Abstract

Lithium dendrite penetration through ceramic electrolytes is known to result in mechanical failure and short circuits, which has impeded the commercialization of all-solid-state lithium anode batteries. However, the underlying mechanism still remains under debate, due in part to a lack of in situ atomic-level observations of the dendrite penetration process. Here, we employ molecular dynamics simulations to reproduce the dynamic process of dendrite nucleation and penetration. Our findings reveal that dynamically generated lithium depositions lead to a continuous accumulation of internal stress, culminating in fracture of the solid electrolyte at dendrite tips. We demonstrate that the classical Griffith theory remains effective in assessing this fracture mode, but it is necessary to consider the electrochemical impact of local lithium ion concentration on the fracture toughness. Additionally, in polycrystalline solid electrolytes, we observe that dendrite nuclei within grains typically deflect towards and propagate along grain boundaries. Simulations and experimental evidence both identify that dendrite induced fractures at grain boundaries exhibit a mixed Mode I and Mode II pattern, contingent on their fracture toughness and the angle between dendrites and grain boundaries. These insights deepen our understanding of dendrite penetration mechanisms and may offer valuable guidance for improving the performance of solid electrolytes.

Similar content being viewed by others

Introduction

All-solid-state lithium batteries (ASSLBs) hold great promise for greater energy density, increased reliability, fast charging, and, most importantly, improved operational safety1,2,3,4. However, the commercialization of ASSLBs has been hindered, due in large part to the growth of lithium dendrites5,6,7,8,9,10,11,12. The penetration of dendrites into solid electrolytes (SEs) poses a significant concern, as it can readily result in mechanical failure or fracture of the SEs, risking potentially catastrophic battery failure. It had been originally anticipated that SEs would prevent the dendrites penetration by virtue of their mechanical rigidity. However, recent experiments have demonstrated dendrite formation and growth in SE systems, such as garnets, thiophosphates, and argyrodites, are much easier than in their liquid counterparts13,14. Obviously, the mechanism of dendrite penetration in ASSLBs remains to be clarified.

Recent studies hold two prevailing views on the mechanism of dendrite penetration. In the context of fracture mechanics, one viewpoint insists that stress accumulates within defects during lithium deposition, ultimately surpassing the mechanical strength of SE and resulting in the formation of cracks9,11,12,15,16,17,18,19,20. In return, the newly formed crack provides vacant space for continuous dendrite growth. The alternative argument suggests that dendrite penetration arises from electrochemical degradation, wherein lithium ions are preferentially reduced to lithium metal at grain boundaries and defects. The resultant lithium metal typically forms as isolated deposits away from the electrode surface. These deposits gradually interconnect, culminating in battery failure5,8,21,22,23. Other potential mechanisms, such as stress corrosion24 and dislocation climbing25,26, have also been proposed to explain the penetration behavior. In the absence of detailed and quantitative data, the root cause of penetration is still under debate.

So far, direct observation of the dendrite penetration process into SEs and the concurrent development of cracks during cell operation still face multiple challenges, such as the inability to observe dendrites buried inside SEs, high sensitivity of lithium, complexity of microstructural features and opacity of SEs27,28. Although a number of state-of-the-art in situ and operando techniques have shown promise in addressing some of the challenges12,17,29,30,31, they remain restricted by limitations in spatial and time resolutions. As a complement to experimental characterization, molecular modeling offers the possibility to directly simulate the dendrite mechanisms with atomic and femtosecond resolution32,33,34,35,36.

In this work, we perform large-scale molecular dynamics (MD) simulations to reveal dendrite penetration mechanisms in SEs. Taking Li7La3Zr2O12 (LLZO) as a model SE, we have directly simulated the entire process of lithium-ion deposition, dendrite nucleation, penetration, and eventual cracking. During deposition, stress progressively builds up within the dendrite, resulting in the fracture of the SE—a process influenced by both mechanics and electrochemistry. By accounting for the effect of lithium-ion concentration on fracture toughness, Griffith’s theory proves effective in quantitatively assessing dendrite-induced fractures. Grain boundaries significantly influence dendrite propagation direction and lithium-ion concentration distribution. Combining simulations and experiments indicates that dendrite-induced fracture at grain boundaries displays a mixed Mode I and Mode II fracture pattern. This behavior is determined by the fracture toughness of the grain boundaries and the relative orientation of dendrites.

Results

Dendrite penetration in single-crystal LLZO

Consider a solid-state battery system consisting of a lithium metal anode and a single-crystal LLZO SE featuring a pre-existing defect, such as a crack, a scratch, or a void, aligned parallel to the [100] direction of the LLZO. Previous studies indicate that among various crystal planes, the (100) plane exhibits the lowest energy37,38. To mimic the electrodeposition process in batteries, an electric field of 0.1 V/ Å is applied to drive lithium ions towards the anode where they are reduced to lithium atoms at the anode and SE interface. An energy barrier of 0.05 eV is chosen for the conversion of a single lithium ion to a lithium atom within LLZO. Simultaneously, an equivalent quantity of lithium ions is introduced to the system to ensure overall charge balance (Supplementary Fig. 1). Further details on the interatomic potentials and simulation procedures can be found in the Methods section.

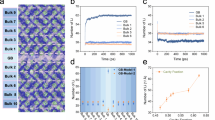

Figure 1a shows the dynamic progression of dendrite penetration in single-crystal LLZO. Initially, the electrodeposition process favors the defect as the nucleation site, leading to a gradual formation of dendrite within the LLZO. Since the pre-existing crack length exceeds that of the dendrite, the crack remains constant in length during t = 0–0.6 ns (Fig. 1b). The continuous deposition of lithium ions facilitates the dendrite’s progressive growth, eventually penetrating the LLZO and initiating crack formation. The dendrite and crack propagation predominantly align with the [100] direction, with sporadic branching along the [−110] direction. Interestingly, a temporary pause of growth for both dendrite and crack occurs between t = 0.65 and 0.75 ns (Fig. 1b and Supplementary Fig. 2), indicating a type of delayed fracture phenomenon. Subsequent lithium deposition leads to a marked acceleration of crack growth after t = 0.95 ns, where the propagation rate surges from 20 to 156 nm/ns, as inferred from the slope in Fig. 1b, suggesting that the energy release rate has surpassed material’s resistance to crack growth, leading to the initiation of unstable propagation. The differential rates of lithium ions deposition and crack propagation cause the dendrite to lag behind the advancing crack tip, a behavior recently captured via in situ X-ray computed tomography9,11.

a Snapshots of the progression of dendrite penetration at specific time intervals: 0, 0.4, 0.9, and 1.2 ns. Yellow and purple particles represent the Li and Zr atoms, respectively. b Temporal variations of dendrite and crack lengths. c Deposition current density and the resultant internal stress within the dendrite. d–g Distribution of lithium ions in single-crystal LLZO during dendrite penetration process. h Trajectories of lithium ions at 0.55 and 0.65 ns, respectively. i Radial distribution function between lithium atom and ion at the dendrite/LLZO interface at 0.55 and 0.65 ns, respectively.

