Abstract

Biosynthesis of steroids by artificially designed cell factories often involves numerous nicotinamide adenine dinucleotide phosphate (NADPH)-dependent enzymes that mediate electron transfer reactions. However, the unclear mechanisms of electron transfer from regeneration to the final delivery to the NADPH-dependent active centers limit systematically engineering electron transfer to improve steroids production. Here, we elucidate the electron transfer mechanisms of NADPH-dependent enzymes for systematically engineer electron transfer of Saccharomyces cerevisiae, including step-by-step engineering the electron transfer residues of 7-Dehydrocholesterol reductase (DHCR7) and P450 sterol side chain cleaving enzyme (P450scc), electron transfer components for directing carbon flux, and NADPH regeneration pathways, for high-level production of the cholesterol (1.78 g/L) and pregnenolone (0.83 g/L). The electron transfer engineering (ETE) process makes the electron transfer chains shorter and more stable which significantly accelerates deprotonation and proton coupled electron transfer process. This study underscores the significance of ETE strategies in steroids biosynthesis and expands synthetic biology approaches.

Similar content being viewed by others

Introduction

Electron-requiring reactions, such as the catalytic processes of cytochrome P4501 and reductases2,3, are essential for numerous biosynthesis steps of steroids. Generally, it starts from nicotinamide adenine dinucleotide phosphate (NADPH) and other electron donor regeneration, which are then transferred to NADPH-dependent enzymes by electron transfer components, and finally reach the catalytic center by residues with electron transfer function4,5,6. To increase the availability of electron donors for steroids productions, existing synthetic biology strategies in metabolic7, cofactor4,8, and enzyme engineering1 primarily focus on modifying cofactor regeneration pathways, or reduce the physical distance between NADPH-dependent enzymes and electron transfer components by using linker peptides9. However, these strategies often overlook the fact that electron transfer to the active center requires a series of residues to facilitate the process through deprotonation and proton-coupled electron transfer (PCET) and the electron transfer in biological systems is typically a multi-step and coordinated process10,11,12,13. Therefore, systematically engineering the above whole electron transfer process (ETE strategy) is considered as a synthetic biology strategy for overcoming multiple electron-requiring rate-limiting steps in the biosynthesis of steroids.

Steroids and their pharmaceutical derivatives14,15,16 involve numerous electron-requiring rate-limiting steps in their biosynthesis from simple carbon sources in Saccharomyces cerevisiae14,17. For instance, the biosynthesis of cholesterol (Cho) and pregnenolone (Prn) required reducing the C7 = C8 double bond (catalyzed by 7-Dehydrocholesterol reductase, DHCR7), cleaving the side chain (catalyzed by P450 sterol side chain cleaving enzyme, P450scc), and other electron-requiring rate-limiting steps2,14. P450scc is composed of CYP11A1/CYP87A and cytochrome P450 reductase (CPR)14. In vertebrates, CYP11A1 paired with adrenodoxin reductase (ADR) and adrenodoxin (ADX) for the cleaving of Cho to synthesize Prn18,19. In plants, CYP87A paired with cytochrome P450 reductase (CPR) to cleave either Cho or campesterol to synthesize Prn18,19. ADX-ADR20,21,22,23 or CPR could capture electrons from NADPH and subsequently transfers them to CYP11A1 and CYP87A via the electron transfer chain, respectively24. DHCR7, a NADPH-dependent ene-reductases, can transfer electrons independently without CPR2,25. Although the crystal structures of NADPH-dependent ene-reductases have been reported to elucidate the binding modes of substrates and NADPH26,27,28, the internal electron transfer mechanism and the residues of the electron transfer chain of DHCR7 remain unclear25. Moreover, the acidic residues of P450scc’s CYP11A1/CYP87A could seize a proton from the hydroxyl group of 20α,22(R)-dihydroxycholesterol, thereby promoting the side-chain cleavage through a two-electron transfer to the heme center29. Considering that the acidic microenvironment in S. cerevisiae could affect the complex electron transfer process30,31,32,33. Given that DHCR7 and P450scc represent two distinct typical modes of the electron transfer chain2, we thus selected these two processes corresponding to two steroids (Cho and Prn) to demonstrate the effectiveness of ETE in improving steroids production.

In this work, to establish standardized steps for ETE process, S. cerevisiae with rate-limiting DHCR7 and P450scc is systematically optimized by engineering the electronic transport residues of NAPDH-dependent enzymes, electronic transport elements, and electronic donor regeneration pathway for efficient complete biosynthesis of Cho and Prn. For ETE of DHCR7 from Bos taurus, introducing polar residues into the reductase domain and replacing tyrosine residues into the electron transfer chain short the distance for capturing electrons and bring more stable electron transfer and efficient substrate capture, respectively. This results in a 68% reduction in the length of the electron transfer chain and a 9.6-fold increase in the activity of the mutation. For ETE of CYP87A (P450scc) from Rehmannia glutinosa, using linker to link reductase and introducing acidic residues into catalytic pocket facilitate deprotonation and accelerated electron transfer. Finally, building upon strengthening the NADPH regeneration pathway, electron transfer partners from Homo sapiens are further integrated to redirect more carbon flux toward Cho and Prn in S. cerevisiae. These ETE methods collectively enable the production of 1.78 g/L of Cho and 0.83 g/L of Prn in a 5-L bioreactor. Thus, our comprehensive and systematic ETE processes provide a paradigm for improving steroids biosynthesis.

Results

DHCR7 is rate-limiting step for complete biosynthesis of Cho in S. cerevisiae

First, we constructed the biosynthetic pathway to produce 7-dehydrocholesterol (Dhc), the key precursor of Cho. Considering the endogenous biosynthetic pathway for ergosterol in S. cerevisiae competes for carbon flux with the pathway for Cho de novo synthesis (Fig. 1A)34, DHCR24 from Gallus with the promoter PTEF was inserted into ERG5 and ERG6 sites to achieve two copies, thereby facilitating the accumulation of Dhc and reducing carbon flux toward ergosterol (Fig. 1A). The resulting strain D7-1 (Supplementary Data 1) produced 203 mg/L of Dhc (Fig. 1B). Subsequently, to convert Dhc into Cho, we screened DHCR7 from four species (Bos taurus, Pangasianodon hypophthalmus, Sus scrofa, and Danio rerio). The resulting strain D7-1 with pY26-BtDhcr7 could produce a maximum Cho production of 31 mg/L (Fig. 1B) but 146 mg/L Dhc was still accumulated (Fig. 1C). Obviously, DHCR7 is the rate-limiting heterologous enzyme and requires engineering.

A Schematic of the yeast mevalonate (MVA) pathway for cholesterol (Cho) biosynthesis. Endogenous synthesis of 2,3-epoxysqualene proceeds via the MVA pathway, followed by cyclization through ERG7 to form lanosterol. In the endoplasmic reticulum, lanosterol is sequentially converted by ERG2/3/7/11/24/25/26/27 into cholesta-5,7,24-trien-3β-ol and ergosterol. Exogenous 24-dehydrocholesterol reductase (DHCR24) and 7-dehydrocholesterol reductase (DHCR7) then convert cholesta-5,7,24-trien-3β-ol toward Cho. ERG5 and ERG6 are knocked out to block flux toward ergosterol. B Cho titers (pink bars) and optical density at 600 nm (OD600) (gray bars) in strain D7-1 expressing Bos taurus (BtDHCR7), Pangasianodon hypophthalmus (PhDHCR7), Sus scrofa (SsDHCR7), or Danio rerio (DrDHCR7) DHCR7. C 7-dehydrocholesterol (Dhc) titers (pink bars) and OD600 (gray bars) in D7-1 expressing BtDHCR7, PhDHCR7, SsDHCR7, or DrDHCR7. Data are presented as mean ± s.d. from three biologically independent replicates. Source data are provided as a Source Data file.

ETE of BtDHCR7 for efficient complete biosynthesis of Cho

Elucidating the catalytic mechanism of DHCR7 and its electron transfer mechanism was crucial for the ETE process. First, BtDHCR7 was modeled by AlphaFold235 (Supplementary Fig. 1) and docked with both Dhc and NADPH to determine the substrate-binding domain and NADPH-binding domain (Fig. 2A and S21). Subsequently, we performed additional docking36 of Dhc within a 10 × 10 × 10 Å box near the substrate channel exit of DHCR7 to find Dhc enters the catalytic pocket process2. Docking result showed that the Gibbs free energy change (ΔG) of Dhc in the substrate capture domain formed by Y430-Y434 was −8.31 kcal/mol, while in the catalytic pocket formed by Y317, the binding energy was −10.25 kcal/mol (Supplementary Fig. 2). Moreover, we also found a conformation (site3) for substrate entry in the channel between the two pockets, but with the lowest ΔG of −5.52 kcal/mol for the binding pose. However, the ΔG at site three was too high (>−6 kcal/mol), preventing it from serving as a stable conformation for further analysis (Supplementary Fig. 2). As shown in Fig. 2A, Dhc could both bind to the substrate-binding domain with Y317 and the surface at the entrance of the catalytic pocket with F430 and F434, which was further named as substrate-recognizing domain. The nicotinamide group of NADPH could bind to Y55, which was formed the NADPH-binding domain of DHCR7. However, how electrons were transferred from the NADPH-binding domain to the active center remained unknown. Aromatic residues, such as phenylalanine and tyrosine, are excellent carriers of electron transfer and could facilitate electron transfer through the resonance stabilization of radical intermediates10,37,38. We happened to discover that there is a series of aromatic residues (Y55, F56, F430, F434, and Y317) between the NADPH-binding domain and the catalytic center, which might form the electron transfer chain of BtDHCR7 (Fig. 2A). To verify our above hypothesis, Y55, F56, F430 and F434 were mutated to alanine while Y317 was mutated into phenylalanine for disturbing electron transfer (Fig. 2B). It showed that a sharp decline in Cho production was observed when one of residues involved in electron transfer was disrupted, and DHCR7 even completely lost its activity with no Cho production when two residues involved in electron transfer were disrupted (Fig. 2B). Moreover, Y317F-DHCR7 mutation completely lost its activity (Fig. 2A, B), suggesting its essential role in finally transferring the electron to the substrate. In conclusion, in step 1 (Fig. 2A), free Dhc was captured by the DHCR7’s substrate-recognizing domain (SRD) through π-π stacking interactions with F434 and F430, subsequently entering the active center composed of Y317 (step 2 shown in Fig. 2A). Simultaneously, electrons from NADPH are captured by Y55 in NADPH-binding domain and transferred through the electron transfer chain (measured as 29.4 ± 4.7 Å) with F56, F430, and F434 to the active center Y317, facilitating the electrophilic addition at the C7 = C8 of Dhc to synthesize Cho (Fig. 2A). Thus, in the electron transfer chain of wild-type BtDHCR7, Y55 played the role for capturing the nicotinamide group of NADPH; F56, F434, and F430 played the role for the transmission of electrons by the π-electron clouds; Y317 played the role for receiving the electron, which then supplies electrons to the C7 = C8 of Dhc.

