Abstract

Gypsum (CaSO4·2H2O) plays a critical role in numerous natural and industrial processes. Nevertheless, the underlying mechanisms governing the formation of gypsum crystals on surfaces with diverse chemical properties remain poorly understood due to a lack of sufficient temporal-spatial resolution. Herein, we use in situ microscopy to investigate the real-time gypsum nucleation on self-assembled monolayers (SAMs) terminated with −CH3, −hybrid (a combination of NH2 and COOH), −COOH, −SO3, −NH3, and −OH functional groups. We report that the rate of gypsum formation is regulated by the surface functional groups and hydrophobicity, in the order of −CH3 > −hybrid > −COOH > −SO3 ≈ − NH3 > − OH. Results based on classical nucleation theory and molecular dynamics simulations reveal that nucleation pathways for hydrophilic surfaces involve surface-induced nucleation, with ion adsorption sites (i.e., functional groups) serving as anchors to facilitate the growth of vertically oriented clusters. Conversely, hydrophobic surfaces involve bulk nucleation with ions near the surface that coalesce into larger horizontal clusters. These findings provide new insights into the spatial and temporal characteristics of gypsum formation on various surfaces and highlight the significance of surface functional groups and hydrophobicity in governing gypsum formation mechanisms, while also acknowledging the possibility of alternative nucleation pathways due to the limitations of experimental techniques.

Similar content being viewed by others

Introduction

Gypsum (CaSO4·2H2O) scale formation is important across diverse fields, impacting industrial processes and environmental systems1,2,3,4,5,6,7. One example is seawater desalination, where gypsum formation on reverse osmosis (RO) membrane surfaces leads to a decline in process performance and increased energy consumption8,9,10,11. In another example, deposition of gypsum on pore surfaces in underground oil reservoirs causes formation damage, which significantly hampers oil recovery efficiency6. A prevailing challenge in managing gypsum scaling is the lack of mechanistic understanding of heterogeneous scale formation on engineered surfaces. Therefore, unraveling the mechanisms of heterogeneous gypsum nucleation is crucial for informing the design of engineered surfaces and developing strategies to mitigate gypsum scaling.

Established over a century and a half ago, classical nucleation theory remains a foundational framework for characterizing nucleation tendencies from supersaturated solutions. This theory is broadly applicable to various substances, including calcite, gypsum, ice, proteins, and beyond5,12,13,14,15. According to classical nucleation theory, nucleation is a process that depends on the competition of nuclei between unfavorable surface energies and favorable bulk-free energies4. Several studies observed the effects of surface chemical properties on gypsum formation5,16,17,18. For instance, increasing surface hydrophilicity and creating superhydrophobic surfaces can potentially delay the formation of gypsum scale16,17,19. Other studies reported the importance of surface carboxylic groups, which could interact with Ca2+ ions and promote the surface nucleation of gypsum20,21,22,23. In contrast, surface hydroxyl groups were found to have minimal or no effect on the formation of gypsum20,22. While these findings highlight the importance of surface chemical properties, the variability in results implies an intricate relationship between gypsum formation and surface properties. Hence, there is a crucial need to develop a comprehensive mechanistic understanding of gypsum nucleation and growth on surfaces with diverse functional groups, charge density, and levels of hydrophilicity.

Surface properties could also affect the initial stage of gypsum crystallization, which is beyond the description of classical nucleation theory. Recent studies with advanced characterization techniques, such as in situ X-ray small- and wide-angle scattering15, high-resolution microscopy24, and time-resolved cryogenic transmission electron microscopy25, have observed stable precursor clusters or nanocrystalline at the early stage of nucleation, which would regulate the nucleation and growth behavior. Nonetheless, these stable prenucleation clusters were predominantly observed in the context of homogeneous nucleation processes, showing distinct kinetics compared to heterogeneous nucleation. Moreover, understanding of the underlying mechanism of this phenomenon is limited by the constraints of experimental observations, particularly the limitations of time and the quenching step.

Computer-based simulations—including density functional theory (DFT) calculations and molecular dynamics (MD) simulations—are powerful techniques for providing in-depth insights into the early stage of the nucleation process3,7,26. The mechanistic insights gained at the atomic and molecular levels could further be used to corroborate experimental results. For example, a combination of experiments and MD simulations revealed that classical nucleation theory can effectively elucidate the intricate mechanism governing calcite crystallization26. In addition to MD simulations, DFT calculations provide atomic-level details that enhance our understanding of the nucleation process27,28,29. However, only a few simulation studies have specifically addressed gypsum nucleation, particularly with respect to heterogeneous nucleation30,31. Consequently, a thorough investigation of the initial stages of gypsum nucleation through computational simulations is clearly warranted.

In this work, we investigated the role of surface properties in gypsum scale formation via systematic experimental observations and MD simulations. Self-assembled monolayers (SAMs) of alkyl thiols on gold surfaces were employed to create surfaces terminated with −NH2, −OH, −COOH, −CH3, −SO3, and −hybrid (a combination of NH2 and COOH) functional groups. An in situ imaging technique was employed to quantify the number of gypsum crystallites forming on these surfaces, enabling the calculation of the nucleation rate. Subsequently, we compared the observed gypsum nucleation rate with the number of cluster ions in the proximity of the surfaces as determined by MD simulations. Our results revealed that classical theories for crystal nucleation and growth combined with MD simulations can provide insights into gypsum nucleation mechanisms on surfaces with different chemical properties. Our findings also led us to propose two distinct gypsum growth mechanisms for hydrophilic and hydrophobic surfaces. On hydrophilic surfaces, gypsum tends to grow vertically, influenced by the attractive induction interactions of adsorbed ions, whereas horizontal growth of gypsum prevails on hydrophobic surfaces.

Results

Fabrication and properties of different functionalized surfaces

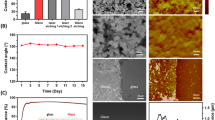

Substrate surfaces with different functional groups were fabricated using SAM. Atomic force microscopy (AFM) showed that the surfaces were relatively smooth, with a mean arithmetic roughness below 1.3 nm (Supplementary Fig. 1). Surface hydrophilicity was assessed via water contact angle measurements with DI water as the probing liquid. As illustrated in Fig. 1, most substrate surfaces were hydrophilic, except for the methyl (−CH3) functionalized surface which exhibits the highest static contact angle (98.10 ± 3.19°). The water contact angles for substrate surfaces terminated with a hybrid of NH2 and COOH, −NH2, −OH, −COOH, and −SO3 groups were 81.83 ± 2.34°, 67.44 ± 6.54°, 60.78 ± 4.26°, 50.50 ± 8.03°, and 32.50 ± 1.78°, respectively.

The molecular structure and contact angles of (A1)−OH, (B1)−COOH, (C1)−NH2, (D1)−CH3, (E1)−SO3, and (F1) hybrid of NH2 and COOH groups terminated self-assembled monolayers. Pink, while, grey, yellow, and blue spheres represent oxygen, hydrogen, carbon, sulfur, nitrogen atoms, respectively. The XPS spectra of representative chemical bonds of (A2)−OH, (B2)–COOH, (C2)−NH2, (D2)−CH3, (E2)−SO3, and (F2) hybrid of NH2 and COOH groups terminated self-assembled monolayers. CPS and a.u. represent counts per second and arbitrary unit, respectively.

