Abstract

Flow chemistry has many advantages over batch synthesis of organic small-molecules in terms of environmental compatibility, safety and synthetic efficiency when scale-up is considered. Herein, we report the 10-step chemo-biocatalytic continuous flow asymmetric synthesis of cyproterone acetate (4) in which 10 transformations are combined into a telescoped flow linear sequence from commercially available 4-androstene-3, 17-dione (11). This integrated one-flow synthesis features an engineered 3-ketosteroid-Δ1-dehydrogenase (ReM2)-catalyzed Δ1-dehydrogenation to form the C1, C2-double bond of A ring, a substrate-controlled Co-catalyzed Mukaiyama hydration of 9 to forge the crucial chiral C17α-OH group of D ring with excellent stereoselectivity, and a rapid flow Corey-Chaykovsky cyclopropanation of 7 to build the cyclopropyl core of A ring. By strategic use of these three key reactions and fully continuous-flow operations, cyproterone acetate (4) is produced in an overall yield of 9.6% in 3 h of total reaction time, this is the highest total number of chemical transformation performance in any other continuous-flow synthesis reported to date.

Similar content being viewed by others

Introduction

The 17α-acetoxyprogesterones are a unique group of progesterone steroidal hormones (1-4, Fig. 1) that elicit an unusually diverse array of pharmacological activities and widespread clinical applications1,2,3,4. One exceptional member of this antiandrogen family, cyproterone acetate (CPA, 4), which was developed by Neumann and co-workers at Schering Co. (USA) and was used in clinical practice as antiandrogen in 19645,6,7,8, is the most potent in blocking androgen-acceptor (AR) interaction and reducing serum testosterone through its weak anti-gonadotropic action3,9,10,11. It can be regarded as the only anti-hormone that cause complete androgen blockade as monotherapy and is clinically used for the treatment of advanced cancers of prostate12,13,14,15, metastatic male breast16,17. In addition, this antiandrogen CPA is prescribed in the forensic psychiatric population for sexually inappropriate behaviour, especially for patients with a history of committing a sexual offence18. This potent AR inhibitor is on 55 National Essential Medicines Lists (EMLs)19,20. Structurally, this steroid (4) shares a progesterone skeleton with C1α, C2α cyclopropyl group, C6-chloro, C6, C7-double bond, and C17α-OAc. Owing to the mesmerizing structure coupled with many medical functions, there has been considerable interest of several research groups that have culminated in asymmetric synthesis of 4 and its derivatives by Rudolf (18-step asymmetric synthesis of 4 from solasodine) (Fig. S1)5,8,21,22, Kongkathip (14-step stereoselective synthesis of 16β-chloro (or bromo)-4 from commercially available 16- dehydropregnenolone acetate, 6.5% overall yield) (Fig. S2)23, Manosroi (improved 12-step, 14-step and 16-step synthetic strategies to access 4 from solasodine, 8.8%-13.7% overall yield) (Fig. S3)24,25. Despite the great advances, the overall efficiency of the reported batchwise approaches is not ideal due to high step count (12-18 steps) with concomitant waste generation and safe concerns of tedious manipulation of hazardous materials and/or highly reactive species/intermediates for achieving complex selective transformations for the synthesis of cyproterone acetate 4.

Flow chemistry has many advantages over batch synthesis of organic small molecules in terms of environmental compatibility, safety and synthetic efficiency especially when scale-up is considered26,27,28 and are beginning to have a significant impact throughout chemical community29,30,31,32,33,34. However, its application in manufacturing active pharmaceutical ingredients (APIs) is still scarce due to the complexity involved with operating a multistep continuous reaction sequence. And there are even fewer cases of fully continuous-flow access to steroidal pharmaceuticals35. Undoubtedly, this is due to the poor solubility and complex reactivity in response to diverse reaction conditions. Herein, taking advantages of flow chemistry, we develop a concise and integrated 10-step continuous flow platform to achieve the chemo-biocatalytic asymmetric synthesis of cyproterone acetate (4) starting from 4-androstene-3, 17-dione (4-AD, 11), in which one biotransformation and nine chemical reactions are integrated into a single telescoped process without conducting any intermediate isolation and purification. To the best of our knowledge, this is the shortest synthetic route to this antiandrogen steroid, and the highest total number of chemical transformation performance in any other continuous-flow synthesis reported to date.

Results

The retrosynthetic analysis of cyproterone acetate

Our retrosynthetic analysis of cyproterone acetate (4), as depicted in Fig. 2a, commenced with the recognition that the late-stage 17α-hydroxy-1α, 2α-cyclopropyl-Δ4,6-diene-3, 20-dione 5 would be obtained from 17α-hydroxy-1α, 2α-cyclopropyl-Δ4,6-diene-3-one-20-ketal 6 via a series of chemical transformations including epoxidation and C6α, C7α-oxide opening/chlorination/dehydration/deprotection cascade. The cyclopropyl core structure of the A ring in 6 should be constructed by two distinct tactics from 17α-hydroxy-Δ1,4,6-triene-3-one-20-ketal 7: 1) Catalytic nucleophilic cyclopropanation using nickel carbene (Ni=CH2) species from DCM as methylene source; 2) a Corey-Chaykovsky cyclopropanation utilizing sulfur ylide derived from trimethylsulfoxonium iodide as methylene source, which could be formed by ketalization of the C20-keto group of 17α-hydroxy-Δ1,4-diene-3, 20-dione 8. The crucial chiral C17α-OH functionality of the D ring in 8 would be forged through Co-catalyzed stereocontrolled Mukaiyama hydration of Δ1,4,16-triene-3, 20-dione 9, which might be accessed from androsta-1,4-diene-3, 17-dione 10 by highly selective ethynylation followed by acid-mediated Rupe rearrangement reaction. The C1, C2-double bond of the A ring in 10 could be generated by means of an unpresented engineered 3-ketosteroid-Δ1-dehydrogenase (Δ1-KstD, ReM2)-catalyzed Δ1-dehydrogenation of 4-androstene-3, 17-dione 11, a commercially available product from sitosterol36. Based on this retrosynthetic analysis, we realized the ten-step synthesis of 4 starting from 11 in batch and particularly constructed a fully continuous-flow synthesis platform of 4 through vast effort as described below (Fig. 2b).

