Abstract

The unique properties of nanomaterials offer vast opportunities to advance sustainable processes. Incidental nanoparticles (INPs) represent a significant part of nanomaterials, yet their potential for sustainable applications remains largely untapped. Herein, we developed a simple strategy to harness INPs to upgrade the waste-to-resource paradigm, significantly reducing the energy consumption and greenhouse gas emissions. Using the recycling of fly ash from municipal solid waste incineration (MSWI) as a proof of concept, we reveal that incidental iron oxide nanoclusters confined inside the residual carbon trigger Fenton-like catalysis by contacting H2O2 at circumneutral pH (5.0–7.0). This approach efficiently detoxifies the adsorbed dioxins under ambient conditions, which otherwise relies on energy-intensive thermal methods in the developed recovery paradigms. Collective evidence underlines that the uniform distribution of iron oxide nanoclusters within dioxin-enriched nanopores enhances the collision between the generated active oxidants and dioxins, resulting in a substantially higher detoxification efficiency than the Fe(II)-induced bulk Fenton reaction. Efficient and cost-effective detoxification of MSWI fly ash at 278‒288 K at pilot scale, combined with the satisfactory removal of adsorbed chemicals in other solid wastes unlocks the great potential of incidental nanoparticles in upgrading the process of solid waste utilization and other sustainable applications.

Similar content being viewed by others

Introduction

The sustainable development of the human society and nature has become the common pursuit in the effort to tackle the global challenges including greenhouse gas emissions, environmental degradation, and resource scarcity1. Nanotechnology, empowered by the distinctive physicochemical properties of materials at the nanoscale, opens the door to advance technical innovations for sustainable environmental remediation, resource recycling, and industrial production2,3,4. Nanomaterials can originate from various sources, both intentionally and unintentionally5,6,7. However, only the engineered nanoparticles with structures that are sophisticatedly manipulated are currently under scrutiny to serve sustainable purposes. The application of these nanoparticles is always plagued by the high manufacturing cost and the associated environmental impacts, prompting us to exploit the potentially positive role of nanomaterials from alternative sources in expediting sustainable processes.

Incidental nanoparticles (INPs) are unintended byproducts of anthropogenic activities5,6,8. Since humans began to tame nature, INPs have been being produced continuously, the rate of which increased significantly after the Industrial Revolution, with the contributions from combustion, agricultural practices, and various industrial activities5. In fact, the distribution of INPs in the natural environment is much more abundant than engineered nanomaterials5,7,9. Directed by the potential risks of nanomaterials, the previous research focused overwhelmingly on the occurrences of INPs and their impacts on human health and ecosystems from the perspective of pollutant. From the other side, INPs can also participate in various physicochemical processes5 regardless of their origins. For example, the illumination of dusts carrying semiconducting metal oxides (e.g., titanium oxide, iron oxide, and zinc oxide) in the atmosphere by sunlight can initiate redox reactions to oxidize organics adsorbed on the surface10. The chemical reactivity endows INPs with the potential to be used as an alternative to engineered nanomaterials in certain cases. However, rare efforts have been made as of yet to harness INPs for sustainable applications.

In this study, we present a simple strategy to leverage incidental nanoparticles in the waste to upgrade the paradigm of waste-to-energy recovery. Combustion represents a pivotal path for energy transfer, and in recent decades has been employed extensively to convert the chemical energy of municipal solid waste (MSW) into electricity11. More than 500 million tonnes of MSW are incinerated annually worldwide12 to generate over 190 TWh of electricity assuming an average heating value of 5.7 MJ kg MSW-1 and 25% energy conversion efficiency12,13,14. MSW incineration would inevitably produce INPs8, which can be efficiently trapped by the air purification system in forms that bind to the micron-sized residues15. The trapped residues are known as MSWI fly ash, which consists mainly of calcium oxides, silicates, and carbon that can be recycled as building auxiliary materials, roadbed materials, and mine filling16. However, the MSWI fly ash recovery is significantly challenged by the intractable dioxins strongly adsorbed inside the nanopores, which hinder their effective collisions with the active oxidants generated in the surrounding solution16,17. Consequently, the developed recovery paradigms have long been relying on the thermal methods like sintering and melting, which are typically energy intensive (2.5‒15.4 GJ per tonne of waste18,19,20,21) and cost ineffective ($40–$219 per tonne of waste19,22), concomitant with additional greenhouse gas emissions (0.41‒2.25 t CO2 per tonne of waste18,19,20,21). We show that simple addition of peroxides at circumneutral pH (pH 5.0–7.0) stimulates the Fenton-like activity of incidental iron oxide nanoclusters for efficient elimination of dioxins in MSWI fly ash under ambient conditions. The impact of localization and speciation of iron oxide nanoclusters on detoxification and the nanopore-induced regulation of Fenton-like oxidation was detailed. This straightforward strategy was successfully applied to detoxify fly ash from different MSW incineration plants and also to degrade contaminants in other solid wastes (i.e., spent activated carbon, spent zeolite, and contaminated soil). The potential of this strategy to upgrade the waste-to-resource recovery process was further validated by low-cost detoxification of MSWI fly ash at pilot scale.

Results and Discussion

MSWI fly ash characterization

The MSWI fly ash samples (see Materials and Methods for detailed sources and Supplementary Fig. 1 for scheme of fly ash production) exhibit diverse irregular morphologies as shown in scanning electron microscopy (SEM) images (Fig. 1a–c), with sizes falling within a wide range of 1.6–46.6 μm and averaging at 11.5 μm (Fig. 1d). The particle size is comparable to that of MSWI fly ash previously documented in the literature23,24. Energy dispersive X-ray spectroscopy (EDX) elemental mapping of randomly-selected particulate ash indicates the presence of calcium, silicon, sodium, potassium, magnesium, chloride, manganese, carbon, iron, copper, zinc, and lead (Supplementary Fig. 2). The major elements in fly ash are calcium (34.4 wt%), silicon (13.7 wt%), and carbon (6.2 wt%). XRD analysis (Supplementary Fig. 3) identified the crystal structures of CaSO4 (JCPDS No. 41-0224), CaCO3 (JCPDS No. 05-0586), Ca3Al2O6 (JCPDS No. 33-0251), SiO2 (JCPDS No. 46-1045), NaCl (JCPDS No. 05-0628), and KCl (JCPDS No. 41-1476). A significant portion of the calcium salts was introduced by the flue gas desulfurization process (Supplementary Fig. 1). The contents of transition metals are less than 1.0 wt% (Supplementary Table 1), challenging a clear identification of their chemical forms. Significant leaching of different metal elements was observed especially at low pH values (Supplementary Fig. 4a).

