Abstract

Intermetallic compounds (IMCs) with ordered atomic structure have gained great attention as nanocatalysts for its enhanced activity and stability. Although the reliance of IMC preparation on high-temperature annealing is well known, a comprehensive understanding of the formation mechanisms of IMCs in this process is currently lacking. Here, we employ aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (AC-HAADF-STEM) to track the formation process of IMCs on carbon supports during in-situ annealing, by taking PtFe as a case study within an industry-relevant impregnation synthesis framework. We directly discern five different stages at the atomic level: initial atomic precursors; Pt cluster formation; Pt-Fe disordered alloying; structurally ordered Pt3Fe formation, and final Pt3Fe-PtFe IMC conversion. In particular, we find that the crucial role of high-temperature annealing resides in facilitating the diffusion of Fe towards Pt, enabling the creation of alloys with the targeted stoichiometric ratio, which in turn provides the thermodynamic driving force for the disorder-to-order transition.

Similar content being viewed by others

Introduction

Supported Pt nanocrystals are important catalysts in industries and energy conversion, particularly in fuel cells, where they help catalyze the oxygen reduction reaction due to their special electronic structure and catalytic efficiency1,2,3,4,5,6. However, their high cost and scarcity limit broader applications. Efforts to reduce costs while maintaining or enhancing performance include developing Pt-based alloys with 3d-transition metals like Fe, Co, Ni, and Cu, thanks to their induced ligand and strain effects7,8,9,10. Traditional Pt alloys typically have disordered structures that are less stable due to metal dissolution and limited enhancement effects. In contrast, structurally ordered intermetallic compounds (IMCs) are increasingly favored for their improved activity and stability in reactions, attributed to stronger ligand/strain effects and better formation energies from mixed-atomic bonding7,11,12.

In the synthesis of Pt intermetallic nanoparticle cathode catalysts, two main approaches are prominent: the colloidal method, involving solution-based synthesis and subsequent annealing after loading Pt-M (M representing transition metals) nanoparticles onto carbon supports11,13; and the impregnation method, which includes depositing metal precursors onto carbon supports through wet-impregnation, followed by annealing14,15. Unlike the colloidal approach, the impregnation technique is recognized for its simplicity and cost-effectiveness, making it suitable for industrial-scale production. However, it typically requires higher annealing temperatures11,12,16,17, easily causing particle sintering and mixed ordered-disordered phases, leading to inferior catalytic performance18,19,20,21. Hence, within the impregnation method, achieving a balance between size growth and ordered structure to maximize the benefits of IMCs presents a challenging task. One of the major hindrances to ending this is the lack of atomic understanding of IMC formation during high-temperature annealing. Although some studies have been conducted to investigate the formation process through ex-situ or in-situ technonogies18,22,23,24,25,26,27,28, the atomic-level knowledge of the role of high-temperature annealing in the formation of IMCs is still fuzzy due to a lack of direct experimental observation. Temperature could exert varying influences on the formation processes across different systems29,30,31. To date, the literature commonly attributes the role of high-temperature annealing in the formation of IMCs to initiating the disorder-to-order phase transition and overcoming the kinetic energy barrier of atomic transport during local rearrangement32,33. Nonetheless, it remains to be ascertained whether high-temperature annealing serves an additional function in facilitating IMC formation, especially in the case of the impregnation method that necessitates strong heating.

In this study, we explore the structural and compositional changes of atomic precursors to PtFe IMC nanoparticles, prepared via impregnation methods and examined through in-situ AC-HAADF-STEM annealing experiments. Tracking the dynamic evolution of metal atoms, precise structural motions from Pt cluster to Pt-Fe disordered alloy, ordering to Pt3Fe IMC, and eventually transforming to PtFe IMC through Fe diffusion are uncovered. Notably, our findings reveal that the formation of PtFe IMC is contingent upon achieving the specific stoichiometric ratio between Pt and Fe, which is facilitated by high-temperature annealing. As the theory of diffusion suggests, high temperature provides the necessary energy to overcome the high energy barriers of Fe atoms diffusing from the support to Pt clusters to achieve the required stoichiometric ratio, confirmed by DFT calculations. Once the desired stoichiometric balance is reached, it thermodynamically supports the transition from a disordered to an ordered phase. These findings may provide valuable guidance for the synthesis of IMC nanomaterials.

