Abstract

In this work, the Cu single-atom catalysts (SACs) supported by metal-oxides (Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC) are used as theoretical models to explore the correlations between electronic structures and CO2RR performances. For these catalysts, the electronic metal-support interaction (EMSI) induced by charge transfer between Cu sites and supports subtly modulates the Cu electronic structure to form different highest occupied-orbital. The highest occupied 3dyz orbital of Al2O3-CuSAC enhances the adsorption strength of CO and weakens C-O bonds through 3dyz-π* electron back-donation. This reduces the energy barrier for C-C coupling, thereby promoting multicarbon formation on Al2O3-CuSAC. The highest occupied 3dz2 orbital of TiO2-CuSAC accelerates the H2O activation, and lowers the reaction energy for forming CH4. This over activated H2O, in turn, intensifies competing hydrogen evolution reaction (HER), which hinders the high-selectivity production of CH4 on TiO2-CuSAC. CeO2-CuSAC with highest occupied 3dx2-y2 orbital promotes CO2 activation and its localized electronic state inhibits C-C coupling. The moderate water activity of CeO2-CuSAC facilitates *CO deep hydrogenation without excessively activating HER. Hence, CeO2-CuSAC exhibits the highest CH4 Faradaic efficiency of 70.3% at 400 mA cm−2.

Similar content being viewed by others

Introduction

Renewable energy-driven electrochemical carbon dioxide reduction reaction (CO2RR) is a promising method for achieving carbon cycle and clean production of chemicals1,2. CO2 molecules are deeply reduced on the Cu-based catalyst surface into hydrocarbons and oxygen-containing compounds such as methane (CH4), ethylene (C2H4), ethanol (EtOH), etc., through multiple electron-proton coupled steps of CO2RR3. Although these high value chemicals and high energy density fuels have broad markets, industrial-scale implementation of CO2RR still has a long way to go4. On the one hand, in aqueous media, water (H2O) molecules serve as the proton source for electrochemical reactions, leading to a conflict between CO2RR and hydrogen evolution reaction (HER)5,6,7,8. The proton-electron coupling properties of CO2RR require effective activation of H2O and smooth proton transfer to avoid excessive activation of H2O, otherwise HER would competitively overwhelm CO2RR. On the other hand, deep hydrogenation of adsorbed CO (*CO) and C-C coupling often coexist and compete with each other, resulting in low product selectivity7,9,10,11. The adsorption and coverage of key *CO intermediate on the catalyst surface are crucial in controlling the selectivity of C2 products10,11. Hence, the rational design and controllable synthesis of catalysts based on the deep understanding of reaction mechanism and structure-activity relationship is crucial for precise regulation of the competitive pathways for CO2RR.

Modulating the electronic structure of a catalyst and elucidating its influence over catalytic activity is an effective approach for studying the structure-activity relationships. To modulate Cu electronic structure, research interest has concentrated on alloying12,13, doping engineering14,15, metal-support interaction (MSI) modulation16,17, and so on. In heterogeneous catalysis, MSI significantly affects the catalytic performance as it modulates the electronic and geometric structures of metal as well as coordination environments. The electronic metal-support interaction (EMSI) was further proposed by Campbell, which goes beyond MSI and provides a much more detailed explanation of the enhanced properties of supported catalysts than MSI18,19,20. EMSI is associated with the orbital rehybridization and charge transfer across the metal-support interface, leading to the formation of new chemical bonds and the realignment of molecular energy levels19,20,21. By precisely controlling the d-band structure of metal through EMSI, the adsorption scaling relation can be disrupted to regulate the adsorption of key intermediates. This is crucial for the precise control of CO2RR pathway because protonating to form key intermediates (such as *COOH and *CHO) is difficult on weakly adsorption surface, while over-strengthening of the adsorption energy would favor HER according to the adsorption scaling relation10,22. However, limited by the intrinsic bulk effects, accurately identifying the orbital information of metal particles or clusters still poses challenges in providing design guidance or performance enhancement explanations for supported catalysts20.

The EMSI based on single-atom catalysts (SACs) provides a bridge for theoretical electronic structure studies and the design of heterogenous catalysts because their electronic structure can be easily characterized through experiments and theoretical calculations20,23,24,25. Strong EMSI not only stabilizes the single-atom metals due to the thermodynamically favorable metal-support bond formation, but also leads to the charge redistribution induced via electron transfer, affecting the energy level distribution of the 3 d orbitals of single atoms26,27,28,29,30. For example, Ma et al. reported that the coordination environment of Fe-N5 raises the energy level of Fe 3dz2 orbital compared to that of Fe-N4, thereby enhancing COOH adsorption and promoting *CO desorption26. Therefore, the energy level of Cu 3d state may be manipulated by coordination structural perturbations of the Cu atom30. Although SACs have been widely used for CO2RR, general relationships between electronic structures and the catalytic behaviors of SAC remain unclear. Hence, a comprehensive atomic-level insights into the structure-activity relationship of Cu SAC is urgently needed for guiding the regulation of *CO deep hydrogenation or coupling.

Herein, the Cu SACs supported by Al2O3 (Al2O3-CuSAC), CeO2 (CeO2-CuSAC), and TiO2 (TiO2-CuSAC) are constructed by atomic layer deposition (ALD) technique and the correlations between the characteristics of electronic structures and the CO2RR performance are rationalized through detailed characterization and density functional theory (DFT) calculations. The switching of supports subtly modulates the electronic structure of Cu sites to form three SACs with completely different highest occupied orbitals (3dyz orbital for Al2O3-CuSAC, 3dx2-y2 orbital for CeO2-CuSAC, and 3dz2 orbital for TiO2-CuSAC). The 3dyz of Al2O3-CuSAC tends to interact with the π* anti-bonding orbital of CO, which enhance CO adsorption on Al2O3-CuSAC and weaken the C-O bonds through 3dyz-π* electron back-donation. Meanwhile, the Cu electron delocalization increases the CO adjacent-adsorption energies on Al2O3-CuSAC. These enhance the C-C coupling on Al2O3-CuSAC, resulting in a lowest ratio of CH4 Faradaic efficiency (FE) to C2 FE (FECH4/FEC2, 1.08). The 3dz2 of TiO2-CuSAC exhibits strong hybridization with the σ bonding and σ* anti-bonding orbitals of H2O, which enhances the adsorption of H2O and promotes H2O dissociation by weakening O-H bonds. Therefore, TiO2-CuSAC exhibits a highest FECH4/FEC2 of 4.14. However, this over activated H2O, in turn, intensifies competing HER, which hinders the high-selectivity production of CH4 on TiO2-CuSAC. The 3dx2-y2 orbital effectively promotes CO2 activation and its localized Cu electronic state inhibits C-C coupling. This makes CeO2-CuSAC exhibit a FECH4/FEC2 of 3.16. Meanwhile, the moderate water activity of CeO2-CuSAC facilitates *CO deep hydrogenation without excessively activating HER, resulting in the highest CH4 FE of 70.3% at 400 mA cm−2.