A The catalysis of 7-dehydrocholesterol (Dhc) by 7-dehydrocholesterol reductase (DHCR7) involved two steps: substrate capture (white region) and substrate binding (yellow region). Recognition sites (white region) are involved in substrate binding; F430 and F434 serve as binding residues. In the catalytic pocket, Y317 donates electrons for catalysis. Y55, F56, F430, F434, and Y317 (marked in red) together form the electron transfer chain. B Residues in the electron transport chain were identified by alanine scanning or by substituting tyrosine with phenylalanine. Y317 of codon-optimized DHCR7 (BtDHCR7) was mutated to Phe and lost activity. C Rationally engineering BtDHCR7 was divided into four steps: 1. Engineering the L67 and L426 of DHCR7’s substrate-recognizing domain; 2. Engineering the W280 and Y290 of DHCR7’s substrate-binding domain; 3. Engineering the A49 and I53 of DHCR7’s NADPH-binding domain; 4. Engineering the F430 and F434 of DHCR7’s electron transfer chain. ETE of BtDHCR7 was step 3 and 4. The two blue arrows represent the capture and transfer of electrons from NADPH to C7 = C8, respectively. The yellow arrow represents DHC entering the catalytic pocket (step 2) after being captured by DHCR7 (step 2). D Rationally engineering BtDHCR7 by engineering substrate-recognizing domain and substrate-binding domain. W280 and Y290 were subjected to saturation mutagenesis, and the mutants with the highest Cho production were shown. L67V-L426A-BtDHCR7 was named M1. L67V-L426A-W280Y-Y290W-BtDHCR7 was named M2. The final OD600 value and Cho yield of fermentation are provided. (E) Rationally engineering BtDHCR7 by engineering NADPH-binding domain and electron transfer chain. I53T-M2 was named as M3. I53T-F430Y-F434Y-M2 was named M4. The final OD600 value and Cho yield of fermentation are provided. F Electron transfer chain 2 was another electronic transfer chain in M4. G Western blot analysis of BtDHCR7 and its variants. 1: WT-BtDHCR7, 2: L67V-BtDHCR7, 3: M1, 4: M2, 5: I53W-M2, 6: M3, 7: F430Y-M3, 8: M4. H Engineering the electron transfer chain of MuBtDHCR7 demonstrated the electron transfer chain 1 was the primary chain. Values are shown as mean ± s. d. from three biological replicates. Source data are provided as a Source Data file.

Based on the catalytic and electron transfer mechanism, SRD, substrate-binding domain (SBD), and electron transfer chain of BtDHCR7 were gradually engineered (Fig. 2C). Firstly, for engineering SRD, we noticed that compared to the conformation of Dhc in the catalytic pocket, the side chain of Dhc in the substrate recognition domain was in a twisted state (Fig. 2C). L67 and L426 of the wild-type BtDHCR7, located within 4 Å of Dhc’s side chain, hindered the side chain from entering the SRD, resulting in a twisted conformation compared to the SBD (Fig. 2C), which thereby reduced BtDHCR7’s catalytic efficiency. Thus, L67 and L426 of BtDHCR7 were mutated into hydrophobic residue of small conformations (G/A/V/I) to avoid the above steric hindrance. As a result, the BtDHCR7-L67V-L426A (M1) variant increased the production of Cho from 31 to 77 mg/L (Fig. 2D). Subsequently, for SBD of DHCR7, we noticed that Dhc only formed a π-π stacking interaction with Y317. To further enhance the affinity of the DHCR7’s SBD for the Dhc, Y290 and W280, which located within 5 Å of the 2C-OH of Dhc were further engineered to push the B-ring of the steroid closer to the Y317 active center and to provide additional intermolecular forces with 2C-OH of Dhc (Fig. 2C). Thus, starting from M1, W280 and Y290 were subjected to saturation mutagenesis. It showed that M1- W281Y-Y291W (M2) variant increased the production of Cho from 77 to 92 mg/L (Fig. 2D). Thirdly, rationally engineering the DHCR7 focused on engineering the electron transfer chain. After iteratively engineering the DHCR7’s SRD and SBD, resulting in M2, its electron transfer chain needed to be engineered. The ETE of BtDHCR7 involved two steps: shortening the distance for NADPH electron capture and engineering the electron transfer residues. In the NADPH-binding domain of the wild type, Y55 is responsible for capturing and transferring electrons. To further reduce the electron capture distance, we engineered the A49 and I53 of M2, located 4 Å from the electron-donating reduced nicotinamide group of NADPH, into polar residues to accelerate obtaining the electrons of NADPH. It showed that M2- I53W and M2- I53T (M3) variants increased the production of Cho to 121 mg/L and 124 mg/L, respectively (Fig. 2E). The mechanistic analysis of BtDHCR7 has confirmed that F430 and F434 in the electron transfer chain not only transferred electrons but also captured the Dhc from the medium. Additionally, we also found that the binding position of F430 with Dhc was similar to that of Y317 with Dhc in the SBD. However, F430 can only facilitate electron transfer and not act as an electron donor, so it was further mutated to tyrosine. It showed that only M3- F430Y variant increased the production of Cho to 179 mg/L (Fig. 2E). Tyrosine could also increase the π-electron cloud density of the conjugated system, thereby further enhancing electron transfer efficiency10. Thus, F434 of electron transfer chain was further mutated into tyrosine, which resulted in M3-F430Y-F434Y (M4, MuDHCR7) variant could increase the production of Cho to 191 mg/L (Fig. 2E), representing a 5.93-fold improvement over wild-type BtDHCR7. Additionally, Western blot (WB) analysis (Fig. 2G) of wild-type BtDHCR7 and its key variants indicated that the ETE process does not affect its expression level in S. cerevisiae. The nearly unchanged OD600 value of the S. cerevisiae with DHCR7 indirectly suggests that the ETE of DHCR7 did not impact growth and metabolism.

Based on the rational engineering of the four regions of DHCR7 described above, the electron transfer chain is theoretically composed of T53, Y430, Y434, and Y317, but biochemical experiments are needed to prove this. Thus, alanine scanning was performed on MuDHCR7 to biochemically verify the electron transfer chain was 1 or 2 (Fig. 2F). The results showed that blocking electron transfer chain 1 (Y55 mutated to alanine or phenylalanine, which cannot capture NADPH electrons) resulted in cholesterol titer of 155 mg/L and 189 mg/L, respectively (Fig. 2H). Blocking electron transfer chain 2 (T53 mutated to alanine or leucine, which cannot capture NADPH electrons) resulted in cholesterol titer of 87 mg/L and 130 mg/L, respectively (Fig. 2H). Obviously, when electron transfer chain 2 is blocked, DHCR7 activity decreases significantly. In contrast, when electron transfer chain 1 is blocked, Y55A-MuDHCR7 exhibits a noticeable reduction in activity, likely due to the absence of aromatic residues in the NADPH-binding domain, which weakens its ability to capture NADPH. Y55F-MuDHCR7, while blocking electron transfer chain 1, retains an aromatic residue in the NADPH-binding domain to facilitate NADPH capture. As a result, Y55F-MuDHCR7 maintains high activity consistent with MuDHCR7. As a result, the electron transfer chain in MuDHCR7 was more favored to be the electron transfer chain 2, composed of T53, Y430, Y434, and Y317 (Fig. 2F).