Results

Formation process of PtFe IMCs

To understand the formation process of PtFe IMCs, we conducted in-situ heating experiments in an AC-HAADF-STEM with atomic resolution. The dispersed metal precursor salts of Pt and Fe supported on commercial carbon black (Black Pearls 2000) were adopted to probe, which were prepared by the conventional wet-impregnation method (see Methods). The in-situ heating experiments were performed from 20 to 1000 °C with 10 °C min−1 heating rate and 1 h holding time at 150, 450, 650, 750, 850, 950, and 1000 °C, respectively. To avoid the continuous change of structure during image acquisition, quick cooling to 20 °C after holding at each temperature point is conducted to freeze the structure (Suppl. Fig. 1). Time series AC-HAADF-STEM images of representative areas captured during in-situ heating are shown in Fig. 1a–e (corresponding low-magnification images are shown in Suppl. Fig. 2). Initially, Pt and Fe atomically disperse on the support at room temperature (Fig. 1a). After heating to 450 °C, Pt aggregates to form Pt clusters indicated by the brighter contrast of Pt atoms (Fig. 1b). Further increasing the temperature to 650 °C results in Fe diffusion into Pt clusters and the formation of Pt-Fe alloy (Fig. 1c). The contrast uniformity of the particle proves a random distribution of Pt and Fe atoms. The disordered alloy feature is also evidenced by the fast Fourier transform (FFT) pattern consistent with the [011] zone axis of face-centered cubic (fcc, A1) Pt-Fe nanocrystals (Fig. 1f, i). When the annealing temperature is increased from 650 to 750 °C, the appearance of the ordered IMC structure is clearly demonstrated from the atomic columns with different contrast (Fig. 1d). Carefully investigating the atomic arrangement and FFT pattern (Fig. 1g) shows that the particle is along the [110] zone axis of face-centered tetragonal (fct, L12) Pt3Fe IMC. The alternating arrangement structure of Pt and Fe atoms corresponding to the particle is shown in Fig. 1j. It is noticed that with continued annealing to 950 °C, PtFe IMC (fct, L10) is present rather than keeping the ordering architecture of Pt3Fe IMC, suggesting further elemental diffusion of Fe into the nanoparticle (Fig. 1e), which is confirmed by the FFT pattern along [110] orientation of PtFe IMC in Fig. 1h. Ex-situ XRD test displays the same result (Fig. 1l), specifically, after heating at 700 °C, the diffraction peak agrees with that of L12 Pt3Fe (ICSD No.56275), while annealing above 900 °C, L10 PtFe (ICSD No.42589) is formed. The probing on the evolution of the ordered structure unveils that the formation of an ordered PtFe IMC first involves the establishment of a Pt3Fe ordered phase followed by further diffusion of Fe to the Pt3Fe nanoparticles. In order to provide more evidence of the phase formations, we conducted the in-situ X-ray absorption fine structure (XAFS) spectrum experiments to track the change of coordination structures during the formation of PtFe IMC. The in-situ XAFS spectra were collected with a custom-built high-temperature XAFS cell (Suppl. Fig. 3). As displayed in the serial X-ray absorption near-edge spectra (XANES) in Fig. 1m, the initial sample PtFe-25 showed a high oxidation state due to the existence form of PtCl62-. After heating to 450 °C, the oxidation state of Pt reduced to near zero, indicating the reduction and aggregation of Pt atoms to form Pt clusters. When annealed to a higher temperature, the further reduced oxidation state implied the alloying. The Fourier transform extended X-ray absorption fine structure spectra (EXAFS) showed that PtFe-25 exhibited a peak at 1.91 Å, which was attributed to Pt-Cl bonds (Fig. 1n). After heating to 450 °C, the Pt-Cl bonds disappeared and Pt-Pt bonds arose at around 2.64 Å. Further annealed to a higher temperature, a peak at 2.40 Å gradually increased, which was assigned to Pt-Fe bonds. To gain further insight into the change of coordination structures during the process, the curve-fitting of the EXAFS spectra was performed (the dotted lines in Fig. 1n and Suppl. Fig. 4). As exhibited in Fig. 1o and Suppl. Table 1, the coordination number of Pt-Fe bonds, along with their ratio relative to Pt-Pt bonds, showed a significant increase from 2.0 and 0.21 at 650 °C to 5.4 and 0.84 at 900 °C, respectively. This substantial change confirms the phase transition process.

a–e Time-series AC-HAADF-STEM images of a specific nanoparticle. Scale bar: 2 nm. f–h FFT pattern of the nanoparticle in c–e and corresponding schematic crystal structure (i–k), respectively. l Ex-situ XRD pattern after heating at different temperatures compared with PtFe (ICSD No.42589) and Pt3Fe (ICSD No.56275). m The normalized in-situ X-ray absorption near-edge spectra (XANES) at the Pt L3-edge of samples annealed at different temperatures. Note: the XX in PtFe-XX represents the annealing temperature. n The k3-weighted Fourier transform extended X-ray absorption fine structure spectra (EXAFS) in R-space. The dotted lines indicate the fitting results. o The change of Pt-Fe, Pt-Pt coordination number and corresponding ratio with the annealing temperature. Source data are provided as a Source Data file.

Further investigations of other nanoparticles acquired during in-situ heating confirmed that ordered atomic arrangement with Pt3Fe structure is generally adopted by the nanoparticles after heating to 750 °C before forming PtFe structure. AC-HAADF-STEM images of nanoparticles presenting the characteristic orientation of Pt3Fe or PtFe IMC nanoparticles are shown in Fig. 2a, c, g, i. One Fe atom surrounded by eight brighter Pt atoms is the [100] orientation of Pt3Fe (Fig. 2a). The corresponding FFT pattern is characterized by diffraction spots with {100} superlattice reflections (Fig. 2b). Another characteristic orientation is the [110] zone axis, where bright and slightly darker atom columns distribute in staggered lines (Fig. 2c and corresponding FFT pattern in Fig. 2d). The [110] zone axis of PtFe reveals alternant bright and dark atom columns in lines parallelly, confirming the L10 IMC atomic structure (Fig. 2g, h). Notably, the atomic arrangement in the [100] orientation of PtFe IMC (Fig. 2i) closely resembles that in the [110] zone axis of Pt3Fe. However, the contrast of darker atom columns is less pronounced in PtFe IMC due to its composition comprising entirely of Fe atoms, as opposed to the alternating Pt and Fe atoms in Pt3Fe. This observation aligns with the simulated STEM images of the two structures and corresponding 3D atom-overlapping Gaussian-function fitting mapping (Fig. 2e, f, k, l).

