Abstract

Closed pores are widely accepted as the critical structure for hard carbon negative electrodes in sodium-ion batteries. However, the lack of a clear definition and design principle of closed pores leads to the undesirable electrochemical performance of hard carbon negative electrodes. Herein, we reveal how the evolution of pore mouth sizes determines the solvation structure and thereby redefine the closed pores. The precise and uniform control of the pore mouth sizes is achieved by using carbon molecular sieves as a model material. We show when the pore mouth is inaccessible to N2 but accessible to CO2 molecular probes, only a portion of solvent shells is removed before entering the pores and contact ion pairs dominate inside pores. When the pore mouth is inaccessible to CO2 molecular probes, namely smaller than 0.35 nm, solvent shells are mostly sieved and dominated anion aggregates produce a thin and inorganic NaF-rich solid electrolyte interphase inside pores. Closed pores are accordingly redefined, and initial coulombic efficiency, cycling and low-temperature performance are largely improved. Furthermore, we show that intrinsic defects inside the redefined closed pores are effectively shielded from the interfacial passivation and contribute to the increased low-potential plateau capacity.

Similar content being viewed by others

Introduction

It is well known that for the commercial use of graphite as the negative electrode in lithium-ion batteries (LIBs), interfacial electrochemistry has played an important role1,2,3. Specifically, the small interlayer spacing of graphite acts as a sieve to regulate the solvation structure of electrolytes and properties of the solid electrolyte interphase (SEI), which is a prerequisite for the high initial coulombic efficiencies (ICEs) and reversible low-potential charge/discharge plateaus (LPPs)4,5. For sodium-ion batteries (SIBs), which are widely accepted as a sustainable and inexpensive supplement to LIBs for large-scale electrochemical energy storage, their commercialization is still constrained by the unsatisfactory electrochemical performance of their carbon negative electrodes. Though hard carbons have shown great potential as negative electrodes in SIBs, their interfacial electrochemistry remains poorly explored and understood. As a result, the improvement of multiple performance parameters to meet the strict demand of practical SIBs is substantially limited, such as the ICE, cycling, and low-temperature performance6. It is not only difficult to characterize the solvation structure and spatial SEI formation process, but also difficult to correlate them with their complex and disordered microstructure of hard carbons, particularly the closed pores7.

After decades of research, a consensus has been reached that closed pores having pore mouths being inaccessible to N2 molecular probes are a prerequisite for increasing the ICE and the emergence of LPPs8,9,10,11,12,13,14. Zheng et al. demonstrated the critical role of closed pores below 1 nm in reducing the SEI thickness and increasing the reversible capacity15. Kamiyama et al. reported a template approach to introduce such pores to increase the sodium storage capacity8. Zhang et al. showed that commercial carbon molecular sieves (CMSs) with an ultra-small pore mouth can produce highly efficient de-solvation when used as negative electrodes in SIBs10. In particular, sieving carbons (SVCs) have been recently proposed to offer new insight into how pore mouth size (PMS) determined the distribution of SEI inside and outside pores11. It is shown the ultra-small pore mouths suppressed significant solvent decomposition within the pores and contributed to the largely increased ICE. However, the influence of varying PMSs on dynamic interfacial processes remains unclear, particular for the solvation structure, leading to the lack of a clear definition and design principle for closed pores. In addition to pores, defects are reported to be critical for high-performance sodium storage of hard carbons, while how defects inside close pores can be deactivated during interfacial side reactions and activated for reversible sodium storage needs to be clarified.

In this work, we reveal that the evolution of solvation structure highly depends on the PMSs. The precise and uniform control of PMS is achieved by using carbon molecular sieves as a model material. Based on detailed electrochemical and spectroscopic studies, it is shown that when the pore mouth is inaccessible to N2 but accessible to CO2 molecular probes, only a portion of coordinated solvent shells is removed before entering the pores, and contact ion pairs (CIPs) dominated inside pores. When the pore mouth is inaccessible to CO2 molecular probes, namely smaller than 0.35 nm, solvent shells are mostly sieved and dominated anion aggregates (AGGs) produce a thin and inorganic (NaF)-rich SEI inside pores. Closed pores are accordingly redefined, and ICE, cycling, and low-temperature performance are largely improved. It is also theoretically and experimentally shown that intrinsic defects inside the redefined closed pores are effectively shielded from the interfacial passivation and contribute to the increased low-potential plateau capacity. This work paves up new but solid ways to understand and exploit closed pores and defects of hard carbon negative electrodes to drive the industrialization of high-performance non-aqueous SIBs.

Results

Precise and uniform control of pore mouth size

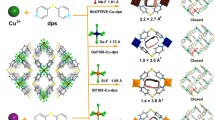

A CMS was selected as a model material due to its relatively uniform distribution of PMSs in the range from 0.3 to 0.5 nm16,17,18. The post-treatments were conducted by heating the CMS at different temperatures, and the resulting carbons are designated CMS-x, where x is the heat treatment temperature. The value of the PMS is determined by the heat treatment temperature.

