. This is particularly relevant for industries seeking to develop next-generation electronic devices that demand both high performance and durability in dynamic environments. Most importantly, we believe this new solution is applicable to a wide range of practical EHD printing scenarios and can further enhance printing performance based on existing approaches. We consider this method to be a highly promising technological advancement with significant potential for future development.

Method and experiments

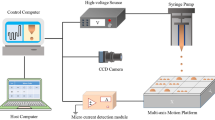

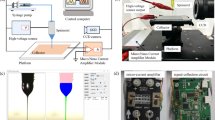

The three-axis electrohydrodynamic (EHD) printing platform is an advanced system designed for high-precision deposition of materials at micro- and nanoscale resolutions as shown in Fig. 2a. The platform comprises several interconnected components that work in harmony to achieve accurate printing results. The syringe pump feeds the ink to the nozzle, where the high-voltage generator facilitates its deposition onto the substrate. The CCD camera and flash lamp provide monitoring and material processing capabilities as shown in Fig. 2c. The computer acts as the control hub, ensuring all components function cohesively to produce precise and reliable EHD printing outcomes.

In this study, we replaced the traditional pulsed voltage waveform with a Pulse Width Modulation (PWM) waveform to drive the electrohydrodynamic (EHD) printing process (as illustrated in Fig. 2b). In typical pulse voltage control, the pulse width generally ranges from several hundred microseconds to several milliseconds. Based on existing research, the minimum pulse width should be greater than both the hydrodynamic relaxation time and the Rayleigh time of the liquid. This ensures sufficient time for the formation of a stable Taylor cone-jet mode. In contrast, our PWM voltage control method subdivides the typical pulse into N smaller sub-pulses, with each sub-pulse having a width on the order from tens to several hundred microseconds. The PWM waveform maintains a constant high-voltage amplitude but modulates the duration of the voltage application by adjusting the duty cycle and frequency. By varying the duty cycle—the ratio of the pulse width (time the voltage is high) to the total period—we achieved precise control over the average electric field applied between the nozzle and the substrate. This precise modulation of the electric field allowed for finer control over the jetting behavior of the ink, leading to more consistent droplet formation and improved deposition accuracy on the substrate. Utilizing the PWM waveform enhanced the stability and resolution of the EHD printing process compared to traditional pulsed voltage methods.

The Fig. 2d illustrates the forces acting on a Taylor cone and its ensuing jet during electrohydrodynamic jetting: a liquid emerges from a nozzle (high voltage electrode), forming a conical shape known as the Taylor cone, which extends into a thin jet directed toward a substrate (ground electrode); the primary forces depicted include the electric field force (Fe) acting downward along the cone and jet surfaces, pulling the charged liquid toward the substrate; the surface tension force (Fγ) acting inward perpendicular to the liquid surfaces, resisting deformation and minimizing surface area; the pressure gradient force (Fp) driving the liquid flow downward inside the jet due to internal pressure differences; the viscous force (Fμ) opposing the flow upward inside the jet, representing internal fluid friction; and gravity (G) acting downward on the liquid mass; additionally, electric field lines are shown as dashed lines extending from the nozzle to the substrate, indicating the electric field distribution, with annotations labeling the nozzle, substrate, Taylor cone, jet, and each force, thereby providing a comprehensive visualization of how these forces interact to form and sustain the Taylor cone and jet in the electrohydrodynamic process. Jet deflection adversely affects positioning accuracy, which is particularly critical in high-precision printing applications. To mitigate these effects, we have implemented strict controls during large-scale printing to ensure verticality of the jet. This includes minimizing environmental airflow, verifying nozzle symmetry and alignment, and employing precise installation techniques to ensure perpendicularity between the nozzle and the substrate.

In our electrohydrodynamic (EHD) simulation model, we employed the Volume of Fluid (VOF) method within OpenFOAM for three-dimensional modeling of the printing process. The VOF method is particularly effective for tracking and capturing the interface between the liquid ink and the surrounding air, which is crucial in simulating the jet formation and breakup in EHD printing. This method allows for accurate representation of the complex free surface dynamics and interfacial phenomena inherent in the process as shown in Fig. 2e.

The computational domain was discretized using a non-uniform mesh density. Specifically, the mesh was refined densely along the central axis—where the most significant fluid dynamics and electric field interactions occur—and became progressively coarser toward the edges of the domain as shown in Fig. 2f. This mesh refinement strategy was adopted to accurately capture the steep gradients in velocity, pressure, and electric field near the nozzle and the jet, while reducing computational demands in regions with less activity. The finer mesh in the central region ensures higher resolution of critical flow features and charge distributions, enhancing the precision of the simulation results. The coarser mesh at the periphery effectively reduces the total number of computational cells, optimizing the simulation efficiency without compromising overall accuracy.