a, c, g, i Nanoparticles with ordered Pt3Fe or PtFe IMC phases in typical zone axis direction during heating: (a) Pt3Fe IMC nanoparticle along [100] zone axis after heating to 750 °C and corresponding FFT pattern (b). c Pt3Fe IMC nanoparticle along [110] zone axis and corresponding FFT pattern (d). e 3D atom-overlapping Gaussian-function fitting mapping of c. f Simulated STEM image of Pt3Fe IMC along [110] zone axis, inset is the corresponding 3D atom-overlapping Gaussian-function fitting mapping. g PtFe IMC nanoparticle along [110] zone axis and corresponding FFT pattern (h). i PtFe IMC nanoparticle along [100] zone axis after heating to 950 °C and corresponding FFT pattern (j). k 3D atom-overlapping Gaussian-function fitting mapping of i. l Simulated STEM image of PtFe IMC along [100] zone axis, inset is the corresponding 3D atom-overlapping Gaussian-function fitting mapping. The inset in a, c, g, i is the corresponding schematic diagram of atomic structure.

Evolution of Pt/Fe ratio and diffusion of Fe atoms

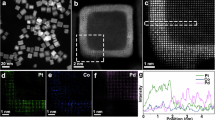

According to the above in-situ observation, the Fe content within nanoparticles undergoes continuous varies during the formation process of PtFe IMC. To monitor the change in Pt/Fe ratio and their distribution in the formation process of PtFe IMC, we performed in-situ energy-dispersive X-ray spectroscopy (EDS) mapping of the same region from RT to 950 °C (Fig. 3 and Suppl. Fig. 5). As shown in Suppl. Fig. 5a, b, Pt and Fe elements distribute uniformly on the carbon support before heating, with Pt showing slight aggregation upon reaching a temperature of 450 °C (Suppl. Fig. 5c, d). When the temperature rose to 650 °C, we observed an obvious concentration of Pt elements within the particle regions accompanied by a minor accumulation of Fe in the same areas, while most Fe elements were still distributed in the particle-free regions (Suppl. Fig. 5e, f). The preferential aggregation of Pt elements was consistent with the observed prior formation of Pt clusters in Fig. 1b. For the high-temperature annealing stage from 750 to 950 °C, the nanoparticles exhibited distinct elemental distribution of both Pt and Fe (Fig. 3a–o); and with the increase in the temperature, the content of Fe gradually increases in the nanoparticles and decreases outside the particle regions, suggesting the domination of alloying in this stage. The quantitative EDS analyses showed an increase in the average Pt/Fe ratio in nanoparticles to 2.9:1 (Pt 74.2%, Fe 25.5%) at 750 °C (Fig. 3a–e), which is close to the targeted stoichiometric ratio of Pt3Fe IMC. Further raising the temperature to 850 °C, the Pt/Fe ratio of nanoparticles changes to 1.2:1 (Pt 55.2%, Fe 44.8%) (Fig. 3f–j) and eventually becomes around 1:1 (Pt 52.0%, Fe 48.0%) at 950 °C (Fig. 3k–o), namely the stoichiometric ratio of PtFe IMC. To monitor changes in the stoichiometric ratio of single particles and substantiate the phase transition, we further conducted the high-magnification in-situ EDS analysis of representative particles across four distinct regions. Illustrated in Fig. 3p–v and Suppl. Figs. 6–10, we observed the variations in the atomic percentages of Pt and Fe across a total of eight particles. Consistently, these particles exhibited similar trends in stoichiometric ratio changes. Initially, at room temperature, Pt and Fe elements were uniformly distributed across the carbon support. Upon heating to 450 °C, the formation of small clusters was noted, with Pt constituting over 90% of these clusters, signaling the initial aggregation of Pt clusters. As the temperature escalated to 650 °C, the Fe content in the nanoparticles rose to approximately 20%, indicative of successful alloy formation. Progressing to 750 °C, an ordered atomic arrangement emerged, and the Fe content further increased. Statistical analysis of the Pt/Fe elemental ratio, as depicted in Suppl. Fig. 10, revealed a ratio of ≈ 3:1, confirming the formation of Pt3Fe IMC. With a further increase in temperature to 850 °C, Fe diffusion into the nanoparticles intensified, reducing the Pt/Fe ratio to about 2:1. This intermediate stoichiometric ratio indicated a phase transition. Ultimately, the elemental contents of Pt and Fe equilibrated, substantiating the formation of the PtFe IMC. The EDS results imply a continuous Fe diffusion into nanoparticles under high temperatures and the necessity of alloying to meet the stoichiometric ratio of IMC prior to atomic ordering. The average values change of the Pt/Fe ratio outside the particle regions during the process were also statistically analyzed by in-situ EDS experiments in four different regions to track the change of leftover Fe on the support. As shown in Suppl. Figs. 11–14, eight specific domains external to the particles were identified within each region, and the atomic percentages of Pt and Fe within these domains were quantitatively assessed. The average results indicated that the atomic percentage of Fe outside the particle areas progressively diminished from approximately 70% to less than 10% during the formation of the PtFe IMC. This consistent trend in the decrease of Fe atomic percentage across all four regions corroborates the hypothesis of Fe atom migration into the particles.

