Abstract

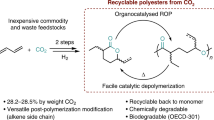

When aiming at the direct use of CO2 for the preparation of advanced/value-added materials, the synthesis of CO2/olefin copolymers is very appealing but challenging. The δ-lactone 3-ethylidene-6-vinyltetrahydro-2H-pyran-2-one (EVP), synthesized by telomerization of CO2 with 1,3-butadiene, is a promising monomer. However, its chemoselective ring-opening polymerization (ROP) is hampered by unfavorable thermodynamics and the competitive polymerization of highly reactive C=C double bonds under usual conditions. Herein, we report the chemoselective ROP of EVP using a phosphazene/urea binary catalyst, affording exclusively a linear unsaturated polyester poly(EVP)ROP, with a molar mass (Mn) up to 16.1 kg·mol−1 and a narrow distribution (Ð < 1.6), which can be fully recycled back to the pristine monomer, thus establishing a monomer-polymer-monomer closed-loop life cycle. In these polyesters, the CO2 content reaches 33 mol% (29 wt%). The reasons for the unexpected chemoselectivity were investigated by Density-functional theory (DFT) calculations. The poly(EVP)ROP features two pendent C=C double bonds per repeating unit, which show distinct reactivity and thus can be properly engaged in sequential functionalizations towards the synthesis of bifunctional polyesters. We disclose here a methodology providing a facile access to bifunctional and recyclable polyesters from readily available feedstocks.

Similar content being viewed by others

Introduction

The direct utilization of carbon dioxide (CO2) to produce valuable chemicals represents a most relevant and timely objective, because CO2 is not only an abundant and inexpensive C1-resource but also a massive contributor to the greenhouse effect1,2. The importance of accessing high value-added products from CO2 has been emphasized by manufacturing degradable polymers3,4. For example, the ring-opening alternating copolymerization of CO2 with epoxides produces degradable aliphatic polycarbonates5,6, which are the only industrial CO2-based polymers. Noteworthy, the large-scale industrial availability of olefins has allowed polyolefins to become the most common synthetic polymers, representing ca. half of the 300 million tons of plastics produced worldwide7. Achieving efficient copolymerization of CO2 with olefins hence represents a major target in terms of sustainability and economics8,9,10. However, little success has been achieved so far in this direction, owing to unfavorable reaction thermodynamics and kinetics under mild conditions11,12,13,14.

Transition metal complexes can catalyze reactions of CO2 with C-C bond formation15 and in the late 1970s, Inoue and coworkers discovered that coupling of CO2 with 1,3-butadiene using a Pd-catalyst produces esters and lactones, in particular the six-membered unsaturated δ-lactone 3-ethylidene-6-vinyltetrahydro-2H-pyran-2-one (EVP, Fig. 1)16, of which the yield and selectivity have been significantly improved over the years17,18,19,20,21,22,23. This multifunctional δ-lactone appears as a promising potential monomer to construct CO2-based polymers24, since it contains 1) a cyclic ester unit that can undergo ring-opening polymerization (ROP) to give polyesters, 2) a terminal olefin that could be engaged in coordination addition polymerization, and 3) an α,β-unsaturated ester subunit that could afford polyacrylates by radical polymerization. However, EVP has received very little attention in polymer chemistry until almost 40 years after its discovery. In 2014, Nozaki and co-workers reported a milestone work with the free-radical homopolymerization of EVP to afford polyacrylates (Fig. 1a)25. Later, Lin and coworkers synthesized high-molar-mass CO2-derived polymers by O2-initiated radical polymerization of EVP under additive/solvent-free conditions26. More recently, the Pd-catalyzed copolymerization of EVP with ethylene was reported (Fig. 1b)27.

a Free-radical polymerization, b coordination copolymerization, c partial hydrogenation to form EtVP and further ring-opening polymerization, d ring-opening homopolymerization, e complete hydrogenation to form DEtP and further ring-opening polymerization, f thiol-ene click polymerization, g cationic copolymerization, h scrambling polymerization, i methanolysis/esterification, j ring-opening/conjugate polymerization.

Although the selective ROP of EVP appears most attractive in view of the degradability and possible functionalization of the resulting aliphatic polyesters, all previous attempts have failed, owing to the stability of a six-membered disubstituted δ-lactone with low ring strain. Moreover, the conjugated double bonds could undergo Michael-addition reactions that would compete against or suppress ROP26,27,28,29,30,31,32. Therefore, previous reports on ROP focused on the hydrogenated derivatives of EVP, including 3-ethyl-6-vinyltetrahydro-2H-pyran-2-one (EtVP, Fig. 1c) and 3,6-diethyl-tetrahydro-2H-pyran-2-one (DEtP, Fig. 1e). For instance, Tonks and coworkers reported the ROP of EtVP or DEtP to form recyclable polyesters, utilizing 1,5,7-triazabicyclo[4.4.0]dec-5-ene (TBD) as the catalyst9,33. At almost the same time, Lin and coworkers synthesized polyesters with high-molar-mass, up to 613.8 kg·mol-1, by ROP of DEtP34. Other strategies include the copolymerization of EVP with other monomers or the transformation of EVP to other reactive intermediates35. For example, the step-growth polymerization of EVP with di- or poly-thiols was developed to synthesize linear or network copolymers containing the intact lactone ring (Fig. 1f)32,36, whereas copolymerization of EVP with β-butyrolactone (BBL) or ε-caprolactone (ε-CL) produced copolyesters (Figs. 1g and 1h, respectively)37,38. Ni and coworkers reported the transformation of EVP to methyl-2-ethylidene-5-hydroxyhept-6-enoate methacrylate (Fig. 1i, MEDMA), a highly reactive trivinyl intermediate, by sequential methanolysis and esterification with methacryloyl chloride31,39. Recently, Eagan and coworkers achieved the polymerization of EVP by ring-opening and 1,4-conjugate reactions (Fig. 1j). The dimer (Di-EVP) was first formed by vinylogous 1,4-conjugate addition and then polymerized to degradable polyesters40.

These recent achievements prompted us to examine the direct ring-opening homopolymerization of EVP, which does not require prior hydrogenation to prepare EtVP or DEtP (Fig. 1c, e). It is noteworthy that the polyesters resulting from direct and selective ROP of EVP (Fig. 1d) retain two different types of C=C double bonds (terminal and internal) with distinct reactivity. Consequently, chemoselective ring-opening homopolymerization of EVP should provide opportunities for a post-functionalization of polyesters, via hydrolysis, click reaction, and cross-linking, and thus open new avenues for the synthesis of CO2-based polymers with tailor-made structures and properties41,42.

Herein, we report the chemoselective ROP of EVP, producing exclusively poly(EVP)ROP (Fig. 1d), catalyzed by a phosphazene/urea binary system. After optimization of the catalyst structure and reaction conditions, a 43% conversion of EVP was achieved and a linear poly(EVP)ROP with a Mn as high as 16.1 kg·mol-1 was successfully synthesized. These polyesters have a high CO2 content (29 wt%) and can be depolymerized back to the pristine monomer. The terminal and internal alkenes of poly(EVP)ROP can be engaged in different post-functionalization reactions, allowing the synthesis of bifunctional CO2-based polyesters.

Results and discussion

Chemoselective ROP of EVP under different conditions

A phosphazene/urea binary catalyst, known to be effective for the selective ROP of α-methylene-γ-butyrolactone (MBL) and α-methylene-δ-valerolactone (MVL)43,44, was used for screening the ROP of EVP. The vinyl-addition polymerization (VAP) of α,β-unsaturated ester has been proposed to proceed via the generation of a carbanion intermediate, which requires a catalyst with a much stronger basicity than that for the ROP pathway. It has been reported that in a base/urea catalytic system, a hydrogen bond donor bis-urea usually shows higher catalytic activity toward the ROP of lactones than a mono-urea under otherwise identical conditions45,46. We initially selected a cyclic trimeric phosphazene base (CTPB) of moderate basicity (pKa = 33.3 in MeCN) and the bis-urea DU8 (Fig. 2) to form the binary catalyst.

