Abstract

Carbon-based perovskite solar cells exhibit a promising application prospect due to its cost effective and attractive hydrophobic nature and chemical inertness, but are still limited to unsatisfied device efficiency. Herein, we design a triple-layer full-carbon electrode for n-i-p typed perovskite solar cells, which is comprised of a modified macroporous carbon layer, a highly conductive graphite layer and a thin dense carbon layer, and each layer undertakes different contribution to improving the cell performance. Based on this full-carbon electrode, inorganic CsPbI3 perovskite solar cells exhibit >19% certified efficiency which is the highest result among carbon-based CsPbI3 devices. On one hand, carbon quantum dots decorated on the macro-porous carbon layer can realize better energy alignment of full-carbon electrode/spiro-OMeTAD/CsPbI3 interface, on the other hand, highly conductive graphite layer is advantageous to carrier transporting. Typically, the top dense carbon layer exhibits significant thermal radiation ability, which can reduce the operational temperature of devices by about 10 °C, both from theoretical simulation and experimental testing. Thereby, packaged full-carbon electrode based CsPbI3 cells exhibit much better photothermal stability at ~70°C accompanied by white light emitting diode illumination, which exhibit no efficiency degradation after 2000 h continuous operational tracking.

Similar content being viewed by others

Introduction

Perovskite solar cells (PSCs) have experienced remarkably rapid development with the power conversion efficiency (PCE) from 3.8% to 26.7%, and some research groups and companies have already attempted upscaling techniques1,2,3,4,5,6. Currently, stabilities of PSCs are the research focus, from materials to devices7,8,9,10,11,12,13,14,15,16. To n-i-p typed PSCs, the instability derived from metal back electrode itself and its related interfaces is always challenging, although Au or Ag back electrodes has already exhibited much better cell performance3,4,5,6,17,18,19,20,21. However, most of metal electrodes including Ag exhibited chemical instability with iodide ions, while relatively stable Au electrode is economically unfeasible for practical application. Carbon electrodes (CEs) are a kind of promising alternatives due to cost effective, good hydrophobic nature, chemical inertness, abundant material availability and suitability for non-vacuum fabrication technology22. So far, the PCE of carbon-based PSCs (c-PSCs) still falls behind corresponding Au-based PSCs23,24. Besides, an easily overlooked issue also needs to be considered, that is, non-photoelectric conversion of the absorbed solar energy could elevate the temperature of an operating PSC and easily result in performance degradation. Therefore, targeted research to simultaneously promote electrical property of CEs, improve interfacial contact and enhance thermal stability is urgently demanded.

Two kinds of c-PSCs are clarified, one is HTL-free mesoscopic c-PSCs and the other is HTL-involved c-PSCs, each with its own advantages and disadvantages (HTL= hole transport layer). HTL-free c-PSCs has relatively good perovskite/carbon interfacial contact by printable technique, however, direct contact of perovskite and CEs could easily cause poor spatial carrier separation23,25,26. Similarly, c-PSCs with HTLs exhibit great potential in enhancing the cell efficiency by regulating energy level alignment and hole extraction capability at the HTL/CE interface, however, direct deposition of CEs on the top of the HTL/perovksite is always a tough task24,27,28,29. Recently, Rao et al. constructed TchPbI3/CsPbI3 1D/3D perovskite heterojunction to improve the hole extraction efficiency at the perovskite/carbon interface (Tchl, thiocholine iodide), which exhibited 19.08% PCE of CsPbI3 HTL-free c-PSCs30. By the aid of solvent exchange method, a kind of self-standing flexible carbon films was reported, which provided an alternative way to fabricating CE-based PSCs including flexible ones by directly hot-pressing carbon films on the top of the spiro-OMeTAD/perovskite27. So far, the most work on c-PSCs have focused on the bulk perovskite itself, interfacial engineering toward perovskite/carbon even electron-transporting layer23,30, however, direct modification toward CEs themselves and related thermal stability studies have been always lacking for these two c-PSCs31.

Herein, we designed a triple-layer full-carbon electrode (F-CE) consisting of a macroporous carbon layer, a highly conductive graphite layer and a thin dense carbon layer, all of which did not need high temperature annealing. And these three carbon layers made different contributions to enhancing the cell performance, that is, the macroporous carbon layer decorated by carbon quantum dots (CQDs) can obtain better energy alignment of F-CE/spiro-OMeTAD/CsPbI3 interface and guarantee good interfacial contact with the HTL, a highly conductive graphite layer was responsible to efficient carrier transporting. These two abilities of the F-CE contributed to >19% certified PCEs of inorganic CsPbI3, which is the highest reported efficiency of carbon-based CsPbI3 solar cells. Besides, noticeable thermal radiation ability of its dense carbon layer was also found, which can reduce the temperature of the operating cell (AM 1.5 G, 1 sun) by ~10 °C and overcome the PCE degradation, both from simulation and experimental results. For operational stability test, no PCE degradation was found in F-CE based CsPbI3 cell under continuously tracking over 2000 h. For low/high temperature-cycling test (−20/60 °C), the F-CE based CsPbI3 cell can sustain 95% of the initial PCE over 100 cycles but relative PCE of the Au electrode-based cells dropped by >35%. Our work provides an alternative route to realize high efficiency carbon-based PSCs with predominant thermal stability by designing multi-functional CEs.

