Abstract

Selective catalytic oxidation (SCO) of NH3 to N2 is one of the most effective methods used to eliminate NH3 emissions. However, achieving high conversion over a wide operating temperature range while avoiding over-oxidation to NOx remains a significant challenge. Here, we report a bi-metallic surficial catalyst (PtSCuO/Al2O3) with improved Pt atom efficiency that overcomes the limitations of current catalysts. It achieves full NH3 conversion at 250 °C with a weight hourly space velocity of 600 ml NH3·h−1·g−1, which is 50 °C lower than commercial Pt/Al2O3, and maintains high N2 selectivity through a wide temperature window. Operando XAFS studies reveal that the surface Pt atoms in PtSCuO/Al2O3 enhance the redox properties of the Cu species, thus accelerating the Cu2+ reduction rate and improving the rate of the NH3-SCO reaction. Moreover, a synergistic effect between Pt and Cu sites in PtSCuO/Al2O3 contributes to the high selectivity by facilitating internal selective catalytic reduction.

Similar content being viewed by others

Introduction

The global emissions of ammonia (NH3) from vehicle exhaust and industrial waste gas streams are estimated to exceed 220,000 tonnes per year, presenting a severe environmental threat and impacting on human health1,2. With the utilization of NH3 as a fuel for various modes of transportation, emissions might increase considerably3,4. Consequently, selective catalytic oxidation (SCO) of NH3 to nitrogen N2 (avoiding over-oxidation to NOx) is increasingly imperative in order to address the issue of unreacted NH3 emissions (referred to as NH3 slip). NH3-SCO offers an attractive approach for treating gas flows containing 100−5000 ppm NH3 and abundant O2, such as waste gases from chemical manufacturing processes, selective catalytic reduction (SCR) of NOx units, biomass gasification processes and NH3 combustion turbines.

NH3-SCO catalysts must be capable of achieving complete conversion of NH3 to N2, while avoiding overoxidation to NOx, and maintaining high stability over a broad operating temperature range (100 °C < T < 450 °C). Noble metal-based catalysts, such as commercial Pt/Al2O3, are renowned for their high efficiencies, however, their selectivity to N2 is low, (ca. 50% for commercial Pt/Al2O3) and the atomic efficiency is also low5. First row transition metals such as Cu and Fe exhibit high N2 selectivity, but require higher operating temperatures (300–500 °C)6,7. In order to enhance the N2 selectivity of Pt-based catalysts, recent developments have aimed at the development of catalysts that leverage the strengths of noble metals and non-noble transition metals through bifunctional catalyst design. Efforts have focused on the bi-metallic catalysts that form somewhat random alloys or mixed oxides8,9,10,11,12,13,14,15,16, and the location of noble metal atoms is difficult to control. However, noble metals nanoparticles favour the oxidation of ammonia to NO, whereas non-noble transition metal oxides are able to selectively reduce NO with NH3 to generate N27,8,9. Therefore, by combining the two types of catalysts using a rational design approach, i.e. ensuring the ratio of the Pt and CuO is optimized to the relative reaction rates of both processes, it should be possible to obtain a highly active and selective catalyst for the NH3-SCO reaction.

Herein, by precisely controlling the amount of Pt atoms on the surface (S) of CuO nanoparticles (NPs, PtSCuO/Al2O3), the catalytic activity and N2 selectivity were enhanced, surpassing commercial Pt/Al2O3 catalysts and also standard co-reduced bi-metallic PtNCuO/Al2O3 (N stands for normal) catalysts. Based on operando and time-resolved X-ray absorption fine structure (XAFS) studies, the Pt atoms are active in the oxidation of NH3. Moreover, the Pt atoms also accelerate the redox activity of the Cu species facilitating the NH3-SCO reaction to achieve high activity and high selectivity to N2.

Results and Discussion

Synthesis and structural characterisation of the PtSCuO/Al2O3 catalyst

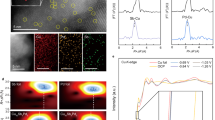

The surface bi-metallic PtSCuO/Al2O3 catalyst was synthesized using galvanic replacement. As the galvanic replacement between Pt and Cu atoms is initiated on the CuO NPs, the Pt atoms form a thin shell on the NP surfaces. For comparison, normal alloy PtNCuO/Al2O3 with the same chemical compositions was synthesized by wet impregnation, resulting in randomly distributed Pt atoms within the CuO NPs. The NPs in both PtSCuO/Al2O3 and PtNCuO/Al2O3 have a similar average particle size of ca. 2 nm (Fig. 1a, b, Supplementary Figs. S1 and S2). The Energy-dispersive spectrometry (EDS) map of PtSCuO/Al2O3 displays a uniform elemental distribution over a wide area (Fig. S3), and within a single PtSCuO/Al2O3 particle (Fig. S4). X-ray diffraction patterns of PtSCuO/Al2O3 and PtNCuO/Al2O3 shows no obvious distinctions from the Al2O3 support (PDF #10-0425) (Fig. S5), indicative of small NPs. Fine-scanned X-ray photoelectron spectroscopy (XPS) of PtSCuO/Al2O3 and PtNCuO/Al2O3 reveals Cu 2p3/2 peaks at 931.8 and 934.6 eV corresponding to Cu+ and Cu2+, respectively (Fig. S6). The chemical environments of the copper ions in both PtSCuO/Al2O3 and PtNCuO/Al2O3 are similar, as determined from extended X-ray absorption fine structure (EXAFS) and X-ray absorption near-edge structure (XANES) measurements, but differ in the chemical states of Pt (Fig. 1c, d and S7). The fitting of EXAFS data reveals the differences between the structures of PtSCuO/Al2O3 and PtNCuO/Al2O3 (Table S1). PtSCuO/Al2O3 has a larger Pt-Pt coordination number (C.N.) of 5.8 ± 1.5 and smaller Pt-Cu C.N. of 1.1 ± 0.7 compared to PtNCuO/Al2O3, which has a Pt-Pt C.N. of 4.5 ± 1.4 and a Pt-Cu C.N. of 5.8 ± 1.7. A smaller overall coordination indicates that most Pt atoms in the PtSCuO/Al2O3 are on the surface whereas the Pt atoms in PtNCuO/Al2O3 reside on the surface and in the NP bulk.