To understand the observed delayed fracture during dendrite penetration, we perform a stress analysis of the dendrite and monitor the temporal deposition of lithium ions, as shown in Fig. 1c. Before t = 0.4 ns, the dendrite grows unrestrictedly, maintaining minimal stress levels internally. A significant gap at the dendrite–LLZO interface initially slows the lithium-ion deposition rate (Supplementary Fig. 3a). Although newly deposited lithium ions start to fill this gap around t = 0.4 ns, minor gaps persist at the interface (Supplementary Fig. 3b). As deposition progresses, the dendrite expands within the confined volume, closing these small gaps and improving interfacial contact (Supplementary Fig. 3c). This enhanced contact decreases interfacial resistance and accelerates lithium-ion deposition39,40, contributing to the rapid accumulation of compressive stress within the dendrite. Once the stress reaches ~10 GPa, a crack is initiated at the initial defect. Following the onset of crack propagation, the stress within the dendrite experiences a slight reduction, stabilizing at around 10 GPa, in line with the observed pause in crack growth in Fig. 1b. This stress level aligns with the internal stresses within dendrites that lead to cracking in nano-sized single-crystal LLZO12. After t = 0.75 ns, the stress rapidly releases, mirroring the rapid progression of crack advance.

We plot the temporal profile of lithium ions concentration in Fig. 1d–g. Initially, the distribution of lithium ions is uniform. Upon charging, lithium ions rapidly migrate toward the dendrite under the strong influence of the applied electric field. It is important to note that the strong electric field not only drives lithium ions deposition but also significantly accelerates lithium ions transport within the electrolyte. The presence of a gap at the dendrite–LLZO interface slows the deposition rate, leading to the accumulation and uneven concentration distribution of lithium ions, as observed at t = 0.1 ns in Fig. 1e. This concentration distribution stabilizes for an extended period, as evidenced by the negligible change between t = 0.1 ns and t = 0.4 ns (Supplementary Fig. 4) until being disturbed after t = 0.6 ns. Enhanced contact increases the deposition rate, reducing lithium concentration and leading to lithium-ion vacancies near the dendrite (Fig. 1f). These vacancies are directly observable in lithium-ion trajectories (Fig. 1h). At the dendrite–LLZO interface, the peak values of the radial distribution functions between lithium atoms and ions exhibit a significant reduction between t = 0.55 and 0.65 ns (Fig. 1i), further confirming the decrease in local lithium-ion concentration near the dendrite. As a result, the dendrite experiences a deficit in lithium-ion replenishment, resulting in the observed delayed fracture. Note that the lithium-ion concentration in most regions within the bulk LLZO ranges from c/c0 = 0.8 to 1.2. The deviation from the stoichiometry of LLZO is a localized and transient result of the dynamic deposition process (see Supplementary Fig. 5). Higher lithium-ion concentrations (c/c0 > 1.2) are observed only at the crack tip and the bottom of the model, as indicated by blue and yellow dashed circles in Supplementary Fig. 6, at t = 0.75 ns. At the crack tip, large tensile stress leads to lithium-ion accumulation, while at the bottom of the model, additional lithium ions are supplied to maintain charge balance as the deposition rate increases. A region of lower lithium-ion concentration (c/c0 < 0.8) occurs near the bottom of the model, marked by the red dashed circle in the Supplementary Fig. 6, where lithium ions are not replenished in time due to a slower diffusion rate near the interface compared to the bulk.

Validity of Griffith theory in assessing LLZO fracture

Numerous studies use Griffith theory to assess crack propagation in brittle SEs such as LLZO12,16,18,19,20. In this context, tensile loading (commonly referred to as Mode I loading in fracture mechanics) is applied perpendicular to the crack surface (Scenario I in Fig. 2a), and the critical stress σc for crack propagation can be calculated as

where Y is a geometrical factor; a is the crack length; \({K}_{IC}\) is the Mode I fracture toughness. Based on the aforementioned analysis, the dendrite-induced crack in the LLZO can be attributed to the accumulation of internal pressure (Scenario II in Fig. 2a), analogous to the crack induced by an expanding screw41. Is the classical Griffith theory still valid in this case?

a Scenarios of dendrite loading and Mode I loading. b Normal stress distribution in the LLZO under dendrite loading (t = 0.6 ns) and Mode I loading. c Calculated critical stresses under dendrite loading (t = 0.6–0.75 ns) and Mode I loading. d Atomic structure of lithium metal inside the dendrite during deposition. e Fraction curves of different crystalline types inside the dendrite. f Schematic representation of the transition process of lithium metal atomic stacking structures, starting from the BCC (left) configuration, moving to the disordered configuration (center), and finally transitioning to the HCP and FCC configurations (right). g Stress distribution inside the dendrite.

To quantitively evaluate the applicability of Griffith theory, we conduct a simulation to analyze the fracture behavior of LLZO under Mode I loading. Figure 2b compares the critical stress states at fracture in LLZO subjected to the two different loadings with the same initial crack length. The stress distribution characteristic at the crack tip under dendrite loading is consistent with that under Mode I loading. Furthermore, LLZO exhibits typical brittle behavior, and the critical stress under Mode I loading aligns with Griffith theory predictions. According to the theory, the critical stress is inversely proportional to the square root of the crack length (indicated by the black line in Fig. 2c). However, the critical stress under dendrite loading exceeds that under Mode I loading (as shown by the blue and red dots in Fig. 2c).

To clarify the observed discrepancy, we analyze the electrodeposition state of lithium metal inside the dendrite. It is known that lithium ions are deposited as amorphous nuclei and then rapidly crystallize, ultimately stabilizing in a body-centered cubic (BCC) lattice structure42. In our simulation, lithium ions are also deposited initially as an amorphous phase, but with a noteworthy distinction: the lithium metal gradually crystallized in a confined space, forming a hybrid structure composed of a face-centered cubic (FCC) and hexagonal close-packed (HCP) arrangement (Fig. 2d–f). Recent studies have indicated that the FCC phase is the ground state structure of lithium metal, and high pressure plays a key role in maintaining the FCC phase. The presence of numerous amorphous phases and grain boundaries (Supplementary Fig. 7) provides multiple pathways for the slip motion of lithium metal, promoting mobility and maintaining uniform pressure inside the dendrite (Fig. 2g). This consistent pressure distribution during deposition satisfies the prerequisite for applying Mode I loading in classical fracture mechanics to assess dendrite loading.