By integrating the VOF method with this tailored mesh configuration in OpenFOAM, we effectively simulated the complex multiphase flow and electrohydrodynamic effects involved in the EHD printing process. This approach allowed us to analyze the jetting behavior and droplet formation with high fidelity, providing valuable insights into the optimization of printing parameters for improved deposition accuracy. More detailed simulation settings can be found in several related papers previously published by our team25,26,27 and Supporting document S1. The evolution of the Taylor cone obtained from the simulations (Fig. 2f left) aligns closely with the experimentally captured Taylor cone (Fig. 2f right) at the same time points, demonstrating the accuracy of the numerical model.

Results and discussion

The influence of duty cycle on the injection process

To investigate the impact of different duty cycles on EHD printing, multiple sets of experiments and simulations were conducted. In both experiments and simulations, a nozzle with an outer diameter of 150μm was used, and blue photocurable ink served as the material. The voltage amplitude was set to 1300 V with a subdivision number of 10. Experiments and simulations were performed at duty cycles ranging from 50% to 100% (typical pulse waveform at 100%), with intervals of 5% between each test.

Figure 3a demonstrates that as the duty cycle is reduced, the printing precision increases, evidenced by a decrease in droplet size. Notably, when the duty cycle drops below 70%, the jetting process fails entirely, as indicated by the red-shaded region, representing an unprintable zone. Experimental observations confirm stable jetting at duty cycles of 80% and above, leading to the classification of the yellow-shaded region as an unstable yet printable zone. This zone may still allow for droplet formation but lacks the consistency required for reliable printing. The green-shaded region, however, signifies a fully stable printing zone.

At a duty cycle of 70% (Fig. 4 Droplet diameter statistics. (a) Duty cycle of 70%. (b) Duty cycle of 80% Fig. 4a), the droplet size distribution spans a wide range, from less than 10μm to nearly 25 μm. This substantial variation indicates poor jetting stability under these conditions. The significant size fluctuations suggest that the jetting process is highly susceptible to disturbances, resulting in inconsistent droplet formation. The cumulative frequency curve exhibits a relatively gradual increase, further emphasizing the dispersed nature of the droplet size distribution.

In contrast, when the duty cycle is increased to 80% (Fig. 4b), the droplet size distribution becomes significantly more concentrated within the range of 20–25 μm, demonstrating improved size uniformity. The cumulative frequency curve shows a steeper growth trend, indicating that the majority of droplets are confined to a narrower size range. This observation suggests that a higher duty cycle stabilizes the electric field force during the jetting process, reducing instability and enabling the generation of more uniform droplets.

Within this stable range, progressively lowering the duty cycle enhances printing precision, allowing for finer control over droplet size without risking instability. In Fig. 3b, we see patterns of continuous droplets printed at duty cycles of 100%, 95%, 90%, 85%, and 75%, displayed sequentially from left to right. A noticeable reduction in droplet size is observed at an 85% duty cycle, where the diameter of the circular droplet (formed by a single DOD event) shrinks to approximately 75% of its size at a 100% duty cycle. Upon entering the unstable printing region (at a 75% duty cycle), the droplet size is further reduced to around 55% of its initial size, indicating a marked impact of lower duty cycles on droplet morphology and size control. Figure 3c further elucidates the jetting process under decreasing duty cycles, with a clear visual progression showing the Taylor cone becoming increasingly narrower as the duty cycle is lowered. This thinning of the Taylor cone reflects a direct influence of duty cycle reduction on jetting dynamics, affirming that lower duty cycles effectively enhance printing precision. The gradual tapering of the Taylor cone structure underscores the potential of duty cycle modulation as a means of achieving finer, more precise droplet control in EHD printing applications.

The Fig. 5 illustrates the variation of average charge density with respect to time for different duty cycles, ranging from 50% to 100%. Overall, the trend shows that as the duty cycle increases, the charge density also increases. This indicates a stronger charge accumulation effect at higher duty cycles. Notably, for duty cycles below 70%, a distinct ‘stepped’ pattern appears in the charge density profile. This feature is particularly evident in the lower duty cycles, suggesting that at lower duty cycles, the charging process is interrupted more frequently, leading to periodic reductions in the rate of charge accumulation. The stepped characteristic indicates the influence of the intermittent nature of the applied voltage, which becomes more prominent as the duty cycle decreases, thus preventing continuous charge growth. As the duty cycle approaches 100%, the curve becomes smoother, implying a continuous increase in charge density without significant interruptions. The result indicates that the duty cycle has a significant impact on the charging behavior, and reducing it can effectively moderate the rate of charge accumulation over time.