Results

Designing three-layer full-carbon electrodes (F-CEs)

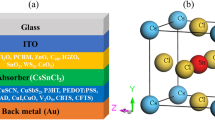

To c-PSCs, severe energy loss is mainly caused by CE itself and CE/perovskite/spiro-OMeTAD interfaces25,28. In this work, we designed a triple-layer full-carbon electrode (F-CE) for n-i-p structured PSCs, as schematically shown in Fig. 1a. Specifically, the F-CE is comprised of a macroporous carbon layer (bottom), a highly conductive graphite layer (middle) and a thin dense carbon layer (top) (details in Methods). For comparison, a single-layer CE and double-layer CE were also prepared, that is, a single-layer CE is only macroporous carbon film derived from solvent-exchange method, a double-layer CE is that the macroporous carbon film was deposited on a graphite paper (Supplementary Fig. 1). The F-CE was obtained when an additional dense carbon film was deposited on another side of the graphite paper of the double-layer CE, which was based on our lab-made conductive-carbon paste and doctor-blade method and dried at 150 °C for 30 min. In these three carbon electrodes, the macroporous carbon film is directly contacted with the spiro-OMeTAD layer. In terms of electrical measurement results, the double-layer CE exhibits slightly better conductance than the F-CE, and the worst conductance is the single-layer CE (Supplementary Fig. 2). As we know, the conductivity of the carbon films is mainly determined by the lateral carrier transfer. Therefore, the above difference mainly lies in relatively lower conductance of the dense carbon film than the graphite layer.

a Schematic diagram of the F-CE. b Structure of the cell and the F-CE. Carbon quantum dots (CQDs) are used to engineer the rear interface. c Scheme image of the mesoporous carbon film modified with CQDs. d Photos of the CQDs solution and its photoluminescence, and high-resolution transmission electron microscope image of the CQDs. Scale bar: 10 nm. Inset: lattice fringe image. e Atomic force microscope morphology (AFM) and Kelvin probe force microscopy surface potential image of the mesoporous carbon film with and without CQDs treatment (The scale bar is 1 μm). f The distribution of surface potential of the mesoporous carbon film with different conditions. g Energy band alignment of the devices. The energy level of CsPbI3 layer was directly referred to UPS testing results from previous work33.

Based on these three CEs, inorganic CsPbI3 PSCs with a device configuration of FTO/compact TiO2/CsPbI3/spiro-OMeTAD/CEs were fabricated32. The average efficiency and the Jsc of the double-layer CE are slightly higher than those of the F-CE (Supplementary Table 1). In fact, to the F-CE based PSC, upper dense carbon film exhibits quite different function from the other two layers, which will be discussed later. When the F-CEs were used to fabricate PSCs, no additional interfacial treatment toward TiO2/perovskite/spiro-OMeTAD was applied, except for the macroporous carbon film side of the F-CE was decorated by carbon quantum dots (CQDs) (Fig. 1b, c). CQDs was reported to exhibit noticeable interface modification ability including improving band alignment and charge extraction33,34. However, CQDs were usually used to passivate the perovskite layer in those c-PSCs, quite different from this work35. Here, untreated F-CE-based PSCs are the control group (Con.) for comparison (Supplementary Fig. 3). Carbon quantum dots (CQDs) were synthesized by hydrothermal method and evenly dispersed in water (Supplementary Figs. 4 and 5)36. These macroporous carbon films were soaked into CQDs aqueous solution at room temperature, then dried at 85 °C for 15 min. These CQDs with the size of ~10 nm is supposed to fill into the uneven surface of the F-CE to reduce the interface roughness (Ra: 79.4 vs. 49.5 nm) (Fig. 1c–e). KPFM measurement indicates that the work function of the macroporous carbon film in the F-CE slightly changes after being modified with CQDs, by calibration with the Au film (Fig. 1f and Supplementary Fig. 6)37. This CQDs treatment can obviously improve the average efficiency of F-CE based CsPbI3 PSCs from 16.54% to 18.72% (Supplementary Table 2). Further investigation has been carried out to explore the influence of CQDs on the F-CE/spiro-OMeTAD interface and carrier transportation. Meanwhile, better energy alignment of CQDs modified F-CE/spiro-OMeTAD/CsPbI3 interface is also obtained, more favorable for carrier transportation. Therefore, the series resistance of the carbon electrode is thus reduced while the interface contact is also improved (Fig. 1g), which is in good accordance with the cell performance38.

F-CE/spiro-OMeTAD interface properties

F-CEs were thermally pressed onto the top of the spiro-OMeTAD layer, which guarantees the close contact between the F-CE and HTL. This can be confirmed by our self-designed pull-off adhesion test, adhesive force of the F-CE/HTL contact reaches 3.6 N cm−2, about two orders of magnitude higher than that of the HTL/Au contact (0.07 N cm−2) (Fig. 2a, b). This is mainly attributed to good flexibility and compressibility derived from macroporous structure of the carbon film, ensuring its good adhesion between the CE and the HTL27. This can also be verified by the changes in the surface morphology and contacting potential difference (CPD) in the HTL/carbon interface after the F-CE was disassembled from the cell (Fig. 2c, d). We can see much rougher HTL surface (Ra= 3.29 vs. 29.6 nm) and smoother CE surface (Ra= 72.4 vs. 28.2 nm), indicating remarkable F-CE/HTL interface contacting property after the hot-pressing is applied. However, all the CPDs of the two sides decrease after being disassembled, that is, for the HTL, the CPD decreases from 529 to 6 mV, comparatively for the F-CE side, decreases from 262 to 119 mV, mainly due to the thermal-press approach can bring the CE and HTL embed into each other and help improving the interfacial stability.