Evaluation of the catalysts in the NH3-SCO reaction

The activities of PtSCuO/Al2O3, PtNCuO/Al2O3, CuO/Al2O3 and Pt/Al2O3 were evaluated in the NH3-SCO reaction. Remarkably, at 200 °C, PtSCuO/Al2O3 consisting of 0.6 wt% Pt and 4.4 % Cu, exhibits a 30-fold higher activity than the commercial catalyst Pt/Al2O3 containing 1 wt% Pt. Moreover, PtSCuO/Al2O3 also shows the highest activity with the lowest T50 (T at 50% conversion), and complete NH3 conversion was achieved at around 250 °C (Fig. 2a, S8 and S9). Under realistic NH3 slip conditions (1000 ppm NH3, weight hourly space velocity (WHSV) of 120 mlNH3·h−1·g−1), full conversion could be achieved at 200 °C using the PtSCuO/Al2O3 catalyst (Fig. 2a). Notably, PtNCuO/Al2O3 with identical Pt and Cu loadings to PtSCuO/Al2O3, requires 300 °C to reach the full conversion under equivalent conditions (Fig. 2a). When the temperature is higher than 250 °C, the N2 selectivity of the PtNCuO/Al2O3, CuO/Al2O3 and Pt/Al2O3 catalysts decrease, due to an increase in the rate of ammonia oxidation to NO (Step 1: 4 NH3 + 5O2 → 4 NO + 6 H2O). In comparison, PtSCuO/Al2O3 consistently maintains >90% selectivity to N2 even at full conversion (Fig. 2b). Pt/Al2O3 has the lowest selectivity to N2 at temperatures above 250 °C, e.g. 55% selectively at 300 °C.

a, b NH3 conversion and N2 selectivity as a function of temperature; c activation energy of PtSCuO/Al2O3, CuO/Al2O3 Pt/Al2O3; d WSHV with refs (Table S210,11,12,13,14,15,16,17,18,19,20,21,22,23); e stability test of PtSCuO/Al2O3 at 200 °C; f activity of MSCuO/Al2O3 catalysts (M = Pt, Ru, Rh, Ag, or Au); g, h NH3 conversion and N2 selectivity as a function of Pt loading and temperature; i NH3 conversion of PtSCuO/Al2O3 with different Pt loadings at 200 °C. Reaction conditions: 50 mg catalyst, 5000 ppm NH3, 5% O2 balanced in He, gas flow: 100 mL/min, WHSV = 600 mL NH3·h−1·g−1.

A series of control experiments were carried out to ensure the influence of internal and external diffusion could be excluded from the kinetic experiments (Fig. S10a, b). The apparent activation energy of PtSCuO/Al2O3 is 40 kJ/mol, which is lower than that of CuO/Al2O3 and Pt/Al2O3 (Fig. 2c), suggesting that the superior activity in the NH3-SCO reaction is due to interactions between the surface Pt atoms and underlying Cu atoms (note that other metal-Cu combinations are less efficient, see below). Additionally, PtSCuO/Al2O3 outperforms most previously reported catalysts in terms of selectivity to N2 (Fig. 2d and Table S2)10,11,12,13,14,15,16,17,18,19,20,21,22,23. Compared to benchmark Pt- and Cu-based catalysts, such as the Pt/Al2O3@Cu/ZSM‑5 core−shell catalyst and Pt/Al2O3 + Cu/SSZ−13 dual-layer wash-coated monolith catalyst, PtSCuO/Al2O3 displays a higher activity at low temperatures and maintains high selectivity at high temperatures20,21,22,23. Notably, PtSCuO/Al2O3 also exhibits exceptional stability, without any signs of reduced activity and N2 selectivity even after 100 h of continuous operation at 200 or 300 °C (Fig. 2e and S10c). After the reaction, the size distribution of the NPs in the PtSCuO/Al2O3 catalyst remains unchanged (Fig. S11), affirming its remarkable stability. The PtSCuO/Al2O3 catalyst is able to operate at low temperatures (200 °C) that are well suited to the cold start of a vehicle, and its high N2 selectivity over a wide operating temperature range (150–450 °C) makes it practical for removal of NH3 from diesel exhausts.

As mentioned above, the Pt and Cu combination in PtSCuO/Al2O3 shows the highest activity, with MSCuO/Al2O3 (M = Pt, Ru, Rh, Ag, or Au) catalysts prepared via galvanic replacement being less active (Fig. 2f and S12). To investigate the special effect of Pt coverage on CuO NPs in the NH3-SCO reaction, the Pt loading was systematically varied from 0 to 1.6 wt% and the performance of the catalysts was evaluated (Fig. 2g–i and S13). Despite all catalysts exhibiting similar particle size distributions irrespective of the Pt loading (Figs. S14−16), their catalytic performance differs significantly. At 200 °C the activity of PtSCuO/Al2O3 shows a volcano plot-like trend with 0.6 wt% Pt, i.e. PtS0.6CuO/Al2O3, being the most active, indicating that optimal Pt surface coverage is important (Fig. 2i). Hence, the Pt-Pt and Pt-Cu coordination environments play a vital role in the NH3-SCO reaction.

Formation of Cu+ and Pt0 at steady state

The internal selective catalytic reduction (i-SCR) mechanism is widely accepted with copper-based catalysts18,24,25,26,27, in which ammonia is oxidized to NOx, and then the formed NOx species react further with NH3 on the Cu sites to afford N2 (Step 2). The first step is the conversion of NH3 and is usually the rate-determining step in NH3 oxidation, which involves metal redox processes27.