To further investigate the impact of different duty cycles on EHD jetting, calculating the fluid velocity field is essential. Figure 6 displays the velocity field’s Z-axis component (vertical velocity) for different PWM duty cycles (50, 75, 85, and 100%) at the same simulation time. The color map illustrates the velocity magnitude along the Z-axis. At a 50% duty cycle, the velocity field is relatively weak, with only moderate upward flow near the central axis of the fluid meniscus. The flow remains mostly symmetric with limited vertical acceleration, indicating that the intermittent application of voltage is insufficient to sustain a strong jet. As the duty cycle increases to 75%, the upward velocity becomes more pronounced, particularly along the jet axis. The flow field shows enhanced vertical movement, with stronger gradients developing near the jet center, suggesting that the increased duty cycle provides more energy to accelerate the fluid upwards. At 85%, the velocity field further intensifies. The flow structure indicates a stronger and more stable jet, as shown by the higher concentration of upward velocity at the jet core. The vortices near the meniscus are also more defined, reflecting increased fluid acceleration and a more focused flow direction. Finally, at 100% duty cycle, the flow field exhibits the highest velocity magnitude along the Z-axis, particularly at the center of the jet. The velocity gradients are sharp, indicating a fully developed jet with strong upward momentum. Calculation results indicate that reducing the duty cycle effectively decreases fluid velocity, which is one reason for improved precision. Additionally, in situations where a reduced jetting velocity is required, lowering the duty cycle can be a useful approach.

Through the calculation of the flow field, we obtained the evolution process of the Taylor cone at different time points. Figure 7 illustrates the impact of varying PWM duty cycles (50%, 75%, 85%, and 100%) on the electrodynamic jet formation process at the same simulation time point. The progression of the jetting dynamics is clearly influenced by the duty cycle, which directly affects the temporal modulation of the applied voltage. At a 50% duty cycle, the meniscus begins to deform, but no full jet formation occurs. The applied voltage is insufficient to induce continuous jetting, resulting in a limited elongation of the fluid meniscus. As the duty cycle increases to 75%, the meniscus experiences greater deformation, with the onset of jet formation becoming apparent. However, the jet remains unstable and does not fully extend. At 85%, the fluid meniscus extends further, and a continuous jet is observed. The increased duty cycle allows for more sustained voltage application, resulting in the formation of a stable jet that nearly reaches the substrate. Finally, at 100% duty cycle, the jet fully extends and droplets begin to form, indicating the highest level of fluid extrusion due to the constant voltage application. The simulation results indicate that reducing the duty cycle is feasible without compromising jetting behavior. Lower duty cycles still allow for effective and stable jetting, with PWM modulation enabling fine control over jetting dynamics and material deposition. This highlights the potential of duty cycle adjustments to achieve precise printing while maintaining consistent droplet formation.

The influence of pulse refinement on the injection process

This section aims to examine the impact of pulse refinement, an essential parameter in PWM waveforms, on the EHD printing process. We conducted a series of experiments and simulations with pulse counts ranging from 10 to 28, increasing by increments of 2 per experiment. By analyzing the effect of varying pulse counts, this study seeks to better understand how pulse refinement influences jetting stability, droplet formation, and overall printing precision in EHD applications.

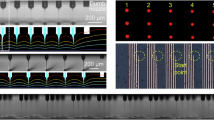

The graph in Fig. 8a shows that, in general, increasing the number of pulses leads to a reduction in droplet size. However, both the experimental and simulation results indicate that the decrease in droplet size is relatively minor—less than 3%—when the number of pulses increases from 10 to 28. This is especially evident compared to the impact of reducing the duty cycle, suggesting that pulse refinement has a relatively weaker influence on droplet size and overall printing performance. Figure 8b illustrates the droplet patterns for different pulse counts (10, 14, 18, 22, and 28, from left to right). The droplet patterns appear consistent across different pulse counts, with only minor variations in size and distribution. This suggests that while pulse refinement does have a slight effect on droplet morphology, it does not significantly alter the overall pattern formation, reinforcing the conclusion that the influence of pulse number on print quality is limited. Figure 8c displays the evolution of the jetting process during printing. The images show a consistent jetting behavior across different stages, with no substantial changes observed as the pulse count is modified. The Taylor cone forms predictably, and the droplet detachment process remains stable throughout, indicating that changes in the number of pulses do not drastically affect the stability or dynamics of jetting, further supporting the notion that the pulse count has a minimal effect on the printing process.