Photovoltaic performance

F-CE-based PSCs were fabricated, which were based on inorganic CsPbI3 perovskites. Perovskite films were fabricated by two-step annealing method. A record 19.68% PCE has been achieved for the F-CE based CsPbI3 cell with short-circuit current density (JSC) of 20.36 mA cm−2, open-circuit voltage (VOC) of 1.170 V and fill factor (FF) of 0.826, and its steady-state PCE is 19.23% (Fig. 3a, b, Supplementary Fig. 7). However, this F-CE does not have scattering property like Au electrode, by comparing EQE spectra and reflectance spectrum (Supplementary Fig. 8). The 1 cm2 CsPbI3 PSCs can present 18.14% PCE with the JSC of 19.71 mA cm−2, the VOC of 1.169 V and the FF of 0.786 (Fig. 3c). Statistic PCE distribution for small size and 1 cm2 CsPbI3 cells are also presented (Supplementary Table 3-4). Typically, a certified PCE of 19.2% (reverse scanning) was also achieved (Supplementary Fig. 9), comparable to corresponding Au electrode-based cell with 20.39% PCE. In the past few years, PCEs of carbon-based inorganic perovskite cells (including CsPbI3, CsPbI2Br, CsPbIBr2 and CsPbBr3) indeed rises linearly (Fig. 3d, Supplementary Table 5). In previous work, the highest reported PCE was ~18% while the PCE gap between the Au and carbon-based devices has exceeded 2% in absolute value. In this work, the PCE gap has already narrowed to <1.0%. In fact, this all-carbon F-CEs was also applicable in hybrid PSCs (i.e. FA0.97Cs0.03Pb(I0.97Br0.03)3), which presented a record 23.5% PCE and 23.1% steady-state PCE (0.089 cm2) as well as 23.07% certified PCE (1 cm2) (Supplementary Figs. 10 and 11)39. Transient photocurrent (TPC) measurement also confirms the influence of CQDs treatment on carrier transfer properties of F-CE based PSCs, that is, this F-CE structure is favourable to interfacial charge transfer (τTPC: 1.94 μs (Con.) vs. 1.81 μs (CQDs treatment)). This is consistent with higher recombination resistance (Rrec) for CQDs treated sample from electrochemical impedance spectroscopy (EIS) and shorter carrier lifetime (τTRPL: 3.97 ns (CQDs treatment) vs. 11.11 ns (Con.)) from time-resolved photoluminescence spectra (Fig. 3e, f, Supplementary Fig. 12)40. These results demonstrate that the F-CE based PSCs exhibit attractive cell performance, also indicating our F-CE technique is promising for the PSCs.

a Current density-voltage (J-V) characteristics of 0.089 cm2 champion CsPbI3 PSCs with Au electrode and F-CE, respectively. b Continuous current output of champion 0.089 cm2 F-CE based CsPbI3 PSCs at a steady-state bias voltage of 1.01 V, demonstrating a PCE of over 19.2% after 2 min operation. c J-V characteristics of 1 cm2 champion CsPbI3 PSCs with F-CE. d Summary of advances in PCEs of carbon-based inorganic CsPb(I, Br)3 PSCs. e Transient photocurrent spectra of the devices under 0 V bias voltage in the dark. f Time-resolved photoluminescence spectra of the FTO/CsPbI3/spiro-OMeTAD/CEs.

Investigation on radiation cooling properties of F-CEs

We experimentally compared the temperatures of the operating cells based on Au electrode and F-CEs under AM 1.5 G illumination (Supplementary Fig. 13), and found that the F-CE can reduce the cell surface temperature by ~10 °C, from 53.1 (Au electrode) to 45.2 °C (F-CE) under 1 sun illumination and from 73.6 to 62.7 °C under 2 sun illumination. Obviously, F-CE exhibits cooling effect on the operating cell, assuming the same fabrication process, and it may enhance the operational stability of the cell41,42,43,44,45,46.

Furthermore, heat dissipation properties of F-CE based PSCs were investigated by theoretical simulations. First, based on finite-element model (FEM), we conducted brief simulation to gain quantitative assessment about heat generation and dissipation properties of the PSCs under illumination47. As shown in Fig. 4a, thermal conduction, convection and radiation are the three main heat dissipation pathways. To the PSC, heat generation properties caused by the light absorption were experimentally evaluated from light reflection/transmission and external quantum efficiency spectra of the cell (Supplementary Figs. 14 and 15). According to preliminary results, it is estimated that the cell approximately absorbs ~ 97% of the solar irradiance by the perovskite layer (46%) and other functional layers (51%) (Fig. 4b). Assuming the cell with 20% PCE, its heating density is estimated to be 780 W m-2 while illuminated under AM 1.5 G (1 sun) 48,49,50.

a Schematic diagram of the sun illumination and heat dissipation pathways of the cell. b Absorption of the AM 1.5 G solar irradiance spectrum by different parts of the cell, estimated from cell external quantum efficiency and reflection/transmission spectra. c Schematic diagram of the triple-layer F-CE comprising of a macroporous carbon layer, a graphite layer and a dense carbon layer. (Note: the dense carbon layer mainly acts as a heat-dissipation layer, not conductive layer, which could be replaced by other high emissivity materials, but carbon materials are the first choice.). d Simulated cell temperature under heating power of 780 W m-2. e IR camera measured temperature of varied electrodes having surface temperature of about 90 °C. f Emissivity and conductance of F-CEs and Au electrode.