X-ray photoelectron spectroscopy (XPS) was employed to analyze the elemental composition and oxidation states of functionalized substrate surfaces (Fig. 1), thereby verifying the successful modification achieved with a variety of function groups. For the −OH functionalized surface, the O1s peaks at 527.6, 529.7, and 531.1 eV were attributed to Au-O or Si-O, originating from the gold-coated silica wafer32, while another peak at 533.3 eV was likely associated with C-OH in 11-mercapto-1-undecanol33. For the −COOH functionalized surface, three distinct components were revealed through deconvolution of the C 1 s spectrum. The first component, detected at 284.8 eV, was attributed to C-C bonds within the aliphatic chain. The second component, observed at 286.6 eV, corresponded to the C-O/C=O bonds associated with the 11-mercaptoundecanoic acid. Lastly, the peak at 288.6 eV originated from the O-C=O bonds within the carboxylic group itself34,35. For the −NH2 functionalized surface, two peaks at 400.0 and 402.2 eV were observed, corresponding to the neutral and protonated N-C species of amine tail groups, respectively36. The −CH3 functionalized surface was primarily composed of C-H bonds (284.8 eV), attributed to the aliphatic chain (−CH2 or −CH3) of the 1-dodecanethiol molecule35. A negligible peak at 287.4 eV was observed, which may be attributed to slightly oxidized carbonaceous atmospheric contaminations, i.e., -C(O)-.37. The −SO3 functionalized surface exhibited two peaks at 160.2 and 165.6 eV, arising from the gold substrate (Au-S) and sulfonic acid (-SO3Na) groups, respectively38. The C 1 s signal was also examined on the hybrid surface and three peaks were observed. The peak centered at 284.8 eV was due to the C-C/C-H bonds of the molecule used. The second peak, shifted by 1.0 eV to higher energy (at 285.8 eV), was ascribed to C-N bond of the amide group. The third peak, located at 287.8 eV, represents either the C=O or C=O-N groups of the amide group39. The signal from N 1 s spectrum is at 400.0 eV (Supplementary Fig. 2), which is attributable to the neutral N-C species. Taken together, these results verify the successful binding of various groups onto the substrate surface.

Nucleation kinetics of gypsum

The influence of different surface functional groups on the formation of crystallites on the substrate was examined through the application of an in situ imaging technique (Fig. 2A). To accelerate nucleation, solutions of CaCl2 and Na2SO4 with a saturation index (σ) ranging from 0.97 to 1.63 were employed for gypsum formation. In all the nucleation experiments, a consistent solution flow rate of 30 mL h−1 was used to the substrates functionalized with various functional groups. The nucleation and growth of gypsum crystallites (Supplementary Fig. 3) on the substrate surface were monitored over time via an optical microscope. The number density of gypsum crystallites was determined as a function of time for various σ values, demonstrating a linear relationship where the number density of gypsum crystallites increased with time for all the collected data. Each type of substrate exhibited a distinct relationship (Fig. 2B and Supplementary Fig. 4). The steady-state rate of heterogeneous nucleation (J0) was calculated from the slope of the number density vs. time. As expected, J0 was proportional to the saturation index of the solution.

A Schematic illustration of gypsum nucleation experiments. B The representative number density of gypsum crystallites versus time for various saturation index (σ) values on surfaces terminated with −OH. The slopes of lines for each supersaturation value represent the steady-state nucleation rate, J0. Similar plots for surfaces terminated with −COOH, −NH2, −CH3, −SO3, and hybrid of NH2 and COOH groups are shown in Supplementary Fig. 4. C Gypsum nucleation rates obey classical nucleation theory; the linear relationship is predicted by Eq. 6 for all surfaces. The slope of the plots, B, represents the substrate-specific thermodynamic barrier to nucleation and is used to estimate gypsum–substrate interfacial free energy, γcs. D The total cluster ions near the surfaces (i.e., the distance between the center of mass (COM) of cluster minus the cluster radius and the surface groups is less than 15 Å) terminated with different functional groups as obtained from the MD simulations. Error bars are derived from the standard deviation of the average values calculated over the last 5 ns.

To quantify the thermodynamic barrier for heterogeneous nucleation of the different substrates, we plotted the relationship between J0 and σ (Fig. 2C). The slopes were calculated using Eq. 6 and were different for all substrates (Table 1). In particular, the −CH3 functionalized substrate had the lowest B value. Since B is a representation of the thermodynamic barrier to nucleation, a lower B value implies a more favorable nucleation. This finding indicates that substrates functionalized with −CH3 groups (or hydrophobic surfaces) displayed a greater propensity for heterogenous nucleation of gypsum, in agreement with previous observations1,2. For the remaining functionalized substrates with more hydrophilic groups, the sequence of the heterogenous nucleation rates follows the order of hybrid > −COOH > −SO3 ≈ −NH3 > −OH surfaces. Interestingly, a higher nucleation rate was observed on the hybrid substrate terminated with −NH3/−COOH than on the −NH3 or −COOH terminated surfaces, suggesting the hybrid substrate was more amenable to gypsum nucleation than the purely aminated or carboxylated substrates. Prior investigations involving diatom biosilica and glass sponges have demonstrated that synergistic interactions between oppositely charged groups can effectively facilitate nucleation and mineralization processes40,41. In contrast to the −COOH terminated substrate surface, the −SO3 and −NH3 surfaces did not create favorable conditions to induce gypsum nucleation. The high nucleation rate on the substrate with −COOH groups could be attributed to the strong complexation reaction between carboxylic groups and Ca2+, which promotes heterogeneous nucleation on the surface20,22,23,42. The substrate surface terminated with −OH groups exhibited the lowest gypsum crystallites count, indicating negligible interaction between hydroxyl groups and gypsum20,22.

To elucidate the impact of distinct functional groups on nucleation rate from a molecular perspective, MD simulations were conducted to examine the incipient stages of gypsum nucleation and CaSO4 growth on six different surfaces. At the beginning of simulations, calcium and sulfate ions are dispersed randomly in solution, predominantly existing as highly hydrated free ions. As the simulations progress, these free ions frequently collide with each other due to electrostatic attractive forces, resulting in the formation of precursor clusters. Monitoring the temporal evolution of free ions and precursor clusters enables us to categorize the nucleation process into two distinct phases. Taking the −CH3 surface as an example, during the initial phase, the rapid decay of free ions coincides with the increase of precursor clusters at 5 ns (Fig. 3A), which manifest as chains, branches, and rings, consistent with prior studies on calcium sulfate nucleation43,44. These clusters subsequently evolve into larger aggregates over time (Supplementary Fig. 5), accompanied by a notable decrease in the number of free ions (Fig. 3A). Notably, the sizes of the three largest clusters undergo significant expansion in proximity to 5 ns (Supplementary Fig. 6). Therefore, the inflection point at about 5 ns could be indicative of a critical point, i.e., indicative of the critical size of nuclei. These findings are consistent with the classical nucleation theory, which suggests the existence of a critical size that categorizes clusters as either subcritical or supercritical45,46. Simultaneously, the hydration degree of calcium ions diminishes and is replaced by coordination with sulfate ions (Fig. 3B). Hence, it can be inferred that a reduction in the number of free ions within the aqueous solution corresponds to a heightened degree of gypsum nucleation. In other words, a greater abundance of cluster ions signifies more pronounced nucleation. Moreover, the maximum cluster size serves as a suitable proxy for nucleation levels, as smaller precursor clusters tend to coalesce into larger ones.