Using the same method as in the previous section, we calculated the evolution of the Taylor cone under different pulse count conditions. Figure 9 demonstrates the impact of varying pulse subdivision numbers on the electrodynamic jetting process. Across these cases, the Taylor cone formation and jetting behavior are visualized over time to assess how the subdivision of the pulse influences the jet formation, stability, and droplet ejection dynamics. In all cases, the Taylor cone exhibits stable formation, with no significant changes in cone size or shape as the pulse subdivision increases from 10 to 28. This suggests that the subdivision number does not drastically affect the overall meniscus or jet formation dynamics in terms of cone size or elongation. However, a notable phenomenon observed with higher pulse subdivisions is the formation of satellite droplets. As the pulse subdivision increases, these satellite droplets are generated along the main jet, particularly evident in the cases with subdivision numbers of 22 and 28.

The appearance of satellite droplets can be attributed to the finer temporal control of the electric field due to increased pulse subdivision. While higher subdivisions enhance the precision of the jetting process, they can also introduce additional instability in the fluid breakup, leading to the formation of secondary droplets. These satellite droplets pose a challenge in maintaining the desired printing resolution and accuracy, as they can cause unintended material deposition.

While the Taylor cone’s overall size and shape remain relatively unaffected by the increase in pulse subdivisions, the higher subdivision numbers lead to an increased likelihood of satellite droplet formation. This highlights a trade-off between enhanced control through finer pulse subdivision and the risk of introducing droplet instability. These findings are critical for optimizing the electrodynamic jetting process, where precise control over jetting dynamics is necessary to balance accuracy and stability in conductive pattern fabrication.

Applicability of PWM waveforms

This section evaluates the applicability of PWM waveforms in different scenarios, focusing on their performance with inks of varying viscosities and surface tensions, as well as their adaptability to different control waveforms and substrate types.

Viscosity was adjusted using glycerol, while surface tension was controlled with leveling agents. The experimental data are summarized in Table 1, with the corresponding jetting behaviors and droplet patterns illustrated in Fig. 10a–j.

For inks with varying viscosities (Inks 1–3 in Table 1), higher viscosity resulted in thinner jets, which enhanced droplet precision. This trend is evident in Fig. 10a–c, where the jet becomes progressively thinner as viscosity increases. However, the formation of the Taylor cone required more time, leading to a reduction in jetting frequency. In contrast, low-viscosity inks (e.g., Ink 1) produced larger satellite droplets due to insufficient resistance to surface tension forces, as shown in Fig. 10d. PWM voltage control with an 85% duty cycle effectively reduced satellite droplet formation and improved droplet uniformity, as demonstrated in Fig. 10e. This highlights the adaptability of PWM control in managing low-viscosity inks to achieve consistent printing results.

For inks with varying surface tensions (Inks 4–6 in Table 1), lower surface tension facilitated the initiation of jetting by reducing resistance; however, it often resulted in jet instability during the retraction phase. This instability led to the formation of smaller, scattered droplets, as observed in Fig. 10i. Higher surface tension provided greater jetting stability but required increased voltage to form a Taylor cone. For low-surface-tension inks, stabilizing jetting was achieved by adjusting the PWM duty cycle to 80%, which extended the duration of the electric field application. This adjustment enhanced the stretching force on the jet and minimized droplet fragmentation, as shown in Fig. 10j.

These experiments demonstrate that viscosity and surface tension play critical roles in jetting behavior and printing stability. PWM voltage control effectively addresses these challenges by enabling real-time adjustments to the duty cycle and frequency. This approach reduces satellite droplet formation in low-viscosity inks and stabilizes jetting for low-surface-tension inks, underscoring the versatility of PWM control in optimizing precision and stability across diverse material properties.