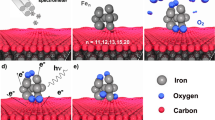

a–c SEM images at different scale bars. d The histogram of size distribution. e Scheme of incidental Fenton-like catalysis for degradation of PCDD/Fs in fly ash. f The degradation kinetics of PCDD/Fs (in TEQ) in the incidental and bulk Fenton-like reactions. g Comparison of H2O2 oxidation with the bulk Fenton reactions for PCDD/Fs removal at varied H2O2 concentrations. h Effect of operational pH on PCDD/Fs removal in the incidental Fenton-like reaction. Conditions: T = 293 ± 1.0 K; pH = 6.0 ± 0.3; [Fe(II)] = 0.5 mM; [H2O2] = 50 mM; [fly ash] = 10 g L−1. The error bars represent the standard deviations from triplicate tests.

Using seventeen polychlorinated dibenzo-p-dioxins / dibenzofurans (PCDD/Fs; Supplementary Table 2 for molecular structures) with defined toxic equivalency factors (Supplementary Table 3) as the surrogates of dioxins, the concentration of dioxins in fly ash was determined to be 9110 ng kg-1. By multiplying the determined concentrations by the international toxic equivalency factors of each species, the toxic equivalent quantity (TEQ) of PCDD/Fs was calculated to be 288.1 ng TEQ kg-1. While the highly chlorinated congeners (i.e., OCDD, 1,2,3,4,6,7,8-HpCDD, and 1,2,3,4,6,7,8-TpCDF) predominate in the ash samples (Supplementary Fig. 5), 2,3,4,7,8-PeCDF and 1,2,3,7,8-PeCDD significantly contribute to the toxic equivalent quantity (Supplementary Fig. 4b). PCDD/Fs can be adsorbed on a variety of components present in MSWI fly ash, including carbon, silicon oxides, and even the heterogeneous metal sites that catalyze the in-situ synthesis of PCDD/Fs during incineration25,26,27. To identify the location of PCDD/Fs in MSWI fly ash, we separated the carbon constituent from the ash sample by alternately washing with NaOH and HNO3 (see Supplementary Method 1 for detailed operation). The separated carbon-enriched sample (73.6 wt% C; Supplementary Table 1) contains a significantly reduced quantity of silicon oxides and metal components but a similar content of PCDD/Fs compared to that in the original sample (Supplementary Fig. 4c). This result aligning with the previous studies28,29 suggest that PCDD/Fs are mostly enriched inside the nanopores of the residual carbon.

H2O2-triggered detoxification of MSWI fly ash

The redox reactions between transition metals and peroxides, known as Fenton or Fenton-like reactions, can produce reactive oxidants and have been widely utilized in various fields, including targeted cancer therapy, sensing, chemical synthesis, and in particular, environmental remediation30,31,32. With this in mind, H2O2, a widely used peroxide, was added to the fly ash suspension (fly ash: H2O = 1: 100) at pH 6.0 and ambient temperature, as an attempt to stimulate the Fenton-like activity of transition metals in MSWI fly ash (Fig. 1e). Following a 10-h reaction, about 73.7% of PCDD/Fs (in TEQ) were removed (Fig. 1f), with H2O2 consumption of ~50% (Supplementary Fig. 6). Since H2O2 cannot directly oxidize PCDD/Fs, this result validates our speculation that the incidental components can efficiently trigger Fenton-like oxidation of PCDD/Fs in MSWI fly ash. Further addition of 0.10–0.50 mM Fe(II) into the reaction mixture only slightly improved the consumption of H2O2 (Supplementary Fig. 6) and the efficiency of PCDD/Fs removal (2.9%–13.6%). The contribution of incidental component-mediated H2O2 oxidation to PCDD/Fs removal (calculated as \(\frac{{\rm{PCDD}}/{\rm{Fs}} {\rm{removal}} {\rm{without}} {\rm{Fe}}({\rm{II}})}{{\rm{PCDD}}/{\rm{Fs}} {\rm{removal}} {\rm{with}} {\rm{Fe}}({\rm{II}})}\)) was more than 84.8% in the Fenton reactions with 0.10–0.50 mM Fe(II), and would be more significant (84.8%–97.5%) by increasing H2O2 dosage from 50 mM to 200 mM (Fig. 1g).

The Fenton and related reactions are sensitive to solution pH due to the participation of H+ and OH– in directing the speciation of reactants and the structure of catalysts33. In general, the optimal pH of Fenton reactions is 2.5–3.5, with the lower end maintaining the reactivity of H2O2 and the upper end to avoid precipitation of metals. In contrast, one can see that the removal of PCDD/Fs in MSWI fly ash was unexpectedly optimized at 5.0–6.0 in the incidental component-mediated H2O2 oxidation system (Fig. 1h). Similar phenomenon has been previously reported in carbon nanotube-confined Fenton-like reactions30,34,35. It is reminiscent of the pioneering works36,37,38 uncovering that the interactions between internal surface with the solution via electrostatic interaction and/or ionic surface propensity drive the change of pH under nanoconfinement. The significantly retarded degradation of PCDD/Fs in fly ash at pH values out of this range is possibly due to the leaching of active metals responsible for catalysis (Supplementary Fig. 4a) or the inactivation of catalysts by hydrolysis. The circumneutral operating pH values would significantly lower the cost associated with pH adjustment, and also enables the integration of this strategy with the industrialized acid-washing process, which usually operates at pH 6.0 ± 2.0.

Besides H2O2, the other peroxides including peroxymonosulfate (PMS), persulfate (PDS), and even O3 are also capable of inducing efficient detoxification of fly ash at pH 4.0–8.0 (Supplementary Fig. 7a). Additional experiments exhibit satisfactory degradation of organic refractory compounds (i.e., atrazine, 2,4,6-trichlorophenol, and benzoic acid) spiked on fly ash (Supplementary Fig. 7b), indicating the broad spectrum of our strategy for efficient detoxification of fly ash containing PCDD/Fs and/or other undesirable organic contaminants.