A commercially available activated carbon (AC) was used as a reference with a bigger PMS, which was produced with a similar biomass precursor for CMS. This AC is especially used for supercapacitors and has a relatively narrow distribution of PMS values below 1 nm19. High-resolution transmission electron microscopy (HRTEM) reveals obvious distinctions in the pore structures for AC and CMSs (Fig. 1a–c and Supplementary Fig. 1). In the case of AC, pores with a large PMS are the result of the misalignment of short and curled graphitic crystallites. In contrast, CMS materials pyrolyzed in the temperature range of 800–1000 °C have larger graphitic crystallites, producing a smaller PMS because of more efficient connection between the crystallites.

HRTEM images of a AC, b CMS-800, and c CMS-1300. The insets are enlarged views of the selected box areas, where graphitic crystallites are delineated by white dotted lines. d N2 and CO2 adsorption/desorption isotherms, e pore size distributions, and f SAXS patterns for AC, CMS-800, and CMS-1300. Source data are provided as a Source Data file.

When increasing the temperature to 1100–1600 °C, the PMS becomes even smaller, as graphitic crystallites develop and interconnect to form a highly turbostratic microstructure20. X-ray diffraction (XRD) validates these findings (Table 1, Supplementary Fig. 2, and Supplementary Note 1). Heteroatoms and oxygen functional groups are effectively reduced in this temperature range which lowers their effect on the interfacial electrochemistry, as evidenced by the similar electrolyte wetting behaviors of AC, CMS-800, and CMS-1300 electrodes (Supplementary Figs. 3–5)21.

The PMSs of these CMSs and AC were measured using N2 and CO2 adsorption-desorption (Fig. 1d and Supplementary Fig. 6a–c). AC has an IUPAC Type-I N2 adsorption/desorption isotherm, indicative of abundant micropores, and its specific surface area (SSA) calculated by the Brunauer-Emmett-Teller (BET) method is 2021 m2 g−1. In contrast, all the CMS samples have Type-III N2 adsorption/desorption isotherms, signifying low porosity. The SSA values of these CMSs (Table 1), are all below 20 m2 g−1. Nevertheless, the CO2 adsorption/desorption isotherms of CMS-800 and CMS-1000 indicate a significant adsorption capacity, accompanied by relatively large SSAs (604 and 383 m2 g−1, respectively). In contrast, at higher heat treatment temperatures than 1000 °C, small CO2 adsorption capacities are indicated, with SSAs all below 20 m2 g−1. The big differences between N2 and CO2 adsorption results are ascribed to the difficulty of N2 diffusion into the ultra-small micropores at 77 K while CO2 with a higher kinetic energy at 273 K could easily enter them22,23. Based on non-local density functional theory (NLDFT) calculations, the minimum measurable pore diameter for N2 at a partial pressure of 0.0001 kPa at 77 K is 0.5 nm while for the same pressure it is 0.35 nm for CO2 at 273 K24,25. Hence, three typical groups can be categorized based on their different PMSs (Fig. 1e, Supplementary Fig. 6d–f and Table 1). Group I includes AC with a PMS larger than 0.5 nm (pores can absorb both N2 and CO2). Group II includes CMS-800 and CMS-1000 with a PMS in the range between 0.35 and 0.5 nm (pores fail to absorb N2 but absorb CO2). Group III includes CMS-1100, CMS-1300, and CMS-1600 with a PMS smaller than 0.35 nm (pores absorb neither N2 nor CO2). The true density results (Supplementary Fig. 7) also confirmed the differences in PMSs among three groups of carbons. Group I and II have higher true density values, indicating that their PMSs are large enough to allow the medium gas (He) to pass through. However, true density significantly decreased with increased heat treatment temperature above 1100 °C (Group III), which is attributed to their ultra-small pore mouths that hinder the entry of He into these carbon matrices9. Small angle X-ray scattering (SAXS) was further conducted to investigate the inner pore characteristics (Fig. 1f and Supplementary Fig. 8). The SSAs and average pore body diameters (PBDs) were calculated using the Teubner-Strey model to fit the signals in the intermediate Q range (Table 1 and Supplementary Note 2)26. The SAXS results show that the CMSs in Group II and Group III have similar SSA and PBD, proving that the only difference between Group II and Group III is their varied PMS.

Solvation structure and interfacial properties

Closed pores have been widely reported to be critical in determining the interfacial electrochemistry and sodium storage properties of hard carbon negative electrodes. The transition from open pores to closed pores leads to efficient desolvation and prevents the formation of an organic-rich SEI inside pores11,27,28. However, the lack of recognition that the PMSs are variable resulted in unclear definitions and design principles for closed pores. Herein, by using CMSs as model materials, we investigate the PMS-dependent solvation structure and interfacial electrochemistry of hard carbon negative electrodes in detail.