Subsequently, we calculate the fracture toughness of single-crystal LLZO at various lithium-ion concentrations to evaluate the impact of local lithium-ion concentration variations near the dendrite on crack behavior. A decreased lithium ions concentration leads to the formation of additional bridges behind the crack tip (Fig. 3a). The reduced concentration of metal cations results in a relatively higher concentration of oxygen anions, thereby promoting the formation of oxygen bridges where multiple oxygen anions share the same cation (Fig. 3b). These oxygen bridges connect the separated surfaces and hinder further crack propagation, consequently enhancing the fracture toughness of LLZO (ranging from 1.25 to 1.46 MPa·m1/2, in Fig. 3c). Thus, to quantitatively assess the LLZO crack behavior using Griffith theory, it is essential to account for the variations in fracture toughness associated with lithium-ion concentration.

a Atomic structure of single-crystal LLZO under a strain loading of 0.13, with normalized lithium ions concentration of c/c0 = 1 and 0.9, respectively. b Schematic of the transition of fracture from cleavage to bridging due to the decreased Li-ions concentration. c Fracture toughness (KIC) under Mode I loading as a function of normalized lithium ions concentration for single-crystal LLZO. d Progression of dendrite penetration in the single-crystal LLZO.

As a result, the progression of dendrite penetration in single-crystal LLZO can be divided into four stages, as shown in Fig. 3d. Initially, stress accumulates progressively inside the dendrite during deposition (Stage I). Simultaneously, a decrease in lithium-ion concentration occurs, contributing to the SE toughening and resulting in delayed fracture (Stage II). Once sufficient lithium-ion levels are reached, dendrites continue to penetrate into the SE (Stage III). As the crack length extends, the crack experiences unstable growth, causing the dendrites to lag behind the cracks. Finally, dendrite propagates along the crack, traversing the entire SE and resulting in catastrophic failure (Stage IV).

Dendrite penetration in polycrystalline LLZO

To investigate the effect of grain boundaries on the dendrite penetration, we construct a polycrystalline LLZO system featuring ∑5(310) grain boundaries, a configuration commonly observed in experiments43. An initial dendrite orientation inclined at 45° to the grain boundary is selected. Details of the model are described in the Methods section.

Figure 4a shows local snapshots of the dendrite penetration in polycrystalline LLZO at different time points. Initially, the dendrite grows straightforward within the grain, maintaining an angle of 45° with respect to the grain boundary during t = 0–0.1 ns (Fig. 4a). As lithium ions continue to deposit, the dendrite tip deflects significantly (from 45° at t = 0.1 ns to 33° at t = 0.4 ns) as it approaches the grain boundary. At t = 0.8 ns, the angle between the dendrite tip and the grain boundary has reduced to 14°, almost aligning parallel to the grain boundary. Subsequently, the dendrite triggers the initiation of unstable crack growth along the grain boundary (Supplementary Fig. 8). The crack propagation results in the creation of free surfaces between the two adjacent grains, which in return prompts the dendrite penetration. The above observations indicate that even if the initial defects or dendrite nuclei are located in the interior of the grain, they tend to deflect toward the grain boundary and continue to grow along the grain boundary. These phenomena are consistent with experimental observations, wherein dendrite-induced intergranular cracks are commonly noted, whereas transgranular cracks are seldom reported29,30,44,45,46.

a Snapshots of the progression of dendrite penetration in polycrystalline LLZO at specific time intervals: 0, 0.1, 0.4, and 0.8 ns. Yellow and purple particles represent the Li metal and Zr atoms, respectively. b Distribution of lithium ions in polycrystalline LLZO during dendrite penetration. c Normalized potential distribution within polycrystalline LLZO at 0.8 ns. d Normalized potential curve on the white dashed line in (c). e Arrhenius plots of diffusion coefficients in Σ5(310) GB and bulk of LLZO, respectively. f Lithium ions trajectory densities from the MD simulations.

Figure 4b shows the distribution of lithium ions inside the LLZO during the dendrite penetration. Initially, lithium ions exhibit uniform distribution throughout the LLZO, with no noticeable accumulations. As deposition continues, the lithium-ion concentration exhibits a step-like pattern along both sides of the grain boundaries. One side exhibits a low concentration, while the other side features a high concentration. At t = 0.4 ns, the concentrations on both sides of the grain boundary are measured to be 0.5 and 1.7, respectively (marked with the gray circle in Fig. 4b), and this difference in concentration increases over time. The presence of the grain boundary appears to impede the diffusion of lithium ions, giving rise to such distinctive concentration distribution. The distribution of lithium ions at grain boundaries resembles a space charge layer and induces changes in the potential field. To model the potential distribution within the system, we employ the finite element method, using the charge distribution of the system at both t = 0 and 0.8 ns as input conditions. Details of the calculation setup can be found in the Methods section.

The potential distributions within the LLZO at t = 0 and 0.8 ns are shown in Supplementary Fig. 9 and Fig. 4c, respectively. At t = 0.8 ns, a large number of lithium-ion vacancies on one side of the grain boundary exhibits a negative charge, while a significant accumulation of lithium ions on the other side exhibits a positive charge. This gives rise to an internal potential between the two sides, leading to a sharp drop in the potential at the grain boundary (Fig. 4d). This finding is in good agreement with the phenomenon observed in recent experiments, where the Galvani potential drops at grain boundaries near the lithium metal electrode during deposition22. The internal electric field acts in the same direction as lithium ions diffusion, indicating that it does not further hinder diffusion47,48,49. Therefore, the atomic structure at the grain boundaries results in a uniform distribution of lithium ions.

To quantitively analyze the effect of grain boundaries on lithium-ion diffusion kinetics, we calculate the lithium-ion diffusivity (D) of the grain boundaries and bulk phase of the LLZO. Calculation details are described in the Methods section. Figure 4e displays the Arrhenius plots of diffusion coefficients in Σ5(310) grain boundary and the bulk of LLZO, respectively. For bulk LLZO, the calculated lithium-ion diffusivity at 300 K is 8.9 × 10−11 cm2/s, and the activation energy (Ea) is 0.48 eV. However, the lithium diffusivity at the grain boundaries is significantly reduced, ~56 times lower at 1.59 × 10−12 cm2/s (Fig. 4e and Supplementary Fig. 10). In addition, the activation energy (Ea) increases to 0.6 eV, suggesting higher energy barriers for diffusion need to be overcome near the grain boundary. Figure 4f and Supplementary Fig. 11 compare the migration probability density of lithium ions at grain boundaries and in the bulk phase. Lithium ions in the bulk phase exhibit continuous diffusion behavior, while those at the grain boundaries display more pronounced discontinuous diffusion behavior, characterized by a higher proportion of immobile lithium ions. It is noteworthy that, despite the pronounced lithium-ion concentration gradient across grain boundaries, lithium dendrite growth does not clearly lean towards areas of either higher or lower concentration. This implies that lithium-ion concentration is not the main factor determining the growth direction of dendrite-induced crack.