a Retrosynthetic analysis of cyproterone acetate (4). b The integrated ten-step continuous-flow asymmetric synthesis of cyproterone acetate (4) in this work. The isolated yield was presented under the arrow at each step. PMS, Phenazine methosulfate; THF Tetrahydrofuran, DCE Dichloroethane, HMPA Hexamethylphosphoramide, TMSOI Trimethylsulfoxonium, m-CPBA m-chloro benzoyl hydroperoxide, DMF N,N-Dimethylformamide, DCM Dichloromethane.

Set up the ReM2-catalyzed Δ1-dehydrogenation of 4-AD in flow

As our studies began, we firstly focused on flow synthesis of 10 from 4-AD (11) in large bulk in China via the biocatalytic Δ1-dehydrogenation (Fig. 2b, S4 and S5). Owing to poor solubility in many organic solvents in the context of steroid chemistry, the requirement to avoid generation of any precipitates needs to be satisfied in processing chain for facilitating fully continuous flow synthesis of targeted molecule 4. Initial solvent screening for this Δ1-dehydrogenation of 11 was conducted to inform continuous reactor selection and enabled a flow proof-of-concept. Following our recent success in the biocatalytic Δ1-dehydrogenation of Δ4-3-ketosteroids into the corresponding Δ1,4-3-ketosteroids by the use of the engineered flavin adenine dinucleotide (FAD)-dependent 3-ketosteroid-Δ1-dehydrogenase (ReM2) in the two-operation flow Autichem-PTFE coil reactor set-up in (+)-boldenone synthesis37. We initiated the exploration of Δ1-dehydrogenation of 10 into 11 in accordance with similar reaction conditions in our reported art (Fig. 3a and Table 1). Our first attempt at the analogous flow Δ1-dehydrogenation reaction proceeded with 45% conversion of 11 when a DMF solution of 11 (1.0 equiv.) and phenazine methosulfate (PMS, 0.1 equiv.) and an aqueous Tris-HCl (50 mM, pH 8.0, DMF/H2O, 1:9) solution of the whole-cell lysate ReM2 (50 mg/mL) were streamed through T-piece mixer into Oscillation agitate reactor I (OAR) at 30 °C with a residence of 15 min and PTFE coil reactor II at same temperature at 45 min residence time (entry 1). A systematic evaluation of residence time (tR1 and tR2) and temperature led to excellent conversion (98%) at 40 °C with a tR1 15 min and tR2 45 min residence time, respectively, affording the desired product 10 in an isolated yield of 88% (entry 7). Further screening solvent showed that DCM, THF and MTBE gave inferior outcome (entries 8-10). Interestingly, when injecting continuously O2 into the reaction mixture, only 0.1 equiv. PMS was required, and residence time was significantly reduced from 60 min to 30 min (compare entry 11 with entry 7). In the meantime, the cost comparative analysis indicated that the total cost of this enzymatic catalysis method for the Δ1-dehydrogenation of 4-AD required about half of that for the traditional chemical oxidation process (Table S1). That suggested the applicability of this method in the field of steroid synthesis.

a The ReM2-catalyzed Δ1-dehydrogenation of 11 into 10 in flow. b The two-step sequential-flow synthesis of 9 via ethynylation/Rupe rearrangement. The reactor I OAR model in a was drawn using AutoCAD. OAR Oscillation agitate reactor, PTFE Polytetrafluoroethylene, DCE Dichloroethane, HMPA Hexamethylphosphoramide, MFC Mass flow controller.

The two-step synthesis of 9 via ethynylation/Rupe rearrangement in flow

Now in possession of requisite 10, our next efforts shifted toward developing two-step flow process38 for Δ1,4,16-triene-3, 20-dione 9 synthesis as shown in Fig. 3b. The strategy in the present reaction sequence was the selective addition of a two-carbon fragment to the C17-keto functionality in 10 via ethynylation39 following by Rupe rearrangement40,41,42. At first, the batch ethynylation reaction between 10 and ethynylmagnesium bromide was investigated and the optimization has been detailed in the Supporting Information (Fig. S6). It was found that this ethynylation worked well at 30 °C in THF to go to completion, generating the desired Δ1,4-diene-3-one-propargylic alcohol 12 in 87% isolated yield (entry 7). Subsequently, we set out to translate the batch-mode protocol to flow-mode regime. However, using the concentration parameters in batch-mode, the flow method caused the precipitation of magnesium salts and resulted in the blocking of PTFE coil reactor and valves. To avoid generation of any precipitation, various combinations of solvent were identified (Fig. S7) and indicated that THF/DCE/HMPA (9:10:1) in all co-solvents tested was optimal for this transformation. At 60 °C, 99% conversion of 10 into 12 was achieved with a residence of 9 min after in-line quenching with 3.0 M aqueous HCl. The resulting solution was directed into a glass gravity separator to carry out in-line liquid-liquid (L/L) separation for working up the product stream and waste water, the exiting flow stream from the first glass column was passed through the stainless-steel column loaded with a (1:1) mixture anhydrous Na2SO4 (dehydrating agent) and SiO2 to remove water and trap the magnesium salts formed during the process. HPLC analysis of the crude mixture indicated that the intermediate 12 displayed sufficiently good purity ( > 95%) to be used in the telescoped process (Fig. S7, entry 11). With an efficient approach to the propargylic alcohol 12, the next step was the integration of steps 2 and 3 into a continuous-flow. This was implemented by connecting reactor III with a T-piece mixer and adding a DCE solution of Eaton′s reagent (MeSO3H·P2O5, 2.0 equiv.) (Figure S8, entry 3) directly to the output of reactor III. A 25 min residence time in coil reactor IV at 80 °C and 3.0 bar back pressure was required for the Rupe rearrangement to reach completion (Figure S9, entry 7). The telescoped two-step process enabled synthesis of 9 in an overall isolated yield of 62% in a total residence time of 90 min with a throughput 0.56 g/h.