The interfacial electric double layer (IEDL) inside pores was monitored in situ using the electrochemical quartz crystal microbalance (EQCM). The potential of zero charge (PZC) is initially determined, as it represents the reference point for IEDL formation. By measuring the minimum differential capacitance (Supplementary Fig. 9), the PZC values for AC, CMS-800, and CMS-1300 negative electrodes were determined to be 1.75, 2.3, and 2.4 V, respectively (Fig. 2a). In the absence of an external electric field, the PZC is governed by the species adsorbed in the inner Helmholtz plane (IHP)29. The higher PZC observed for the CMS-1300 negative electrode indicates that its IHP contains more anions due to characteristic adsorption. The evolution of the IEDL structure around PZC is reflected in the changed mass of the electrode (Fig. 2b and Supplementary Note 3). The mass at the PZC increases gradually from AC, CMS-800 to CMS-1300, indicating that a larger number of anions, characterized by higher molecular mass and crowding effects, are adsorbed within the IHP30. This result is consistent with the differences in the PZC values of three carbon negative electrodes. During the discharge process, the electrode mass initially decreases and then increases with PZC as the turning point, indicating a rearrangement of anions and cations30,31. For AC, there is almost no mass change in the anion migration region (>PZC). Whereas, in the cation migration region (<PZC), the mass-to-charge ratio of the carrier is close to that of bare Na+ (Fig. 2c and Supplementary Fig. 10). This suggests that a large number of solvent molecules adsorbed in the IHP hinder the migration of PF6− and force the de-solvation of Na+, leaving a large amount of free solvent inside pores30. For CMS-800, the more mass change indicates that the increased presence of anions within the IHP facilitates ion migration. However, the mass-to-charge ratio of the migrating cations (10.4 ng μC−1) is much higher than the theoretical value for Na+ (0.24 ng μC−1), suggesting that there are still a lot of solvents remain coordinated with Na+, with an estimated coordination number of 11.1. In contrast, for CMS-1300, the mass-to-charge ratio of the migrated cations (2.4 ng μC−1) is significantly lower, corresponding to a coordination number of 2.3, which implies a solvation structure mostly composed of aggregated anions with minimum solvents.

a Differential capacitance values of three negative electrodes across the working potential range of the electric double layer. The vertical line indicates the potential of zero charge (PZC). The vertical axis represents the capacitance per unit surface area of the material. AC negative electrode uses a smaller voltage window than CMS-800 and CMS-1300 negative electrodes because the electrolyte decomposes at high potentials. b The CV curve (dashed line) and the mass change-potential profile during discharge (solid line) for the three negative electrodes. The vertical dashed line marks the PZC. The left and right vertical axes represent the mass change and the current change per unit surface area of the material, respectively. c The mass change-charge profile corresponding to the selected section in (b). d Raman spectra in the regions of 710–780 cm−1, e C=O peaks in FTIR spectra, and f 19F ssNMR spectra of the electrolytes in the three negative electrodes after an initial discharge to 1.5 V. The fitted data in d and e are depicted with short dashed lines. Sodium atoms are shown as gray spheres. Fluorine atoms and phosphorus atoms are shown as blue and yellow spheres, respectively. Source data are provided as a Source Data file.