To provide a comprehensive comparison and emphasize the unique advantages of PWM voltage control, additional analyses were conducted alongside other drop-on-demand (DoD) techniques, including biased voltage pulse, trapezoidal voltage, and AC voltage. The outcomes of these comparisons are presented in Fig. 11 and Table 2. To evaluate the adaptability of PWM control across various substrate properties, experiments were performed on six substrates with differing roughness, thickness, and material compositions. As shown in Table 2, PWM control was implemented with adjustable duty cycles and voltage amplitudes optimized for each substrate.

a Existing EHD-printing waveform control method. b Waveform after applying the PWM method. c Printed dot array on silanized glass. d Printed dot array on a microscope slide. e Printed dot array on PET film. f Printed dot array on photo paper. g Printed dot array on a copper plate. h Printed dot array on FR4

Biased voltage pulse and trapezoidal voltage demonstrated reasonable droplet uniformity under specific conditions but showed limited adaptability to substrates with high roughness or complex material properties. In contrast, PWM voltage control exhibited consistent droplet uniformity and spacing across all tested substrates. For example, on silanized glass (Sa = 0.6513), PWM achieved more uniform droplet patterns compared to biased voltage pulse (Figure c vs. Figure d). Similarly, on PET film (Sa = 0.6430), trapezoidal voltage resulted in irregular patterns, whereas PWM control maintained stable jetting and droplet formation (Fig. 11f vs. Fig. 11g).

The advantages of PWM voltage control were particularly evident on challenging substrates, such as copper plates and photo paper, where high roughness or low surface adhesion often destabilize conventional DoD methods. On these substrates, PWM control minimized satellite droplet formation and improved droplet uniformity, as shown in Fig. 11g, h. Unlike trapezoidal voltage, which requires intricate optimization of waveform slopes, PWM achieved similar or superior performance through straightforward duty cycle adjustments, eliminating the need for waveform-specific tuning.

The experimental findings indicate that PWM voltage control not only expands the operational window compared to biased voltage pulse and trapezoidal voltage but also reduces hardware complexity compared to AC voltage. By enabling real-time adjustments of duty cycle and frequency, PWM control provides a versatile and efficient approach for high-resolution printing on substrates with diverse properties.

Printing conductive patterns using PWM waveforms

In this subsection, to verify the effectiveness of the experimental method, nano-silver material (with a viscosity of 150 cP) was used as the ink to print continuous lines and patterns. All tests were conducted under atmospheric pressure (101.3 kPa) with an ambient temperature maintained between 23–25 °C. For higher precision experiments, particularly those requiring micron-scale accuracy, the temperature was controlled within ±1 °C. Humidity was adjusted between 40 and 60%.

Figure 12 provides an analysis of the effects of voltage and duty cycle modulation on the quality and consistency of printed nano-silver lines, highlighting both the advantages and limitations of these parameter adjustments for EHD printing. Figure 12a illustrates the outcome when the applied voltage is reduced from 1300 V to 1200 V. The lowered voltage results in a reduction of jetting velocity, which subsequently leads to the appearance of scalloping along the printed lines. This is attributed to the decreased momentum of the ink stream, which results in an unstable deposition process. The reduction in voltage weakens the electric field strength, leading to inconsistent droplet ejection that forms the wavy “scalloped” structures seen along the printed lines. In Fig. 12b, the printed pattern at an 85% duty cycle is presented, demonstrating well-defined edges and high boundary precision. The use of an 85% duty cycle appears to achieve an optimal balance between jetting stability and control over droplet deposition, resulting in uniform line formation. The reduced duty cycle contributes to finer control over the jetting dynamics, allowing for improved spatial resolution without compromising the consistency of the printed lines. Figure 12c shows the results when the duty cycle is further decreased from 79% to 75%. While this reduction effectively narrows the printed line width, there is a noticeable deterioration in edge precision. The instability at lower duty cycles may lead to fluctuating Taylor cone dynamics, resulting in uneven droplet formation and irregular line boundaries. This suggests that while reducing the duty cycle can improve resolution, there is a trade-off in terms of the stability of droplet ejection, where reduced duty cycles led to diminished line quality due to inconsistent jetting behavior. Figure 12d demonstrates the outcome when the duty cycle is further decreased to 70%, where discontinuities in the printed lines are evident. At this lower duty cycle, the reduced effective voltage causes insufficient energy for consistent droplet ejection, leading to breaks in the printed pattern. This phenomenon supports the notion that duty cycles below a certain threshold can disrupt the printing process, ultimately compromising the continuity of the printed structures. Both voltage and duty cycle are crucial parameters in controlling the quality of EHD printing. Lowering the voltage may lead to undesirable scalloping due to reduced jetting velocity, while decreasing the duty cycle has the potential to improve printing resolution but at the cost of stability. Specifically, duty cycles between 80% and 85% appear to provide an optimal trade-off between precision and stability, allowing for high-quality, continuous lines with well-defined boundaries. Excessively low duty cycles (such as 70%) can cause discontinuities, highlighting the need for careful optimization of these parameters to achieve desired printing outcomes. These findings suggest that the control of both voltage and duty cycle is essential for maintaining high-resolution and consistent printed features in EHD applications. The video of the circuit printing process can be found in Supplementary S2.