The ROP reactions were first conducted between 25 °C and −70 °C to investigate the effect of temperature on the chemoselectivity, with ratios EVP/CTPB/DU8/BnOH = 50/1/1.5/1 and [EVP]0 = 5.0 M in THF (Supplementary Table 1, runs 1−5). 1H NMR data were collected on crude mixtures to monitor the conversion of EVP, the formation of ring-opening products (oligo(EVP)ROP for Mn < 2.0 kg·mol-1 or poly(EVP)ROP for Mn ≥ 2.0 kg·mol-1) and other by-products at different reaction temperatures (Fig. 3). As anticipated, rapid vinylogous 1,4-conjugate Michael addition occurred at room temperature (25 °C), resulting in the selective formation of Di-EVP (Fig. 1j), as indicated by the typical 1H NMR signal at 7.07 ppm of the reaction mixture (Fig. 3b) and purified product (Supplementary Fig. 1). To realize the selective ROP of EVP, subsequent polymerization reactions were conducted at lower temperatures. At 0 °C (Supplementary Table 1, run 2), both 1H NMR resonances at 7.07 and 6.91 ppm were observed (Fig. 3c), suggesting the presence of a mixture of Di-EVP, formed by 1,4-conjugate Michael addition, and of oligo(EVP)ROP from ROP (vide infra), respectively. If exclusive formation of oligo(EVP)ROP with 13% conversion was achieved at −20 °C within 8 h (Supplementary Table 1, run 3; Fig. 3d), a further decrease of the temperature to −50 °C resulted in selective ROP and a 30% conversion of EVP within 8 h (Table 1, run 1; Fig. 3e). Under such conditions, the oligo(EVP)ROP obtained had a molar mass (Mn) of 1.5 kg·mol-1, which was lower than the theoretical value (2.4 kg·mol-1), probably because of the inevitable occurrence of transesterification during polymerization, as evidenced by the relatively broad dispersity (Đ = 1.42; Supplementary Fig. 2a). However, only a 13% conversion of EVP was observed at −70 °C (Supplementary Table 1, run 5; Fig. 3f), which was significantly lower than that obtained at −50 °C. This phenomenon is probably due to the decreasing solubility of the CTPB/DU8 mixture at −70 °C, which limits the interactions between phosphazene and urea47. In addition, the polymerization reaction was also carried out for 16 h at −70 °C, and the conversion of EVP was still only 13% (Supplementary Table 1, run 13), as observed after 8 h reaction time (Supplementary Table 1, run 5). As shown in Supplementary Fig. 18, the polymerization solution of EVP with a 13% conversion is frozen at −70 °C, which limits the further polymerization. These results suggested that performing the reaction below 0 °C is a prerequisite for the chemoselective ROP of EVP48. To gain a deeper insight into this reaction, the thermodynamics for ROP of EVP were studied with ratios EVP/CTPB/DU8/BnOH = 50/1/1.5/1 and [EVP]0 = 5.0 M in THF at different temperatures (from –10 to –50 °C), and the results are summarized in Supplementary Table 2. The equilibrium monomer concentration, [EVP]eq, was measured to be 4.60, 4.35, 4.10, 3.80, and 3.50 M at –10 °C, –20 °C, –30 °C, –40 °C, and –50 °C, respectively. The Van’t Hoff plot of ln[EVP]eq versus 1/T yields a straight line (R2 = 0.998) with a slope of –0.40 and an intercept of 3.05 (Supplementary Fig. 3). The enthalpy change (ΔHp) and entropy change (ΔSp) for the ROP of EVP are −0.80 kcal·mol-1 and −6.1 cal·mol-1·K-1, respectively, resulting in a ceiling temperature (Tc) of –141 °C at [EVP]0 = 1 M and of 5 °C at [EVP]0 = 5 M according to the Dainton’s equation (Tc = ΔHp /(ΔSp + Rln[EVP]0), where R is the gas constant)49. It is surprising that the thermodynamics for the ROP of EVP are more similar for the five-membered γ-butyrolactone (γ-BL: ΔHp = −1.29 kcal·mol-1, ΔSp = −9.5 cal·mol-1·K-1, and Tc (1 M) = − 136 °C) and α-methylene-γ-butyrolactone (MBL: ΔHp = −1.41 kcal·mol-1, ΔSp = −9.6 cal·mol-1·K-1, and Tc (1 M) = −126 °C)48,50, than for the six-membered hydrogenated EtVP (ΔHp = −2.7 kcal·mol-1, ΔSp = −9.2 cal·mol-1·K-1, and Tc (1 M) = 18.3 °C) and DEtP (ΔHp = −3.1 kcal·mol-1, ΔSp = −11.7 cal·mol-1·K-1, and Tc (1 M) = 6 °C)34,51. These results further confirm that ROPs of EVP need to be conducted at low temperature, similarly to γ-BL and MBL. Furthermore, we also evaluated the propensity of EVP to undergo a thermodynamically favorable ROP using a methodology recently reported by Hoye52, where an equilibrium for ring-opening of EVP in 2 vol% CD3OD in CDCl3 was monitored by 1H NMR (Supplementary Fig. 4). The percentage of ring-opened product at equilibrium is 17%, which is similar to the case of γ-BL monomer (18.7%) and consistent with the measured thermodynamic parameters in this study.

a EVP monomer and b−f crude ROP mixtures obtained using the CTPB/DU8 binary catalyst at different temperatures (Supplementary Table 1, runs 1−5). The calculations of selectivity are based on the integrations for peaks at 6.91 ppm (poly(EVPROP)) and 7.07 ppm (Di-EVP).

Not only the temperature but also the molar ratio phosphazene/urea in the binary catalytic system were found to be critical for the chemoselective ROP of EVP (Table 1, run 1 and Supplementary Table 1, runs 6−8). The ratio CTPB/DU8 influences the monomer conversion and the selectivity of the polymerization (Supplementary Fig. 5). For instance, polymerizations conducted with a ratio CTPB/DU8 = 1/0 or 1/0.7 produced mixtures of Di-EVP and ROP products, as shown by the 1H NMR resonances at 7.07 and 6.91 ppm, and the selectivity for ROP was only 36% or 57%, respectively (Supplementary Fig. 5, blue and red; Supplementary Table 1, runs 6 and 7). To achieve the exclusive ROP of EVP (100% through ROP pathway), at least 1.5 equiv. of DU8 to CTPB was required (Table 1, run 1). However, a large excess of urea relative to base (CTPB/DU8 = 1/3; Supplementary Table 1, run 8) resulted in a decreased conversion, which is consistent with previous work53, although the selectivity for the ROP of EVP remained high.

Encouraged by these results, combinations of CTPB with various ureas (Fig. 2, U4, U7−U9 with known pKa values) were further tested as binary organocatalysts for the ROP of EVP (Table 1, runs 5, and 8−10). When U4 with a pKa value of 22.8 in DMSO was used (Table 1, run 5), a mixture of Di-EVP and oligo(EVP)ROP was obtained (Supplementary Fig. 6). Exclusive ROP of EVP was achieved with U7 (pKa = 18.7 in DMSO) as a cocatalyst (Supplementary Fig. 7), and a 20% conversion of EVP was obtained within 8 h, producing oligo(EVP)ROP with a Mn = 0.9 kg·mol-1 (Table 1, run 8). As shown in Supplementary Fig. 8, U8 with a pKa value of 17.8 led to a conversion and selectivity (Table 1, run 9) similar to U7. However, a further increase in the acidity of the urea led to a significant decrease in the conversion of EVP, and U9 (pKa = 13.8 in DMSO) combined with CTPB only resulted in a 6% conversion under otherwise identical conditions (Table 1, run 10; Supplementary Fig. 9). It is assumed that the more acidic U9 formed with CTPB a relatively robust adduct that reduced the catalytic capability6,54. In addition to CTPB, the commercially available phosphazenes t-BuP4 (pKa = 42.7 in MeCN) and t-BuP2 (pKa = 33.5 in MeCN) (Fig. 2) were tested in combination with DU8, and chemoselective ROPs of EVP (Supplementary Table 1, runs 9 and 10) were observed. We also found that the monomer concentration dramatically influences the activity in the ROP of EVP. Decreasing the concentration of EVP resulted in lower conversions (Supplementary Table 3, runs 5 and 6), whereas attempts to perform bulk polymerization failed, because the pure EVP monomer immediately became very viscous at −50 °C. The oligo(EVP)ROP or poly(EVP)ROP with different molar masses were successfully obtained by adjusting the molar ratio of EVP to BnOH. ROP with EVP/BnOH ratios varying from 50/1, 50/0.5 to 50/0.25 produced oligo(EVP)ROP or poly(EVP)ROP with increased Mns from 1.5, 3.6 to 6.5 kg·mol-1, respectively (Table 1, runs 1, 12 and 13; Supplementary Fig. 2). However, further decreasing the initiator loading (EVP/BnOH = 50/0.125; Table 1, run 14) indeed resulted in a decreased conversion, probably because of the lower concentration of anionic active species. The lower conversion and the more significant transesterification (Ð = 1.58) led to a low Mn of 2.4 kg·mol-1.