The evolution of solvation structure inside pores derived from different PMSs were identified by ex-situ Raman spectroscopy after an initial discharge to 1.5 V, prior to the SEI formation (Fig. 2d). Excess electrolyte within interparticle spaces and on the particle surface was dried to eliminate signal interference from the neat electrolyte outside pores. The A1g vibration mode of PF6− produced Raman bands between 740 and 760 cm−1, depending on its coordination state32. For AC, the solvation structure remains to be solvent-separated ion pairs (SSIPs) that sodium ions are fully coordinated with solvents. Along with the decrease of PMSs, different degrees of desolvation occur. For CMS-800, a portion of the solvent shells is removed, and the anions coordinate with the partially desolvated sodium ions through electrostatic forces to form CIPs33, characterized as the main solvation structure. It is worth noting that there are also AGGs inside pores. For CMS-1300, no SSIPs and much less number of CIPs are detected, proving that most solvent molecules are sieved. In contrast, the AGGs was shown to be the dominated solvation structure inside the pores34. The de-solvation process can be further identified from the perspective of solvent molecule coordination using Fourier transform infrared spectroscopy (FTIR) (Fig. 2e). The C=O peaks of EC and DEC molecules show red-shift due to their coordination with Na+ 35,36. These coordination peaks have higher intensity as the solvent amount decreases and the salt concentration increases37,38. Compared to AC and CMS-800, CMS-1300 has higher coordinated solvent peaks, indicating a deeper desolvation which leads to the formation of AGGs as shown in the Raman results. The solvation structure inside the pores can be further verified using magic-angle-spinning (MAS) solid-state nuclear magnetic resonance. The high-speed rotation (15 kHz) of the test system facilitates the rapid diffusion of ions into the pores39,40. As shown in Fig. 2f and Supplementary Fig. 11, as the PMS decreases, the chemical shifts of 19F and 23Na in the electrolyte inside the pore gradually move to higher fields, indicating an enhanced Na+-PF6− interaction41,42. This indicates a solvation structure characterized by a higher degree of anion aggregation, which is consistent with the Raman and EQCM results. These findings highlight the critical role of the pore mouth in determining the solvation structure and the IEDL. For AC with SSIPs and free solvents filling the pores, a large amount of solvents adsorbed at the IHP lead to an excessive and organic-rich SEI27,43,44,45. For CMS-800 with a CIPs-dominated solvation structure, there is still considerable solvents adsorbed at the IHP, which still leads to the organic components within the SEI. In contrast, for CMS-1300 with AGGs-dominated solvation structure, anions highly aggregate in the IHP and leads to the inorganic-rich SEI46. Therefore, closed pores are redefined by using CO2 as the probe, namely pores with a PMS smaller than 0.35 nm.

Ex-situ SAXS of carbon negative electrodes before and after cycling are conducted to describe the distribution of SEI inside the pores. The results show that, in the AC, CMS-800, and CMS-1300 negative electrodes after cycling, there is a decreasing trend in the intensity of the intermediate peaks and a right shift in position (Fig. 3a–c), which respectively indicate the reductions in the pore volume and pore diameter26,47. Based on the Teubner-Strey model fitting (Supplementary Table 1 and Supplementary Note 2), the pore diameter of the AC shrinks from 2.6 to 1.1 nm after cycling, while for CMS-800 it shrinks from 1.47 to 1.28 nm. These results imply that the pores of AC are mostly filled by SEI and pores of CMS-800 are partially filled. In sharp contrast, the pore volume and diameter of CMS-1300 remains almost unchanged, indicating that a minimum amount of SEI is generated inside the pores. Moreover, CMS-1300 has the least SEI distributed both on the surface and within the bulk phase, as shown in the TEM results (Supplementary Figs. 12–15). In addition to the distribution of SEI, more detailed composition information was obtained by X-ray photoelectron spectroscopy (XPS) depth profiling and time-of-flight secondary-ion mass spectrometry (TOF-SIMS). XPS results show that C, O, F, and Na are observed from the surface to bulk (Supplementary Fig. 16), indicating that the the SEI exists throughout the carbon matrix, which agrees well with the TEM-EDX results. The SEI observed in the three carbon negative electrodes is comprised of both organic and inorganic components. The former consists of polyethers and sodium alkyl carbonates containing -C2HO and -CHO2 ion species, such as ROCO2Na, mainly originating from solvent decomposition (Fig. 3d–f and Supplementary Fig. 17)44,48. These organic components can also be identified by signals such as C-O, C=O, and O=C-O in the C 1s peak and O 1s peak (Supplementary Figs. 18 and 19). The latter include NaF and Na2CO3, arising from the decomposition of NaPF6 salt and the solvent, respectively33,49,50, can also be identified by the -CO3 signal in the C 1s peak and the inorganic fluorine signal in the F 1s peak (Supplementary Fig. 20). Compared with the AC and CMS-800 negative electrodes, the SEI formed in the CMS-1300 negative electrode has a much lower content of organic components and a higher concentration of NaF (Supplementary Figs. 21 and 22). Moreover, in the 3D TOF-SIMS maps, the distribution of organic components in the SEI of the CMS-1300 negative electrode is almost confined to the surface and rarely observed in the bulk phase. NaF is the dominant phase in the SEI of the CMS-1300 negative electrode, quite different from what is observed in the AC and CMS-800 negative electrodes (Fig. 3d–f). Additionally, the CMS-1300 negative electrode consistently maintains a high C-C content under prolonged Ar+ sputtering (Supplementary Fig. 23), indicating fewer SEI components inside the pores, which is consistent with the conclusion based on SAXS and TEM.

a–c SAXS patterns of three carbon negative electrodes before and after 10 cycles. The cycles were conducted at 25 °C using specific current of 50 mA g−1. All three carbon negative electrodes reached the desodiation state. The arrows represent the direction of the peak’s movement. 3D TOF-SIMS visual maps for negative secondary ion mode of d AC, e CMS-800, and f CMS-1300 negative electrodes after 10 cycles. g–i Operando characterization of SEI formation by EQCM. The CV curves (blue) and the mass change-charge profiles (red) of the SEI formation process, i.e., from A to C, for g AC, h CMS-800, and i CMS-1300 negative electrodes. The cycling process was performed at 25 °C using specific current of 50 mA g−1. Source data are provided as a Source Data file.