The active species

The active species generated during incidental component-triggered H2O2 oxidation of fly ash was qualitatively analyzed by EPR spectrum using either 5,5-dimethyl-1-pyrroline-N-oxide (DMPO) or 2,2,6,6-tetramethyl-4-piperidinol (TEMP) as the spin trap. No triplet signal of 2,2,6,6-tetramethyl-4-piperidinol-N-oxyl radical (TMPN; 1:1:1) was observed in the EPR spectrum of the reaction mixture despite an extension of the reaction duration from 30 s to 300 s (Supplementary Fig. 8), indicating the negligible role of singlet oxygen (1O2) in PCDD/Fs oxidation. Conversely, the quartet signal of DMPO-HO• (1:2:2:1) was enhanced by extending the reaction interval in the DMPO-trapped EPR spectrum, confirming the formation of HO• (Fig. 2a). The addition of tertiary butanol (TBA) as a HO• scavenger significantly retarded the degradation of PCDD/Fs (Fig. 2b), evidencing the vital contribution of HO• to fly ash detoxification. Upon addition of 10 M methanol into the reaction system, a weak signal of DMPO-OOH• can be discerned in the complex EPR spectrum (Supplementary Fig. 9). The deprotonated form of superoxide radicals (O2•–), which dominates at pH 6.0 ( > 94%; pKa = 4.8), can act as a nucleophile enabling dehalogenation of polyhalogenated aromatic hydrocarbons with second-order rate constants of 10-1–103 M-1 s-1 in aprotic solvents39,40,41. However, the reaction rates are expected to be 100–200 times lower in H2O due to strong solvation and rapid disproportionation40,41, resulting in little, if any, contribution of HO2•/O2•– to PCDD/Fs degradation. Furthermore, the specific O-atom transfer reaction was used as an indicator of metal-centered active oxidants (Mn+=O). By external addition of 400 μM phenylmethyl sulfoxide (PMSO) into the mixture of fly ash and H2O2, phenylmethyl sulfone (PMSO2) was generated in a yield of 2.3% (Supplementary Fig. 10). It is reasonable to suggest that high-valent iron species (FeIV=O/FeV = O) dominates the O-atom transfer reaction given that such reactions have been rarely reported for other detected metal-centered active oxidants (i.e., Cu42 and Mn43). The addition of 100 mM dimethyl sulfoxide (DMSO), which can rapidly scavenge HO• (6.6 × 109 M-1 s-1)44 and high-valent iron species (e.g., 1.26 × 105 M-1 s-1 for FeIV = O45) instead of 1O2 and HO2•/O2•–, completely inhibited PCDD/Fs degradation (Fig. 2b). These results manifest that, notwithstanding the low yield, high-valent iron species together with HO• contribute to detoxification of PCDD/Fs-enriched MSWI fly ash.

a EPR spectra of different oxidation systems. b Effect of different scavengers on the kinetics of TEQ reduction. c Change of the TEQ value of PCDD/Fs during oxidation. Default conditions: T = 293 ± 1.0 K; pH = 6.0 ± 0.3; [H2O2] = 50 mM; [fly ash] = 10 g L-1. For a: [DMPO] = 100 mM. The error bars represent the standard deviations from triplicate tests.

Evolution of PCDD/Fs

The transformation of PCDD/Fs at different H2O2 concentrations is detailed in Fig. 2c and Supplementary Fig. 11. In the presence of 50 mM H2O2, the TEQ values of PCDD/F congeners decreased simultaneously (Fig. 2c), coinciding with the HO•-dominated attack of low selectivity. By lowering H2O2 dosage to 10 mM to decelerate the kinetics of PCDD/Fs degradation, PCDDs containing more than six Cl substituents were gradually degraded as the reaction proceeded, while the TEQ of PCDFs and low-chlorinated PCDDs first increased and thereafter decreased (Supplementary Fig. 11). The formation of all PCDF congeners in the first 5-h oxidation stage is consistent with the previous findings that PCDFs are formed during the oxidation of aromatic compounds by Fe-involved advanced oxidation processes46,47. With respect to PCDDs, the evolution of PCDD congeners is indicative of dechlorination, which was possibly mediated by the reductive radicals generated from the oxidation of coexisting organics. In addition, HO• addition and/or nucleophilic substitution mediated by the metal-peroxide complexes48,49 could also contribute to dechlorination. The vulnerable sites for electrophilic and nucleophilic attack were predicted via orbital-weighted dual descriptor calculations (see Supplementary Method 2 for details and Supplementary Data 1 for atomic coordinates). The results show that the O sites of PCDD/Fs are susceptible to electrophilic attack, while most of the C atoms in the aromatic rings can be attacked by nucleophiles (Supplementary Fig. 12). These reactive sites are susceptible to HO• attack as predicted by Fukui function calculations, using 2,3,7,8-TeCDF, 2,3,7,8-TeCDD, OCDF, and OCDD as examples (Supplementary Fig. 13).

Identification of the active catalytic sites in MSWI fly ash

More efforts were devoted to identifying the active components responsible for effective catalysis. Most of the metal components in MSWI fly ash were washed off to obtain the carbon-enriched ash sample for degradation of PCDD/Fs (see Supplementary Table 1 for characteristics) by H2O2 alone and Fenton reaction systems. In contrast to the efficient removal of PCDD/Fs in the original fly ash, the TEQ of the carbon-enriched sample was reduced by only 21.4% and 61.6% after 10-h H2O2 oxidation and Fenton reaction, respectively (Fig. 3a). During Fenton reaction, the contribution of incidental component-mediated H2O2 oxidation (30.2%) to the removal of PCDD/Fs in the carbon-enriched sample was ~2.8 times lower than that in the original fly ash (84.8%). These observations underscore the critical role of ash components in catalyzing H2O2 oxidation of PCDD/Fs.

a Degradation kinetics of PCDD/Fs in the carbon-enriched ash sample by H2O2 alone and the bulk Fenton reaction. b Effect of the externally added inorganics on the reduction of TEQ in the Fenton reaction. c Plots of Fe content of different fly ash samples with the detoxification efficiency. d Plots of Fe content with the apparent degradation rate of OCDD in different fly ash samples. e Reduction of TEQ in the original and solvent-extracted ash samples. Default conditions: T = 293 ± 1.0 K; pH = 6.0 ± 0.3; [H2O2] = 50 mM; [fly ash] = 10 g L-1. For b: [Ca2+] = 3000 mg L−1; [Mg2+] = 100 mg L−1; [Al3+] = 250 mg L-1; [SiO32-] = 400 mg L-1; [Cu2+] = 10 mg L-1; [Cl–] = 200 mg L-1; [SO42–] = 50 mg L-1; [CaSO4] = 10000 mg L-1; [SiO2] = 2700 mg L-1; [Al2O3] = [MgO] = [CuO] = [Fe2O3] = 333 mg L−1. For c: the concentration of fly ash was varied to ensure the same initial TEQ (0.9 ng TEQ). The error bars represent the standard deviations from triplicate tests.

The sluggish oxidation of PCDD/Fs in the carbon-enriched ash sample excluded the residual carbon as an active catalyst for H2O2 decomposition. Furthermore, the iron leached from fly ash was less than 56.3 μM ( ~ 11.4% of Fe(II) dosage) at pH ≥ 4.0 (Supplementary Fig. 4a), suggesting its insignificant role in catalytic H2O2 oxidation. External addition of other metal ions detected in the leaching experiments also exhibited a marginal effect on the detoxification of the carbon-enriched ash sample by Fenton reaction (Fig. 3b). Similar results were observed by physically mixing the carbon-enriched ash sample with the representative metal oxides (i.e., CaSO4, SiO2, Al2O3, MgO, CuO, and Fe2O3; Fig. 3b), foretelling that the interaction of active components with carbon-containing PCDD/Fs might be pivotal for catalytic detoxification.

