Abstract

The precise fabrication and regulation of the stable catalysts with desired performance still challengeable for single atom catalysts. Here, the Ru single atoms with different coordination environment in Ni3FeN lattice are synthesized and studied as a typical case over alkaline methanol electrooxidation. The Ni3FeN with buried Ru atoms in subsurface lattice (Ni3FeN-Ruburied) exhibits high selectivity and Faradaic efficiency of methanol to formate conversion. Meanwhile, operando spectroscopies reveal that the Ni3FeN-Ruburied exhibits an optimized adsorption of reactants along with an inhibited surface structural reconstruction. Additional theoretical simulations demonstrate that the Ni3FeN-Ruburied displays a regulated local electronic states of surface metal atoms with an optimized adsorption of reactants and reduced energy barrier of potential determining step. This work not only reports a high-efficient catalyst for methanol to formate conversion in alkaline condition, but also offers the insight into the rational design of single atom catalysts with more accessible surficial active sites.

Similar content being viewed by others

Introduction

In recent years, single-atom catalysts (SACs) have attracted extensive attentions, particularly regarding the regulation of site activity and the synthesis of high loading catalysts1,2,3,4. Generally, the isolated single atom sites in SACs act as active centers in catalytic reactions due to the specific coordination environment and enhanced charge polarizations5,6,7. Wherein, the preferential bonding of reactants and intermediates to the isolated single atoms may induce structural evolutions in valence states and surface reconstruction8, leading to the change of intrinsic activity and increased competition reaction performance. Besides, the catalytic performance is often hindered by the limited loading of single atoms, while most other constituent atoms within the material remain underutilized9,10,11. Stimulating more stable and optimized surficial atoms to work as reaction centers12, thereby improving the overall atomic utilization efficiency within the catalysts, presents a significant approach for the further development of SACs.

Electrochemical methanol oxidation reaction (MOR) under alkaline conditions has been applied in overall water splitting to reduce the overpotential along with value-added formate synthesis13,14,15. Ni-based electrocatalysts have emerged as particularly candidates for MOR with various types of catalysts and reaction pathways, which has led to potential controversies regarding the reaction process and structural evolution15,16,17,18,19,20. For example, Wang and co-workers proposed series works of Ni-based hydroxide regarding electrophilic lattice oxygen and surface reconstruction21. Li and co-workers demonstrated that the Ni/NiB hetero-structure exhibits high methanol oxidation performance without self-reconstruction during electrochemical process22. Based on the above discoveries, it is reasonable to speculate that the MOR performance of given catalysts could be influenced by the surficial states of active sites. Hence, it is a significant case to optimize the surface activity of the catalysts and validate the structural evolution during alkaline MOR. Upon this, burying single atoms at the subsurface lattice of catalysts may help to optimize the surficial active sites and thus improve the overall catalytic performance: (1) burying single atoms into the subsurface lattice of substrates can protect the metal atoms form over-bonding with reactants, surface reconstruction, and competition reaction. (2) the buried single atoms can significantly regulate the electronic states of surrounding atoms along with favorable adsorption of reactants. Consequently, the intrinsic activity of more metal sites in the substrate could be optimized, thereby increasing the number of overall active sites.

In this work, Ru single atoms buried into the subsurface lattice of Ni3FeN (Ni3FeN-Ruburied) by fast Joule-heating synthesis for highly efficient alkaline methanol to formate conversion was presented to elaborate our proposed speculation. X-ray absorption spectroscopy (XAS) and density-functional theory (DFT) calculations clarified the coordination environment of buried Ru atoms, which caused the rearrangement of the local electronic structure of surface metal atoms. The Ni3FeN-Ruburied displayed a remarkably high FE under the potential range from 1.4 to 1.6 V (vs RHE), along with ideal stability, suggesting its superior electrocatalytic selectivity and activity. Further operando characterizations, and theoretical simulations revealed that the buried Ru single atoms have activated surface atom activity along with the optimized reactants adsorption and suppressed structural reconstruction, consequently leading to the high selectivity towards formate. This work provides a perspective and valuable approach for activating more surficial active sites via the strategy of burying single atoms.

Results

Synthesis and characterizations

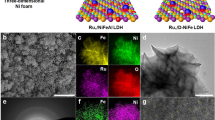

As shown in Fig. 1a, the Ni3FeN-Ruburied were synthesized through a two-step approach: (1) Ru atoms were incorporated into the NiFe oxychloride as the precursor; (2) The as-prepared precursor was nitrogenized to anti-perovskite Ni3FeN-Ruburied with buried Ru atoms by fast Joule-heating synthesis. Additionally, the surface-loaded single Ru atoms (Ni3FeN-Rusurface) was prepared by traditional nitrogenization strategy in a tubular furnace for a long annealing time (Fig. 1a). The fast Joule-heating synthesis with the rapid heating and quenching process helps to preserve and freeze the specific structure of materials, enabling the targeted design and fabrication of electrocatalysts with tailored coordination environments23. In this manuscript, it is proposed that the rapid Joule-heating process involved in forming the substrate material confines metal single atoms from the precursor within the subsurface lattice, whereas the slow annealing process in a tubular furnace allows more metal single atoms to migrate to the material’s surface during the formation of substrate lattice. The X-ray diffraction (XRD) pattern of Ni3FeN-Ruburied displays the diffraction peaks located at 41.5°, 48.3°, and 70.8°, highly consistent with the (111), (200), and (220) planes of anti-perovskite Ni3FeN (JCPDS: 50-1434), indicating the incorporation of single atoms has slightly influence on the crystal phase of the substrate except for slight lattice expansion (Supplementary Fig. S1). Figure 1b displays a typical transmission electron microscope (TEM) image of Ni3FeN-Ruburied, revealing the gathered nanoparticles with an average size of around 200 nm. The Ni3FeN-Rusurface and Ni3FeN counterparts exhibit a similar morphology to that of Ni3FeN-Ruburied, suggesting the applicable synthetic approach of the NiFe nitrides (Supplementary Figs. S2a, S3a). Furthermore, a continuous lattice fringes with the space of 2.20 Å could be observed in the high-resolution TEM (HRTEM) image of Fig. 1c, attributing to the (111) crystal plane of Ni3FeN substrate. Besides, the (100) plane with the interplanar spacing of 3.77 Å could also be observed (Supplementary Fig. S4a). Besides, the HRTEM images of pure Ni3FeN and Ni3FeN-Rusurface also displayed the (100) and (111) crystal planes (Supplementary Figs. S2,S3)24. In order to confirm the incorporation of Ru atoms, high-angle annular dark field scanning TEM (HAADF-STEM) measurements were conducted. As shown in Fig. 1d, a series of bright dots, attributed to the Ru single atoms, were dispersed in the lattice of Ni3FeN-Ruburied, which could also be confirmed in the annular bright field STEM (ABF-STEM) image (Supplementary Fig. S4b)25. Similar bright dots in HAADF-STEM and corresponding black dots in ABF-STEM images of Ni3FeN-Rusurface could also be detected (Supplementary Fig. S3). Furthermore, the energy-dispersive spectroscopy (EDS) mapping illustrated in Fig. 1e and Supplementary Figs. S5, S6 confirmed the uniform distribution of Ni, Fe, N, and Ru elements in the series samples. Besides, the loading amount of Ru single atoms, collected by inductively coupled plasma-atomic emission spectroscopy (ICP-AES), were calculated as 2.98 and 3.74% for Ni3FeN-Ruburied and Ni3FeN-Rusurface.

a Illustration of the synthetic strategy proposed in this work (Note: The model diagram of Joule-heating device and tubular furnace was drawn. Refer to our lab instruments). b TEM and c HRTEM images of the as-prepared Ni3FeN-Ruburied. d HAADF-STEM image with atomic resolution of the Ni3FeN-Ruburied (the Ru single atoms were highlighted in red circles). e Elemental mapping and corresponding STEM images of the Ni3FeN-Ruburied.