The evolution of SEI composition was characterized using operando EQCM (Fig. 3g–i, Supplementary Fig. 24 and Supplementary Note 3). For AC, the SEI is mainly composed of large molecular organic components, as evidenced by the mass-to-charge ratio of A1C1, which is significantly greater than that of ROCO2Na (1.08 μg mC−1)51. For CMS-800, the molecular weight of the SEI components is substantially lower than that of AC. However, it is still dominated by organic components, according to the mass-to-charge ratio of A2C2, which still exceeds that of ROCO2Na. For CMS-1300, obvious SEI stratification is observed as the potential decreases. Within the high potential region (1.4–0.87 V), the SEI formed is predominantly composed of inorganic materials, as indicated by the mass-to-charge ratio of A3B3, which is close to that of NaF (0.44 μg mC−1)51. In the low potential region (0.87–0.4 V), organic components with smaller molecules than those of AC and CMS-800 are generated, indicating the suppression of solvent decomposition. It has been reported that such a SEI can facilitate a reversible stable interfacial reaction with hard carbon negative electrodes, thereby promising a high ICE and long cycle life43. In brief, 0.35 nm is highlighted as a critical PMS for hard carbon negative electrodes to regulate their interfacial chemistry. The solvation structure formed inside the pores is critical to the kinetics of the sodium storage process. Therefore, for the practical use of hard carbon negative electrodes in a full cell, the PMS must be carefully controlled.

Electrochemical performance

As shown in Fig. 4a, Supplementary Fig. 25, and Supplementary Table 2, the differences in the PMS lead to distinct sodium storage properties. For AC (Group I carbon), the potential profile initially shows a pseudo plateau at 0.8 V, followed by a monotonically decreasing discharge potential to 0 V. The ICE and reversible capacity are only 17% and 118 mAh g−1, which have resulted from the excessive solvent decomposition of SSIPs to form a thick and organic-dominated SEI. For CMS-800 (Group II carbon), a short low-potential plateau emerges in the potential profile. However, there is still an obvious irreversible slope region, leading to a low ICE of 61%, indicating the necessity of controlled de-solvation to achieve a high ICE. In contrast, CMS-1300 (Group III carbon) has a potential profile comprised of a highly reversible slope region and an extended low-potential plateau region, leading to a markedly improved ICE of 91% and a high reversible capacity of 306 mAh g−1. CMSs in Group III with ultra-small PMSs (smaller than 0.35 nm) all have an ICE greater than 80%, originating from the highly efficient desolvation.

a Potential profiles of the first cycle, at specific current of 0.05 A g−1 and 25 °C. b Cycling performance at specific current of 0.05 A g−1 and 25 °C. c EIS studies at 0.6 V and 0.1 V during initial discharge process using specific current of 0.05 A g−1 and 25 °C. d Low-temperature performance, and e Charge curves at 25 °C and −40 °C. Source data are provided as a Source Data file.

Cycling at small specific current (0.05 A g−1) was conducted to evaluate the impact of PMS on the interface stability (Fig. 4b). It is reported that the formation of a stable SEI on the carbon negative electrode requires the average coulombic efficiency (CE) to be higher than 99% throughout the cycling52. In the case of CMS-1300, the SEI quickly stabilizes (CE reaching 99%) after the first 15 cycles and a high capacity-retention of 95% is kept over 200 cycles. In contrast, a longer period of 25 cycles is required to stabilize the SEI of CMS-800, during which its capacity rapidly decays and only 76% remains over 200 cycles. AC requires the longest SEI formation time of more than 40 cycles.

Electrochemical impedance spectroscopy (EIS) was conducted during discharge to better understand the interfacial electrochemistry (Fig. 4c and Supplementary Fig. 26). An equivalent circuit model was used to fit the high-frequency and mid-frequency semicircles in the Nyquist plots to calculate the SEI resistance (RSEI) and charge-transfer resistance (Rct) (Supplementary Fig. 27 and Supplementary Table 3). The only high-frequency semicircle observed in the Nyquist plot between 1.0 and 0.6 V refers to electrolyte decomposition and SEI formation43,53. At this stage, the RSEI of CMS-1300 is notably smaller than that of CMS-800 and AC, particularly at 0.6 V, when organic species predominantly emerge. This proves that the ultra-small pore mouth sieves most of the solvents and thus impedes their excessive decomposition27,54. Upon further discharge to 0.1 V, electrolyte decomposition of CMS-800 and CMS-1300 negative electrodes is almost complete, indicated by the emergence of a charge transfer process, whereas electrolyte decomposition in the AC negative electrode persisted. In the case of CMS-800 and CMS-1300 negative electrodes, the desolvation and transport of sodium ions across the SEI contribute to the RSEI values in this stage50,55. The sustained smaller RSEI of CMS-1300 during subsequent sodiation implies that the thin and inorganic-rich SEI promotes the de-solvation dynamics and interfacial sodium diffusion. Furthermore, as indicated by the lowest Rct of CMS-1300 below 0.1 V, the energy barrier for the reaction inside the pores is reduced due to the facile interfacial electrochemistry.