Computational simulation analysis for ETE of BtDHCR7 process

Rational engineering of BtDHCR7, particularly through ETE, has achieved remarkable results but still needed to employ computational simulations to deeply analyze the specific electron transfer mechanisms. In the engineered SRD of DHCR7, modifying the hydrophobic residues L67 and L426 to smaller hydrophobic residues enabled the steroid side chain to a more extended conformation, thereby releasing the constraints imposed by the wild-type substrate recognition domain on the steroid side chain (Fig. 3A). Consistently, an increase in B-factor fluctuations (Fig. 3C) in the steroid side chain region within the SRD, further confirming that the L67A and L426A mutations expanded DHCR7’s SRD to better accommodate Dhc. The binding affinity analysis of the SRD of WTDHCR7 and MuDHCR7 (residues within 4 Å of the substrate) for Dhc showed that L67V and L426A reduced the repulsive forces of 10 and 15 kJ/mol on the substrate side chain to −2 and 1 kJ/mol, respectively (Fig. 3D). Binding affinity analysis revealed that these mutations reduced repulsive forces within the SRD, facilitating substrate entry and enhancing DHCR7’s catalytic efficiency. In the engineered SBD of DHCR7, Y290W provided a repulsive force of 37.8 kJ/mol on the steroid A/B ring, while the W280Y provided an attractive force of −48.0 kJ/mol (Fig. 3G), thereby reducing the distance between the C7 = C8 and the catalytic site Y317 from 4.5/4.0 Å to 3.8/3.9 Å (Fig. 3E, F). In engineering NADPH-binding domain, the nicotinamide group of NADPH is positioned closer to T53 within 3.1 Å, and its distance from Y55 is reduced from 6.5 Å to 5.7 Å (Fig. 3B). The electron transfer chains of wild-type BtDHCR7 and MuDHCR7 are composed of Y55-F56-F430-F434-Y317 and T53-Y430-Y434-Y317, respectively (Fig. 3B). Different from the wild type, the electron transfer chain in MuDHCR7 started with T53 capturing the nicotinamide group of NADPH, using the π-electron clouds of Y434 and Y430 to transmit electrons, again reaching at the active site Y317, which supplies electrons to the C7 = C8 of Dhc. Firstly, we used 100-ns replica exchange molecular dynamics (REMD) simulation to analyze the dynamic changes of distances between the electron transfer residues in BtDHCR7 and M4 (Fig. 4A), respectively. Starting from the capture of electrons from NADPH by the electron transfer chain, the distances from the nicotinamide group of NADPH to T53 (wild-type BtDHCR7) and Y55 (MuBtDHCR7) were 5.8 ± 0.8 Å and 4.2 ± 0.4 Å, respectively (Fig. 4A). Subsequently, the distances between residues in the electron transfer chain of wild-type BtDHCR7 remain within 5–10 Å, whereas that of M4 can be stably maintained within 2–5 Å (Fig. 4A). As a result, the electron transfer chain length of WT-DHCR7 and MuDHCR7 was 29.4 ± 4.7 and 21.3 ± 3.9 Å, respectively (Fig. 4A).

A L67 and L426 of DHCR7’s substrate-recognizing domain were engineered. L67V and L426A allow the steroid side chain to expand. The Dhc marked in the yellow and grey stick represented the conformation in the modified SRD and wild-type SRD, respectively. B Left: NADPH located in the wild-type DHCR7. Residues with electron transfer functions are rendered in yellow sticks. Right: NADPH located in the MuBtDHCR7. Residues with electron transfer chain 1 and 2 functions are rendered in red and yellow sticks, respectively. C B-Factor values of SRD of WTBtDHCR7 (black) and MuBtDHCR7 (red) with Dhc complexes in 100 ns. D Free energy calculation for residues within 4 Å of Dhc in the DHCR7’s SRD. The red bar represents wild-type BtDHCR7 (WT-BtDHCR7). The gray bar represents mutant BtDHCR7 (Mu-BtDHCR7). E Y290 and W280 were engineered for shortening Y317-C7/C8 distances. The DHC marked in the yellow and pink stick represented the conformation in the wild-type substrate-binding domain and mutant substrate-binding domain, respectively. F The distances between Y317 and C7/C8 of Dhc. G Free energy calculation for residues within 4 Å of Dhc in the DHCR7’s SBD. The red bar represents WT-BtDHCR7. The gray bar represents mutant Mu-BtDHCR7. Source data are provided as a Source Data file.

A Analyzing electron transport chain length of DHCR7 by replica exchange molecular dynamics (REMD) simulation in 100 ns. Red: analyzing the distances of MuDHCR7. Black: analyzing the distances of WTDHCR7. B 2D sketch of the electron transfer process in wild type DHCR7 (WTDhcr7) and mutant DHCR7 (MuDHCR7). The electron transfer chain was rendered in blue. (1) and (2) showed Y317 or Y430 provided two electrons to C7 = C8. C Analyzing the electron capture and catalytic residues of DHCR7. An another electron transfer chain was formed by T53, Y430, Y434, and Y317. Y317 and Y430 were both the catalytic centers of MuDHCR7. MD simulation was used to determine the distance changes from the active groups of NADPH to T53 (red) and Y55 (black) for giving electrons within 100 ns. The distance changes from C7 = C8 to Y317 (MuDHCR7, black), Y317 (WTDHCR7, red), and Y430 (MuDHCR7, blue) for receiving electrons within 100 ns. D QM/MM calculated energy profile (in kcal/mol) for the C7 = C8 addition reaction in engineered catalytic pocket 1 (black) and catalytic pocket 2 (purple). QM/MM calculation optimized structures of key residues involved in the reaction, and key distances are given in angstroms. TS1 and TS2 were shown the Y317 for catalyzing Dhc. TS1’ and TS2’ were shown the Y430 for catalyzing Dhc. E The catalytic residues of MuDHCR7 were determined by alanine scanning. Y317 and Y430 in mutant DHCR7 were determined as the catalytic residues. Values are shown as mean±s. d. from three biological replicates. Source data are provided as a Source Data file.

Enhancing the efficiency of electron transfer from the terminal residues of the electron transfer chain 2 to the substrate was also the crucial step in the ETE process (Fig. 4B). We have confirmed that Y317 was the key electron-donating residue in the active pocket. MD simulation results showed that the distance between Y317 of MuBtDHCR7 and the C7 = C8 double bond of the substrate is 3.9 ± 0.14 Å, with the length and fluctuation range of this distance being lower than that of wild-type BtDHCR7 (4.1 ± 0.52 Å) (Fig. 4C). This indirectly indicated that the Y317 of M4 could provide electrons to the substrate more effectively. Notably, the ETE of BtDHCR7 also involved engineering the SRD. F430 of wild type BtDHCR7 SRD only facilitated electron transfer without providing electrons to the substrate and was further mutated into tyrosine for possessing both electron transfer and electron donation capabilities to the substrate, which significantly enhanced the activity of DHCR7 (Fig. 4C). To verify our conclusion as Y430 was another catalytic center, Y317, Y430 and Y434 were further mutated to alanine, respectively (Fig. 4E). Consistent with our conclusion, M4- Y317A-Y430A and M4- Y430A-Y434F variants both lost activities. However, the activity of M4- Y317A and M4- Y317A-Y434A variants decreased but did not disappear, indicating that the catalytic reaction in pocket Y430 takes precedence over that in pocket Y317 (Fig. 4E). We noticed that the two active pockets formed by Y317 or Y430 have similar binding conformation with Dhc. Thus, we extracted the catalytic pockets involving Y317-Y280 and Y430-Y434, along with the substrate, for performing QM/MM calculations (Fig. 4D). In step 1, the phenolic oxygen of Y317 or Y430 first transferred an electron and hydrogen to C8, polarizing the C7 = C8 double bond and rendering C7 electron deficient. The C8-Dhc toke a proton from Y317 or Y430 to generate intermediate (Int1) via the transition state (TS1), which required an activation-free energy barrier of 21.4 and 18.9 kcal/mol (Fig. 4D). In step 2, a water molecule positioned at the active site, aided by a hydrogen-bond network with Y317 or Y430 and low proton transfer energy, rapidly donated a proton (H⁺) to C7, which required an activation-free energy barrier of 13.1 and 11.1 kcal/mol (Fig. 4D). This concerted electron and proton transfer (PCET) ultimately transforms the C7 = C8 double bond into a stable saturated C7-C8 single bond, completing the reduction process. Thus, QM/MM calculations confirmed that Y430, as an engineered catalytic site, exhibits reaction energy barriers similar to those of Y317. Both computational simulations and biochemical experiments jointly confirm that Y430 was the catalytic site. Due to the introduction of Y430 to form an active center, the electron transfer chain 3 (Fig. 3B) starts with T53 capturing the nicotinamide group’s electron of NADPH and transferring the electron to the active site Y430, which supplies electrons to the C7 = C8 of DHC. Thus, the electron transfer chain 3 was further shortened from 21.3 ± 4.7 Å to 9.5 ± 2.2 Å (Figs. 3B and 4A). As a result, the ETE process of BtDHCR7 brought another catalytic site, which further shortened the electron transfer chain by 68%, which significantly increased the activity.

Optimizing the elements of P450scc systems for complete biosynthesis of Prn

Constructing an efficient de novo biosynthesis pathway for Prn requires obtaining effective P450scc catalytic components (Fig. 5A)39. Firstly, we screened CYP11A1/CYP87A within the P450scc system. CYP11A1/CYP87A sequences from 28 different species (26 CYP11A1 derived from animals, 2 CYP87A species from plants) were retrieved from the National Center for Biotechnology Information (NCBI) database and used to conduct a phylogenetic tree analysis (Supplementary Fig. 3). Notably, animal-derived CYP11A1 requires pairing with ADR and ADX to function, while plant-derived CYP87A requires pairing with Arabidopsis thaliana cytochrome P450 reductase 2 (ATR2) to be functional. CYP11A1 and CYP87A enzymes were selected to introduce into the D7-1 with pY26-MuBtDHCR7 strain for further catalytic validation (Fig. 5C, D). Moreover, ADR and ADX from H. sapiens and ATR from Arabidopsis thaliana were selected to serve as redox partners. As a result, G1_BtADR/X (BmCYP11A1-BtADR-BtADX) gave the best Prn production among animal source CYP11A1, reaching 25 mg/L (Fig. 5C). Considering that the signal peptides of animal-derived CYP11A1, ADR, and ADX are targeted to the mitochondria, and that S. cerevisiae lacks the enzymes needed to transport cholesterol to the mitochondria, we further truncated the signal peptides of pre-selected BmCYP11A1, BtADR, and BtADX (Fig. 5B). The results showed that truncating only the ADX signal peptide yielded the highest cholesterol production, reaching up to 36 mg/L (Supplementary Fig. 4). CYP87A from R. glutinosa (RgCYP87A3) gave the best Prn production among plant source CYP87A, reaching 94 mg/L. (Fig. 5C, D). Similarly, based on the structural prediction results of RgCYP87A3, the signal peptide at positions 21, 22, 23, 24, 25, 26 and 27 of RgCYP87A3 were respectively truncated. However, the Prn yield showed no improvement (Supplementary Fig. 5). Additionally, Western blot (WB) analysis of wild-type BmCYP11A1, CYP87A4 and RgCYP87A3 indicated that the expression level and activity of plant-derived CYP87A in S. cerevisiae are slightly higher than that of BmCYP11A1 with the highest activity among animal-derived CYP11A1 (Fig. 5B). Thus, RgCYP87A3 was selected for further engineering.