The surface chemical states and electronic structure were also confirmed by X-ray photoelectron spectroscopy (XPS) and X-ray absorption near edge structure (XANES). As depicted in Supplementary Fig. S7, the peaks located at 851.6 eV (Ni 2p1/2) and 869.1 eV (Ni 2p3/2) in the Ni 2p XPS spectrum were assigned to the metallic state of Ni while the peaks located at 854.0 eV (Ni 2p1/2) and 871.9 eV (Ni 2p3/2) were related to the Ni2+ that is attributed to the surface oxidation26. As concluded by fitting the Ni 2p spectra of the as-prepared samples, the ratios of Ni0 to Ni2+ were 0.348 for Ni3FeN, 0.336 for Ni3FeN-Ruburied and 0.257 for Ni3FeN-Rusurface, suggesting that the Ru atoms at the Ni3FeN lattice with different local configuration may lead to the different surface valence states of the substrate. Similarly, the Fe 2p XPS peaks at 706.72 eV (Fe 2p1/2) and 719.33 eV (Fe 2p3/2) could be assigned to the Fe0 species of metallic iron nitride, while XPS peaks at 710.25 eV (Fe 2p1/2) 723.90 eV (Fe 2p3/2) are mainly related to the surface oxidation of Fe2+ (Supplementary Fig. S8)27,28. Owing to the successful incorporation of Ru atoms into metallic Ni3FeN lattice, the main component of Ru species in Ru 3p XPS spectra exhibits a low valence state of Ru0 (Supplementary Fig. S9).

The 3d electronic states of the Ni and Fe elements near the catalyst’s surface were also measured by soft XANES, in which the peak intensity of the L2,3-edge is highly associated with the occupied states of d orbits. As shown in Supplementary Fig. S10, the absorption peaks at 855.45 and 873.21 eV could be assigned to the L3 and L2 edge adsorption of Ni XANES spectra29. The Ni3FeN-Ruburied displays the moderate L3-edge intensity between Ni3FeN-Rusurface and Ni3FeN, suggesting that the Ru single atoms mildly modified the electronic states of Ni in Ni3FeN-Ruburied, which is consistent with the XPS results. In addition, the highest L3-edge absorption peak of Fe XANES spectrum for Ni3FeN-Ruburied could be observed, indicating the more empty states of Fe d orbital in Ni3FeN-Ruburied (Supplementary Fig. S11)30. The adsorption peaks at 400.01 and 403.30 eV for N K-edge XANES spectra could be attributed to the electron transition from unoccupied hybridized N 2p to metal 3d orbitals31. The slightly decreased peak a indicates the strong interaction between Ru and N atoms (Supplementary Fig. S12). As a conclusion, the incorporation of Ru single atoms into the anti-perovskite lattice moderately regulated the surface chemical states along with internal charge transfer.

The local geometric configuration of the Ni3FeN-Ruburied was further investigated by hard X-ray absorption fine structure (XAFS). Generally speaking, the buried single atoms at the subsurface lattice may exhibit a saturated coordination environment, while the surface-anchored single atoms mainly display the unsaturated coordination configuration32. As shown in Fig. 2a, the Ru K-edge XANES spectra of Ni3FeN-Ruburied and Ni3FeN-Rusurface display similar features while much differing from the Ru foil and RuO2, implying the isolated dispersive configuration in Ni3FeN lattice. It can be observed that the absorption edge of Ni3FeN-Rusurface is higher than that of Ni3FeN-Ruburied, suggesting that the surface-doped Ru atoms are more likely to be oxidized when exposed to the ambient atmosphere33,34. In comparison, the Ni K-edge XANES spectra only exhibit different features from foil counterparts with no obvious shift of absorption edge, indicating the incorporation of Ru didn’t significantly change the three-dimensional electronic structure of Ni (Fig. 2d). Additionally, the adsorption edge of Fe K-edge of Ni3FeN-Ruburied shifted to lower photon energy (ca. 0.4 eV) after loading Ru single atoms while no significant changes for Ni3FeN-Rusurface, which could be attributed to the internal charge polarization among Fe and Ni, Ru atoms (Fig. 2g). As discussed above, the chemical states of Ni and Fe near the catalyst’s surface are different to that in bulk materials, suggesting the specific advantage in adjusting the local electronic structure. The Fourier transform extended XAFS (FT-EXAFS) curves were then conducted to figure out the local geometric structure of the obtained samples. As shown in Fig. 2b, the FT-EXAFS curve of Ru K-edge in R space for Ni3FeN-Ruburied exhibits three adsorption peaks at 1.46, 1.91, and 2.40 Å, attributed to the Ru-N bond, in-plane Ru-Ni bond and Ru-Fe/Ru bond. We can find that the Ni3FeN-Ruburied displayed similar peak intensity of Ru-N and Ru-Ni bonds to Ni3FeN-Rusurface while significantly higher intensity of Ru-Fe/Ru bond. The EXAFS fitting results further confirmed that the coordination number (CN) of the Ru-Fe/Ru bond is close to the theoretical value of Ru single atoms that are located at apex Fe sites of anti-perovskite Ni3FeN lattice (Fig. 2c and Supplementary Table S1). In comparison, the CN of Ru-Fe/Ru further indicates the unsaturated coordination environment of Ru single atoms in Ni3FeN-Rusurface (Supplementary Fig. S13). Different from the local electronic structure of Ru single atoms, the incorporation of Ru into the subsurface lattice sites may rearrange the geometric structure of Ni and Fe (e.g., CN and bond length). As depicted in Fig. 2e, the R-space spectra of Ni show two separate peaks at around 1.38 and 2.21 Å, corresponding to the Ni-N and Ni-Fe/Ru bonds. We can see that the Ni3FeN-Ruburied exhibits a lower bond length of Ni-Fe/Ru (2.20 Å) compared to that of Ni3FeN-Rusurface and Ni3FeN (2.22 Å) along with a lower CN, indicating that the incorporation of Ru single atoms significantly leads to the lattice distortion. Besides, the EXAFS fitting results also demonstrated that the CN of Ni-Fe/Ru bond slightly decreased due to the substitution of Fe atoms (Fig. 2f, Supplementary Fig. S14, and Supplementary Table S2)35. The similar conclusion could also be observed in the R-space curves analysis illustrated in Fig. 2h, i, Supplementary Fig. S15, and Supplementary Table S3. The XANES simulations were then conducted to further clarify the three-dimensional configuration of Ru atoms in Ni3FeN lattice by using theoretical structural models (Supplementary Fig. S16). As expected, the simulated Ru K-edge XANES spectrum of the theoretical Ni3FeN-Ruburied model displays well-reproduced features that are highly consistent with the experimental spectrum, further confirming the local structure of Ru. Hence, we can conclude that the incorporation of Ru atoms after fast Joule-heating treatment is preferred to locate at the subsurface lattice, while the slow annealing with a long treatment time is more likely to shift to the surface of Ni3FeN.

a Ru K-edge (Insert is the enlarged zone of absorption edge in dashed box), d Ni K-edge, and g Fe K-edge (Insert is the enlarged zone of absorption edge in dashed box) XANES spectra of the as-obtained Ni3FeN-Ruburied, Ni3FeN-Rusurface, and necessary counterparts. FT-EXAFS curves for b Ru K-edge, e Ni K-edge (Insert is the enlarged zone in dashed box), and h Fe K-edge (Insert is the enlarged zone in dashed box) displayed at R space for the as-obtained Ni3FeN-Ruburied, Ni3FeN-Rusurface, and counterparts. EXAFS fitting curves for c Ru K-edge, f Ni K-edge, and i Fe K-edge for the samples.

