Abstract

A single-atom catalyst with generally regarded inert Zn–N4 motifs derived from ZIF-8 is unexpectedly efficient for the activation of alcohols, enabling alcohol-mediated alkylation and transfer hydrogenation. C-alkylation of nitriles, ketones, alcohols, N-heterocycles, amides, keto acids, and esters, and N-alkylation of amines and amides all go smoothly with the developed method. Taking the α-alkylation of nitriles with alcohols as an example, the α-alkylation starts from the (1) nitrogen-doped carbon support catalyzed dehydrogenation of alcohols into aldehydes, which further condensed with nitriles to give vinyl nitriles, followed by (2) transfer hydrogenation of C=C bonds in vinyl nitriles on Zn–N4 sites. The experimental results and DFT calculations reveal that the Lewis acidic Zn-N4 sites promote step (2) by activating the alcohols. This is the first example of highly efficient single-atom catalysts for various organic transformations with biomass-derived alcohols as the alkylating reagents and hydrogen donors.

Similar content being viewed by others

Introduction

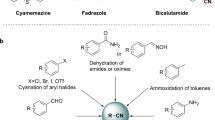

Nitriles are one of the most important and versatile functional groups in organic compounds, which can easily be diversified into numerous important products such as amines, amides, acids, and nitrogen-containing heterocycles1,2,3. Among different kinds of nitriles, α-alkylated nitriles are important building blocks in various bioactive natural products, pharmaceuticals, and agrochemicals4,5. Thus, the synthesis of α-alkylated nitriles has received great interest for a long time6,7,8. Traditional methods used alkyl halides as the alkylating reagents for the synthesis of α-alkylated nitriles, requiring large amounts of inorganic bases and reducing agents9. Moreover, these methods inevitably released stoichiometric amounts of toxic reagents, conflicting with the green chemistry principle. Thus, alternative methods are highly required for the synthesis of α-alkylated nitriles in an economical and environmentally friendly fashion.

Carbonyl compounds and alcohols are two kinds of the most readily available starting materials with relatively low cost, either from fossil fuel resources or renewable biomass10,11,12,13. Therefore, the use of carbonyl compounds or alcohols as the alkylating reagents for the synthesis of α-alkylated nitriles would be more attractive from a sustainable viewpoint, as it only releases water as the byproduct. Synthesis of α-alkylated nitriles from carbonyl compounds and nitriles starts from the base-catalyzed condensation of carbonyl compounds and nitriles to generate the vinyl nitrile intermediates, followed by the transition metal-catalyzed hydrogenation of vinyl nitrile intermediates into α-alkylated nitriles with H2 or other hydrogen donors14. Unlike carbonyl compounds, alcohols can serve as hydrogen donors and alkylating agents at the same time15. Therefore, it is highly desirable in the synthesis of α-alkylated nitriles with alcohols as the alkylating reagents by borrowing hydrogen strategy (Fig. 1, Prior work)6,16. As shown in Table S1, these methods for the α-alkylation of nitriles were almost based on homogeneous noble or non-noble metal complexes, including Ru17,18,19,20,21,22, Ir23,24,25, Rh26, Os27, Ni28,29,30,31, Co32,33,34,35, Mn36,37,38,39, and Fe complexes40,41. Different kinds of base additives, such as KOH, NaOH, and KOtBu, were required for these reported homogeneous catalytic systems. The air- and moisture-sensitive KOtBu and NaOtBu were the most common base additives with maximum loadings of up to 4 equiv.25. Generally, the reported homogeneous catalysts were active for aromatic alcohols and some limited aliphatic alcohols. For example, α-alkylation of phenyl acetonitrile with ethanol gave rise to a 69% yield of the aim product over Mn complex, while only a trace amount of the methylated product was observed in the α-alkylation with methanol under identical conditions36. Similar results were also observed over the homogeneous CoIII–NHC complex, which was only active for the C3~C10 aliphatic alcohols34. Moreover, the tedious preparation procedures for ligands and metal complexes, the difficult recycling and reuse of homogeneous metal complexes, and the possible contamination of aim pharmaceutical products by the trace amount of metal also limited the industrial application of homogeneous methods for α-alkylation. Therefore, it is highly desirable to design active and stable heterogeneous catalysts for the α-alkylation of nitriles with alcohols, but it remains challenging due to the intrinsic weak activity of supported metal nanoparticles.

To the best of our knowledge, there were few kinds of heterogeneous catalysts for the α-alkylation of nitriles with alcohols, including hydrotalcite-supported Ru (Ru/HT)42,43, MgO-supported Pd (Pd/MgO)44, and layered double hydroxide-supported Ag nanoparticles (Ag/Mg4Al-LDH)45 (Table S1). In these reported heterogeneous catalysts, the strong basic supports (HT, MgO, and Mg4Al-LDH) in these catalysts avoided the use of base additives. High-cost Ru/HT and Pd/MgO exhibited higher activity and stability compared with Ag/Mg4Al-LDH. An H2 treatment at 140 °C after each run was required for the Ag/Mg4Al-LDH catalyst to maintain its activity, although it still gradually decreased from 97% for the first run to 85% for the third run. Furthermore, the Ag/Mg4Al-LDH catalytic system was only limited to active aromatic alcohols (Table S1, Entry 34). Therefore, there still exists a large room to design novel heterogeneous non-noble catalyst systems for the α-alkylation of nitriles with alcohols, demonstrating the advantages in terms of high activity, broad range of substrate scope, and high stability.

Supported metal nanoparticles are the most common kind of heterogeneous catalysts for chemical reactions. The α-alkylation of nitriles with alcohols over supported metal nanoparticles started with the dehydrogenation of alcohols on the surface of metal nanoparticles, leaving two active hydrogen species (Hδ+ and Hδ–) on the surface of metal nanoparticles, which were used for the hydrogenation of vinyl nitrile intermediates. In this mechanism, the key dehydrogenation step was much easier for aromatic alcohols compared with aliphatic alcohols due to the enhancement of electron density on the α-Csp3–H bond by the conjugated aromatic ring. Thus, the cleavage of a negative H atom from the α-Csp3–H bond to the metallic surface was much easier as compared with that for aliphatic alcohols46,47. Therefore, the above-mentioned heterogeneous catalysts (Pd–MgO and Ag/Mg4Al-LDH) were only active for the α-alkylation of nitriles with aromatic alcohols.

In contrast to the dehydrogenation mechanism, the hydrogen transfer mechanism could also proceed via the direct hydrogen atom transfer from alcohols to the hydrogen acceptors, such as the –NO2 group and C=N bonds. In the hydrogen transfer mechanism, the key step is the activation of alcohols to facilitate the hydrogen atom transfer from α-Csp3–H bonds to the hydrogen acceptors. The –OH group in alcohols can be regarded as a Lewis base, and thus, introducing Lewis acid sites to the catalysts should activate the –OH group via the Lewis acid/base interaction. Inspired by the fact that the single Zn atom catalyst with the Zn–N4 motifs can serve as the Lewis acid sites for the activation of epoxides to achieve efficient CO2 cycloaddition with epoxides48, we envisage that the single Zn atom catalyst would serve as a good candidate for catalyzing the α-alkylation of nitriles with wide scope alcohols via the hydrogen atom transfer mechanism with high efficiency.

ZIF-8, as one of the most common zeolitic imidazolate frameworks, can be easily prepared by the coordination of Zn2+ with 2-methylimidazole49. In recent years, ZIF-8 has been widely used as the host to other metal cations or metal complexes either by the partial substitution of Zn2+ with metal cations or the encapsulation of metal complexes into their inner framework for the preparation of single metal atom catalysts (Co, Ni, Ru, Pt, et al.) by the pyrolysis method50,51, because of the generally accepted fact that Zn atoms could be evaporated and removed at high pyrolysis temperature (>900 °C). However, little attention has been paid to the catalytic contribution of the remaining trace amount of single Zn atoms in the as-prepared catalysts. Herein, the single Zn atom catalyst is facilely prepared by the pyrolysis of ZIF-8, and it is discovered to be active for the α-alkylation of nitriles with different kinds of alcohols including aliphatic and aromatic ones (Fig. 1, This work). More excitingly, the as-prepared single Zn atom catalyst is also effective for the α-alkylation of ketones, alcohols, esters, amides, amines, keto acids, sulfones, and N-heterocycles with alcohols, as well as the hydrogenation of nitroarenes, ketones, aldehydes, pyridine-N-oxide, sulfoxides and olefins by ethanol. To the best of our knowledge, this is the first example of a versatile application in catalysis.