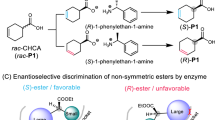

The Co-catalyzed Mukaiyama hydration of 9

With a robust flow approach to accessing Δ1,4,16-triene-3, 20-dione 9 in hand, anothor critical step in the synthesis of 4 was the installization of the chiral C17α-OH group of D ring in 8. An efficient Co(acac)2-catalyzed Mukaiyanma hydration of α, β-unsaturated ketones into α-hydroxyketones using PhSiH3 and O2 in THF followed by P(OEt)3 workup under batch conditions has been documented by Mukaiyama and co-workers as early as 198943. As a proof of principle, we aspired to adapt this elegant strategy to the generation of 8 via a substrate-controlled diastereoselective Co-catalyzed Mukaiyama hydration. At the onset of this studies (Table 2), with Co(acac)2 as the catalyst (3.0 mol%), the Δ1,4,16-triene-3, 20-dione 9 was subjected to Mukaiyama conditions (PhSiH3, O2, THF, r.t.) followed by room temperature reductive treatment by P(OEt)3 to result in the formation of the desired product 8 in 56% with dr > 20:1 (Table 2 entry 1) after in-line evaporation through a tube-in-tube device44(Figure S10 and Table S2). Next, the reaction in the different solvents was examined. It was found that the reaction was very sensitive for the reaction media. When the reaction was performed in MeOH, no expected product was obtained (entry 2). The use of chloride solvent such as DCM and DCE was found to be less effective than THF (compare entries 3 and 4 with entry 1). To our delight, the reaction in EtOH showed best efficiency with regard to the yield of 8 (94%) and excellent diastereoselectivity (dr > 20:1) (entry 5). Taking EtOH as solvent, other Co catalysts including CoCl2, CoBr2, Co(OAc)2 and Co(acac)3 were tested for this transformation, the results revealed the former three did not exhibit any catalytic performances, no hydration product 8 was formed (entries 6-8), whereas the last one gave very poor yield of 24% (entry 9). It is noteworthy that lowering the Co(acac)2 loading to 2.0 mol% could still maintain the outcome of this hydration (entry 10). However, further decrease to 1.0 mol% in the catalyst loading disfavored the reaction to deliver only 88% yield (entry 11).

Having firmly established an efficient method for the installation of C17α-OH in D ring of 8, we further investigated the scope and this asymmetric Mukaiyama hydration on other 16-dehydrosteroid analogues as depicted in Table 2. Under the optimized reaction conditions using Co(acac)2 as the catalyst, a variety of 16-dehydrosteroids proceeded to produce access to the desired skeleton including OH at C21, OAc at C21, C3-keto, C9, 11β- C17α-hydroxyl steroids (8, 8c-8k) in moderate to high yields and in excellent diastereoselectivities (dr > 20:1-99:1). In these steroidal substrates, various functional groups in the steroidal epoxy, as well as several other types of carbon-carbon bonds at C1-C2, C4-C5 and C9-C11 were well-tolerated under the current reaction conditions, thus providing a great opportunity for further functionalization. But the steroidal substrate with hydroxyl group at the C-3 position in A-ring underwent complete conversion to give complex mixtures, which could not be separated or purified by flash column chromatography, and no product 8i was formed. Furthermore, for steroidal substrate possessing C9α, C11β-fluorohydrin functionality, no conversion into 8j was observed, even after being heated to 45 °C for 8 h (Fig. 4a).

With the desire to effect asymmetric Mukaiyama hydration in flow mode, the possibility of performing the hydration of 9 in continuous flow as a discrete operation was next investigated (Fig. 4b). We firstly examined the reaction in EtOH as a single solvent. Pleasingly, a full conversion of 9 was observed with only 10 min residence time at 25 °C under 1.0 mL/min of O2 gas, resulting in the generation of 8 in 80% isolated yield (Figure S11, entry 1). To omitting the DCE evaporation/switch in-line for upstream and downstream reaction telescoping during continuous processing, a mixture of DCE and EtOH (1:1) was used as a co-solvent, the reaction was conducted under the optimized reaction conditions (9.0 mol%, 35 °C, O2 gas, 2.0 bar back-pressure) in 12.5 min, the desired steroid 8 was obtained in 78% isolated yield with > 20:1 dr (entry 8), this result highlighted the advantage of a mild flow protocol for synthesis of 8.