Electrocatalytic performance of MOR under alkaline condition

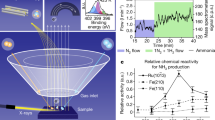

The electrocatalytic MOR performance of as-prepared samples were then collected to further investigate the intrinsic influence among coordination environment. As shown in Fig. 3a, the linear sweep voltammetry (LSV) curves of Ni3FeN-Ruburied exhibit a significantly decreased onset potential and increased current density when methanol was contained in the electrolyte. Additionally, the Ni3FeN-Ruburied requires a low potential of 1.41 V (vs RHE) to reach the current density of 50 mA cm−2 for MOR, which is 159 mV lower than that of LSV curve collected at KOH solution. In comparison, the Ni3FeN-Ruburied requires the lowest potential to reach the current densities among as-prepared samples (Fig. 3b), indicating that the saturated-coordinated Ru atoms can effectively promote the catalytic performance. As is known to all, the overall MOR performance of the catalyst is highly associated with the methanol concentration owing to the competitive relationship between MOR and oxygen evolution reaction (OER). As depicted in Supplementary Fig. S17, the current density increases gradually with the increase of methanol concentration from 0 M to 1 M. When the methanol concentration is lower than 1 M, the decay of current density under 0.3 and 0.5 M methanol maybe due to the lack of methanol molecules and electrooxidation on the catalyst’s surface. The oxidation peak located at 1.44 V (vs RHE) in the cyclic voltammetry (CV) curve under the KOH electrolyte indicates the structural reconstruction. Taking into consideration that the buried Ru atoms in the subsurface lattice of Ni3FeN substrate may lead to more optimized surficial active sites, which could serve as the active sites in subsequent MOR process, a higher number of active sites is expected to be promoted. As shown in Fig. 3c and Supplementary Fig. S18, the electrochemical double-layer capacitance (Cdl) of Ni3FeN-Ruburied (5.99 mF cm−2) is higher than that of Ni3FeN (1.43 mF cm−2) and Ni3FeN-Rusurface (2.44 mF cm−2), implying more active sites in Ni3FeN-Ruburied during MOR process. Considering the local configuration of Ru atoms, it could be speculated that incorporating Ru atoms into a subsurface lattice of Ni3FeN substrate can effectively activate more surficial active sites and serve as the catalytic centers towards MOR.

a 95% iR-compensated LSV curves of Ni3FeN-Ruburied in 1.0 M KOH electrolyte with and without 1 M methanol (resistance value is 0.43 ohm). b Comparison of the applied potentials to reach different current densities for Ni3FeN-Ruburied, Ni3FeN-Rusurface, and Ni3FeN. c Cdl values of the as-prepared samples achieved by CV measurements under different scan rates. d Faradaic efficiency of methanol to formate conversion at different potentials. e Faradaic efficiency of formate obtained after 5 h test at 1.5 V (vs RHE) along with charge consumption. f Chronoamperometry curve of the stability test (Note: the electrolyte was refreshed every 12 h). (Note: error bars represent the standard deviation obtained from three individual measurements).

The Faradaic efficiency (FE) of methanol to formate conversion was then calculated by chronoamperometry test under the potential of 1.4 to 1.6 V (vs RHE). The FEs of Ni3FeN-Ruburied are mostly near 90% and can be as high as 98.98% at 1.5 V (vs RHE), which is significantly higher than those of Ni3FeN and Ni3FeN-Rusurface (Fig. 3d and Supplementary Fig. S19), indicating the high selectivity of methanol to formate conversion. Besides, the FEs of Ni3FeN-Rusurface are higher than that of Ni3FeN at the potential lower than 1.5 V (vs RHE) but lower when the applied potentials are higher than 1.5 V (vs RHE), which may because of the promoted OER performance of Ni3FeN-Rusurface driven by potential induced electrooxidation. The comparison of LSV curves for the as-prepared samples also demonstrated that the surface-anchored Ru atoms could enhance the OER performance, while the subsurface-incorporated Ru atoms significantly promote the MOR performance (Supplementary Fig. S20). Besides, the oxidation peaks of Ni species to NiOOH could be observed in the OER process but absent in the MOR process, which could be attributed to the inevitable surface structural reconstruction owing to the hydroxyl adsorption and attack during OER. Besides, the onset potential of Ni3FeN-Ruburied for MOR is significantly lower than that of OER, suggesting that the presence of methanol can reduce the onset potential owing to the lower standard potential of MOR, thereby increasing the current density for Ni3FeN-Ruburied with a faster reaction kinetics. Moreover, the LSV curves of nitrogen-doped carbon-supported Ru single atoms (marked as RuSA@NC) under both OER and MOR conditions show negligible current densities compared to that of Ni3FeN-Ruburied (Supplementary Fig. S21), indicating that the Ru atoms mainly contribute to the stimulation of Ni3FeN substrate rather than serving as the catalytic centers. The continuous measurement at a continuous potential was then conducted to investigate the overall selectivity (Fig. 3e). The FE of formate is maintained with an increased charge consumption during the continuous reaction at the potential of 1.5 V (vs RHE) for 5 h. As for the stability test, the Ni3FeN-Ruburied can maintain the current density for 120 h (Fig. 3f), indicating an ideal stability of Ni3FeN-Ruburied.

Mechanism study probed by operando measurements

The oxidation potential could induce structural self-reconstruction of the catalysts during the reaction process36,37, in which the new generalized oxyhydroxide may form synergistic catalytic sites with the original catalyst, thereby breaking the adsorption of hydroxyl and methanol molecules and enhancing the competitive OER activity38. In particular, the hydroxyl groups adsorbed on the catalyst surface may contribute to the structural evolution of the catalyst under operating conditions39,40. Hence, we speculate that the differences in catalytic performance between samples primarily arise from the impact of different anchoring sites of Ru atoms on the structural evolution during the reaction process. The Ni, Fe, and Ru K-edge XAFS spectra were collected at different working potentials to investigate the structural evolution of the Ni3FeN-Ruburied during the electrocatalytic MOR process from open circuit potential (OCV) and applied potentials. As shown in Fig. 4a, b, the Ni K-edge absorption edge slightly shifted to higher photon energy along with a blue-shifted Ni-metal bond in R space and slightly increased coordination number of Ni-N/O bond, which may be caused by the adsorbed reactants on the catalyst surface. Additionally, the feature of XANES spectra began to change when the potential was applied to 1.6 V (vs RHE), with a shoulder peak beginning to rise at 1.9 Å in R space, indicating the inevitable corrosion under the high oxidation potential (Supplementary Fig. S22 and Table S2). We proceeded with the investigation into the structural variations of Fe elements under different working voltages (Fig. 4c, d). The absorption edge of the Fe K-edge didn’t exhibit a noticeable shift, and the corresponding XANES spectral shape also showed no significant alterations, implying the high charge transfer efficiency between Fe sites and intermediates (Supplementary Fig. S23 and Table S3). Considering the unique local coordination environment of Ru, we speculate that the saturated-coordinated Ru atoms in Ni3FeN-Ruburied effectively enhance the activity of surface Ni and Fe atoms. In other words, maintaining the activity of active sites and ensuring the overall stability of the catalyst is the key aspects for high-efficiency MOR. As shown in Fig. 4e, the absorption edge of the Ru K-edge gradually shifts to higher photon energy with the increase of applied bias, indicating that the Ru atoms play an important role in the charge output during MOR. Besides, the increased coordination number of Ru-N/O and Ru-Ni bonds may be because of the structural distortion under the applied potentials (Fig. 4f, Supplementary Fig. S24, and Table S1)41,42. The local electronic structures for Ni3FeN-Ruburied can also be observed from the wavelet transform EXAFS (WT-EXAFS) plots, in which the shift of the maximum further demonstrates the structural evolution consistent with the above discussions (Fig. 4g–i).