Based on these parameters, the interior temperature of the cell was simulated when various heat dissipation configurations were considered using a finite element model (FEM) (Supplementary Fig. 16 and Table 6). The thickness of the perovskite layer or charge transfer layers were found not to affect thermal simulation results (Supplementary Fig. 17), that is, the perovskite absorption layer was thick enough to mainly realize light absorption. As presented in Fig. 4c and d, at room temperature, the interior temperature of the cell could reach 102.1 °C if there is no heat dissipation. If the cell emits the heat from a single surface (e.g. the conductive glass surface), the temperature could obviously decrease to 70.2 °C. This may be the actual condition of a PSC with metal electrode. However, if the electrode itself can emit thermal radiation, the cell temperature will continuously decrease to 57.6 °C, which can guarantee the cell working properly (Supplementary Fig. 18). Here, in our FEM model for heat radiation simulation, the absorption of ambient black body radiation was not taken into consideration, however, different ultimate temperature (0, 25, 30 and 40 °C) was adopted, representing the thermal absorption in some degree. This cooling effect of the dual-face thermal radiation always works whatever the ambient temperature is (Supplementary Fig. 19). When the cell works in the vacuum (for example, the near space), this cooling effect benefiting from the dual-face thermal radiation will be more attractive (Supplementary Fig. 20).

Heat dissipation properties of varied electrodes from PSCs were also explored. Here, two temperatures were defined, IR apparent temperature TIR (measured with IR camera) and actual surface temperature T0 (measured with thermocouple) (Fig. 4e). When T0 increased to 90 °C, TIR of the Au electrode was 38.7 °C, and TIR of Sn: In2O3 (ITO) was 48.6 °C. Surprisingly, TIR of our triple-layer F-CE can reach 89.5 °C, quite close to the T0, however, to the double-layer without thermal radiative layer, its TIR was 66.4 °C. Thermal radiation ability of these electrodes was further quantified by the emissivity (ε). Based on the Equation of ε ≈ (TIR/T0)4, the ε of the Au and ITO electrodes was 0.54 and 0.62, respectively (Fig. 4f) 51, while the ε of single-layer carbon electrode was 0.98. When a graphite layer was introduced, the ε decreased to 0.76, indicating the conductivity of the double-layer carbon electrode was enhanced (Fig. 4f and Supplementary Fig. 21). However, to our designed triple-layer (F-CE), its ε reached 0.99 instead, close to an ideal black body52,53. Further simulation results indicated that slight increase in the surface emissivity of the electrode will directly affect the device temperature (Supplementary Fig. 22). Considering this heat dissipation effect of the F-CE may be weakened by packaging materials, two materials (ultra-clear glass and PP films (polypropylene)) were attempted to package 1 cm2 F-CE based CsPbI3 PSCs. In comparison to ultra-clear glass, lower surface temperature of the PP/F-CE was obtained, and the higher the environment temperature, the greater the impact (Supplementary Fig. 23). Therefore, in order to effectively take advantage of radiation cooling property of the F-CE, it is highly necessary to select appropriate packaging materials in the future.

Stability testing of F-CE based CsPbI3 PSCs

Firstly, ambient phase stability of the CsPbI3 film in the unencapsulated cell was significantly enhanced. As indicated by time-dependent X-ray diffraction (XRD) (Supplementary Fig. 24), β-phase CsPbI3 of Au based PSCs gradually transformed into δ-phase after being illuminated for several hours in ambient conditions. Comparatively, the CsPbI3 from the F-CE based PSC can well keep β-phase with constant XRD intensity in the illumination aging duration. Furthermore, we carried out different aging processes to evaluate the operational stability of F-CE based CsPbI3 PSCs. After working at the maximum power point (MPP) under AM 1.5 G (1 sun) for 3000 s in ambient conditions, no PCE degradation was found for unencapsulated F-CE based cells, however, the PCE of the Au-based cell dropped to 92% of its initial value (Fig. 5a). We further tracked 2000 h operational stability in N2 atmosphere while keeping the cell continuously worked under steady-state bias voltage (0.95 V) and white LED illumination (initial cell current density 20 mA cm-2). The PCE of the F-CE based cell slightly increased in the first 400 h, then kept almost constant from 500 to 2000 h (Fig. 5c). To our knowledge, this is one of the best operational stability results among the CsPbI3 solar cells reported so far (Supplementary Table 7). Instead, the PCE of the Au based cell continuously degraded in the whole aging process, only sustaining 82% of its initial PCE after 2000 h. In addition, we conducted low-high temperature (-20/60 °C) aging test for 100 cycles by using a semiconductor cooling plate, and the time duration at each temperature in one cycle is 15 min (Fig. 5d). After the aging, the PCE of the Au-based cell dropped to <70% of its initial value, whereas the F-CE based cell can sustain 95% of its initial value. This better temperature-cycling stability mainly benefits from both temperature buffering effect of the F-CE and robust HTL/F-CE interface contact (Supplementary Fig. 25). Furthermore, comparison of concentrated light illumination on CsPbI3 PSCs over 50 min revealed that, the PCE of the F-CE based cell only decreased to 94% of its initial value, whereas the PCE of the Au electrode-based cell obviously dropped to 78% (Fig. 5b and Supplementary Figs. 26 and 27). It is also demonstrated that the temperature itself has obvious influence on the shelf life of the cell (Supplementary Fig. 13), and only 10 °C enhancement will significantly reduce the device stability of Au-based devices (Supplementary Fig. 28). Finally, we compared 1 cm2 encapsulated Au (ultra-clear glass as packaging material) and F-CE based PSCs (PP as packaging material) to test the stability simultaneously under continuous LED illumination and different temperature environment (the hot plate was set from 21 to 67.8°C) for 150 h. Obviously, F-CE-based device exhibited much better photothermal stability than corresponding Au-based PSCs, and the PP-covered F-CE based PSCs exhibited better photothermal stability than ultra-clear glass-covered ones (Supplementary Fig. 29). Thermal radiative property of the F-CE indeed can improve the thermal stability of PSCs. Additionally, our F-CE exhibits obvious advantages over other screen-printed carbon electrodes and traditional metal electrodes reported in the literature, including better conductivity, good heat dissipation, low preparation cost, high device efficiency and good stability (Supplementary Table 8).