The two-step continuous-flow synthesis of 7 from 8

With the success in highly diastereoselective construction of 8 in flow, we turned our attention to develop a telescoped Δ6-dehydrogenation/ketalization protocol in continuous-flow for the synthesis of 17α-hydroxy-Δ1,4,6-diene-3-one-20-ketal 7. The flow configuration for the two-step sequence is outlined in Fig. 5a. The patented batchwise procedure24 for the preparation of 17α-hydroxy-Δ1,4,6-triene-3, 20-dione 13 via a chemo-regioselective Δ6-dehydrogenation of 8 using chloranil as the oxidant, was firstly considered to be redesigned into a flow process. In the reported work on Δ6-dehydrogenation toward 13, tetra-butanol (t-BuOH) has been shown to be the solvent of choice. Therefore, a solvent switch from t-BuOH used for the Δ6-dehydrogenation to DMF is needed to enable a telescoped process from 8 to 13. To decide whether this solvent wrap is more beneficial to be performed prior to or after the dehydrogenation, some preliminary batch experiments were conducted to evaluate the performance of the reaction in DMF and t-BuOH. Promisingly, a solvent examination in batch revealed that full conversion to 13 was achieved within 3 h at 100 °C in DMF, whereas approximately 10 h were required in t-BuOH at the same temperature. Continuous-flow dehydrogenation experiments were next studied by exploring the independent flow process by starting with purified 8. Our initial attempt to perform the flow dehydrogenation reaction could proceed with an unsatisfied conversion of 8 into 13 (30%, Figure S12, entry 1) when a DMF solution of 8 (51.3 mM, 1.0 equiv.) and a DMF solution of chloranil (123.1 mM, 1.2 equiv.) were streamed into PTFE coil reactor VI through a T-piece mixer at 100 °C with a residence time of 15 min. Following further optimization of temperature and residence time (entries 2-7), a complete conversion of 8 into 13 was implemented at 140 °C with a 4 min residence time (entry 7). The resultant flow stream of 13 exiting reactor VI after in-line work-up (three gravity L/L separations and one evaporation by tube-in-tube device) was then mixed with a premixed DCM solution of ethylene glycol (4.5 equiv.), trimethyl orthoformate (TMOF, 3.9 equiv.) and TsOH (0.1 equiv.) using a T-piece mixer and passed through PTFE coil reactor VII at 40 °C and with the use of 4.0 bar back-pressure. As seen from Figure S13, the ketalization reaction merely resulted in 66% conversion of 13 to 7 in 20 min of residence time (entry 1). A systematic optimization of reaction temperature, residence time and back pressure led to 98% conversion at 90 °C under the above same residence time and back-pressure. Through this two-step flow process, the desired product 7 was produced in 63% overall yield in 110 min of total residence time after in-line quenching with sat. aq. NaHCO3, in-line L/L separation and in-line evaporation. In this two-step flow setup, the synchronization loop coil was used to match the time-scale between gravity L/L separator V and gravity L/L separator VI, ensuring DCM effluent could synchronously enter gravity L/L separator VII.

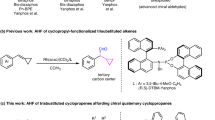

The Nickel-catalyzed nucleophilic cyclopropanation of 7

With working flow route to 7 in hand, we were poised to prepare 17α-hydroxy-1α, 2α-cyclopropyl-Δ4,6-diene-3-one-20-ketal 6 under batch and continuous flow conditions. The touchstone disconnection of our retrosynthetic strategy hinged on the successful stereocontrolled construction of the cyclopropyl subunit in the A ring of 7 to complete the important core. The documented batch Nickel-catalyzed nucleophilic cyclopropanation reactions of electron-deficient alkenes are typically carried out using DCM as a methylene source appeared to be ideally suited to this task, as it has been reported to generate a wide variety of chiral cyclopropane motifs in an efficient fashion dictated by ligand45. We speculated that this methodology might have the capability to promote the nucleophilic cyclopropanation of 7 for the elaboration of cyclopropyl ring and the installation of two contiguous stereocenters in a one step process. Different ligands were investigated for Ni-catalyzed asymmetric nucleophilic cyclopropanation of 7 (Fig. 6b). The box ligand L2 (15 mol%), Ni(dme)Br2 (15 mol%) and Mn (6.0 equiv.) in a 1:10 mixture of DCM and DMA solvents at room temperature for 12 h to give the desired product 6 in 92% isolated yield (Figure S14). Lower to poor efficiencies were observed when the reactions were performed using the other PyBox ligands. Encouraged by our excellent results, we went ahead to show the steroidal scope of the reaction upon finding the optimal reaction conditions, and the results are summarized in Fig. 6a. Moderate to high yield of products (77%-92%) were noticed when a series of steroidal derivatives including androsterol (7a and 7c), androsterones (7b) and progesterones (7d-7h). Unfortunately, the steroidal substrates such as 7i and 7j failed to engage in this catalytic nucleophilic cyclopropanation.

a The steroidal substrate scope of the catalysis. Reaction condition: steroid substrate (1.0 equiv.), Ni(dme)Br2 (15 mol%), (S)-i-prPyBox (L2) (15 mol%), Mn (6.0 equiv.), 1:10 DCM/DMA, r.t., 20 h. Isolated yields were determined after purification by column chromatography. b Evaluation of box ligands for Ni-catalyzed nucleophilic cyclopropanation of 7. Reaction conditions: 7 (0.3 mmol), Ni(dme)Br2 (15 mol%), ligand (15 mol%), Mn (6.0 equiv.), DCM/DMA (1:10), r.t., 20 h. Determinted by LC-MS integration against 7 as an external standard.

Having recognized the potential of this methodology to assemble cyclopropyl motif to steroidal skeleton in batch- mode. We subsequently investigated the flow synthesis of 6 to work towards the goal of a fully multiple reaction sequence in cyproterone acetate synthesis chemistry. To our dismay, after numerous attempted experimentations, no success to this transformation under continuous-flow conditions was achieved, leading us to conclude that this failure would be a difficult reaction to translate continuous flow and therefore an alternative strategy was sought.

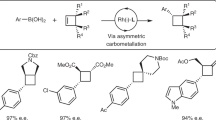

The Corey-Chaykovsky cyclopropanation of 7 in flow

We next proceeded to examine whether the Corey-Chaykovsky cyclopropanation46 would be applicable to the asymmetric synthesis of 6 in flow. As such, the initial Corey-Chaykovsky cyclopropanation investigation and optimization work were conducted between 7 and trimethyl sulfoxide iodide (TMSOI) in batch via a sequential nucleophilic addition/ring-closure mechanisms. It was found that the MeONa promoted the nucleophilic cyclopropanation in full conversion in DMF at room temperature (see Figure S15). Based on the above batch results, the flow Corey-Chaykovsky reactions for 7 was performed by MeONa as a base, and the configuration of the flow reactor used was depicted in Fig. 5b and Table 3. Initial trial was conducted on the purified 7 with TMSOI. The cyclopropanation gave incomplete conversion of 7 into 6 at 25 °C within 10 min residence time (12%, entry 1). After evaluation of another three different temperatures (80, 90 and 100 °C), the reaction at 100 °C gave a superior outcome (98% conversion and 81% isolated yield) (entry 4). Further optimization showed that shortening residence time to 7.5 min from 10 min was not beneficial (entry 5), and increase in temperature gave low isolated yield (71%) albert full consumption of 7 (entry 6).