To further elucidate the catalyst structure-activity and catalytic mechanism in the reaction interface during the MOR and OER process, operando electrochemical impedance spectroscopy (EIS) was measured at different potentials43. It’s well known that the intrinsic oxidation of the catalyst or the oxidized chemical reagent in the electrolyte is specified in the high-frequency region, while the low-frequency region corresponds to the uneven charge dispersion generated by oxidation species. As shown in Fig. 5a and Supplementary Fig. S25, the Bode plots from 1.1 to 1.3 V (vs RHE) for both MOR and OER exhibit slight charge transfer response in the high-frequency region originating from the weak charge transfer between the diffusion double layer and catalyst21. When the working potential is higher than 1.35 V (vs RHE), the obvious phase angle appears in the low-frequency region that corresponds to the OER process while the higher frequency mainly contributed by electrooxidation of catalysts under hydroxyl attack. However, when the electrolyte was replaced with 1 M KOH containing 1 M methanol, only one single phase angle peak appeared at the high-frequency region near 100 Hz, which could be attributed to the MOR process. Besides, the absence of phase angles that correspond to the structural reconstruction further indicates the stable surface structure of Ni3FeN-Ruburied44,45. This phenomenon could also be probed in the Nyquist plots (Fig. 5b and Supplementary Fig. S26). The changed features in high and low-frequency regions under KOH electrolyte correspond to the electrooxidation of the catalyst and the oxygen generation, respectively. By combining the numerical fitting of equivalent circuits, the values of R1 for both circuits are large when the applied potential is below 1.35 V (vs RHE), indicating the weak charge transfer before the reaction. The rapid decrease of R1 in the high-frequency region and the appearance of R2 in the low-frequency region could be observed under higher potential during OER, implying the electrooxidation of catalysts to oxyhydroxide and the accelerated intermediates diffusion46. On the contrary, only R1 decreases with voltage variation, while R2 in the low-frequency region does not show any reaction during the MOR process, indicating the fast transform of methanol to formate and the absence of catalysts reconstruction (Supplementary Tables. S4, S5)22.

a Operando EIS curves collected at different potentials and the corresponding (Note: the red color represents the larger value while the blue color represents the smaller value). b Nyquist plots under 1 M KOH with and without 1 M methanol electrolyte for Ni3FeN-Ruburied. c Operando Raman spectroscopies of the Ni3FeN-Rusurface and Ni3FeN-Ruburied at different working potentials during the MOR process. d Operando ATR-SEIRAS spectra of the Ni3FeN-Ruburied under different potentials at 1 M KOH with 1 M methanol electrolyte. e Periodic electrochemical measurement over Ni3FeN-Ruburied.

Taking into consideration that Raman spectroscopy is sensitive to the surface structure of the catalyst, the operando Raman spectra under different working potentials were collected to verify the structural evolution. As shown in Fig. 5c, two peaks of 456 and 539 cm−1 for Ni3+-O and 1053 cm−1 for NiOO- for Ni hydroxide start to rise at the potential of 1.35 V (vs RHE) on Ni3FeN-Rusurface, indicating the structural reconstruction under oxidized potential46,47. In comparison, only an adsorption peak of CH3OH at 1020 cm−1 could be observed for Ni3FeN-Ruburied, further confirming the strong adsorption of methanol molecules along with the resistance to structural reconstruction. The stronger adsorption of methanol molecules on the Ni3FeN-Rusurface surface may contribute to the prohibited structural reconstruction from hydroxyl attack during MOR. We further conducted operando synchrotron radiation attenuated total reflected surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS) to investigate the evolution of key intermediates. As shown in Fig. 5d, the Ni3FeN-Ruburied displays the obvious adsorption peak of ν(C-OH) of methanol molecules (~1050 cm−1) and weaker adsorption of H2O molecules (1650 cm−1), indicating that the methanol molecules may easier adsorbed on the Ni3FeN-Ruburied surface. The strong peaks at 1228 cm−1 and 1592 cm−1 could be attributed to the ν(C-OH) and ν(OCO) bands of formate, confirming the high selectivity of MOR. Besides, the consecutive blue shift of ν(C-OHmethanol) infrared bands further implies the fast charge transfer between catalyst and intermediates along with the fast reaction kinetics. Compared to the Ni3FeN and Ni3FeN-Ruburied, the Ni3FeN-Rusurface exhibits the strongest adsorption peak of H2O molecules, attributing to the strong affinity of unsaturated-coordinated Ru atoms to oxygen-related species (Supplementary Fig. S27).

Given that the hydroxyl adsorption plays a key role in the structure reconstruction of transition metal-based electrocatalysts, which is hardly to distinguish the hydroxyl and water adsorption due to the similar infrared brand wavenumber. Here, the Zeta potential was measured to understand the adsorption of hydroxyl on the catalysts surface. The Zeta potentials of Ni3FeN-Ruburied and Ni3FeN-Rusurface are −39.93 and −40.10 mV, respectively. The more negative Zeta potential value of Ni3FeN-Rusurface indicates the stronger adsorption of hydroxyl on its surface, which may contribute to the surface reconstruction during the reaction process. Besides, the CO-striping measurement, as a powerful probe for the investigation of the hydroxyl adsorption capacity, of the Ni3FeN-Ruburied shows a more negative CO oxidation peak potential occurs at 0.646 V than that of Ni3FeN-Rusurface (0.774 eV) (Supplementary Fig. 28)48. Hence, the experimental results on hydroxyl adsorption indicate that distinct local configurations of Ru atoms may influence the affinity between the catalysts and hydroxyl groups, with Ru atoms buried in the subsurface lattice exhibiting weaker hydroxyl adsorption compared to those confined to the surface lattice. As shown in Fig. 5e, a significant current density could be observed when the operating potential was set at 1.41 V (vs RHE) at KOH containing methanol electrolyte owing to the transformation of methanol to formate in periodic chronoamperometry measurements over Ni3FeN-Ruburied. In comparison, no obvious current density could be collected due to the high operating potential of the OER process under the electrolyte without methanol. When the potential was then set as 1.01 V (vs RHE) after an open circuit for 400 s, a significantly larger reduction current could be observed (black line) in the KOH electrolyte without methanol than that with methanol (red line), demonstrating absence of the surface structural reconstruction during MOR. Hence, we can speculate that the optimized surface atoms driven by burying subsurface lattice Ru atoms can significantly regulating the adsorption of reactants and intermediates along with inhibited surface structural reconstruction.

Theoretical insights into the reaction mechanism

Density-functional theory (DFT) calculations were conducted to gain insights into the intrinsic catalytic feature of the as-prepared samples. We established the theoretical models by incorporating various coordination states of Ru into the anti-perovskite Ni3FeN lattice, in which the (111) crystal plane was initially selected as a demonstration to investigate the catalytic performance (Supplementary Figs. S29,S30). Charge analysis found that the incorporation of Ru atoms can activate the surface atoms through charge redistribution (Fig. 6a and Supplementary Fig. S31). Additional simulations of the charge density cloud intuitively illustrate the induced charge polarization, which will facilitate the subsequent binding of methanol molecules (Supplementary Fig. S32). As reflected in the adsorption energies for methanol molecules, Ru-incorporated lattices hold more negative values compared to the pristine Ni3FeN surface (Supplementary Fig. S33). Wherein, various metal sites on the catalyst surfaces were examined to identify the most stable configurations for methanol adsorption. As illustrated in Supplementary Fig. S33, methanol preferentially binds to the exposed surface sites of Fe and Ru for the pristine Ni3FeN and Ni3FeN-Rusurface substrates, respectively. In the Ni3FeN-Ruburied system, the Fe4 site exhibits the most favorable methanol adsorption compared to other metal sites. These metal sites of Fe (Ni3FeN), Ru (Ni3FeN-Rusurface), and Fe4 (Ni3FeN-Ruburied) will serve as the initial reaction sites for methanol oxidation. The surface-incorporated system exhibits the strongest charge polarization, resulting in a tight interaction with methanol, which could pose challenges for the subsequent reaction process. In contrast, the moderate adsorption observed on the Ru-buried surface is anticipated to make contributions to the reaction process. Meanwhile, the adsorption energies of hydroxyl on various catalyst surfaces were compared with those of methanol to evaluate the electrooxidation conditions with Ru incorporation. As shown in Supplementary Table S6, the hydroxyl adsorption is weaker than methanol on the Ni3FeN-Ruburied surface, indicating that the electrooxidation of this catalyst would be suppressed under MOR conditions. Conversely, the unsaturated-coordinated Ni3FeN-Rusurface exhibits more favorable hydroxyl adsorption, which may lead to structural reconstruction, consistent with experimental observations. This oxidation tendency of the Ni3FeN-Rusurface catalyst could be traced back to structural features and electronic structure properties with the incorporation of Ru49,50,51.