PCE tracking of the cells operating a under normal and b 10× concentrated AM 1.5 G illumination in ambient conditions. c 2000 h PCE tracking of the cells continuously operating under light illumination (initial cell current density 20 mA cm-2) and bias voltage (0.95 V) in N2 atmosphere. d Low (-20 °C) ~ high (60 °C) temperature cycling test in N2 atmosphere for 100 cycles.

In conclusion, we have successfully developed a three-layer F-CEs, which not only has attractive interfacial contact ability and electrical properties, but also has high heat dissipation property, in comparison to conventional carbon electrodes. Our F-CEs contribute to >19% certified PCEs of inorganic CsPbI3, which is the highest reported efficiencies based on CEs. Typically, the F-CE exhibits attractive radiation cooling effect to enhance thermal stability of the PSCs, which can reduce the temperature of the operating cell by about 10 °C, both from simulation and experimental results. Besides, the F-CE based CsPbI3 PSCs demonstrate remarkable operational stability with almost no efficiency degradation after 2000 h continuous operational tracking, and CsPbI3 PSCs exhibited good stability under different concentrated light illumination. Our three-layer CEs provides a simple and efficient strategy to enhance PCE and thermal stability of CsPbI3 PSCs.

Methods

Materials

Lead (II) iodide (PbI2), chlorobenzene (CB), N, N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO) and 4-tert-butylpyridine (TBP) were purchased from Alfa Aesar. Cesium iodide (CsI) and bis(trifluoromethane)sulfonimide lithium salt (LiTFSI) were from Sigma-Aldrich. Hydroidic acid (HI, 55.0-58.0%) was from Aladdin. Spiro-OMeTAD was from Luminescence Technology Corp. (Lumtec). Tris(2-(1H-pyrazol-1-yl)-4-tert-butylpyridine)-cobalt (III) tris(bis(trifluoromethyl sulfonyl)imide) (FK209, Co(III)TFSI) was from Dyesol. Poly(3-hexylthiophene-2, 5-diyl) (P3HT) was from Rieke Metals. Unless stated otherwise, solvents and chemicals were directly used without further purification. DMAPbI3 and conductive carbon paste were homemade by following the previous work27,32.

Carbon quantum dots (CQDs) synthesis

CQDs were prepared as follows, citric acid (1.0507 g) and ethylenediamine (335 μL) was dissolved in DI-water (10 mL). Then the solution was transferred to a poly(tetrafluoroethylene) (Teflon)-lined autoclave (30 mL) and heated at 200 °C for 5 h. After the reaction, the reactors were cooled to room temperature naturally. The product, which was brown-black and transparent, was subjected to dialysis in order to obtain the CQDs33.

Carbon electrode (CE) fabrication

Firstly, a dense carbon film (as thermal radiative layer) was deposited by doctor blade method on the back of the carbon graphite paper, and dried at 150 °C for 30 min. Subsequently, the lab-made conductive-carbon paste was coated on the other side of graphite paper by doctor blade to give wet carbon films. Then, the carbon films were soaked into ethanol for 10 min at room temperature to remove the solvents, and dried at 70 °C for 15 min to finish three-layer all-carbon electrode (F-CE). The carbon film derived from this solvent exchange method was defined as C1 films (as contacting layer). For CQDs modified carbon films, C1 or F-CE was soaked into CQDs aqueous solution for 2 min at room temperature, then dried at 85 °C for 15 min. Here, the C1/CQDs film was defined as C2 film.