The poly(EVP)ROP and oligo(EVP)ROP samples were carefully analyzed by NMR spectroscopy (Fig. 4 and Supplementary Fig. 10), which revealed that homopolymerization of EVP occurred by a selective ROP process. The assignments were based on 1H–1H COSY, 1H–13C HSQC and DEPT experiments (Supplementary Figs. 11−13). In the typical 1H NMR spectrum of the poly(EVP)ROP obtained in Table 1 run 13 (Fig. 4a), the signals at 6.91 (Hc), 5.81 (Hh) and 5.26 (Hi) ppm are characteristic of olefinic protons, and are associated with resonances at 138.02 (Cc), 136.40 (Ch) and 116.57 (Ci) ppm in the 13C NMR spectrum (Fig. 4b). The MALDI-TOF spectrum of the same poly(EVP)ROP sample is shown in Fig. 4c, which displays only one series of signals assigned to a linear chain structure with BnO/H end groups. The two neighboring molecular ion peaks are separated by 152.2 g·mol-1, which is fully consistent with the exact molar mass of the EVP repeating unit. The NMR and MALDI-TOF MS spectra clearly confirmed the selective ROP of EVP and the production of linear poly(EVP)ROP polyester. No phosphazene/water initiation is observed in the MALDI-TOF spectra (Supplementary Figs. 14 and 15). To the best of our knowledge8,9,10, this is the only report of a direct and selective ROP of EVP. A CO2-based polymer with two distinct unsaturated functional groups (terminal and internal alkenes) has thus been developed (Fig. 1d).

a 1H NMR (400 MHz, CDCl3), b 13C NMR (100 MHz, CDCl3), and c MALDI-TOF spectra of poly(EVP)ROP obtained in Table 1 run 13 (Mn = 6.5 kg·mol-1, Ð = 1.24).

Computational Investigation of the ROP Mechanism

To elucidate the origin of the chemoselective ROP of EVP, both ROP and 1,4-conjugate addition dimerization pathways were studied and compared by DFT calculations. To simplify the calculations, the urea was considered to be completely deprotonated in the model reaction, and the chain initiations involved in the ROP and 1,4-conjugate addition dimerization pathways were mediated by the complex (INT0) resulting from the interaction of benzyl alcohol with deprotonated DU8, which was well documented in previous reports43,53. As shown in Fig. 5, nucleophilic attack of methoxy-anion chain end BnO− of BnOH on the carbonyl carbon atom of EVP takes place via a transition state (TS) TS1ROP with an energy barrier (ΔG‡ROP) of 11.4 kcal·mol-1 to generate an intermediate (INT) INT1ROP. Then, ring-opening of EVP occurs via TS2ROP to form INT2ROP, with an exothermal energy of 4.3 (11.1−6.8) kcal·mol-1, in which a new methoxy-anion chain end resulting from the ring-opening of EVP is stabilized by DU8 molecule through hydrogen-bonding interactions, being similar to the bisthiourea-nitrate complex formed in the bisthiourea-catalyzed Henry reactions55.

For the 1,4-conjugate addition dimerization pathway, a hydrogen from the methyl of EVP is captured by BnO− of BnOH to surmount a TS1dim with an energy barrier of 16.2 kcal·mol-1, which further removes a benzyl alcohol and rearranges to afford INT1dim. This INT1dim attacks the methine carbon atom of the second EVP molecule through TS2dim to form a dimer INT2dim with an energy barrier of 11.7 (20.6−8.9) kcal·mol-1. Furthermore, the complex INT3dim containing a dimer of EVP is generated by addition of benzyl alcohol via TS3dim with an energy barrier of 2.6 (8.2−5.6) kcal·mol-1. By contrast, the ROP pathway overcomes a free-energy barrier of 11.4 kcal·mol-1, which is more kinetically favorable than a 1,4-conjugate addition dimerization (with the whole energy barrier of 20.6 kcal·mol-1, ΔG‡dim). The rate-determining step of the ROP or 1,4-conjugate addition dimerization pathway by CTPB/DU8 (intramolecular bis-urea mechanism) is nucleophilic attack by the BnO− anion (TS1ROP) or by carbanion (TS2dim), respectively.

As previously reported, two possible mechanisms, intramolecular bis-urea mechanism and activated-U mechanism45,46, can be considered for the DU8 mediated polymerization of EVP. We also considered these two pathways computationally (Supplementary Fig. 17). In the activated-U mechanism, DU8 is firstly activated by itself through intramolecular hydrogen-bond interactions as suggested by the H4···O2 (1.75 Å) and H3···O2 (2.33 Å) contacts. In contrast, the bis-urea activated intermediate INT0 appears lower in energy (0.0 vs 5.5 kcal·mol-1) than the activated-U intermediate INT0iso. Further nucleophilic attack on EVP takes place via TS1ROPiso with an energy barrier of 12.3 kcal·mol-1, which is higher than that (11.4 kcal·mol-1) of the bis-urea activated pathway. Therefore, the greater stability of INT0 and TS1ROP (11.4 vs 17.8 kcal·mol-1) and easier nucleophilic attack make the bis-urea activation mechanism more favorable in the DU8-assisted EVP polymerization. To further verify this bis-urea effect, another bis-urea DU6 (Fig. 2) was prepared and used for the ROP of EVP (Table 1, runs 11, and 16−19). DU6 can be seen as the bis-analogue of mono-urea U6. Although DU6 has a computed pKa of 19.6 similar to that (19.4) of U6, the former led to a significantly higher conversion of EVP (43%) than the latter (22%) under otherwise identical conditions (Table 1, run 11 vs run 7). The resulting poly(EVP)ROP obtained by DU6 has a Mn of 2.2 kg·mol-1, which is also higher than that by U6 (1.3 kg·mol-1). These results are consistent with the results from mono-urea U8 or bis-urea DU8 and previous reports43,45,46. It is interesting that a conversion of EVP as high as 43% was obtained with DU6 (Table 1, run 11), because precipitation of the resulting polymer from solution under these conditions (Supplementary Fig. 18) shifts the equilibrium towards propagation. It is noteworthy that poly(EVP)ROP with a Mn as high as 16.1 kg·mol-1 was successfully synthesized using this highly reactive CTPB/DU6 as the catalyst and BDM as a bifunctional initiator for 24 h (Table 1, run 19; EVP/CTPB/DU6/BDM = 50/1/1.5/0.125). This Mn of 16.1 kg·mol-1 was relatively lower than the theoretical one (Mn,theor = MEVP (152.19 g·mol-1) × ([EVP]0:[I]0) × conversion + MBDM (138.07 g·mol-1) = 20.8 kg·mol-1), probably because the precipitation of the resulting polymer from solution resulted in heterogeneous polymerization conditions and more significant transesterification during polymerization (Đ = 1.55). It is noteworthy that the CO2-based polymers with relatively low Mn and terminal hydroxyl groups represent a class of high value-added polyols and are widely used in the manufacturing of degradable polyurethanes56,57.

In the case of mono-ureas, a reaction mechanism involving only one urea was considered, according to previous research53,58. As shown in Supplementary Fig. 16, nucleophilic attack of the BnO− of BnOH on the carbonyl C atom of EVP occurs via a TS1ROP (U8) with an energy barrier of 12.3 kcal·mol-1 to INT1ROP (U8), being accompanied by a proton (H1) transfer from BnOH to deprotonated U8. Then, the ring-opening of EVP occurs via TS2ROP (U8) with an energy barrier of 2.6 kcal·mol-1 to form INT3ROP (U8) in which a new methoxy-anion chain end from the ring-opening of EVP is stabilized by one U8 molecule through hydrogen-bonding interactions. Finally, a proton is transferred from U8 to the oxygen atom of the new methoxy-anion chain end to accomplish the ring-opening polymerization cycle. Therefore, the rate-determining step of ROP by mono-urea is the ring-opening process with the ΔG‡ROP of 14.7 kcal·mol-1.