a Charge distribution of the Ni3FeN-Ruburied system, the active site of Fe4 and the buried Ru atom have been labeled for clarity, in which, the pink, orange, and cyan balls stand for Fe, Ru, and Ni atoms, respectively. b Gibbs free energy profiles for alkaline MOR on Ni3FeN-Ruburied, Ni3FeN-Rusurface, and Ni3FeN surfaces and the c reaction pathway in current work, wherein, the pink balls stand for Fe atoms, orange for Ru, cyan for Ni, blue for N, red for O, white for H, and brown for C atoms. d Illustration of the d-band centers. e COHP curves of CH3OH interaction on different samples, the ICOHP values (eV/bond) are listed above to demonstrate the bonding interaction between metal and intermediates.

Gibbs free energy analysis of the whole reaction pathway offers a comprehensive picture of this mechanism (Fig. 6b, c and Supplementary Figs. S34–36). The potential determining step (PDS) for pristine Ni3FeN and Ni3FeN-Ruburied is located at the conversion from *CHO to *HCOOH, while for the unsaturated-coordinated Ni3FeN-Rusurface, the desorption of HCOOH acts as the PDS52. In which, Ni3FeN-Ruburied exhibits the lowest energy barrier of 0.31 eV, compared to the Ni3FeN-Rusurface (0.94 eV) and pristine Ni3FeN (0.77 eV) surfaces. Meanwhile, regarding reaction selectivity, the significant energy barrier for the rupture of the C-H bond in *HCOOH suppresses the side transformation to *COOH, thereby favoring formate as the dominant product. In addition, the dissociation of H2O to oxygen evolution was also investigated to demonstrate the competition reaction performance for the series samples (Supplementary Figs. S37–40). In contrast to MOR, Ni3FeN-Rusurface exhibits the lowest energy barrier for H2O dissociation, suggesting a significant potential for oxygen evolution. This heightened competitive reaction could be attributed to the strong interaction between the Ru-incorporated surface and the adsorbates, thereby promoting H2O dissociation. While for the Ni3FeN-Ruburied system, the weakened binding of water molecules leads to a higher energy barrier for oxygen evolution, consistent with the above operando characterizations. Additionally, the Fe2 site on the Ni3FeN-Rusurface catalyst was considered as a potential reaction site due to its strong methanol adsorption. As shown in Supplementary Figs. S41–S43, significant charge redistribution could be found with the incorporation of surface Ru. Notably, compared to the Ni3FeN and Ni3FeN-Ruburied samples, the Ni3FeN-Rusurface catalyst with Fe2 site exhibits the highest energy barrier for MOR and the lowest barrier towards water dissociation, indicating that Ni3FeN-Ruburied could maintain the superior catalytic performance among the three synthesized catalysts.

Given the polycrystalline feature of our synthesized catalyst samples, the catalytic performance on the exposed (100) facets for Ni3FeN-Ruburied, Ni3FeN, and Ni3FeN-Rusurface have also been investigated (Supplementary Figs. S44,S45). As shown in Supplementary Figs. S46–S49, Ni3FeN-Ruburied holds the lowest energy barrier of 0.65 eV for the formation of *HCOOH, while Ni3FeN and Ni3FeN-Rusurface catalysts display higher barriers of 0.77 and 1.51 eV, respectively, suggesting the superior catalytic activity for the unsaturated Ni3FeN-Ruburied system. In contrast, the dissociation of H2O for oxygen evolution would be suppressed on the Ni3FeN-Ruburied surface with a high barrier of 2.39 eV, indicating a preferential selectivity towards MOR (Supplementary Figs. S50, S51). By examining the (111) and (100) facets, we could conclude that the Ni3FeN-Ruburied catalyst exhibits ideal catalytic performance, featured by the lowest energy barrier of PDS and favorable reaction selectivity for formate production.

To better understand the intrinsic adsorption behavior across various samples, we conducted the analysis of d-band centers for the associated active sites. As shown in Fig. 6d, the d-band center of Ni3FeN-Ruburied(Fe4) is calculated at −2.85 eV, which is significantly lower than that of the surface incorporated Ni3FeN-Rusurface (Ru site, −1.38 eV). This confirmed that the buried Ru single atoms can regulate the surficial local electronic structure through bond coordination, thus tuning the corresponding adsorption of reactants and intermediates. The integrated crystal orbital Hamiltonian population (ICOHP) simulations were also performed to investigate the interaction between metal active sites and the key intermediates53. Specially, the reactant *CH3OH and the intermediate *HCOOH involved in the PDS were considered. As depicted in Fig. 6e, the ICOHP value for Fe4-O bond on Ni3FeN-Ruburried catalyst is −0.36 eV, which is less negative than the value of −0.63 eV for Ru-O bond in Ni3FeN-Rusurface system. This suggests a mitigated interaction between the metal site and CH3OH for the Ni3FeN-Ruburied sample, potentially facilitating subsequent dehydrogenation. Additionally, the intermediate *HCOOH also exhibits a moderate binding affinity to the metal site for the Ni3FeN-Ruburied system, with an ICOHP value of −0.29 eV, compared to −0.52 eV for the Ni3FeN-Rusurface catalyst (Supplementary Fig. S52). As a result, the energy barrier of the PDS could be reduced with the optimized intermediate adsorption.

Discussion

As discussed above from the operando measurements and theoretical simulations, the superior catalytic performance of Ni3FeN-Ruburied could be concluded as follows: (1) the saturated-coordinated Ru atoms at the subsurface lattice of Ni3FeN-Ruburied effectively activate surface metal atoms, leading to the rearrangement of local electronic structure; (2) the intrinsic activity of surface atoms has been stimulated towards alkaline MOR, significantly optimizing the adsorption of reactants and intermediates during the reaction process; (3) the rearranged surface states of catalysts have promoted the reaction kinetics along with better resistance to surface reconstruction. (4) the specifically regulated local structure helps to reduce the energy barrier of PDS and promotes the selectivity of methanol to formate conversion.

In summary, we have demonstrated the concept that burying single atoms into the subsurface lattice of the substrate can intrinsically optimize the catalytic activity of surficial active sites. Impressively, the model Ni3FeN-Ruburied catalyst achieves a high FE of methanol to formate conversion over 90% under a wide potential range with ideal stability. A series of characterizations further indicate that the buried Ru single atoms can effectively optimize the adsorption of methanol and hydroxyl while exhibiting high resistance to electrochemical structure reconstruction, thus leading to the selective formation of the formate. DFT calculations revealed that such optimized adsorption of reactants and intermediates could be attributed to the rearranged electronic structure induced by the buried Ru atoms in the subsurface lattice of Ni3FeN-Ruburied. This work lays out the modulation principles underlying the local coordination environment, which could offer a valuable insight for the activation of more surface active sites via burying single atoms into the subsurface lattice.