HAADF-STEM images and corresponding EDS elemental mapping of the same region annealing at different temperatures: (a–d) 750 °C, (f–i) 850 °C, and (k–n) 950 °C. e, j, o Statistic analysis of Pt/Fe ratio in each particle at different temperatures: (e) 750 °C, (j) 850 °C, and (o) 950 °C. HAADF-STEM images and corresponding EDS elemental mappings of the same nanoparticle at 750 °C (p, q), 850 °C (r, s) and 950 °C (t, u). v Quantitative analysis of the atomic percentage of Pt and Fe elements corresponding to the white square area at different temperatures. Source data are provided as a Source Data file.

Furthermore, we also study the formation process of PtFe IMC under H2 atmosphere to understand the influence of the gaseous environment. The gradual increase of particle size and decrease in the quantity of single atoms on the support are observed with the elevating temperature (Suppl. Figs. 15 and 16). The similar five stages of structural evolution (Suppl. Fig. 17) and change of Pt/Fe ratio (Suppl. Fig. 18) are also present under H2 atmosphere, which indicates that the necessity of meeting stoichiometric ratio prior to the formation of IMC is not affected by the gas environment.

Phase transition from Pt3Fe to PtFe

As the transition from Pt3Fe to PtFe is ubiquitous in the formation of PtFe IMC according to the in-situ observation, we tracked the detailed transition process by probing a single Pt3Fe particle during in-situ heating from 750 to 1000 °C (Fig. 4, corresponding low-magnification images are shown in Suppl. Fig. 19). The original particle is polycrystalline and composed of two distinct Pt3Fe grains (Fig. 4a). The two grains are aligned nearly along [100] (see FFT patterns in Fig. 4e), while the right part slightly tilts towards [01-1] orientation. Adding masks in the Fourier space which includes superlattice spots of Pt3Fe {001} (indicated by orange circles), a filtered image only containing information from the left part of Pt3Fe was acquired through inverse fast Fourier transform (iFFT) treatment and imposed to HAADF-STEM image (Fig. 4i, the original iFFT image is shown in Suppl. Fig. 20). The two grains have (011) plane as their boundary. The corresponding atomic model is shown in Fig. 4m to explain the atomic structure and orientation relationship. After heating to 850 °C, the right part converts to PtFe IMC along [0–11] through diffusion of residual Fe atoms from around (Fig. 4b, f). At this time, the left grain still maintains its original composition and orientation, but tilts slightly towards [011]. Similar Fourier filters were applied from the PtFe {011} superlattice spots (marked by yellow circles) and imposed to the original HAADF-STEM images (Fig. 4j, the original iFFT images are shown in Suppl. Fig. 21). The Pt3Fe (011) of the left grain closely contacts with the PtFe (100) in the right part (Fig. 4n, enlarged interface images are shown in Suppl. Fig. 22). This orientation relationship may be ascribed to the similar d-spacings of Pt3Fe (011) (2.732 Å) and PtFe (100) (2.761 Å). Continuing the heating process up to 950 °C further induces the transformation of the left part to PtFe ordered structure along [4 3 1] (Fig. 4c,g). The transformation is achieved through Fe atoms inserted from the PtFe (100) plane in the right grain to the Pt3Fe (010) of the left part. The initiation of Pt3Fe-to-PtFe transition at the (010) surface suggests that this crystal face has the highest energetic driving force and the lowest activation energy for the phase transition, also influenced by crystal face matching34. Fe atoms are supplied from residual Fe on support as the initial feed ratio of Pt and Fe is 1:1.2. The unaltered right grain proves this point (Fig. 4k, o). After further annealing at 1000 °C, the atoms around the surface of the nanoparticle become neatly arranged from slight disorder while the internal structure remains unchanged, which indicates that surface reconstruction mainly occurs at this stage (Fig. 4d, h, l, p). Observations of other particles in this temperature range display the same orientation relationship and Fe insert according to the atomic contrast (Fig. 4q–t). Atomic-scale data on the Fe diffusion towards the nanoparticle was also displayed in Suppl. Fig. 23, the Fe atoms gradually diffused into the upper left part of the nanoparticle, and therefore inducing the decrease of contrast. Moreover, to track the changing stoichiometric ratio during the phase transition of the two grains in a single particle, we conducted in-situ EDS analysis of a single particle with the same two grains and the phase transition process as the particle in Fig. 4. As displayed in Suppl. Fig. 24, the two grains in the particle both showed Pt3Fe phase at 750 °C. The corresponding Pt/Fe stoichiometric ratio of the whole particle is about 3.34, consistent with the Pt3Fe phase. During the temperature increase to 850 °C, the atomic arrangement showed obvious change (Suppl. Fig. 24b–d). Besides, the Pt/Fe stoichiometric ratio changed to 1.78 (Suppl. Fig. 24b) and gradually decreased to 1.64 (Suppl. Fig. 24d) before the completion of the phase transition of the right grain. The change in Pt/Fe stoichiometric ratio indicated the Fe diffusion and enhancement of alloying towards the particle before the phase transition. At 850 °C, the right grain transitioned to the PtFe phase according to the FFT pattern while the left grain remained in the Pt3Fe phase (Suppl. Fig. 24e). The Pt/Fe stoichiometric ratio of the particle was 1.58 at this point, which also implied the coexistence of Pt3Fe and PtFe phase. During the temperature increase to 950 °C, the atomic arrangement in left grain showed distinct variation and the right grain also exhibited slight change (Suppl. Fig. 24f). Moreover, the Pt/Fe stoichiometric ratio decreased to 1.36, indicating the further diffusion of Fe towards the particle prior to the phase transition. When the temperature reached 950 °C, both the left and right grains presented the PtFe phase (Suppl. Fig. 24g). Accordingly, the Pt/Fe stoichiometric ratio changed to 1.07. The statistics of the changes in the Pt and Fe stoichiometric ratio in different stages clearly exhibited the gradual increase of Fe content and alloying in the particle (Suppl. Fig. 24h). As shown in Suppl. Fig. 25, the analysis of the Pt and Fe stoichiometric ratio changes within the two grains indicated that the Fe content in the right grain increased significantly from 27.48 at.% to 42.89 at.% between 750 and 850 °C, and remained largely unchanged between 850 and 950 °C. In contrast, the Fe content in the left grain fluctuated around 20 at.% between 750 and 850 °C, but rapidly increased to 48 at.% between 850 and 950 °C. These findings unveil the evolution process from Pt3Fe to PtFe at the atomic level and highlight the key role of atomic diffusion in achieving the desired stoichiometric composition for IMC formation. To estimate the contribution of residual Fe on the support and Fe from right grain to the Fe entering left grain, we probed the change of Pt/Fe stoichiometric ratio in the right grain and different support regions during the transition of the left grain from Pt3Fe phase to PtFe phase (Suppl. Fig. 26). As shown in Suppl. Fig. 26f–j, the Fe content in the support region near the left grain reduced from 50.61 at.% at 850 °C to 11.62 at.% at 950 °C, indicating a significant reduction of approximately 38.99 at.% in Fe content. Noticeably, the Fe content in the right grain fluctuated around 55 at.% during the process (Suppl. Fig. 26k–o). Meanwhile, the Fe content in the support region near the right grain reduced from 40.68 at.% at 850 °C to 1.00 at.% at 950 °C (Suppl. Fig. 26p–t). Considering the observed Fe inserting from the right grain to the left one in Fig. 4, the role of the right grain is more like a Fe atom channel for the Fe atoms on the support near the right grain. The gradual increase in Fe content in the left grain confirms that Fe diffused into it (Suppl. Fig. 26u–y). The roughly equivalent decrease in Fe content near both the left (38.99 at.%) and right grains (39.68 at.%) indicated that the two ways may provide a similar proportion of contribution to the overall stoichiometric change in the left grain.