A Overviewing the de novo biosynthetic pathway of Prn production in S. cerevisiae. B Western blot analysis of BmCYP11A1, CYP87A4, RgCYP87A3 and its variants. C Cho production strain D7-1 was engineered to de novo biosynthesize Prn by introducing different combinations of CYP11A1 and CPR. RgCYP11A1 from R. glutinosa with ATR from A. thaliana produced 93.5 mg/L Prn. G1-G26 of CYP11A1 were derived from animals and compared with Bos taurus ADR and Bos taurus ADX. G27-G28 of CYP87A were derived from plants and compared with Arabidopsis thaliana cytochrome P450 reductase 2 (ATR2). The accession numbers of G1-G6 were shown in Supplementary Data 6. D G1-G26 of CYP11A1 were derived from animals and compared with Homo sapiens ADR and Homo sapiens ADX. G27-G28 of CYP87A were derived from plants and compared with Arabidopsis thaliana cytochrome P450 reductase 2 (ATR2). E The residues within a range of 4 Å near Cho in the heme center in WTRgCYP87A3 are shown. F Alanine scanning the residues within a range of 4 Å near Cho in WTRgCYP87A3 for determining residues for side chain cleaving. Moreover, Y105 and Y107 were also mutated into phenylalanine for determining the side chain cleaving function. G Engineering V118A-RgCYP87A3 using ETE strategy. V118 and A281 were mutated into acidic residues for proton extraction, respectively. V118A-A281D-T285E produced 243 mg/L Prn. ADR/X means ADR and ADX. Values are shown as mean ± s. d. from three biological replicates. Source data are provided as a Source Data file.

ETE of RgCYP87A for efficient complete biosynthesis of Prn and mechanism analysis

CYP87A can utilize its heme center to hydroxylate substrates and in combination with residues near the heme achieved side chain cleavage29. However, the side chain cleavage residues of RgCYP11A1 remain unknown. First, residues of RgCYP87A3 within 4 Å region of Cho were selected for alanine scanning and tyrosine was mutated to phenylalanine to determine the side chain cleavage residues (Fig. 5E). Considering that the knocking out the ERG6 inherently limits transformation efficiency and the introduction of CYP450 both reduced S. cerevisiae growth activity, the identification of RgCYP87A3 and its variants was conducted by transforming them into the C800 strain (Supplementary Data 1) with less metabolism engineering. After a three-day fermentation, 300 mg/L of Cho was added into the fermentation for the next two-days catalyzing process. As a result, RgCYP87A3-Y105A and RgCYP87A3-Y105F variant completely lost the ability of side chain cleavage and was identified as a side chain cleavage residue. Moreover, RgCYP87A3-V118A variant could increase the Prn production from 161 to 197.0 mg/L by adding 300 mg/L Cho as the substrate (Fig. 5F) and was selected for the next generation of engineering process. Based on the docking results, we found that Y105 is close to the C22-OH group, allowing it to abstract the proton and facilitate the subsequent side chain cleavage (Fig. 5E). Subsequently, QM/MM calculations analyzed the steps involved in Cho side-chain cleavage by RgCYP87A3. The results showed that the C22-OH took a proton from Y105 to generate intermediate (Int1) via the transition state (TS1), which requires highest the energy barrier of 13.5 kcal/mol in deprotonation of cleaving process (Fig. 6G). Moreover, the excessive distance of the steroid side chain from the Fe=O center similarly resulted in an energy barrier of 6.3 kcal/mol for the PCET process. The high energy barrier of deprotonation in the side chain cleavage process limits the efficiency of RgCYP87A3. We noticed that the naturally alkaline microenvironment in R. glutinosa benefited RgCYP87A3 for facilitating the final step of Prn synthesis by capturing the proton from the hydroxyl group of 20α,22(R)-dihydroxycholesterol to form an ionic bond40, thereby promoting electron transfer and enabling side-chain cleavage. Thus, starting from RgCYP87A3-V118A variant, A281 and T285 within 4 Å of C22-OH-Cho were further engineered into acidic residues for accelerating deprotonation process, which was the second-generation modification of RgCYP87A3 and belong to the ETE process. Finally, we found that the A281D-T285E variant of V118A-RgCYP87A3 (MuRgCYP87A3) could produce 243 mg/L of Prn (Fig. 5G).

A The conformation of Cho in the catalytic pocket of wild-type (cyan stick) and Mutant (green stick) RgCYP87A3. V118A, A281D, and T285E were shown in red. B In the wild-type catalytic pocket, the distances of C20 and C22 of Cho from the FeO center are 3.9 Å each. In the mutant catalytic pocket, these distances are 4.2 Å for C20 and 2.6 Å for C22. C Free energy calculation for residues within 4 Å of Cho in wild type (WT-RgCYP87A3, red) and mutant (Mu-RgCYP87A3, gray) RgCYP87A3’s heme center. D Schematic drawings the three steps of side chain cleaving process by D281, E285, and heme center. E Distances between FeO (heme) of WTRgCYP87A3 and C20/22 of Cho were measured by MD simulation in 100 ns. F Distances between FeO (heme) of MuRgCYP87A3 and C20/22 of Cho were measured by MD simulation in 100 ns. G QM/MM calculation calculated energy profile (in kcal/mol) for RgCYP87A3 cleaving Cho side chain process in engineered catalytic pocket (red) and wild type pocket (black). (H) QM/MM-optimized the structures in the RgCYP87A3 and mutant RgCYP87A3 cleaving reaction. Key distances of TS1, TS2, TS3, TS1’, TS2’, and TS3’ are given in Å. Values are shown as mean±s. d. from three biological replicates. Source data are provided as a Source Data file.

The biosynthesis of Prn by cutting the side chain of Cho with P450scc was a complex process involving two hydroxylation as the first step, followed by the loss of two protons from the two hydroxyl groups and ultimately the formation of a ketone group (Fig. 6D) as the second step29. For the first step, ensuring that the two carbon positions requiring hydroxylation were stably positioned above the heme center and in similar distances were the key to efficient dihydroxylation41. 100-ns MD simulation of RgCYP87A3 and Cho complexes (Fig. 6A, B) indicated that 20C and 22C were more stably exposed above the center of the heme (Fig. 6E, F), which further accelerated dihydroxylation process. Additionally, free energy calculations revealed that the D281 and E285 of MuRgCYP87A3 could contribute intermolecular forces of −48 kJ/mol and −51 kJ/mol, respectively (Fig. 6C). The stronger binding forces allow Cho to bind more stably in the substrate pocket of CYP87A3 for higher catalytic efficiency. For the second step, QM/MM calculation of wild type RgCYP87A3 suggests that the lack of acidic residues within 4 Å distance around 20α,22(R)-dihydroxycholesterol to capture its proton limited deprotonation process. Thus, we further performed QM/MM calculation for examining the deprotonation process (2) of proton abstraction from the 22-hydroxyl group in MuRgCYP87A3, which was engineered by ETE (Fig. 6G). Introducing T293E into the catalytic pocket of CYP87A3, compared to the original Y105, allows for closer proximity to the 22-OH proton (reduced from 2.3 Å to 1.5 Å), which further lowered the reaction energy barrier (from 13.5 kcal/mol to 9.1 kcal/mol) (Figs. 6G, H). Moreover, we also found that the engineered catalytic pocket of MuRgCYP87A3 reduced the distance between the steroid side chain and the FeO center from 2.7 Å to 1.8 Å, thereby lowering the energy barrier of the PCET process (3) during steroid cleavage from 6.3 to 3.4 kcal/mol (Figs. 6G, H). As a result, ETE process effectively promoted the deprotonation and PCET process, which further accelerated electron transfer efficiency and significantly improved the Prn production from 197 to 243 mg/L (Fig. 5G).

ETE of S. cerevisiae for efficient complete biosynthesis of Cho and Prn

The above obtained BtDHCR7 and RgCYP87 A3 variants with the highest catalytic efficiency (MuDHCR7 and MuRgCYP87A3) were used to construct de novo biosynthesis pathway of Cho and Prn in S. cerevisiae. Before this, the precursor metabolic pathway of Cho synthesis was strengthened (Fig. 7A). First, the mevalonate (MVA) pathway was strengthened by integrating tHMG1 and ID11 into the TY1 multiple copy sites42 of D7-1, resulting in D7-2. D7-2 with pY26-MuDHCR7 produced 228 mg/L Cho (Fig. 7B). ERG2 and ERG3 were further integrated into TY3 multiple copy sites of D7-2 for increasing the conversion rate of squalene to Cho, resulting in D7-3. D7-3 with pY26-MuDHCR7 produced 267 mg/L Cho (Fig. 7B). Subsequently, MuDHCR7 was integrated into the D7-3 genome in single, double, and multiple copy numbers, respectively (Supplementary Fig. 6 and Supplementary Fig. 7). As a result, D7-3 with two copies of MuDHCR7 (D7-4) could produce 303 mg/L Cho (Fig. 7B).