Methods

Chemicals

Iron (III) chloride (FeCl3, 99%), Nickel chloride hexahydrate (NiCl2·6H2O, 99%), Methanol (CH4O, ≥99.9%) and Propylene Oxide (PO) (C3H6O, 99%) were purchased from Shanghai Macklin Biochemical Co., Ltd. RuCl3 were obtained from ZhongNuo Advanced Material (Beijing) Technology Co., Ltd. Sodium formate (CHO2Na AR, 99.5%) was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. Ethanol (C2H6O, 99.7%), and Potassium hydroxide (KOH, 95%) were purchased from Sinopharm Chemical Reagent Co., Ltd. 5 wt% Nafion was purchased from Suzhou Sinero Technology Co., Ltd. Deuterium oxide was purchased from Sigma-Aldrich. Deionized water (18.25 MΩ·cm−1) was obtained from a laboratory ultrapure water machine.

Synthesis of Ni3FeN

Firstly, ferric chloride and nickel chloride were dispersed by ethanol solution to form 1.0 mol L−1 solutions, respectively. Then, add 1.5 mL nickel chloride solution, 0.5 mL ferric chloride solution, and 9 mL ethanol into the same bottle and stir together for 30 min. Secondly, 2.6 mL PO was drop-casted into the above solution and kept stirring for another 12 h. The precursor was collected by centrifugation and washed with deionized water several times followed by lyophilization overnight (192 mg of precursor could be obtained). To obtain Ni3FeN samples, 60 mg precursor was annealed at 500 °C for 3 h under an NH3 atmosphere in a tubular furnace (Yield 43.33%).

Synthesis of Ni3FeN-Rusurface and Ni3FeN-Ruburied

The preparation of the precursor was the same as that of Ni3FeN except for adding a calculated amount of ruthenium chloride (195 mg of precursor could be obtained). The Ni3FeN-Rusurface was obtained by annealing 60 mg precursor at 500 °C for 3 h under an NH3 atmosphere in a tubular furnace. To get the Ni3FeN-Ruburied, the precursor powder was wrapped in a tailored carbon cloth measuring 5 cm long and 4 cm wide. The two ends of the carbon cloth were connected to a fast Joule-heating device via a conductive copper plate and operating under an NH3 atmosphere. The direct current parameters were set as 5 V 10 A for 2 s during fast Joule-heating synthesis. Moreover, the temperature was quickly dropped to room temperature when the direct current is stopped (Yield: Ni3FeN-Rusurface is 45.00%, Ni3FeN-Ruburied is 56.67%).

Synthesis of RuSA@NC

Firstly, 250 mg of glucose and 5 g dicyandiamide were dissolved into deionized water and stirred for 3 h. Then, 2 mL of RuCl3 aqueous solution with a concentration of 0.0125 M were dropwise into the above solution and stirred for another 3 h. Followed by magnetic stirring at the temperature of 80 °C overnight to evaporate the water, the final solid products were ground to a fine powder (5.23 g precursor could be obtained). After annealing at tubular furnace at 900 °C for 2 h under Ar atmosphere. The RuSA@NC sample could be obtained (Yield: 20%).

Characterizations

The crystal structure of the given sample was obtained by X-ray diffraction (XRD) with an 18 kW advanced X-ray diffractometer with Cu Kα radiation (λ = 1.54056 Å). The morphology and microstructure were observed by a JEOL-F200 field emission TEM with an acceleration voltage of 200 kV, and energy-dispersive X-ray spectroscopy (EDS) mapping images were taken under a scanning TEM model. The HAADF-STEM images were collected by Titan Themis Z field emission transmission electron microscope. The metal content was collected by inductively coupled plasma-atomic emission spectroscopy (ICP-AES). The compositions were analyzed by an X-ray photoelectron spectroscopy (XPS) which was conducted with a Mg Kα achromatic X-ray source. The ion chromatography (IC) data was measured on ICS-3000. Raman spectroscopy was obtained on the Horiba Oddessay Raman microscope. X-ray absorption fine structure (XAFS) spectra were collected at the beamline BL14W1 in the Shanghai Synchrotron Radiation Facility (SSRF). The synchrotron-radiation Fourier transform infrared spectroscopy was conducted in the National Synchrotron Radiation Laboratory (NSRL) at the beamline BL01B. Ru XANES calculations were carried out using the FEFF8 code, with the self-consistent potential and full multiple scattering (FMS) evaluated at a radius of 5.0 Å. The Dirac-Hara exchange-correlation potential was set to 0.2 with a specified imaginary potential vi0. In order to compare the calculated and experimental spectra, a rigid energy shift of 2 eV toward higher energy was applied to the calculated spectrum.

Electrochemical measurements

Electrochemical data were collected by a typical three-electrode system on a CHI760E workstation (Shanghai Chenhua Co., Ltd.) in 1.0 M KOH solution for OER while in 1.0 M KOH with 1.0 M methanol for MOR at room temperature and ready to use every time. The pH of 1.0 M KOH (pH = 13.98 ± 0.02) electrolyte was tested by pH meter, which was calibrated by using pH buffer solutions (pH = 4.00, pH = 6.86, and pH = 9.18). A glassy carbon electrode (GCE, Tianjin Aida Co., Ltd.) with a diameter of 3 mm was served as the working electrode, while the Pt mesh (1 cm2, Tianjin Aida Co., Ltd.) and Hg/HgO electrode (1 M KOH, Tianjin Aida Co., Ltd.) served as the counter electrode and reference electrode, respectively. Typically, 5 mg of the as-prepared catalyst was uniformly dispersed in 1 mL mixed solution consisting of 700 μL of DI water, 250 μL of ethanol, and 50 μL of 5 wt% Nafion solution. Then, the working electrode was prepared by dropping 5 μL of the catalyst ink onto the GCE and dried at room temperature (catalyst loading on a working electrode: 354 µg cm−2). For the electrocatalytic performance test, the LSV curves were recorded from 1.0 V (vs RHE) to 1.6 V (vs RHE) at a scan rate of 5 mV·s−1 with and without 95% iR-compensation (the resistance was measured by the electrochemical workstation everytime). The Cdl was evaluated by CV measurements at the potential window of 1.124 to 1.224 V (vs RHE) with different scan rates of 20, 40, 60, 80, 100, and 120 mV s−1, respectively. By plotting ∆j/2 at 0.25 V (vs RHE) as a function of scan rate, the fitted slope representing Cdl value. The long-term stability test was tested under working conditions and refresh the electrolyte every 12 h to avoid over-accumulation of formate. The EIS data were performed over a frequency range from 0.01 Hz to 100,000 Hz with an AC amplitude of 5 mV. The Hg/HgO reference electrode was calibrated using an H2-saturated three-electrode system, with Hg/HgO serving as the reference electrode, Pt mesh, and Pt wire serving as the working and counter electrodes, respectively. The measured potentials were converted to reversible hydrogen electrode (RHE) potentials according to the Nernst equation:

Calculations of Faradaic efficiency of Ni3FeN-Ruburied for MOR tests was calculated according to following equation:

F is the Faraday constant (96485 C mol−1). c is the concentration of the product formate. V is the electrolyte volume. n is the transferred electron number. Qtotal is the total charge during the electrochemical process.