Perovskite solar cells fabrication

Laser-patterned FTO glass (8.5 Ω sq-1) was cleaned sequentially with a mild detergent, alkali liquor, distilled water, and ethanol in an ultrasonic bath. Prior to use, FTO substrates were treated with ozone for 30 min. The substrate sizes for small-area (0.09 cm-1) and large-area (1.0 cm-1) cells are 1.5 × 1.5 and 2.0 × 3.0 cm2, respectively. For the compact TiO2 layer, a 0.125 M titanium (IV) isopropoxide sol-gel precursor solution was spin-coated on the FTO glass at 3000 rpm, then sintered at 500 °C for 1 h. It was further treated with 0.025 M TiCl4 aqueous solution for 30 min, then sintered at 500 °C for 1 h to afford the TiO2/FTO substrate. TiO2 substrates were transferred into a nitrogen-filled glove box for subsequent device fabrication. In details, the CsPbI3 active layer was obtained by spin-coating precursor solution on 50 °C pre-warmed TiO2/FTO substrate 3000 rpm for 30 s, which consisted of DMAPbI3 (462.7 mg), CsI (189.6 mg) and thiocyanate molten salt (0.3 mg) in 1 ml DMF/DMSO mixed solvent (v: v = 85: 15)32. Then, CsPbI3 precursor films were firstly placed onto the hotplate with 70 °C for ~ 3 min, then heated at 200 °C for 10 min in the air (~15% RH) to afford the CsPbI3 layer. Afterwards, 20 μL spiro-OMeTAD (60 mM in chlorobenzene with additives of LiTFSI, FK209 and TBP at doping molar ratios of 0.5, 0.03 and 3.3) was spin-coated at 3000 rpm for 30 s on the top of CsPbI3 perovskite layer and heated at 60 °C for 8 min in a N2-filled glovebox. For thermal stability testing, spiro-OMeTAD was replaced by P3HT (15 mg ml-1), which was spin-coated at 2500 rpm for 25 s in a N2-filled glovebox, then P3HT films were heated at 100 °C for 10 min. For carbon electrode-based devices, two kinds of carbon films were directly hot-pressed on the top of spiro-OMeTAD or P3HT layer under a pressure of 0.7 MPa, more details can be found in our previous work30. For comparison with Au electrode-based devices, 80 nm-thickness Au electrode was deposited via thermal evaporation under the vacuum of 10-7 Torr.

Characterizations

UV-Vis transmission and reflection spectra (200-3000 nm) were recorded on a spectrophotometer (UV-3600 plus, Shimadzu, Japan). XRD patterns were performed by using 40 kV, 40 mA Cu Kα (λ = 0.15406 nm) radiation by Mini Flex 600 (Rigaku, Japan). Surface morphologies of carbon films and complete device were studied by scanning electron microscopy (SEM, Sigma 300, Zeiss, Germany). Transmission electron microscopy (TEM) images were obtained on JEM-F200CF (JEOL). Atomic force microscopy (AFM) and Kelvin probe force microscopy (KPFM) measurements were carried out on atomic force microscope (Multimode 9, Bruker, Germany) at room temperature in the dark. AFM and KPFM were used to probe top-view surface morphologies and surface potential, respectively. Infrared imaging measurements were carried out at room temperature (~25 °C) by using a FLIR thermal infrared camera (FLIR ONE Pro, FLIR, USA). Optical images of samples were obtained on metallographic microscope (OLYMPUS, BX61). CQDs for Fourier transform infrared (FT-IR) characterization were dispersed in deionized water. FT-IR spectra were performed on TENSOR 27 spectrometer.

All the current density-voltage (J-V) characteristics was carried out on Keithley 2602 source meter with a scan rate of 50 mV s-1 under AM 1.5 G (100 mW cm-2) irradiance from a solar simulator (Zolix SS150A). The solar simulator was calibrated to 1 sun (100 mW cm-2) AM 1.5 G illumination by using a certified Si reference cell with KG-3 filter (Enlitech, certified by Enlitech in accordance with IEC 60904-1: 2006, spectral mismatch correction factor: 0.36%). The solar cells were masked with a black mask to define the active area of 0.09 cm2 and 1.0 cm2, respectively. J-V measurements of non-encapsulated solar cells were performed in air at ambient condition, the scanning speed was 50 mV s-1 with a delay time of 0.3 s. Transient photocurrent (TPC) spectra were obtained by our lab-made setup, in which the cell was excited by 532 nm pulse laser (Brio, 20 Hz, 4 ns) and the photovoltage decay process was recorded by a digital oscilloscope (Tektronix, DPO 7104)54. Electrochemical impedance spectroscopy (EIS) was performed in the dark in the frequency range from 1 to 1 × 106 Hz on IM6ex electrochemical work station (ZAHNER) under 0.8 V bias. Time-resolved transient photoluminescence (PL) spectra were carried out on PL spectrometer (FLS 900, Edinburgh Instruments), excited with a picosecond-pulsed diode laser (EPL-445) with 444.6 nm and measured at 730 nm after excitation. The External quantum efficiency (EQE) of non-encapsulated solar cells were measured in air on Enli Technology (Taiwan) EQE system, and a standard monocrystalline Si cell was used as the reference. No pre-light soaking and pre-bias were applied over the measurement time. The Adhesion between different electrodes and HTL tested by tape-tear method. The strength of the adhesion can be reflected by the peak reading of the tension meter (HANDPI, HP-100).

Stability test

All the stability studies involved in this work were based on unencapsulated devices. The devices were operated under the normal and concertrated AM 1.5 illumination in ambient condition, respectively. The long-term operation stability of the devices was tested under continuous white LED illumination in N2 atmosphere and constant bias voltage applied. The devices for thermal cycle stability were placed on a temperature control platform in N2 glove box, and a certain program is used to perform high and low temperature cycles.

Heat-transfer simulation

Finite-element (FEM) heat transfer simulations were performed using COMSOL Multiphysics (COMSOL, Inc.). The Glass, perovskite, spiro-OMeTAD and Au electrode with the dimensions of 0.5 × 0.5 × 2.0 mm3, 0.5 × 0.5 × 0.0005 mm3, 0.5 × 0.5 × 0.0002 mm3, and 0.5 × 0.5 × 0.00008 mm3 was modeled, respectively. The initial temperature was set to 25 °C in the entire model. No temperature boundary conditions were applied. To simplify the model, the heat fluxes taken by perovskite absorption layer under 1 Sun illumination is equivalent to 780 W m-2, when the cell is assumed with 20% PCE. The heat transfer analysis required specification of thermal conductivity, specific heat density in this study which are listed in Supplementary Table 6.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

All related data are presented in the published paper and Supplementary Information/Source Data file (Figshare https://doi.org/10.6084/m9.figshare.28630853).