Crucial role of iron loaded on the residual carbon

We aimed to clarify the potential role of active components loaded on the carbon by comparing the H2O2-mediated degradation of PCDD/Fs in fly ash samples with varied element contents. To this end, the fly ash samples from different MSW incineration plants and those prepared by washing the original fly ash at different pH values (see Supplementary Table 4 for characteristics) were selected as targets. We observed a linear correlation between the 10-h detoxification efficiency and the iron content, rather than the content of other metals in different fly ash samples (Fig. 3c and Supplementary Fig. 14a–d). Moreover, using OCDD as a representative of PCDD/Fs, one can see that the pseudo-first-order rate constant of OCDD degradation (Supplementary Fig. 15) correlated well with the iron content but also poorly with the content of other metals (Fig. 3d and Supplementary Fig. 14e–g), highlighting the crucial role of iron-loaded on the carbon as the active center to trigger Fenton-like catalysis.

It has been reported that the solvent-extractable environmentally persistent free radicals (EPFRs) bound to iron oxides would participate in redox reactions with O2 or, in this case, H2O2, to produce reactive species50. However, extraction of EPFRs on fly ash following the previous protocol (Supplementary Method 3 for the detailed procedure) did not weaken the DMPO-HO• signal in the EPR spectrum of the reaction mixture (Supplementary Fig. 14h). Additionally, the removal of EPFRs in the extracted fly ash also exerted a negligible effect on TEQ reduction (Fig. 3e), implying the marginal role of EPFRs bound on iron in catalyzing the decomposition of H2O2 to active oxidants.

Localization and speciation of the incidental iron

The efficient Fenton-like catalysis is highly dependent on the characteristics of iron species in MSWI fly ash. Therefore, the localization and structure of the loaded iron species were characterized in detail. It is challenging to directly analyze Fe distribution in the residual carbon by EDX mapping due to the low iron content and the limited penetration distance of incident electrons (0.8–9.0 μm at an acceleration voltage of 5.0–20 keV vs. ~ 11 μm particle size in average). In this regard, the fly ash particle was sectioned to a slice with a thickness of ~50 nm by focused ion beam technique (FIB; see Supplementary Method 4 for the operational procedure). EDX mapping of the as-prepared slice indicates the uniform distribution of iron species in the carbon (Fig. 4a). A close observation of the sample by high-angle dark-field scanning transmission electron microscopy (HADDF-STEM) with EDX mapping reveals that most of iron species exist as nanoclusters with sizes ranging from 0.6 to 2.8 nm and averaging at 1.8 nm (Fig. 4b). Only a few sporadic particles appear to have larger sizes, typically in the range of 4.0–10.0 nm (Supplementary Fig. 16a). The high-resolution TEM (HRTEM) image shows a lattice spacing of ~2.2 Å (Fig. 4c and Supplementary Fig. 16b), probably belonging to the (113) crystalline lattice of Fe2O3.

a SEM imaging and EDX mapping of the prepared fly ash slice. b Representative HAADF-STEM image of the fly ash slice. The inset is the size distribution of iron oxide nanoclusters, and the right-side figures show EDX imaging of the selected area. c Representative HRTEM image of the iron oxide nanoclusters. Normalized Fe K-edge XANES spectra (d) and phase-corrected FT-EXAFS spectra (e) of fly ash and reference samples. The inset figure in Fig. 4d shows the relationship between Fe valence and the related energy. f Fitting of the FT-EXAFS spectrum of fly ash. SEM imaging and EDX mapping of the ash samples with iron oxides loaded on the outer surface (g) and inside the pores (h). i Detoxification efficiency of different fly ash samples after mixing with H2O2 for 5 h. Conditions for (i): T = 293 ± 1.0 K; pH = 6.0 ± 0.3; [H2O2] = 50 mM; [fly ash] = 10 g L−1. The error bars represent the standard deviations from triplicate tests.

X-ray absorption spectroscopy was recorded to figure out the structure of iron nanoclusters. The Fe K-edge X-ray absorption near-edge structure (XANES) spectrum shows that the valence state of iron species in fly ash is between +2 and +3 (Fig. 4d). In virtue of the plots of the edge absorption energy with the valence state of the reference samples, the valence state of iron species was fitted to be ~2.4. The prominent peaks at 1.80 Å and 2.85 Å in the Fourier-transformed k3-weighted extended X-ray absorption fine structure (FT-EXAFS) spectrum (Fig. 4e) refer to the first corresponding shell of Fe−O coordination and the second shell of Fe−O−Fe scattering, respectively. The FT-EXAFS spectrum of fly ash in R space can be satisfactorily fitted (Fig. 4f and Supplementary Table 5 for fitting parameters) with contributions from two Fe−O paths and two Fe−O−Fe paths of Fe2O3 and FeO, reasonably suggesting that these iron nanoclusters are mainly in the form of Fe2O3 and FeO. The confined iron oxide nanoclusters can be formed via direct combustion of municipal wastes containing carbon and iron, or following a sequence of iron oxidation, reduction, organic-assisted vaporization, and condensation inside the residual carbon during MSW incineration51. The satisfactory detoxification in four continuous runs (60.1%‒72.7%) evidences that these iron sites are stable for Fenton-like catalysis (Supplementary Fig. 17 and Method 5 for detailed procedure).

Effect of iron localization on the detoxification efficiency

Since iron oxides are uniformly distributed in the residual carbon, it is important to distinguish the impact of their localizations on the efficiency of Fenton-like catalysis. For this purpose, iron oxides (~2.50 wt% Fe) were deliberately loaded inside the pores or on the outer surface of the carbon-enriched ash samples by controlling the impregnation conditions (Supplementary Method 6 for details). The iron-loaded samples were sectioned by FIB to expose the internal surfaces. EDX mapping of the sectioned samples, in combination with line scanning analysis along the cross-sections, illustrated that Fe was dispersed inside the internally loaded ash sample but predominantly located in the peripheral region of the counterpart (Fig. 4g–h). EXAFS analysis of the samples showed that the loaded iron oxides were also in the form of Fe2O3 and FeO (Supplementary Fig. 18), similar to those found in fly ash. By mixing the iron-loaded ash samples with H2O2 at pH 6.0, the degradation of PCDD/Fs was more efficient in the Fe-confined ash sample than in the counterpart, both outperforming the unloaded ash sample (Fig. 4i). Taken together, these results unveil that the iron oxide nanoclusters confined inside the carbon contributed incomparably to PCDD/Fs removal in fly ash.

Nanopore-induced regulation of Fenton-like detoxification

Recall that the efficiency of nanoconfined Fenton-like detoxification catalyzed by iron oxide nanoclusters was much higher than that of the Fe(II)-triggered bulk Fenton reaction at pH 5.0–7.0 (Fig. 1g), even when the content of iron oxides (28.5 mg Fe in 3.0 g fly ash) is less than that of externally-added Fe(II) (i.e., 33.6 mg Fe(II)). The detoxification efficiency depends on the characteristics of the active oxidants, the rate at which they are generated, as well as their effective collisions with PCDD/Fs in fly ash52,53. The experimental results unfold that HO• dominated PCDD/Fs removal in the nanoconfined Fenton-like reaction, in a similar manner to the bulk Fenton reaction. Moreover, it is well-documented that the reactivity of heterogeneous iron oxides toward H2O2 is much lower than the dissolved Fe(II)54. In consideration of the fact that both iron oxide nanoclusters and PCDD/Fs are confined in the nanopores of the residual carbon, it is reasonable to surmise that the nanopores trigger nanoconfinement effects to exert an influence on reactant diffusion and the effective concentrations of reactants to alter the reaction outcomes55,56.