Step 1: 4 NH3 + 5O2 → 4 NO + 6 H2O

Step 2: 4 NO + 4 NH3 + O2 → 4 N2 + 6 H2O

4 NO + 4 NH3 + 3 O2 → 4 N2O + 6 H2O

Adding Pt into CuO will boost Step 1, as metallic Pt is usually the best catalyst for low-temperature combustion reactions1,28,29. In operando XAFS under SCO conditions, indicated that the initial Pt4+ species in the PtSCuO/Al2O3, PtNCuO/Al2O3 and Pt/Al2O3 catalysts are reduced to Pt0 in the temperature ranges 100–250, 200–300 and 250–300 °C, respectively, and are subsequently re-oxidized to Pt4+ (Fig. 3b and S17–19). Pt/γ-Al2O3 (2 wt%) has been previously studied by operando XAS and was shown to undergo reduction between 230 − 260 °C23, which is similar the catalysts reported herein. When the temperature is lower than 250 °C, the Pt species are mainly in metallic state in PtSCuO/Al2O3, which improved the activity of Step 1 (Figs. 3b, 4g), while Pt species are in a more oxidated state in PtNCuO/Al2O3, and Pt/Al2O3. In situ, XAFS under different gas atmospheres confirms that Pt species in PtSCuO/Al2O3 are readily oxidized when the feed gas composition changes from reducing to oxidizing at 200 °C (Fig. S20).

a operando Cu K-edge XAFS, signal intensity of the Cu+ 1s-4p transition peak at 8982 eV in a NH3/O2 atmosphere at different temperatures; b operando Pt L3-edge, signal intensity of the white line of the Pt L3-edge at 11567 eV in a NH3/O2 atmosphere at different temperatures (reaction conditions: 5000 ppm NH3, 5% O2 balanced in He, gas flow: 100 mL/min); c H2-TPR of different catalysts; operando Cu K-edge XANES spectra of PtSCu/Al2O3 (d), PtNCu/Al2O3 (e) and CuO/Al2O3 (f) in different gases at 200 °C; in situ NAP-NEXAFS spectra, Cu L-edge (AEY mode) of different catalysts at 200 °C under NH3 (g) or NH3/O2 (h) atmospheres; i Cu L-edge (AEY mode) of PtSCu/Al2O3 under various gas atmospheres at 200 °C (gas pressure 1 mbar).

Change of CuO:Cu2O ratio in PtSCuO/Al2O3 (a) and CuO/Al2O3 (b) with time under NH3 or O2 environments at different temperatures (the catalysts are exposed to a flow of 5000 ppm NH3/He or 5% O2/He with flow rate 15 mL/min); change of CuO:Cu2O ratio in the PtSCuO/Al2O3 catalyst with time under NH3 (d) and O2 (e) environments at different gas concentrations; reaction order for NH3 (c) and O2 (f) in the whole apparent reaction or half reaction; g operando Cu K-edge XANES spectra of the PtSCu/Al2O3, PtNCu/Al2O3 and CuO/Al2O3 catalysts under NH3 + O2 at 200 °C (5000 ppm NH3, 5% O2 balanced in He, gas flow: 100 mL/min); Comparation between TOF of the full NH3-SCO reaction and Cu2+ reduction rate in Cu/Al2O3 (h) and PtSCu/Al2O3 (i).

Although Pt is predominant in the surface layer, the underlying Cu atoms modulate the surface electronic structure to improve both the catalytic activity and durability. To assess the redox behaviour (essential for the formation of N2 from the oxidation of NH3) and monitor structural changes of the CuO NPs and surface Pt under relevant NH3-SCO reaction conditions, operando XAFS measurements were performed in fluorescence mode at the Pt L3-edge and transmission mode at the Cu K-edge under steady-state conditions between 25 and 400 °C (Fig. 3a–c and S21–23). Figure 3a illustrates the evolution of the Cu K-edge XAFS spectra at the Cu+ 1 s → 4p transition in PtSCuO/Al2O3, PtNCuO/Al2O3, and CuO/Al2O3 during the NH3-SCO reaction (NH3 5000 ppm, O2 5%) as a function of temperature. Between 100 and 250 °C, Cu2+ in PtSCuO/Al2O3 is partially reduced to Cu+, even under excess O2, as evidenced by the more pronounced peak intensity of the Cu K-edge at 8982 eV (the typical feature for CuI(NH3)2 1 s → 4p XANES) (Fig. 3a). Above 250 oC the Cu+ feature at 8982 eV disappears and is accompanied by an increase in the white-line intensity at 8996 eV (Fig. 3a, S21 and 24), indicative of oxidation of Cu+ to Cu2+. In comparison, the peak intensity of the Cu K-edge at 8982 eV in PtNCuO/Al2O3 only increases slightly between 100 and 250 °C, whereas Cu+ in CuO/Al2O3 is almost constant over the entire temperature range (Fig. 3a, S23–25). As the feed gas composition is changed from reducing to oxidizing, the Cu species in PtSCuO/Al2O3 are readily reduced and oxidized at 200 °C (Fig. 3d and S26), whereas the Cu species in CuO/Al2O3 do not change (Fig. 3f).

In situ near ambient pressure-near edge X-ray absorption fine structures (NAP-NEXAFS) of the catalysts under a NH3 atmosphere (1 mbar) confirms the superior redox properties of PtSCuO/Al2O3, with a more pronounced peak observed at 934.2 eV corresponding to Cu+ (Fig. 3g). Additionally, the formation of Cu+ in PtSCuO/Al2O3 under a NH3/O2 atmosphere was validated by in situ NAP-NEXAFS (Fig. 3h). In the NAP-NEXAFS studies, the Cu species in the PtSCuO/Al2O3 catalyst return to their original redox states after exposure to different gases (Fig. 3i). This switching between Cu+ and Cu2+ confirms the reversibility of the oxidation state of Cu species in PtSCu/Al2O3, as well as the high stability of the catalyst together with the 100 h stability tests at 200 °C (Fig. 2e). Based on the operando XAFS and in situ NAP-NEXAFS studies, the Cu species in PtSCuO/Al2O3 undergo facile redox switching compared to PtNCuO/Al2O3 and CuO/Al2O3, which is in agreement with the hydrogen-temperature programmed reduction (H2-TPR) results, in which the PtSCuO/Al2O3 catalyst has the lowest reduction temperature, indicating that surface Pt species enhance the reduction ability of CuO NPs (Fig. 3c).