A Time evolution of cluster number and free ions, taking -CH3 surface as an example for analysis. The insets are the potential structures (chains, branches, and rings) of precursor clusters at the first stage, and the large clusters with an amorphous structure at the second stage of prenucleation process. B Time evolution of Ca-So and Ca-Ow bond numbers, which represent the coordination number of Ca2+ ions with SO42− ions and water molecules, respectively.

While the nucleation stages of gypsum in solution remain remarkably similar (Fig. 3A and Supplementary Fig. 7), the nucleation degree varies across different surfaces (Supplementary Fig. 8). To assess the impact of surface groups on gypsum nucleation, only clusters near the surface (i.e., where the distance between the clusters center of mass (COM) minus its size and the surface groups is less than 15 Å) were calculated for comparison. The quantity of cluster ions and the maximum cluster size, which are crucial attributes governing the nucleation process and are challenging to ascertain experimentally47, were tallied. Figure 2D reveals the highest concentration of cluster ions in the vicinity of −CH3 surface, followed by the order of −hybrid > −COOH > −NH2 > −SO3 > −OH surfaces, in accordance with experimental findings. The observed trend in the maximal cluster size near the surface of various substrates (Supplementary Fig. 9) aligns consistently with this result. The findings from this study, along with recent investigations on calcite and calcium phosphate nucleation, offer compelling evidence supporting the effectiveness of classical nucleation theory in predicting the intricate nucleation rate on diverse surfaces with distinct chemical properties26,48.

Mechanisms of gypsum nucleation

Molecular dynamics simulations were employed to gain deeper insights into the heterogeneous nucleation of gypsum on diverse substrates. Based on classical nucleation theory, heterogeneous nucleation of a crystal requires nucleation of a solid–liquid phase boundary on a foreign surface49,50,51,52. For instance, calcium and sulfate ions can interact with the hydrophilic polar groups on the surface. However, further nucleation of calcium and sulfate ions to form CaSO4 clusters is impeded on the hydrophilic surface due to the adhered water layers. On the contrary, hydrophobic surfaces could potentially facilitate the nucleation of calcium and sulfate ions to form CaSO4 clusters2. Regardless of whether it occurs during the early pre-nucleation or later crystallization stages of CaSO4, the process involves the displacement of the CaSO4 to the hydration layer on the functionalized surfaces. As a result, the competitive interaction strength between water and CaSO4 clusters with the surface plays a critical role in gypsum nucleation on the surface16,18,53. This competitive interaction strength can be quantitively described as the debonding work of CaSO4, which describes the energy necessary to displace water by CaSO4 at the substrate-water interface54:

where Wdebonding_CaSO4, ΔECaSO4/surface, ΔECaSO4/water, ΔEwater/surface, and A represent the debonding work, the interaction energy between CaSO4 and the surface, the interaction energy between CaSO4 and water, the interaction energy between water and the surface, and the contact area of the interface, respectively. The molecular models employed for calculating interaction energies are illustrated in Supplementary Fig. 10. A negative Wdebonding_CaSO4 value suggests a spontaneous debonding process accompanied by energy release, while a positive value suggests the system requires external energy. Consequently, a more negative Wdebonding_CaSO4 value indicates that CaSO4 is more capable of displacing water at the substrate-water interface. The Wdebonding_CaSO4 values for the five substrate-water systems are all negative, which implies that each debonding process occurs spontaneously. The magnitude of debonding work follows a sequence of −hybrid > −COOH > −NH2 > −OH > −CH3 surfaces (Fig. 4A). The outcome of this debonding work on hydrophilic surfaces aligns with earlier cluster analyses and experimental findings. Notably, the debonding work magnitude on the hydrophobic −CH3 surface is the smallest, implying the presence of an alternative nucleation mechanism.

A The debonding work of CaSO4 displacing water from surfaces terminated with different functional groups. B The energy ratios (ER) of between CaSO4 and surfaces terminated with different functional groups. ER is obtained from the adhesion work of the CaSO4-surface interface divided by the debonding work of water. Error bars are derived from the standard deviation of the average values calculated over the last 5 ns.

In addition to debonding work, the energy ratios (ER) of CaSO4-surface interfaces were also calculated to quantify the influence of water layer on CaSO4-surface interfaces54:

where Wadhesion is the adhesion work of the CaSO4-surface interface (Supplementary Fig. 11A), and Wdebonding_water is the debonding work of water (Supplementary Fig. 11B).

A higher ER value indicates that the CaSO4-surface interface is less vulnerable to the water layer. As illustrated in Fig. 4B, the ER value of CaSO4-surface follows a sequence of −hybrid > −COOH > −NH2 ≈ −OH > −CH3 surfaces. This finding indicates that the CaSO4-hybrid surface interface is the least susceptible to the water layer, whereas the CaSO4-CH3 surface interface displays the highest susceptibility. Both the debonding work and ER values collectively indicate that the competitive interaction strength between ions and water with surface groups plays a crucial role in gypsum nucleation on hydrophilic surfaces. Conversely, gypsum nucleation on hydrophobic surfaces may involve an alternative mechanism.

Due to the weak interaction between ions and −CH3 groups, it is presumed that ions in proximity to the surface can move more freely, thereby enhancing the probability of ion collisions that lead to the formation of larger clusters. Consequently, −CH3 and −hybrid surfaces, representing hydrophobic and hydrophilic surface groups, respectively, were selected for comparing the standard deviation (SD) of potential energy at equivalent distances from the surface groups. In general, a greater disparity in potential energy corresponds to a heightened energy barrier that adsorbed ions must overcome when traversing the surface. As illustrated in Fig. 5A, the SD of potential energy for the −CH3 surface indicates a substantially lower energy barrier for ion movement comparing with that of the −hybrid surface, as demonstrated in Supplementary Fig. 12. Moreover, the horizontal self-diffusion coefficient (Dxy) and mean-square displacement (MSDxy) of CaSO4 pairs on −CH3 and −hybrid surfaces were calculated to quantitatively characterize the diffusion capability of surface ions. Specifically, two pairs of CaSO4, initially positioned in close proximity to the surface and submerged in the aqueous solution with an approximate separation of 20 Å between them, were monitored for their diffusion behavior.

A Standard deviation (SD) of potential energy for surfaces terminated with CH3 and hybrid functional groups. The inset is a schematic diagram depicting the potential energy surface. B Horizontal self-diffusion coefficient (Dxy) of CaSO4 pairs on surfaces terminated with CH3 and hybrid functional groups. The inset i and ii are the trajectory lines of two CaSO4 pairs above the surfaces terminated with CH3 and hybrid functional groups, respectively. Each bar in Fig. 5b is the mean ± s.d. (n = 3). C Representative simulation snapshots of CaSO4 clusters on –CH3 and –hybrid surfaces. The ions are colored to distinguish different CaSO4 clusters and the water molecules were removed for clarification. D Ion distribution with the distance along the direction perzpendicular to the surfaces with different functional groups. E Schematic diagram on the calculation of the maximum adhesion force (Fmax) and repulsion distance (DR) of CaSO4 probe. F The maximum attraction force (Fmax) and repulsion distance (DR) of CaSO4 probe approaching to the surface with pre-adsorbed ions.