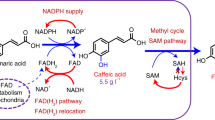

A Primary and secondary metabolic pathways for Cho and Prn synthesis in S. cerevisiae, along with the synthesis pathway for the electron donor (NADPH). Subcellular structure was created in BioRender. Chen, Q. (2025) https://BioRender.com/9smi93r. B Metabolic engineering and ETE of S. cerevisiae for Cho production. 3-hydroxy-3-methylglutaryl-CoA reductase 1 (tHMG1) encoded truncated 3-hydroxy-3-methylglutaryl-CoA reductase. IDI1 encoded isopentenyl-diphosphate delta isomerase 1. ERG2 encoded C-8 sterol isomerase. ERG3 encoded C-5 sterol desaturase. Hs_ADR encoded adriamycin from H. sapiens. Hs_ADX encoded adrenodoxin from H. sapiens. GDH encoded glutamate dehydrogenase from Bacillus subtilis. FPK encoded phosphoketolase from Bifidobacterium breve. PTA encoded phosphotransacetylase from Clostridium kluyveri. Gpp1 encoded glycerol-3-phosphate phosphatase 1. C Cellular NADPH/NADP+ ratios in the engineered D7−6, D7-7, and D7-8; samples for NADP(H) quantification were harvested after 48 h. The NADPH/NADP+ ratio was determined using the NADP+/NADPH quantitation kit. D High-density fermentation for Cho production in a medium supplemented with glucose for about 16 h and nitrogen for 72 h. Fermentation is divided into three stages, shown from light to dark. Glucose was added at 16 h, and YPD was added at 72 h. Values are shown as mean±s. d. from three biological replicates. Source data are provided as a Source Data file.

After optimizing the carbon flux through metabolic engineering, D7-4 was continuously engineered by ETE strategy (Fig. 7B). Given that the animal-derived electron transfer system supplied electrons to the endogenous ERG25 in S. cerevisiae20,21,22,23, thereby directing more carbon flux toward the subcellular structures involved in animal sterol synthesis, two electron transfer systems (adrenodoxin reductase (ADR)-adrenodoxin (ADX) from H. sapiens and human cytochrome b5, respectively) were integrated into D7-4, resulting in D7-5 and D7-6, respectively. D7-5 with b5 could produce 282 mg/L Cho, while D7-6 with both ADR and ADX produced 382 mg/L Cho (Fig. 7B). Subsequently, through fluorescent protein localization experiments, we observed that RgCYP87A3 was anchored to the endoplasmic reticulum, while DHCR7 and ADR are localized near the mitochondria-associated regions of the endoplasmic reticulum (Supplementary Fig. 8). ERG25 was also anchored near the mitochondria-associated regions of the endoplasmic reticulum, aligning closely with the positioning of DHCR7 and ADR in these regions (Supplementary Fig. 9). Then, a glucose 6-phosphate dehydrogenase (GDH) from Bacillus subtilis was integrated into D7-6 for recycling NADPH and enhancing the electron transfer efficiency, resulting in D7-7. This strain could produce 425 mg/L Cho (Fig. 7B). Besides enhancing the cofactor regeneration efficiency, FPK and PTA were introduced into the PPP for NADPH regeneration (D7-8). Consequently, D7-8 could synthesize 460 mg/L of Cho (Fig. 7B). To test whether the ETE process improves the efficiency of yeast NADPH regeneration, the ratio of NADPH/NADP+ of D7-6, D7-7, and D7-8 were measured, respectively. It showed that the ratio of NADPH/NADP+ from D7-6 to D7-8 increased from 0.3 to 0.8 using the electron transfer strategy (Fig. 7C). The strains D7-8 were used to produce Cho through fermentation in a 5-L bioreactor (Fig. 7D). The fermentation process of Cho biosynthesis is divided into two stages: In the first stage, 40 g/L glucose, 10 g/L yeast extract, and 20 g/L tryptone are provided, and fermentation takes place at 220 rpm and 30 °C for about 16 h. In the second stage, after the 40 g/L glucose is used up, 800 g/L glucose is gradually added. Moreover, the addition rate of 800 g/L glucose was 10 mL/h during 16–72 h of fermentation. To ensure that the accumulation of alcohol in the fermentation system does not affect yeast growth, the glucose flow rate was reduced to 2 mL/h in 72–144 h. The nitrogen sources (including 200 g/L peptone and 100 g/L yeast extract) were added at 72 h for the purpose of the strain grew well and produce more Cho accumulation. When the OD600 value was below 100, the feeding rate was set at 7 mL/h. Once the OD600 value exceeded 100, the feeding rate was adjusted to 15 mL/h until the end of fermentation. Finally, the titers of Cho reached 1.78 g/L (Fig. 7D).

For Prn production, pY26-MuRgCYP87A3-ATR were introduced into D7-8, resulting in D7-9 could produce 162 mg/L Prn. Subsequently, wild type RgCYP87A3-ATR and MuRgCYP11A1-ATR were integrated into the genome of strain D7-8 to achieve a more stable fermentation synthesis, resulting in D7-10-1 and D7-10-2. D7-10-2 with MuRgCYP87A3 could produce 194 mg/L of Prn, an increase of 138% compared to the wild type. Reducing the physical distance between redox partners and CYP450 enzymes is a strategy to enhance the electron transfer efficiency (ETE) of P450 enzymes1. Thus, to enhance electron transfer efficiency, MuRgCYP87A3 and ATR were linked using the flexible peptide GGGGS (Fig. 8A), resulting in D7-10-3. As a result, D7-10-3 could produce 261 mg/L Prn (Fig. 8A), an increase of 37% compared to the D7-10-2. Moreover, for comparing the catalytic efficiency improvements achieved by shortening the internal electron transfer chain formed by amino acid residues with those resulting from directly shortening the physical distance between CYP and CPR.

A Engineering S. cerevisiae for Prn production using ETE strategy. Promoting electron transfer efficiency using peptides to shorten the distance between RgCYP87A3 and ATR. B High-density fermentation for Prn production in a medium supplemented with glucose for about 16 h and nitrogen for 72 h. Values are shown as mean±s. d. from three biological replicates. Source data are provided as a Source Data file.

Finally, the strains D7-10-3 were used to produce Prn through fermentation in a 5-L bioreactor (Fig. 8B). The fermentation process of Prn biosynthesis is also divided into two stages: In the first stage, 40 g/L glucose, 10 g/L yeast extract, and 20 g/L tryptone are provided, and fermentation takes place at 220 rpm and 30 °C for about 16 h. In the second stage, after the 40 g/L glucose is used up, 800 g/L glucose is gradually added. Moreover, the addition rate of 800 g/L glucose was 10 mL/h during 16–72 h of fermentation. To ensure that the accumulation of alcohol in the fermentation system does not affect yeast growth, the glucose flow rate was reduced to 2 mL/h in 72–144 h. The nitrogen sources (including 200 g/L peptone and 100 g/L yeast extract) were added at 72 h for the purpose of the strain growing well and producing more Cho accumulation. The feeding rate was set at 7 mL/h until the end of fermentation. Finally, the titers of Prn reached 0.83 g/L (Fig. 8B).

Discussion

The ETE strategies established in this study included engineering electronic transfer residues of two types of NADPH-dependent enzymes, engineering electronic transport element for directing carbon flux, and engineering electronic donor regeneration pathway. Advancing beyond traditional synthetic biology strategies, the ETE approach in this study refines electron transfer engineering down to the residue level1,4,13.

Previous studies26,27,28 have reported numerous crystal structures of NADPH-dependent enone reductases, aiming to clarify the binding modes of the substrate and NADPH to better understand the electron transfer chain. Compared with the crystal structure of DHCR7 from Methylomicrobium alcaliphilum2, NADPH was both found to located in the three small α-helices and a β-parallel domain. But in our study, Dhc was found to not only bind to the two exposed α-helices on the surface of DHCR7 (consistent with what previously reported2) and near the NADPH binding domain, but also to bind to the internal cavity of DHCR7 (far away from NADPH binding domain). Moreover, SRD5A2 (Human steroid 5α-reductase 2), a steroid reductase, was found to use NADPH to directly transfer a hydride to testosterone, facilitated by glutamate and tyrosine residues that polarize the C-3 carbonyl group, promoting reduction at the ∆4,5 double bond28,43. However, our study showed that when the residues of the pocket closer to NADPH were mutated to alanine, DHCR7 did not completely lose its activity. In contrast, when Y317 in another binding pocket, which was farther from NADPH, was mutated to alanine, DHCR7 completely lost its activity. This suggests that the mode of Dhc binding near NADPH cannot directly provide hydride for the double bond reduction reaction in wild-type DHCR7. This also indirectly indicated the presence of a longer electron transfer chain from NADPH to Y317.