Results

Theoretical analysis of electronic structure

To explore the structure-activity relationship of Cu single-atom electronic structure in selective *CO deep hydrogenation or coupling, theoretical analysis based on DFT + U calculations was conducted. By loading Cu single atoms on Al2O3, CeO2, and TiO2 supports to modulate the electronic structure of Cu single-atom (Supplementary Fig. 1 and Supplementary data 1), named as Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC. As shown in Supplementary Fig. 2, the partial density of states (PDOS) of Cu 3 d orbitals of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC surfaces are calculated, and the respective energy levels of 3 dxy, 3 dx2-y2, 3dyz, 3dxz, and 3dz2 are plotted based on their d-band center (Fig. 1a)30. Instead of forming a broad d-band, each 3d state is spatially highly localized with a narrow energy window. On Al2O3-CuSAC, the 3dyz is the highest occupied-orbital; on CeO2-CuSAC, the 3dx2-y2 is the highest occupied-orbital; while on TiO2-CuSAC, the 3dz2 is the highest occupied-orbital. Clearly, changing the support can significantly affect the highest occupied-orbital of the Cu single-atom due to the orbital rehybridization and charge transfer across the metal-support interface (Supplementary Fig. 3)21. Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC each present Cu single-atoms with three completely different highest occupied-orbitals. The highest occupied d-orbitals often play an important role in regulating the binding modes of intermediates because the electrons filled on the orbital closer to the Fermi level (Ef) are more active27. From the orbital wave functions, it can be observed that the 3dyz orbital (localize in Z axis) symmetry and energy-match with the π* orbital of CO, facilitating the formation of 3dyz-π* bonds (Fig. 1b). The 3dz2 orbital symmetry and energy-match with the σ orbital of CO as well as σ/σ* orbital of H2O, thereby aiding in the formation of dz2-σ/σ* bonds (Fig. 1b and Supplementary Fig. 4). The 3dx2-y2 orbital symmetry and energy-match with the π* orbitals of CO2, promoting the formation of 3dx2-y2-π* bonds.

a The Cu 3 d diagrams of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC, respectively. b The binding modes of CO and H2O interacting with Cu site. c The Cu 3 d PDOS of Al2O3-CuSAC with adsorbed CO and H2O, as well as PDOS of CO and H2O orbitals after adsorbed (The inset is an enlarged view of the dashed line in c). The COHP curves of Cu−C bonds and Cu-O bonds in d Al2O3-CuSAC and e TiO2-CuSAC. f Free energy diagram for the dissociation of *H2O. g The ELF of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC. h Schematic diagram of CO adjacent-adsorption on Al2O3-CuSAC surface. i The CO adsorption energy of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC. Relevant source data are provided as a Source Data file.

Figure 1c and Supplementary Figs. 5, 6 show the PDOS of CO and H2O molecular frontier orbitals as well as the PDOS of CO and H2O adsorption on Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC surfaces. The PDOS proves that the strong hybridization between CO and Cu atom mainly contributes from the 3dyz and 3dz2 orbital, and the hybridization between H2O and Cu mainly contributes from the 3dz2 orbital. The hybridization of the Cu 3d orbital with the CO σ is primarily contributed by the 3dz2 orbital, while the contribution to the CO π* is mainly from the 3dyz orbital. This aligns with the analysis of the orbital wave functions. On Al2O3-CuSAC, the 3dz2 orbital of Cu hybridize with σ orbital of CO, while stronger hybridization occurs between the highest occupied 3dyz orbital and π* orbital of CO than that of CeO2-CuSAC and TiO2-CuSAC31. The d-band center of 3dyz (−0.26 eV) on Al2O3-CuSAC are closer to the Ef than that on CeO2-CuSAC (−0.50 eV) and TiO2-CuSAC (−0.64 eV), making more active electrons in 3 dyz easily back-donate to the π* of CO as formation of Cu-CO bonds29,32. Moreover, due to anti-bonding feature of the π* orbital, the 3dyz-π* bonding will weaken C-O bonds in *CO, which can facilitate the subsequent reactions of *CO (hydrogenation or coupling)29,32. In contrast, the highest occupied 3dz2 orbital of TiO2-CuSAC exhibits strong hybridization with the σ orbital of CO, while the hybridization between 3dyz and π* is lower than that of Al2O3-CuSAC (Supplementary Fig. 6a). Due to the bonding and anti-bonding orbitals of H2O is σ and σ*, the hybridization between Cu 3d and H2O on TiO2-CuSAC are remarkably stronger than that on Al2O3-CuSAC and CeO2-CuSAC (Fig. 1c and Supplementary Fig. 6b, d), leading to an enhanced ability for TiO2-CuSAC to adsorb H2O. In addition, the interaction between the dz2 orbital and the anti-bonding σ* orbital weakens the O-H bonds, thereby promoting the dissociation of H2O. On CeO2-CuSAC, the highest occupied 3dx2-y2 orbital tends to couple with the lowest π* orbital of CO2 (Supplementary Fig. 7), weakening C-O bonds and favoring hydrogenation on the low-coordinate O atom to form the crucial *COOH intermediate, thereby promoting the activation of CO2 to form *COOH27,33.

The CO adsorption energies of Cu single-atom on these three supports follows the order Al2O3-CuSAC (−1.22 eV) > CeO2-CuSAC (−0.74 eV) > TiO2-CuSAC (−0.46 eV), consistent with the energy level arrangement of the 3dyz orbital (Supplementary Fig. 8 and Fig. 1a). The H2O adsorption energies are strongly related to the position of the 3dz2 orbital energy level, showing the order TiO2-CuSAC (−0.89 eV) > Al2O3-CuSAC (−0.30 eV) > CeO2-CuSAC (−0.16 eV). The crystal orbital Hamilton population (COHP) was further used to analyze the Cu-C bond strength in Cu-CO and the Cu-O bond strength in Cu-H2O (Fig. 1d, e and Supplementary Fig. 9)34. On Al2O3-CuSAC, the Cu single-atom exhibits the strongest Cu-C bonding with an integrated COHP (ICOHP) of −3.88 eV, followed by CeO2-CuSAC (−3.71 eV) and TiO2-CuSAC (−3.65 eV). Below the Ef, there are fewer filling electrons in the anti-bonding orbitals for Cu-C compared to that of Cu-O on Al2O3-CuSAC, indicating that 3dyz is more favorable for bonding with CO. In contrast, TiO2-CuSAC exhibits the highest ICOHP of −2.45 eV, suggesting that the 3dz2 orbital is favor for 3dz2-H2O bonds. Moreover, TiO2-CuSAC exhibits the lowest H2O dissociation energy of −0.52 eV, succeeded by Al2O3-CuSAC and CeO2-CuSAC (Fig. 1f). This provides sufficient activated protons for *CO deep hydrogenation to form CH4. However, excessive activation of H2O could enhance competitive HER, and the formation energy of H2 on TiO2-CuSAC is as low as 0.18 eV, which may significantly suppress CO2RR activity (Supplementary Fig. 10). On the pure CeO2 (111) surface far away from Cu single-atom sites, the dissociation energy of H2O is 1.33 eV, which can also provide sufficient protons for CO adsorbed on Cu single-atom sites hydrogenation.

After coordination between Cu and O, a large amount of charge accumulates around the O atom, while Cu carries the positive charge due to the higher electronegativity of O than that of Cu. Bader charge analysis shows that the Bader charge of Cu is 10.13 |e−| in Al2O3-CuSAC, 10.57 |e−| in CeO2-CuSAC, and 10.37 |e−| in TiO2-CuSAC (Supplementary Fig. 11). The electron localization function (ELF) obtained from DFT calculations indicates that Al2O3 attracts more electrons from Cu, leading to electron delocalization around the Cu single atom (Fig. 1g)35. Further calculations are performed for the top-adsorption energy and adjacent-adsorption energies of CO on the Cu single-atom, and the corresponding adsorption modes are shown in Fig. 1h and Supplementary Fig. 12. On Al2O3-CuSAC, there is only a slight decrease in the CO adjacent-adsorption energies (−0.35 to −1.44 eV) compared to the top-adsorption energy (Fig. 1i). This indicates that the delocalized electronic state of Cu on Al2O3-CuSAC enables more CO molecules to adsorb around the Cu atom for C-C coupling36. On CeO2-CuSAC, the electronegativity of Cu is higher than that of Ce, enabling Cu to attract electrons from Ce, significantly reducing the electron delocalization around the Cu single-atom (Fig. 1g). As a result, the adjacent-adsorption energies of CO (0.35 to −0.65 eV) on the Cu atom significantly decreases compared to top-adsorption energy, making *CO more likely to undergo deep hydrogenation in the form of individual top-adsorption rather than C-C coupling.