a–d Time-series AC-HAADF-STEM images. e–h FFT patterns correspond to the orange and blue dashed squares in a–d, respectively. False color is added to guide the vision. i HAADF-STEM image imposed with iFFT image (orange color), generated from the superlattice spots of Pt3Fe {001}. j–l HAADF-STEM images imposed with iFFT image (yellow color), generated from the superlattice spots of PtFe {011}. Inset is the FFT pattern used to generate the iFFT image. m–p Atomic models corresponding a–d to illustrate the orientation relationship and structure evolution. q–t HAADF-STEM images of nanoparticles that are transforming from Pt3Fe to PtFe through Fe diffusion. Scale bar: 2 nm.

Theoretical understanding of the formation of PtFe IMCs

In the formation process of PtFe IMC, high temperature plays an important role in supplying sufficient activation energy for atom diffusion and overcoming the energy barrier for alloying. According to the DFT calculations, when a Fe atom supported on graphene diffuses to a Pt9 cluster to form a Pt9Fe alloy, there is kinetically a 3.38 eV energy barrier that hinders the change of stoichiometric composition, which can only be overstrode at a high temperature (Fig. 5a and Suppl. Fig. 27). Moreover, we constructed a Pt45Fe14 cluster to represent the Pt3Fe nanoparticle and calculated the energy barrier for a near Fe atom supported on graphene diffusing into the cluster. The corresponding optimized structures were exhibited in Suppl. Fig. 28. As shown in Fig. 5b, the kinetic energy barrier for a Fe atom alloying with the Pt45Fe14 cluster is 3.44 eV, close to the 3.38 eV energy barrier needed to alloy a Fe atom with the Pt9 cluster. The high energy barrier in alloying a Fe atom with both Pt9 cluster or Pt45Fe14 cluster elucidates the important role of heating in alloying before transitioning to a PtFe IMC. As shown in the binary phase diagrams of Pt-Fe (Fig. 5c), with the increase of Fe content, the thermodynamically favorable phase evolves from disorder Pt-Fe alloy to Pt3Fe IMC and finally PtFe IMC. In consequence, the attainment of the stoichiometric composition is considered a prerequisite for generating the necessary thermodynamic driving force required for the disorder-to-order transition7,35. According to our in-situ observation, the formation of PtFe IMC experiences five different stages: initial atomic precursors; Pt clusters formation; Pt-Fe disordered alloying; structurally ordered Pt3Fe formation, and Pt3Fe-PtFe IMC conversion (Fig. 5d). Pt atoms agglomerate preferentially from atomically dispersed precursors to form clusters due to the different reduction potentials of Pt and Fe. As the reaction progresses, Fe atoms diffuse into Pt clusters and form disordered alloys. Importantly, the initial feed ratio of Pt and Fe is 1:1.2 and excessive Fe promotes its diffusion into Pt clusters. The Pt3Fe ordering is first achieved under continuing heating, then further Fe diffusion to meet the targeted stoichiometric ratio of PtFe and the conversion from Pt3Fe IMC to PtFe IMC happens. The atomic diffusion of Fe is proved to be indispensable in the formation of IMCs.