It has been reported that the low-temperature performance of hard carbons is closely related to their interfacial properties1. We have assessed the capacity retention of three carbon negative electrodes (AC, CMS-800, and CMS-1300) at temperatures ranging from 0 °C to −40 °C at specific current of 0.05 A g−1 and have compared them with that at 25 °C (Fig. 4d). We used ether-based electrolytes to significantly reduce the polarization of the sodium metal in a half-cell configuration56,57. Theoretically, the low-temperature performance of the negative electrodes is determined by their charge storage mechanism and desolvation dynamics. The AC negative electrode primarily relies on capacitive charge storage as the main mechanism for sodium storage, leading to a naturally high capacity retention at low temperatures, but at the expense of a low energy density. For the CMS-800 and CMS-1300 negative electrodes, the low-potential plateau primarily originates from the formation of sodium clusters inside pores. Operando XRD further proves that there is no obvious formation of intercalation compounds, as evidenced by the absence of a distinct peak shift (Supplementary Fig. 28). However, sodium still inserts between the interlayers and possibly exists in the form of ions58. In this case, desolvation is the rate-determining step at low temperatures due to its high energy barrier53. The CMS-1300 negative electrode, with the lowest RSEI, has the highest capacity-retention of 82% at −40 °C compared with that at 25 °C, and its low-potential plateau capacity is almost completely preserved (Fig. 4e). For comparison, the CMS-800 negative electrode, with a higher RSEI, shows a significant reduction in the low-potential plateau capacity at −40 °C and has a capacity retention of only 48% compared to its value at 25 °C.

Underestimated role of defects

Within the pores of hard carbons, defects serve as the main sites for sodium storage, but they are also widely recognized to induce interfacial side reactions due to the high reactivity13,59,60. To investigate the relationship between defects and interfacial electrochemistry, we evaluated the change in defect concentration of AC, CMS-800, and CMS-1300 negative electrodes before and after cycling by Raman tests (Fig. 5a and Supplementary Fig. 29). The D-band of the CMS-1300 negative electrode has excellent reversibility indicating the defects are hardly involved in the irreversible reactions. Conversely, in the case of the AC and CMS-800 negative electrodes, the D peak intensity exhibits an irreversible decrease in the initial cycle. In particular, the AC negative electrode displays a significant weakening of the D-band during the aging period, suggesting that defects are primarily passivated in the electrolyte decomposition process. These observations demonstrate that defects can be reversibly utilized if the PMS is well controlled, which provides a direction for the design of high-capacity carbon negative electrodes, as evidenced by SVCs11. Furthermore, we performed operando Raman spectroscopy to investigate the effect of defects inside the pores on the charge storage (Fig. 5b, c). The G-band undergoes a reversible red shift in peak position during cycling, which is attributed to the transfer of negative charge to carbon, weakening the C-C bond by occupying the π* anti-bonding band61,62. The D-band has changes in peak intensity during cycling, indicating the elimination or restoration of defects as reactive sites63. Compared to the AC and CMS-800 negative electrodes, the CMS-1300 negative electrode has a distinct and reversible weakening of the D peak intensity during discharge accompanied by a red shift of the G peak position in the sloping region. This indicates that a significant number of defects serve as active sites for charge transfer, in accordance with the low Rct in the EIS analysis, which contributes to the increased low-potential plateau capacity. In contrast, AC and CMS-800 negative electrodes have only a negligible weakening of the D-band intensity and a shift in the G-band peak in the sloping region, indicating a limited contribution of defects to charge storage. These results show that ultra-small pore mouths play a crucial role in protecting defects from electrolyte decomposition and interface passivation, thereby facilitating their utilization for reversible sodium storage, especially at the low-potential plateau.

a Raman spectra of the three carbon negative electrodes in their original state, after aging, and after the first cycle. The D-band, situated at around 1350 cm−1, originates from sp2 carbon atoms in rings at defects. The G-band, located at around 1580 cm−1, originates from aromatic sp2 carbon atoms. b, c Operando Raman spectra of three carbon negative electrodes during the initial discharge/charge in the region centered on b G-band and c D-band. The transition point from discharge to charge is labeled by dashed lines. The discharge/charge process was performed at 25 °C using specific current of 50 mA g−1. d Calculated model of Na+ absorbed in various kinds of defects based on DFT, along with e the optimized structure of NaC7.5 and sequential difference of energy as a function of the number of Na+ adsorbed. Source data are provided as a Source Data file.