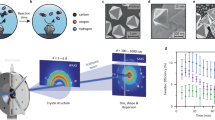

Synthesis and characterization

To verify the results of DFT calculations, Cu atoms were deposited on α-Al2O3, rutile TiO2, and fluorite CeO2 supports using ALD technique. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) images indicate that the morphologies of these three supports consist of irregular nanoparticles (NPs) with particle sizes larger than 50 nm, thus avoiding size effects of supports (Supplementary Figs. 13 and 14)37. X-ray diffraction (XRD) patterns and high-resolution TEM (HRTEM) images confirm that the supports are pure phases of Al2O3, TiO2, and CeO2 (Supplementary Figs. 14 and 15). Benefiting from the ALD technique relying on sequential molecular-level self-limiting surface reactions38,39, the Cu atom can anchor on supports in the form of a single atom (Fig. 2a). The Inductively coupled plasma optical emission spectrometer (ICP-OES) measurements indicate that the Cu loading amounts for Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC are 1.28 ± 0.23, 1.43 ± 0.09, and 1.76 ± 0.17 wt%, respectively (Supplementary Table 1). Aberration-corrected high-resolution high-angle annular dark-field scanning TEM (HAADF-STEM) images show that Cu atoms are atomically dispersed in Al2O3, TiO2, and CeO2 supports (Fig. 2b–d), without the presence of any visible clusters at both low and high magnifications (Supplementary Fig. 16). XRD patterns and SEM images of the samples after ALD further confirm that no observable Cu NPs are deposited on supports (Supplementary Figs. 17 and 18). HAADF-STEM and energy dispersive X-ray spectroscopy (EDS) element-mapping images indicate that Cu is evenly distributed throughout the Al2O3, TiO2, and CeO2 supports (Fig. 2e, f). By controlling the ALD process, Cu NPs loaded heterogenous catalysts were also prepared to serve as an expansion of EMSI catalysts (Supplementary Fig. 19). The catalysts loaded with Cu NPs on Al2O3 and CeO2 are named Al2O3-CuNPs and CeO2-CuNPs, respectively. The Cu loading amounts for Al2O3-CuNPs and CeO2-CuNPs are 2.91 ± 0.34 and 3.34 ± 0.53 wt%, respectively (Supplementary Table 2). The statistical particle size distribution of Cu NPs based on TEM images displays that the average diameter of Cu NPs loaded onto Al2O3 and CeO2 are 20.0 ± 0.3 nm and 17.4 ± 0.4 nm, respectively (Supplementary Figs. 20 and 21). HRTEM images of Al2O3-CuNPs and CeO2-CuNPs both reveal interfaces between Cu NPs and the supports, with the Cu NPs partly and firmly socketed onto the support surface (Supplementary Figs. 20e and 21b).

a Schematic of the synthesis process for Cu SAC support with metal-oxide. High-resolution HAADF-STEM images of b Al2O3-CuSAC, c CeO2-CuSAC, and d TiO2-CuSAC. Atomic models: Al, gray; Ce, yellow; Ti, bule; and O, red. HAADF-STEM and EDS element-mapping images of e Al2O3-CuSAC, f CeO2-CuSAC, and g TiO2-CuSAC.

To acquire the structural information of Cu/metal-oxides SAC, synchrotron-based X-ray adsorption spectroscopy and X-ray photoelectron spectroscopy (XPS) were performed. In the X-ray absorption near-edge structure (XANES) spectra, the absorption edges for Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC shift to higher energy than that of Cu-foil, indicating that the Cu atoms are in an oxidized state (Supplementary Fig. 22)40. The first peaks of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC are similar and close to that of CuO (8986.4 eV) in the first derivative of XANES spectra (Fig. 3a), indicating that the valence of Cu species in Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC are close to +241. Only one apparent peak at 1.50 Å corresponding to the first coordination shell of Cu-O scattering can be detected in the extended X-ray absorption fine structure (EXAFS) spectra of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC (Fig. 3b). This confirms that Cu atoms are atomically dispersed because no Cu-O-Cu or Cu–Cu metallic bonds are observed. The EXAFS fitting data for Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC are shown in Fig. 3c, Supplementary Fig. 23, and Supplementary Table 3. The average Cu-O coordination numbers of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC are 3.37, 3.67, and 3.41, respectively. Combined with the results of theoretical calculations (Cu1-O3 has the lowest free energy; Supplementary Fig. 1), these data reveal that the local structure of Cu/metal-oxides SAC comprised one isolated Cu atom may coordinate with about three oxygen atoms (Cu1-O3 units) in the triangular pyramid structure between the Cu and O atoms (Fig. 3d)41,42. The fitting of Cu 2p XPS spectra indicate that the predominant oxidation state on the surfaces of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC is Cu2+, with proportions of 86.2%, 85.5%, and 86.4%, respectively. (Fig. 3e). Compared to CuO, the Cu 2p XPS peaks of Al2O3-CuSAC and TiO2-CuSAC shift to higher binding energy, while Ti 2p and Al 2p XPS peaks shift to lower binding energy than that of pure Al2O3 and TiO2 (Supplementary Fig. 24). It means that the electron transfers from Cu to the adjacent Al2O3 and TiO2 supports, which results from the strong EMSI between Cu and metal-oxide supports. In contrast, the Cu 2p XPS peak shifts to lower binding energy on the surface of CeO2-CuSAC, indicating that Cu attracts electrons from CeO2 supports, possibly due to the higher electronegativity of Cu compared to Ce atom. These results of electron transfer between Cu and the supports are consistent with DFT calculations.

a The first derivatives of XANES spectra. b The corresponding k2-weighted Fourier transform spectra of EXAFS. c Fitting of k2-weighted EXAFS data of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC in the region of 1.0–2.5 Å. d The proposed Cu1-O3 configuration of Cu/metal-oxide SAC. Atomic models: Metal, yellow, Cu, bule; and O, red. e The Cu 2p XPS spectra. f The Raman spectra of CO adsorption on Cu/metal-oxide SACs, Cu2O, and Cu. g In-situ Raman spectra of CO adsorption on Al2O3-CuSAC for long-term electrolysis at −1.5 V without iR correction. h In-situ Raman spectra of CeO2-CuSAC for long-term electrolysis at −1.5 V without iR correction. Relevant source data are provided as a Source Data file.

Using CO as a probe molecule, the atomic dispersion of Cu atoms and the stability of Cu single-atoms during the CO2RR process can be characterized by in-situ Raman spectroscopy (Fig. 3f)43. In the 0.1 M CO-saturated KHCO3 solution, Raman peaks attributed to linear top adsorption (atop) of CO (C-O stretching vibration) are observed at 2087 and 2058 cm−1 for Cu2O and Cu, respectively44. Bridged adsorption of CO (i.e., CO adsorbed on two adjacent Cu atoms) is also observed on the Cu surface. In contrast, bridged adsorption of CO is not detected on the Cu SAC surface. Raman spectra collected on the supports show that there is no peak in the range from 1800 cm−1 to 2200 cm−1, suggesting that there is no CO adsorption on the supports (Supplementary Fig. 25). Therefore, the Raman peaks located at 2110, 2105, and 2123 cm−1 can be attributed to CO atop on the Cu single-sites of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC45. DFT calculations based on the Blyholder model reveal differences in the frequency of C-O stretching vibrations between Cu single sites and Cu cluster sites (Supplementary Fig. 26), providing the basis for spectroscopic measurements to assess the stability of Cu single atoms. The stability of Cu single-atoms correlates well with the affinity between the Cu sites and supports, specifically, strong interactions between Cu and O lead to high stability43. To evaluate the stability of Cu single-atoms during the electroreduction process, a constant potential of −1.5 V (all potentials in this work are vs. the reversible hydrogen electrode, RHE) was applied to Al2O3-CuSAC electrode for 60 min. After electrolysis at −1.5 V for 60 min, no corresponding Raman peaks are observed for CO bridge-adsorption on metal Cu sites (Fig. 3g), indicating that Cu remains anchored in supports in the form of single-atoms during the electrolysis process. The reduce in intensity of CO atop Raman peaks could be attributed to the accumulation of bubbles during long-term electrolysis. Similarly, the stability of the supports during electrolysis is maintained due to the high reduction potentials of Al2O3, CeO2, and TiO2. Specifically, after prolonged CO2 electrolysis, CeO2-CuSAC does not show Raman peaks caused by oxygen defects of CeO2 (570 cm−1), and the first-order F2g Raman peak characteristic of CeO2 (463 cm−1) remains present during the whole CO2RR process (Fig. 3h)46. In-situ Raman spectra of Al2O3-CuSAC and TiO2-CuSAC also confirm their stability during long-term electrolysis (Supplementary Fig. 27)47.