Our study suggested that an electron transfer chain composed of five aromatic residues transfers electrons from Y56 to the active site Y317, facilitating the catalytic process. Moreover, the ETE of DHCR7’s NADPH binding domain found that the mutation of I53Y, I53W, and I53T could enhance its activity. The side chains of tyrosine, threonine, and tryptophan capture hydride from NADPH to form O-H or N-H bonds, thereby facilitating electron transfer. Consistent with our findings, ErCry4a (cryptochrome 4a from the night-migratory European robin) was also found to capture electrons by form N-H bond with FADH and transfer electrons to the active site through other three tryptophan residues44. Tyrosine residue of ribonucleotide reductase (RNR) could bind to hydride transfer, donating electrons from the Fe2+, and utilized proton-coupled electron transfer (PCET) between residues in the electron transfer chain to transfer electrons to the active site45. Subsequently, unlike PCET process, wild-type DHCR7 transfers electrons via an electron tunneling pathway formed by three phenylalanine residues. Because the sp2 hybridized carbon atoms in the benzene ring exhibit higher electronegativity compared to sp3 hybridized carbons, leading to electron-withdrawing properties through the inductive effect38. Consistently, the ordered stacking of molecular layers was enhanced by introducing π–π stacking interactions in the material, thereby creating hopping channels for electron transfer and improving the efficiency of interfacial charge transfer46. More important, phenylalanine was found to play a crucial role for transferring electron in the long P450 monooxygenase electron transfer chain, which was mutated to alanine resulting P450 completely lost its electron transfer ability6,38. For designing an electron transfer chain composed of aromatic residues, the ETE process in our study focused on replacing phenylalanine with tyrosine residues. This substitution causes a greater change in the redox potential (ΔE°) of the residues in the electron transfer chain during protonation/deprotonation, thereby increasing the electron transfer rate in PCET reactions10,45. Consistently, our study also revealed that substituting phenylalanine with tyrosine in the electron transfer residues increased the π-electron cloud density of the conjugated system10, which resulted in the evolution of the electron transfer residues to donate electrons to the substrate and a shorter-more stable electron transfer chain. Interestingly, ETE of DHCR7 imparted catalytic activity to the substrate capture domain, which is located closer to the NADPH-binding domain. Moreover, the observation that the NADPH binding domain was far away from the catalytic pocket might be a key reason for the low catalytic activity of wild type DHCR7 from Bos taurus. F430Y, like Y317, could acquire two electrons from the electron transfer chain. The carbon atoms at the C7 = C8 double bond of 7-DHC are highly electronegative. The phenolic oxygen of Y317 could transfer an electron and hydrogen to C8, polarizing the C7 = C8 double bond and rendering C7 electron deficient. The reduction mechanism of steroid reductases reported in current studies primarily came from alkaliphilic bacteria and mammals26,28, whose microenvironments lack abundant protons. Given that fermentation in S. cerevisiae produces acidic metabolites (such as organic acids), the intracellular environment became acidic (around pH=5.5)30,33. Subsequently, a water molecule positioned at the active site, aided by a hydrogen-bond network and low proton transfer energy, rapidly donates a proton (H⁺) to C7. This concerted electron and proton transfer (PCET) ultimately transforms the C7 = C8 double bond into a stable saturated C7-C8 single bond, completing the reduction process.

The ETE process was also effective for oxidation-reduction partner-dependent enzymes, such as P450scc14,39. By ETE engineering, we increased the de novo biosynthesis yield of Prn nearly 11-fold compared to the previously reported titer14. A combination of phylogenetic analysis and empirical catalytic experiments revealed that plant-derived P450scc possessed a longer evolutionary history and higher activity compared with animal-derived P450scc. In animal-derived CYP11A1, the rate-limiting step is the first hydroxylation of Cho18. Our study suggested that the rate-limiting step in plant-derived CYP87A is the third cleavage step. Furthermore, QM/MM calculations in this study revealed that the rate-limiting step in the side chain cleavage process by RgCYP87A3 was the proton abstraction from C22-OH-Cho19,29. Interestingly, the naturally alkaline microenvironment in R. glutinosa benefited CYP87A for facilitating the final step of Prn synthesis by capturing the proton from the hydroxyl group of 20α,22(R)-dihydroxycholesterol to form an ionic bond40, thereby promoting electron transfer and enabling side-chain cleavage. Unlike the ionic bonds that captured protons, introducing the acidic residues into the RgCYP87A3 catalytic center by ETE could form covalent bonds with the C22-OH-Cho to accelerate electron transfer. Additionally, introducing the flexible peptide GGGGS to decrease the physical distance between CYP87A and its redox partner enhanced electron transfer efficiency, further boosting catalytic activity1,9. However, in terms of improvement magnitude, the acceleration of electron transfer achieved by using linker peptides to shorten the distance between the redox partner and P450 surpasses the enhancement obtained through substrate pocket engineering to expedite heme-to-substrate electron transfer (Supplementary Fig. 10). Because the upper limit of improvement achieved by using linkers to shorten the distance between the redox partner and CYP is significantly greater than that achieved by reducing the electron transfer distance between the substrate and the heme.

The complete biosynthesis of animal sterols from simple carbon sources in a cellular factory is a complex multi-enzyme catalytic process involving numerous redox reactions3. In fact, the electron transfer in S. cerevisiae is a highly complex process from metabolism perspective31,32. Consistent with the findings of Chen et al.4, introducing GDH, FPK, and PTA enzymes into S. cerevisiae to drive the PPP for efficient NADPH regeneration in our study effectively enhanced Cho and Prn production. More innovatively, the ETE strategy used in this study introduced the electron transfer system from the species producing the target product, thereby directing more carbon flux towards the target product. This is because animal-derived ADR and ADX20,21,22,23 are primarily localized in the mitochondrial matrix, while ERG2547,48,49 relies on iron-sulfur clusters synthesized within the mitochondrial matrix of S. cerevisiae for electron transfer. By introducing electron transfer components from the species of origin for the target product, an efficient pairing with ERG25 can be achieved, thereby enhancing its catalytic activity. This enhancement further improves the metabolic pathway efficiency of heterologous NADPH-dependent enzymes (DHCR7, DHCR24, and RgCYP87A3) near specific organelles, such as mitochondria. The ETE strategy ensures the enrichment of upstream metabolic intermediates within the same region, laying a solid foundation for the synthesis of the target steroids.

In conclusion, our study elucidated the electron transfer mechanisms of various types of NADPH-dependent enzymes involved in steroids biosynthesis and systematically designed the electron transfer process from regeneration to the final delivery to the active centers for the high-level production of steroids. Thus, the ETE strategy offered an efficient and advanced strategy for developing cell factories to synthesize steroids efficiently.

Methods

Chemicals

Standards of 7-dehydrocholesterol, cholesterol, and pregnenolone (analytical grade) were purchased from Macklin Reagent (Shanghai, China). NaCl, leucine, tryptophan, histidine, uracil, tryptone, glucose, yeast extract, and glycerol (analytical grade) were all purchased from Sangon (Shanghai, China). ProteinFind Anti His Mouse Monoclonal Antibody and ProteinFind Goat Anti-Mouse lgG (H + L) were both purchased from TransGen (Beijing, China).

Strains and plasmids

All strains used in this study were listed in Supplementary Data 1. Plasmids were used for heterologous expression of DHCR7, CYP11A1-ADR-ADX, and CYP87A-ATR2 in S. cerevisiae were listed in Supplementary Data 2. Primers used for constructing heterologous gene expression plasmids, mutants, and the upstream and downstream homologous arms of the genomic integration sites are listed in Supplementary Data 3. A Gibson assembly kit (TransGen, Beijing, China)was used to insert the required gene fragments into the vector50. E. coli JM109 was used for constructing all plasmids. The starting strains for constructing cell factories for steroid synthesis are all S. cerevisiae C800. All the primers and the constructed plasmids were confirmed by Sanger sequencing by Sangon Biotechnology Co., Ltd. (Shanghai, China). Sangon Biotech (Shanghai, China) synthesized the codon optimized for all DHCR7, DHCR24, CYP11A1, CYP87A, ATR, ADR, ADX, b5, FPK, and PTA genes (Supplementary Data 4) and primers. Escherichia coli JM109 was purchased from TransGen Biotech (Beijing, China) and used as the host for gene cloning.

Culturing S. cerevisiae for cholesterol and pregnenolone production

S. cerevisiae fermentation could be categorized into two types: using free plasmids and genes integrated into the genome. When S. cerevisiae was fermented using the free plasmid pY26-1 with uracil label (Ura), Ura-deficient yeast nitrogen base (YNB) medium (20 g/L glucose, 1.74 g/L amino acid–free YNB, 5 g/L ammonium sulfate, 0.05 g/L leucine, 0.05 g/L histidine, 0.05 g/L tryptophan, and 0.05 g/L uracil) was used for fermentation. When S. cerevisiae was fermented by integrating genes into the genome, a yeast extract peptone dextrose (YPD) medium consisting of 20 g/L peptone, 10 g/L yeast extract, and 20 g/L glucose was used. Shake flask cultivation experiments were performed using 250 mL flasks, with each flask containing 25 mL of YPD or YNB medium. The seeds cultivated for 17 h were inoculated at 1% (v/v) into 25 mL of YPD or YNB medium and then incubated at 220 rpm and 30 °C for 72 h.