Diffusion of reactants inside the nanopores determines the spatial distribution of HO•, which is a crucial factor governing the effective collisions with PCDD/Fs, given the limited diffusion distance of the short-lived HO• (~200 nm). In the current case, finite-element method (FEM) simulations were conducted to offer more details concerning the effect of reactant diffusion inside the nanopores on PCDD/Fs removal. In the simulations, the carbon was simplified to feature a spherical shape (Supplementary Fig. 19a) with a tortuosity (τ) of 10 57. The conceptual model endows the carbon with an inert surface (see Supplementary Method 7 for simulation details). H2O2 and Fe(II) that exists initially in the bulk solution can diffuse into the carbon and concurrently react following the classical Haber-Weiss cycle to produce HO• (Supplementary Fig. 19b). Using the Wilke-Chang equation, the diffusion coefficients of H2O2, Fe(II), and HO• in the bulk solution at 293 K were calculated to be 2.16 × 10-9 m2 s-1, 8.02 × 10-10 m2 s-1, and 3.27 × 10-9 m2 s-1, respectively (Supplementary Method 8 for calculations). The pore diameter of the carbon-enriched sample is averaged at 5.8 nm (Supplementary Fig. 20). In this case, the diffusion of reactants in the nanopores is controlled by both bulk diffusion and Knudsen diffusion (Supplementary Method 8), with the effective diffusion coefficients ranging from 1.94 × 10-10 – 6.20 × 10-10 m2 s-1 (Supplementary Table 6). We found that diffusion of H2O2 into the carbon with a diameter of 10 μm completed within 50 ms (Fig. 5a–c). This result is in accordance with the previous studies58 elucidating that the inward diffusion of H2O2 was only slightly limited in the activated carbon of small size (<180 μm). Increase of the diameter of carbon substantially prolonged the diffusion time to reach the center of carbon (i.e., ~50 ms for 10 μm vs ~ 500 s for 1000 μm; Supplementary Fig. 21a–b). Accordingly, the impeded inward diffusion of H2O2 would reduce the efficiency of the incidental iron nanocluster-induced Fenton-like catalysis. This is supported by lower detoxification efficiency of dioxin-enriched activated carbon with a larger size (Supplementary Fig. 22; see Supplementary Method 6 for procedure).

The spatial distribution of H2O2 in the bulk solution and the inert carbon at (a) 0 ms, (b) 10 ms, and (c) 50 ms in the absence of Fe(II). d SEM imaging of the cross-section of fly ash impregnated in 0.5 mM Fe(III) for 5 h and line scanning analysis of Fe(III) along the cross-section. The spatial distribution of HO• generated from Fenton reaction in the bulk solution and the inert carbon at (e) 0 ms, (f) 10 ms, and (g) 50 ms. h The spatial distribution of HO• in the bulk solution and the Fe(II)-confined carbon at 50 ms. Conditions for (d): T = 293 ± 1.0 K; pH = 6.0 ± 0.3; [Fe(III)] = 0.5 mM; [fly ash] = 10 g L−1; adsorption time = 5 h.

A similar result was observed for Fe(II) diffusion in the absence of H2O2 (Supplementary Fig. 21c–d). However, when the rapid consumption by H2O2 ( ~ 3 s for 0.50 mM Fe(II), 50 mM H2O2, and a second-order rate constant of 70 M-1 s-1) and the strong adsorption of Fe(II) on the carbon (effective diffusion coefficient of 10-12 m2 s-159,60) were considered, negligible Fe(II) penetrated into the interior of carbon (Supplementary Fig. 23). Therefore, the depth of penetration of the generated Fe(III) into the carbon determines the size of the reaction zone. However, line scanning analysis of the carbon-enriched ash sample impregnated in 0.5 mM Fe(III) solution at pH 6.0 for 5 h shows that Fe(III) is predominantly located on the outer surface (Fig. 5d). In this case, the active species are generated in the periphery of the carbon (Fig. 5e–g and Supplementary Fig. 24a), thereby impeding their access to PCDD/Fs adsorbed near the center of the carbon. Conversely, when Fe(II) of the same content is confined inside the carbon, the distribution of active species becomes uniform inside the carbon along with the rapid inward diffusion of H2O2 (Fig. 5h and Supplementary Fig. 24b), leading to a larger reaction zone and subsequently facilitating PCDD/Fs removal.

Feasibility of the strategy for practical applications

We evaluated H2O2-mediated degradation of PCDD/Fs in the fly ash samples collected from different MSW incineration plants (Supplementary Table 4 for characteristics). The initial TEQ of PCDD/Fs in these fly ash samples ranged from 255.4 to 823.6 ng TEQ kg-1. After a 10-h reaction with 50 mM H2O2, the TEQ of most fly ash samples was reduced by 68.9%–92%, with only two exceptions where less than 50% of TEQ reduction was observed (Fig. 6a). While other unidentified components in fly ash could also contribute to catalytic TEQ reduction, the linear relationship between TEQ reduction and the iron content (Fig. 3c) indicates that the variance in the efficiency of fly ash detoxification should be dominantly related to different Fe contents. The feasibility of this strategy for practical applications was further validated by a pilot-scale experiment. About 30 kg of fly ash was mixed with tap water with a solid-to-liquid ratio of 2.2–2.5 in a customized mechanical mixer (Fig. 6b), with the operational conditions referred to the industrialized acid washing process to facilitate the possible integration of both units. The pH of the suspension was adjusted to 5.9–6.9 using HCl. The addition of 50 mM H2O2 induced the reduction of TEQ from ~345.4 ng TEQ kg-1 to ~53.9 ng TEQ kg-1 even at low temperatures (278–288 K; Fig. 6c and Supplementary Fig. 25 for kinetics). The detoxification efficiency can be further improved by the increase of H2O2 dosage (Fig. 6c). The operating cost (Supplementary Method 9 for calculation), whether the wastewater treatment is considered, is remarkably lower than that of the traditional thermal disposal processes ($40–$21919,22; Fig. 6d). Of note is that the operating condition of our strategy is similar to that of the industrial washing process. This would enable the integration of Fenton-like oxidation with the industrial washing process, thereby further reducing the operating cost associated with the consumption of water and electricity as well as the treatment of the produced wastewater.