The telescoped three-step cascade synthesis of 4 in flow

With 17α-hydroxy-1α, 2α-cyclopropyl-Δ4,6-diene-3-one-20-ketal 6 in hand, a telescoped three-step flow protocol38 was then used to execute the synthesis of targeted molecule 4. Prior to further construction of the chloro-Δ6-ene moiety, we focused on forming epoxy unit between C6 and C7. Initial batch approach using m-CPBA oxidation under Kongkathip’s25 conditions (m-CPBA, DCM, r.t., 18 h) delivered smoothly the desired product 17α-hydroxy-6α, 7α-epoxy-1α, 2α-cyclopropyl-Δ4-ene-3-one-20-ketal 14 in 72% isolated yield. The batch conditions were translated to flow, only 39% conversion was observed at room temperature with a residence time of 20 min (Figure S16, entry 1). Pleasingly, the optimized flow epoxidation process led to complete conversion of 6 in a mixed solvent of DCM and DMF (1:1) at 110 °C with a 6.0 bar back-pressure in 20 min residence time, a 72% isolated yield of 14 was obtained (entry 13) after in-line quenching with sat. aq. Na2S2O3 solution, in-line removal of m-chlorobenzoic acid by-product from m-CPBA oxidation with aq. 1% NaOH solution, in-line L/L extraction with DCM, in-line gravity L/L separation and in-line evaporation of DCM using tube-in-tube devices (Figure S17).

Having now established an epoxidation process compatible with the flow mode, the next step in the reaction sequence was the cyproterone 5 (a precursor of 4) formation through a flow epoxide ring-opening/chlorination/dehydration/deprotection cascade of 14. On the basis of reaction conditions known from the previously performed the analogues DMA·HCl-mediated epoxide ring- opening/chlorination/dehydration cascade reaction25 using an improved batch protocol (addition of 1.0 equiv. of 14 to 8.0 equiv. of DMA·HCl in DMF), we attempted the same stoichiometry under a variety of conditions (Figure S18) in a continuous-flow setup as outlined in Figure S19. Initially, the reaction at 120 °C with a 20 min residence time was undertaken. The reaction appeared to have gone to completion with the use of an 8.0 bar back-pressure. LC-MS results indicated that 14 was completely consumed to give the desired 5 and undehydration product chlorohydrin 15 in the proportions of 40% and 60%, respectively (Figure S18, entry 1). However, it was found that raising the reaction temperature to 180 °C and back-pressure to 16.0 bar with a residence time of 35 min led to significantly improved yield to 98% of 5 along with a negligible amount of 15, furnishing 5 in an isolated yield of 67% under otherwise identical conditions (entry 8).

With the flow synthesis of 5 accomplished, the endgame to complete the synthesis of 4 was the selective O-acylation of 17α-OH to form the 17α-OAc. However, incomplete conversion (83%) was observed in early attempts using known batch conditions47 to achieve this transformation (Figure S20, entry 1). Our attention was turned to screen other acylation agents. Attempted acylation of 5 with acetic chloride instead of Ac2O under the above same conditions and acetic acid under conditions developed by Kongkathip25 produced a mixture component only very small quantity of 4 (entries 2 and 3). Alternatively, reaction of 5 with isopropenyl acetate under catalysis of TsOH at room temperature according to the protocol reported by Ahmed48 produced 4 in 80% isolated yield (entry 4). The Amberlyst15 as the catalyst in DCM gave the similar outcome (entry 5). To facilitate adaption to a flow process, the Amberlyst15-mediated acetylation have unequivocally proven to be superior in flow process compared with the TsOH catalytic conditions. We opted for a pack-bed reactor with Amberlyst15 as the packing catalyst. Initial flow tests showed low conversion (21%) of starting material 5 within 15 min residence time at room temperature without a back-pressure regulator (Figure S21, entry 1). Increasing reaction temperature to 40 °C resulted in a moderate conversion (68%, entry 3). An increase in residence time led to significantly improved performances (entries 4 and 5). Gratifyingly, amounts of Amberlyst15 catalyst in this system was augmented to 3.5 gram from 2.5 gram affording the best result to generate the desired product 4 in 75% isolated yield under the reaction conditions of entry 6 in Figure S21.

Next, we sought to telescope the three optimized modules to establish a streamlined three-step flow synthesis of target molecule 4 (Fig. 7). After minor modifications to previously optimized flow conditions from Figure S17, S19 and S22, the telescoped synthesis of 4 was achieved. With this setup, cyproterone acetate (4) was isolated in 35% overall yield with a total residence time of 164 min and a production rate of 127.4 mg/h. The flow system was found to be stable for at least 5 h, demonstrating the stability and robustness of this process over time.