The horizontal self-diffusion coefficient of the hydrophobic −CH3 surface is significantly greater than that of the hydrophilic hybrid surface, as illustrated in Fig. 5B and Supplementary Fig. 13. This difference indicates a superior ion diffusion capacity on the −CH3 surface and a heightened likelihood for small CaSO4 clusters to expand into larger clusters in a horizontal direction. This observation is further supported by the trajectory lines of two CaSO4 pairs above −CH3 and −hybrid surfaces (the inset figures (i) and (ii) of Fig. 5B). When considering both scenarios, we observe two distinct nucleation pathways for CaSO4 clusters on hydrophobic and hydrophilic surfaces. On hydrophobic surfaces, CaSO4 clusters exhibit a weaker affinity to the surface and tend to aggregate into larger, planar clusters within the bulk solution. Conversely, CaSO4 clusters exhibit a stronger adsorption capacity on hydrophilic surfaces, leading to multisite nucleation. This multisite nucleation encourages ions to form upright clusters oriented vertically to the surface, as illustrated in Fig. 5C. It is worth noting that unstable upright clusters, situated at a single adsorption site, are more susceptible to displacement by dynamic water flow compared to the flat clusters with a larger surface contact area.

In contrast, prior research has demonstrated that ions exhibit a higher affinity for adsorption on hydrophilic surfaces as opposed to hydrophobic ones, potentially resulting in ion enrichment at the interface between the substrate and water52,55,56. Through careful examination of ion distribution along the direction perpendicular to the substrates, we observed a distinctive pattern: on hydrophilic surfaces, the ion count decreases as distance increases, while on the hydrophobic −CH3 surface, the opposite trend emerges (Fig. 5D). This finding suggests that more ions are directly adsorbed on hydrophilic surfaces compared to the hydrophobic −CH3 surface. Nevertheless, when summing the ion count within a distance of less than 25 Å, the cumulative ion number for the hydrophobic −CH3 surface is the largest (Supplementary Fig. 14). This observation provides additional support for the notion that gypsum nucleation on the hydrophobic −CH3 surface primarily takes place through bulk nucleation rather than being induced by ion adsorption.

For hydrophilic and charged surfaces, the adsorption of more counter ions on the surface can promote nucleation1,16,53. However, it has been documented that an excessive net charge can trigger electrostatic repulsion when the interfacial ion concentration reaches extremely high levels57,58. Consequently, an alternative pre-adsorbed ion layer model was constructed. As a representation of hydrophilic surfaces, the −hybrid surface was selected, and an ion layer with varying quantities was deliberately positioned upon it. Subsequently, a small CaSO4 probe containing several calcium and sulfate ions approached the surface from a considerable distance, enabling the computation of the total force exerted by the CaSO4 probe, as illustrated in Fig. 5E. The pre-adsorbed ion layer model, devoid of water molecules, was employed to assess the impact of ion adsorption on the surface deposition dynamics of CaSO4. Notably, the maximum adhesion force of the CaSO4 probe shows a non-monotonic trend as ion concentration increases, first rising and then declining. Considering the attributes of the Lennard-Jones (LJ) potential, it becomes evident that as atoms come into close proximity, the prevailing interaction transitions from attraction (over long distances) to repulsion (at shorter distances). Thus, a repulsion distance was defined to describe the range of the repulsive force. This distance was calculated by subtracting the zero-crossing point of the surface groups’ density profile from the force zero-crossing point of the CaSO4 probe. The repulsion distance expands as the number of ions increases (Fig. 5F). This result suggests that an excess of ions adsorbed on the surface hinders further ion adsorption, thereby shedding light on why gypsum nucleation on hydrophobic surfaces is, to some extent, more pronounced than on hydrophilic surfaces.

The above results identify two nucleation pathways for hydrophilic and hydrophobic surfaces: surface-induced nucleation with vertical growth and bulk nucleation with horizontal growth, as illustrated in Fig. 6. The first pathway is initiated by the adsorption of ions onto surfaces and typically manifests as multisite nucleation. In this process, ion adsorption sites serve as pivotal anchors, facilitating the formation of clusters that grow vertically, and perpendicular to the surface. In contrast, the second pathway unfolds when the interaction between ions and the surface is relatively weak. This permits bulk ions near the surface to collide and fuse into larger clusters. On hydrophobic surfaces, where robust adsorption sites are lacking, clusters tend to expand horizontally, adopting a flat configuration that can subsequently accumulate on the surface.

Discussion

The intricate interplay between gypsum and a foreign surface distinguishes this process from the non-classical nucleation model, which is widely considered the most prevalent mechanism for gypsum nucleation in homogeneous supersaturated solutions15,24,43. For example, a previous study using in situ small-angle X-ray scattering revealed that gypsum nucleation initiates from the aggregation of sub-3 nm primary species or CaSO4 precursor15. Other in situ techniques, including high-resolution transmission electron microscopy (TEM), cryo-TEM, and scanning electron microscopy (SEM), have provided valuable insights into homogeneous nucleation processes15,24,43,59. However, these techniques may face challenges in fully capturing in situ heterogeneous nucleation due to the complex interplay between nuclei and foreign surfaces under hydrated conditions.

Compared to gypsum nucleation in bulk solutions, the interactions between gypsum and surfaces in heterogeneous nucleation render the process more complex and less understood, particularly regarding the relationship between the kinetics and structures of critical gypsum nuclei. Here, we employed in situ microscopic observations to directly investigate gypsum formation under fully hydrated conditions on these surfaces. This approach allows us to observe the well-ordered water molecules around functionalized surfaces, which play a crucial role in influencing the thermodynamics of nucleation and growth, as supported by previous studies60,61. Such a focus on heterogeneous nucleation provides a different perspective from the conditions studied in the aforementioned literature. Our experimental and simulation results corroborate that gypsum nucleation aligns with classical nucleation theory. On hydrophilic surfaces, gypsum nucleation is primarily induced by specific ion adsorption sites (i.e., functional groups). This induction leads to the growth of gypsum crystals oriented vertically. Moreover, variations in the rates of gypsum nucleation on distinct hydrophilic surfaces can be explained through their respective debonding energies. In contrast, hydrophobic surfaces exhibit weak interactions between surface functional groups and gypsum, resulting in bulk nucleation, low potential energy, and rapid self-diffusion in the horizontal direction.

Given that nucleation data can be fitted using CNT even when the pathway is non-classical26, we recognize that fitting our data to CNT does not definitively imply a classical nucleation mechanism. To explore the possibility of an intermediate phase that may arise in non-classical pathways, we conducted surface plasmon resonance microscopy experiments, which allow for the nanoscale spatiotemporal identification of nuclei by accurately measuring the refractive index of individual nuclei without interference from background signals62,63. Since the refractive index of crystalline materials is often higher than that of amorphous or liquid materials64,65, the phase transformation of CaSO4 in the early nucleation process could be identified by this method, which would show a sudden signal change. By tracking the trajectories of CaSO4 formed on the surface, a time-resolved plasmonic image sequence was captured (Supplementary Fig. 15a). Upon nucleation, a typical scattering pattern was clearly observed. As time progressed, the plasmonic intensity increased (Supplementary Fig. 15b), indicating CaSO4 nuclei growth. Notably, the monotonically increasing plasmonic intensity suggests that an abrupt phase transition in CaSO4 is unlikely. Additionally, we calculated the great changes in the RDF of sulfur atom pairs of sulfate with time. To identify the specific structure of the clusters, we compared the RDF diagrams of amorphous phases and the perfect crystal of CaSO4, using ion concentrations within the typical supersaturation range for homogeneous nucleation. As illustrated in Supplementary Fig. 16, the RDF peaks of amorphous calcium sulfate appeared broad and flattened, while the RDF peaks of crystalline calcium sulfate were sharp and well-defined, indicating a degree of long-range order. Simulations performed for the clusters over the period from 0 to 50 ns suggest that the behavior of the clusters was similar to that of a crystal phase. Therefore, no direct evidence of an intermediate phase was observed.