a Calculated energy analysis of a Fe atom alloying with a Pt9 cluster. b Calculated energy analysis of a Fe atom alloying with a Pt45Fe14 cluster. CI-NEB: climbing image-nudged elastic band. c Binary phase diagrams of Pt-Fe. d Schematic illustration of the formation process of PtFe IMC. Source data are provided as a Source Data file.

The change in the number of single atoms is also tracked to illustrate atomic diffusion. As seen in Suppl. Figs. 29 and 30, the number of single atoms only decreases slightly at the temperature below 450 °C, but significant disappearance is observed at 650 °C, along with noticeable particle growth. Most single atoms vanish when the temperature goes up to 750 °C and almost cannot be seen higher than this temperature. Besides, particle migration coalescence (PMC) of IMC nanoparticles happens during high-temperature annealing (Suppl. Fig. 31).

Discussion

In summary, using in-situ heating AC-HAADF-STEM, we demonstrated a detailed formation process of PtFe IMC at the atomic level. Before the conversion to the final PtFe IMC, it undergoes the states of Pt cluster, Pt-Fe disordered alloy, and Pt3Fe IMC. Moreover, we discovered that the prerequisite of transformation to PtFe intermetallic phase is precise compositional control to meet the specific stoichiometric ratio, which is accomplished by enhancing diffusion through high-temperature annealing. In this regard, future research might focus on innovating material strategies to lower alloying energy barriers for achieving IMC formation at lower temperatures. This could address size control challenges due to high-temperature annealing and advance high-performance IMC catalyst development in industries.

Methods

Chemicals

Potassium chloroplatinate (K2PtCl6), iron (III) chloride (FeCl3), and absolute ethyl alcohol (≥99.5%) were purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China). Black Pearls 2000 carbon black (BP2000) was purchased from Cabot. Deionized (DI) water from Milli-Q System (Millipore, Billerica, MA) was used in all our experiments. All chemicals were used as received without further purification.

Sample preparation

The precursors of IMC formation were prepared through a simple impregnation method. Specifically, 50 mg BP2000 was fully dispersed in 100 mL water. 6.8 mg K2PtCl6 and 9.4 mg FeCl3 were added to the suspension and stirred overnight. Further rotary evaporation of the liquid was performed to attain the precursor powder.

In-situ heating in TEM under vacuum

The prepared precursor was dispersed onto the in-situ heating chip purchased from DENS company. The in-situ heating experiments were conducted on a spherical aberration-corrected JEM-ARM 200 F scanning transmission electron microscope with an accelerating voltage of 200 kV combined with the in-situ heating holder (Wildfire S3 single-tilt holder) provided by DENS company. To exclude the influence of e-beam irradiation, the electron beam was turned off during the temperature-rise period and only used when imaging.

In-situ heating in TEM under H2 atmosphere

The in-situ heating experiments under H2 atmosphere were performed on environmental transmission electron microscope Hitachi HF5000 at Shanghai Institute of Ceramics, Chinese Academy of Sciences. The experiments were conducted under flowing 10% H2/90% N2 with a flow velocity of 2 cm3 STP min−1 and a pressure of 5 Pa.

In-situ EDS analysis

The in-situ low-magnification EDS mappings were acquired on Talos F200X combined with the in-situ heating holder (Wildfire S3 single-tilt holder) provided by DENS company. Collection of each EDS mapping was performed after quick cooling to 20 °C following holding at each temperature point. The pixel size was 137.6 pm and dwell time was set as 5 μs during EDS mapping. The in-situ high-magnification EDS mappings for representative particles were acquired on double-spherical aberration-corrected STEM Titan Themis Z combined with the in-situ heating holder (NanoEx) provided by Thermo Fisher Scientific company. The EDS mappings were acquired under an accelerating voltage of 300 kV with a spot size of 9 and screen current of 0.1 nA. The pixel size was 23.82 pm and dwell time was set as 2 μs. The particle regions were determined according to the corresponding HAADF-STEM images.

In-situ XAFS experiment

The in-situ XAFS spectra at the Pt L3-edge in transition mode were collected at the BL14W1 and BL20U beamline in the Shanghai Synchrotron Radiation Facility with a custom-built high-temperature XAFS cell. The energy was calibrated using a Pt foil. The metal precursor salts of Pt and Fe supported on commercial carbon black were pressed into tablet with an inner diameter of 10 mm and loaded on the center of high-temperature XAFS cell. XAFS spectra were initially collected at RT. Subsequently, the XAFS cell was incrementally heated at a rate of 15 °C min−1 under an inert argon atmosphere to the designated temperature points: RT, 450, 650, 700, 800, and 900 °C. XAFS spectra were recorded at each of these set temperature points, with a holding time of 20 min at each temperature. XAFS data processing was conducted using the IFEFFIT package and following standard analysis procedures. The spectra were calibrated, averaged, pre-edge background subtracted, and postedge normalized using the Athena program in the IFEFFIT software package36. The data fitting was performed using the Artemis program in the IFEFFIT software package.