Figure 13 demonstrates the practical application of PWM waveform control in electrohydrodynamic (EHD) printing, particularly in fabricating conductive circuits on flexible materials and intricate grayscale patterns on glass substrates. Figure 13a illustrates the process of printing nano-silver circuits onto a flexible PET substrate. The setup includes a test electrode and nano-silver ink deposited onto the PET substrate using a PWM-controlled EHD printing approach. By leveraging the advantages of PWM modulation, such as precise control over droplet size and deposition rate, this method enables the creation of well-defined conductive pathways, which are essential for flexible electronics. The PWM waveform modulation, as discussed in previous sections, is critical for balancing precision and jetting stability, allowing the printed structures to maintain both flexibility and conductivity. Figure 13b presents the printed results, where the nano-silver circuits on PET are shown. The printed circuit is flexible and can be applied directly to wearable electronics, as depicted in the image on the left. The zoomed-in view highlights the precision achieved with the PWM-controlled process, with uniform line width and minimal defects. The consistency in the printed lines confirms the effectiveness of the PWM-modulated jetting in maintaining droplet stability, which is crucial when printing onto deformable substrates like PET. This capability demonstrates the potential of PWM-controlled EHD printing for applications in flexible and wearable electronics, where the ability to conform to complex surfaces without compromising performance is key. Figure 13c shows another application of PWM-controlled EHD printing, where grayscale images are printed onto glass substrates. The images were processed into grayscale dot patterns, which were then printed using a drop-on-demand (DOD) approach controlled by the PWM waveform with a droplet diameter of 7 microns and a resolution of 3600 DPI can be achieved. The leftmost image shows the overall setup, with the printed glass slide in hand. The detailed images on the right reveal the high fidelity of the printed patterns, capturing complex structures like the Parthenon, Big Wild Goose Pagoda and Terracotta Warriors. The video of the on-demand printing process can be found in Supplementary S3.

The application of PWM modulation allowed for precise control of droplet deposition, enabling fine gradations in grayscale that are essential for rendering such detailed imagery. This demonstrates the versatility of PWM-controlled EHD printing in producing intricate patterns, not only for electronic circuitry but also for decorative or functional elements that require high-resolution patterning. The use of PWM waveforms in EHD printing has proven to be an effective strategy for enhancing both the precision and versatility of printed patterns. Whether it is for creating conductive circuits on flexible PET substrates or intricate grayscale patterns on glass, PWM control plays a pivotal role in regulating droplet formation and ensuring consistent deposition. This ability to fine-tune the printing process opens up a wide array of potential applications, from wearable electronics and sensors to artistic and functional coatings.

Conclusion

This study successfully demonstrated the application of PWM waveform control in electrohydrodynamic (EHD) printing to enhance printing precision, stability, and adaptability. Through both experimental and numerical simulations, it was shown that PWM control, specifically via adjustments in duty cycle and pulse subdivision numbers, allows for effective modulation of the printing process, enabling precise control over droplet size and jetting behavior. Lower duty cycles were shown to improve edge precision, resulting in a reduction of droplet diameter by approximately 25%, while still maintaining stable printing. However, reducing the duty cycle below 75% led to discontinuities in the printed lines, indicating the need for careful optimization to balance precision and print continuity. Furthermore, increasing pulse subdivision from 10 to 28 was observed to reduce droplet size by up to 3%, though higher subdivisions also increased the likelihood of satellite droplet formation, highlighting a trade-off between precision and stability.

Compared to existing control waveforms, such as biased voltage pulse, trapezoidal voltage, and AC voltage, PWM modulation demonstrated clear advantages in adaptability and performance. PWM control provides finer, real-time tunability by enabling adjustments to duty cycles and pulse frequencies, which are challenging to achieve with conventional methods. For example, on smooth substrates, PWM achieves comparable or superior results to AC voltage with reduced hardware complexity. On rougher substrates, PWM outperforms trapezoidal voltage by maintaining consistent droplet uniformity and compensating for surface irregularities. These improvements position PWM as a versatile solution for high-precision printing across diverse material types and conditions.