References

Kojima, A. et al. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 131, 6050–6051 (2009).

Green, M. A. et al. Solar cell efficiency tables (Version 65). Prog. Photovolt. Res. Appl. 33, 3–15 (2025).

Yu, S. et al. Homogenized NiOx nanoparticles for improved hole transport in inverted perovskite solar cells. Science 382, 1399–1404 (2023).

Chen, H. et al. Improved charge extraction in inverted perovskite solar cells with dual-site-binding ligands. Science 384, 189–193 (2024).

Park, J. et al. Controlled growth of perovskite layers with volatile alkylammonium chlorides. Nature 616, 724–730 (2023).

Peng, W. et al. Reducing nonradiative recombination in perovskite solar cells with a porous insulator contact. Science 379, 683–690 (2023).

Burlingame, Q. C., Loo, Y.-L. & Katz, E. A. Accelerated ageing of organic and perovskite photovoltaics. Nat. Energy 8, 1300 (2023).

Bu, T. et al. Modulating crystal growth of formamidinium-caesium perovskites for over 200 cm2 photovoltaic sub-modules. Nat. Energy 7, 528 (2022).

Tan, S. et al. Stability-limiting heterointerfaces of perovskite photovoltaics. Nature 605, 268–273 (2022).

Knight, A. J. & Herz, L. M. Preventing phase segregation in mixed-halide perovskites: a perspective. Energy Environ. Sci. 13, 2024–2046 (2020).

Zhou, J. et al. Highly efficient and stable perovskite solar cells via a multifunctional hole transporting material. Joule 8, 1 (2024).

Arora, N. et al. Perovskite solar cells with CuSCN hole extraction layers yield stabilized efficiencies greater than 20%. Science 358, 768–771 (2017).

Steele, J. A. et al. Thermal unequilibrium of strained black CsPbI3 thin films. Science 365, 679–684 (2019).

Zhao, X. et al. Accelerated aging of all-inorganic, interface-stabilized perovskite solar cells. Science 377, 307–310 (2022).

Szostak, R. et al. In situ and operando characterizations of metal halide perovskite and solar cells: insights from lab-sized devices to upscaling processes. Chem. Rev. 6, 3160–3236 (2023).

Shi, L. et al. Gas chromatography-mass spectrometry analyses of encapsulated stable perovskite solar cells. Science 368, eaba2412 (2020).

Chen, S. et al. Preventing lead leakage with build-in resin layers for sustainable perovskite solar cells. Nat. Sustainability 4, 636–643 (2021).

Wu, S. et al. A chemically inert bismuth interlayer enhances long-term stability of inverted perovskite solar cells. Nat. Commun. 10, 1161 (2019).

Chen, R. et al. Rear electrode materials for perovskite solar cells. Adv. Funct. Mater. 32, 2200651 (2022).

Ming, W., Yang, D., Li, T., Zhang, L. & Du, M.-H. Formation and diffusion of metal impurities in perovskite solar cell material CH3NH3PbI3: Implications on solar cell degradation and choice of electrode. Adv. Sci. 5, 1700662 (2017).

Behrouznejad, F., Shahbazi, S., Taghavinia, N., Wu, H.-P. & Diau, E. W.-G. A study on utilizing different metals as the back contact of CH3NH3PbI3 perovskite solar cells. J. Mater. Chem. A 4, 13488 (2016).

Mashhoun, S. et al. Resolving a critical instability in perovskite solar cells by designing a scalable and printable carbon based electrode-interface architecture. Adv. Energy Mater. 8, 1802085 (2018).

Liu, J. et al. Electron injection and defect passivation for high-efficiency mesoporous perovskite solar cells. Science 383, 1198–1204 (2024).

Shao, J.-Y. et al. Recent progress in perovskite solar cells: material science. Sci. China-Chem. 66, 10–64 (2023).

Yan, K. et al. High-performance graphene-based hole conductor-free perovskite solar cells: Schottky junction enhanced hole extraction and electron blocking. Small 11, 2269–2274 (2015).

Kohlrausch, E. C. et al. Advances in carbon materials applied to carbon-based perovskite solar cells. Energy Technol. 11, 2200676 (2023).

Zhang, H. et al. Self-adhesive microporous carbon electrodes for efficient and stable perovskite solar cells. Adv. Funct. Mater. 28, 1802985 (2018).

Beynon, D. et al. All-printed roll-to-roll perovskite photovoltaics enabled by solution-processed carbon electrode. Adv. Mater. 35, 2208561 (2023).

Zhang, C. et al. Ti 1–graphene single-atom material for improved energy level alignment in perovskite solar cells. Nat. Energy 6, 1154–1163 (2021).

Lin, J. et al. Eliminating hole extraction barrier in 1D/3D perovskite heterojunction for efficient and stable carbon-based CsPbI3 solar cells with a record efficiency. Adv. Mater. 36, 2404561 (2024).

Wu, Z. et al. Highly efficient and stable perovskite solar cells via modification of energy levels at the perovskite/carbon electrode interface. Adv. Mater. 31, 1804284 (2019).

Yu, B. et al. Efficient (>20 %) and stable all-inorganic cesium lead triiodide solar cell enabled by thiocyanate molten salts. Angew. Chem. Int. Ed. 60, 13436–13443 (2021).