Previous studies observed that the fundamental concepts of classical nucleation theory remain applicable for calcite, iron (hydr)oxide, and ice nucleation on foreign surface13,66,67,68,69. A non-classical nucleation process has also been found in surface-induced nucleation1,2. It is important to note that the preference for nucleation on either hydrophilic or hydrophobic surfaces can vary significantly based on the particular mineral system and experimental conditions in play. Factors such as supersaturation, temperature, the presence of impurities, and the surface functional groups play crucial roles in the nucleation process. Additionally, several simulations have suggested that pathway selection could be modulated by adjusting the interaction between nuclei and the foreign surface13,70. In this work, steady-state nucleation experiments with supersaturated solutions were conducted on different foreign surfaces to ensure the successful application of classical concepts.

Contrary to previously proposed scenarios1,18, we conclude that surface free energy is insufficient for predicting gypsum nucleation on different surfaces. When plotting the surface energy of each substrate against their respective B values (i.e., thermodynamic barriers to nucleation), no robust correlation is observed (Supplementary Fig. 17). Furthermore, surface free energy measurements of hydrophilic surfaces revealed only marginal differences, which contradicted earlier assumptions that surfaces with higher negative charges would result in accelerated nucleation rates10,17,20,22,23.

Revisiting the concept of interfacial free energy (γ) within classical nucleation theory, it signifies the collective energy of the crystal-liquid-substrate system and is presented in Eq. S4 in the Supplementary Note. 2. A large γSC (crystal-substrate) coupled with a small γSL (substrate-liquid) contributes to a high interfacial free energy. Consequently, nucleation rates hinge upon the competition between the energetics involved in gypsum nuclei formation on the substrate and the establishment of a new substrate-nuclei interface, as opposed to the energetics of water displacement near the substrate, where water is attracted. However, it is important to note that the measured surface free energy, as determined by DLVO theory, pertains to the energy associated with the substrate-air interface. In this study, we calculate the debonding work, which quantitatively describes the energy needed to displace water by the CaSO4 cluster on the substrate-water interface. This debonding work aligns well with the observed nucleation rate on hydrophilic surfaces.

This study takes a significant stride in understanding the gypsum nucleation mechanism through a combination of experimental observations and MD simulations. Our findings align with CNT, providing a foundation for a more comprehensive and precise grasp of heterogeneous gypsum nucleation on surfaces, a critical aspect in the effective management of mineral scaling in various industrial processes (e.g., membrane desalination). Nonetheless, it is important to recognize the limitations of our experimental techniques—specifically, the inability to directly observe critical cluster sizes, dissolved clusters, and crystalline structures that remain internally amorphous. It is possible that certain non-classical processes may have evaded our detection. Consequently, deeper exploration into the early stages of gypsum’s complex growth patterns on diverse surfaces, using advanced characterization techniques operating at the sub-nano scale or even smaller, will be more convincible to comprehensively capture these potential alternative pathways.

Methods

Preparation and characterization of functionalized surfaces

Substrates for gypsum nucleation were prepared by first coating silicon wafers with a 5-nm thick titanium (99.995%, Kurt J. Lesker Co., USA) layer followed by coating with an 80-nm gold (99.999%, Kurt J. Lesker Co., USA) layer via a thin film deposition system (EJ1800, Kurt J. Lesker Co., USA). Prior to the functionalization of the substrates, the surfaces were cleaned and activated using the approach developed by Biolin Scientific71. The cleaning process involved the removal of potential organic contaminates on the substrate surfaces by exposing them to UV-ozone for 10 min, and then submerging the surfaces in a 5:1:1 mixture of ultrapure DI water, 25% v/v ammonium hydroxide, and 30% v/v hydrogen peroxide for 15 min at a temperature of 70–75 °C. After cleaning, the substrates were rinsed with ultrapure DI water and dried with nitrogen gas. The cleaned substrates were then immersed in ethanol-based, 1.5 mM solutions of six different alkanethiols from Sigma-Aldrich: 11-mercaptoundecanoic acid, 1-dodecanethiol, sodium 2-mercaptoethanesulfonate, 11-amino-1-undecanethiol, hydrochloride, 11-mercapto-1-undecanol, and a mixture of 11-mercaptoundecanoic acid and 11-amino-1-undecanethiol, hydrochloride. After 24 h, the functionalized substrates were rinsed with ethanol and dried with nitrogen gas.

The affinity of water to the substrate surface was determined by measuring the water contact angle utilizing the sessile-drop method with a goniometer (Attension-Biolin Scientific Inc., USA)9. For each substrate surface, water contact angles were measured at eight different locations on each substrate surface, and the obtained data was analyzed using post processing software (VCA Optima XE, AST Products Inc., USA). Substrate surface chemical composition and valence states were analyzed by X-ray photoelectron spectroscopy (XPS, VersaProbe II, PHI Inc., USA) using monochromatic Al Kα radiation and with a 0.47 eV system resolution. The binding energy was calibrated with C 1 s peaks at 284.8 eV. Peak fitting and data analysis were conducted using Casa-XPS software. Substrate surface roughness was evaluated using atomic force microscopy (Dimension Icon, Bruker Co., USA). Surface scans (5 μm × 5 μm) were probed at 5 random locations on each sample, and the arithmetic mean roughness (Ra) was calculated. Surface plasmon resonance microscopy experiments were conducted on sensing chips modified with a self-assembled monolayer using a commercial inverted microscope (Ti microscope, Nikon, Japan), equipped with a 100× oil-immersion objective lens (NA = 1.49). This setup provides exceptional sensitivity for detecting variations in interface refractive indices, allowing for real-time, label-free detection of dynamic processes in solution63. Illumination was achieved by a 660 nm superluminescent diode to excite surface plasmon resonance62. Plasmonic images were captured by a CCD camera (Pike-032B, Allied Vision Technologies) through a 0.46 × zoom-out lens (Nikon, Japan)62.

Nucleation rate measurements

To isolate the surface-induced heterogeneous nucleation process, experiments were performed under conditions where no homogeneous nucleation in the bulk solution takes place. In these experiments, calcium chloride and sodium sulfate solutions were prepared and transferred into two separate polypropylene 60-mL syringes. The two solutions were mixed at a 1:1 volume ratio and then introduced into a custom-built acrylic glass flow chamber. Inside the flow chamber, the substrate was placed in a space with a diameter of 25 mm and a depth of 1.5 mm. The flow rate was maintained at 30 mL h−1. The experiments were conducted at room temperature (25 °C) at various solution saturation indices, ranging from 0.97 to 1.63 (Supplementary Table 1). The saturation index (σ) is defined as Eq. 3:

where α is the ion activity, as calculated by PHREEQC software (version 3.0)72, and Ksp is solubility product for Ca2+ and SO42− (Ksp = 10−4.58)73.