The applicability of PWM control was further validated with inks of varying viscosities and surface tensions, as well as on substrates with different properties. For low-viscosity inks, PWM effectively minimized satellite droplet formation, while for high-viscosity inks, it maintained stable jetting and enhanced droplet precision. For inks with low surface tension, PWM reduced scattering during the jetting process by optimizing the duration of electric field application. Similarly, PWM performed consistently across substrates with varying roughness, including flexible PET films and rigid glass, achieving high-resolution printing results. These capabilities underscore the robustness of PWM modulation in managing diverse ink-substrate combinations and meeting the demands of complex printing environments.

The use of PWM-controlled EHD printing demonstrated significant advantages in printing conductive patterns on flexible substrates like PET, achieving line widths as narrow as 20 μm with minimal deviation, as well as in generating detailed grayscale patterns on glass. These results confirm that PWM modulation offers improved control over jetting dynamics and material deposition, thus enabling more consistent, high-quality patterning with 3600 DPI. The findings from this study provide valuable insights for the advancement of high-resolution, flexible electronics manufacturing. Overall, PWM-controlled EHD printing is positioned as a promising technology with substantial potential for the fabrication of next-generation electronic devices, combining high performance with the adaptability required for use in dynamic environments.

References

Kim, I. et al. Microstructures in all-inkjet-printed textile capacitors with bilayer interfaces of polymer dielectrics and metal–organic decomposition silver electrodes. ACS Appl. Mater. Interfaces 13, 24081–24094 (2021).

Jung, C. et al. Electrohydrodynamic‐Printed Polyvinyl Alcohol‐Based Gate Insulators for Organic Integrated Devices. Adv. Eng. Mater. 24, 2100900 (2022).

Vescio, G. et al. Flexible inkjet printed high-k HfO 2-based MIM capacitors. J. Mater. Chem. C. 4, 1804–1812 (2016).

Park, Y.-G. et al. Three-dimensional, high-resolution printing of carbon nanotube/liquid metal composites with mechanical and electrical reinforcement. Nano Lett. 19, 4866–4872 (2019).

Kwon, J. et al. Three-dimensional monolithic integration in flexible printed organic transistors. Nat. Commun. 10, 54 (2019).

Yuan, X. et al. A 3D-printed, alternatively tilt-polarized PVDF-TrFE polymer with enhanced piezoelectric effect for self-powered sensor application. Nano Energy 85, 105985 (2021).

Liu, X. et al. Ionic liquid-assisted 3D printing of self-polarized β-PVDF for flexible piezoelectric energy harvesting. ACS Appl. Mater. Interfaces 13, 14334–14341 (2021).

Kim, S.-Y. et al. High-resolution electrohydrodynamic inkjet printing of stretchable metal oxide semiconductor transistors with high performance. Nanoscale 8, 17113–17121 (2016).

Jiang, S. et al. Flexible metamaterial electronics. Adv. Mater. 34, 2200070 (2022).

Kim, F. et al. Direct ink writing of three-dimensional thermoelectric microarchitectures. Nat. Electron 4, 579–587 (2021).

Scheideler, W. J. et al. Low‐temperature‐processed printed metal oxide transistors based on pure aqueous inks. Adv. Funct. Mater. 27, 1606062 (2017).

Lee, K.-H. et al. Ultrahigh areal number density solid-state on-chip microsupercapacitors via electrohydrodynamic jet printing. Sci. Adv. 6, eaaz1692 (2020).

Lai, W. et al. Electrospray deposition for electronic thin films on 3D freeform surfaces: From mechanisms to applications. Adv. Mater. Technol. 9, 2400192 (2024).

Li, Y. et al. Advanced multi-nozzle electrohydrodynamic printing: mechanism, processing, and diverse applications at micro/nano-scale. Int J. Extrem Manuf. 7, 012008 (2024).

Yin, Z. et al. Electrohydrodynamic printing for high resolution patterning of flexible electronics toward industrial applications. InfoMat 6, e12505 (2024).

Mkhize, N. & Bhaskaran, H. Electrohydrodynamic Jet Printing: Introductory Concepts and Considerations. Small Sci. 2, 2100073 (2021).

Yin, Z. et al. Flexible electronics manufacturing technology and equipment. Sci. China Technol. Sci. 65, 1940–1956 (2022).

Zhang, H. et al. Recent advances in nanofiber-based flexible transparent electrodes. Int. J. Extrem Manuf. 5, 032005 (2023).

Reizabal, A. et al. Electrohydrodynamic 3D Printing of Aqueous Solutions. Small 19, e2205255 (2023).