Reduction of Cu2+ to Cu+ and Pt4+ to Pt0 takes place in the same temperature range for PtSCuO/Al2O3, which is not the case for PtNCuO/Al2O3, indicating a better redox synergy between the two metals in the former. Hence, it would appear that Pt0 induces the reduction of Cu2+ to Cu+ in PtSCuO/Al2O3. PtNCuO/Al2O3 and Pt/Al2O3 are more resistant to reduction and oxidation in the course of the reaction, since both the Cu and Pt oxidation states do not vary significantly (Fig. 3a, b). In the light-off curve of PtSCu/Al2O3 shown in Fig. S27, the reaction rate increases rapidly from 150 °C, which corresponds to the formation temperature of the CuI(NH3)2 species (Fig. 3a), so that the formation of the Cu+ is considered to be a trigger for the NH3-SCO reaction. The highest activity for the NH3-SCO reaction between 100 and 250 °C is found for PtSCuO/Al2O3, which has the highest abundance of Cu+. Compared with PtNCuO/Al2O3 and CuO/Al2O3, the superior redox properties of Cu and Pt species in PtSCuO/Al2O3 lead to higher activity at lower temperatures.

Determination of the Cu+/2+ redox rate

In situ energy dispersive EXAFS (EDE) under modulation excitation of net-reducing (NH3) to net-oxidizing (O2) gas environments was used to probe the redox behaviour of Cu+/2+ in the PtSCuO/Al2O3 and CuO/Al2O3 catalysts. For both catalysts oxidation to Cu2+ is much faster than reduction to Cu+, partially due to the higher concentration of O2 (5%) used compared to NH3 (5000 ppm) (Fig. 4a, b). Notably, the rates for oxidation and reduction in PtSCuO/Al2O3 is much higher than in CuO/Al2O3 at all temperatures, which is in agreement with the steady-state study (see Fig. 3).

At 200 °C, the reaction order of NH3 in the half-reaction (2NH3 + 6CuO → N2 + 3Cu2O + 3H2O) is facilitated by Pt is almost 0, which is consistent with the apparent reaction order of NH3 (0.2) in the overall SCO reaction (4NH3 + 3O2 → 2N2 + 6H2O) (Fig. 4c, d). In this case, the NH3 that reacts is limited to those that absorb on the PtSCuO/Al2O3 surface, a key step for both the SCO reaction and the reduction of Cu2+. The amount of Cu+ in PtSCuO/Al2O3 is dependent on the oxygen concentration (Fig. 4e, f), with a reaction order of 0.7. The O2 order for the SCO reaction is 0 and −0.9 for the PtSCuO/Al2O3 and CuO/Al2O3 catalysts (Fig. 4f), respectively, indicating that the lattice O participates in the oxidation process due to the surface coverage of NH3 on the PtSCuO/Al2O3 catalyst (Mars–van Krevelen mechanism)30,31. The lower reaction order for O2 in the NH3-SCO reaction implies facile oxygen activation takes place on the surface of the PtSCuO/Al2O3 catalyst. In the absence of NH3, however, for the reaction O2 + 2 Cu2O → 4 CuO, the gas phase oxygen surface coverage is rate determining27. Overall, the redox behaviour of Cu+/2+ is important for the i-SCR mechanism in the overall NH3-SCO process12,32, with the Cu+/2+ redox kinetics aligned with the overall SCO kinetics.

To further validate that the Cu2+ reduction is the rate-determining step, we compare the Cu+/2+ redox rate with the turnover frequency (TOF) of the whole NH3-SCO reaction (Fig. 4h, i, S28). With both PtSCuO/Al2O3 and CuO/Al2O3, the Cu+ oxidation rate is faster than Cu2+ reduction rate, and the Cu+ oxidation rate consistently surpasses the NH3 oxidation rate (i.e. TOF of the whole NH3-SCO reaction) (Fig. S28). This implies that the Cu+ oxidation step is not the rate-determining step in both PtSCuO/Al2O3 and CuO/Al2O3 catalysts. For both catalysts, the TOF is comparable to the rate of Cu2+ reduction to Cu+, indicating that Cu2+ reduction should be the rate-determining step (Fig. 4h, i). At 250 °C, NH3 conversion for PtSCuO/Al2O3 is over 50% and thus in the diffusion region. Therefore, the Cu2+ reduction rate from the in situ EDE experiment is much higher than the calculated TOF from converion (Fig. 4i). It is noteworthy that the Cu+/2+ redox rate with PtSCuO/Al2O3 is consistently superior than the Cu+/2+ redox rate with CuO/Al2O3 across all temperatures. This confirms that the enhanced Cu+/2+ redox rate promotes the activity.

Fast Cu+/2+ redox rate leads to higher selectivity of N2

Pt/Al2O3 is effective at oxidizing ammonia but lacks selectivity to nitrogen gas, especially above 250 °C (Fig. 2b and S9). With Pt/Al2O3, unfavourable over-oxidation to N2O and NO takes place on the surface of the PtO2 nanoparticles (Step 2 in the i-SCR)11,19,33. Compared to Pt/Al2O3, the Cu in the PtSCuO/Al2O3 catalyst considerably improves the selectivity to N2 while not affecting the low-temperature activity (Fig. 2a, b), due to the excellent SCR performance of Cu species34,35. In Step 2 of the i-SCR mechanism, NO oxidation on the Cu2+ site forms HONO-like species, and the Cu2+ is reduced to Cu+36. Subsequently, the HONO-like species react further with adsorbed NH3 to generate N2 and H2O, and the Cu+ is then oxidized by O2 to regenerate Cu2+, thus completing the redox cycle.