The measurement of BtDHCR7 variants was conducted as follows: the pY26-DHCR7 plasmid (with the PTEF promoter driving DHCR7 expression) was constructed and transformed into the D7-1 strain (the feature was described in Supplementary Data 1). During fermentation, single colonies were selected and grown in 25 mL of Ura- YNB medium for 72 h. The Cho yield and the final OD600 value were then measured for determining the activity of BtDHCR7 variants. The measurement of CYP11A1 and CYP87A was conducted as follows: the plasmid pY26-MuBtDHCR7-CYP11A1-ADR-ADX (with the PTEF PGDH, PPGK1, and PTDH1 promoter driving DHCR7, CYP11A1, ADR, and ADX expression, respectively.) or pY26-MuBtDHCR7-CYP87A-ATR (with the PTEF PGDH, and PPGK1 promoter driving DHCR7, CYP87A, and ATR expression, respectively.) was constructed and transformed into the D7-1 strain (the feature was described in Supplementary Data 1). During fermentation, single colonies were selected and grown in 25 mL of Ura- YNB medium for 72 h. The Prn yield was then measured for determining the activity of CYP11A1 and CYP87A. The measurement of RgCYP87A was conducted as follows: the plasmid pY26-MuBtDHCR7-RgCYP87A3-ATR (with the PTEF PGDH, and PPGK1 promoter driving DHCR7, CYP87A, and ATR expression, respectively.) was constructed and transformed into the C800 strain (the feature was described in Supplementary Data 1). Single colonies were selected and grown in 25 mL of Ura- YNB medium for 72 h. Subsequently, the culture was centrifuged and was resuspended in PBS solution (pH 5.5) to an OD600 = 20. A final concentration of 300 mg/L Cho was added to initiate the reaction. The Prn yield in the fermentation broth was measured after 48 h.

The medium included 40 g/L glucose, 10 g/L yeast extract, 20 g/L peptone, and 1.2 g of FeSO4·7H2O (sterilized by filtration and added at the time of inoculation) for fermentation in a 5-L bioreactor containing 2.5 L of YPD medium. Additionally, an antifoaming agent at a concentration of 0.1‰ was added before sterilizing the medium (150 μL of antifoam added, ensuring no foaming occurred during fermentation, with sterilization at 115 °C for 20 min). Throughout the process, the pH was maintained between 5.4 and 5.6 using 5 M NaOH. The feed medium (1.5 L) consisted of 800 g/L glucose, 18 g/L KH2PO4, 10.24 g/L MgSO4·7H2O, 7 g/L K2SO4, and 0.56 g/L NaSO3, sterilized at 115 °C for 20 min. Trace element solution A (metal ions) was added at a rate of 20 mL/L and trace element solution B (vitamins) at a rate of 24 mL/L, both sterilized by filtration. Additionally, 800 mL of nitrogen source medium was prepared, which included 160 g peptone and 80 g yeast extract. The steps for preparing the seed culture for the fermentation tank were as follows: A few fresh yeast colonies were picked up using an inoculation loop. These colonies were inoculated into a flask containing 10 mL of YPD medium. The flask was incubated at 220 rpm and 30 °C for 17–20 h to prepare the primary seed culture. Then, 1.5% of the primary seed culture was transferred into a 500-mL flask containing 200 mL of YPD medium. This flask was incubated at 220 rpm and 30 °C for another 17–20 h to prepare the secondary seed culture, which was used to inoculate the fermentation tank. It was ensured that the medium used for the seed cultures was consistent with the medium used in the fermentation tank.

The fermentation process of Cho and Prn biosynthesis in 5-L bioreactor was divided into three stages: (1) 40 g/L glucose, 10 g/L yeast extract, and 20 g/L tryptone were provided, and fermentation occurred at 220 rpm and 30 °C for about 16 h. (2) After 40 g/L glucose was used up, 800 g/L glucose was gradually added. Moreover, the addition rate of 800 g/L glucose was 10 mL/h during 16–72 h of fermentation. (3) The glucose flow rate was reduced to 2 mL/h in 72–144 h to ensure that the accumulation of alcohol in the fermentation system did not affect cell growth. The nitrogen sources were added after 72 h for promoting cell growth and product accumulation.

Extraction of cholesterol and pregnenolone from S. cerevisiae

The culture broth (1 mL) was sampled, transferred to a 2 mL crushing tube, and centrifuged at 3500 × g for 20 min. Then, the supernatant was removed. Subsequently, a saponification solution of potassium hydroxide was prepared in ethanol with a mass fraction of 30% (90% ethanol). Further, 2 mL of MP with bacterial cells was added to 1 mL of saponification solution and heated to 88 °C for 3 h to carry out a reflux saponification reaction. Subsequently, the saponification solution was transferred into a 5 mL centrifuge tube, and 1 mL of water and 1 mL of ether were added. The mixture was vigorously shaken for 10 min and centrifuged at 11,000 × g and 4 °C for 20 min. Then, 500 μL of the supernatant was collected for subsequent analysis using gas chromatography, high-performance liquid chromatography (HPLC), HPLC coupled with mass spectrometry (HPLC-MS), and nuclear magnetic resonance (NMR).

Gas chromatography, HPLC-MS, and NMR analysis for fermentation products

The fermentation products including 7-dehydrocholesterol, cholesterol, and pregnenolone were measured using gas chromatography (GC) analysis. GC-MS analyses were carried out using a Shimadzu TQ8050 NX instrument (Japan) equipped with a flame ionization detector (FID) and an AI1310 autosampler using an HP-5 MS column (length 30 m, internal diameter 0.25 mm, and film thickness 0.25 mm) with helium as carrier gas at a flow rate of 1 mL/min. The injector was held at 300 °C, and the FID temperature was 280 °C. The oven temperature was held at 220 °C for 1 min, increased at a rate of 20 °C/min to 300 °C, and held at this temperature for 5 min. Chromatograms were acquired and processed using the instrument’s native software (Shimadzu LabSolution version 5.99). Peak identification was confirmed by comparing retention times with authentic standards, and integration was performed automatically with manual verification. The results were shown in Supplementary Fig. 11 and Supplementary Fig. 12. The total number of sample and control are 1, three times of biological replicates.

HPLC-MS analysis using an Agilent 1290II-6460 instrument was conducted with a C18 column (Agilent EP-C18, 2.1 × 50 mm2, 1.8 m). The mobile phase A was acetonitrile, and the mobile phase B was a 0.5% trifluoroacetic acid aqueous solution. The liquid-phase conditions were as follows: flow rate: 1 mL/min; column temperature: 30 °C; and dual wavelength: 241 and 254 nm. The gradient elution conditions were as follows: 0 min to 15 min: 5% A and 95% B to 80% A and 20% B; 15 min to 20 min: 80% A and 20% B; and 20 min to 30 min: 80% A and 20% B to 5% A and 95% B. The testing time for each sample was 30 min. The mass spectrometry acquisition parameters were as follows: ion source type: ESI mode; MS2 scan polarity: positive; m/z range: 50-600; ion source temperature: 350 °C; nebulizer gas flow rate: 10 L/min; pressure: 45 psi; capillary voltage: 4000 V; and fragmentor: 100 V. MS data were initially processed using Agilent MassHunter Workstation Software (version 8.0) to identify peaks based on retention times and accurate mass measurements. Annotation was further validated by comparing mass-to-charge ratios with those from authentic standards. The elution times (Supplementary Fig. 13) of pregnenolone (Supplementary Fig. 14), 7-dehydrocholesterol (Supplementary Fig. 15) and cholesterol (Supplementary Fig. 16) compounds can be clearly distinguished, and the synthesis of these substances was confirmed by their mass-to-charge ratios. The total number of sample and control are 1, three times of biological replicates.

For NMR analysis, the S. cerevisiae was saponified after fermentation. Then, the products were extracted with diethyl ether and dried with Na2SO4. Subsequently, the solvent was removed with a rotary evaporator. Samples were purified using a SHIMADZU LC-20AR semi-preparative chromatography system using a Shim-pack GIST C18 column (10 mm × 250 mm, 5 μm, SHIMADZU, Japan) at 254 nm, 30 °C. The elution program consisted of acetonitrile and water (50:50) at a flow rate of 5 mL/min and elution for 40 minutes. The organic solvent was then evaporated to obtain the purified samples. The purified samples were dissolved in CDCl3 and subsequently characterized by nuclear magnetic resonance (NMR). The purified samples (20 mg/mL) were dissolved in CDCl3 and subsequently characterized by nuclear magnetic resonance (NMR) spectra with a Bruker Avance III 600 MHz nuclear magnetic resonance spectrometer (Bruker BioSpin, Karlsruhe, Germany). NMR spectra were recorded on 500 MHz for 1H and 126 MHz for 13 C in CDCl3. MestReNova software (version 14.0) was used to analyze and process data. The results were shown in Supplementary Fig. 17, Supplementary Fig. 18, Supplementary Fig. 19, and Supplementary Fig. 20.

Determining the NADPH/NADP+ ratio

The NADPH/NADP+ ratio of S. cerevisiae was quantified using an NADP/NADPH quantitation kit (Sigma–Aldrich). The 48-h fermentation broth was centrifuged at 3500 × g and 4 °C for 15 min. The cells were disrupted using glass beads and resuspended in a phosphate-buffered saline solution (pH 7.4) to OD600 = 5. Subsequently, the samples were processed following the protocol to determine the ratio of NADPH to NADP+. The samples were extracted from cells using an extraction buffer, and the proteins were removed using a centrifugal column4. Samples and standards were added to the wells. Then, the reaction mixture was added and incubated at room temperature for 5 min to convert NADP+ into NADPH. The NADPH developer was added and incubated for 2 h, allowing the reaction to cycle. During the 2 h incubation period, the reaction was analyzed multiple times using a microplate reader. The reaction was stopped with a stop solution.