Mixed-mode fracture

We conduct simulations using two incident angles of the dendrite relative to the grain boundary (i.e., θ = 0° and 60°). Further details regarding the model parameters can be found in the Methods section. When the incident angle of the dendrite is parallel to the grain boundary (i.e., θ = 0°), the dendrite traverses along the grain boundary (Fig. 5a, b). The stress distribution map in Fig. 5c obviously shows stress concentration at the crack tip, while the atomic displacement map in Fig. 5d displays a symmetric crack opening pattern. These observations collectively suggest Mode I fracture. Moreover, Li|LLZO|Li symmetric cell is tested from 0.02 mA cm−2 to 0.3 mA cm−2 for 1 h cycle at 25 °C to evaluate the dendrite growth as displayed in Supplementary Fig. 12. It is observed that the cell fails due to a short circuit at 0.15 mA cm−2 after 4.5 h. Hence, the critical current density (CCD) is 0.1 mA cm−2. In addition, a scanning electron microscope (SEM) was used to scan the interface between LLZO and Li metal after an 8 h cycle, as shown in Fig. 5e, f. The uneven deposition of lithium ions leads to dendrite formation at the Li–LLZO interface, which subsequently induces a Mode I crack in LLZO. The magnified image in Fig. 5f clearly shows the direction of crack propagation aligned parallel to the dendrite growth, closely matching our simulation results.

Atomic structures at the initial (a) and during penetration (b) of a dendrite at an incidence angle of 0° to the grain boundary. The polycrystalline model features a ∑5(310) grain boundary. c Normal stress distribution of the polycrystalline LLZO. d Horizontal displacement distribution of the polycrystalline LLZO. Cross-section SEM observations of Mode I fracture in polycrystalline LLZO with 20 µm (e) and 5 µm (f) scales, respectively.

When the incident angle of the dendrite is θ = 60°, the dendrite continues to grow along the grain boundary, but the fracture pattern significantly diverges from the θ = 0° case (Fig. 6a, b). The shear stress distribution map (Fig. 6c) reveals that shear stress is broadly distributed along the grain boundary instead of concentrating at the crack tip. Additionally, the atomic displacement map (Fig. 6d) highlights an asymmetric crack pattern. These two characteristics collectively confirm that the dendrite induced a predominantly Mode II fracture at the grain boundary.

Atomic structures at the initial (a) and during penetration (b) of a dendrite at an incidence angle of 60° to the ∑5(310) grain boundary. c Shear stress distribution in the polycrystalline LLZO. d Vertical displacement distribution of the polycrystalline LLZO. Cross-section SEM observations of peeling of polycrystalline LLZO surface with 50 µm (e) and 10 µm (f) scales, respectively. Simulated atomic structures of the polycrystalline LLZO surface before (g) and after (h) peeling. The surface peeling model was constructed by rotating several grains around a random axis oriented along the [001] direction.

We observed a distinct peeling phenomenon in polycrystalline LLZO, as shown in Fig. 6e, f. The dendrite penetrates the LLZO, causing a deflected crack that ultimately leads to LLZO peeling. This observation provides additional evidence for the presence of Mode II fracture. Molecular simulations are conducted to replicate the dynamic peeling process, as presented in Fig. 6g, h and Supplementary Fig. 13. The dendrite penetration into the polycrystalline LLZO induces the Mode II crack at the grain boundary, resulting in sliding between two adjacent grains and their subsequent peeling from the LLZO.

The observations from Figs. 5 and 6 indicate that dendrite penetration leads to mixed-mode fractures (Mode I and Mode II fractures, as shown in Fig. 7a, b) at the grain boundaries of polycrystalline LLZO. Our calculations of fracture toughness for both the bulk and grain boundaries of LLZO (Fig. 7c) reveal that, in comparison to the bulk, the grain boundaries exhibit markedly lower Mode I and Mode II fracture toughness (\({K}_{Ic}^{GB}\) and \({K}_{IIc}^{GB}\)). Additionally, the \({K}_{IIc}^{GB}\) of the grain boundaries is much smaller than \({K}_{Ic}^{GB}\), estimated as \({K}_{IIc}^{GB}\approx 0.33{K}_{Ic}^{GB}\) at the ∑3(112) grain boundary, indicating the Mode II fracture is more likely to occur at grain boundaries as opposed to the Mode I fracture.

Schematic illustration of the fracture modes with the dendrite-grain boundary angle at 0° (a) and 60° (b). c Mode I and Mode II fracture toughness of the bulk and along the grain boundary. Grain boundaries R1, R2, and R3 are formed by rotating multiple grains around a randomly oriented axis along the [001] direction. d Phase map of dendrite-induced intergranular and transgranular fracture at the grain boundary. \({K}_{Ic}^{gen}\) is calculated based on a grain boundary model where the orientation of the crystal axis and the angle are established entirely randomly through rotation.

To investigate the deflection of dendrites at grain boundaries, we develop an analytical model based on fracture mechanics. In this model, the dendrite is initially inclined at an angle θ to the grain boundary of the SE (Supplementary Fig. 14b). Both the grain and grain boundary are treated as uniform and isotropic materials. Based on our previous findings, the pressure within the dendrite is assumed to be uniform. Detailed derivations of the model are provided in the Methods section. Figure 7d shows the phase diagram of intergranular and transgranular cracks as a function of incidence angle and fracture toughness ratio (ω = \({K}_{IIc}^{GB}/{K}_{Ic}^{gen}\)), derived from the theoretical model. The results indicate that dendrite transgranular growth is confined to a narrow range of parameters (ω > 0.43 and θ > 73°, indicated by the blue region in Fig. 7d). For instance, using the toughness of the R3 grain boundary as a reference, transgranular growth of dendrites is observed only for θ > 78°. Specifically, at the ∑3(112) grain boundary, dendrites grow along the grain boundary at all observed angles. The pronounced reduction in \({K}_{IIc}^{GB}\) significantly increases the likelihood of dendrites deflecting and propagating along grain boundaries. These results are consistent with experimental observations, showing that dendrites seldom penetrate across grain boundaries, rather they predominantly move along them instead29,30,44,45,46. Thus, improving the mechanical properties of grain boundaries and strategically designing and optimizing their pathways are crucial for mitigating and controlling dendrite penetration.

Discussion

We would like to point out that this work focuses on investigating the process of dendrite penetration into SEs and the concurrent development of cracks during cell operation. To facilitate dendrite penetration, a virtual wall is adhered to the LLZO, confining the deposited lithium ions within the defect (Supplementary Fig. 15). As deposition continues, the dendrite gradually expands and ultimately penetrates the SE. This boundary condition setup aligns with scenarios where the inflow rate of lithium atoms into the defect exceeds the outflow rate (Supplementary Fig. 16), particularly under conditions of high current rates, large defect sizes, or significant stack pressure.