Operando DRIFTS confirm that the combination of Pt and Cu sites in PtSCuO/Al2O3 contributes to improved selectivity via the i-SCR (Fig. 5a, b), to achieve the high selectivity to N2 (above 90% over all temperatures)37. The bands observed at 1625 and 1,256 cm−1 may be assigned to asymmetric and symmetric deformation of ammonia chemisorbed on Lewis acid sites of Al2O3, respectively27. Large amounts of NH3 (1625 and 1256 cm−1) are adsorbed on the Lewis acid sites at temperatures below 200 °C. The amount of adsorbed NH3 decreases as the temperature increases, and –NH2 species (evidenced by a peak at 1580 cm–1 in the IR spectra) gradually emerge at temperatures above 250 °C38,39. It is likely that NH3 dissociatively adsorbs as −NH2 on the surface of the PtSCuO/Al2O3 catalysts. It has been reported that NH3 adsorption on Lewis acid sites is responsible for NH3 oxidation activity, but does not significantly impact N2 selectivity40. The presence of Pt in the PtSCuO/Al2O3 catalyst enhances the Cu+/Cu2+ redox recycle, which leads to a higher NH3 oxidation rate. The Lewis acid sites on Al2O3 observed at 1625 and 1256 cm−1 have more pronounced peaks and are more reactive than the Brønsted acid sites (1460 cm−1) in the NH3-SCO reaction, since the intensity of the peak at 1460 cm−1 hardly changes. It has also been reported that NH3 species adsorbed on Brønsted acid sites can promote the conversion of NOx formed during NH3 oxidation, thereby improving overall selectivity to N2 through the i-SCR mechanism41. NH3 adsorbed on Brønsted acid sites were detected from room temperature to 350 °C on the PtSCuO/Al2O3 catalyst, but are not observed on the CuO/Al2O3 catalyst. This phenomenon suggests that NH3 species adsorbed on Brønsted acid sites of the PtSCuO/Al2O3 catalyst are more stable than those on CuO/Al2O3. Presumably the increased stability significantly enhances the selectivity of the NH3–SCO reaction to N2 on the PtSCuO/Al2O3 catalyst. The peak at 1405 cm−1 may be assigned to NH3 coordinated to Cu and the peak at 1378 cm−1 may be attributed to NH3 coordinated to Pt36,42. The presence of Pt in the PtSCuO/Al2O3 catalyst boosts the Cu+/Cu2+ redox cycle, which leads to a higher i-SCR rate and therefore a higher yield to N2.

NH3 emissions are expected to increase in the future and selective catalytic oxidation (SCO) of NH3 to N2 is one of the principle approaches used to eliminate these emissions. The PtSCuO/Al2O3 catalyst reported here is superior to the commercial Pt/Al2O3 catalysts with respect to both activity and selectivity, achieving full conversion of 5000 ppm NH3 at 250 °C, with selectivity to N2 between 90 and 100% depending upon the temperature. Based on the moderate operating conditions and the excellent selectivity across a broad temperature range, the catalyst is even suitable for cold start applications such as controlling diesel engine emissions. Operando XAFS and time-resolved energy dispersive EXAFS studies were used to show that the enhanced redox rate of the Cu species, induced by the Pt sites in PtSCuO/Al2O3, leads to enhanced activity. Operando DRIFTS further demonstrate that the interactions between the Pt and Cu sites contribute to the high selectivity via the i-SCR reaction. Overall, this study illustrates the dynamic changes in the chemical state of the active sites in nanoscale catalysts under relevant reaction conditions, highlighting the importance of operando studies to gain a mechanistic understanding of structure–reactivity correlations. The results will help to guide future catalyst design, such as non-noble metal counterparts.

Methods

Catalyst preparation

Synthesis of Cu/Al2O3

γ-Al2O3 (0.5 g, Johnson Matthey) was dispersed in ethanol (20 mL) with vigorous stirring at room temperature. To the resulting suspension, a solution containing Cu(NO3)2.3H2O (100 mg, 0.4 mmol) in ethanol (5 mL) was slowly added, and stirring was continued for 12 h at room temperature. The reaction mixture was then heated at 40 °C under stirring until all the solvent had evaporated. The remaining solid was heated to 300 °C for 1 h under 15% H2/Ar at a heating rate of 5 °C/min in a tube furnace to afford Cu/Al2O3.

Synthesis of PtSCu/Al2O3

The PtSCu/Al2O3 catalyst was prepared via galvanic replacement between the Cu NPs and H2PtCl6. Cu/Al2O3 was dispersed in ethanol (25 mL) under a nitrogen atmosphere, and the resulting suspension was heated at 60 °C for 10 min. A solution of H2PtCl6 (6 mg) dissolved in ethanol (2 mL) was added slowly to the reaction mixture. After stirring for 6 h at 60 °C, the solution was cooled to room temperature, and then the solid was collected by centrifugation and washed with ethanol (5 × 30 mL). After drying at 40 °C for 24 h, the PtSCu/Al2O3 catalyst was obtained as a grey powder.

Synthesis of Pt/Al2O3

1 wt% Pt/Al2O3 was prepared using the wetness impregnation method. H2PtCl6·6H2O (13.4 mg) was dissolved in deionised water and then added into γ-Al2O3 (0.5 g) ethanol suspension. The solvent was then removed at 60 °C and the sample was heated at 300 °C for 1 h under 15% H2/Ar at a heating rate of 5 °C/min.

Ex situ characterisation

X-ray diffraction (XRD)

XRD patterns were recorded on a StadiP diffractometer (STOE) with a Mo source (Kα = 0.7093165 Å). The operating voltage and current were 40 kV and 30 mA, respectively. 2θ in the range of 2–40° were collected with a resolution of 0.015° for each step.

H2-TPR

the measurements were performed on an FD-2000 reactor and quantified using an AO2000 analyser. Typically, 50 mg catalyst was placed in a quartz tube and pre-treated in He at 300 °C for 30 min to remove the surface absorbed species. After cooling to room temperature, the sample was heated in 5% H2/N2 (100 mL/min) at a rate of 5 °C/min, then kept at 350 °C for 30 mins.

TEM

Aberration-corrected bright field (BF) and annular dark field (ADF) scanning transmission electron microscopy (STEM) was performed on a JEOL (Tokyo, Japan) ARM300CF (E02) operating 300 kV. Simultaneous energy dispersive x-ray (EDX) spectroscopy and aberration-corrected BF/ADF-STEM imaging was performed on a JEOL ARM200CF (E01) operating at 200 kV and equipped with JEOL dual silicon drift detectors at the electron Physical Sciences Imaging Centre (ePSIC) at Diamond Light Source (UK) (DLS). The ARM300CF operated with a convergence semi-angle of 26.2 mrad and BF and ADF collection semi-angles of 0-31.6 and 77.0-209.4, respectively. The ARM200CF operated with a convergence semi-angle of 23.0 mrad with BF and ADF collection semi-angles of 0–21.9 and 37.5–128.3 respectively. Single-pass EDX spectra were collected with drift correction. Data were acquired and processed using the Gatan Microscopy Suite (a.k.a. Digital Micrograph)43. Nanoscale catalyst particles were prepared via a standard preparation route: a small amount (<20 mg) of catalyst powder was dispersed in approximately 5 ml of ethanol, before sonication and drop casting approximately 1 ml of supernatant onto holey carbon coated, gold TEM support grids. Gold was used instead of the more typical copper grid to avoid overlapping fluorescent signals with the sample during EDX mapping. The average particle size was calculated based on more than 100 particles for each sample.