Su, R. et al. 3D-Printed Micro/Nano-Scaled Mechanical Metamaterials: Fundamentals, Technologies, Progress, Applications, and Challenges. Small 19, e2206391 (2023).

Cong, C. et al. Electrohydrodynamic printing for demanding devices: A review of processing and applications. Nanotechnol. Rev. 11, 3305–3334 (2022).

Jung, E. M., Lee, S. W. & Kim, S. H. Printed ion-gel transistor using electrohydrodynamic (EHD) jet printing process. Org. Electron 52, 123–129 (2018).

Hassan, R. U. et al. High-resolution, transparent, and flexible printing of polydimethylsiloxane via electrohydrodynamic jet printing for conductive electronic device applications. Polymers 14, 4373 (2022).

Wang, H. et al. High-efficiency and high-resolution patterned quantum dot light emitting diodes by electrohydrodynamic printing. Nanoscale Adv. 5, 1183–1189 (2023).

An, S. et al. Effect of viscosity, electrical conductivity, and surface tension on direct-current-pulsed drop-on-demand electrohydrodynamic printing frequency. Appl. Phys. Lett. 105, 214102 (2014).

Phung, T. H., Kim, S. & Kwon, K.-S. A high speed electrohydrodynamic (EHD) jet printing method for line printing. J. Micromech. Microeng. 27, 095003 (2017).

Guo, Y. et al. Pulsation Characteristics of Corona Discharge in Electrohydrodynamic Process Using Ionic Liquid. IEEE Trans. Plasma Sci. 47, 5234–5238 (2019).

Jamshidian, M., et al. Pulsed coaxial drop-on-demand electrohydrodynamic printing. Phys. Fluids, 35, 032110 (2023).

Coppola, S. et al. Drop-on-Demand Pyro-Electrohydrodynamic Printing of Nematic Liquid Crystal Microlenses. ACS Appl Mater. Interfaces 16, 19453–19462 (2024).

Gong, H. et al. Characterization of electrohydrodynamic drop-on-demand injection of viscoelastic fluids in pulsed voltage. J. Manuf. Process 94, 255–265 (2023).

Gong, H. et al. Research on the printing mechanism of electrohydrodynamic satellite-free droplets in pulsed voltage. J. Manuf. Process 101, 300–310 (2023).

Gong, H. et al. Additive Manufacturing for Terahertz Metamaterials on the Dielectric Surface based on Optimized Electrohydrodynamic Drop-on-demand Printing Technology. ACS Appl Mater. Interfaces 16, 4222–4230 (2024).

Gong, H. et al. Generation of neutral droplets via waveform optimization for stable electrohydrodynamic drop-on-demand printing. J. Manuf. Process 112, 103–111 (2024).

Li, H. et al. Residual oscillation suppression via waveform optimization for stable electrohydrodynamic drop-on-demand printing. Addit. Manuf. 55, 102849 (2022).

Chen, H. et al. Precise Electrohydrodynamic Direct-Write Micro-Droplets Based on a Designed Sinusoidal High-Voltage AC Power. Instruments 4, 7 (2020).

Yang, J., Cho, B. & Chung, J. Optimization of pulsed voltage waveform for electrohydrodynamic jetting on-demand. J. Mech. Sci. Technol. 32, 3775–3786 (2018).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No.U24B2053, 52035010), in part by Shaanxi Key Industry Chain Project under Grant 2020ZDLGY14-08, in part by the National 111 Project under Grant B14042, in part by Natural Science Basic Research Program of Shaanxi (Program No. 2023-JC-QN-0407 and 2023-JC-YB-320), in part by General Program of National Natural Science Foundation of China (No. 52275372), in part by the Aeronautical Science Foundation of China (Grant Nos. 20230018081023), in part by National Natural Science Foundation of China grant (Grant Nos. 52405411).

Author information

Authors and Affiliations

Contributions

Dongqiao Bai: Conceptualization, Methodology, Investigation, Writing - Original Draft. Jin Huang: Supervision, Funding acquisition, Writing - Review & Editing. Hongxiao Gong: Conceptualization, Methodology, Formal analysis, Writing - Review & Editing. Jianjun Wang: Software, Data curation, Validation. Mengyang Su: Visualization, Investigation. Pengbing Zhao: Resources, Project administration. Chaoyu Liang: Methodology, Formal analysis.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bai, D., Huang, J., Gong, H. et al. Application of pulse width modulation control in EHD waveform to optimize printing performance. Microsyst Nanoeng 11, 117 (2025). https://doi.org/10.1038/s41378-025-00901-x

Received:

Revised:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41378-025-00901-x