In reality, whether dendrites nucleate and penetrate the electrolyte or deposit uniformly is influenced by various factors, such as current density, applied external pressure, and defect size. For example, we remove the virtual wall adhered to the LLZO, allowing lithium atoms to deposit freely. This setup simulates the scenario of a cell without stack pressure. In the absence of external pressure, SEs generally suffer from serious interface contact loss and uneven interfacial contact during repeated lithium plating and stripping, leading to local current concentrations that trigger lithium dendrite growth (Supplementary Fig. 17). As shown in Supplementary Fig. 18, under high pressure, the lithium atoms are pushed back and tend to deposit vertically upwards, aligning with experimental studies50.

In contrast, applying moderate stack pressure can help maintain close interfacial contact during cycling (Supplementary Fig. 19). To simulate this scenario, we reposition the virtual wall to a certain distance above the LLZO to provide downward pressure, allowing the deposited lithium to propagate laterally outside the defect (Supplementary Fig. 20). When the defect size is small, lithium atoms flow out of the defect, resulting in uniform deposition without dendrite formation (Supplementary Fig. 21). However, when the initial defect size is large, dendrites nucleate and continue to grow, even as some lithium atoms flow out (Supplementary Fig. 22). Moreover, the effect of current density on dendrite nucleation is shown in Supplementary Fig. 23. Electric field values ranging from 0.1 to 0.03 V/Å are selected for comparison. A lower current density slows the inflow rate of lithium atoms into the defect, allowing the deposited lithium to gradually propagate laterally outside the defect, thereby promoting uniform deposition. Thus, to prevent dendrite nucleation, several strategies are proposed, such as charging at a low current rate or reducing interfacial defect size through mechanical polishing, applied stack pressure, and surface treatments to improve adhesion.

In addition, our simulation method primarily converts lithium ions to metallic lithium, without considering electron trapping at grain boundaries. This limitation arises from the molecular simulation framework’s inability to adequately account for electron transfer and leakage processes. Therefore, the current MD model cannot adequately describe the electrochemical degradation behavior at grain boundaries. A more comprehensive understanding of the complex mechanisms of lithium plating and stripping requires further analysis through multiscale modeling techniques51,52.

Summary

In summary, large-scale MD simulations are performed to enable direct atomic-scale investigation in the process of dendrite penetration into SEs and the concurrent development of cracks during cell operation. Our findings demonstrate that the fracture process is governed by both mechanical and electrochemical dynamics. Specifically, as lithium ions are deposited, internal stress within the dendrites builds up, eventually causing SE fracture at the dendrite tip. While Griffith’s theory remains applicable for evaluating dendrite-induced fractures in battery systems, it tends to underestimate the critical stress required for fracture. This discrepancy primarily arises from an increase in the SE’s toughness due to the localized reduction in lithium-ion concentration. In polycrystalline SEs, initial defects or dendrite nuclei within the grain often deflect towards and propagate along the grain boundaries. Both simulations and experiments demonstrate fracture at grain boundaries predominantly occurring in a mixed mode. Notably, a decrease in Mode II fracture toughness at grain boundaries is identified as a key factor driving intergranular crack. These findings offer atomic insights into the penetration mechanisms of dendrites and contribute essential knowledge towards improving the performance of SEs.

Methods

Simulations

The atomistic modeling of dendrite penetration in LLZO includes an initial lithium metal dendrite, the LLZO, and the source of lithium ions. We selected a partially formed dendrite as the initial structure to ensure computational efficiency. The interactions among the LLZO atoms are modeled with the Buckingham–Coulomb potential53, which can describe both the short-range nuclear repulsion and long-range Coulombic attraction or repulsion. This potential is also effective in describing the interactions between vacancies54. The interactions between lithium metal atoms are modeled with the second nearest-neighbor embedded MEAM force field55. The UFF force field56 is used to describe the interactions between lithium atoms and LLZO. Details of the force field parameters, along with validations—such as surface energies, elastic parameters, phase change behavior, lattice constants, lithium-ion diffusivity in LLZO, and the interfacial adhesion at the lithium-LLZO interface—are provided in Supplementary Notes 1 and 2. Periodic boundary conditions are applied in x and z directions, and the boundaries are left free in the y direction (Fig.1a). In this work, using the NVT ensemble would have inevitably introduced boundary pressures that could affect the crack behavior of the SE. Therefore, we selected the NPT ensemble to avoid such issues. The size-dependent behavior under the NPT ensemble condition and the validity of the results are discussed in Supplementary Note 3. MD simulations are performed using an NPT ensemble at a constant temperature of 300 K. An electric field of 0.1 VÅ−1 is applied to the system along y direction to accelerate the lithium ions diffusion. In MD simulations of the lithium battery charging process, a weak electric field may fail to provide a sufficient driving force for ion motion, resulting in low computational efficiency. Conversely, an excessively high electric field may separate cations and anions, damaging the material. Our selected electric field value provides an optimal balance between computational efficiency and maintaining structural integrity (Supplementary Note 4). A cutoff radius of 1.75 Å, corresponding to the deposition energy barrier of 0.05 eV, is selected for converting lithium ions into atoms within LLZO. Lithium ions within this radius from lithium metal atoms undergo transformation into metal atoms. This energy barrier closely aligns with the nucleation barrier for lithium plating in Li|LLZO cells57. The relationship between the lithium deposition energy barrier and cutoff radius is illustrated in Supplementary Fig. 32. Simultaneously, an equivalent number of lithium ions are randomly generated in the lithium source region to maintain charge balance within the system. (Supplementary Fig. 1). The LLZO polycrystalline structures with a Σ5(310) grain boundary were constructed, consisting of two LLZO grains with their Zr sub-lattice (310) planes inclined at an angle of 36.9° relative to each other (Supplementary Fig. 33a). In this configuration, some ions nearly overlapped, leading to system energy divergence. To address this, ions positioned less than 0.2 Å apart were removed. The stoichiometry at the grain boundary, calculated as Li8La3.5Zr2O13.2 (Supplementary Fig. 33c), confirms a slight but reasonable segregation at the grain boundary58. Information on the computational models of single-crystal and polycrystalline cases can be found in the Supplementary Figs. 34–37.