Results

Catalyst preparation and characterization

ZIF-8, as one of the most common zeolitic imidazolate frameworks, is used as the precursor for the preparation of single Zn atom catalysts (abbreviated as Zn–N4–C) via the thermal pyrolysis strategy (Fig. 2a). First, ZIF-8 is prepared by the solvent-thermal method according to the well-known procedure52, and the X-ray diffraction (XRD) patterns of the as-prepared ZIF-8 are in accordance with the standard card (Fig. S1). As the boiling point of Zn is 908 °C, the pyrolysis temperature is set at 950 °C to evaporate off most of Zn atoms. The content of Zn in the as-prepared Zn–N4–C catalyst is determined to be 2.1 wt.% by the inductively coupled atomic emission spectrometer (ICP-AES). Due to the release of Zn atoms and gases, abundant micropores and mesopores are formed in the Zn–N4–C catalyst as evidenced by the Brunauer−Emmett−Teller (BET) method (Fig. S2). Nitrogen adsorption/desorption isotherms of Zn–N4–C show a type IV pattern with the characteristic of mesoporous structure as well as the I-type isotherm with equilibrium in the P/P0 range of 0−0.1 as the characteristic of microporous structure, and the total surface area is large up to 1277 m2/g (Table S2). The large surface area and abundant pores benefit the transfer of substrate molecules to the active sites and the desorption of product molecules from catalyst surfaces.

The morphology of the as-prepared Zn–N4–C catalyst is first characterized by transmission electron microscopy (TEM). TEM images of Zn–N4–C (Fig. 2b~d) and the ZIF-8 precursor (Fig. S3a~c) indicate that Zn–N4–C still retains the dodecahedral shape of ZIF-8 even after the thermal treatment at 950 °C, but the surface of Zn–N4–C becomes rough. No zinc nanoparticles or zinc clusters are observed in the TEM images of Zn–N4–C (Fig. 2b–d). The powder XRD pattern of the Zn–N4–C catalyst only shows a broad shoulder peak and a weak peak with 2θ centering at 24.6° and 42.4°, corresponding to the (002) and (100) planes of the graphitic carbon, respectively53. In consistence with the TEM results, no diffraction peaks for Zn-related species are observed in the XRD pattern of Zn–N4–C (Fig. 2e). Raman spectra also confirm the presence of graphitic carbon (G band) and the defected carbon (D band) with the ID/IG value of 1.05, suggesting that Zn–N4–C has abundant defects (Fig. 2f). Furthermore, we resort to the aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (AC-HAADF-STEM) to probe atomically dispersed Zn atoms. As shown in Fig. 3a, many isolated Zn atoms,

a The aberration-corrected HAADF-STEM image of Zn–N4–C (single-atom Zn is highlighted with red circles), b Zn K-edge XANES spectra of Zn–N4–C, ZnO and Zn foil, c Fourier transforms (FTs) of the k2-weighted c(k) functions of the EXAFS spectra for the Zn K-edge, d, e Corresponding EXAFS fitting curves in k and R space, respectively; inset shows a model of the Zn environment, f WT-EXAFS image of Zn–N4–C catalyst.

which are identified by the separated bright dots and mark with red cycles, are well dispersed over the sample. These above characterizations reveal that single Zn atoms are indeed embedded in the nitrogen-doped carbon layers.

X-ray photoelectron spectroscopy (XPS) is used to explore the valence states of Zn and N in the surface of Zn–N4–C catalyst. The XPS survey spectra also reveal that the catalyst is composed of C, N, O, and Zn elements (Fig. S4a). The high-resolution C 1s XPS spectrum of the Zn–N4–C material can be resolved into four chemically shifted components centered at 284.6, 285.9, 287.3, and 288.9 eV, respectively, corresponding to C–C/C=C, C–N/C–O, C=O bonds, and π-π* satellite (Fig. S4b)54. There are three components in the spectrum of O 1s XPS corresponding to C=O at 530.5 eV, C–O at 532.1 eV, and O–C=O or H2O at 533.6 eV (Fig. S4c)54. The N 1s XPS spectrum of Zn–N4–C is fitted into four nitrogen species, including pyridinic N (398.5 eV), Zn–Nx (399.6 eV), pyrrolic N (400.2 eV), and graphitic N (401.2 eV) (Fig. 2g & Table S3)55. It is noted that the atom percentage (at.%) of pyridinic N atoms, which are well known to serve as the coordination sites to metal single atoms by forming the isolated M−Nx structure56, is up to 50.4 at.%. In order to further confirm the existence of Zn–Nx, the Zn 2p spectrum of the Zn–N4–C catalyst is also fitted (Fig. S5). It shows two peaks with the binding energies at 1021.3 and 1044.5 eV, corresponding to the Zn 2p3/2 and Zn 2p1/2 orbital, respectively57. Moreover, the binding energy of Zn 2p3/2 (1021.3 eV) of Zn–N4–C is different from that for ZnO (1022.0 eV)58, which suggests that only Zn–Nx rather than ZnO is the zinc species in the Zn–N4–C catalyst (Fig. S5).

The valence state and the precise local environment of Zn in the Zn–N4–C catalyst are further identified by the Zn K-edge X-ray absorption near-edge structure (XANES) spectra. As shown in Fig. 3b, the energy of the absorption threshold for Zn–N4–C is higher than that for the Zn foil reference and close to that for ZnO. Thus, the valance state of zinc species in Zn–N4–C is close to +2. The Fourier transform (FT) k2-weighted extended X-ray absorption fine structure (EXAFS) spectrum of Zn–N4–C (Fig. 3c) exhibits only one obvious peak located at 1.67 Å, which is attributed to the Zn–N construction. On the meanwhile, no scattering peaks derived from Zn–Zn coordination are observed in Zn–N4–C. These results further confirm the atomic dispersion of Zn in the Zn–N4–C catalyst, which is consistent with the observation from Fig. 3a. First-shell EXAFS fitting is performed to extract structural parameters (Fig. 3d, e, Table S4). On the basis of the best-fitting results, each single Zn atom in Zn–N4–C is coordinated by four N atoms (The illustration in Fig. 3e). EXAFS wavelet transforms (WT) analysis is further employed to ascertain the coordination environment of Zn. As shown in Fig. 3f, WT analysis of Zn–N4–C exhibits the well-resolved maxima around 5.3 Å−1, which arises from Zn–N bonds. While the maxima around 6.5 Å−1 and 6.0 Å−1 are observed in the WT-EXAFS images of Zn foil and ZnO (Fig. S6), which are assigned to the Zn–Zn and Zn–O bonds, respectively. All of these characterizations confirm that Zn species are present in single atoms with a Zn–N4 motif in the Zn–N4–C catalyst.

Catalytic activity test

The α-alkylation of phenyl acetonitrile with benzyl alcohol is used as the model reaction to evaluate the catalytic performance of the as-prepared Zn–N4–C catalyst. To our great pleasure, Zn–N4–C demonstrates an excellent catalytic performance towards this transformation, affording a phenyl acetonitrile conversion of 93% within 4 h at 200 °C (Table 1, Entry 1). To further identify the role of single Zn atoms in Zn–N4–C towards the α-alkylation of phenyl acetonitrile, the Zn-free nitrogen-doped carbon material (NC-950) is also prepared from ZIF-8 while the pyrolysis time is prolonged to 5 h to completely remove the single Zn atoms and reserve the similar carbon structure with Zn–N4–C. ICP-AES results reveals that the content of Zn in NC-950 is below the detection limit (<10−4%). Interestingly, a low conversion of 9% is observed over NC-950 under the same conditions, giving rise to 2,3-diphenylacrylonitrile as the sole product (Table 1, Entry 2). According to these results listed in Entries 1 & 2, we can conclude that the single Zn atoms in the Zn–N4–C catalyst plays a crucial role in α-alkylation of nitriles with alcohols. The poisoning experiment by KSCN results in a great decrease in the catalytic activity of Zn–N4–C, because of the strong affinity of SCN- with Zn atoms in the Zn–N4–C catalyst59, further confirming the significant role of the Zn–N4 motif in this transformation (Table 1, Entries 3 vs 1). The specific role of the single Zn atom sites in the α-alkylation of nitriles will be discussed in the following Mechanism section. In addition, these results also suggest that the nitrogen-doped carbon materials deliver a poor ability to catalyze the dehydrogenation of alcohols, which is not surprising as carbon materials has been reported to be able to catalyze some dehydrogenation or transfer hydrogenation reactions60,61,62,63. For example, Qi and Nie reported that the carbon catalyst showed high activity for the room temperature acceptorless dehydrogenation of N-heterocycles60, which even outperformed some reported noble metal catalysts.