Gypsum nucleation on the functionalized substrate surface was monitored by optical microscopy (10× objective, Zeiss). We note that the resolution of the optical microscope was insufficient to directly observe the formation of gypsum crystallites on the substrate surface5,18. As a result, the nucleation rates we reported in this study were based on the assumption that each crystal observed from the optical microscope was initiated from a single crystallite and all crystals were formed heterogeneously on the substrate surface. We calculated the nucleation rates based on the following key assumptions:

Each crystal observed optically was originated from a single nucleus. We assume that each nucleus overcame the energy barrier necessary to reach a critical size and subsequently grew into an optically observable crystallite. This assumption is substantiated by the data collected during the intervals when the spacing between crystallites was significantly large (Supplementary Fig. 3 A). During these intervals of steady nucleation, each crystal manifested as a distinct, well-faceted rhombohedrum. Moreover, the linear relationship of crystal appearance over time, as illustrated in Fig. 2 and Supplementary Fig. 4, supports the independence of nucleation events. The absence of such linearity would suggest interdependencies among nucleation events, which was not observed.

Classical nucleation theory

Based on classical nucleation theory, the rate of crystallization on a substrate surface can be described by

where J0 is the steady-state rate of heterogeneous nucleation, A is a kinetic pre-factor, which includes rates of ion attachment, diffusion, and desolvation, kB is the Boltzmann constant, T is the absolute temperature, and ΔG is the free energy barrier to form a critically sized crystal. The latter is defined as

where F is a constant that depends on the crystal shape factor, ω is the molecular volume of gypsum, γ is interfacial energy of the crystal-substrate-liquid system, and σ is the saturation index, defined earlier (Eq. 3).

Substituting Eq. 5 into 4 and rewriting to a linear form yields

where

By determining the slope of ln(J0) vs. 1/σ2, we can obtain B, which is proportional to the substrate-specific thermodynamic barriers to nucleation and is used to estimate gypsum–substrate interfacial free energies, γ.

Molecular dynamics simulations

All molecular simulations were performed using the large-scale atomic/molecular massively parallel simulator (LAMMPS) package74. To accelerate nucleation events within a feasible simulation timescale and minimize computational costs, the simulation was performed at elevated supersaturation levels. The simulation models were constructed by placing a supersaturated calcium sulfate (CaSO4) solution consisting of 9000 water molecules, 75 calcium ions, and 75 sulfate ions above the substrates modified with different functional groups. The size of the simulation box is 5.77 nm × 5.77 nm × 14.56 nm, and the volume of the aqueous solution is about 2.7 × 105 nm3. There is a vacuum slab around 3 nm along the perpendicular direction to the substrate. Once the initial models were constructed, an energy minimization was first performed to minimize the system’s potential energy via the steepest descent algorithm. The simulation systems were then relaxed to simulate the nucleation process of gypsum in the NVT (isothermal-isovolume) ensemble at the temperature of 300 K for 20 ns. The last 5 ns are adopted for the data analysis. The time step for the Velocity-Verlet integration scheme is 1 fs. CHARMM force field75 was used for the substrate, and single point charge/extended (SPC/E) model76 was adopted for the water molecules. In addition, the interactions of calcium, sulfate, sodium, and chloride ions were described by widely used ion force field parameters77,78,79. The interactions among different types of atoms were computed by the Lorentz–Berthelot (LB) mixing rules. The inner and outer cutoff distances were set as 0.8 nm and 1.2 nm. The long-range Coulomb electrostatic interactions were treated by particle-particle-particle mesh (PPPM) algorithm. The OVITO software80 was used for visualization.

Cluster analysis of simulation data

Cluster analysis of the simulation data was based on the simulation snapshots taken at 0.1 ns intervals. We first defined the CaSO4 cluster, which was an aggregation of (Ca)n(SO4)m ions where (m + n) is larger than 2, by the first valley value of the radial distribution function (RDF) profile of Ca-S pairs. As shown in Supplementary Fig. 18, the SO42− and Ca2+ are considered as a CaSO4 cluster when the distance between Ca and S atoms is lower than 4.25 Å. Therefore, the calcium and sulfate ions in the simulation systems can be categorized as cluster ions and free ions. Although there are water molecules bound to ions, only the solute ion-pairs were considered in the cluster analysis. The cluster size is calculated as the total number (n + m) of calcium and sulfate ions in the clusters. At each frame, the cluster number, cluster size, cluster ion number, and free ion number were recorded. The clusters were classified as the clusters near the surface and the clusters in the bulk solution according to their gyration radius and the relative position with surfaces along the Z direction. When the distance between the center of mass (COM) of clusters minus the cluster gyration radius and the surface is less than 15 Å, the clusters are thought to be the clusters near the surface; otherwise, the clusters are in the bulk solution. The position of the boundary line of the surface is determined by identifying the location at which the density of the terminal functional groups reaches half of its peak density.

Data availability

The data supporting the findings of this work are available within the paper and its Supplementary Information files. All other relevant source data are available from the corresponding authors on request. Source data are provided with this paper.

References

Huang, X., Li, C., Zuo, K. & Li, Q. Predominant effect of material surface hydrophobicity on gypsum scale formation. Environ. Sci. Technol. 54, 15395–15404 (2020).

Yin, Y. et al. Which surface is more scaling resistant? A closer look at nucleation theories for heterogeneous gypsum nucleation in aqueous solutions. Environ. Sci. Technol. 56, 16315–16324 (2022).

Demichelis, R., Raiteri, P., Gale, J. D., Quigley, D. & Gebauer, D. Stable prenucleation mineral clusters are liquid-like ionic polymers. Nat. Commun. 2, 590 (2011).

Gebbie, M. A. et al. Experimental measurement of the diamond nucleation landscape reveals classical and nonclassical features. Proc. Natl Acad. Sci. USA 115, 8284–8289 (2018).

Hamm, L. M. et al. Reconciling disparate views of template-directed nucleation through measurement of calcite nucleation kinetics and binding energies. Proc. Natl Acad. Sci. USA 111, 1304 (2014).

Kargozarfard, Z., Haghtalab, A., Ayatollahi, S. & Badizad, M. H. Molecular dynamics simulation of calcium sulfate nucleation in homogeneous and heterogeneous crystallization conditions: an application in water flooding. Ind. Eng. Chem. Res. 59, 22258–22271 (2020).

Li, L. et al. Unraveling nucleation pathway in methane clathrate formation. Proc. Natl Acad. Sci. USA 117, 24701–24708 (2020).

Hoang, T. A., Ang, M. & Rohl, A. L. Effects of process parameters on gypsum scale formation in pipes. Chem. Eng. Technol. 34, 1003–1009 (2011).

Jaramillo, H., Boo, C., Hashmi, S. M. & Elimelech, M. Zwitterionic coating on thin-film composite membranes to delay gypsum scaling in reverse osmosis. J. Membr. Sci. 618, 118568 (2021).

Liu, Y. & Mi, B. Effects of organic macromolecular conditioning on gypsum scaling of forward osmosis membranes. J. Membr. Sci. 450, 153–161 (2014).

Rolf, J. et al. Inorganic scaling in membrane desalination: models, mechanisms, and characterization methods. Environ. Sci. Technol. 56, 7484–7511 (2022).