a Detoxification of fly ash from different MSW incineration plants by incidental Fenton-like catalysis. b The 100-L mechanical mixer for pilot-scale experiments. The right-side figure is the top view of the reaction tank. c Effect of H2O2 concentration on the detoxification efficiency. The control line of 50 ng TEQ kg−1 is derived from a technical specification for pollution control of fly-ash from municipal solid waste incineration in China (HJ 1134-2020). d Comparison of the operating cost of incidental Fenton-like catalysis and traditional thermal disposal processes for fly ash detoxification. The cost of thermal treatment does not contain the cost of pretreatment (i.e., the washing process). e Incidental Fenton-like degradation of different contaminants in various wastes containing iron. Conditions for a: T = 293 ± 1.0 K; pH = 6.0 ± 0.3; [H2O2] = 50 mM; the concentration of fly ash was varied to ensure the same initial TEQ (0.9 ng TEQ). Conditions for c: T = 283 ± 5.0 K; pH = 6.4 ± 0.5; fly ash = 30 ± 1.0 kg; tap water = 66–75 L; [H2O2] = 50 mM. Conditions for e: T = 313 ± 1.0 K; pH = 6.0 ± 0.3; [waste] = 10 g L−1; [H2O2] = 100 mM.

Moreover, this strategy was applied to purify the spent activated carbon, spent zeolite, and contaminated soil of different Fe contents (Supplementary Table 7 for detailed characteristics). First, PCDD/Fs of 24.3‒81.3 ng TEQ kg-1 were pre-adsorbed on the above solid wastes (Supplementary Method 10 for procedure). By mixing 100 mM H2O2 with each of solid waste for 10 h, the TEQ of PCDD/Fs was reduced by 59.9%–85.1% (Fig. 6e). Besides PCDD/Fs, the other adsorbed chemicals bearing different structures (i.e., atrazine, methadone, diacetone alcohol, n-hexadecanoic acid, and octadecanoic acid (54.3%–95.1%; Supplementary Method 11 and Supplementary Fig. 26 for identification) can also be degraded efficiently (Fig. 6e), manifesting the broad spectrum of this strategy for removal of organic contaminants in solid wastes containing active transition metals.

In conclusion, this work elucidates that incidental iron oxide nanoclusters confined inside the residual carbon trigger H2O2 decomposition at pH 5.0–7.0 to produce HO• and other active oxidants, resulting in efficient detoxification of fly ash under ambient conditions. The short distance between the catalytic centers and PCDD/Fs within the nanopores effectively alleviates the diffusion limitation of active species for efficient degradation. The pilot-scale detoxification of fly ash combined with the satisfactory removal of organic contaminants in various wastes underlines the huge potential of the incidental transition metal-triggered confined Fenton-like catalysis for sustainable waste-to-resource recovery. We also believe that exploring more methods to harness INPs from various sources would benefit other sustainable applications.

Methods

Chemicals

The details of the chemicals used for extraction, analysis, and other investigations were provided in Supplementary Note 1. The PCDD/Fs standards were purchased from Willington Laboratories Inc. The fly ash samples were collected directly from the fabric filters in MSW incineration plants. One ash sample used for the primary investigation was collected from a washing process in a fly ash processing line (Hangzhou Huihong Environmental Technology Co., Ltd.), in which the Fenton-like detoxification process is to be integrated. All fly ash samples contain activated carbon, which was injected in gas treatment systems before the fabric filters to reduce the concentrations of PCDD/Fs and volatile heavy metals in the flue gas (Supplementary Fig. 1 for fly ash production process). Additionally, several fly ash samples with different metal contents were prepared by washing the original fly ash in aqueous solutions with different pH values (Supplementary Method 1).

Characterization

The morphology and constituents of fly ash were recorded by scanning electron microscopy (SEM, S-3400 II, Hitachi) coupled with an energy-dispersive X-ray spectroscopy detector. The spatial distribution of iron was analyzed by EDX mapping after sample sectioning by FIB (JEOL JIB 4501 MultiBeam FIB–SEM platform; see Supplementary Method 4 for the detailed procedure). The morphologies of iron species in the fly ash were characterized by TEM (FEI Titan G2 60-300), with details for sample preparation in Supplementary Method 4 and Supplementary Fig. 27. X-ray absorption fine structure spectra at the Fe K-edge was analyzed at room temperature in Shanghai Synchrotron Radiation Facility with Fe foil as reference. The crystal structures of the metal components in the fly ash were characterized by XRD (D8 Advance diffractometer, Bruker) using Cu Kα radiation (λ = 1.54056 Å).

Experimental procedures

Degradation experiments were carried out in 100 mL Erlenmeyer flasks at 293 ± 1.0 K under magnetic stirring. Unless otherwise specified, three grams of fly ash and 0.50 mM Fe(II) (for homogeneous Fenton reactions) were added to 100 mL ultrapure water. Different fly ash samples were used for different purposes. In detail, the original MSWI fly ash samples from different sources were used to determine the catalytic activity; the carbon-enriched fly ash with/without iron loading was employed to explore the role of components in catalytic detoxification. To identify the crucial role of iron, the MSWI fly ash samples after being washed at different pH values were used. The pH of the suspension was then adjusted to 6.0 ± 0.3 with HNO3, NaHCO3, and NaOH. Adjusting the pH of the solutions only slightly reduces the concentration of dissolved Fe(II) (Supplementary Fig. 28). The reaction was initiated by adding 50 mM H2O2. After the predetermined reaction time, the suspension was rapidly filtered through 0.22 μm glass fiber membranes. The collected fly ash and filtrates were then extracted for PCDD/Fs analysis. Degradation experiments with varied intervals were performed to visualize the kinetics of detoxification.

Analytical methods

Detoxification of fly ash was expressed in terms of the reduction of TEQ of PCDD/Fs. Concentrations of 17 PCDD/F congeners were analyzed by the high-resolution gas chromatography interfaced with a high-resolution mass spectrometer (HRGC–HRMS) following the U.S. EPA method 1613 (Supplementary Fig. 29 and Supplementary Method 12 for details of pretreatment and analysis). The limit of detection (LOD) and limit of quantification (LOQ) were calculated to be 0.1–0.5 pg and 0.4–2.0 pg, respectively (Supplementary Table 8). The recovery efficiencies of PCDD/Fs ranged from 61.3% to 80.3%, with an average of 72.2% (Supplementary Table 3). Atrazine and other model compounds were quantified using ultrahigh performance liquid chromatography (UHPLC, U3000, Dionex) with the operating conditions detailed in Supplementary Table 9. The contents of metals leached at different pH values and contained in the fly ash were determined by inductively coupled plasma optical emission spectrometry (ICP-OES; iCAP7400, Thermo Scientific; see Supplementary Method 13 for details). The generated active species were qualitatively analyzed by electron paramagnetic resonance spectroscopy (EPR; A300, Bruker) using DMPO or TEMP as the spin traps. The environmentally persistent free radicals on fly ash were analyzed by EPR directly or after solvent extraction following the reported protocol (Supplementary Method 3 for details).