We further theoretically investigate how various types of defects are utilized during sodium storage through density functional theory (DFT) simulations. Schematic structures of various defects and their sodium storage voltages were calculated and are shown in Fig. 5d, including single vacancy (VC), 555–777 double vacancy (VC2), 585 double vacancy (VC2’), triangular vacancy (Vtri), hexagonal vacancy (Vhex), and armchair (AC) and zigzag edges (Supplementary Data 1–10). Overall, the calculated voltage decreases with the reduction of the vacancy size, from ~3.0 V of Vhex to 0.8 V of VC2. It is worth mentioning that the VC2 defect has the lowest formation energy of these defects. This structure should partially contribute to the observed capacity at low voltage in CMS samples. In comparison, sodium cannot be effectively adsorbed on perfect graphene layers (single layer denoted as SL, double layer denoted as DL). To simulate the origin of the capacity of CMS-1300, we construct a defect model with four VC2 defects in a 7 × 7 supercell of graphene (Fig. 5e). The sequential energy difference is all negative for up to 12 Na+ adsorbed in this system except 0.04 eV for n = 7 (Supplementary Data 11−22), indicating that all 12 Na+ can be effectively adsorbed on this model structure and the stoichiometric ratio of sodium to carbon is 1:7.5 (the model structure is denoted as NaC7.5). The theoretical capacity regarding NaC7.5 is around 300 mAh g−1, which is in line with the tested capacity of CMS-1300, suggesting that intrinsic defects are the primary origin for its high capacity. To conclude, rational design principles for high-performance hard carbon negative electrodes proposed in this work are redefined close pores with PMS smaller than 0.35 nm and abundant intrinsic defects inside closed pores.

Discussion

The present study reveals how the evolution of PMSs determine the solvation structure of hard carbon negative electrodes and thereby redefines closed pores, as illustrated in Fig. 6. When the pore mouth is completely open (>0.5 nm), accessible to both N2 and CO2 molecular probes, sodium ions enter the pores without de-solvation and maintain the solvation structure as SSIPs, leading to substantial solvent adsorption in the IHP. As a result, the pore is filled with a thick and organic-rich SEI, and the intrinsic defects are deactivated. As the pore mouth gradually closes, desolvation is triggered before the ions enter the pore, showcased by SVCs with tightened pore mouth. However, when the pore mouth is between 0.35 nm and 0.5 nm, inaccessible to N2 but accessible to CO2 molecular probes, only a portion of coordinated solvents is removed before entering the pores, and contact ion pairs dominate inside pores, while the solvent continues to dominate the IHP. Hence, a considerable amount of organic-based SEI fills the pores, and the intrinsic defects are still partially passivated, resulting in a low ICE and a short low-potential plateau. When the pore mouth is smaller than 0.35 nm, inaccessible to CO2 molecular probes, solvents are mostly sieved and AGGs dominate solvation structure. This results in PF6− enrichment in the IHP and the formation of a thin and inorganic (NaF)-rich SEI. Closed pores are accordingly redefined, and ICE, cycling, and low-temperature performance are largely improved. Moreover, intrinsic defects inside the pores are effectively shielded from the interfacial passivation and contribute to the increased low-potential plateau capacity.

The crystallites are shown as blue lines, the SEI is shown as orange, the inner Helmholtz layer (IHP) is pointed out by the black bidirectional arrows and the defects are shown as the vacancies in Hexatomic rings. The three solvation structures inside the pores are SSIP solvent-separated ion pairs, CIP contact ion pairs, and AGG anion aggregates.

By using CMS as a model material, this work redefines closed pores with pore mouths inaccessible to CO2 molecular probes. For typical hard carbons, they are produced by carbonization using carbohydrates or biomass as the precursors. Therefore, varying conditions should be carefully controlled to develop redefined closed pores according to the properties of different precursors64,65. In addition, the present redefinition is based on EC-based ester solvent systems, the compatibility between PMS and solvated ion sizes must be taken into account, and further research is needed for other electrolyte systems.

Inside redefined close pores, defects play a key role in initiating and extending the low-potential plateau. This work theoretically showed the defect-dependent sodium storage properties. Further advancements in precisely controlling defects, especially intrinsic defects, are necessary to tailor the aggregation state of sodium clusters and thereby regulate the low-potential plateau66. As already revealed by SVCs, there is a linear correlation between the surface area of sodiophilic pore surface and low-potential plateau capacity. Therefore, the influence of extrinsic defects on the sodiophilic pore surface upon low-potential sodium storage and their precise control should also be thoroughly explored6,60. These insights will pave up new ways to understand and exploit close pores and defects of hard carbon negative electrodes to drive the industrialization of high-performance non-aqueous SIBs.