Operando measurements

The operando XAFS measurement was conducted in a traditional three-electrode electrochemical cell conducted by Si (111) mode at BL14W1 of SSRF (Supplementary Fig. S53a), in which the absorption edge of measured elements was corrected by foil sample. The catalyst was uniformly dispersed in 1 mL ethanol solution and then dropped onto the carbon paper to prepare a working electrode. The Pt mesh (1 cm2) and Hg/HgO electrode served as the counter electrode and reference electrode, while the 1 M KOH containing 1 M methanol solution served as the electrolyte. The operando XAFS measurement was conducted after CV for 10 min until a reproducible CV curve was achieved. The XAFS data were collected at different reaction potentials by chronopotentiometry. The obtained data were analyzed by ARTEMIS software containing the FEFF code. The operando Raman spectroscopy is conducted on the Horiba Oddessay Raman microscope. The catalysts were first loaded on the carbon paper and fabricated on the electrochemical cell (Supplementary Fig. S53b). The wavelength of the laser is 532 nm with a 50x long-focus objective. The spectral shifts were firstly calibrated by a Si wafer of 520.7 cm−1. The electrochemical Raman spectra were collected during chronopotentiometry under different reaction potentials. The operando ATR-SEIRAS was conducted at NSRL BL01B beamline under attenuated total reflection mode with an electrochemical cell (Supplementary Fig. S53c). A semi-cylindrical Si prism coated with 50-nm-thin Au film for reflection. The catalyst ink was then dropped onto the Au film and dried under ambient. All spectra were collected by averaging 64 scans at a resolution of 4 cm−1 using a Bruker Vertex 80 V spectrometer equipped with a liquid nitrogen-cooled mercury cadmium telluride (LN-MCT) detector. The background spectrum was recorded under open-circuit voltage conditions, while subsequent spectra were obtained by applying voltage in stepwise increments.

DFT calculations

All calculations in this study were carried out by density-functional theory (DFT) within the framework of the Vienna Ab initio Simulation Package (VASP)54,55. The generalized gradient approximation (GGA) in the Perdew–Burke–Ernzernhof (PBE) exchange-correlation functional was chosen for geometric optimizations and electronic structure simulations56. The projector augmented wave (PAW) method was adopted to consider the plane-wave expansion57,58. A kinetic energy cutoff of 450 eV was applied, and the Brillouin zone was sampled using a Monkhorst-Pack k-mesh of 3 × 3 × 1. The energy convergence criterion for the electronic self-consistent field iterations was set at 10−5 eV, with a residual force threshold of 0.02 eV·Å−1 to ensure the accuracy of the structural and electronic calculations. The pristine model system was built with Ni3FeN (111) slab surface, represented within a 2 × 2 supercell. To prevent surface interaction, a vacuum layer of 15 Å was established along the z-direction.

The formulas for calculating Gibbs free energy in this article are the following44

where ΔE is the reaction energy change which is obtained from the DFT simulations. ΔZPE denotes the change in zero-point energy, and ΔS is the change in entropy, in which, T was set to be 298.15 K.

The adsorption energies between adsorbates (such as methanol) and various catalyst surfaces are calculated using the following formula:

In this equation, Esubstrate/adsorbate represents the DFT-calculated energy of the catalyst surface with the adsorbate interacted, while Esubstrate and Eadsorbate refer to the energies of the pristine substrate and adsorbate, respectively. According to this formula, a more negative value of Eads indicates a stronger interaction between the adsorbate and the substrate surface, suggesting a more stable adsorption structure.

Data availability

Source data are provided as a Source Data file. The atomic coordinates of the optimized models are provided at https://doi.org/10.5281/zenodo.14223416. Source data are provided with this paper.

References

Zhuang, Z. et al. Reversely trapping atoms from a perovskite surface for high-performance and durable fuel cell cathodes. Nat. Catal. 5, 300–310 (2022).

Zhao, Q.-P. et al. Photo-induced synthesis of heteronuclear dual-atom catalysts. Nat. Synth. 3, 497–506 (2024).

Wei, X. et al. Dynamic reconstitution between copper single atoms and clusters for electrocatalytic urea synthesis. Adv. Mater. 35, 2300020 (2023).

Wu, H. et al. Distance effect of Ni-Pt dual sites for active hydrogen transfer in tandem reaction. Innovation 1, 100029 (2020).

Shang, H. et al. Engineering unsymmetrically coordinated Cu-S1N3 single atom sites with enhanced oxygen reduction activity. Nat. Commun. 11, 3049 (2020).

Pan, Y. et al. Boosting the performance of single-atom catalysts via external electric field polarization. Nat. Commun. 13, 3063 (2022).

Liang, H. et al. Exploring the Ni 3d orbital unpaired electrons induced polarization loss based on Ni single-atoms model absorber. Adv. Funct. Mater. 33, 2212604 (2023).

Liu, X. et al. Dynamic surface reconstruction of single-atom bimetallic alloy under operando electrochemical conditions. Nano. Lett. 20, 8319–8325 (2020).

Liu, J.-C., Xiao, H. & Li, J. Constructing high-loading single-atom/cluster catalysts via an electrochemical potential window strategy. J. Am. Chem. Soc. 142, 3375–3383 (2020).

Wang, J., Li, Z., Wu, Y. & Li, Y. Fabrication of single-atom catalysts with precise structure and high metal loading. Adv. Mater. 30, 1801649 (2018).

Zhou, Y. et al. Multilayer stabilization for fabricating high-loading single-atom catalysts. Nat. Commun. 11, 5892 (2020).

Li, H. et al. Activating and optimizing MoS2 basal planes for hydrogen evolution through the formation of strained sulphur vacancies. Nat. Mater. 15, 48–53 (2016).

Hao, J. et al. In situ facile fabrication of Ni(OH)2 nanosheet arrays for electrocatalytic co-production of formate and hydrogen from methanol in alkaline solution. Appl. Catal. B: Environ. 281, 119510 (2021).

Chen, Y. X. et al. Formate, an active intermediate for direct oxidation of methanol on Pt electrode. J. Am. Chem. Soc. 125, 3680–3681 (2003).

Zhu, B. et al. Unraveling a bifunctional mechanism for methanol-to-formate electro-oxidation on nickel-based hydroxides. Nat. Commun. 14, 1686 (2023).

Wang, J. et al. Toward electrocatalytic methanol oxidation reaction: Longstanding debates and emerging catalysts. Adv. Mater. 35, 2211099 (2023).

Cheng, H., Dong, B., Liu, Q. & Wang, F. Direct electrocatalytic methanol oxidation on MoO3/Ni(OH)2: exploiting synergetic effect of adjacent Mo and Ni. J. Am. Chem. Soc. 145, 26858–26862 (2023).

Cao, C. et al. Divergent paths, same goal: a pair-electrosynthesis tactic for cost-efficient and exclusive formate production by metal-organic-framework-derived 2D electrocatalysts. Adv. Mater. 33, 2008631 (2021).

Li, S. et al. Coordination environment tuning of nickel sites by oxyanions to optimize methanol electro-oxidation activity. Nat. Commun. 13, 2916 (2022).

Chen, W. et al. Vacancy-induced catalytic mechanism for alcohol electrooxidation on nickel-based electrocatalyst. Angew. Chem. Int. Ed. 63, e202316449 (2024).

Chen, W. et al. Activity origins and design principles of nickel-based catalysts for nucleophile electrooxidation. Chem. 6, 2974–2993 (2020).

Qi, Y. et al. Insights into the activity of nickel boride/nickel heterostructures for efficient methanol electrooxidation. Nat. Commun. 13, 4602 (2022).

Yao, Y. et al. High-entropy nanoparticles: synthesis-structure-property relationships and data-driven discovery. Science 376, eabn3103 (2022).

Zhao, S. et al. Defect-rich Ni3FeN nanocrystals anchored on N-doped graphene for enhanced electrocatalytic oxygen evolution. Adv. Funct. Mater. 28, 1706018 (2018).

He, Q. et al. Achieving efficient alkaline hydrogen evolution reaction over a Ni5P4 catalyst incorporating single-atomic Ru sites. Adv. Mater. 32, 1906972 (2020).