Wang, Z. et al. Enhanced charge extraction enabled by amide-functionalized carbon quantum dots modifier for efficient carbon-based perovskite solar cells. Chem. Eng. J. 479, 147736 (2024).

Zhu, J. et al. Elimination of defect and strain by functionalized CQDs dual-engineering for all-inorganic HTMs-free perovskite solar cells with an ultrahigh voltage of 1.651 V. Nano Energy 104, 107920 (2022).

Tang, H. et al. Carbon quantum dot-passivated perovskite/carbon electrodes for stable solar cells. ACS Appl. Nano Mater. 4, 13339–13351 (2021).

Zhu, S. et al. Highly photoluminescent carbon dots for multicolor patterning, sensors, and bioimaging. Angew. Chem. Int. Ed. 52, 3953–3957 (2013).

Palermo, V., Palma, M. & Samori, P. Electronic characterization of organic thin films by Kelvin probe force microscopy. Adv. Mater. 18, 145–164 (2006).

Jena, A. K., Kulkarni, A. & Miyasaka, T. Halide perovskite photovoltaics: Background, status, and future prospects. Chem. Rev. 119, 3036–3103 (2019).

Li, Y. et al. Efficient, stable formamidinium-cesium perovskite solar cells and minimodules enabled by crystallization regulation. Joule 6, 676–689 (2022).

Wang, J. et al. Tuning an electrode work function using organometallic complexes in inverted perovskite solar cells. J. Am. Chem. Soc. 143, 7759–7768 (2021).

Tress, W. et al. Performance of perovskite solar cells under simulated temperature-illumination real-world operating conditions. Nat. Energy 4, 568–574 (2019).

Wang, Y. et al. Thermodynamically stabilized β-CsPbI3–based perovskite solar cells with efficiencies >18%. Science 365, 591–595 (2019).

Haschke, J. et al. The impact of silicon solar cell architecture and cell interconnection on energy yield in hot & sunny climates. Energy Environ. Sci. 10, 1196–1206 (2017).

Pei, F. et al. Thermal management enables more efficient and stable perovskite solar cells. ACS Energy Lett. 6, 3029–3036 (2021).

Choi, K. et al. Heat dissipation effects on the stability of planar perovskite solar cells. Energy Environ. Sci. 13, 5059–5067 (2020).

Singh, P. & Ravindra, N. M. Temperature dependence of solar cell performance- an analysis. Sol. Energy Mater. Sol. Cells 101, 36–45 (2012).

Xu, L. et al. Heat generation and mitigation in silicon solar cells and modules. Joule 5, 631–645 (2021).

Yang, N. et al. Improving heat transfer enables durable perovskite solar cells. Adv. Energy Mater. 12, 2200869 (2022).

Thirsk, R., Kuipers, A., Mukai, C. & Williams, D. The space-flight environment: the international space station and beyond. Can. Med. Assoc. J. 180, 1216–1220 (2009).

Oliveira, M. C. C. D., Diniz Cardoso, A. S. A., Viana, M. M. & Lins, V. D. F. C. The causes and effects of degradation of encapsulant ethylene vinyl acetate copolymer (EVA) in crystalline silicon photovoltaic modules: A review. Renew. Sust. Energy Rev. 81, 2299–2317 (2018).

Tang, K. et al. A thermal radiation modulation platform by emissivity engineering with graded metal-insulator transition. Adv. Mater. 32, e1907071 (2020).

Zhu, L., Raman, A. P. & Fan, S. Radiative cooling of solar absorbers using a visibly transparent photonic crystal thermal blackbody. Proc. Natl Acad. Sci. 112, 12282–12287 (2015).

Moore, G. E. & Allison, H. W. Spectral and total thermal emissivities of oxide-coated cathodes. J. Appl. Phys. 12, 431–435 (1941).

Li, Y. et al. Exploiting electrical transients to quantify charge loss in solar cells. Joule 4, 472–489 (2020).

Acknowledgements

This work was financially supported by the Ministry of Science and Technology of the People’s Republic of China (2021YFB3800103 (D. L.)) and the National Natural Science Foundation of China (Nos. 52361145847 (Q. M.), 52172260 (D. L.), 52203368 (B. Y.), 52227803 (Q. M.), 52222212 (J. S.)).

Author information

Authors and Affiliations

Contributions

B. Y. fabricated and characterized solar cells, conducted temperature simulations based on the device model under different conditions, and performed the synthesis and characterization of the CQDs. B. Y. and J. S. conducted temperature measurements, and wrote the first draft of the paper. B. Y. and Y. Li conducted AFM and KPFM experiments and analyses, performed stability tests on the devices. Y. Li fabricated 1 cm2 carbon-based PSCs, Y. C. conducted SEM experiments, Y. Li and Y. C. performed SEM analysis together, and S. T. conducted XRD measurements. F. M. conducted TEM measurement. H. W. performed EQE measurements. Y. Luo. helped to conduct stability testing. D. L. and Q. M. supervised the project and revised the paper. All authors discussed the results and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, B., Shi, J., Li, Y. et al. Regulating three-layer full carbon electrodes to enhance the cell performance of CsPbI3 perovskite solar cells. Nat Commun 16, 3328 (2025). https://doi.org/10.1038/s41467-025-58672-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-58672-y

This article is cited by

-

A Comprehensive Device Modeling of 2D/3D Perovskite Solar Cell with an Optimized Design: A SCAPS-1D Simulation Study

Transactions on Electrical and Electronic Materials (2025)

-

Research progress on perovskite solar cells based on organic carbon electrodes

Carbon Letters (2025)