In addition, ZIF-8 is also subjected to be pyrolyzed at 1000 °C to generate the other kind of single Zn atom catalyst (abbreviated as ZIF-8-1000). Preliminary characterizations such as TEM image (Fig. S3d~f), XRD pattern (Fig. 2f), and XPS spectra (Figs. S5 and S7) reveal that the structure of ZIF-8-1000 is almost the same as the structure of Zn–N4–C. Thus, Zn species in ZIF-8-1000 should also be present in the single atoms embedded in the nitrogen-doped carbon layer. Compared with Zn–N4–C, the only distinct difference is that much more Zn atoms evaporated off by increasing the pyrolysis temperature from 950 °C to 1000 °C, resulting in a lower Zn content in ZIF-8-1000 (1.0 wt.% vs 2.1 wt.%, Table S5) and a larger surface area of ZIF-8-1000 (1400.3 vs 1277.0 m2/g, Table S2). As expected, the conversion of phenyl acetonitrile greatly decreases from 93% over the Zn–N4–C catalyst to 40% over the ZIF-8-1000 catalyst (Table 1, Entries 1 vs 4), because of the lower Zn content in ZIF-8-1000 with the same catalyst loading. Furthermore, the catalytic performance of Zn–N4–C is also compared with commercially available Pt/C, Pd/C, and Ru/C catalysts. The Zn–N4–C catalyst demonstrates a comparable conversion compared with Ru/C (Table 1, Entries 1 vs 5) and much higher conversion than Pt/C and Pd/C catalysts (Table 1, Entries 1 vs 6 & 7). In addition, it is noted that the α-alkylation of phenyl acetonitrile with benzyl alcohol over these noble metal catalysts gives 2,3-diphenylacrylonitrile as the major product (Table 1, Entries 5~7), indicating that the α-alkylation of phenyl acetonitrile over these noble metal nanoparticles proceeds via the first step of the dehydrogenation of alcohols into aldehydes by the release of H2 molecules, which is different from the Zn–N4–C catalytic system. Interestingly, the Zn phthalocyanine macromolecule with a Zn–N4 motif similar to Zn–N4–C catalysts shows no catalytic activity (Table 1, Entry 8). These results suggest that the micro-environment of the Zn–N4 motif and the nitrogen-doped carbon material are both crucial for the α-alkylation of nitriles with alcohols. As expected, other zinc catalysts such as ZnO and Zn(NO3)2.6H2O also show no activity for the α-alkylation of phenyl acetonitrile (Table 1, Entries 9 & 10).

Then, the reaction conditions are optimized for the α-alkylation of phenyl acetonitrile with benzyl alcohol over the Zn–N4–C catalyst. First, the effect of reaction solvents is studied (Table S6). It is noted that the properties of the solvents, such as the polarity, show no obvious influence on this transformation. Hexane, toluene, p-xylene, and tetrahydrofuran (THF) give high phenyl acetonitrile conversions (83~97%), while other solvents such as 1,4-dioxane and dichloromethane give low conversions (2~6%). Hexane is found to be the best solvent, which gives the highest conversion of 93% and the highest selectivity of 2,3-diphenylpropionitrile in 89% within 4 h at 200 °C in the presence of NaOH additive (Table S6, Entry 3). Next, the effect of base additives is investigated. As shown in Table S7, the base additives show a great influence on both phenyl acetonitrile conversion and benzyl alcohol conversion. High conversions of phenyl acetonitrile and benzyl alcohol are obtained using strong bases such as NaOH and NaNH2 (Table S7, Entries 1~2), while poor conversions of phenyl acetonitrile and benzyl alcohol are both observed with weak bases (Table S7, Entries 3~6). NaNH2 is screened to the best base additive, affording a high phenyl acetonitrile conversion of 95% and >99% selectivity of 2,3-diphenylpropionitrile in hexane within 4 h at 200 °C (Table S7, Entry 2). The detailed role of the base in the α-alkylation of nitriles is discussed in the following Mechanism section. In addition, the α-alkylation of phenyl acetonitrile is also sensitive to the reaction temperature (Fig. S8). Interestingly, the Zn–N4–C catalyst even demonstrates activity at a low temperature of 80 °C. However, 2,3-diphenylacrylonitrile is the only product within 4 h at low temperatures (80~100 °C). 2,3-diphenylpropionitrile is produced at high reaction temperatures of 120~200 °C, and the selectivity of 2,3-diphenylpropionitrile is observed to increase greatly with higher reaction temperature (Fig. S8). These above results suggest that the final step of the transfer hydrogenation of vinyl nitriles intermediates into the α-alkylated nitriles is much more difficult than other steps, which should be the rate-determining step. Furthermore, kinetic studies of the α-olefination of phenyl acetonitrile into 2,3-diphenylacrylonitrile with benzyl alcohol (Fig. S9), and the transfer hydrogenation of 2,3-diphenylacrylonitrile with benzyl alcohol are conducted (Fig. S10). The apparent activation energy is calculated according to the Arrhenius plot with reaction constants obtained at different reaction temperatures. The apparent activation energy of the α-olefination of phenyl acetonitrile into 2,3-diphenylacrylonitrile is calculated to be 27.94 kJ/mol over the Zn–N4–C catalyst (Fig. S9), while that is much higher (76.58 kJ/mol) for the transfer hydrogenation of 2,3-diphenylacrylonitrile into 2,3-diphenylpropionitrile (Fig. S10). The kinetic data clearly confirm that the transfer hydrogenation of 2,3-diphenylacrylonitrile into 2,3-diphenylpropionitrile is the rate-determining step in the α-alkylation of phenyl acetonitrile, which is in accordance with the above experimental results.

Finally, the time course of the α-alkylation of phenyl acetonitrile with benzyl alcohol is recorded at 160 °C. The 2,3-diphenylacrylonitrile intermediate remains in a low content during the reaction process, and 2,3-diphenylpropionitrile is obtained with quantitative yield (>99%) after 12 h (Fig. S11). It should be pointed out that the catalytic activity of Zn–N4–C is comparable with some of the reported homogeneous catalysts or even higher than those of reported noble metal catalysts, including Ru/HT and Pd/MgO as listed in Table S1 (Entries 32~33) and the commercial Ru/C, Pt/C, and Pd/C catalysts as listed in Table 1 (Entries 5~7). For example, the α-alkylation of phenyl acetonitrile over Ru/HT and Pd/MgO was performed at 180 °C with large amounts of alcohols (Table S1, Entries 32~33)42,44. It was noted that other methods generally used at least 2 equiv. of aromatic alcohols for α-alkylation of phenyl acetonitriles, while 1.1 equiv. of aromatic alcohols are only used in our catalytic method. By increasing benzyl alcohol loading to 2 equiv., the loading of NaNH2 can decrease to 0.25 equiv., affording 2,3-diphenylpropionitrile with a high yield of 90% after 24 h (Table 1, Entry 11).

Substrate scope

Next, the scope of the α-alkylation of nitriles over the Zn–N4–C catalyst is studied (Fig. 4). First, different kinds of alcohols are used as the alkylating reagents. The α-alkylation of phenyl acetonitrile with the mono-substituted benzyl alcohols proceeds smoothly, affording the corresponding α-alkylated nitriles with good to excellent yields (Pro.1~Pro.12, Pro.14). Although the electronic properties of the substituted groups are not very significant, substrates with the electron-donating groups are observed to be more active than those with electron-withdrawing groups (Pro.2 & Pro.10~Pro.12 vs Pro.5~Pro.9). The position of the substituted groups also shows some influence on the substrate activity. For example, the activity of methyl-substituted benzyl alcohol decreases in order of 4-methylbenzyl alcohol, 3-methylbenzyl alcohol, and 2-methylbenzyl alcohol (Pro.2~Pro.4), due to the steric hindrance of the substituted groups. To get high yields of the corresponding α-alkylated nitriles from the α-alkylation of phenyl acetonitrile with 2-methylbenzyl alcohol, a high reaction temperature at 180 °C is required (Pro.4). In addition, the Zn–N4–C catalyst is also effective for the substrates with aromatic-fused rings (Pro.15~Pro.16) and hetero-aryl rings containing O, S, and N atoms (Pro.17~Pro.22), affording the corresponding α-alkylated nitriles with high yields. Generally, hetero-aryl rings with S atoms cause the poisoning of metallic nanoparticle catalysts, because of the strong affinity of hetero-atoms in these hetero-aryl rings to the metallic nanoparticles64. In our case, the single Zn atom sites should have much stronger interaction with the negative oxygen atoms in alkoxyl groups than the heteroatoms in the aromatic ring, because the single Zn atoms are the Lewis acid sites, binding firmly with the Lewis base (alkoxyl groups)65. Notably, halide-substituted benzyl alcohols (F, Cl, and Br) efficiently participate in the alkylation process, affording the corresponding α-alkylated nitriles with high yields without affecting the sensitive halide groups (Pro.5~Pro.7). The dehalogenation of the halide substituted aromatic substrates is generally observed over supported metallic nanoparticle catalysts, especially in the presence of base additives66. This is due to the different reaction mechanisms of the α-alkylation of nitriles between the Zn–N4–C catalyst and the supported metallic nanoparticles. As discussed in the following section, the α-alkylation of nitriles over the Zn–N4–C catalyst proceeds via the transfer hydrogenation mechanism, while the reaction over metallic nanoparticles proceeds via the dehydrogenation-hydrogenation mechanism. The in-situ formed active H species can also promote dehalogenation66. On the meanwhile, the α-alkylation of phenyl acetonitrile with poly-substituted benzyl alcohols is also successful, but the high reaction temperature of 180 °C and long reaction time are required to achieve high yields of the corresponding α-alkylated nitriles (Pro.23~Pro.26), because of the large steric hindrance of these poly-substituted benzyl alcohols. Compared with aromatic alcohols, aliphatic alcohols, particularly methanol and ethanol, are much more inert and commonly used as reaction solvents. Therefore, it is challenging to use aliphatic alcohols for the α-alkylation of nitriles even over noble metal catalysts. To our great pleasure, the Zn–N4–C catalyst is also active for α-alkylation of phenyl acetonitrile with aliphatic alcohols including primary (methanol, ethanol, n-propanol, n-butanol, n-pentanol, n-hexanol) and secondary ones (iso-propanol), affording the corresponding α-alkylated nitriles with high to excellent yields (Pro.27~Pro.33). In addition, it is noted that the activity of non-branched aliphatic alcohols decreases with an increase of the carbon number (Pro.28~Pro.33). As discussed in the Mechanism section, the main reaction route over the Zn–N4–C catalyst is the transfer hydrogenation mechanism. The reaction starts the activation of alcohols with the single Zn atom sites. Therefore, the non-branched aliphatic alcohols with more carbon atoms have larger steric hindrance to release the H atom from the α-C–H bond in alcohols, demonstrating lower activity.