Gu, Y. et al. Electronic structure tuning in Ni3FeN/r-GO aerogel toward bifunctional electrocatalyst for overall water splitting. ACS Nano 12, 245–253 (2018).

Wang, Q. et al. 3D carbon nanoframe scaffold-immobilized Ni3FeN nanoparticle electrocatalysts for rechargeable zinc-air batteries’ cathodes. Nano Energy 40, 382–389 (2017).

Cui, Z., Fu, G., Li, Y. & Goodenough, J. B. Ni3FeN-supported Fe3Pt intermetallic nanoalloy as a high-performance bifunctional catalyst for metal-air batteries. Angew. Chem. Int. Ed. 56, 9901–9905 (2017).

Zhou, M. et al. Modulating 3d Orbitals of Ni atoms on Ni-Pt edge sites enables highly-efficient alkaline hydrogen evolution. Adv. Energy Mater. 11, 2101789 (2021).

Pattammattel, A. et al. High-sensitivity nanoscale chemical imaging with hard x-ray nano-XANES. Sci. Adv. 6, eabb3615 (2020).

Pandey, N., Gupta, M., Phase, D. & Gupta, A. In situ N K-edge XANES study of iron, cobalt and nickel nitride thin films. J. Synchrotron Radiat. 28, 1504–1510 (2021).

Tan, W. et al. Fine-tuned local coordination environment of Pt single atoms on ceria controls catalytic reactivity. Nat. Commun. 13, 7070 (2022).

Zhang, Y. et al. Tuning the interaction between ruthenium single atoms and the second coordination sphere for efficient nitrogen photofixation. Adv. Funct. Mater. 32, 2112452 (2022).

Zhu, Y. et al. Supported ruthenium single-atom and clustered catalysts outperform benchmark Pt for alkaline hydrogen evolution. Adv. Mater. 35, 2301133 (2023).

Li, Z. et al. Alloy-strain-output induced lattice dislocation in Ni3FeN/Ni3Fe ultrathin nanosheets for highly efficient overall water splitting. J. Mater. Chem. A 9, 4036–4043 (2021).

Jiang, H., He, Q., Zhang, Y. & Song, L. Structural self-reconstruction of catalysts in electrocatalysis. Acc. Chem. Res. 51, 2968–2977 (2018).

Jiang, H. et al. Tracking structural self-reconstruction and identifying true active sites toward cobalt oxychloride precatalyst of oxygen evolution reaction. Adv. Mater. 31, 1805127 (2019).

Zhang, N. et al. Surface activation and Ni-S stabilization in NiO/NiS2 for efficient oxygen evolution reaction. Angew. Chem. Int. Ed. 61, e202207217 (2022).

Cao, D. et al. Operando X-ray spectroscopy visualizing the chameleon-like structural reconstruction on an oxygen evolution electrocatalyst. Energy Environ. Sci. 14, 906–915 (2021).

Gao, L. et al. Recent advances in activating surface reconstruction for the high-efficiency oxygen evolution reaction. Chem. Soc. Rev. 50, 8428–8469 (2021).

Ou, Z. et al. Organic ligand engineering for tailoring electron-phonon coupling in 2D hybrid perovskites. Nano. Lett. 24, 5975–5983 (2024).

Li, B. et al. Manipulating the electronic structure of Li-rich manganese-based oxide using polyanions: Towards better electrochemical performance. Adv. Funct. Mater. 24, 5112–5118 (2014).

Zhou, S. et al. Amphiphilic cobalt phthalocyanine boosts carbon dioxide reduction. Adv. Mater. 35, 2300923 (2023).

Ruiz-Camacho, B. et al. EIS analysis of oxygen reduction reaction of Pt supported on different substrates. Int. J. Hydrog. Energ. 42, 30364–30373 (2017).

Banerjee, S., Han, X. & Thoi, V. S. Modulating the electrode–electrolyte interface with cationic surfactants in carbon dioxide reduction. ACS Catal. 9, 5631–5637 (2019).

Li, Y. et al. Operando spectroscopies unveil interfacial FeOOH induced highly reactive β-Ni(Fe)OOH for efficient oxygen evolution. Appl. Catal. B Environ. 318, 121825 (2022).

Diaz-Morales, O., Ferrus-Suspedra, D. & Koper, M. T. The importance of nickel oxyhydroxide deprotonation on its activity towards electrochemical water oxidation. Chem. Sci. 7, 2639–2645 (2016).

Zhou, Y. et al. Long-chain hydrocarbons by CO2 electroreduction using polarized nickel catalysts. Nat. Catal. 5, 545–554 (2022).

Fang, H. et al. Dispersed surface Ru ensembles on MgO (111) for catalytic ammonia decomposition. Nat. Commun. 14, 647 (2023).

Kuang, M. et al. Efficient nitrate synthesis via ambient nitrogen oxidation with Ru-doped TiO2/RuO2 electrocatalysts. Adv. Mater. 32, 2002189 (2020).

Jin, J. et al. Microenvironment engineering of Ru single-atom catalysts by regulating the cation vacancies in NiFe-layered double hydroxides. Adv. Funct. Mater. 32, 2109218 (2022).

Koper, M. T. Analysis of electrocatalytic reaction schemes: distinction between rate-determining and potential-determining steps. J. Solid. State Electr. 17, 339–344 (2013).

Maintz, S., Deringer, V. L., Tchougréeff, A. L. & Dronskowski, R. LOBSTER: a tool to extract chemical bonding from plane-wave based DFT. J. Comput. Chem. 37, 1030–1035 (2016).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558 (1993).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758 (1999).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (12225508, L. Song, U23A20121, L. Song, 12074002, L. Shan, 12205301, H. Liu), National Key Research and Development Program of China (2022YFA1403203, L. Shan), the University Synergy Innovation Program of Anhui Province (GXXT-2023-036, Y. Lin), Anhui Provincial Department of Education university natural science research project (2023AH050113, Y. Lin, 2024AH050070, L. Yang), the Major Basic Program of Natural Science Foundation of Shandong Province (ZR2021ZD01, L. Shan), Natural Science Foundation of Anhui Province (2208085QB30, Y. Lin, 2308085MB47, L. Yang), We thank the Shanghai synchrotron radiation facility (BL14W1, SSRF) and National Synchrotron Radiation Laboratory (Infrared spectroscopy and microspectroscopy, MCD endstation, NSRL) for help in characterizations. L. Yang thanked Hefei Advanced Computing Center and the High-Performance Computing Platform of Anhui University for computational support. Y. Lin acknowledges the Hefei In-situ Technology. Co., Ltd. for experimental help in Joule-heating synthesis.

Author information

Authors and Affiliations

Contributions

Y.L., B.G., and J.Z. conducted the sample synthesis and electrochemical measurements and wrote the draft. Y.L., L. Shan, and L. Song conceived the idea and revised the manuscript. R.Z. and L.Y. carried out DFT calculations and analyzed the corresponding results. W.C. and Z.Y. performed part of the materials synthesis and data analysis. H.L., Z.Q., K.X., and X.L. helped to perform the operando ATR-SEIRAS and Raman measurements and analyzed the data.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Jing-Li Luo, Fuxian Wang, Lai Feng, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lin, Y., Geng, B., Zheng, R. et al. Optimizing surface active sites via burying single atom into subsurface lattice for boosted methanol electrooxidation. Nat Commun 16, 286 (2025). https://doi.org/10.1038/s41467-024-55615-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-55615-x

This article is cited by

-

Atomic diffusion pathway mediated subsurface engineering

Nature Communications (2025)

-

Unraveling the Durable Water Oxidation Mechanism of Multi-principal Elemental Metal Catalyst

Chemical Research in Chinese Universities (2025)