X-ray absorption fine structure (XAFS)

XAFS of the Pt L3-edge (11.564 keV) and Cu K-edge (8.979 keV) were carried out at the Diamond Light Source (UK) and SPring-8 (Japan). Samples were directly pressed into pellets for fluorescence measurements of the Pt L3-edge and transmission measurements of the Cu K-edge. Pt foil or Cu foil standards were used for energy shift calibration.

XAFS data involved merging three spectra to improve signal quality and were processed using the Demeter software package (including Athena and Artemis). Athena software was used to analyse the XANES data. Artemis software was used to fit the k2-weighted EXAFS data in real space with 3.0 Å−1 < k < 12.0 Å−1 and 1.0 Å <R < 3.3 Å. The calculated amplitude reduction factor S02 from the EXAFS analysis of Cu foil was 0.878, which was used as a fixed parameter for EXAFS fitting. The coordination numbers and bond lengths were calculated based on the reported structures from the Crystal open database: Cu (No. 9013014), CuO (No. 1011148), Pt (No. 9008480), and PtO2 (No. 1008935).

Operando Pt L3-edge and Cu K-edge XAFS

Operando XAFS experiments were performed at SPring-8 (Japan). 100 mg of pelletised catalysts were measured at 8780–10200 eV for Cu K edge in transmission mode and 11345–12745 eV for Pt L3-edge in fluorescence mode at different temperatures and under various gas atmospheres. Spectra processing was performed with Athena software.

Operando DRIFTS

DRIFTS was performed on a PerkinElmer Frontier FT-IR Spectrometer. The sample was heated in He at 350 °C for 30 min to remove surface contamination. After cooling to room temperature, the sample was exposed to 5000 ppm NH3 or 5%O2/He for 30 minutes, during which spectra were recorded. Then, the sample was heated from 30 to 450 °C with a ramp of 10 °C/min. The spectra were recorded from 4400 to 500 cm−1 with a resolution of 2 cm−1. Background spectra were recorded in He and subtracted from the sample spectrum for each measurement.

In situ energy dispersive EXAFS (EDE)

Cu K edge EDE measurements were carried out on the I20-EDE beamline at the Diamond Light Source (UK). For in situ experiments the samples were sieved (125–200 µm) and filled into a quartz tube (5.5 mm). An identical tube filled with Al2O3 was used as the background. The gas flow was 40 mL/min and spectra were taken when switching the gases. Each condition was run 6 times, and the results were merged for the final spectra.

In situ near ambient pressure-near edge X-ray absorption fine structure (NAP-NEXAFS) spectroscopy

In situ NAP-NEXAFS experiments were performed on the B07 beamline at the Diamond Light Source (UK)44. The X-rays are sourced from a bending magnet (D41) and a plane grating monochromator (PGM) with an energy range from 80 to 2000 eV (soft X-ray range) and flux of 6 × 1010 photons/s with 0.1 A ring current using a 111 µm slit and an 80 µm × 200 µm beam spot size. The reaction products were monitored online using an electron impact mass spectrometer (“PRISMA”, PFEIFFER VACUUM GmbH, Asslar (Germany)) connected directly to the main experimental chamber by a leak valve. The pressure in the specimen chamber was precisely controlled at 1 mbar by simultaneous operation of several mass flow controllers for reactive gases and a PID-controlled throttle valve for pumping gas out. Temperature control was achieved by two K-type thermocouples. NEXAFS spectra at Cu L-edge (925–940 eV) were measured in Auger electron yield (AEY) mode.

Measurements were performed under various gas conditions with a total pressure of 1 mbar. In situ experiments employing PtSCu/Al2O3, PtNCu/Al2O3 and CuO/Al2O3 were carried out at 200 °C under NH3 + O2 (NH3/O2: 1:10) or NH3. For experiments carried out under various gas atmospheres at 200 °C, the sequence of different gas atmospheres follows NH3 + O2 (ratio: 1:10), NH3, NO + NH3 (ratio: 1:1) and NH3 + O2 (ratio: 1:10). All spectra were recorded under steady-state conditions.

Catalytic performance measurements

The performance of the catalysts in the NH3-SCO reaction was evaluated in a fixed-bed flow reactor at a gas flow rate of 100 mL/min, which consists of 5000 ppm NH3, 5 vol% O2, and the He balance. In a typical experiment, 50 mg of catalyst was placed in the reaction tube, and quantification of the products was performed with an online quadrupole mass spectrometer quantitative gas analyser (Hiden Analytical, UK). The reaction was investigated at temperatures ranging from 100 °C to 450 °C. The reaction was kept stable for at least 30 minutes after attaining a steady state at each reaction temperature to detect the MS signals of (NH3 and O2) and products (N2, N2O and NO).

To obtain the activation energy, 50 mg catalyst powder was immobilized in a fixed-bed flow reactor and a gas flow rate of 100 mL/min, consisting of 5000 ppm NH3, 5 vol% O2, and a He balance was applied. The reaction was investigated at temperatures ranging from 140–180 °C for PtSCu/Al2O3, 180–220 °C for Pt/Al2O3 and 200–240 °C for CuO/Al2O3.

To obtain the reaction order for NH3, the O2 was kept at 5%, while the concentration of NH3 was varied, i.e. 2500, 4000, 5000, 6000 and 7000 ppm. All the tests were performed at 150 °C for PtSCu/Al2O3, and 220 °C for CuO/Al2O3.

To obtain the reaction order for O2, the NH3 was kept at 5000 ppm, while the concentration of O2 was varied, i.e. 5, 6, 7, 8, 9 and 10%. All the tests were performed at 150 °C for PtSCu/Al2O3 and 220 °C for CuO/Al2O3.