Reaction conditions: aromatic alcohols (0.55 mmol), nitriles (0.5 mmol), hexane (10 mL), the Zn–N4–C catalyst (20 mg), NaNH2 (1 equiv.), N2 (10 bar) and 160 °C; b These reactions are performed at 180 °C; c These reactions are performed at 200 °C. Note: Aliphatic alcohols are also used as the solvents; The yields in Fig. 4 are the isolated yields; The “Pro. x” represents “Product x”, and “x” is the number of the compound synthesized in this manuscript. The red part represents that it derives from alcohol.

Thereafter, the scope of the aryl acetonitriles for the α-alkylation with benzyl alcohol is studied (Fig. 4). To our delight, various kinds of aryl acetonitriles undergo the alkylation process with benzyl alcohol smoothly, affording the desired α-alkylated nitriles with the yields of 77~99% (Pro.34~Pro.50). Again, the effect of the electronic properties and the position of the substituted groups in the aryl acetonitriles show similar influence as those for the aromatic alcohols.

Mechanistic study

In the following section, the reaction mechanism of the α-alkylation of nitriles with alcohols is studied over the Zn–N4–C catalyst. First, the role of base in the α-alkylation of nitriles is studied by the α-alkylation of phenyl acetonitrile with benzyl alcohol, which includes three consecutive steps. The effect of base on the initial step of the dehydrogenation of benzyl alcohol is studied (Table S8). The dehydrogenation of benzyl alcohol without a base gives a conversion of 9% within 4 h at 160 °C over the Zn–N4–C catalyst. It is noted that the external base shows no significant influence on the dehydrogenation of alcohol (Table S8, Entries 1~4). As discussed in Table 1, the nitrogen-doped carbon demonstrates the ability to promote the dehydration of benzyl alcohol (Table 1, Entry 2). Unlike the α-alkylation of phenyl acetonitrile, the dehydrogenation of benzyl alcohol over Zn–N4–C and NC-950 gives similar conversions, which suggests that the presence of single Zn atoms shows no improvement on the dehydrogenation of benzyl alcohol over nitrogen-doped carbon material (Table S8, Entries 4 & 7). On the meanwhile, ZIF-8-1000 also demonstrates similar activity as Zn–N4–C in the dehydrogenation of benzyl alcohol (Table S8, Entry 6). Furthermore, the presence of KSCN shows no effect on the dehydrogenation of benzyl alcohol (Table S8, Entries 4 vs 5), while a great decrease is observed in the α-alkylation of phenyl acetonitrile with benzyl alcohol (Table 1, Entries 1 vs 3). These results further confirm that the single Zn atoms are not responsible for the dehydrogenation of benzyl alcohol. The α-alkylation of nitriles starts with the dehydrogenation of alcohols into aldehydes over the nitrogen-doped carbon, followed by the coupling and transfer hydrogenation reactions.

After the formation of aldehydes, the second step is the condensation of phenyl acetonitrile with benzaldehyde. The results listed in Table S9 show that a strong base such as NaNH2 is required to effectively promote the second condensation step to generate the intermediate, 2,3-diphenylacrylonitrile. The critical role of base is to capture the Hδ+ from α-C–H in nitriles to generate the corresponding carbon anions, which then serve as the nucleophilic reagents to attack the carbonyl groups in the in-situ formed aldehydes to generate the vinyl nitrile intermediates. In addition, it is noted that Zn–N4–C also has weak basicity to promote the condensation step with a very low conversion of 2% (Table S9, Entry 2), while that is 93% with the same weight of NaNH2 (Table S9, Entry 6). CO2-TPD profile reveals that Zn–N4–C has weak basic sites of 0.2 mmol/g (Fig. S12), which should be mainly derived from the basic nitrogen atoms (pyridine N).

After the formation of vinyl nitriles, the final step is the hydrogenation of C=C bonds in vinyl nitrile intermediates to generate α-alkylated nitriles. First, the hydrogenation of 2,3-diphenylacrylonitrile is carried out over the Zn–N4–C catalyst under 1 bar H2, which is about 2.5 times the theoretic amount of H2 required for the complete dehydrogenation of benzyl alcohol according to the empty volume of our autoclave, but only a very low conversion of 5% is attained (Table S10, Entry 8). However, a high yield of 61% is achieved under the same conditions using benzyl alcohol as the hydrogen donor (Table S10, Entry 6). These results suggest that the transformation of vinyl nitrile intermediates into α-alkylated nitriles is a transfer hydrogenation process. Indeed, the conversion of benzyl alcohol is observed to increase from 9% to 15% in the presence of Zn–N4–C without NaNH2 (Table S10, Entries 1 vs 2), because 2, 3-diphenylacrylonitrile could serve as the hydrogen acceptor to promote the release of hydrogen atoms from benzyl alcohol. Interestingly, the transformation of 2,3-diphenylacrylonitrile greatly accelerates with higher base loadings (Table S10, Entries 2~6). Therefore, the transfer hydrogenation of vinyl nitriles into α-alkylated nitriles is synergistically promoted by Zn–N4–C and NaNH2. The role of NaNH2 in this transfer hydrogenation is the capture of Hδ+ from the hydroxyl group (–OH) in alcohols to generate the active alkoxyl group (RCH2O–). Then the RCH2O– species combine with the single Zn atoms in the Zn–N4–C catalyst via the Lewis acid-base interaction as described above. After the activation of RCH2O– species by the single Zn atom sites, the H atom from –Cα–H in RCH2O– species transfers smoothly to hydrogenate the vinyl nitrile intermediates into α-alkylated nitriles. Density functional theory (DFT) calculation is carried out to study the activation of RCH2O– species by the single Zn atoms in the Zn–N4–C catalyst (Fig. S13). The charge distribution and the bond length of –Cα–H in the free and activated benzyl alcohol are calculated. As shown in Fig. S13, Bader charge analysis reveals that the single Zn atoms serve as the electron pool to accommodate the electron by the coordinated N atoms, and then the electron of 0.530 e– is transferred from the Zn–N4–C catalyst to the adsorbed alkoxyl group (C6H5CH2O–) via single Zn atoms. After activation of the alkoxyl group by the Zn–N4 motif, the H atom in –Cα–H gets 0.097 e–. On the meanwhile, the length of the –Cα–H bond prolongs from 1.099 Å to 1.111 Å. Thus, the transfer hydrogenation reaction becomes easier in the presence of vinyl nitrile intermediates as the hydrogen acceptor.