Haji-Akbari, A. & Debenedetti, P. G. Direct calculation of ice homogeneous nucleation rate for a molecular model of water. Proc. Natl Acad. Sci. USA 112, 10582–10588 (2015).

Li, C., Liu, Z., Goonetilleke, E. C. & Huang, X. Temperature-dependent kinetic pathways of heterogeneous ice nucleation competing between classical and non-classical nucleation. Nat. Commun. 12, 4954 (2021).

Manuel Garcı́a-Ruiz, J. Nucleation of protein crystals. J. Struct. Biol. 142, 22–31 (2003).

Stawski, T. M. et al. Formation of calcium sulfate through the aggregation of sub-3 nanometre primary species. Nat. Commun. 7, 11177 (2016).

Ray, J. R. et al. Hydrophilic, bactericidal nanoheater-enabled reverse osmosis membranes to improve fouling resistance. ACS Appl. Mater. Inter. 7, 11117–11126 (2015).

Cao, B., Ansari, A., Yi, X., Rodrigues, D. F. & Hu, Y. Gypsum scale formation on graphene oxide modified reverse osmosis membrane. J. Membr. Sci. 552, 132–143 (2018).

Giuffre, A. J., Hamm, L. M., Han, N., De Yoreo, J. J. & Dove, P. M. Polysaccharide chemistry regulates kinetics of calcite nucleation through competition of interfacial energies. Proc. Natl Acad. Sci. USA 110, 9261 (2013).

Su, C. et al. Robust superhydrophobic membrane for membrane distillation with excellent scaling resistance. Environ. Sci. Technol. 53, 11801–11809 (2019).

Mi, B. & Elimelech, M. Gypsum scaling and cleaning in forward osmosis: measurements and mechanisms. Environ. Sci. Technol. 44, 2022–2028 (2010).

Shaffer, D. L., Tousley, M. E. & Elimelech, M. Influence of polyamide membrane surface chemistry on gypsum scaling behavior. J. Membr. Sci. 525, 249–256 (2017).

Xie, M. & Gray, S. R. Gypsum scaling in forward osmosis: Role of membrane surface chemistry. J. Membr. Sci. 513, 250–259 (2016).

Wang, J. et al. Enhanced gypsum scaling by organic fouling layer on nanofiltration membrane: Characteristics and mechanisms. Water Res. 91, 203–213 (2016).

Van Driessche, A. E. S. et al. The Role and Implications of Bassanite as a Stable Precursor Phase to Gypsum Precipitation. Science 336, 69–72 (2012).

Saha, A. et al. New insights into the transformation of calcium sulfate hemihydrate to gypsum using time-resolved cryogenic Transmission Electron Microscopy. Langmuir 28, 11182–11187 (2012).

Smeets, P. J. M. et al. A classical view on nonclassical nucleation. Proc. Natl Acad. Sci. 114, E7882–E7890 (2017).

Lutsko, J. F. How crystals form: A theory of nucleation pathways. Sci. Adv. 5, eaav7399.

Wang, J., Li, Y. & Xu, R. First-principles calculations on electronic structure and interfacial stability of Mg/NbB2 heterogeneous nucleation interface. Surf. Sci. 691, 121487 (2020).

Ferrante, F., Prestianni, A., Cortese, R., Schimmenti, R. & Duca, D. Density functional theory investigation on the nucleation of homo- and heteronuclear metal clusters on defective graphene. J. Phys. Chem. C. 120, 12022–12031 (2016).

Byrne, E. H., Raiteri, P. & Gale, J. D. Computational insight into calcium–sulfate ion pair formation. J. Phys. Chem. C. 121, 25956–25966 (2017).

Li, H.-J. et al. Insights into water-mediated ion clustering in aqueous CaSO4 solutions: pre-nucleation cluster characteristics studied by ab initio calculations and molecular dynamics simulations. Phys. Chem. Chem. Phys. 19, 11390–11403 (2017).

Shircliff, R. A. et al. Angle-resolved XPS analysis and characterization of monolayer and multilayer silane films for DNA coupling to silica. Langmuir 29, 4057–4067 (2013).

López, G. P., Castner, D. G. & Ratner, B. D. XPS O 1s binding energies for polymers containing hydroxyl, ether, ketone and ester groups. Surf. Interface Anal. 17, 267–272 (1991).

Kim, N. et al. Surface enhanced Raman scattering artificial nose for high dimensionality fingerprinting. Nat. Commun. 11, 207 (2020).

Hajiraissi, R. et al. Adsorption and fibrillization of islet amyloid polypeptide at self-assembled monolayers studied by QCM-D, AFM, and PM-IRRAS. Langmuir 34, 3517–3524 (2018).

Marmisollé, W. A., Capdevila, D. A., de la Llave, E., Williams, F. J. & Murgida, D. H. Self-assembled monolayers of NH2-terminated thiolates: Order, pKa, and Specific adsorption. Langmuir 29, 5351–5359 (2013).

Devillers, S., Hennart, A., Delhalle, J. & Mekhalif, Z. 1-Dodecanethiol self-assembled monolayers on Cobalt. Langmuir 27, 14849–14860 (2011).

Su, J., Feng, C., Wu, Y. & Liang, J. A novel gold-nanocluster-based fluorescent sensor for detection of sodium 2-mercaptoethanesulfonate. RSC Adv. 9, 18949–18953 (2019).

Kehrer, M. et al. XPS investigation on the reactivity of surface imine groups with TFAA. Plasma Process. Polym. 16, 1800160 (2019).

Kröger, N., Lorenz, S., Brunner, E. & Sumper, M. Self-assembly of highly phosphorylated silaffins and their function in biosilica morphogenesis. Science 298, 584 (2002).

Cha, J. N. et al. Silicatein filaments and subunits from a marine sponge direct the polymerization of silica and silicones <em>in vitro<. emgt. Proc. Natl Acad. Sci. USA 96, 361 (1999).

Aizenberg, J., Black, A. J. & Whitesides, G. M. Control of crystal nucleation by patterned self-assembled monolayers. Nature 398, 495–498 (1999).

Stawski, T. M. et al. The structure of CaSO4 nanorods: the precursor of gypsum. J. Phys. Chem. C. 123, 23151–23158 (2019).

Li, H.-J. et al. Structures and dynamic hydration of CaSO4 clusters in supersaturated solutions: A molecular dynamics simulation study. J. Mol. Liq. 324, 115104 (2021).

Sleutel, M., Lutsko, J., Van Driessche, A. E. S., Durán-Olivencia, M. A. & Maes, D. Observing classical nucleation theory at work by monitoring phase transitions with molecular precision. Nat. Commun. 5, 5598 (2014).

Van Driessche, A. E. S. et al. Nucleation of protein mesocrystals via oriented attachment. Nat. Commun. 12, 3902 (2021).

Sleutel, M. & Van Driessche, A. E. S. Role of clusters in nonclassical nucleation and growth of protein crystals. Proc. Natl Acad. Sci. USA 111, E546–E553 (2014).

Habraken, W. J. E. M. et al. Ion-association complexes unite classical and non-classical theories for the biomimetic nucleation of calcium phosphate. Nat. Commun. 4, 1507 (2013).

De Yoreo, J. J. & Vekilov, P. G. Principles of crystal nucleation and growth. Rev. Mineral. Geochem. 54, 57–93 (2003).