To evaluate the external diffusion limitation, catalyst performance was tested under different flow rates. Different amounts of catalyst powder was immobilized in a fixed-bed flow reactor and the WHSV maintained at 600 mL NH3/g/h. The reaction was investigated at different flow rates of 25, 50, 75, 100, 125 or 150 mL/min at 200 °C and 250 °C.

To evaluate the internal diffusion limitation, the performance of catalysts of differing particle sizes was tested. 50 mg catalyst powder with different particle sizes, including <250 µm, 250–500 µm, and >500 µm, were immobilized in a fixed-bed flow reactor and a gas flow rate of 100 mL/min, consisting of 5000 ppm NH3, 5 vol% O2, and a He balance was applied.

Data availability

All data generated in this study are provided in the article and Supplementary Information files.

References

Svintsitskiy, D. A. et al. Insight into the Nature of Active Species of Pt/Al2O3 Catalysts for low Temperature NH3 Oxidation. ChemCatChem 12, 867–880 (2020).

Decarolis, D. et al. Spatial Profiling of a Pd/Al2O3 Catalyst during Selective Ammonia Oxidation. ACS Catal. 11, 2141–2149 (2021).

Andersen, S. Z. et al. A rigorous electrochemical ammonia synthesis protocol with quantitative isotope measurements. Nature 570, 504–508 (2019).

Chakraborty, D. et al. Bottom-Up Design of a Copper–Ruthenium Nanoparticulate Catalyst for Low-Temperature Ammonia Oxidation. Angew. Chem. 129, 8837–8841 (2017).

Wang, F. et al. Nanosize Effect of Al2O3 in Ag/Al2O3 Catalyst for the Selective Catalytic Oxidation of Ammonia. ACS Catal. 8, 2670–2682 (2018).

Jabłońska, M. & Palkovits, R. Copper based catalysts for the selective ammonia oxidation into nitrogen and water vapour—Recent trends and open challenges. Appl. Catal. B: Environ. 181, 332–351 (2016).

Jabłońska, M. Progress on Selective Catalytic Ammonia Oxidation (NH 3 ‐SCO) over Cu−Containing Zeolite‐Based Catalysts. ChemCatChem 12, 4490–4500 (2020).

Lan, T. et al. Selective catalytic oxidation of NH 3 over noble metal-based catalysts: state of the art and future prospects. Catal. Sci. Technol. 10, 5792–5810 (2020).

Gao, F. et al. Advances in selective catalytic oxidation of ammonia (NH3–SCO) to dinitrogen in excess oxygen: A review on typical catalysts, catalytic performances and reaction mechanisms. J. Environ. Chem. Eng. 9, 104575 (2021).

Liang, C., Li, X., Qu, Z., Tade, M. & Liu, S. The role of copper species on Cu/γ-Al2O3 catalysts for NH3–SCO reaction. Appl. Surf. Sci. 258, 3738–3743 (2012).

Svintsitskiy, D. A. et al. The State of Platinum and Structural Features of Pt/Al2O3 Catalysts in the Reaction of NH3 Oxidation. J. Struct. Chem. 60, 919–931 (2019).

Olofsson, G., Wallenberg, L. R. & Andersson, A. Selective catalytic oxidation of ammonia to nitrogen at low temperature on Pt/CuO/Al2O3. J. Catal. 230, 1–13 (2005).

Kušar, H. M. J., Ersson, A. G., Vosecký, M. & Järås, S. G. Selective catalytic oxidation of NH3 to N2 for catalytic combustion of low heating value gas under lean/rich conditions. Appl. Catal. B: Environ. 58, 25–32 (2005).

Lin, S. D., Gluhoi, A. C. & Nieuwenhuys, B. E. Ammonia oxidation over Au/MO /γ-Al2O3—activity, selectivity and FTIR measurements. Catal. Today 90, 3–14 (2004).

Gang, L. et al. Alumina-Supported Cu–Ag Catalysts for Ammonia Oxidation to Nitrogen at Low Temperature. J. Catal. 206, 60–70 (2002).

Yang, M., Wu, C., Zhang, C. & He, H. Selective oxidation of ammonia over copper-silver-based catalysts. Catal. Today 90, 263–267 (2004).

Shrestha, S., Harold, M. P., Kamasamudram, K. & Yezerets, A. Ammonia Oxidation on Structured Composite Catalysts. Top. Catal. 56, 182–186 (2013).

Cui, X. et al. Selective catalytic oxidation of ammonia to nitrogen over mesoporous CuO / RuO 2 synthesized by co-nanocasting-replication method. J. Catal. 270, 310–317 (2010).

Li, Y. & Armor, J. N. Selective NH3 oxidation to N2 in a wet stream. Appl. Catal. B: Environ. 13, 131–139 (1997).

Ghosh, R. S. et al. Enhanced Selective Oxidation of Ammonia in a Pt/Al2O3@Cu/ZSM-5 Core-Shell Catalyst. ACS Catal. 10, 3604–3617 (2020).

Dhillon, P. S., Harold, M. P., Wang, D., Kumar, A. & Joshi, S. Y. Optimizing the dual-layer Pt/Al2O3 + Cu/SSZ-13 washcoated monolith: Selective oxidation of NH3 to N2. Catal. Today 360, 426–434 (2021).

Dhillon, P. S., Harold, M. P., Wang, D., Kumar, A. & Joshi, S. Y. Modeling and analysis of transport and reaction in washcoated monoliths: Cu-SSZ-13 SCR and dual-layer Cu-SSZ-13 + Pt/Al2O3 ASC. React. Chem. Eng. 4, 1103–1115 (2019).

Marchuk, V., Sharapa, D. I., Grunwaldt, J. D. & Doronkin, D. E. Surface States Governing the Activity and Selectivity of Pt-Based Ammonia Slip Catalysts for Selective Ammonia Oxidation. ACS Catal. 14, 1107–1120 (2024).

Curtin, T., O’ Regan, F., Deconinck, C., Knüttle, N. & Hodnett, B. K. The catalytic oxidation of ammonia: Influence of water and sulfur on selectivity to nitrogen over promoted copper oxide/alumina catalysts. Catal. Today 55, 189–195 (2000).

Chmielarz, L. et al. Selective catalytic oxidation of ammonia to nitrogen over Mg-Al, Cu-Mg-Al and Fe-Mg-Al mixed metal oxides doped with noble metals. Appl. Catal. B 130–131, 152–162 (2013).