DFT calculation is further used to study the mechanism of the transfer hydrogenation of 2, 3-diphenylacrylonitrile into 2, 3-diphenylpropiononitrile, which is the key and rate-determining step in the whole reaction. The capture of Hδ+ by NaNH2 from the hydroxyl group (–OH) in benzyl alcohol (C6H5CH2OH) is exothermic by −1.54 eV (Fig. 5), and then the C6H5CH2O– species tightly combine with the single Zn atom sites in the Zn–N4–C catalyst via the Lewis acid-Lewis base interaction. After the activation of C6H5CH2O– species, the negative H atom from –Cα–H in C6H5CH2O– transfers to one carbon atom in C=C bonds of the 2,3-diphenylacrylonitrile intermediate [C6H5–C1H=C2(CN)C6H5]. DFT calculations reveal that the transfer of the H atom from –Cα–H in C6H5CH2O– to the C1 atom (energy barrier, Ea = 0.82 eV) is energetic more favorable than that to the C2 atom in C6H5–C1H=C2(CN)C6H5 (Ea = 2.79 eV) (Figs. 5 and S14). This is in accordance with the difference in the charge distribution of C1 and C2 atoms. The C1 and C2 in C6H5–C1H=C2(CN)C6H5 are partially positively and negatively charged, respectively, due to the strong electron-withdrawing properties of the nitrile group. Thus, the negative H atom from –Cα–H bonds in C6H5CH2O– species should be added to the C1 atom in the C6H5–C1H=C2(CN)C6H5 intermediate, which is also confirmed by the following iso-topic labeling experiments. After the addition of the first H atom to C1 atom to generate the reactive intermediate (C6H5–C1H2–C2*(CN)C6H5), the addition of the positive H atom (H+) in NaNH3+ to C2 atom in C6H5–C1H2–C2*(CN)C6H5 to give rise to the final product of C6H5–CH2–CH(CN)C6H5 is very easy (Ea = 0.33 eV). To further demonstrate the significant role of single Zn atom in the transfer hydrogenation of vinyl nitrile intermediates into α-alkylated nitriles, the energy barrier of the transfer hydrogenation of 2,3-diphenylacrylonitrile into 2,3-diphenylpropiononitrile by the nitrogen-doped carbon material is also calculated by the same method. The energy barrier of the transfer of the first H atom to the C=C bond in 2,3-diphenylpropiononitrile is more than three times higher over the single Zn atom site (Ea : 2.69 eV vs 0.82 eV), (Fig. 5).

Furthermore, isotopic labeling experiments using CH3OD and CD3OD as the hydrogen donor are performed to study the kinetics of abstracting the H from the –OH group and the α-C–H, respectively (Fig. S15). The kinetic isotope effect (KIE) value of CH3OD to CH3OH is calculated to be 1.11, while the KIE value of CD3OD to CH3OH is determined to be 2.27 (Fig. S15). By deducting the contribution of –OD from CD3OD in the KIE value of CD3OD to CH3OH, the approximate KIE value of CD3OH to CH3OH should reach up to 2.16. Therefore, isotopic labeling experiments suggest that the cleavage of the H from –Cα–H in alcohols is the rate-determining step, requiring much higher energy. More importantly, the products of the transfer hydrogenation of the 2,3-diphenylacrylonitrile intermediate [C6H5–C1H=C2(CN)C6H5] with CH3OH and CH3OD show the distinct fragment peak of the benzyl group with the same value of 91, while that is 92 using CD3OD (Fig. S16). These results confirm that the H atom from –OH group is added to the C2 carbon not C1 carbon in [C6H5–C1H=C2(CN)C6H5], in accordance with the above DFT calculation.

Based on the above experiments and DFT calculation results, a possible reaction mechanism for the α-alkylation of phenyl acetonitrile and benzyl alcohol is proposed (Fig. 6). A small amount of benzyl alcohol dehydrogenates to benzaldehyde, followed by condensation with phenyl acetonitrile to 2,3-diphenylacrylonitrile in the presence of NaNH2, which is used to initiate the subsequent transfer hydrogenation reaction. The Hδ+ from –OH group of benzyl alcohol is captured by NaNH2 to produce alkoxy anion, which is adsorbed on the Zn-N4 site. Subsequently, α-C–H of the alkoxy anion and Hδ+ transfer to the C1 and C2 atoms of 2,3-diphenylacrylonitrile (C6H5–C1H=C2(CN)C6H5), respectively, giving rise to the target 2,3-diphenylpropiononitrile and benzaldehyde. Then, benzaldehyde undergoes the condensation with phenyl acetonitrile to generate 2,3-diphenylacrylonitrile, and the next cycle of the transfer hydrogenation process starts.

Further application of our developed method

The good catalytic performance of the Zn–N4–C catalyst in the α-alkylation of nitriles with a wide range of alcohols inspires us to extend the scope of our developed method. First, the α-alkylation of different substrates is studied. The N-alkylation of aniline with the representative alcohols, including methanol, ethanol, and benzyl alcohol, proceeds smoothly, affording the corresponding mono N-monoalkylated anilines with excellent yields (Fig. 7, Pro.51~Pro. 53). No significant steric hindrance is observed for the N-ethylation of o-chloroaniline and o-methylaniline (Fig. 7, Pro.54~Pro. 55). However, the coupling of o-phenylenediamine with alcohols gives rise to 2-alkyl benzimidazoles with high to quantitative yields (Fig. 7, Pro.56~Pro. 57). As shown in Fig. S17, synthesis of 2-alkyl benzimidazoles from the coupling of o-phenylenediamine with alcohols includes three steps: (I) the initial dehydrogenation of alcohols into aldehydes; (II) the condensation of the in-situ formed aldehydes with –NH2 groups to give the Schiff base intermediates (RNH=CR), and (III) cyclization and dehydration process to generate 2-alkyl benzimidazoles. The failure in the formation of N-alkylated products suggests that the cyclization process by the internal nucleophilic addition of –NH2 group to the Schiff base is kinetically and thermodynamically favorable. Besides anilines, N-alkylation of benzylamine is also successful with secondary amine as the major product (Fig. 7, Pro.59). The N-ethylation of N-ethylbenzylamine gives rise to the corresponding tertiary amine with a high yield of 91% (Fig. 7, Pro.60). Besides the active anilines and benzylamines, the Zn–N4–C catalyst is also active for the N-ethylation of aliphatic butylamine (Fig. 7, Pro.61). Interestingly, the alkylation of indole at the C2 position rather than N-alkylation is observed (Fig. 7, Pro.62~Pro.63), while the ethylation of 2-methylindole at the C3 position proceeds, affording 2-methyl-3-ethylindole in a yield of 94% (Fig. 7, Pro.64). On the meanwhile, the ethylation of quinoxaline simultaneously at C2 and C3 positions gives 2,3-diethyl quinoxaline (Fig. 7, Pro.65), and the alkylation of 2-methylquinoxaline with ethanol or benzyl alcohol proceeds smoothly at the C3 position (Fig. 7, Pro.66~Pro.67).

Reaction conditions: substrate (0.5 mmol), benzyl alcohol (5 mmol), hexane (10 mL), the Zn–N4–C catalyst (20 mg), NaNH2 (1 equiv.), N2 (10 bar), and 180 °C; Note: Methanol and ethanol are used as the reaction solvent, when they are used as the alkylating reagents; The yields in Fig. 7 are the isolated yields; The “Pro. x” represents “Product x”, and “x” is the number of the compound synthesized in this manuscript. The blue part represents that it derives from alcohol as alkylating reagents.

Then, the alkylation of more challenging substrates is studied. The N-alkylation of benzamide is successful without the reduction of amide, giving N-alkylated benzamides in high yields (Fig. 7, Pro.68~Pro.69). However, N-alkylation of indolin-2-one (one kind of lactam) is failed, and the alkylation at the C2 position is observed (Fig. 7, Pro.70~Pro.71), because of the active C2–H via the conjugation structure of C2 with aromatic ring. As for the N,N-disubstituted acetamides, the C-alkylation products are observed with relatively lower yields than aromatic amides (Fig. 7, Pro.72~Pro.73). The single Zn atom catalyst is also discovered to be active in the α-alkylation of sulfones without the reduction of the sulfone group (Fig. 7, Pro.74~Pro.76). However, the simultaneous α-alkylation and the reduction of ketone groups are observed for the ketone and keto acids, when using ethanol as the alkylated reagent and the reaction solvent (Fig. 7, Pro.77~Pro.78). The only α-alkylated products in high yields are obtained in the α-alkylation of ketones using the controlled loading of alcohols (e.g. 1.1 equiv. of benzyl alcohol) (Fig. 7, Pro.79~Pro.82). Then, we try to carry out the α-alkylation of esters by alcohols, both ethyl acetate and tert-butyl acetate could generate the corresponding alkylated products with poor selectivities due to the accompanying transesterification reaction (Fig. 7, Pro.83~Pro.84). Although the α-alkylation of δ-valerolactone is successful, the hydrolysis of the δ-valerolactone is also observed (Fig. 7, Pro.85). The α-alkylation of different kinds of secondary alcohols is successful, affording the α-alkylated secondary alcohols with high to excellent yields (Fig. 7, Pro.86~Pro.88).

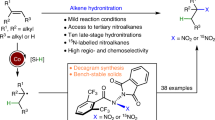

Besides the alkylation of different kinds of substrates, we are also interested in the transfer hydrogenation of some substrates with different functional groups by ethanol. The transfer hydrogenation of some functional groups by ethanol instead of H2 is much more preferable because ethanol is the renewable hydrogen source, which can be industrially produced with low cost. However, the use of ethanol as the hydrogen donor is very challenging, even over noble metal catalysts, as ethanol is highly inert. To our great pleasure, Zn–N4–C could effectively activate ethanol to promote the transfer hydrogenation of nitroarenes, ketones, aldehydes, pyridine-N-oxide, sulfoxides, and olefins with excellent to quantitative yields (Table 2). It should be pointed out that the transfer hydrogenation of these functional groups by ethanol do not require the use of base additives. In addition, the transfer hydrogenation of nitrobenzene by alcohols gives imines as the products, which is formed by the condensation of in-situ aniline and aldehydes, and the further hydrogenation of imines to secondary amines is not observed in this case (Table 2, Entries 9~10). 2-Alkyl benzimidazoles are formed when 2-nitroaniline is used as the substrate (Table 2, Entries 11~12).