CO2RR performance

Electrochemical experiments on Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC were conducted in a flow cell with constant potential electrolysis. The main gas products observed during CO2RR are CH4, C2H4, CO, and H2, with minor liquid products (Supplementary Fig. 28). Prior to assessing the CO2RR performance of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC, thorough consideration was given to exclude the potential impacts of surface hydroxide adsorption, charge transfer resistance of the support, and Cu loading amounts on the CO2RR performance of catalysts through a series of electrochemical, BET, and SEM measurements (Supplementary Figs. 29–31 and Supplementary Note 1). The linear sweep voltammetry (LSV) curves indicate that the current densities of Al2O3-CuSAC increase the fastest with potential, followed by CeO2-CuSAC and TiO2-CuSAC (Fig. 4a). Meanwhile, the current densities of the samples measured with CO2 gas at all applied potentials are higher than those recorded with Ar gas, indicating the occurrence of CO2RR. The smallest difference in current density values between measurements of TiO2-CuSAC in CO2 and Ar atmospheres indicates that TiO2-CuSAC exhibits the highest HER activity and H2O dissociation ability, followed by CeO2-CuSAC and Al2O3-CuSAC. The product distribution from −1.1 V to −1.5 V is displayed in Supplementary Fig. 28. At −1.1 V, the ratio of CH4 FE to C2 FE for Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC is 1.08, 3.16, and 4.14 respectively, and it increases as the potential becomes more negative (Fig. 4b). As predicted by the electronic structure, Al2O3 exhibits the highest selectivity of C2 among these three catalysts, while CeO2-CuSAC and TiO2-CuSAC show selectivity towards CH4. An analysis of the CH4 kinetic isotopic effect (KIE), defined as the ratio of CH4 generation rate in H2O and D2O-based electrolytes, was performed to assess the impact of electronic structures on the proton transfer process for CO2RR (Fig. 4c and Supplementary Fig. 32). The KIE values of Al2O3-CuSAC are higher than CeO2-CuSAC and TiO2-CuSAC at all potentials and close to 2, indicating that its rate-determining step involves H2O dissociation6. TiO2-CuSAC has the lowest KIE value, indicating that the 3dz2 orbital significantly accelerates the activation process of H2O, while CeO2-CuSAC shows moderate dissociation rates of H2O. Considering the moderate CO adsorption energy and the localized electronic state of CeO2-CuSAC, CeO2-CuSAC demonstrates the highest CH4 FE of 70.3%, especially at high current density of 400 mA cm−2 (Fig. 4d). Al2O3-CuSAC and TiO2-CuSAC have relatively low CH4 FE values of 46.5% and 53.7%, respectively. CeO2-CuSAC exhibits excellent performance in terms of the CH4 FE and partial current density compared to previously reported excellent catalysts (Supplementary Fig. 33 and Supplementary Table 4)48.

a The LSV curves of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC with CO2 and Ar as supply gases. b The FECH4/FEC2 of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC at the potentials form −1.1 V to −1.5 V. c KIE of H/D for CO2RR-to-CH4 conversion at different potentials. d The corresponding FEs at high current densities. e FEs of Al2O3-CuNPs for CO2RR at different current densities. Long-term stability of f CeO2-CuSAC and g Al2O3-CuNPs at a constant current density of 400 mA cm−2. a–g No iR correction was applied to calculate the applied potential. The error bars represent standard deviations from at least three independent measurements. Relevant source data are provided as a Source Data file.

Further testing was conducted on the CO2RR performance of Al2O3-CuNPs and CeO2-CuNPs to validate the structure-activity relationships based on EMSI for guiding the design of supported catalysts. Due to the promotion of C-C coupling by the Cu electronic structure in Al2O3-CuSAC, it exhibits a higher FECH4/FEC2. When extending Cu single-atoms to Cu nanoparticles, more sites for CO or CHO adsorption and coupling on the Cu surface can lead to the increased selectivity of C2 product (Supplementary Fig. 34). The FEs of various C2 products, including C2H4, acetate (AcO–), and EtOH, over the Al2O3-CuNPs within a current density range of 200 to 1000 mA cm–2, are depicted in Fig. 4e. Specifically, under the condition of constant current electrolysis, the enhanced C2 selectivity of Al2O3-CuNPs is observed, achieving the highest C2 FE of 81.3% at 900 mA cm−2. In contrast, the selectivity of C2 on CeO2-CuNPs do not significancy increase as the sites for C-C coupling increased, with the C2 FE of 35.8% and CH4 FE of 40.2% at 500 mA cm−2 (Supplementary Fig. 35). The LSV curves also reveal that Al2O3-CuNPs displays a larger CO2 response current density than CeO2-CuNPs (Supplementary Fig. 36). The long-term durability of CeO2-CuSAC and Al2O3-CuNPs were evaluated by continuous CO2RR at 400 mA cm−2, with timely replacement of the electrolyte and clean the GDE to avoid salt deposit (Fig. 4f, g). The applied potential of CeO2-CuSAC maintains stability for 70 h, with the CH4 FE consistently remaining above 55%. Al2O3-CuNPs also shows stability for 70 h with a FEC2 stable above 62%. Finally, SEM, XRD, XPS, and TEM measurements were conducted on CeO2-CuSAC and Al2O3-CuNPs catalysts after stability tests, along with ICP-MS measurement on the electrolyte (Supplementary Figs. 37, 38 and Supplementary Table 5). These results collectively confirm the stability of the catalysts during long-term CO2RR tests (Supplementary Note. 2).