Fully continuous-flow synthesis of cyproterone acetate

With the optimized conditions for each step in hand, we were finally able to complete the 10-step continuous-flow asymmetric synthesis of the target molecule 4 as an integrated process (the whole scheme and live scene please see Supplementary Fig. S23-S26 and Supplementary Movie 1). Androsta-1, 4-diene-3, 17-dione 10 could be continuously obtained from 4-AD using the ReM2 as biocatalyst via the flow Δ1-dehydrogenation in Oscillation agitate reactor (OAR, Shenzhen E-zheng tech Co. China). The resulting DCE solution containing 10 was mixed with DCE/HMPA (9:1) via T-piece mixer and was concentrated by a in-line tube-in-tube concentrator under precise control of temperature and nitrogen flow rate to make the volume ratio of DCE/HMPA to 9:1 for matching the next-step reaction conditions and pumped into a stainless steel column packed with a 1:1 mixture of anhydrous Na2SO4 and SiO2 as dehydrating agent. Then, anhydrous DCE/HMPA solution of 10 and anhydrous THF solution of enthynylmagnesium bromide (0.5 M) were combined at a T-piece mixer and heated at 60 °C in reactor III where the ethynylation took place to genetrate the DCE solution of 12 after in-line quenching with aq. HCl (0.3 M) and in-line seperation by gravity L/L separator II. A solution of Eaton’s reagent (MeSO3H·P2O5) in dry DCE was mixed with the upstream containing 12 and pumped into reactor III at 80 °C for 25 min to carry out Rupe rearrangement, affording the DCE solution of 9 after in-line neutralization with sat. aq. NaHCO3, and passed through a cross-shaped mixer to incorporate with O2 and Co(acac)2/PhSiH3 in EtOH to proceed Mukaiyama hydration in reactor IV at 35 °C for 12.5 min, and subsequently reductive treatment of the flow from reactor V and an EtOH solution of P(OEt)3 in reactor IV at room temperature gave a DCE/EtOH solution of 8, which was transmitted to a series of in-line work-up to switch the solvent to DMF. The resulting DMF solution of 8 was directly connected to the integrated two-step (Δ6-dehydrogenation and ketalization) flow system to provide a DMF solution of 7, and mixed with a DMF solution of TMSOI and MeONa, and subjected to Corey-Chaykovsky cyclopropanation into reactor VIII at 100 °C for 10 min to implement the construction of cyclopropyl unit in the steroidal A ring, in which a telescoped flow work-up system consisting of in-line L/L extraction, in-line L/L separation and in-line tube-in-tube evaporation were employed to produce a clean DCM/DMF stream of 6, which was concatenated into the previously integrated three-step flow sequence in Fig. 7 to continue moving on epoxidation, epoxide opening/chlorination/dehydration/deprotection cascade and O-acetylation, including in-line L/L extraction, in-line L/L separation, in-line tube-in-tube evaporation, in-line match of time-scale by synchronized loop and in-line solvent switch, to complete the asymmetric synthesis of target molecule 4. After in vacuo evaporation of solvent of the output from the 10 steps sequential-flow reaction, Recrystallization of the crude product from EA afforded chemically and optically pure 4 ([α]D20 = 156.4 (c = 1.0, acetone), lit.49: [α]D20 = 152-157 (c = 1.0, acetone)) as a white solid in an overall isolated yield of 9.6% (857 mg) and 99% purity over the 10 steps starting from 4-androstene-3, 17-dione (4-AD).

Discussion

In summary, enabled by flow chemistry, we have successfully achieved the 10-step chemo-biocatalytic asymmetric synthesis of cyproterone acetate (4) in a fully continuous flow-mode from commercially available 4-androstene-3, 17-dione (4-AD, 11) without conducting intermediate separation and purification with a total reaction time of 3 h. Both of the C1, C2-double bond of A-ring and chiral C17α-OH group of D ring were forged in a catalytic manner in flow. To the best of our knowledge, this is the shortest synthetic route towards this important steroid, and the highest total number of chemical transformation performance in any other continuous-flow synthesis reported to date. This technique also showed great advantage over the reported methods for the synthesis of cyproterone acetate in terms of cost and productivity (Table S3). These achievements were benefitted from the attributes of adapting fully multi-step continuous-flow reaction sequence and choosing reagents and solvents that had downstream compatibility and resulted in minimal side-product formation. We believe that such a one-flow-through approach could be readily applied to the synthesis of other APIs and natural products. We have also shown that Ni-catalyzed batch-mode cyclopropanation using DCM as methylene source could offer a strategic insight into designing assembly of disubstituted three-membered ring on A ring in steroids. The swift adoption of these techniques and principles constituted an efficient paradigm for molecular assembly and will certainly have a significant impact throughout synthetic organic chemistry. In particular, this work has a high possibility to be developed into industrial products.

Methods

General procedure for Mukaiyama hydration of 9-9k

A solution of PhSiH3 (0.6 mmol, 2.0 equiv.) in EtOH (500 μL) was added to a solution of 9-9k (0.3 mmol, 1.0 equiv.) and Co(acac)2 (2.0 mol%) in EtOH (500 μL) at 0 °C. Then, the reaction mixture was stirred at 25 °C for 6 h. After complete consumption of the starting substrate 9-9k, then P(OEt)3 (0.3 mmol, 1.0 equiv.) was added, and the mixture was stirred at room temperature for 10 min. The reaction mixture was quenched by the addition of H2O (1.0 mL). The phases were separated, and the aqueous layer was extracted with DCM (3 × 2 mL). The combined organic phases were washed with brine (2 × 2 mL) and dried with Na2SO4. After filtration and removal of the solvents in vacuo the crude product 8-8k was purified by column chromatography (200-300 mesh) on silica gel (PE:EA = 8:1) to afford pure 8-8k. The diastereoselectivities of 8-8c, 8g-8h were determined by 2D NMR analysis, and the diastereoselectivities of 8d-8f were determined by HPLC analysis on a chiral stationary phase (Chiralcel AD-H column).