Simulation of STEM images

STEM images were simulated using the multislice method in the QSTEM software package developed by Koch37. The image parameters used in the simulation were adjusted according to the experimental condition.

Ex-situ XRD test

The X-ray diffraction (XRD) patterns of samples were conducted on Rigaku Miniflex-600 operating at the voltage of 40 kV and the current of 15 mA with Cu Kα radiation (λ = 1.5406 Å). XRD measurement condition: step: 0.02°, scan speed: 10° min−1.

Computational details

All the DFT calculations were performed by using Vienna ab initio Simulation Package (VASP)38,39. The projector augmented wave (PAW) potentials were used to describe ion-electron interaction40. The electronic exchange and correlation effects were described by the generalized gradient approximation (GGA)41 with the PerdewBurke-Ernzerhof (PBE)42 functional. The kinetic energy cutoff of 500 eV was used. All the structures were fully relaxed, the convergence criteria for force and energy were set to be 10−5 eV and 10−2 eV Å−1, respectively. The Brillouin zones were sampled at 3×3×1 Gamma-centered K-point grid43. The vacuum space of 20 Å was set to avoid the interaction between adjacent images. The semi-empirical dispersion-corrected DFT-D3 scheme proposed by Grimme et al.44 was used to describe the van der Waals interaction. The climbing image nudged-elastic-band (CINEB) method was used to search transition state45. The reaction energy and barrier were defined as ΔE = EFS−EIS and Ea = ETS−EIS, where EIS, EFS, and ETS refer to the energies of the corresponding initial state, final state and transition state, respectively.

Data availability

The data that support the findings of this study are available from the corresponding authors upon request. Source data are provided with this paper.

References

Shao, M., Shoemaker, K., Peles, A., Kaneko, K. & Protsailo, L. Pt monolayer on porous Pd Cu alloys as oxygen reduction electrocatalysts. J. Am. Chem. Soc. 132, 9253–9255 (2010).

Meng, C. et al. Atomically and electronically coupled Pt and CoO hybrid nanocatalysts for enhanced electrocatalytic performance. Adv. Mater. 29, 1604607 (2017).

Xie, C. et al. Ambient reductive amination of levulinic acid to pyrrolidones over Pt nanocatalysts on porous TiO2 nanosheets. J. Am. Chem. Soc. 141, 4002–4009 (2019).

Xu, H., Shang, H., Wang, C. & Du, Y. Ultrafine Pt‐based nanowires for advanced catalysis. Adv. Funct. Mater. 30, 2000793 (2020).

Wang, X. et al. Pt-confinement catalyst with dendritic hierarchical pores on excellent sulfur-resistance for hydrodesulfurization of dibenzothiophene and 4, 6-dimethyldibenzothiophene. Green. Energy Environ. 7, 324–333 (2022).

Rao, P. et al. One‐dimensional PtFe hollow nanochains for the efficient oxygen reduction reaction. Carbon Energy 4, 1003–1010 (2022).

Yan, Y. et al. Intermetallic nanocrystals: syntheses and catalytic applications. Adv. Mater. 29, 1605997 (2017).

Huang, X. et al. High-performance transition metal–doped Pt3Ni octahedra for oxygen reduction reaction. Science 348, 1230–1234 (2015).

Chong, L. et al. Ultralow-loading platinum-cobalt fuel cell catalysts derived from imidazolate frameworks. Science 362, 1276–1281 (2018).

Wu, J. et al. Icosahedral platinum alloy nanocrystals with enhanced electrocatalytic activities. J. Am. Chem. Soc. 134, 11880–11883 (2012).

Li, J. et al. Hard-magnet L10-CoPt nanoparticles advance fuel cell catalysis. Joule 3, 124–135 (2019).

Li, J. et al. Fe stabilization by intermetallic L10-FePt and Pt catalysis enhancement in L10-FePt/Pt nanoparticles for efficient oxygen reduction reaction in fuel cells. J. Am. Chem. Soc. 140, 2926–2932 (2018).

Li, J. & Sun, S. Intermetallic nanoparticles: synthetic control and their enhanced electrocatalysis. Acc. Chem. Res. 52, 2015–2025 (2019).

Wang, D. et al. Structurally ordered intermetallic platinum–cobalt core–shell nanoparticles with enhanced activity and stability as oxygen reduction electrocatalysts. Nat. Mater. 12, 81–87 (2013).

Zhang, B. et al. General strategy for synthesis of ordered Pt3M intermetallics with ultrasmall particle size. Angew. Chem. Int. Ed. 59, 7857–7863 (2020).

Yin, P. et al. Synthesis of platinum intermetallic nanoparticle fuel cell catalysts within secure inter-particle distance on carbon blacks. Appl. Catal. B 328, 122543 (2023).

Song, T. W. et al. Intermetallic PtFe electrocatalysts for the oxygen reduction reaction: Ordering degree‐dependent performance. Small 18, 2202916 (2022).

Xiong, Y. et al. Revealing the atomic ordering of binary intermetallics using in-situ heating techniques at multilength scales. Proc. Natl Acad. Sci. USA 116, 1974–1983 (2019).