DFT calculations and spectroscopic insights into CO2RR

Afterward, the DFT calculations were further carried out to reveal the effect of the electronic structures on the selectivity of CO2RR products. First, the energy required for converting CO2 to *CO was calculated for these three models, followed by the formation energy of CH4 through deep hydrogenation of *CO (Fig. 5a and Supplementary Tables 6, 7). Consistent with the conclusions from electronic structure analysis, the highest occupied 3dx2-y2 orbital reduces the reaction energy for CO2 activation to form *COOH on CeO2-CuSAC (−0.38 eV), which is significantly lower than that on Al2O3-CuSAC and TiO2-CuSAC surfaces. The *COOH intermediate is reduced to the CO* species by reacting with a proton and releasing a H2O molecule. Subsequently, in the branch of *CO hydrogenation to *CHO or *COH, the *CHO should be the major species formed from *CO hydrogenation on these surfaces because the reaction energy required for *CHO formation is lower than that for *COH (Supplementary Fig. 39). The reaction energy for *CO hydrogenation on TiO2-CuSAC is the lowest with 0.02 eV, followed by CeO2-CuSAC of 0.61 eV and Al2O3-CuSAC of 0.66 eV. In the pathway for *CHO to form CH4, the reaction of *CHOH with a proton and release of H2O to form *CH is the rate-limiting step for CO2RR-to-CH4. The reaction energies for *CHOH to *CH on Al2O3-CuSAC and CeO2-CuSAC are as high as 1.31 eV and 0.90 eV, respectively. In contrast, the reaction energy for *CH is reduced to 0.46 eV due to the active protons on TiO2-CuSAC. Subsequently, the energy barriers for C-C coupling on these three surfaces were calculated, which is crucial for the formation of C2 products and competes with *CO deep hydrogenation. Specifically, the energy barrier for *CO-*CHO coupling is the lowest with 0.37 eV on Al2O3-CuSAC, followed by TiO2-CuSAC of 0.61 eV and CeO2-CuSAC of 0.80 eV (Fig. 5b and Supplementary Fig. 40). It is noteworthy that on all three surfaces, the reaction energy for *CO dimerization is higher than that for asymmetric coupling of *CO-*CHO (Supplementary Fig. 41), suggesting a coupling mechanism on Cu SAC surfaces where *CO is hydrogenated to *CHO and couples with surrounding CO intermediates. DFT calculations further indicate that when the active sites on the Al2O3 support switch from Cu single-atom to Cu cluster, the consecutive Cu sites strongly inhibit the thermodynamic generation of CH4 while maintaining high selectivity towards C2 products (Supplementary Fig. 42).

a Free energy diagram for CO2RR to form CH4. b Free energy diagram for *CO-*CHO coupling. In-situ ATR-IRAS spectra of CO2RR over c, d Al2O3-CuSAC and e CeO2-CuSAC. In-situ ATR-IRAS of O-H stretching vibration for f Al2O3-CuSAC, g CeO2-CuSAC, and h TiO2-CuSAC. i Fraction of free H2O in the electrode-electrolyte interface. c–i No iR correction was applied to calculate the applied potential. Relevant source data are provided as a Source Data file.

The in-situ attenuated total reflectance infrared absorption spectroscopy (ATR-IRAS) was further carried out at different potentials to reveal the intermediate absorption manners in different reaction pathways. The infrared (IR) bands at Al2O3-CuSAC and CeO2-CuSAC are assigned to corresponding intermediates based on independently reported studies (Supplementary Table 8). The IR band at 1301 cm−1 can be attributed to O-H deformation of *COOH, a critical intermediate in the CO2 to *CO conversion pathway (Fig. 5c, e)49,50. The IR bands at 1242 and 1263 cm−1 can be attributed to C-H stretching vibration of *CHO and *C-H deformation in the pathway for *CO deep hydrogenation to produce CH451,52,53. On CeO2-CuSAC, IR band (1738 cm−1) attributed to the C = O stretching vibration of *CHO can also be detected54. The IR bands at 1340 and 1415 cm−1 can be assigned to the O*CCHO intermediate formed after asymmetric coupling of *CO and *CHO55. The CHO part of O*CCHO is at 1340 cm−1, and the CO part of O*CCHO is at 1415 cm−1. The IR band at 2105 cm−1 on Al2O3-CuSAC can be attributed to top-adsorption of CO (Fig. 5d), while no *CO intermediate is detected on CeO2-CuSAC (Supplementary Fig. 43), possibly due to low *CO concentration or rapid consumption through hydrogenation56. The broad IR band in the range of 1550–1700 cm−1 can be attributed to H-O-H bend of adsorbed H2O, with the peak on Al2O3-CuSAC surface appearing noticeably larger than that on CeO2-CuSAC surface, consistent with DFT calculations. To avoid the influence of the broad IR band from H2O and verify whether the adsorbed species on Al2O3-CuSAC surface contain hydrogen, in-situ ATR-IRAS were repeated using D2O instead of H2O (0.1 M CO2-saturated KDCO3 in D2O). The H2O band disappears and is redshifted to 1188 cm−1, which is consistent with the in-plane bending vibration (D-O-D) of D2O (Supplementary Fig. 44)54,57. The adsorbed carbonate band is blueshifted in the deuterated system to 1496 cm−1, which is consistent with recent reported work52. This is likely due to the deuteration altering the carbonate-bicarbonate equilibrium and the carbonate adsorption process55. The asymmetric C = O stretching vibration of *CO2− can be detected at 1601 cm−1 57. Notability, the IR bands around 1242 (*CHO), 1263 (*C-H), 1301 (*COOH), and 1340 (O*CCHO) cm−1 obviously shifted to 1227 (*CDO), 1257 (*C-D), 1285 (*COOD), and 1317 (O*CCDO) cm−1 in D2O, suggesting their relation with hydrogen53. On the Al2O3-CuSAC surface, the IR bands of *CHO and *CO both undergo a redshift with increasing potential, which is caused by the Stark effect (Fig. 5c, d)57. This indicates that *CO and *CHO are in-situ generated, and coupling reactions occur between them58. Moreover, the intensity of O*CCHO is significantly higher than that of *C-H, indicating that the Al2O3-CuSAC is more favorable for C-C coupling reactions. In contrast, on the CeO2-CuSAC surface, the intensity of *C-H is significancy higher than that of O*CCHO, suggesting that *CO on the CeO2-CuSAC surface is more conducive to hydrogenation, leading to the generation of a large amount of CH4.

The state of H2O molecules near the electrode-electrolyte interfaces of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC were then analyzed. The broad band in 3000–3800 cm−1 represents the stretching vibration mode of the O-H bond (Fig. 5f–h), and the broad band can be divided into three peaks near 3610, 3450, and 3250 cm−1 through Gaussian fitting according to the distinct hydrogen bonding environments of water (Supplementary Fig. 45)6,59. They belong to water without hydrogen-bonds (free H2O), with weak hydrogen-bonds (liquid-like H2O), and strong hydrogen-bonds (ice-like H2O), respectively. In general, an increased degree of hydrogen-bonds lowers the energy of the O-H stretch, and thus the dissociation energies of H2O increased in the order: free H2O <liquid-like H2O <ice-like H2O59,60. On TiO2-CuSAC, the initial proportion of free H2O is 98%, much higher than CeO2-CuSAC of 30% and Al2O3-CuSAC of 20%. This suggests that the TiO2-CuSAC surface is enriched with free H2O, providing more active protons for *CO deep hydrogenation and the HER reaction. As the potential becomes more negative, the proportion of free H2O on the three electrode surfaces gradually decreases, indicating the consumption of free H2O involved in surface reactions (Fig. 5i). The consumption rate of free H2O on the TiO2-CuSAC surface is the fastest (30% V−1) due to the strong hydrolytic ability of TiO2-CuSAC. However, an excess of active hydrogen enhances competing HER, increasing the H2 FE of TiO2-CuSAC. In contrast, the low abundance of free H2O and weak hydrolytic ability of Al2O3-CuSAC (10.8% V−1) make *CO more prone to coupling rather than deep hydrogenation. CeO2-CuSAC, positioned in between Al2O3-CuSAC and TiO2-CuSAC, balances *CO deep hydrogenation and the HER well, resulting in a CH4 FE as high as 70.3%.