Denton, J. K. et al. Molecular-level origin of the carboxylate head group response to divalent metal ion complexation at the air–water interface. Proc. Natl Acad. Sci. USA 116, 14874–14880 (2019).

Wiechert, A. I. et al. Influence of hydrophilic groups and metal-ion adsorption on polymer-chain conformation of amidoxime-based uranium adsorbents. J. Colloid Interface Sci. 524, 399–408 (2018).

Koleini, M. M., Badizad, M. H., Kargozarfard, Z. & Ayatollahi, S. The impact of salinity on ionic characteristics of thin brine film wetting carbonate minerals: An atomistic insight. Colloids Surf. A Physicochem. Eng. Asp. 571, 27–35 (2019).

Duffy, D. M. & Harding, J. H. Simulation of organic monolayers as templates for the nucleation of calcite crystals. Langmuir 20, 7630–7636 (2004).

Sun, W. & Wang, H. Moisture effect on nanostructure and adhesion energy of asphalt on aggregate surface: A molecular dynamics study. Appl. Surf. Sci. 510, 145435 (2020).

Koleini, M. M., Badizad, M. H., Kargozarfard, Z. & Ayatollahi, S. Interactions between Rock/Brine and Oil/Brine interfaces within thin brine film wetting carbonates: a molecular dynamics simulation study. Energy Fuels 33, 7983–7992 (2019).

Loewenstein, L. M. & Mertens, P. W. Adsorption of metal ions onto hydrophilic silicon surfaces from aqueous solution: Effect of pH. J. Electrochem. Soc. 145, 2841–2847 (1998).

Rathinam, K. et al. Surface-induced silica scaling during brackish water desalination: the role of surface charge and specific chemical groups. Environ. Sci. Technol. 53, 5202–5211 (2019).

Jeon, H., Lee, H., Kang, K. H. & Lim, G. Ion concentration polarization-based continuous separation device using electrical repulsion in the depletion region. Sci. Rep. 3, 3483 (2013).

Du, J. S., Bae, Y. & De Yoreo, J. J. Non-classical crystallization in soft and organic materials. Nat. Rev. Mater. 9, 229–248 (2024).

Navrotsky, A., Mazeina, L. & Majzlan, J. Size-driven structural and thermodynamic complexity in iron oxides. Science 319, 1635–1638 (2008).

Jun, Y.-S., Kim, D. & Neil, C. W. Heterogeneous nucleation and growth of nanoparticles at environmental interfaces. Acc. Chem. Res. 49, 1681–1690 (2016).

Wu, G., Lv, W.-L., Qian, C. & Liu, X.-W. High-throughput identification of single nanoparticles via electrochemically assisted high-resolution plasmonic Scattering Interferometric Microscopy. Nano Lett. 24, 6124–6130 (2024).

Wu, G., Qian, C., Lv, W.-L., Zhao, X. & Liu, X.-W. Dynamic imaging of interfacial electrochemistry on single Ag nanowires by azimuth-modulated plasmonic scattering interferometry. Nat. Commun. 14, 4194 (2023).

Wang, X., Wu, G., Zhou, B. & Shen, J. Optical constants of crystallized TiO2 coatings prepared by sol-gel process. Materials 6, 2819–2830 (2013).

Yao, J. K. et al. High refractive index TiO2 film deposited by electron beam evaporation. Surf. Eng. 25, 257–260 (2009).

Van Driessche, A. E. S. et al. Molecular nucleation mechanisms and control strategies for crystal polymorph selection. Nature 556, 89–94 (2018).

Bai, G., Gao, D., Liu, Z., Zhou, X. & Wang, J. Probing the critical nucleus size for ice formation with graphene oxide nanosheets. Nature 576, 437–441 (2019).

Chou, P.-I. et al. Surface functional groups affect iron (Hydr)oxide heterogeneous nucleation: implications for membrane scaling. Environ. Sci. Technol. 57, 11056–11066 (2023).

Wu, X., Lee, B. & Jun, Y.-S. Interfacial and activation energies of environmentally abundant heterogeneously nucleated Iron(III) (Hydr)oxide on Quartz. Environ. Sci. Technol. 54, 12119–12129 (2020).

Whitelam, S. Control of pathways and yields of protein crystallization through the interplay of nonspecific and specific attractions. Phys. Rev. Lett. 105, 088102 (2010).

Guan, Y. F. et al. Surface functionalization of reverse osmosis membranes with sulfonic groups for simultaneous mitigation of silica scaling and organic fouling. Water Res. 185, 116203 (2020).

Parkhurst, D. L. & Appelo, C. Description of input and examples for PHREEQC version 3—a computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. Us. Geol. Surv. Tech. Methods 6, 497 (2013).

Ball, J. W. & Nordstrom, D. K. in Open-File Report, Edn. Version 2.0 (1991).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

MacKerell, A. D. Jr. et al. All-atom empirical potential for molecular modeling and dynamics studies of proteins. J. Phys. Chem. B 102, 3586–3616 (1998).

Berendsen, H. J. C., Grigera, J. R. & Straatsma, T. P. The missing term in effective pair potentials. J. Phys. Chem. C. 91, 6269–6271 (1987).

Åqvist, J. Ion-water interaction potentials derived from free energy perturbation simulations. J. Phys. Chem. C. 94, 8021–8024 (1990).

Williams, C. D., Burton, N. A., Travis, K. P. & Harding, J. H. The development of a classical force field to determine the selectivity of an aqueous Fe3+-EDA Complex for TcO4- and SO42+. J. Chem. Theory Comput. 10, 3345–3353 (2014).

Smith, D. E. & Dang, L. X. Computer simulations of NaCl association in polarizable water. J. Chem. Phys. 100, 3757–3766 (1994).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2009).

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Award Nos. 52200025 (Y.F.G.), 51821006 (H.Q.Y.), 52192684 (H.Q.Y.), and 12241203 (F.C.W.), and also acknowledged in part by the National Science Foundation through the Engineering Research Center for Nanotechnology-Enabled Water Treatment under Award No. EEC-1449500 (M.E.). F.C.W. acknowledges the Youth Innovation Promotion Association CAS (2020449). This publication was developed under a graduate fellowship awarded to Y.F.G. by the China Scholarship Council (CSC). The numerical calculations in this work were conducted in the Supercomputing Center of University of Science and Technology of China.

Author information

Authors and Affiliations

Contributions

Y.F.G., H.Q.Y., and M.E. designed the research; Y.F.G. performed the research; X.Y.H., F.C.W., and H.A.W. conducted the molecular simulations; Y.F.G., X.Y.H., F.C.W., H.Q.Y., V.K., Z.X.W., and M.E. analyzed the results; and Y.F.G., X.Y.H., W.Y.P., H.Q.Y., and M.E. wrote the paper. All authors contributed to discussion of the results and the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Tomasz Stawski, Haibo Yi and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Guan, YF., Hong, XY., Karanikola, V. et al. Gypsum heterogenous nucleation pathways regulated by surface functional groups and hydrophobicity. Nat Commun 16, 713 (2025). https://doi.org/10.1038/s41467-025-55993-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-55993-w

This article is cited by

-

In situ investigation of the effect of functional groups in polymeric flocculants on the adsorption of kaolin and Pb2+

Colloid and Polymer Science (2025)