In the 1,4-conjugate addition dimerization pathway, a hydrogen from the methyl of EVP is captured by the BnO− of BnOH via TS1dim (U8) with an energy barrier of 18.6 kcal·mol-1 to generate INT1dim (U8) while a proton is transferred from BnOH to the deprotonated U8. Then, benzyl alcohol is removed and a rearrangement leads to the more stable INT2dim (U8) with a carbanion. The carbanion attacks the methine carbon atom of the second EVP through TS2dim (U8) to provide a dimer INT3dim (U8) with an energy barrier of 11.7 (20.3−8.6) kcal·mol-1. An electronic rearrangement leads to a more stable INT4dim (U8). Furthermore, the complex INT5dim (U8) containing a dimer of EVP is generated via TS3dim (U8) by addition of benzyl alcohol with an energy barrier of 5.7 (8.8−3.1) kcal·mol-1. Finally, a proton transfers from U8 to a BnO− by releasing an energy of 2.7 kcal·mol-1. By contrast, the ROP pathway overcomes a free-energy barrier of 14.7 kcal·mol-1, which is kinetically more favorable than the 1,4-conjugate addition dimerization (ΔG‡dim: 20.3 kcal·mol-1). The rate-determining step of the ROP or 1,4-conjugate addition dimerization pathway by CTPB/U8 (mono-urea mechanism) is ring-opening (TS2ROP) or nucleophilic attack by carbanion (TS2dim), respectively.

To gain a deeper insight into the effect of ureas on the activity and selectivity of EVP polymerization, the pKa values of different ureas and the rate-determining steps of both the ROP and 1,4-conjugate addition dimerization pathways mediated by CTPB/ureas (U4, U7, and U9) were also examined computationally, and the results are collected in Supplementary Table 4. In comparison with U8, the less acidic U4 (pKa,exp = 22.8 and pKa,cal = 22.0) shows a smaller energy-barrier gap (ΔG‡dim − ΔG‡ROP = 3.9 vs 5.6 (U8) kcal·mol-1) between the EVP ROP pathway and the 1,4-conjugate addition dimerization pathway, which is consistent with the experimentally observed low selectivity (47%). Conversely, the more acidic U9 (pKa,exp = 13.8 and pKa,cal = 13.9) shows a larger ΔG‡dim − ΔG‡ROP (8.8 kcal·mol-1), again consistent with the selectivity of 100% observed experimentally. For comparison, U7, U8, and DU8 with similar acidity (pKa,cal = 19.0, 17.9, and 18.1) all show large ΔG‡dim − ΔG‡ROP (5.0, 5.6, and 9.2 kcal·mol-1), thus resulting in high selectivity of ROP. However, the lower ΔG‡ROP (11.4 vs 14.1 (U7) and 14.7 (U8)) in the case of DU8 is consistent with higher conversion (30%) in comparison with U7 (20%) and U8 (22%). This could be ascribed to intramolecular interactions involving the bis-urea.

To expand the range of catalytic systems for EVP polymerization, we computationally tested the catalytic performances of other urea derivatives (Fig. 2, U1−U3, U5, and U6) for this reaction. The results are summarized in Supplementary Table 4, and indicate that U1−U3 with low acidities (pKa,cal > 21) showed small energy-barrier gaps (ΔG‡dim − ΔG‡ROP < 4.0 kcal·mol-1) and thus low selectivity for EVP ROP. In the case of U5, both low conversion and selectivity were observed experimentally because of its low solubility under polymerization conditions. Furthermore, calculations suggested that U6 (pKa,cal = 19.4) had a similar acidity to U7 (pKa,cal = 19.0) and also exhibited similar ΔG‡ROP (13.6 and 14.1 kcal mol-1) and ΔG‡dim − ΔG‡ROP (5.0 kcal·mol-1). Gratifyingly, similar catalytic activities and selectivities were observed experimentally for U6 and U7 (Supplementary Table 4, runs 6 and 8), illustrating the potential of DFT calculations for developing high-performance catalysts. In summary, the chemoselectivity for ROP of EVP should primarily depend upon the acidities of the ureas, namely their pKa values, which determines the energy-barrier gap (ΔG‡dim − ΔG‡ROP) between the ROP pathway and the 1,4-conjugate addition dimerization pathway. As shown in Supplementary Table 4, all the ureas with a pKa value lower than 19.6 are highly chemoselective for ROP of EVP. In addition, the tethered structure of bis-urea (DU6 and DU8) could favor the catalytic activity, probably because of the implication of a bis-urea assisted intramolecular mechanism.

Post-functionalization of poly(EVP)ROP

Poly(EVP)ROP features two C=C double bonds per repeating unit with distinct reactivity, which can be properly engineered by post-functionalization to generate bifunctional polyesters with tunable properties. For instance, the internal alkene of poly(EVP)ROP was selectively functionalized by Michael addition, leaving the terminal alkene unreacted (Fig. 6a1). Thus, benzyl mercaptan was used as a representative thiol and reacted with poly(EVP)ROP in DMF at 20 °C in the presence of DBU as the catalyst59,60. The selective functionalization of the internal alkene was confirmed by NMR spectroscopy (Fig. 6b, Supplementary Figs. 19 and 20) and GPC (Supplementary Fig. 23) of the resulting polyester. In comparison with Fig. 6b1, b2, the signal at 6.91 ppm (Ha) assigned to the internal alkene has disappeared, while the original resonances at 5.81 (Hc) and 5.26 (Hb) ppm for the terminal alkene remain but are shifted to 5.67 (Hc’) and 5.25 (Hb’) ppm. In addition, two new resonances at 3.70 (He) and 1.24 (Hf) ppm are observed for the −S–CH2–(He) and −S–CH–CH3 (Hf) protons, respectively, which confirmed the selective Michael addition of the internal double bond affording poly(EVP)S1 (Fig. 6a1).

a Post-functionalization of poly(EVP)ROP via sequential (1) Michael addition reaction and (2) photoinduced thiol-ene click reaction. (b) Stacked 1H NMR spectra (400 MHz, CDCl3) of (1) poly(EVP)ROP (Mn = 6.5 kg·mol-1; Table 1 run 13), (2) poly(EVP)S1 produced via selective Michael addition reaction, and (3) poly(EVP)S1+S2 produced via two sequential Michael addition and click reactions. (c) Stacked 1H NMR spectra (400 MHz, CDCl3) of (1) pristine EVP monomer for comparison; (2) recovered EVP monomer from recycling; (3) poly(EVP)ROP synthesized from recycled monomer (Supplementary Table 1 run 12).

Next, the terminal alkene was reacted with isobutyl mercaptan via photoinduced thiol-ene click reaction in the presence of 2,2-dimethoxy-2-phenylacetophenone (DMPA) to install the second functional group and yield a bifunctional polyester (Fig. 6a2, Supplementary Figs. 21 and 22)61, as indicated by the disappearance of the original resonances at 5.67 (Hc’) and 5.25 (Hb’) ppm of the terminal alkene, in comparison with Fig. 6b2, b3. The post-functionalization of poly(EVP)ROP and the successful preparation of a thiolated polyester were further supported by GPC analysis, which indicated a significantly increased Mn from 6.5 to 8.5 to 14.3 kg·mol-1 after post-functionalization (Supplementary Fig. 23). This stepwise strategy allows the preparation of a wide range of bifunctional polymeric structures, which are not accessible by ROP of the hydrogenated derivatives EtVP and DEtP33,34.