Data availability

The data that supports the findings of the study are included in the main text and supplementary information files. Raw data can be obtained from the corresponding author upon request. Source data are also provided as a Source Data file. Source data are provided with this paper.

References

Díaz, S. et al. Pervasive human-driven decline of life on Earth points to the need for transformative change. Science 366, eaax3100 (2019).

Mauter, M. S. et al. The role of nanotechnology in tackling global water challenges. Nat. Sustain. 1, 166–175 (2018).

Gilbertson, L. M. et al. Guiding the design space for nanotechnology to advance sustainable crop production. Nat. Nanotechnol. 15, 801–810 (2020).

Pokrajac, L. et al. Nanotechnology for a sustainable future: Addressing global challenges with the international network4sustainable nanotechnology. ACS Nano 15, 18608–18623 (2021).

Schindler, M. et al. Natural, incidental, and engineered nanomaterials and their impacts on the Earth system. Science 363, eaau8299 (2019).

Miernicki, M., Hofmann, T., Eisenberger, I., von der Kammer, F. & Praetorius, A. Legal and practical challenges in classifying nanomaterials according to regulatory definitions. Nat. Nanotechnol. 14, 208–216 (2019).

Barhoum, A. et al. Review on natural, incidental, bioinspired, and engineered nanomaterials: history, definitions, classifications, synthesis, properties, market, toxicities, risks, and regulations. Nanomaterials 12, 177 (2022).

Yang, Y. et al. Discovery and ramifications of incidental Magnéli phase generation and release from industrial coal-burning. Nat. Commun. 8, 1–11 (2017).

Westerhoff, P. et al. Low risk posed by engineered and incidental nanoparticles in drinking water. Nat. Nanotechnol. 13, 661–669 (2018).

George, C., Ammann, M., D’Anna, B., Donaldson, D. & Nizkorodov, S. A. Heterogeneous photochemistry in the atmosphere. Chem. Rev. 115, 4218–4258 (2015).

Ding, Y. et al. A review of China’s municipal solid waste (MSW) and comparison with international regions: Management and technologies in treatment and resource utilization. J. Clean. Prod. 293, 126144 (2021).

Kaza, S., Yao, L., Bhada-Tata, P. & Van Woerden, F. What a waste 2.0: A global snapshot of solid waste management to 2050 (World Bank Publications, 2018).

Kumar, A. & Samadder, S. R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 69, 407–422 (2017).

dos Santos, I. F. S., Mensah, J. H. R., Gonçalves, A. T. T. & Barros, R. M. Incineration of municipal solid waste in Brazil: An analysis of the economically viable energy potential. Renew. Energ. 149, 1386–1394 (2020).

Walser, T. et al. Persistence of engineered nanoparticles in a municipal solid-waste incineration plant. Nat. Nanotechnol. 7, 520–524 (2012).

Zhang, Y. et al. Treatment of municipal solid waste incineration fly ash: State-of-the-art technologies and future perspectives. J. Hazard. Mater. 411, 125132 (2021).

Jiang, X., Zhao, Y. & Yan, J. Disposal technology and new progress for dioxins and heavy metals in fly ash from municipal solid waste incineration: A critical review. Environ. Pollut. 311, 119878 (2022).

Bayer, P., Heuer, E., Karl, U. & Finkel, M. Economical and ecological comparison of granular activated carbon (GAC) adsorber refill strategies. Water Res. 39, 1719–1728 (2005).

Liu, F., Liu, H., Yang, N. & Wang, L. Comparative study of municipal solid waste incinerator fly ash reutilization in China: Environmental and economic performances. Resour. Conserv. Recy. 169, 105541 (2021).

Gong, Y. et al. Environment–Energy–Economy analysis and related technical transition strategies for spent activated carbon regeneration in China. ACS Sustain. Chem. Eng. 10, 11512–11523 (2022).

Zhai, Y. et al. Regional CO2 accounting and market layout of incinerator fly ash management in China. Sci. Total Environ. 881, 163336 (2023).

Huang, T., Chiueh, P. & Lo, S. Life-cycle environmental and cost impacts of reusing fly ash. Resour. Conserv. Recy. 123, 255–260 (2017).

De Boom, A. & Degrez, M. Belgian MSWI fly ashes and APC residues: A characterisation study. Waste Manag. 32, 1163–1170 (2012).

Li, B. et al. Degradation characteristics of dioxin in the fly ash by washing and ball-milling treatment. J. Hazard. Mater. 339, 191–199 (2017).

Huang, H. & Buekens, A. De novo synthesis of polychlorinated dibenzo-p-dioxins and dibenzofurans Proposal of a mechanistic scheme. Sci. Total Environ. 193, 121–141 (1996).

Fujimori, T., Takaoka, M. & Takeda, N. Influence of Cu, Fe, Pb, and Zn chlorides and oxides on formation of chlorinated aromatic compounds in MSWI fly ash. Environ. Sci. Technol. 43, 8053–8059 (2009).

Zhou, H., Meng, A., Long, Y., Li, Q. & Zhang, Y. A review of dioxin-related substances during municipal solid waste incineration. Waste Manag. 36, 106–118 (2015).

Huang, Y., Takaoka, M., Takeda, N. & Oshita, K. Partial removal of PCDD/Fs, coplanar PCBs, and PCBs from municipal solid waste incineration fly ash by a column flotation process. Environ. Sci. Technol. 41, 257–262 (2007).

Liu, H., Wei, G. & Zhang, R. Removal of carbon constituents from hospital solid waste incinerator fly ash by column flotation. Waste Manag. 33, 168–174 (2013).

Yang, Z., Qian, J., Yu, A. & Pan, B. Singlet oxygen mediated iron-based Fenton-like catalysis under nanoconfinement. Proc. Natl Acad. Sci. USA. 116, 6659–6664 (2019).

Tang, Z., Zhao, P., Wang, H., Liu, Y. & Bu, W. Biomedicine meets Fenton chemistry. Chem. Rev. 121, 1981–2019 (2021).

Xu, X. et al. Revealing *OOH key intermediates and regulating H2O2 photoactivation by surface relaxation of Fenton-like catalysts. Proc. Natl Acad. Sci. USA. 119, e2205562119 (2022).

Pignatello, J. J., Oliveros, E. & MacKay, A. Advanced oxidation processes for organic contaminant destruction based on the Fenton reaction and related chemistry. Crit. Rev. Environ. Sci. Technol. 36, 1–84 (2006).

Guo, D. et al. Silicate-enhanced heterogeneous flow-through electro-Fenton system using iron oxides under nanoconfinement. Environ. Sci. Technol. 55, 4045–4053 (2021).

Gao, X., Yang, Z., Zhang, W. & Pan, B. Carbon redirection via tunable Fenton-like reactions under nanoconfinement toward sustainable water treatment. Nat. Commun. 15, 2808 (2024).

Di Trani, N., Pimpinelli, A. & Grattoni, A. Finite-size charged species diffusion and pH change in nanochannels. ACS Appl. Mater. Interfaces 12, 12246–12255 (2020).