Catalyst stability and gram-scale experiments

The stability and reusability of the Zn–N4–C catalyst are examined. The α-alkylation of phenyl acetonitrile with benzyl alcohol is used as the model reaction to evaluate the stability of the Zn–N4–C catalyst. As shown in Fig. S18, the Zn–N4–C catalyst could be reused at least six times without obvious attenuation of activity. Besides the achievement of the stable conversion of phenyl acetonitrile for each run, the selectivity of the two products is also stable. In addition, the hot filtrating experiments indicate that the reaction stops after the removal of the Zn–N4–C catalyst (Fig. S19), revealing the stability of the catalyst. Then, some characterizations of the spent Zn–N4–C catalyst are collected (Figs. S20~24). The content of Zn in the reaction mixture is below the detection limit (<10−4%), which suggests that no leach of Zn into the reaction mixture. XRD patterns and TEM images of the spent Zn–N4–C catalyst reveal that the carbon structure remains in the spent catalyst without the observation of zinc species (Figs. S20~21). XPS of Zn species in the spent Zn–N4–C catalyst is also the same as that of the fresh catalyst, and the binding energies of the two fitted peaks are 1021.3 and 1044.5 eV, confirming that the Zn–Nx motif remains after the reaction (Fig. S22a). Raman spectra of the spent Zn–N4–C catalyst also shows no difference as compared with that of the fresh sample, which only shows two peaks of the graphitic carbon (G band) and the defected carbon (D band) without the change of ID/IG value (Fig. S23). The recycling experiments and the characterizations of the spent Zn–N4–C catalyst confirm that the catalyst is highly stable without the change of catalyst structure, due to the following two reasons. On the one hand, the Zn–N4–C catalyst is prepared by the pyrolysis of ZIF-8 at high temperature, and thus its structure should be resistant to harsh reaction conditions. On the other hand, the single Zn atom is stabilized by four nitrogen atoms embedded in the carbon structure, while that is not the case for the supported metal nanoparticles, which are often observed to lose activity, due to the aggregation of metal nanoparticles and the leach of metal nanoparticles into the reaction solution.

Finally, we have conducted the gram-scale experiments in the α-alkylation of phenyl acetonitrile (1.17 g, 10 mmol) with benzyl alcohol by enlarging the catalyst loading and the base loading. The quantitative conversion and the excellent selectivity of 2,3-diphenylpropionitrile remain in gram-scale experiments, showing that the Zn–N4–C catalyst show promising application (Table S11).

Discussion

In conclusion, we successfully develop a new method for the α-alkylation of phenyl acetonitrile with alcohols over heterogeneous non-noble single Zn atom catalysts, which demonstrate comparable or even higher catalytic activity over the reported noble metal catalysts. Zn–N4–C and NaNH2 are both crucial to the α-alkylation of nitriles with alcohols. The Zn–N4 motif in Zn–N4–C is the active site for the transfer hydrogenation of the vinyl nitriles intermediate. The external base of NaNH2 is responsible for the second step of the condensation of the in-situ formed aldehydes with nitriles to generate vinyl nitriles and promoted the transfer hydrogenation of the vinyl nitriles intermediate by capturing Hδ+ from the –OH group of alcohols. Kinetic studies indicate that the Zn–N4–C catalyst has lower activation energy for the α-olefination of phenyl acetonitrile with alcohols compared with the transfer-hydrogenation of C=C bond in vinyl nitrile intermediates, indicating that the transfer hydrogenation of vinyl nitriles into alkylated nitriles is the rate-determining step in the α-alkylation of phenyl acetonitrile. In addition, DFT calculations reveal that H δ+ from –OH group and H δ- from α-C–H of benzyl alcohol preferably transfer to the C2 and C1 atoms of 2,3-diphenylacrylonitrile (C6H5–C1H=C2(CN)C6H5) to obtain 2,3-diphenylpropiononitrile with lower energy barriers, respectively. More excitingly, the Zn-N4-C catalyst is capable of promoting a broad range of carbon and nitrogen alkylation reactions including alkylation of ketones, alcohols, N-heterocycles, amides, keto acids, and esters, and N-alkylation of anilines, benzyl amines, and aliphatic amines with biomass-derived alcohols as the alkylating reagents as well as hydrogen source. In addition, the single Zn atom catalyst is also effective for the transfer hydrogenation reactions.

Methods

Materials

All of the chemicals were purchased from Aladdin Chemicals Co. Ltd. (Beijing, China) and used as received. The alcohols with a super purity are purchased from J&K Chemicals Company. All other chemicals and solvents were used from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China).

Catalyst preparation

Typically, a methanol solution (30 mL) of Zn(NO3)2·6H2O (1.19 g, 4 mmol) is gradually added to a methanol solution (15 mL) of 2-methylimidazole (1.31 g, 16 mmol) with a vigorous stirring in a flask for 1 h at room temperature. Then, the mixed solution is transferred into a 100 mL Teflon-lined stainless-steel autoclave and heated at 120 °C for 4 h. The as-formed white product is separated by centrifugation, washed with methanol several times, and finally dried at 70 °C under a vacuum overnight to get the white ZIF-8. Then, ZIF-8 is transferred into a ceramic boat and heated at 950 °C for 1 h with a heating rate of 5 °C/min nitrogen gas in a tube furnace. A single Zn atom catalyst (labeled as Zn–N4–C) is obtained after naturally cooling to room temperature.

Catalyst characterization

TEM images are obtained on a Talos F200X electron microscope at an acceleration voltage of 200 kV. X-ray powder diffraction (XRD) measurements are performed on a Bruker advanced D8 powder diffractometer (Cu Kα), which operates at a scanning rate of 0.016°/s in the 2θ range of 10–80°. XPS experiments are conducted on a Thermo VG scientific ESCA MultiLab-2000 spectrometer with a monochromatized Al Kα source (1486.6 eV) and a constant analyzer pass energy of 25 eV. The zinc content is determined by ICP-AES on an IRIS Intrepid II XSP instrument (Thermo Electron Corporation). Raman spectra are performed on a confocal laser micro-Raman spectrometer (Thermo Fischer DXR) equipped with a diode laser of excitation of 532 nm (laser serial number: AJC1200566). Nitrogen physical adsorption-desorption isotherm measurements are conducted at 77 K on a quantachrome Autosorb-1-C-MS instrument. The samples are pretreated at 300 °C for 2 h under vacuum before measurements. Surface area is determined by the standard BET method based on the relative pressure between 0 and 1. The pore size distribution is calculated using the non-local density functional theory method.

The obtained XAFS data was processed in Athena (version 0.9.26) for background, pre-edge line, and post-edge line calibrations. Then Fourier transformed fitting was carried out in Artemis (version 0.9.26). The k3 weighting, k-range of 3−10 Å−1 for 1 sample (3−12.948 Å−1 and 3−12.615 Å−1 for Zn sample) and R range of 1−3 Å were used for the fitting (R range of 1−3 Å were used for the fitting). The four parameters, coordination number, bond length, Debye-Waller factor and E0 shift (CN, R, σ2, ΔE0) were fitted without anyone was fixed, constrained, or correlated.

For Wavelet Transform analysis, the χ(k) exported from Athena was imported into the Hama Fortran code. The parameters were listed as follow: R range, 1−4 Å, k range, 0−12.5 Å−1 for Zn sample (0–12.5 Å−1 for Zn foil and ZnO), k weight, 3, and Morlet function with κ = 10, σ = 1 was used as the mother wavelet to provide the overall distribution.

General procedures

α-Alkylation of nitriles with alcohols: In a typical run, benzyl alcohol (0.55 mmol), phenyl acetonitrile (0.5 mmol), the Zn–N4–C catalyst (20 mg), NaNH2 (1 equiv.) and hexane (10 mL) are charged into a 40 mL autoclave. The air in the autoclave is removed by the flush of N2 five times, and finally, the autoclave is charged with 10 bar N2 at room temperature. The autoclave is heated from room temperature to 180 °C within a few minutes and the reaction is started at 180 °C for a certain time. After cooling to room temperature, the liquid product is diluted with ethanol and analyzed with GC-FID and GC-MS. The residues are purified by column chromatography using a gradient of hexane and ethyl acetate (eluent system) to afford the pure products. The structure of the products is characterized by GC-MS, 1H-, and 13C-NMR.