To determine the diffusion coefficients (D) for lithium ions in LLZO, we calculate the MSD at five distinct temperatures (700, 750, 800, 850, and 900 K) using the NVT ensemble. The MSD data were collected over a 0.5 ns MD simulation window. The diffusion coefficient calculation is calculated from:

where N and d refer to the total number of lithium ions and the dimensionality (d = 3 in our system) in the system, respectively; t0 is the initial time, and ri(t) represents the displacement of the ith lithium ion at time t. To determine the diffusivity at room temperature, we extrapolated the higher-temperature data collected between 700 and 900 K. Then, the activation energy (Ea) was then calculated by fitting the Arrhenius equation, and the results were plotted in Fig. 4e.

where D0 is the pre-exponential factor, and kB is the Boltzmann constant. We separately calculated the diffusivity in the regions 4 Å away from the grain boundaries and 8 Å away from the grain centers for both grain boundary and bulk. For better illustration, the model and region division are shown in Supplementary Fig. 38.

All MD simulations are conducted using the Large-scale Atomic/Molecular Massively Parallel Simulator package59. The atomic model was constructed using the Atomsk software60. For visualization purposes, atomistic configurations and trajectories were analyzed using Ovito software61. To classify the local structural environments of lithium atoms, we employ the polyhedral template matching method62 with a root-mean-square deviation cutoff of 0.15. To calculate the migration probability density of lithium ions, we utilize the diffusion module of pymatgen63 and further visualize the results using Vesta software64.

Modeling the space charge layer in SEs is a complex challenge. Such modeling requires rigorous prediction of charged point defect concentrations, involving a self-consistent treatment of atomic chemical potentials, ionic electrochemical potentials, electrostatic potentials, and electronic structure. However, this level of detail is beyond the capability of MD simulations. For more comprehensive information on space charge layer modeling and spatial profiles of defect concentrations under open-circuit equilibrium, please refer to work65.

Finite element calculations are conducted using COMSOL Multiphysics 5.5 simulation software. The electric potential distribution in LLZO is determined by solving Poisson’s equation, which can be expressed as:

where \(\varepsilon\) is the relative permittivity, \(\phi\) is the electric potential, and \(\rho\) is the charge density obtained from MD simulations66. The electric field magnitude in the vertical direction is set to be 0.1 V/Å. The grid size used in the simulations is 2–4 Å. The relative permittivity of LLZO is set to be 15267.

Analytical methods

We have developed an analytical model for predicting dendrite penetration in polycrystalline SEs using a plane strain framework. The schematic diagram of the model is shown in Supplementary Fig. 14a. From the preceding discussion, it is evident that there exists uniform pressure within the dendrite, which can be effectively represented as a Mode I loading. In the direction of an angle α with respect to the crack, the fracture toughness factor KI(α) and KII(α) can be computed using the following equation68:

In this equation, KI0 represents the stress intensity factor computed considering the uniform pressure distribution within the dendrite, while C11 and C21 are coefficients determined by the angle α:

When α is non-zero, as depicted by Eq. (6), KII(α) is not equal to zero. This indicates that crack propagation in the α direction is driven by a combination of mode I and mode II stress intensity factors. Given the disparate critical fracture toughness factors for Mode I (KIc) and II (KIIc) fractures in SEs, and drawing from the Tsai–Hill failure criteria69,70, we have adopted the following mixed-mode fracture criterion for polycrystalline SEs:

In the course of lithium ions deposition, the expansion of dendrites, induced by the deposition of fresh lithium metal, results in an ever-increasing KI0. When a dendrite encounters a grain boundary at an angle θ, and if it continues to propagate along its initial trajectory, this can be categorized as transgranular fracture, with α = 0. Substituting the fracture toughness factors for Mode I (\({K}_{Ic}^{bulk}\)) within the grain into Eq. (7), we derive the criterion function for transgranular fracture:

Conversely, if the dendrite propagates along a direction inclined at an angle θ, it is regarded as an intergranular fracture. Substituting the fracture toughness factors for Mode I (\({K}_{Ic}^{GB}\)) and II (\({K}_{{II}c}^{GB}\)) at the grain boundary into Eq. (7), we derive the criterion function for intergranular fracture:

Henceforth, we can establish the following criteria for fracture initiation and crack propagation within a polycrystalline structure:

Experiments

Synthesis

The synthesis of LLZO ceramics used stoichiometric LiOH (Alfa Aesar, 99.995%), La(OH)3, and ZrO2 (Aladdin Reagent, 99.99%), as well as a 10 wt.% excess of LiOH to compensate for volatile Li components. The powder was wet-milled in ethanol for 18 h, followed by drying at 80 °C in a drying oven for 12 h, and then heated in air at 900 °C for 12 h to ensure the formation of cubic LLZO phase. After that, the powders were ball-milled for 12 h again. Following this, the powders were pressed into pellets with a diameter of 10 mm at 500 MPa and sintered in air at 1200 °C for 15 h. During sintering, the pellets were covered with the mother powders and put in a covered magnesium oxide crucible in a tube furnace.

Electrochemical performance test

For electrochemical measurements, the sintered particles were polished with 200, 400, 600, and 1200 grit SiC abrasive paper. The thickness of the pellets was 800–1000 μm. The lithium metal discs were purchased from China Energy Lithium Co., Ltd, with a purity of ≥99.9%, a diameter of 15.6 mm, and a thickness of 1 mm. Li|LLZO|Li symmetric cells were assembled in an argon-filled glove box, and Li metal was attached to both sides of the LLZO and then heated to 180 °C for 1 min on a heating table to enhance the contact at the interface. Then the cells were packaged in 2032-coin cell cases and the edge of the cells was sealed by epoxy resin. CCD cycling test of Li|LLZO|Li symmetric cell was conducted using CT2001A cell test system from Wuhan LAND Electronic Co., Ltd at different current densities (from 0.02 mA cm−2 to 0.3 mA cm−2) for 1 h cycle at 25 °C.

Characterization

SEM observation high voltage is 5 kV using a focused ion beam (FEl Helios NanoLab 600i). To minimize the effects of electron beam irradiation, we controlled the current to 0.17 nA and kept the magnification below 6000×. Additionally, we used backscattered electrons as the imaging signal to enhance the contrast between Li dendrites and LLZO. The all-solid-state symmetric cells were assembled and disassembled in an argon-filled glovebox at 25 °C. After extraction from the coin cells, the LLZO SE was mounted onto the SEM sample holder and transferred in a sealed, argon-filled bag to prevent air exposure. During the transfer process, the sample remained at 25 °C, and its exposure to air was kept below 30 s before being placed into the SEM vacuum chamber.

Data availability

All data generated in this study are available in the manuscript, Supplementary Information, and can also be obtained upon request from the corresponding author. The related data for initial and final MD configurations have been deposited in the Zenodo database, https://doi.org/10.5281/zenodo.14851581. Source data are provided with this paper.

References

Han, X. et al. Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat. Mater. 16, 572–579 (2017).

Janek, J. & Zeier, W. G. A solid future for battery development. Nat. Energy 1, 16141 (2016).