Western blot analysis

In Western blots, the BtDHCR7, BtDHCR7 variants, RgCYP87A3, BmCYP11A1, and CYP87A4 in the S. cerevisiae were all labeled with his-tag. ProteinFind Anti His Mouse Monoclonal Antibody was used as the primary antibody with a dilution of 1:2000. ProteinFind Goat Anti-Mouse lgG (H + L) was used as the second antibody with a dilution of 1:5000. S. cerevisiae with above membrane protein were harvested at by centrifugation at 4000 × g for 10 minutes at 4 °C. The pellet was washed twice with ice-cold PBS and resuspended in a membrane protein extraction buffer containing 50 mM Tris-HCl (pH 7.5), 150 mM NaCl, 1% Triton X-100, 0.5% sodium deoxycholate, and 0.1% SDS supplemented with a protease inhibitor cocktail. Cell disruption was achieved using glass bead vertexing under ice-cold conditions for 15 minutes. The lysate was centrifuged at 12,000 × g for 15 min at 4 °C to remove debris. The supernatant was further centrifuged at 100,000 × g for 1 h at 4 °C to isolate the membrane fraction. The pellet containing membrane proteins was resuspended in 50 mM Tris-HCl (pH 7.5), 1% SDS and stored at −80 °C until analysis. Protein concentration was determined using a BCA assay. A total of 50 μg of membrane protein crude enzyme was used for subsequent WB analysis51.

Fluorescent Protein Analysis in S. cerevisiae

The subcellular localization analysis of BtDHCR7, RgCYP87A3, BmCYP11A1, BtADR, BtADX, and ERG25 was performed by fusing the target enzyme gene sequences with a fluorescent protein sequence using a GGGGS linker. Fluorescence imaging was conducted using a Leica DM6000 microscope equipped with 515–560 nm excitation for RFP (561 nm laser) and 470 nm excitation for GFP (488 nm laser). Living cells were prepared on slides, and images were captured at ambient temperature using a monochrome CCD camera. Consistent microscope intensity and acquisition durations were maintained across all samples. Specific parameters included a 20× objective, 70.0 μm × 70.0 μm field of view, 2.0 μs exposure time, and cumulative scanning for both RFP and GFP channels (561 nm: PMT voltage 700; 488 nm: PMT voltage 600). Synchronization and preview functions were disabled.

Phylogenetic for analyzing CYP11A1 and CYP87A

The evolutionary trees were constructed according to Kumar et al.52. All residue sequences of CYP11A1 were downloaded from the NCBI database and saved in Fast Alignment Search Tool-All (FASTA) format. All accession numbers of CYP11A1 and CYP87A were listed in Supplementary Data 5. The multiple-sequence alignments of CYP11A1 and CYP87A from different species were conducted using ClustalX 2.0, and phylogenetic trees were constructed using Molecular Evolutionary Genetics Analysis (MEGA) 11.0 and the neighbor-joining method.

Molecular docking

The structure of DHCR7 from Bos taurus (BtDhcr7) and CYP11A1 from R. glutinosa (RgCYP87A3) were obtained using AphaFold2. Moreover, the structures of all BtDhcr7 and RgCYP87A3 variants were rebuilt using the wild-type protein structure as the template in SWISS-MODEL. Heme was docked to the RgCYP87A3 using AlphaFill53 and the enzyme structure was optimized using 100 ns of kinetic simulation. The models of 7-dehydrocholesterol, cholesterol, and pregnenolone were obtained using ChemSketch. The docking of substrates and DHCR7/RgCYP87A3 was carried out using AutoDock Vina54. To investigate the binding conformation of substrate within the active site of enzymes, we employed a combination of molecular dynamics (MD) simulations and molecular docking. A 100-ns MD simulation of enzyme was conducted to explore its conformational space, generating 50,000 snapshots sampled at 2 ps intervals. To ensure diverse sampling of enzyme conformations, these snapshots were grouped into ten representative clusters using a hierarchical agglomerative clustering approach. For each representative structure, molecular docking was performed with AutoDock Vina, treating the receptor as rigid while allowing all rotatable torsion bonds of substrate to remain flexible. Docking grid boxes were centered on the catalytic residues, with dimensions of 20 × 20 × 20 Å and a spacing of 0.4 Å. From the docking simulations, 500 independent docking runs were performed for each receptor conformation, and the resulting poses were clustered based on an RMSD cutoff of 2.0 Å. The binding poses were then ranked using an energy-based scoring function. Among these, a single binding conformation was selected based on its energy score, structural plausibility, and consistency with known catalytic mechanisms of enzyme. This final binding pose was further validated through additional MD simulations, confirming its stability and relevance in the catalytic process.

Molecular dynamics simulation

The coordinates of ligands were optimized in the Gaussian 09 package with B3LYP theory level and 6-31 G* basis set29. The parameters of ligands for molecular dynamics were analyzed using the Antechamber tool in the general Amber force field form, and charges were fitted using the RESP method55,56. The topology of proteins was described using an Amber 99SB-ILDN all-atoms force field57. After energy minimization, NVT ensemble, and NPT ensemble equilibrium, 100-ns molecular dynamics simulations were applied for each protein–ligand group using GROMACS 2021.5 package with periodic boundary conditions58,59,60. The Nose–Hoover thermostat coupling methods were used to maintain the system temperature at 298 K61. The cutoff switching function for nonbonded van der Waals interaction started at 1.2 nm and reached zero at 1.35 nm. Long-range electrostatic interactions were calculated using particle mesh Ewald summation62. The cutoff distance was set at 1.2 nm to separate the direct and reciprocal spaces. The linear constraint solver algorithm was applied to describe the bond length constraint63. The protein–ligand complex was dissolved in a box full of simple point-charge water molecules with sodium and chloride ions as counterions64. Simulations were carried out with a time step of 2 fs, and the data were saved every 4 ps. The snapshots of simulation results were visualized using VMD software65. The distance between atoms was calculated by grabbing atoms from the index file and using “gmx distance” command to calculate the distance variation between 0 and 100 ns separately. A gmx_mmPBSA toolkit was used to disassemble and calculate the free energy of the residues of CYP11A1 and DHCR7 in 80–100 ns, taking the average value as the result. The binding energy was calculated using the gmx_mmpbsa script (source code available at https://jerkwin.github.io/gmxtools/). The xtc file generated from the MD simulation was centered and extracted for the stable 80–100 ns interval. Using the gmx_mmpbsa script in conjunction with the xtc, tpr, and topol files, binding energy values were calculated for each 1 ns interval within the 80–100 ns timeframe. The average of these values was taken as the final binding energy. The RMSD of wild type BtDHCR7 and MuBtDHCR7 were shown in Supplementary Fig. 21 and Supplementary Fig. 22. The RMSF analysis for WTDhcr7 and MuDhcr7 with Dhc in Y317 catalytic pocket was shown in Supplementary Fig. 23. The RMSD of WTRgCYP87A3 and MuRgCYP87A3 (V118A-A281D-T285E) were shown in Supplementary Fig. 24 and Supplementary Fig. 25. B-factor analysis for WTRgCYP87A3 and MuRgCYP87A3 (V118A-A281D-T285E) were shown in Supplementary Fig. 26.

The method for performing replica exchange molecular dynamics (REMD) simulations is as follows: To study the temperature-dependent behavior of the system, molecular dynamics (MD) simulations were conducted using GROMACS 2021.5 package. A total of 16 independent replicas were simulated, with each replica initialized at a specific temperature ranging from 298.15 K to 310 K. The replicas were equilibrated independently to ensure consistency among simulations. The simulations employed the Charmm36 force field, with the system solvated and neutralized by adding 0.15 M NaCl. All bond lengths were constrained using the LINCS algorithm, allowing for a time step of 2 fs. Long-range electrostatics were calculated using the Particle Mesh Ewald (PME) method with a real-space cutoff of 1.2 nm. Van der Waals interactions were truncated at 1.2 nm, with a force-switching function applied. Temperature control was achieved using a velocity-rescaling thermostat with a coupling constant of 0.1 ps, while isotropic pressure coupling was applied using a 1 bar Parrinello-Rahman barostat with a coupling constant of 2.0 ps. Each simulation was performed for 100 ns, with replica exchanges attempted every 1 ps. System configurations were saved every 200 ps for subsequent analysis. Initial velocities for each replica were generated randomly according to the Maxwell-Boltzmann distribution at their respective temperatures. Post-simulation, trajectories and energy outputs were analyzed to extract structural and thermodynamic properties.

QM/MM calculation

The QUICKSTEP and FIST modules of the CP2K software package (version 8.2) were used to run the QM and MM calculations, aiming to investigate the transition state behavior of enzyme-catalyzed reactions. The QM/MM simulations integrated quantum mechanical (QM) and molecular mechanical (MM) methodologies, wherein the reactive region was modeled using QM methods and the surrounding environment was described with MM approaches. The reactive region, comprising (specific QM region atom descriptions), was characterized using density functional theory (DFT) with the PBE functional and the DZVP-MOLOPT-SR-GTH basis set. Core electrons were represented through GTH pseudopotentials. To enhance the accuracy of intermolecular interactions, DFT-D3 dispersion corrections were incorporated. The MM region consisted of (number of MM region atoms) atoms, modeled with the AMBER force field to account for bonded and non-bonded interactions. The QM and MM regions were coupled through electrostatic embedding, with the QM region polarized by the electrostatic field of the MM region. A cutoff distance of 12 Å was applied for electrostatic coupling. The initial system was equilibrated via classical molecular dynamics (MD) simulations at 298.14 K. The equilibrated structure was then subjected to QM/MM geometry optimization. Transition state identification was achieved using the nudged elastic band (NEB) method. To confirm the nature of the transition states, vibrational frequency analysis was performed to ensure the presence of only one imaginary frequency along the reaction coordinate. Subsequently, single-point energy calculations for the transition states were refined using the B3LYP/D3 functional and the def2-TZVP basis set. Noticed, all of the reactions of the CYP450 were studied in the S = 3/2 (“S” represents the total spin quantum number). The frequencies of the optimized DHCR7’s and RgCYP87A3’s TSs were shown in Supplementary Table 1 and Supplementary Table 2. Cartesian coordinates of all states were shown in Supplementary Data 6.

QM calculation