α-Alkylation of other substrates with alcohols: The procedure of the α-alkylation of other substrates with alcohols is the same as described above for the α-alkylation of nitriles with alcohols by the replacement of nitriles with other substrates including ketones, alcohols, esters, amides, amines, anilines, keto acids, sulfones, and N-heterocycles.

Transfer hydrogenation of substrates with different functional groups: These reactions were performed without the use of base additive. The procedure of the transfer hydrogenation of these substrates with different functional groups is the same as above without the addition of base additive, and the replacement of nitriles with other substrates including nitroarenes, ketones, aldehydes, pyridine-N-oxide, sulfoxides and olefins.

Analytic methods

Agilent 7890 A gas chromatography (GC) instrument with a cross-linked capillary HP-5 column (30 m × 0.32 mm × 0.4 mm) is used to analyze the products by a flame ionization detector. N2 as the carrier gas flowed at 40 mL/ min. Standard analysis conditions are described as follows: injector temperature 300 °C, detector temperature 300 °C, column temperature program: from 50 °C (hold 1.5 min) to 300 °C (hold 3 min) at a heating rate of 10 °C/ min. The structures of products are identified by nuclear magnetic resonance technology (Bruker TCI IIITM 600 MHz).

DFT calculation method

The spin-polarized DFT calculations in this study are performed by the Vienna ab initio simulation package (VASP)67. The projector augmented wave pseudo-potentials and Perdew−Burke−Ernzerhof (PBE) functional within the generalized gradient approximation is used to perform DFT calculations68. According to the experimental characterizations, a reasonable model of the Zn–N4–C catalyst is built, which was compose of the Zn–N4 motifs. The Gamma centered k-point grid of 2 × 2 × 1 is used to sample the Brillouin zone69. A vacuum layer of ~20 Å in the z-direction is used to avoid the interaction between the upper and lower slabs. A cutoff energy of 400 eV is provided for the well-converged energy values. All the atomic positions are relaxed until the forces on each atom were <0.03 eV/Å and the energy difference between two ionic relaxation steps is smaller than 10−3 eV. The “climbing images” nudged elastic band (CI-NEB) algorithm is used to search transition states (TS) with 7 intermediate images along the reaction path70.

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information files. All other relevant raw data can be obtained from the corresponding author upon request. Source data are provided with this paper.

References

Chandrashekhar, V. G., Baumann, W., Beller, M. & Jagadeesh, R. V. Nickel-catalyzed hydrogenative coupling of nitriles and amines for general amine synthesis. Science 376, 1433–1441 (2022).

Qin, J. Z. et al. An enzyme-mimic single Fe-N3 atom catalyst for the oxidative synthesis of nitriles via C─C bond cleavage strategy. Sci. Adv. 8, eadd1267 (2022).

Bagal, D. B. & Bhanage, B. M. Recent advances in transition metal‐catalyzed hydrogenation of nitriles. Adv. Synth. Catal. 357, 883–900 (2015).

Kato, K., Ikeuchi, K., Suzuki, T. & Tanino, K. Total synthesis of 2-isocyanoallopupukeanane: Construction of caged skeleton by intramolecular alkylation of bromonitriles. Org. Lett. 24, 6407–6411 (2022).

Chen, Z. H. et al. Enantioselective nickel-catalyzed reductive aryl/alkenyl-cyano cyclization coupling to all-carbon quaternary stereocenters. J. Am. Chem. Soc. 144, 4776–4782 (2022).

Obora, Y. Recent advances in α-alkylation reactions using alcohols with hydrogen borrowing methodologies. ACS Catal. 4, 3972–3981 (2014).

Huang, F., Liu, Z. & Yu, Z. C-alkylation of ketones and related compounds by alcohols: transition-metal-catalyzed dehydrogenation. Angew. Chem. Int. Ed. 55, 862–875 (2016).

Irrgang, T. & Kempe, R. 3d-Metal catalyzed N- and C-alkylation reactions via borrowing hydrogen or hydrogen autotransfer. Chem. Rev. 119, 2524–2549 (2019).

Kulp, S. S. & McGee, M. J. Oxidative decyanation of benzyl and benzhydryl cyanides. A simplified procedure. J. Org. Chem. 48, 4097–4098 (1983).

Ge, R. et al. Selective electrooxidation of biomass-derived alcohols to aldehydes in a neutral medium: Promoted water dissociation over a nickel-oxide-supported ruthenium single-atom catalyst. Angew. Chem. Int. Ed. 61, e202200211 (2022).

Thiyagarajan, S. & Gunanathan, C. Catalytic cross-coupling of secondary alcohols. J. Am. Chem. Soc. 141, 3822–3827 (2019).

Rorrer, J. E., Bell, A. T. & Toste, F. D. Synthesis of biomass-derived ethers for use as fuels and lubricants. ChemSusChem 12, 2835–2858 (2019).

Lluna-Galan, C., Izquierdo-Aranda, L., Adam, R. & Cabrero-Antonino, J. R. Catalytic reductive alcohol etherifications with carbonyl-based compounds or CO2 and related transformations for the synthesis of ether derivatives. ChemSusChem 14, 3744–3784 (2021).

Motokura, K. et al. One-pot synthesis of α-alkylated nitriles with carbonyl compounds through consecutive aldol reaction/hydrogenation using a hydrotalcite-supported palladium nanoparticle as a multifunctional heterogeneous catalyst. Tetrahedron Lett. 46, 5507–5510 (2005).

Pan, H. J. et al. Asymmetric transfer hydrogenation of imines using alcohol: efficiency and selectivity are influenced by the hydrogen donor. Angew. Chem. Int. Ed. 55, 9615–9619 (2016).

Jafarzadeh, M., Sobhani, S. H., Gajewski, K. & Kianmehr, E. Recent advances in C/N-alkylation with alcohols through hydride transfer strategies. Org. Biomol. Chem. 20, 7713–7745 (2022).

Roy, B. C. et al. ortho-Amino group functionalized 2,2′-bipyridine based Ru(II) complex catalysed alkylation of secondary alcohols, nitriles and amines using alcohols. Org. Chem. Front. 5, 1008–1018 (2018).

Zhu, Z. H. et al. α-Alkylation of nitriles with alcohols catalyzed by NNN′ Pincer Ru(II) complexes bearing bipyridyl imidazoline ligands. Organometallics 38, 2156–2166 (2019).

Thiyagarajan, S. & Gunanathan, C. Facile ruthenium(II)-catalyzed α-alkylation of arylmethyl nitriles using alcohols enabled by metal–ligand cooperation. ACS Catal. 7, 5483–5490 (2017).

Kuwahara, T., Fukuyama, T. & Ryu, I. Synthesis of alkylated nitriles by [RuHCl(CO)(PPh3)3]-catalyzed alkylation of acetonitrile using primary alcohols. Chem. Lett. 42, 1163–1165 (2013).

Huang, S. et al. Ru(II)‐PBTNNXN complex bearing functional 2‐(pyridin‐2‐yl)benzo[d]thiazole ligand catalyzed α‐alkylation of nitriles with alcohols. Appl. Organomet. Chem. 34, e5451 (2020).

Cheung, H. W. et al. Dialkylamino cyclopentadienyl ruthenium(II) complex-catalyzed α-alkylation of arylacetonitriles with primary alcohols. Dalton Trans. 39, 265–274 (2010).

Arslan, B. & Gulcemal, S. α-Alkylation of arylacetonitriles with primary alcohols catalyzed by backbone modified N-heterocyclic carbene iridium(I) complexes. Dalton Trans. 50, 1788–1796 (2021).

Panda, S., Saha, R., Sethi, S., Ghosh, R. & Bagh, B. Efficient α-alkylation of arylacetonitriles with secondary alcohols catalyzed by a phosphine-free air-stable iridium(III) complex. J. Org. Chem. 85, 15610–15621 (2020).

Kong, Y. Y. & Wang, Z. X. Iridium‐catalyzed α‐alkylation of arylacetonitriles using secondary and primary alcohols. Asian J. Org. Chem. 9, 1192–1198 (2020).

Li, J. et al. Atmosphere-controlled chemoselectivity: Rhodium-catalyzed alkylation and olefination of alkylnitriles with alcohols. Chem. Eur. J. 23, 14445–14449 (2017).

Buil, M. L. et al. Osmium catalyst for the borrowing hydrogen methodology: α-Alkylation of arylacetonitriles and methyl ketones. ACS Catal. 3, 2072–2075 (2013).

Bera, S., Bera, A. & Banerjee, D. Nickel-catalyzed hydrogen-borrowing strategy: Chemo-selective alkylation of nitriles with alcohols. Chem. Commun. 56, 6850–6853 (2020).

Mouhsine, B., Karim, A., Dumont, C., Suisse, I. & Sauthier, M. Efficient and clean nickel catalyzed α‐allylation reaction of nitriles. Adv. Synth. Catal. 363, 1457–1462 (2021).