Discussion

In summary, Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC are successfully constructed by ALD technique, and based on these catalysts, the correlations between the characteristics of electronic structures and the CO2RR performance are proposed through detailed characterization and DFT calculations. The EMSI between Cu sites and Al2O3 support ranks the 3dyz orbital as the highest occupied orbital, which enhances the adsorption strength of CO and weakens C-O bonds through 3dyz-π* electron back-donation. This reduces the energy barrier for C-C coupling, thereby promoting the formation of C2 products on Al2O3-CuSAC. The EMSI between Cu sites and TiO2 support ranks the 3dz2 orbital as the highest occupied orbital, which enhances the adsorption of H2O and promotes H2O dissociation, thus lowering the energy barrier for forming CH4. However, this over activated H2O, in turn, intensifies competing HER, which hinders the high-selectivity production of CH4 on TiO2-CuSAC. The EMSI between Cu sites and CeO2 support ranks the 3dx2-y2 orbital as the highest occupied orbital, which promotes CO2 activation and protonation. CeO2-CuSAC effectively balances the CO adsorption strength with the activation of H2O, resulting in the highest CH4 FE of 70.3% among the three SACs at 400 mA cm−2. This structure-activity relationship based on EMSI can provide inspiration for the design of supported catalysts. Under this guidance, it is predicted that Cu nanoparticles loaded on Al2O3 exhibit higher C2 selectivity than those on CeO2, and a C2 FE of 81.3% at 900 mA cm−2 is achieved. This work not only provides an efficient catalyst for potential industrial application, but also gives an in-depth understanding of the CO2RR mechanisms that may inspire the rational design of other catalysts for the controlled CO2RR.

Methods

Preparation of Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC

The pure α-Al2O3, fluorite CeO2, and rutile TiO2 were purchased from Shanghai Yaoyi Alloy Material Co., Ltd. To deposit Cu single-atoms on Al2O3, CeO2, and TiO2 supports, the atomic layer deposition (ALD) method was used. Firstly, 0.1 g of supports was evenly dispersed in a crucible, and then the crucible was placed inside the vacuum chamber, where the ALD took place. The vacuum chamber temperature was maintained at 280 °C during the ALD process. Bis(hexa-fluoroacetylacetonato) copper(II) (Cu(hfac)2, 99.99%, Nanjing Ai Mou Yuan Scientific Equipment Co. Ltd.) was used as Cu precursors, and H2O was used as reducing agent. Cu(hfac)2 was kept at 150 °C and the N2 carrier gas was kept at 170 °C. The ALD cycle followed a precise sequence: introducing Cu(hfac)2 through a solenoid valve for 50 ms and purging the chamber with N2 for 12 s. At this point, the pressure response in the vacuum chamber was 0.5 Pa. Thereafter, H2O was injected for 100 ms and another round of N2 cleaning was executed for 30 s. This deposition cycle was repeated 150 times. After ending the ALD cycles, the vacuum chamber was immediately heated to 480 °C with 5 °C min−1 and kept at 480 °C for 3 h to firmly anchor Cu single atoms on supports.

Preparation of Al2O3-CuNPs and CeO2-CuNPs

The preparation of Al2O3-CuNPs and CeO2-CuNPs was generally similar to the method used for SAC. The difference was: introducing Cu(hfac)2 through a solenoid valve for 3 s and purging the chamber with N2 for 12 s. At this point, the pressure response in the vacuum chamber was 10 Pa. Thereafter, H2O was injected for 200 ms and another round of N2 cleaning was executed for 15 s. This deposition cycle was repeated 100 times.

Electrochemical CO2RR measurements

The obtained catalysts were made into electrode ink for CO2RR measurements. 2 mg of catalyst was ultrasonically dispersed into a solution containing 200 μL of isopropanol (99.9%, MERYER Co. Ltd.), 300 μL of deionized water, and 20 μL of Nafion (5 wt%, Alfa Aesar Co. Ltd.) to form electrode ink. For CO2RR test, drop 80 μL of electrode ink onto the gas diffusion electrode (GDE, 1.0 cm2 active area) and then GDE were heated at 60 °C for 0.5 h to remove residual isopropanol. The activity and selectivity of the obtained catalysts were tested in a flow cell comprising the GDE cathode (YLS-30T, Sinoro Energy Mall), anion-exchange membrane (Fumasep FAB-PK-130, 130 μm, Sinoro Energy Mall), Ag/AgCl electrode (3.0 M KCl), and the IrO2@Ti mesh (0.5 mm thickness) anode. Supply 20 standard cubic centimeter per minutes (sccm) of CO2 to the cathode side and 1.0 M KOH (20.0 mL) anolyte stream that flowed through the anode at a rate of 10.0 mL min−1. A solution of 1.0 M KOH (20.0 mL) was used as cathode electrolyte. The CO2RR performance for the obtained catalysts was evaluated by applying different currents with a current amplifier in the three-electrode system at the electrochemical workstation (CHI660E, Chenhua) with a current amplifier. The LSV curves test was conducted at potentials from 0 V to −1.5 V vs. RHE with the scan rate of 50 mV s−1. Potentials vs. Ag/AgCl reference electrode were converted to RHE reference scale using the following equation without iR compensation:

The gas products were quantified by gas chromatography (GC, FULI INSTRUMENTS GC9790 Plus) equipped with thermal conductivity detector (TCD) and flame ionization detector (FID) detectors. The GC was calibrated by five standard gases (H2, CO, CH4, C2H4 and C2H6 in CO2) before use. The FEs of liquid products were calculated using the total amount of the products collected at anodes and cathodes. The liquid product was detected by liquid 1H nuclear magnetic resonance (NMR) spectroscopy (Bruker, AVANCE III 400 MHz NanoBAY), and 500 μL of electrolyzed electrolyte, 100 μL of D2O (99.9%, MERYER Co. Ltd.) and 10 μL of DMSO (0.4 μL mL−1, MERYER Co. Ltd.) were mixed uniformly in the NMR tube. FE of the CO2RR products were computed from:

where F is the Faraday constant (96485 C mol−1), n is the total product (in mole), e is the number of transferred electrons for each product, and Q is the current time integral the amount of charge obtained.

Characterizations

The powder XRD patterns were obtained on a powder diffractometer (Rigaku Smart Lab 3 kW) using Cu Kα X-ray source. The SEM images of the samples were obtained using a JSM-7800F SEM. The TEM images were obtained with a Talos 200X G2 transmission scanning microscopy at 200 kV. High-angle annular dark-field-scanning transmission electron microscopy (HAADF-STEM) characterizations were carried out on a FEI Titan3 G2 60–300 equipped with double aberration correctors, which was operated at 200 kV. The X-ray absorption spectroscopy at the Cu K-edge was obtained at the BL14W beamlines at the Shanghai Synchrotron Radiation Facility (SSRF) (Shanghai, China), using a Si (111) crystal monochromator operated in transmission mode. The spectra were processed and analyzed by the software codes Athena and Artemis. XPS was performed on a Thermo Scientific ESCALAB 250Xi instrument using Al Kα X-ray source. The binding energy of the collected spectra was calibrated by the C 1 s binding energy of 284.8 eV. The inductively coupled plasma mass spectrometry (ICP-MS) datas were determined using an Aglient 7850 (Ms) system. Nitrogen sorption isotherms at 77 K were obtained on Micromeritics ASAP 2460.

In-situ Raman spectroscopy measurements

In-situ Raman spectra was recorded on laser Raman spectrometer (LabRAM HR Evolution) with 785 nm laser (25% intensity). The in-situ Raman spectroscopy measurements were performed in the Raman cell (Tianjin Gaoss Union Technology Co. Ltd.) with a quartz optical window, an Ag/AgCl (3.0 M KCl) reference electrode and a Pt counter electrode. Each Raman spectra was recorded for three accumulations with an acquisition time of 20 s. The Raman cell was filled with 0.1 M CO-saturated KHCO3 electrolyte, and the CO flow rate was maintained at 2 sccm during the CO adsorption measurements. The structural evolution of the supports on Al2O3-CuSAC, CeO2-CuSAC, and TiO2-CuSAC during the CO2RR process was conducted in 0.1 M CO2-saturated KHCO3 electrolyte, and the flow rate of electrolyte was sat as 2 sccm to remove bubbles.