Kato, Y. et al. High-power all-solid-state batteries using sulfide superionic conductors. Nat. Energy 1, 16030 (2016).

Janek, J. & Zeier, W. G. Challenges in speeding up solid-state battery development. Nat. Energy 8, 230–240 (2023).

Han, F. et al. High electronic conductivity as the origin of lithium dendrite formation within solid electrolytes. Nat. Energy 4, 187–196 (2019).

Kazyak, E. et al. Li penetration in ceramic solid electrolytes: operando microscopy analysis of morphology, propagation, and reversibility. Matter 2, 1025–1048 (2020).

Wang, H. et al. Linking the defects to the formation and growth of Li dendrite in all‐solid‐state batteries. Adv. Energy Mater. 11, 2102148 (2021).

Reisecker, V. et al. Effect of pulse-current-based protocols on the lithium dendrite formation and evolution in all-solid-state batteries. Nat. Commun. 14, 2432 (2023).

Ning, Z. et al. Dendrite initiation and propagation in lithium metal solid-state batteries. Nature 618, 287–293 (2023).

Kasemchainan, J. et al. Critical stripping current leads to dendrite formation on plating in lithium anode solid electrolyte cells. Nat. Mater. 18, 1105–1111 (2019).

Ning, Z. et al. Visualizing plating-induced cracking in lithium-anode solid-electrolyte cells. Nat. Mater. 20, 1121–1129 (2021).

Gao, H. et al. Visualizing the failure of solid electrolyte under GPa-level interface stress induced by lithium eruption. Nat. Commun. 13, 5050 (2022).

Cao, D. et al. Lithium dendrite in all-solid-state batteries: growth mechanisms, suppression strategies, and characterizations. Matter 3, 57–94 (2020).

Takada, K. Progress and prospective of solid-state lithium batteries. Acta Mater. 61, 759–770 (2013).

Porz, L. et al. Mechanism of lithium metal penetration through inorganic solid electrolytes. Adv. Energy Mater. 7, 1701003 (2017).

Fincher, C. D. et al. Controlling dendrite propagation in solid-state batteries with engineered stress. Joule 6, 2794–2809 (2022).

Sun, H. et al. In situ visualization of lithium penetration through solid electrolyte and dead lithium dynamics in solid-state lithium metal batteries. ACS Nano 15, 19070–19079 (2021).

Athanasiou, C. E. et al. Operando measurements of dendrite-induced stresses in ceramic electrolytes using photoelasticity. Matter 7, 95–106 (2024).

Klinsmann, M., Hildebrand, F. E., Ganser, M. & McMeeking, R. M. Dendritic cracking in solid electrolytes driven by lithium insertion. J. Power Sources 442, 227226 (2019).

Hao, F., Wang, W. & Mukherjee, P. P. Electrochemical-reaction-driven interfacial stress in a solid-solid layered architecture. Phys. Rev. Appl. 11, 034038 (2019).

Liu, X. et al. Local electronic structure variation resulting in Li ‘filament’ formation within solid electrolytes. Nat. Mater. 20, 1485–1490 (2021).

Zhu, C. et al. Understanding the evolution of lithium dendrites at Li6.25Al0.25La3Zr2O12 grain boundaries via operando microscopy techniques. Nat. Commun. 14, 1300 (2023).

De Jonghe, L. C., Feldman, L. & Beuchele, A. Slow degradation and electron conduction in sodium/beta-aluminas. J. Mater. Sci. 16, 780–786 (1981).

Qi, Y., Ban, C. & Harris, S. J. A new general paradigm for understanding and preventing Li metal penetration through solid electrolytes. Joule 4, 2599–2608 (2020).

Shishvan, S. S., Fleck, N. A., McMeeking, R. M. & Deshpande, V. S. Dendrites as climbing dislocations in ceramic electrolytes: Initiation of growth. J. Power Sources 456, 227989 (2020).

Shishvan, S. S., Fleck, N. A., McMeeking, R. M. & Deshpande, V. S. Growth rate of lithium filaments in ceramic electrolytes. Acta Mater. 196, 444–455 (2020).

Zhang, L. et al. Recent advances in in-situ and operando characterization techniques for Li7La3Zr2O12-based solid-state lithium batteries. Mater Horiz. 10, 1479–1538 (2023).

Yang, S. et al. In situ characterization of lithium-metal anodes. J. Mater. Chem. A 10, 17917–17947 (2022).

Krauskopf, T. et al. Lithium-metal growth kinetics on LLZO garnet-type solid electrolytes. Joule 3, 2030–2049 (2019).

Swamy, T. et al. Lithium metal penetration induced by electrodeposition through solid electrolytes: example in single-crystal li6la3zrtao12garnet. J. Electrochem. Soc. 165, A3648–A3655 (2018).

Peng, X. et al. Unraveling Li growth kinetics in solid electrolytes due to electron beam charging. Sci. Adv. 9, eabq3285 (2023).

Lee, H. G., Kim, S. Y. & Lee, J. S. Dynamic observation of dendrite growth on lithium metal anode during battery charging/discharging cycles. npj Comput. Mater. 8, 103 (2022).

Selis, L. A. & Seminario, J. M. Dendrite formation in Li-metal anodes: an atomistic molecular dynamics study. RSC Adv. 9, 27835–27848 (2019).

Yang, M., Liu, Y. & Mo, Y. Lithium crystallization at solid interfaces. Nat. Commun. 14, 2986 (2023).

Yang, M. & Mo, Y. Interfacial defect of lithium metal in solid‐state batteries. Angew. Chem. Int. Ed. 60, 21494–21501 (2021).

Yang, M., Liu, Y., Nolan, A. M. & Mo, Y. Interfacial atomistic mechanisms of lithium metal stripping and plating in solid‐state batteries. Adv. Mater. 33, 2008081 (2021).

Thompson, T. et al. Electrochemical window of the Li-ion solid electrolyte Li7La3Zr2O12. ACS Energy Lett. 2, 462–468 (2017).

Gao, B., Jalem, R. & Tateyama, Y. Surface-dependent stability of the interface between garnet Li7La3Zr2O12 and the Li metal in the all-solid-state battery from first-principles calculations. ACS Appl. Mater. Interfaces 12, 16350–16358 (2020).

Zhang, X., Wang, Q. J., Harrison, K. L., Roberts, S. A. & Harris, S. J. Pressure-driven interface evolution in solid-state lithium metal batteries. Cell Rep. Phys. Sci. 1, 100012 (2020).

Meyer, A., Xiao, X., Chen, M., Seo, A. & Cheng, Y.-T. A power-law decrease in interfacial resistance between Li7La3Zr2O12 and lithium metal after removing stack pressure. J. Electrochem. Soc. 168, 100522 (2021).