Wang, Z. et al. Structurally ordered low‐Pt intermetallic electrocatalysts toward durably high oxygen reduction reaction activity. Adv. Funct. Mater. 29, 1902987 (2019).

Bele, M. et al. A highly active PtCu 3 intermetallic core–shell, multilayered Pt-skin, carbon embedded electrocatalyst produced by a scale-up sol–gel synthesis. Chem. Commun. 50, 13124–13126 (2014).

Jung, W. S. & Popov, B. N. New method to synthesize highly active and durable chemically ordered fct-PtCo cathode catalyst for PEMFCs. ACS Appl. Mater. Interfaces 9, 23679–23686 (2017).

Gatalo, M. et al. Insights into thermal annealing of highly-active PtCu3/C Oxygen Reduction Reaction electrocatalyst: an in-situ heating transmission Electron microscopy study. Nano Energy 63, 103892 (2019).

Ma, T. et al. Toward phase and catalysis control: tracking the formation of intermetallic nanoparticles at atomic scale. Chem 5, 1235–1247 (2019).

Qi, Z. et al. Sub-4 nm PtZn intermetallic nanoparticles for enhanced mass and specific activities in catalytic electrooxidation reaction. J. Am. Chem. Soc. 139, 4762–4768 (2017).

Yang, Y. et al. Deciphering chemical order/disorder and material properties at the single-atom level. Nature 542, 75–79 (2017).

Zhou, J. et al. Observing crystal nucleation in four dimensions using atomic electron tomography. Nature 570, 500–503 (2019).

Zeng, W.-J. et al. Phase diagrams guide synthesis of highly ordered intermetallic electrocatalysts: separating alloying and ordering stages. Nat. Commun. 13, 7654 (2022).

Chen, X. et al. Composition-dependent ordering transformations in Pt–Fe nanoalloys. Proc. Natl Acad. Sci. USA 119, e2117899119 (2022).

Allnatt, A. & Chadwick, A. Thermal diffusion in crystalline solids. Chem. Rev. 67, 681–705 (1967).

Manning, J. R. Correlation factors for diffusion in nondilute alloys. Phys. Rev. B 4, 1111 (1971).

Matzke, H. Atomic mechanisms of mass transport in ceramic nuclear fuel materials. J. Chem. Soc., Faraday Trans. 86, 1243–1256 (1990).

Xiao, W., Lei, W., Gong, M., Xin, H. L. & Wang, D. Recent advances of structurally ordered intermetallic nanoparticles for electrocatalysis. ACS Catal. 8, 3237–3256 (2018).

Zhou, M., Li, C. & Fang, J. Noble-metal based random alloy and intermetallic nanocrystals: syntheses and applications. Chem. Rev. 121, 736–795 (2020).

Chi, M. et al. Surface faceting and elemental diffusion behaviour at atomic scale for alloy nanoparticles during in-situ annealing. Nat. Commun. 6, 8925 (2015).

Zeng, W.-J. et al. Alloying matters for ordering: synthesis of highly ordered PtCo intermetallic catalysts for fuel cells. Inorg. Chem. 62, 5262–5269 (2023).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Rad. 12, 537–541 (2005).

Koch, C. T. Determination Of Core Structure Periodicity And Point Defect Density Along Dislocations (Arizona State University, 2002).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Perdew, J. P., Ernzerhof, M. & Burke, K. Rationale for mixing exact exchange with density functional approximations. J. Chem. Phys. 105, 9982–9985 (1996).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Acknowledgements

This work was supported by the National Key Research and Development Program of China (2022YFB3807602 and 2019YFA0307900, Y.L.), the Youth Innovation Promotion Association of CAS (2020458, Y.L.), and National Natural Science Foundation of China (52122212, Y.L.; 12274391, Y.L.; Grants 22325903, H.L.; 22221003, H.L.; 22102167, Y.Z.; 22321001, Y.L.), the Key Research Program of Frontier Sciences, CAS (ZDBS-LY-SLH003, Y.L.), Postdoctoral Fellowship Program of CPSF (GZC20232511, X.H.), China Postdoctoral Science Foundation (2023M743348, X.H.), the Plan for Anhui Major Provincial Science & Technology Project (Grants 202203a0520013 and 2021d05050006, H.L.). The calculations were performed on the Supercomputing Center of the University of Science and Technology of China and Ningbo Artificial Intelligence & High Performance Computing Center. We thank the photoemission end stations BL14W1 and BL20U in Shanghai Synchrotron Radiation Facility (SSRF) for help in characterizations. We thank Dr. Chaobin Zeng from Hitachi High-tech (Shanghai) Co., Ltd and Dr. Chenxi Zhu from Shanghai Institute of Ceramics for their help with the experiments.

Author information

Authors and Affiliations

Contributions

Y. Lin, F. Xu, L. Tong, and H. Liang conceived the idea and co-wrote the paper. X. Han and X. Tai carried out the sample synthesis, characterization, and in-situ TEM experiments. Y. Zhou calculated the DFT calculation. C. Chen drew the schematic diagram. G. Wu and X. Hong discussed the results and helped with modifications to the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Han, X., Zhou, Y., Tai, X. et al. In-situ atomic tracking of intermetallic compound formation during thermal annealing. Nat Commun 15, 7200 (2024). https://doi.org/10.1038/s41467-024-51541-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-51541-0