Burch, R. & Southward, B. W. L. Low-temperature, dean catalytic combustion of N-bearing gasified biomass using a novel NH3 trapping catalyst. Chem. Commun. 2, 1115–1116 (2000).

Guan, X. et al. Designing Reactive Bridging O2-at the Atomic Cu-O-Fe Site for Selective NH3Oxidation. ACS Catal. 12, 15207–15217 (2022).

Nilsen, O., Kjekshus, A. & Fjellvåg, H. Reconstruction and loss of platinum catalyst during oxidation of ammonia. Appl. Catal. A: Gen. 207, 43–54 (2001).

Scheuer, A. et al. Dual layer automotive ammonia oxidation catalysts: Experiments and computer simulation. Appl. Catal. B: Environ. 111–112, 445–455 (2012).

Mars, P. & van Krevelen, D. W. Oxidations carried out by means of vanadium oxide catalysts. Chem. Eng. Sci. 3, 41–59 (1954).

Doornkamp, C. & Ponec, V. The universal character of the Mars and Van Krevelen mechanism. J. Mol. Catal. A: Chem. 162, 19–32 (2000).

Cheng, Y., Song, W., Liu, J., Zhao, Z. & Wei, Y. Simultaneous removal of PM and NO x over highly efficient 3DOM W/Ce 0.8 Zr 0.2 O 2 catalysts. RSC Adv. 7, 56509–56518 (2017).

Sun, M. et al. Different reaction mechanisms of ammonia oxidation reaction on Pt/Al2O3 and Pt/CeZrO2 with various Pt states. ACS Appl. Mater. Interfaces 11, 23102–23111 (2019).

Wang, J., Zhao, H., Haller, G. & Li, Y. Recent advances in the selective catalytic reduction of NOx with NH3 on Cu-Chabazite catalysts. Appl. Catal. B: Environ. 202, 346–354 (2017).

Han, L. et al. Selective Catalytic Reduction of NOx with NH3 by Using Novel Catalysts: State of the Art and Future Prospects. Chem. Rev. 119, 10916–10976 (2019).

Zhang, Q. et al. In situ DRIFTS studies on CuO-Fe2O3 catalysts for low temperature selective catalytic oxidation of ammonia to nitrogen. Appl. Surf. Sci. 419, 733–743 (2017).

Burch, R. & Southward, B. W. L. W. L. A Novel Application of Trapping Catalysts for the Selective Low-Temperature Oxidation of NH3 to N2 in Simulated Biogas. J. Catal. 195, 217–226 (2000).

Zhang, L. & He, H. Mechanism of selective catalytic oxidation of ammonia to nitrogen over Ag/Al2O3. J. Catal. 268, 18–25 (2009).

Cha, B. J. et al. In Situ Spectroscopic Studies of NH3 Oxidation of Fe-Oxide/Al2 O3. ACS Omega 8, 18064–18073 (2023).

Lin, M. et al. Role of the Acid Site for Selective Catalytic Oxidation of NH 3 over Au/Nb 2 O 5. ACS Catal. 9, 1753–1756 (2019).

Jabłońska, M. et al. Zeolite y modified with palladium as effective catalyst for selective catalytic oxidation of ammonia to nitrogen. J. Catal. 316, 36–46 (2014).

Yang, J. et al. Time-resolved in situ DRIFTS study on NH 3 -SCR of NO on a CeO 2 /TiO 2 catalyst. Catal. Sci. Technol. 12, 1245–1256 (2022).

Gatan, Inc., United States of America, DigitalMicrograph Software. https://www.gatan.com/products/tem-analysis/gatan-microscopy-suite-software. Accessed 27 October 2024.

Held, G. et al. Ambient-pressure endstation of the Versatile Soft X-ray (VerSoX) beamline at Diamond Light Source. J. Synchrotron Radiat. 27, 1153–1166 (2020).

Acknowledgements

We thank the EPSRC for the UKRI Postdoctoral Fellowship (MSCA) to Lu Chen (EP/X022986/1). We thank the EPSRC (EP/S018204/2, EP/Z001730/1 and EP/Y036220/1) for financial support. We thank EPFL for financial support. We thank the beamline scientists at the SPring-8 (BL14B2, 2022B1758) and Diamond Light Source for the provision of beamtimes (I20-EDE: SP30622-1, B07: SI33257-1) and the scientists in the Electron Physical Science Imaging Centre (EPSIC: MG31922). XAS measurements were performed at BL14B2 of SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (Proposal No. 2022B1758). We thank the UK Catalysis Hub for the provision of DRIFTS. We thank the Soleil synchrotron (Galaxies beamline: 20221122), the European Synchrotron Radiation Facility (ID-24 beamline: CH-6856 and CH-7062) and the MAX IV (Balder beamline: 20230511) for the provision of beamtimes.

Author information

Authors and Affiliations

Contributions

L.C., X.G., and F.R.W. conceived of the presented idea. L.C., F.R.W. and P.J.D. secured the fundings. L.C. carried out catalysts synthesis and catalytic evaluations, X.G. verified the analytical methods. L.C., X.G., H.A. and F.R.W. carried out the operando XAS study, and L.C. and X.G. analysed the data. L.Z. and Z.F. contributed to the XRD measurements and the XPS measurements. L.C., X.G., Z.W., L.K. and S.H. carried out the in-situ EDE studies. L.C., X.G., X.S. and Z.Y. carried out the NAP-NEXAFS studies with the support from M.V.S., B.K. and G.H. X.G., C.A. and D.H. conducted the TEM measurements. L.C., X.G. performed DRIFTS experiments with the support from D.D. and J.C. L.C., P.J.D. and F.R.W. wrote the paper, and all authors contributed to the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Michael Harold, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, L., Guan, X., Fei, Z. et al. Tuning the selectivity of NH3 oxidation via cooperative electronic interactions between platinum and copper sites. Nat Commun 16, 26 (2025). https://doi.org/10.1038/s41467-024-54820-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-54820-y

This article is cited by

-

Cascade catalysis on dual-atom iridium-tungsten catalysts for enhanced ammonia selective oxidation

Nature Communications (2025)