Chemical recycling and thermal properties of poly(EVP)ROP

As aforementioned, a ceiling temperature (Tc) of −141 °C at [EVP]0 = 1 mol·L-1 or 5 °C at [EVP]0 = 5 mol·L-1 was calculated according to the Dainton’s equation49. This low Tc value provides the possibility for facile chemical recycling of the polyesters. For example, the bulk thermolysis of poly(EVP)ROP with an Mn of 6.5 kg·mol-1 was investigated for the recovery of the EVP monomer. Indeed, its heating at 150 °C under reduced pressure using 5 wt% Sn(Oct)2 as the catalyst afforded the pure EVP monomer. Vacuum distillation allowed easy recovery of the EVP monomer in high yield (96%) and high purity (>99.5%), as confirmed by both 1H NMR (Fig. 6c2) and gas chromatography (Supplementary Fig. 24). After simple drying over CaH2, the recovered EVP monomer could be repolymerized with a conversion of 29% to oligo(EVP)ROP with Mn = 1.4 kg·mol-1 and Ð = 1.46 (Supplementary Table 1, run 12, Fig. 6c3 and Supplementary Fig. 25), values which are very similar to those for the polymer obtained from the original monomer (Table 1, run 1, Mn = 1.5 kg·mol-1 and Ð = 1.42). These results successfully establish the “monomer-polymer-monomer” closed-loop life cycle for EVP and demonstrate that poly(EVP)ROP is a highly promising sustainable polymeric material62,63.

The thermal stability of poly(EVP)ROP was analyzed by differential scanning calorimetry (DSC; Supplementary Fig. 26) and thermogravimetry (TGA; Supplementary Fig. 27). As shown in Supplementary Fig. 26, poly(EVP)ROP is amorphous, as indicated by the absence of crystallization and melting transition peaks in the DSC curve. Poly(EVP)ROP with a Mn of 16.1 kg·mol-1 exhibited a Tg value of −18.3 °C, which is higher than reported for hydrogenated EVP-derivatives (−38.8 °C and −42.0 °C for poly(EtVP) and poly(DEtP), respectively)33. In addition, DSC analyses showed that the Tgs can be easily tuned by functionalization, and poly(EVP)S1 and poly(EVP)S1+S2 have a Tgs of −7.1 (Supplementary Fig. 28) and −17.6 °C (Supplementary Fig. 29), respectively. As show in Supplementary Fig. 27, the TGA of poly(EVP)ROP with a Mn of 6.5 kg·mol-1 displays three successive steps, the initial extrusion of EVP, followed by the cross-linking of the pendant double bonds and the final decomposition50. The relatively low temperature of 74.4 °C at 5% weight loss (Td,5%) may be ascribed to the presence of hydroxyl-terminated polymer chains susceptible of backbiting reactions at high temperature to afford the EVP monomer, which was verified by 1H NMR analysis (Supplementary Fig. 34). To improve the polymer thermal stability, acryloyl chloride was introduced and reacted with the terminal hydroxyl group of the polymer. The ω-terminal acrylate group capped poly(EVP)ROP (Supplementary Figs. 30 and 31) showed good thermal stability with only a 5% weight loss at 291 °C (Supplementary Fig. 32). In contrast, the mono-functionalized poly(EVP)S1 displayed a one-step decomposition profile with a Td,5% at 270.4 °C and Td,95% at 430.9 °C (Supplementary Fig. 28), while the bifunctionalized poly(EVP)S1+S2 showed a Td,5% at 303.6 °C and Td,95% at 392.0 °C (Supplementary Fig. 29). Note that the mono-functionalized poly(EVP)S1 has a broader decomposition profile than bifunctionalized poly(EVP)S1+S2. This result is consistent with cross-linking of the pendant double bonds occurs at high temperature50.

In summary, EVP obtained by telomerization of CO2 and 1,3-butadiene has been selectively homopolymerized by ring-opening using a phosphazene/urea binary catalyst. A class of bifunctional aliphatic polyesters poly(EVP)ROP was thus successfully developed. The catalytic activity and chemoselectivity were highly dependent upon the nature of the ureas and the polymerization conditions. Comparative DFT calculations on ROP and 1,4-conjugate addition dimerization pathways were performed to elucidate the details of the reactions and the origin of the chemoselectivity of the ROP of EVP. The resulting poly(EVP)ROP can be chemically recycled back to the monomer at 150 °C in the presence of Sn(Oct)2, establishing the complete polymer recyclability. Moreover, poly(EVP)ROP containing two pendent C=C double bonds with distinct reactivity could be easily and selectively post-functionalized to produce bifunctional polyesters. This study will not only provide a promising route to prepare bifunctional and recyclable CO2-based aliphatic polyesters with diverse properties, but also highlight the progress that can be made in using CO2 and 1,3-butadiene as feedstocks for the synthesis of more added-value chemicals.

Methods

Materials

The monomer EVP dried over CaH2 for 24 h and distilled under reduced pressure. THF was purified by first purging with dry nitrogen, then by passing through columns of activated alumina. 3-Chloroperoxybenzoic acid (75%) and benzyl mercaptan (98%) were obtained from Aladdin and 2,2-dimethoxy-2-phenylacetophenone (DMPA, 98%) from Energy Chemical Co. Benzyl alcohol (BnOH, 99%) was purchased from J&K Scientific. Solutions of 1-tert-Butyl-2,2,4,4,4-pentakis(dimethylamino)-2λ5,4λ5-catenadi(phosphazene) (t-BuP2) in THF (2.0 mol/L) and of 1-tert-butyl-4,4,4-tris(dimethylamino)-2,2-bis[tris(dimethylamino)phosphoranylidenamino]-2λ5,4λ5-catenadi(phosphazene) (t-BuP4) in n-hexane (0.8 mol/L) were purchased from Sigma-Aldrich and used as received. All other chemicals were purchased from commercial suppliers and used without further purification unless otherwise noted.

Instruments

Nuclear magnetic resonance (NMR) spectra were recorded on a Bruker AVANCE NEO 400 MHz NMR spectrometer (400 MHz for 1H NMR, 100 MHz for 13C NMR). Correlation spectroscopy (COSY) and heteronuclear single-quantum coherence (HSQC) techniques were used to assist in the assignment of 1H and 13C NMR spectra. The molar mass (Mn) and dispersity (Ð = Mw/Mn) were determined by Gel Permeation Chromatography (GPC) equipped with an Agilent HPLC system, a 1260 Hip degasser, a 1260 Iso pump and a 1260 differential refractometer detector. One PLgel 5 μm guard column and three Mz-Gel SDplus (103 Å, 104 Å, and 105 Å) columns were connected in series. The GPC columns were eluted with THF at 1.0 mL/min at 40 °C. The sample concentration used for GPC analysis was 5 mg/mL. Matrix-assisted laser desorption/ionization time-of-flight mass spectroscopy (MALDI-TOF MS) analyses were conducted on a Bruker Microflex MALDI-TOF MS spectrometer equipped with a 337 nm nitrogen laser. Trans-2-[3-(4-tert-butylphenyl)-2-methyl-2-propenylidene]-malononitrile (DCTB) was used as the matrix and CF3COONa as the ionization agent. Differential scanning calorimetry (DSC) was performed using a TA differential scanning calorimeter DSC 25 that was calibrated using high purity indium. Measurements were performed under N2 atmosphere with a flow rate of 50 mL/min. Each sample with a mass of 5–10 mg was used for the measurement. Tgs were determined from the second scan at a heating rate of 5 °C/min following a slow cooling rate of 5 °C/min to remove the influence of thermal history. Thermogravimetric analysis (TGA) measurements were performed on a STA 800 thermogravimetric analyzer. The samples were heated from room temperature to 600 °C at a heating rate of 10 °C/min under N2 atmosphere with a flow rate of 40 mL/min. The post-functionalization experiments were carried out in an ultraviolet lamp box, using an ultraviolet high-pressure mercury lamp (GGZ250) with a wavelength of 365 nm and a power of 250 W. All polymerizations were performed using a cooling bath (EYELA PSL-2000, –80 °C to 20 °C, 100–800 rpm, TOKYO RIKAKIKAI CO., LTD) to control the reaction temperature.