General procedure for Nickel-catalyzed cyclopropanation of 7a-7j

In a N2-filled glovebox, Ni(dme)Br2 (13.8 mg, 45 μmol, 15 mol%), (S)-i-prPyBox (13.5 mg, 45 μmol, 15 mol%), and Mn (98.9 mg, 1.8 mmol, 6.0 equiv.) were added to a 2-dram reaction vial charged with a magnetic stir bar. A 1.3 mL stock solution containing 7a-7j (0.3 mmol, 1.0 equiv.) dissolved in 1:10 DCM:DMA was then added. The reaction vial was sealed and removed from the glove-box, the reaction mixture was stirred at room temperature for 12 h. An aliquot was taken from the crude mixture, diluted with MeOH, and filtered through a 1.5 cm silica pad. The conversion of starting material was calculated based on LC-MS integration. The reaction mixture was quenched by the addition of H2O (500 μL). The phases were separated, and the aqueous layer was extracted with DCM (3 × 5 mL). The combined organic phases were washed with brine (2 × 5 mL) and dried with Na2SO4. After filtration and removal of the solvents in vacuo, the crude 6a-6j was purified by column chromatography on silica gel (200-300 mesh, PE:EA = 4:1-10:1) to afford pure 6a-6j.

For optimization of the reaction conditions, see Supplementary Fig. S6-S26. For the experimental procedures, spectroscopic and physical data of compounds, see Supplementary Substrate Synthesis and Characterization, Co-catalyzed Mukaiyama Hydration Substrate Scope and Ni-catalyzed Cyclopropanation Substrate Scope. For NMR spectra of synthetic intermediates, see Supplementary NMR Data. For the HPLC analysis spectra of compounds 8 d, 8e and 8 f, see Supplementary Chiral HPLC Data. For the crystal structure of compounds 6, 6 d and 8, see Supplementary X-Ray Diffraction Data.

Data availability

The authors declare that the data supporting the findings within the paper and its Supplementary Information files are available from the corresponding author. The crystallographic data in this work have been deposited at the Cambridge Crystallographic Data Centre under accession code CCDC 2345010 (6), CCDC 2345002 (6 d) and CCDC 2345000 (8). Copies of the data can be obtained free of charge via https://www.ccdc.cam.ac.uk/structures/. The cif files are presented in the Supplementary Data 1. The raw data for Fig. 6b are provided in the Source Data file. The live scene of the running ten-step fully continuous flow synthesis of 4 could be found in the Supplementary Movie 1. Source data are provided with this paper.

References

Laskowski, R. A. et al. Procheck: A program to check the stereochemical quality of protein structures. J. Appl. Crystallogr 26, 283–291 (1993).

Neumann, F. The antiandrogen cyproterone acetate: Discovery, chemistry, basic pharmacology, clinical use and tool in basic research. Exp. Clin. Endocr. Diab 102, 1–32 (1994).

Fruzzetti, F. & Bitzer, J. Review of clinical experience with estradiol in combined oral contraceptives. Contraception 81, 8–15 (2010).

Sahin, Y. & Kelestimur, F. Medical treatment regimens of hirsutism. Reprod. BioMed. Online 8, 538–546 (2004).

Bitzer, J., Römer, T. & Lopes da Silva Filho, A. The use of cyproterone acetate/ethinyl estradiol in hyperandrogenic skin symptoms-a review. Eur. J. Contracep. Repr. 22, 172–182 (2017).

Pucci, E. & Petraglia, F. Treatment of androgen excess in females: Yesterday, today and tomorrow. Gynecol. Endocrinol. 11, 411–433 (1997).

Wolfgang, H., Emanuel, K., Ulrich, K. Process for the manufacture of modified products of 17α-hydrdroxyprogesterone esters. DE1119266B (1961).

Rudolf, W. Chloro-1, 2 alpha-methylene-delta 6-17 alpha hydroxyprogesterone compounds andcompositions. US3234093A6 (1966).

Ormerod, A. D. Handbook of systemic drug treatment in dermatology. Brit. J. Dermatol. 148, 1289–1289 (2003).

Kuhl, H. Pharmacology of estrogens and progestogens: Influence of different routes of administration. Climacteric 8, 3–63 (2005).

Hammerstein, J. Antiandrogens: Clinical aspects//Orfanos, C. E., Happle, R. Hair and Hair Diseases. Berlin, Heidelberg; Springer Berlin Heidelberg 827–886 (1990).

Di Silverio, F. et al. Incidental prostatic carcinoma: Four-year follow-up after treatment with cyproterone acetate. Eur. Urol. 18, 263–266 (2017).

Schröder, F. H. Cyproterone acetate–mechanism of action and clinical effectiveness in prostate cancer treatment. Cancer 72, 3810–3815 (1993).

De Voogt, H. J. The position of cyproterone acetate (CPA), a steroidal anti-androgen, in the treatment of prostate cancer. Prostate 21, 91–95 (1992).

Goldenberg, S. L. & Bruchovsky, N. Use of cyproterone acetate in prostate cancer. Urol. Clin. N. Am. 18, 111–122 (1991).

Kuijpers, S. M. E. et al. Toward a lowest effective dose of cyproterone acetate in trans women: Results from the enigi study. J. Clin. Endocrinol. Metab. 106, e3936–e3945 (2021).

Barradell, L. B. & Faulds, D. Cyproterone. Drug. Aging 5, 59–80 (1994).

Seidenfeld, J. et al. Single-therapy androgen suppression in men with advanced prostate cancer. Ann. Intern. Med. 132, 566–577 (2000).

Laschet, U. & Laschet, L. Antiandrogens in the treatment of sexual deviations of men. J. Steroid Biochem. 6, 821–826 (1975).

Nikolaou, D. & Gilling-Smith, C. Hirsutism. Curr. Obstet. Gynaecol. 15, 174–182 (2005).

Glintborg, D. et al. Management of endocrine disease: Optimal feminizing hormone treatment in transgender people. Eur. J. Endocrinol. 185, R49–R63 (2021).

Ringold, H. J. et al. Steroids. CXXVII. 16-halo progestational agents. J. Am. Chem. Soc. 81, 3485–3486 (1959).

Sakee, U., Kongkathip, N. & Kongkathip, B. The first syntheses of 16β-chloro-and 16β-bromo-cyproterone acetate. Synth. Commun. 33, 1695–1706 (2003).