In-situ ATR-IRAS measurements

In situ ATR-IRAS was performed on a Nicolet iS50 spectrometer equipped with an HgCdTe (MCT) detector and a VeeMax III (PIKE Technologies) accessory. The measurement was conducted in an electrochemical single-cell furnished with Pt and Ag/AgCl as counter and reference electrodes. The cell was filled with 0.1 M CO2-saturated KHCO3 electrolyte. A fixed-angle Si prism (60°) coated with catalysts embed into the bottom of the cell served as the working electrode. Chronoamperometry was used for CO2RR test and was accompanied by the spectrum collection (32 scans, 4 cm−1 resolution). All spectra were subtracted with the background.

DFT calculations

All DFT calculations were performed using Vienna ab initio simulation package (VASP)61. The ion-electron interactions are represented by the projector augmented wave (PAW) method and the electron exchange-correlation by the generalized gradient approximation (GGA) with the Perdew-Burke-Ernzerhof (PBE) exchange-correlation functional62,63. The Kohn-Sham valence states were expanded in a plane-wave basis set with a cut-off energy of 450 eV and Brillouin-zone integrations were performed using a (3 × 3 × 1) Monkhorst-Pack mesh during the optimization. The bottom three atomic layers were fixed and the vacuum space was 15 Å to avoid interactions with their periodic images in all calculations. The structure converges until all the forces on the free atoms were less than 0.05 eV Å–1. The electronic self-consistent field cycles were set at 10−5 eV. The calculation was performed using generalized gradient approximation with DFT + U and U - J = 3.0 eV for Cu 3 d; U - J = 3.0 eV for Ti 3 d; U - J = 5.0 eV for Ce 4 f. The DFT + U method was employed to calculate final structures and energies without entropy. The chemical potential of the proton-electron pair (H+ + e−) was equated with the chemical potential of a hydrogen molecule (H2) at the standard hydrogen electrode (SHE) potential reference64. The climbing-image-nudged-elastic-band (CI-NEB) method was applied to locate transition structures and the profile of the potential-energy surface (PES) was constructed accordingly65. Frequency calculations were applied to verify the adsorbed intermediates and the transition states (with only one imaginary frequency). The detailed DFT calculation process and descriptions can be found in Supplementary Figs. 46, 47 and Supplementary Note 3.

Data availability

Source data are provided with this paper and are available from the corresponding authors upon request. Source data are provided as a Source Data file. Source data are provided with this paper.

References

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Bushuyev, O. S. et al. What should we make with CO2 and how can we make it? Joule 2, 825–832 (2018).

Wang, Z. et al. Advanced catalyst design and reactor configuration upgrade in electrochemical carbon dioxide conversion. Adv. Mater. 35, e2303052 (2023).

Jouny, M., Luc, W. & Jiao, F. General techno-economic analysis of CO2 electrolysis systems. Ind. Eng. Chem. Res. 57, 2165–2177 (2018).

Ge, W. et al. Dynamically formed surfactant assembly at the electrified electrode-electrolyte interface boosting CO2 electroreduction. J. Am. Chem. Soc. 144, 6613–6622 (2022).

Ni, W. et al. Molecular engineering of cation solvation structure for highly selective carbon dioxide electroreduction. Angew. Chem. Int. Ed. 62, e202303233 (2023).

Liu, J. et al. Switching between C2+ products and CH4 in CO2 electrolysis by tuning the composition and structure of rare-earth/copper catalysts. J. Am. Chem. Soc. 145, 23037–23047 (2023).

Lin, Y. et al. Tunable CO2 electroreduction to ethanol and ethylene with controllable interfacial wettability. Nat. Commun. 14, 3575 (2023).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Zheng, M. et al. Electrocatalytic CO2-to-C2+ with ampere-level current on heteroatom-engineered copper via tuning *CO intermediate coverage. J. Am. Chem. Soc. 144, 14936–14944 (2022).

Zhang, J. et al. Accelerating electrochemical CO2 reduction to multi-carbon products via asymmetric intermediate binding at confined nanointerfaces. Nat. Commun. 14, 1298 (2023).

Li, Y. C. et al. Binding site diversity promotes CO2 electroreduction to ethanol. J. Am. Chem. Soc. 141, 8584–8591 (2019).

Zhong, M. et al. Accelerated discovery of CO2 electrocatalysts using active machine learning. Nature 581, 178–183 (2020).

Sun, Y. et al. Boosting CO2 electroreduction to C2H4 via unconventional hybridization: high-order Ce4+ 4f and O 2p interaction in Ce-Cu2O for stabilizing Cu+. ACS Nano 17, 13974–13984 (2023).

Zhang, L. et al. Oxophilicity-controlled CO2 electroreduction to C2+ alcohols over Lewis acid metal-doped Cuδ+ catalysts. J. Am. Chem. Soc. 145, 21945–21954 (2023).

Lee, C. W. et al. Metal–oxide interfaces for selective electrochemical C–C coupling reactions. ACS Energy Lett 4, 2241–2248 (2019).

Belgamwar, R. et al. Defects tune the strong metal-support interactions in copper supported on defected titanium dioxide catalysts for CO2 reduction. J. Am. Chem. Soc. 145, 8634–8646 (2023).

Bruix, A. et al. A new type of strong metal-support interaction and the production of H2 through the transformation of water on Pt/CeO2(111) and Pt/CeOx/TiO2(110) catalysts. J. Am. Chem. Soc. 134, 8968–8974 (2012).

Campbell, C. T. Catalyst-support interactions: electronic perturbations. Nat. Chem. 4, 597–598 (2012).

Yang, J., Li, W., Wang, D. & Li, Y. Electronic metal-support interaction of single-atom catalysts and applications in electrocatalysis. Adv. Mater. 32, e2003300 (2020).

Shi, Y. et al. Electronic metal-support interaction modulates single-atom platinum catalysis for hydrogen evolution reaction. Nat. Commun. 12, 3021 (2021).

Nørskov, J. K., Bligaard, T., Rossmeisl, J. & Christensen, C. H. Towards the computational design of solid catalysts. Nat. Chem. 1, 37–46 (2009).

Liang, X., Fu, N., Yao, S., Li, Z. & Li, Y. The progress and outlook of metal single-atom-site catalysis. J. Am. Chem. Soc. 144, 18155–18174 (2022).

Liu, D., He, Q., Ding, S. & Song, L. Structural regulation and support coupling effect of single-atom catalysts for heterogeneous catalysis. Adv Energy Mater 10, 202001482 (2020).

Lee, B.-H. et al. Electronic interaction between transition metal single-atoms and anatase TiO2 boosts CO2 photoreduction with H2O. Energy Environ. Sci. 15, 601–609 (2022).

Huang, J. R. et al. Single-product faradaic efficiency for electrocatalytic of CO2 to CO at current density larger than 1.2 A cm-2 in neutral aqueous solution by a single-atom nanozyme. Angew. Chem. Int. Ed. 61, e202210985 (2022).

Wu, Q. J. et al. Atomically precise copper nanoclusters for highly efficient electroreduction of CO2 towards hydrocarbons via breaking the coordination symmetry of Cu site. Angew. Chem. Int. Ed. 62, e202306822 (2023).

Wang, J. et al. Atomically dispersed metal-nitrogen-carbon catalysts with d-orbital electronic configuration-dependent selectivity for electrochemical CO2-to-CO reduction. ACS Catal 13, 2374–2385 (2023).

Zhu, W. et al. Activating *CO by strengthening Fe–CO π-backbonding to enhance two-carbon products formation toward CO2 electroreduction on Fe–N4 sites. Adv. Funct. Mater. 34, 202402537 (2024).