General procedure for the polymerization of EVP (Table 1, run 1)

A flame-dried Schlenk tube was charged with BnOH (0.04 mmol, 4.2 μL), CTPB (0.04 mmol, 48 mg), DU8 (0.06 mmol, 36 mg), and THF (0.14 mL) in a glove box. The Schlenk tube was sealed with a septum and immersed into a cooling bath set to −50 °C. After equilibrium at −50 °C for 10 min under stirring, EVP (2.0 mmol, 0.26 mL) was injected into the Schlenk tube to begin the polymerization. After the desired reaction time, a few drops of acetic acid in trichloromethane were added to quench the reaction and a small portion of the solution was taken and used to determine the conversion of EVP by 1H NMR. The remaining solution was purified by column chromatography (5:1 hexane: ethyl acetate) to remove the monomer and CTPB, then precipitated in DCM at −10 °C to remove urea. A sticky oil was obtained after concentration in vacuo (73 mg, yield: 24%). The resulting polymer was analyzed by NMR, and GPC. 1H NMR (400 MHz, CDCl3): δ 7.36 (s, 4 H, Ar-H of initiator), 6.96-6.84 (m, 13 H), 5.89-5.75 (m, 13 H), 5.34-5.08 (m, 39 H), 2.49-2.27 (m, 26 H), 1.89−1.69 (m, 63 H) ppm; 13C NMR (100 MHz, CDCl3): δ 167.30, 166.67, 141.06, 138.53, 138.03, 136.46, 132.92, 132.51, 128.53, 128.07, 127.97, 116.58, 114.57, 74.13, 72.09, 66.21, 36.23, 33.35, 22.25, 14.13 ppm. Mn = 1.5 kg·mol-1, Ð = 1.42.

General procedure for the polymerization of EVP (Table 1, run 13)

A flame-dried Schlenk tube was charged with BnOH (0.01 mmol, 1.0 μL), CTPB (0.04 mmol, 48 mg), DU8 (0.06 mmol, 36 mg), and THF (0.14 mL) in a glove box. The Schlenk tube was sealed with a septum and immersed into a cooling bath set to −50 °C. After equilibrium at −50 °C for 10 min under stirring, EVP (2.0 mmol, 0.26 mL) was injected into the Schlenk tube to begin the polymerization. After the desired reaction time, a few drops of acetic acid in trichloromethane were added to quench the reaction and a small portion of the solution was taken and used to determine the conversion of EVP by 1H NMR. The remaining solution was poured into methanol (50 mL) at −10 °C to precipitate the polymer, which was dried overnight under vacuum in an oven (yield: 82 mg, 27%). The resulting polymer was analyzed by GPC, DSC, and TGA. Mn = 6.5 kg·mol-1, Ð = 1.24. Tg = −21.9 °C, Td, 5% = 74.4 °C, Td, 95% = 486.5 °C.

Depolymerization of poly(EVP) catalyzed by Sn(Oct)2

A single neck flask was charged with 1.3 g poly(EVP)ROP (Mn = 6.5 kg·mol-1) and (173 mg, 5 mol%) Sn(Oct)2, and heated to 150 °C for 10 min. The recycled EVP was collected by distillation under reduced pressure, purified by passing through a silica-packed short column and collected in 96% yield.

Preparation of poly(EVP)S1 via Michael addition reaction

A mixture of 120 mg poly(EVP)ROP (Mn = 6.5 kg·mol-1), 926 μL benzyl mercaptan (7.9 mmol, 10 equiv.), and 12 μL DBU (0.08 mmol, 0.1 equiv.) was dissolved in 0.2 mL DMF. The reaction mixture was stirred at 20 °C for 6 h. An aliquot of the solution was withdrawn and used to determine the conversion by 1H NMR. The remaining mixture was poured into excess cold methanol ( − 10 °C). Poly(EVP)S1 was obtained as a precipitate, which was washed twice with cold methanol and then dried under vacuum at room temperature (196 mg, yield: 90%). The resulting polymer was analyzed by NMR, GPC, DSC and TGA. 1H NMR (400 MHz, CDCl3): δ 7.28-7.21 (m, 5 H), 5.80-5.50 (m, 1 H), 5.33-5.02 (m, 3 H), 3.70 (s, 2 H), 2.87-2.69 (m, 1 H), 2.48-2.30 (m, 1 H), 1.84-1.32 (m, 4 H), 1.31-1.18 (m, 3 H) ppm; 13C NMR (100 MHz, CDCl3): δ 172.08, 137.04, 134.99, 127.85, 127.50, 126.02, 116.67, 73.44, 50.05, 40.60, 34.26, 30.83, 25.08, 18.30 ppm. Mn = 8.5 kg·mol-1, Ð = 1.22. Tg = -38.8 °C, Td, 5% = 270.4 °C, Td, 95% = 430.9 °C.

Preparation of poly(EVP)S1+S2 via thiol-ene click reaction

A flame-dried Schlenk tube was charged with 85 mg poly(EVP)S1, 3.4 mg (0.013 mmol, 4 wt%) DMPA and 0.5 mL chloroform, then 100 μL isobutyl mercaptan (0.9 mmol, 3 equiv.) was added into the Schlenk tube via a gastight syringe. The tube was then irradiated by UV light at 365 nm for 4 h. The reaction mixture was poured into excess cold methanol (−10 °C) and the precipitate obtained was washed twice with excess cold methanol (−10 °C) and then dried under vacuum at room temperature (106 mg, yield: 94%). The resulting polymer was analyzed by NMR, GPC, DSC and TGA. 1H NMR (400 MHz, CDCl3): δ 7.29-7.21 (m, 5 H), 5.07-4.77 (m, 1 H), 3.72 (s, 2 H), 2.90-2.71 (m, 1 H), 2.60-2.24 (m, 5 H), 1.92-1.36 (m, 7 H), 1.30-1.20 (m, 3 H), 0.97 (s, 6 H) ppm; 13C NMR (100 MHz, CDCl3): δ 172.38, 137.09, 127.86, 127.53, 126.04, 116.92, 71.99, 49.67, 40.42, 34.22, 33.05, 30.78, 27.54, 25.23, 21.09, 18.16 ppm. Mn = 14.3 kg·mol-1, Ð = 1.28. Tg = -42.0 °C, Td, 5% = 303.6 °C, Td, 95% = 392.0 °C.

Preparation of ω-terminal acrylate-capped poly(EVP)ROP

200 mg (∼0.031 mmol of hydroxy end groups) poly(EVP)ROP (Table 1 run 13) was dissolved in 3 mL anhydrous dichloromethane. The solution was cooled using an ice/NaCl bath, and 43 μL of triethylamine (0.31 mmol, 10.0 equiv) was added. Then, an acryloyl chloride (0.31 mmol, 10.0 equiv) solution (25 μL mL of acryloyl chloride in 3 mL dichloromethane) was added dropwise. The reaction mixture was stirred for 2 h at 0 °C and for another 24 h at room temperature. The reaction mixture was then precipitated by pouring into excess cold methanol (−10 °C). The solid was washed twice with excess cold methanol (−10 °C) and then dried under vacuum at room temperature (190 mg, yield: 95%). The resulting polymer was analyzed by NMR. 1H NMR (400 MHz, CDCl3): δ 7.35 (s, 5 H, Ar-H of initiator), 6.44-6.40 (m, 1 H, CH = CH2 of end group), 6.17-6.11 (m, 2 H, CH = CH2 of end group), 6.96-6.84 (m, 42 H), 5.89-5.75 (m, 44 H), 5.34-5.08 (m, 131 H), 2.49-2.27 (m, 86 H), 1.89-1.69 (m, 222 H).

Data availability

The authors declare that the data supporting this study are available within the paper and the Supplementary information File. All other data is available from the authors upon request. Source data (coordinates of the optimized structures) are provided with this paper. Source data are provided with this paper.

References

Grignard, B., Gennen, S., Jérôme, C., Kleij, A. W. & Detrembleur, C. Advances in the use of CO2 as a Renewable Feedstock for the Synthesis of Polymers. Chem. Soc. Rev. 48, 4466–4514 (2019).

Zhu, Y., Romain, C. & Williams, C. K. Sustainable Polymers from Renewable Resources. Nature 540, 354–362 (2016).

Aresta, M., Dibenedetto, A. & Angelini, A. Catalysis for the Valorization of Exhaust Carbon: from CO2 to Chemicals, Materials, and Fuels. Technological Use of CO2. Chem. Rev. 114, 1709–1742 (2014).