Ye, L. & Li, X. A dynamic stability design strategy for lithium metal solid state batteries. Nature 593, 218–222 (2021).

Wang, X. et al. Glassy Li metal anode for high-performance rechargeable Li batteries. Nat. Mater. 19, 1339–1345 (2020).

Cheng, L. et al. Effect of surface microstructure on electrochemical performance of garnet solid electrolytes. ACS Appl. Mater. Interfaces 7, 2073–2081 (2015).

Ren, Y., Shen, Y., Lin, Y. & Nan, C.-W. Direct observation of lithium dendrites inside garnet-type lithium-ion solid electrolyte. Electrochem. Commun. 57, 27–30 (2015).

Cheng, E. J., Sharafi, A. & Sakamoto, J. Intergranular Li metal propagation through polycrystalline Li6.25Al0.25La3Zr2O12 ceramic electrolyte. Electrochim. Acta 223, 85–91 (2017).

Sudo, R. et al. Interface behavior between garnet-type lithium-conducting solid electrolyte and lithium metal. Solid State Ion. 262, 151–154 (2014).

Wu, J.-F. & Guo, X. Origin of the low grain boundary conductivity in lithium ion conducting perovskites: Li3xLa 0.67−xTiO3. Phys. Chem. Chem. Phys. 19, 5880–5887 (2017).

Sasano, S. et al. Atomistic origin of Li-ion conductivity reduction at (Li3xLa2/3–x) TiO3 grain boundary. Nano Lett. 21, 6282–6288 (2021).

Polczyk, T., Zając, W., Ziąbka, M. & Świerczek, K. Mitigation of grain boundary resistance in La2/3-xLi3xTiO3 perovskite as an electrolyte for solid-state Li-ion batteries. J. Mater. Sci. 56, 2435–2450 (2021).

Kazyak, E. et al. Understanding the electro-chemo-mechanics of Li plating in anode-free solid-state batteries with operando 3D microscopy. Matter 5, 3912–3934 (2022).

Tian, H.-K., Liu, Z., Ji, Y., Chen, L.-Q. & Qi, Y. Interfacial electronic properties dictate Li dendrite growth in solid electrolytes. Chem. Mater. 31, 7351–7359 (2019).

Feng, M., Liu, X., Harris, S. J., Sheldon, B. W. & Qi, Y. A multiscale model to understand the interface chemistry, contacts, and dynamics during lithium stripping. J. Mech. Phys. Solids 193, 105878 (2024).

Klenk, M. J. & Lai, W. Finite-size effects on the molecular dynamics simulation of fast-ion conductors: a case study of lithium garnet oxide Li7La3Zr2O12. Solid State Ion. 289, 143–149 (2016).

Yuan, F., Zhang, Y. & Weber, W. J. Vacancy–vacancy interaction induced oxygen diffusivity enhancement in undoped nonstoichiometric ceria. J. Phys. Chem. C 119, 13153–13159 (2015).

Kim, Y.-M., Jung, I.-H. & Lee, B.-J. Atomistic modeling of pure Li and Mg–Li system. Model. Simul. Mater. Sci. Eng. 20, 035005 (2012).

Rappé, A. K., Casewit, C. J., Colwell, K., Goddard, W. A. III & Skiff, W. M. UFF, a full periodic table force field for molecular mechanics and molecular dynamics simulations. J. Am. Chem. Soc. 114, 10024–10035 (1992).

Yoo, J. Y. et al. Stabilizing Li growth using Li/LLZO composites for high‐performance Li‐metal‐based batteries. Adv. Funct. Mater. 34, 2308103 (2024).

Yu, S. & Siegel, D. J. Grain boundary contributions to Li-ion transport in the solid electrolyte Li7La3Zr2O12 (LLZO). Chem. Mater. 29, 9639–9647 (2017).

Thompson, A. P. et al. LAMMPS—a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 271, 108171 (2022).

Hirel, P. Atomsk: a tool for manipulating and converting atomic data files. Comput. Phys. Commun. 197, 212–219 (2015).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2009).

Larsen, P. M., Schmidt, S. & Schiøtz, J. Robust structural identification via polyhedral template matching. Model. Simul. Mater. Sci. Eng. 24, 055007 (2016).

Ong, S. P. et al. Python Materials Genomics (pymatgen): a robust, open-source Python library for materials analysis. Comput. Mater. Sci. 68, 314–319 (2013).

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272–1276 (2011).

Swift, M. W., Swift, J. W. & Qi, Y. Modeling the electrical double layer at solid-state electrochemical interfaces. Nat. Comput. Sci. 1, 212–220 (2021).

Templeton, J. A., Jones, R. E., Lee, J. W., Zimmerman, J. A. & Wong, B. M. A long-range electric field solver for molecular dynamics based on atomistic-to-continuum modeling. J. Chem. Theory Comput. 7, 1736–1749 (2011).

Loho, C., Djenadic, R., Bruns, M., Clemens, O. & Hahn, H. Garnet-type Li7La3Zr2O12 solid electrolyte thin films grown by CO2-laser assisted CVD for all-solid-state batteries. J. Electrochem. Soc. 164, A6131 (2016).

Anderson, T. L. & Anderson, T. L. Fracture Mechanics: Fundamentals and Applications (CRC Press, 2005).

Hill, R. Theory of mechanical properties of fibre-strengthened materials—III. Self-consistent model. J. Mech. Phys. Solids 13, 189–198 (1965).

Tsai, S. W. Strength theories of filamentary structure. in Fundamental Aspects of Fiber Reinforced Plastic Composites (Interscience Publishers, 1968).

Acknowledgements

Y.L. acknowledges support from the National Natural Science Foundation of China (Grants No. 12372097), the Fundamental Research Funds for the Central Universities (Grant No. HIT.OCEF.2022013), and the Natural Science Foundation of Heilongjiang Province of China (Grants No. YQ2024A005).

Author information

Authors and Affiliations

Contributions

Y.L. and H.G. conceived and supervised the project; B.Z. performed the molecular and FEM simulations; B.Z. and B.Y. performed the visualization of results. X.H. and P.Y. conducted the materials synthesis and characterizations; J.Z. established the analytical model. B.Z. and Y.L. analyzed the data and proposed the mechanisms. Y.L. and B.Z. wrote the first draft of the manuscript with discussion and feedback from X.Y., H.T., and C.W. All authors discussed the results and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Ryo Kobayashi, Seungho Yu, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, B., Yuan, B., Yan, X. et al. Atomic mechanism of lithium dendrite penetration in solid electrolytes. Nat Commun 16, 1906 (2025). https://doi.org/10.1038/s41467-025-57259-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-57259-x

This article is cited by

-

A review on polymer electrolyte materials in context to modifications in PVDF-HFP polymer host

Journal of Solid State Electrochemistry (2025)