He, C., Lee, C. H., Meng, L., Chen, H. T. & Li, Z. Selective orbital coupling: an adsorption mechanism in single-atom catalysis. J. Am. Chem. Soc. 146, 12395–12400 (2024).

Wang, Q. et al. Atomically dispersed s-block magnesium sites for electroreduction of CO2 to CO. Angew. Chem. Int. Ed. 60, 25241–25245 (2021).

Ding, J. et al. Atomic high-spin cobalt(II) center for highly selective electrochemical CO reduction to CH3OH. Nat. Commun. 14, 6550 (2023).

Wang, J. et al. Direct electrochemical synthesis of acetamide from CO2 and N2 on a single-atom alloy catalyst. ACS Appl. Mater. Interfaces 15, 53436–53445 (2023).

Ouyang, Y. et al. Selectivity of electrochemical CO2 reduction toward ethanol and ethylene: the key role of surface-active hydrogen. ACS Catal. 13, 15448–15456 (2023).

Yang, J. et al. The electronic metal-support interaction directing the design of single atomic site catalysts: achieving high efficiency towards hydrogen evolution. Angew. Chem. Int. Ed. 60, 19085–19091 (2021).

Zhou, Y. et al. Dopant-induced electron localization drives CO2 reduction to C2 hydrocarbons. Nat. Chem. 10, 974–980 (2018).

Parastaev, A. et al. Boosting CO2 hydrogenation via size-dependent metal-support interactions in cobalt/ceria-based catalysts. Nat. Catal. 3, 526–533 (2020).

Li, J. et al. Highly active and stable metal single-atom catalysts achieved by strong electronic metal-support interactions. J. Am. Chem. Soc. 141, 14515–14519 (2019).

Gao, J. et al. Solar reduction of carbon dioxide on copper-tin electrocatalysts with energy conversion efficiency near 20%. Nat. Commun. 13, 5898 (2022).

Jiang, Y. et al. Pushing the performance limit of Cu/CeO2 catalyst in CO2 electroreduction: a cluster model study for loading single atoms. ACS Nano 17, 2620–2628 (2023).

Zhao, H. et al. The role of Cu1-O3 species in single-atom Cu/ZrO2 catalyst for CO2 hydrogenation. Nat. Catal. 5, 818–831 (2022).

Chen, S. et al. Lewis acid site-promoted single-atomic Cu catalyzes electrochemical CO2 methanation. Nano. Lett. 21, 7325–7331 (2021).

Zhang, L. et al. Elucidating the structure-stability relationship of Cu single-atom catalysts using operando surface-enhanced infrared absorption spectroscopy. Nat. Commun. 14, 8311 (2023).

Gunathunge, C. M., Li, J., Li, X., Hong, J. J. & Waegele, M. M. Revealing the predominant surface facets of rough Cu electrodes under electrochemical conditions. ACS Catal. 10, 6908–6923 (2020).

Yang, T. et al. Catalytic structure design by AI generating with spectroscopic descriptors. J. Am. Chem. Soc. 145, 26817–26823 (2023).

Wang, F. et al. Active site dependent reaction mechanism over Ru/CeO2 catalyst toward CO2 methanation. J. Am. Chem. Soc. 138, 6298–6305 (2016).

Ilie, A. G. et al. Principal component analysis of Raman spectra for TiO2 nanoparticle characterization. Appl. Surf. Sci. 417, 93–103 (2017).

Zhou, X. et al. Stabilizing Cu2+ ions by solid solutions to promote CO2 electroreduction to methane. J. Am. Chem. Soc. 144, 2079–2084 (2022).

Zhang, X. D. et al. Asymmetric low-frequency pulsed strategy enables ultralong CO2 reduction stability and controllable product selectivity. J. Am. Chem. Soc. 145, 2195–2206 (2023).

Firet, N. J. & Smith, W. A. Probing the reaction mechanism of CO2 electroreduction over Ag films via operando infrared spectroscopy. ACS Catal. 7, 606–612 (2016).

Shao, F. et al. In situ spectroelectrochemical probing of CO redox landscape on copper single-crystal surfaces. Proc. Natl Acad. Sci. USA 119, e2118166119 (2022).

Shan, W. et al. In situ surface-enhanced Raman spectroscopic evidence on the origin of selectivity in CO2 electrocatalytic reduction. ACS Nano 14, 11363–11372 (2020).

Yan, X. et al. Synergy of Cu/C3N4 interface and cu nanoparticles dual catalytic regions in electrolysis of CO to acetic acid. Angew. Chem. Int. Ed. 62, e202301507 (2023).

Kim, Y. et al. Time-resolved observation of C-C coupling intermediates on Cu electrodes for selective electrochemical CO2 reduction. Energy Environ. Sci. 13, 4301–4311 (2020).

Delmo, E. P. et al. In situ infrared spectroscopic evidence of enhanced electrochemical CO2 reduction and C-C coupling on oxide-derived copper. J. Am. Chem. Soc. 146, 1935–1945 (2024).

Tao, Z., Pearce, A. J., Mayer, J. M. & Wang, H. Bridge sites of Au surfaces are active for electrocatalytic CO2 reduction. J. Am. Chem. Soc. 144, 8641–8648 (2022).

Chernyshova, I. V., Somasundaran, P. & Ponnurangam, S. On the origin of the elusive first intermediate of CO2 electroreduction. Proc. Natl Acad. Sci. USA 115, E9261–E9270 (2018).

Liang, Y. et al. Stabilizing copper sites in coordination polymers toward efficient electrochemical C-C coupling. Nat. Commun. 14, 474 (2023).

Wang, Y. et al. Strong hydrogen-bonded interfacial water inhibiting hydrogen evolution kinetics to promote electrochemical CO2 reduction to C2+. ACS Catal. 14, 3457–3465 (2024).

Wang, Y. H. et al. In situ Raman spectroscopy reveals the structure and dissociation of interfacial water. Nature 600, 81–85 (2021).

Kressea, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Peterson, A. A., Abild−Pedersen, F., Studt, F., Rossmeisl, J. & Nørskov, J. K. How copper catalyzes the electroreduction of carbon dioxide into hydrocarbon fuels. Energy Environ. Sci. 3, 1311–1315 (2010).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J Chem. Phys. 113, 9901–9904 (2000).

Acknowledgements

This work was supported by the following grants: National Natural Science Foundation of China (No. 52071183, 51871122). The authors would like to thank Meiyu Li from Shiyanjia Lab (www.shiyanjia.com) for tests of the XANES and EXAFS.

Author information

Authors and Affiliations

Contributions

Y.C., H.L., (Nankai University), and H.L. (Tianjin University) supervised this project. Y.Z. designed and performed most of the experiments and analyzed the experimental data. F. C. performed the SEM measurements and analyzed the results. Y. Z., X.Y., and Y. G. conducted the catalytic tests. X.Z. and Z.L. performed the Raman measurements. Y. Z. and H. L. (Tianjin University) performed the ATR-IRAS measurements. W.W., F.L., D.H., Y.X., and Y. Z. carried out the theoretical calculations. Y.Z., Y.C., and F.L. performed the TEM measurements and analyzed the results. Y.X. and Y.Z. performed the BET and XAFS measurements. All authors participated in the discussion of the research.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Y., Chen, F., Yang, X. et al. Electronic metal-support interaction modulates Cu electronic structures for CO2 electroreduction to desired products. Nat Commun 16, 1956 (2025). https://doi.org/10.1038/s41467-025-57307-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-57307-6

This article is cited by

-

High single-pass conversion of nitrous oxide to dinitrogen in gas-diffusion-electrolyzer

Nature Communications (2025)

-

Carbon nanoboxes for boosting electrocatalytic reactions: recent progress and perspectives

Ionics (2025)

-

Advances in modifying porous carbon fibers for boosting electrocatalytic reactions

Ionics (2025)