Deacy, A. C., Kilpatrick, A. F. R., Regoutz, A. & Williams, C. K. Understanding Metal Synergy in Heterodinuclear Catalysts for the Copolymerization of CO2 and Epoxides. Nat. Chem. 12, 372–380 (2020).

Bhat, G. A. & Darensbourg, D. J. Coordination Complexes as Catalysts for the Coupling Reactions of Oxiranes and Carbon Dioxide. Coord. Chem. Rev. 492, 215277 (2023).

Zhang, J., Wang, L., Liu, S. & Li, Z. Synthesis of Diverse Polycarbonates by Organocatalytic Copolymerization of CO2 and Epoxides: From High Pressure and Temperature to Ambient Conditions. Angew. Chem. Int. Ed. 61, e202111197 (2022).

Stürzel, M., Mihan, S. & Mülhaupt, R. From Multisite Polymerization Catalysis to Sustainable Materials and All-Polyolefin Composites. Chem. Rev. 116, 1398–1433 (2016).

Tang, S. & Nozaki, K. Advances in the Synthesis of Copolymers from Carbon Dioxide, Dienes, and Olefins. Acc. Chem. Res. 55, 1524–1532 (2022).

Rapagnani, R. M. & Tonks, I. A. 3-Ethyl-6-vinyltetrahydro-2H-pyran-2-one (EVP): a Versatile CO2-Derived Lactone Platform for Polymer Synthesis. Chem. Commun. 58, 9586–9593 (2022).

Eagan, J. M. The Divergent Reactivity of Lactones Derived from Butadiene and Carbon Dioxide in Macromolecular Synthesis. Macromol. Rapid Commun. 44, 2200348 (2022).

Rummelt, S. M., Zhong, H., Korobkov, I. & Chirik, P. J. Iron-Mediated Coupling of Carbon Dioxide and Ethylene: Macrocyclic Metallalactones Enable Access to Various Carboxylates. J. Am. Chem. Soc. 140, 11589–11593 (2018).

Moha, V., Cozzula, D., Hölscher, M., Leitner, W. & Müller, T. E. A DFT Study on the Co-polymerization of CO2 and Ethylene: Feasibility Analysis for the Direct Synthesis of Polyethylene Esters. ChemSusChem 9, 1614–1622 (2016).

Price, C. J., Reich, B. J. E. & Miller, S. A. Thermodynamic and Kinetic Considerations in the Copolymerization of Ethylene and Carbon Dioxide. Macromolecules 39, 2751–2756 (2006).

Bastero, A., Franciò, G., Leitner, W. & Mecking, S. Catalytic Ethylene Polymerisation in Carbon Dioxide as a Reaction Medium with Soluble Nickel(II) Catalysts. Chem. – Eur. J. 12, 6110–6116 (2006).

Braunstein, P., Matt, D. & Nobel, D. Reactions of Carbon Dioxide with Carbon-Carbon Bond Formation Catalyzed by Transition-Metal Complexes. Chem. Rev. 88, 747–764 (1988).

Inoue, Y., Sasaki, Y. & Hashimoto, H. Incorporation of CO2 in Butadiene Dimerization Catalyzed by Palladium Complexes. Formation of 2-Ethylidene-5-hepten-4-olide. Bull. Chem. Soc. Jpn. 51, 2375–2378 (1978).

Yang, Z., Shen, C. & Dong, K. Hydroxyl Group-Enabled Highly Efficient Ligand for Pd-Catalyzed Telomerization of 1,3-Butadiene with CO2. Chin. J. Chem. 40, 2734–2740 (2022).

Wang, J. et al. The Ultrasmall Palladium Nanoparticles Catalyzed Telomerization of CO2 with 1,3-Butadiene at Room Temperature: Selective Synthesis of δ-Lactone. ChemistrySelect 5, 9404–9408 (2020).

Balbino, J. M., Dupont, J. & Bayón, J. C. Telomerization of 1,3-Butadiene with Carbon Dioxide: A Highly Efficient Process for δ-Lactone Generation. ChemCatChem 10, 206–210 (2018).

Song, J. et al. Selective Synthesis of δ-Lactone via Palladium Nanoparticles-Catalyzed Telomerization of CO2 with 1,3-Butadiene. Tetrahedron Lett. 57, 3163–3166 (2016).

Braunstein, P., Matt, D. & Nobel, D. Carbon Dioxide Activation and Catalytic Lactone Synthesis by Telomerization of Butadiene and Carbon Dioxide. J. Am. Chem. Soc. 110, 3207–3212 (1988).

Behr, A. & Juszak, K.-D. Palladium-catalyzed Reaction of Butadiene and Carbon Dioxide. J. Organomet. Chem. 255, 263–268 (1983).

Sharif, M., Jackstell, R., Dastgir, S., Al-Shihi, B. & Beller, M. Efficient and selective Palladium-catalyzed Telomerization of 1,3-Butadiene with Carbon Dioxide. ChemCatChem 9, 542–546 (2017).

Tang, S. et al. Sustainable Copolymer Synthesis from Carbon Dioxide and Butadiene. Chem. Rev. 124, 3590–3607 (2024).

Nakano, R., Ito, S. & Nozaki, K. Copolymerization of Carbon Dioxide and Butadiene via a Lactone Intermediate. Nat. Chem. 6, 325–331 (2014).

Liu, M., Sun, Y., Liang, Y. & Lin, B.-L. Highly Efficient Synthesis of Functionalizable Polymers from a CO2/1,3-Butadiene-Derived Lactone. ACS Macro Lett. 6, 1373–1378 (2017).

Tang, S., Zhao, Y. & Nozaki, K. Accessing Divergent Main-Chain-Functionalized Polyethylenes via Copolymerization of Ethylene with a CO2/Butadiene-Derived Lactone. J. Am. Chem. Soc. 143, 17953–17957 (2021).

Hill, M. R., Tang, S., Masada, K., Hirooka, Y. & Nozaki, K. Incorporation of CO2-Derived Bicyclic Lactone into Conventional Vinyl Polymers. Macromolecules 55, 3311–3316 (2022).

Hardouin Duparc, V., Shakaroun, R. M., Slawinski, M., Carpentier, J.-F. & Guillaume, S. M. Ring-Opening (co)Polymerization of Six-Membered Substituted δ-Valerolactones with Alkali Metal Alkoxides. Eur. Polym. J. 134, 109858 (2020).

Nozaki, K. New Polymers Made from Carbon Dioxide and Alkenes. Bull. Chem. Soc. Jpn. 94, 984–988 (2021).

Zhang, Y. et al. Combination of Ethylene, 1,3-Butadiene, and Carbon Dioxide into Ester-Functionalized Polyethylenes via Palladium-Catalyzed Coupling and Insertion Polymerization. Macromolecules 52, 2504–2512 (2019).

Chen, L., Ling, J., Ni, X. & Shen, Z. Synthesis and Properties of Networks Based on Thiol-ene Chemistry Using a CO2-Based δ-Lactone. Macromol. Rapid Commun. 39, 1800395 (2018).

Rapagnani, R. M., Dunscomb, R. J., Fresh, A. A. & Tonks, I. A. Tunable and Recyclable Polyesters from CO2 and Butadiene. Nat. Chem. 14, 877–883 (2022).

Lou, Y., Xu, L., Gan, N., Sun, Y. & Lin, B. L. Chemically Recyclable Polyesters from CO2, H2, and 1,3-Butadiene. Innovation 3, 100216 (2022).

Behr, A. & Henze, G. Use of Carbon Dioxide in Chemical Syntheses via a Lactone Intermediate. Green Chem. 13, 25–39 (2011).

Haack, V., Dinjus, E. & Pitter, S. Synthesis of Polymers with an Intact Lactone Ring Structure in the Main Chain. Angew. Makromol. Chem. 257, 19–22 (1998).

Yue, S. et al. Ring-Opening Polymerization of CO2-Based Disubstituted δ-Valerolactone toward Sustainable Functional Polyesters. ACS Macro Lett. 10, 1055–1060 (2021).

Chen, K. et al. A Topology-Defined Polyester Elastomer from CO2 and 1,3-Butadiene: A One-Pot-One-Step “Scrambling Polymerizations” Strategy. Angew. Chem. Int. Ed. 134, e202213028 (2022).