Manosroi, A. E. Process for the manufacture of unsaturated 6-halogen-3-keto steroids. DE1075114B (1960).

Manosroi, A. et al. Further syntheses of cyproterone acetate. EP1359154A1 (2003).

Perera, D. et al. A platform for automated nanomole-scale reaction screening and micromole-scale synthesis in flow. Science 359, 429–434 (2018).

Kirschning, A. et al. PASSflow syntheses using functionalized monolithic polymer/glass composites in flow-through microreactors. Angew. Chem. Int. Ed. 40, 3995–3998 (2001).

Chatterjee, S. et al. Automated radial synthesis of organic molecules. Nature 579, 379–384 (2020).

Wan, L. et al. Flow chemistry in the multi-step synthesis of natural products. Green. Synth. Catal. 3, 243–258 (2022).

Pastre, J. C., Browne, D. L. & Ley, S. V. Flow chemistry syntheses of natural products. Chem. Soc. Rev. 42, 8849–8869 (2013).

Natho, P. & Luisi, R. Flow chemistry as green technology for the genesis and use of organometallic reagents in the synthesis of key building blocks and APIs-An update. Tetra. Green. Chem. 2, 100015 (2023).

Slattery, A. et al. Automated self-optimization, intensification, and scale-up of photocatalysis in flow. Science 383, eadj1817 (2024).

Porta, R., Benaglia, M. & Puglisi, A. Flow chemistry: Recent developments in the synthesis of pharmaceutical products. Org. Process Res. Dev. 20, 2–25 (2016).

Burange, A. S., Osman, S. M. & Luque, R. Understanding flow chemistry for the production of active pharmaceutical ingredients. iScience 25, 103892 (2022).

Guo, Y. et al. Continuous-flow synthesis of the nucleobase unit of remdesivir. Engineering 21, 92–100 (2023).

Li, X. et al. Efficient conversion of phytosterols into 4-androstene-3, 17-dione and its C1, C2-dehydrogenized and 9α-hydroxylated derivatives by engineered Mycobacteria. Microb. Cell Fact. 20, 158 (2021).

Zhang, Y. et al. Batch and continuous flow asymmetric synthesis of anabolic-androgenic steroids via a single-cell biocatalytic Δ1-dehydrogenation and C17β-carbonyl reduction cascade. Green. Chem. 25, 3223–3235 (2023).

Russell, M. G. & Jamison, T. F. Seven-step continuous flow synthesis of linezolid without intermediate purification. Angew. Chem. Int. Ed. 58, 7678–7681 (2019).

Deng, Q. et al. Generation of ethynyl-grignard reagent in a falling film microreactor: An expeditious flow synthesis of propargylic alcohols and analogues. Adv. Synth. Catal. 356, 2931–2936 (2014).

Nitta, I. et al. The syntheses of the corticoid side chain. III. A new synthesis of 17α, 21-dihydroxypregna-1, 4-diene-3, 20-dione 17, 21-diacetate from androsta-1, 4-diene-3, 17-dione. B. Chem. Soc. Jpn 58, 981–986 (1985).

Wei, J. et al. Divergent chemo- and biocatalytic route to 16β-methylcorticoids: Asymmetric synthesis of betamethasone dipropionate, clobetasol propionate, and beclomethasone dipropionate. Angew. Chem. Int. Ed. 63, e202313952 (2024).

García-Álvarez, J. et al. Novel rhenium (i) catalysts for the isomerization of propargylic alcohols into α, β-unsaturated carbonyl compounds: An unprecedented recyclable catalytic system in ionic liquids. Chem. Commun. 47, 6470–6472 (2011).

Mukaiyama, T. et al. Oxidation-reduction hydration of olefins with molecular oxygen and 2-propanol catalyzed by bis(acetylacetonato)cobalt(II). Chem. Lett. 18, 449–452 (1989).

Deadman, B. J. et al. A prototype device for evaporation in batch and flow chemical processes. Green. Chem. 15, 2050–2055 (2013).

Liu, M., Le, N. & Uyeda, C. Nucleophilic carbenes derived from dichloromethane. Angew. Chem. Int. Ed. 62, e202308913 (2023).

Ebner, C. & Carreira, E. M. Cyclopropanation strategies in recent total syntheses. Chem. Rev. 117, 11651–11679 (2017).

Holt, E. et al. An electrochemical approach to directed fluorination. J. Org. Chem. 88, 2557–2560 (2023).

Ahmed, N. & van Lier, J. E. Molecular iodine in isopropenyl acetate (IPA): A highly efficient catalyst for the acetylation of alcohols, amines and phenols under solvent free conditions. Tetrahedron Lett. 47, 5345–5349 (2006).

Cyproterone acetate, European Pharmacopoeia 11.0, 1094 https://www.drugfuture.com/standard/ (2012).

Acknowledgements

We gratefully acknowledge the financial support from the National Key Research and Development Program (Grant No. 2021YFF0600704 to D.C.), the Major Program of Qingyuan Innovation Laboratory (Grant No. 00122001to F.C.), and the Start-up Fund of Fudan University (Grant No. JIH1615026Yto L.W.).

Author information

Authors and Affiliations

Contributions

F.C. conceived the idea, guided the project. F.C. and Y.Z. wrote the manuscript. Y.Z. made the initial observations and analyzed the results. Y.Z. explored substrate scope and performed derivatizations. Y.Z. and M.L. explored continuous-flow experiments. M.L., X.Z., L G., L.W., and D.C. did experiment assistance and analysis for NMR.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interest.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Y., Liu, M., Zheng, X. et al. Flow chemistry-enabled asymmetric synthesis of cyproterone acetate in a chemo-biocatalytic approach. Nat Commun 16, 1064 (2025). https://doi.org/10.1038/s41467-025-56371-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-56371-2