Saha, R., Panda, S., Nanda, A. & Bagh, B. Nickel-catalyzed α-alkylation of arylacetonitriles with challenging secondary alcohols. J. Org. Chem. 89, 6664–6676 (2024).

Genc, S., Arslan, B., Gulcemal, D., Gulcemal, S. & Gunnaz, S. Nickel-catalyzed alkylation of ketones and nitriles with primary alcohols. Org. Biomol. Chem. 20, 9753–9762 (2022).

Singh, A. & Findlater, M. Cobalt-catalyzed alkylation of nitriles with alcohols. Organometallics 41, 3145–3151 (2022).

Paudel, K., Xu, S. & Ding, K. α-Alkylation of nitriles with primary alcohols by a well-defined molecular cobalt catalyst. J. Org. Chem. 85, 14980–14988 (2020).

Boity, B., Sidiqque, M. & Rit, A. Amine-functionalized bifunctional Co(III)-NHC complexes: Highly effective phosphine-free catalysts for the α-alkylation of nitriles. Chem. Commun. 60, 3142–3145 (2024).

Chakraborty, P., Garg, N., Manoury, E., Poli, R. & Sundararaju, B. C-alkylation of various carbonucleophiles with secondary alcohols under CoIII-catalysis. ACS Catal. 10, 8023–8031 (2020).

Jana, A., Reddy, C. B. & Maji, B. Manganese catalyzed α-alkylation of nitriles with primary alcohols. ACS Catal. 8, 9226–9231 (2018).

Borghs, J. C., Tran, M. A., Sklyaruk, J., Rueping, M. & El-Sepelgy, O. Sustainable alkylation of nitriles with alcohols by manganese catalysis. J. Org. Chem. 84, 7927–7935 (2019).

Donthireddy, S. N. R. & Rit, A. Heteroditopic NHC ligand supported manganese(I) complexes: Synthesis, characterization, and activity as non-bifunctional phosphine-free catalyst for the α-alkylation of nitriles. Chem. Eur. J. 30, e202302504 (2024).

Bera, K. & Mukherjee, A. Chemoselective α-alkylation of nitriles with primary alcohols by manganese(I)-catalysis. Chem. Asian J. 18, e202300157 (2023).

Song, D. G. et al. Correction: blue-light induced iron-catalyzed chemoselective α-alkylation and α-olefination of arylacetonitriles with alcohols. Org. Chem. Front. 10, 5908–5919 (2023).

Ma, W. et al. Iron-catalyzed alkylation of nitriles with alcohols. Chem. Eur. J. 24, 13118–13123 (2018).

Motokura, K. et al. A ruthenium-grafted hydrotalcite as a multifunctional catalyst for direct α-alkylation of nitriles with primary alcohols. J. Am. Chem. Soc. 126, 5662–5663 (2004).

Motokura, K. et al. Environmentally friendly one-pot synthesis of α-alkylated nitriles using hydrotalcite-supported metal species as multifunctional solid catalysts. Chem. Eur. J. 12, 8228–8239 (2006).

Corma, A., Ródenas, T. & Sabater, M. J. Monoalkylations with alcohols by a cascade reaction on bifunctional solid catalysts: Reaction kinetics and mechanism. J. Catal. 279, 319–327 (2011).

Izquierdo-Aranda, L., Adam, R. & Cabrero-Antonino, J. R. Silver supported nanoparticles on [Mg4Al-LDH] as an efficient catalyst for the α-alkylation of nitriles, oxindoles and other carboxylic acid derivatives with alcohols. ChemSusChem. 16, e202300818 (2023).

Wang, Y. et al. Transfer hydrogenation of alkenes using ethanol catalyzed by a NCP pincer iridium complex: Scope and mechanism. J. Am. Chem. Soc. 140, 4417–4429 (2018).

Liu, C. et al. Catalytic activity enhancement on alcohol dehydrogenation via directing reaction pathways from single- to double-atom catalysis. J. Am. Chem. Soc. 144, 4913–4924 (2022).

Yang, Q., Yang, C. C., Lin, C. H. & Jiang, H. L. Metal-organic-framework-derived hollow N-doped porous carbon with ultrahigh concentrations of single Zn atoms for efficient carbon dioxide conversion. Angew. Chem. Int. Ed. 58, 3511–3515 (2019).

Bennett, T. D. et al. Hybrid glasses from strong and fragile metal-organic framework liquids. Nat. Commun. 6, 8079 (2015).

Liang, X., Fu, N., Yao, S., Li, Z. & Li, Y. The progress and outlook of metal single-atom-site catalysis. J. Am. Chem. Soc. 144, 18155–18174 (2022).

An, Z. et al. Highly active, ultra-low loading single-atom iron catalysts for catalytic transfer hydrogenation. Nat. Commun. 14, 6666 (2023).

Chen, C. et al. Highly active heterogeneous catalyst for ethylene dimerization prepared by selectively doping Ni on the surface of a zeolitic imidazolate framework. J. Am. Chem. Soc. 143, 7144–7153 (2021).

Liu, S. W. et al. Atomically dispersed iron sites with a nitrogen–carbon coating as highly active and durable oxygen reduction catalysts for fuel cells. Nat. Energy 7, 652–663 (2022).

Li, Z. G. et al. Single-atom Zn for boosting supercapacitor performance. Nano Res. 15, 1715–1724 (2021).

Yang, F. et al. Highly efficient CO2 electroreduction on ZnN4-based single-atom catalyst. Angew. Chem. Int. Ed. 57, 12303–12307 (2018).

Chen, Y. et al. Atomic Fe dispersed on N-doped carbon hollow nanospheres for high-efficiency electrocatalytic oxygen reduction. Adv. Mater. 31, e1806312 (2019).

Han, L. et al. Stable and efficient single-atom Zn catalyst for CO2 reduction to CH4. J. Am. Chem. Soc. 142, 12563–12567 (2020).

Song, P. et al. Zn single atom catalyst for highly efficient oxygen reduction reaction. Adv. Funct. Mater. 27, 1700802 (2017).

Yang, X. et al. Unveiling the axial hydroxyl ligand on Fe-N4-C electrocatalysts and its impact on the pH-dependent oxygen reduction activities and poisoning kinetics. Adv. Sci. 7, 2000176 (2020).

Hu, H. T. et al. Metal-free carbocatalyst for room temperature acceptorless dehydrogenation of N-heterocycles. Sci. Adv. 8, eabl9478 (2022).

Lu, X. M. et al. Synergetic roles of pyridinic nitrogen and carbonyl sites in nitrogen-doped carbon for the metal-free transfer hydrogenation reactions. Appl. Catal. B Environ. 324, 122277 (2023).

Luo, Z. et al. Transition metal-like carbocatalyst. Nat. Commun. 11, 4091 (2020).

Yang, H., Cui, X., Dai, X., Deng, Y. & Shi, F. Carbon-catalysed reductive hydrogen atom transfer reactions. Nat. Commun. 6, 6478 (2015).

Feng, S. Q. et al. Sulfur-poisoning on Rh NP but sulfur-promotion on single-Rh1-site for methanol carbonylation. Appl. Catal. B Environ. 325, 122318 (2023).

Xie, C. et al. Zn-Nx sites on N-doped carbon for aerobic oxidative cleavage and esterification of C(CO)-C bonds. Nat. Commun. 12, 4823 (2021).

Sahoo, B. et al. A biomass-derived non-noble cobalt catalyst for selective hydrodehalogenation of alkyl and (hetero)aryl halides. Angew. Chem. Int. Ed. 56, 11242–11247 (2017).

Notario-Estevez, A., Kozlov, S. M., Vines, F. & Illas, F. Electronic-structure-based material descriptors: (in)Dependence on self-interaction and Hartree-Fock exchange. Chem. Commun. 51, 5602–5605 (2015).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 3–15 (1999).

Monkhorst, H. J. & Pack, J. D. Special points for brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Acknowledgements

The authors thank the National Natural Science Foundation of China (21922513) and Natural Science Foundation of Hubei Province (2024AFD360).

Author information

Authors and Affiliations

Contributions

X.X.L. and Z.H.Z. proposed the project, designed the experiments, and wrote the manuscript; X.X.L. performed the whole experiments; L.H. carried out the DFT calculation; Y.D.M., P.Z., and G.Q.S. contribute the discussion of the results; L.F.Z. did some contribution in the revised version. Z.H.Z. supervised the whole project. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Osama El-Sepelgy, Wenbin Yi and the other, anonymous, reviewer for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, X., Huang, L., Ma, Y. et al. Enable biomass-derived alcohols mediated alkylation and transfer hydrogenation. Nat Commun 15, 7012 (2024). https://doi.org/10.1038/s41467-024-51307-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-51307-8

This article is cited by

-

Decatungstate-photocatalyzed transfer hydrogenation of unsaturated compounds using alcohol as the hydrogen source

Nature Communications (2026)