Chen, L. et al. Chemoselective RAFT Polymerization of a Trivinyl Monomer Derived from Carbon Dioxide and 1,3-Butadiene: From Linear to Hyperbranched. Macromolecules 50, 9598–9606 (2017).

Garcia Espinosa, L. D., Williams-Pavlantos, K., Turney, K. M., Wesdemiotis, C. & Eagan, J. M. Degradable Polymer Structures from Carbon Dioxide and Butadiene. ACS Macro Lett. 10, 1254–1259 (2021).

Becker, G. & Wurm, F. R. Functional Biodegradable Polymers via Ring-Opening Polymerization of Monomers without Protective Groups. Chem. Soc. Rev. 47, 7739–7782 (2018).

Xu, Y.-C., Ren, W.-M., Zhou, H., Gu, G.-G. & Lu, X.-B. Functionalized Polyesters with Tunable Degradability Prepared by Controlled Ring-Opening (Co)polymerization of Lactones. Macromolecules 50, 3131–3142 (2017).

Shen, Y. et al. Chemoselective Polymerization of Fully Biorenewable α-Methylene-γ-Butyrolactone Using Organophosphazene/Urea Binary Catalysts Toward Sustainable Polyesters. CCS Chem. 3, 620–630 (2020).

Li, J., Liu, F., Liu, Y., Shen, Y. & Li, Z. Functionalizable and Chemically Recyclable Thermoplastics from Chemoselective Ring-Opening Polymerization of Bio-renewable Bifunctional α-Methylene-δ-valerolactone. Angew. Chem. Int. Ed. 61, e202207105 (2022).

Fastnacht, K. V. et al. Bis- and Tris-Urea H-Bond Donors for Ring-Opening Polymerization: Unprecedented Activity and Control from an Organocatalyst. ACS Macro Lett. 5, 982–986 (2016).

Spink, S. S., Kazakov, O. I., Kiesewetter, E. T. & Kiesewetter, M. K. Rate Accelerated Organocatalytic Ring-Opening Polymerization of l-Lactide via the Application of a Bis(thiourea) H-bond Donating Cocatalyst. Macromolecules 48, 6127–6131 (2015).

Liu, Y., Zhang, J., Kou, X., Liu, S. & Li, Z. Highly Active Organocatalysts for Stereoselective Ring-Opening Polymerization of Racemic Lactide at Room Temperature. ACS Macro Lett. 11, 1183–1189 (2022).

Hong, M. & Chen, E. Y. X. Completely Recyclable Biopolymers with Linear and Cyclic Topologies via Ring-opening Polymerization of γ-Butyrolactone. Nat. Chem. 8, 42–49 (2016).

Olsén, P., Odelius, K. & Albertsson, A.-C. Thermodynamic Presynthetic Considerations for Ring-Opening Polymerization. Biomacromolecules 17, 699–709 (2016).

Tang, X. et al. The Quest for Converting Biorenewable Bifunctional α-Methylene-γ-butyrolactone into Degradable and Recyclable Polyester: Controlling Vinyl-Addition/Ring-Opening/Cross-Linking Pathways. J. Am. Chem. Soc. 138, 14326–14337 (2016).

Lou, Y., Xu, J., Xu, L., Chen, Z. & Lin, B.-L. Chemically Recyclable CO2-Based Solid Polyesters with Facile Property Tunability. Macromol. Rapid Commun. 43, 2200341 (2022).

Jin, M. & Hoye, T. R. Lactone Ring-Opening Equilibria in Methanol by 1H NMR Analysis: An Assessment of the Ring-Opening Polymerizability of Lactone Monomers. Macromolecules 56, 1122–1129 (2023).

Lin, B. & Waymouth, R. M. Urea Anions: Simple, Fast, and Selective Catalysts for Ring-Opening Polymerizations. J. Am. Chem. Soc. 139, 1645–1652 (2017).

Hong, M., Chen, J. & Chen, E. Y. X. Polymerization of Polar Monomers Mediated by Main-Group Lewis Acid–Base Pairs. Chem. Rev. 118, 10551–10616 (2018).

Breugst, M. & Houk, K. N. Computational Analysis of Cyclophane-Based Bisthiourea-Catalyzed Henry Reactions. J. Org. Chem. 79, 6302–6309 (2014).

Scharfenberg, M., Hilf, J. & Frey, H. Functional Polycarbonates from Carbon Dioxide and Tailored Epoxide Monomers: Degradable Materials and Their Application Potential. Adv. Funct. Mater. 28, 1704302 (2018).

Subhani, M. A., Koehler, B., Guertler, C., Leitner, W. & Mueller, T. E. Transparent Films from CO2-Based Polyunsaturated Poly(ether carbonate)s: A Novel Synthesis Strategy and Fast Curing. Angew. Chem. Int. Ed. 55, 5591–5596 (2016).

Zhang, X., Jones, G. O., Hedrick, J. L. & Waymouth, R. M. Fast and Selective Ring-Opening Polymerizations by Alkoxides and Thioureas. Nat. Chem. 8, 1047–1053 (2016).

Xiang, L., Liu, X. F., He, Y. X. & Zhang, K. Eye-Readable Dynamic Covalent Click Reaction and Its Application in Polymer Synthesis. Macromolecules 53, 5434–5444 (2020).

Hoyle, C. E. & Bowman, C. N. Thiol-Ene Click Chemistry. Angew. Chem. Int. Ed. 49, 1540–1573 (2010).

Sathyan, A., Hayward, R. C. & Emrick, T. Ring-Opening Polymerization of Allyl-Functionalized Lactams. Macromolecules 52, 167–175 (2019).

Li, X. L., Clarke, R. W., Jiang, J. Y., Xu, T. Q. & Chen, E. Y. X. A Circular Polyester Platform Based on Simple Gem-Disubstituted Valerolactones. Nat. Chem. 15, 278–285 (2023).

Zhu, J. B., Watson, E. M., Tang, J. & Chen, E. Y. X. A Synthetic Polymer System with Repeatable Chemical Recyclability. Science 360, 398–403 (2018).

Liu, S., Ren, C., Zhao, N., Shen, Y. & Li, Z. Phosphazene Bases as Organocatalysts for Ring-Opening Polymerization of Cyclic Esters. Macromol. Rapid Commun. 39, 1800485 (2018).

Zhao, N. et al. Selective Ring-Opening Polymerization of Non-Strained γ-Butyrolactone Catalyzed by A Cyclic Trimeric Phosphazene Base. Angew. Chem. Int. Ed. 56, 12987–12990 (2017).

Lin, B. & Waymouth, R. M. Organic Ring-Opening Polymerization Catalysts: Reactivity Control by Balancing Acidity. Macromolecules 51, 2932–2938 (2018).

Lin, L. et al. Nonstrained γ-Butyrolactone to High-Molecular-Weight Poly(γ-butyrolactone): Facile Bulk Polymerization Using Economical Ureas/Alkoxides. Macromolecules 51, 9317–9322 (2018).

Acknowledgements

Z.L. acknowledges support from the National Key R&D Program of China (2021YFA1501600) and National Natural Science Foundation of China (22031005). S.L. acknowledges the support from the Ministry of Education of the People’s Republic of China. Z.L. and P.B. acknowledge the support from the 111 Project (No. D17004). X.K. acknowledges support from the National Natural Science Foundation of China (22171038).

Author information

Authors and Affiliations

Contributions

Pierre Braunstein, Shaofeng Liu, and Zhibo Li conceived the idea and designed the experiments. Jinbo Zhang, Junhao Shen, and Yong Shen performed the experiments and analyzed and processed the data. Xiaohui Kang and Lihang Jiang performed DFT calculations and prepared the corresponding part of the manuscript. Jinbo Zhang and Lihang Jiang contributed equally in this work. All authors co-wrote the manuscript and participated in data analyses and discussions.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, J., Jiang, L., Liu, S. et al. Bifunctional and recyclable polyesters by chemoselective ring-opening polymerization of a δ-lactone derived from CO2 and butadiene. Nat Commun 15, 8698 (2024). https://doi.org/10.1038/s41467-024-52090-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-52090-2

This article is cited by

-

Gram-scale selective telomerization of isoprene and CO2 toward 100% renewable materials

Nature Communications (2025)