Munoz-Santiburcio, D. & Marx, D. Confinement-controlled aqueous chemistry within nanometric slit pores: Focus review. Chem. Rev. 121, 6293–6320 (2021).

Zhu, Y. et al. Ionic surface propensity controls pH in nanopores. Chem 8, 3081–3095 (2022).

Roberts, J. L. Jr, Calderwood, T. S. & Sawyer, D. T. Oxygenation by superoxide ion of CCl4, FCCl3, HCCl3, p,p’-DDT and related trichloromethyl substrates (RCCl3) in aprotic solvents. J. Am. Chem. Soc. 105, 7691–7696 (1983).

Bielski, B. H. J. Reactivity of HO2/O2- radicals in aqueous solution. J. Phys. Chem. Ref. Data 14, 1041–1100 (1985).

Hayyan, M., Hashim, M. A. & AlNashef, I. M. Superoxide ion: Generation and chemical implications. Chem. Rev. 116, 3029–3085 (2016).

Elwell, C. E. et al. Copper–oxygen complexes revisited: Structures, spectroscopy, and reactivity. Chem. Rev. 117, 2059–2107 (2017).

Li, H., Yuan, N., Qian, J. & Pan, B. Mn2O3 as an electron shuttle between peroxymonosulfate and organic pollutants: The dominant role of surface reactive Mn(IV) species. Environ. Sci. Technol. 56, 4498–4506 (2022).

Buxton, G. V., Greenstock, C. L., Helman, W. P. & Ross, A. B. Critical review of rate constants for reactions of hydrated electrons, hydrogen atoms and hydroxyl radicals (•OH/•O–) in aqueous solution. J. Phys. Chem. Ref. Data 17, 513–886 (1988).

Pestovsky, O. & Bakac, A. Aqueous ferryl (IV) ion: Kinetics of oxygen atom transfer to substrates and oxo exchange with solvent water. Inorg. Chem. 45, 814–820 (2006).

Vallejo, M., San Román, M., Irabien, A. & Ortiz, I. Comparative study of the destruction of polychlorinated dibenzo-p-dioxins and dibenzofurans during Fenton and electrochemical oxidation of landfill leachates. Chemosphere 90, 132–138 (2013).

Vallejo, M., San Román, M. F., Ortiz, I. & Irabien, A. Overview of the PCDD/Fs degradation potential and formation risk in the application of advanced oxidation processes (AOPs) to wastewater treatment. Chemosphere 118, 44–56 (2015).

Yang, Z., Shan, C., Pan, B. & Pignatello, J. J. The Fenton reaction in water assisted by picolinic acid: Accelerated iron cycling and co-generation of a selective Fe-based oxidant. Environ. Sci. Technol. 55, 8299–8308 (2021).

Yang, Z., Cui, Y., Pan, B. & Pignatello, J. J. Peroxymonosulfate activation by Fe(III)–picolinate complexes for efficient water treatment at circumneutral pH: Fe(III)/Fe(IV) cycle and generation of oxyl radicals. Environ. Sci. Technol. 57, 18918–18928 (2023).

Zhao, S. et al. Formation and evolution of solvent-extracted and nonextractable environmentally persistent free radicals in fly ash of municipal solid waste incinerators. Environ. Sci. Technol. 53, 10120–10130 (2019).

Thipse, S. S. & Dreizin, E. L. Metal partitioning in products of incineration of municipal solid waste. Chemosphere 46, 837–849 (2002).

Yang, Z. et al. Toward selective oxidation of contaminants in aqueous systems. Environ. Sci. Technol. 55, 14494–14514 (2021).

Cai, J. et al. Accurate removal of toxic organic pollutants from complex water matrices. Environ. Sci. Technol. 56, 2917–2935 (2022).

Yang, X. J., Xu, X. M., Xu, J. & Han, Y. F. Iron oxychloride (FeOCl): An efficient Fenton-like catalyst for producing hydroxyl radicals in degradation of organic contaminants. J. Am. Chem. Soc. 135, 16058–16061 (2013).

Qian, J., Gao, X. & Pan, B. Nanoconfinement-mediated water treatment: From fundamental to application. Environ. Sci. Technol. 54, 8509–8526 (2020).

Yu, Z. et al. Kinetics driven by hollow nanoreactors: an opportunity for controllable catalysis. Angew. Chem., Int. Ed. 62, e202213612 (2023).

Georgi, A. & Kopinke, F.-D. Interaction of adsorption and catalytic reactions in water decontamination processes: Part I. Oxidation of organic contaminants with hydrogen peroxide catalyzed by activated carbon. Appl. Catal., B 58, 9–18 (2005).

Huling, S. G., Kan, E. & Wingo, C. Fenton-driven regeneration of MTBE-spent granular activated carbon—effects of particle size and iron amendment procedures. Appl. Catal., B 89, 651–658 (2009).

Onganer, Y. & Temur, Ç. Adsorption dynamics of Fe(III) from aqueous solutions onto activated carbon. J. Colloid Interface Sci. 205, 241–244 (1998).

Kaveeshwar, A. R. et al. Pecan shell based activated carbon for removal of iron(II) from fracking wastewater: adsorption kinetics, isotherm and thermodynamic studies. Process Saf. Environ. Prot. 114, 107–122 (2018).

Acknowledgements

This study was supported by National Natural Science Foundation of China (Grant No. 21925602/22106069/22236003/22476086), the Natural Science Foundation of Jiangsu Province (Grant No. BK20210188). We appreciate Dr. Yuchi Zhong and Mr. Lingwei Ren from Hangzhou Huihong Environmental Protection Technology Co., LTD for their invaluable assistance in the pilot-scale demonstration. We are also grateful to the High-Performance Computing Center (HPCC) of Nanjing University for the numerical calculations on its blade cluster system.

Author information

Authors and Affiliations

Contributions

Z.Y. and B.P. conceived the research. Z.Y., Y.Y., and B.P. designed the experiments. Y.Y., M.L., Z.Y., J.Z., and F.L. carried out the experiments. Y.Y., Z.Y., W.Z., and B.P. analyzed the data. Z.Y., Y.Y., W.Z., W.F., and B.P. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

Z.Y., Y.Y., and B.P. are the inventors of a patent filed by Nanjing University related to the detoxification of fly ash by H2O2 presented here (Chinese Patent ZL 202310935899.5 granted on Mar. 8th, 2024). The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Junjie Zhang and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, Z., Yin, Y., Liang, M. et al. Incidental iron oxide nanoclusters drive confined Fenton-like detoxification of solid wastes towards sustainable resource recovery. Nat Commun 16, 146 (2025). https://doi.org/10.1038/s41467-024-55625-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-55625-9

This article is cited by

-

Bioaccessibility and availability of trace elements coprecipitated with aluminum-substituted iron oxides

Environmental Geochemistry and Health (2025)