Methods

Materials synthesis

The CMS was type 1.5GN-H and purchased from Kuraray Chemical (Japan), whose specifications can be found in the MSDS data sheet. It is a porous carbon material using coconut shell as a precursor. These CMSs were subsequently carbonized at different temperatures (between 600 and 1500 °C) for 2 h in an argon stream with a heating rate of 5 °C min−1. The resulting samples are named as CMS-T, where T is the carbonization temperature. The active carbon is type YP80F, which was purchased from Kuraray Chemical (Japan) and uses a similar precursor as CMS.

Morphological, structural and compositional characterization

HRTEM was conducted using a JEOL JEM 2100F operated at 200 kV. To characterize the morphology of the SEI, the battery after 10 cycles was disassembled in the glove box to obtain a working electrode at the full de-sodiated state. The active materials were scraped off and dispersed ultrasonically in pure DEC solvent. Drop the dispersion onto the sample stage and dry in the glove box. The information of surface functional groups was obtained from Fourier Transform-Infrared Spectroscopy (iS50 FT-IR, Thermo Scientific). XRD was carried out at 25 °C on a Rigaku D/Max 2500 PC diffractometer on CuKa radiation (λ = 1.54056 Å). Raman spectra were conducted on MicroRaman system (LabRAM HR spectrometer, Horiba) with an argon ion laser (532 nm). The Fourier-transform infrared (FTIR) spectra were collected by the Nicolet 6700 FTIR spectrometer, where the electrode was placed directly on the windows testing holders. To characterize the electrolyte structure inside the pores of electrodes, the batteries were disassembled in an argon-filled glove box after initial discharge to 1.5 V. The working electrode was dried in the glove box at 25 °C until no liquid sheen remains, at which point the neat electrolyte within the interparticle space and on the surface was removed. The drying duration was carefully controlled to prevent the electrolyte signal inside pores from diminishing due to excessive drying. The sample transfer process was encapsulated in a vacuum box. The 19F and 23Na ssNMR experiments with MAS were performed on a Bruker AVANCE III 400 MHz spectrometer with a 1.3 mm double-resonance HX probe. All spectra were acquired with a 90°pulse-acquire sequence at a sample spinning speed of 15 kHz. The 19F chemical shifts were calibrated using neat hexafluorobenzene (C6F6) at −164.9 ppm as external reference. The 23Na chemical shifts were calibrated using a 1 M NaCl aqueous solution at 0 ppm as an external reference. For ssNMR measurements, the batteries were disassembled in an argon-filled glove box after the initial discharge at specific current of 50 mA g−1 until a cutoff potential of 1.5 V was reached. The electrodes were collected from the Cu foil and transferred into the 3.2 mm rotor at 25 °C without rinsing and sealed with a Vespel cap in a short time so that exposure to air or moisture was avoided.

N2 adsorption-desorption at 77 K and CO2 adsorption-desorption experiments at 273 K were conducted using a BELSORP MAX-II analyzer. The SSA and pore diameter distribution were analyzed by BET method and NLDFT method, respectively. The true density measurements were made on a BELPycno analyzer using the gas (He) displacement method. SAXS was performed using a Xeuss 2.0 SAXS/WAXS System with a Cu X-ray source of 30 W (wave length of 0.1542 nm) and X-ray spot of 0.8 × 0.8 mm in size was adopted. The scattering vector (Q) ranges were adjusted by sample-camera distance setting of 0.55 m for 1800 s to cover a broad angular range using a virtual detector mode of three images combined, and the corresponding scattering vector Q value was 0.01–1.1 Å−1. The two-dimension scattering data were transformed in one-dimension data curves with a Foxtrot 3.2.4 software. The measured intensity was collected for absolute intensity using glassy carbon as a standard sample and has been calibrated to exclude the influence of all related factors including the sample thickness, air, and sample holder scattering etc26. The SAXS data were analyzed using the SasView 4.2.2 software. XPS measurements (Thermal Fisher Scientific Escalab-Xi+ with Ar+ etching equipment) were conducted to investigate the chemical information. To characterize the composition of SEI, the depth-profiling XPS was performed. The batteries were disassembled in the glove box after 10 cycles at the full de-sodiation state. The working electrode was rinsed using pure DEC solvent and then dried in the glove box. The TOF-SIMS was conducted by PHI nanoTOF II instrument, where the electrode foils were bombarded by Bi3++ beams of 30 keV with 2 nA of ion current. An area with dimensions of 100 × 100 μm was adopted.

Electrochemical measurements

Electrochemical measurements were carried out using 2032-type coin cells containing an electrolyte of a 1 M NaPF6 dissolved in a mixture of ethylene carbonate (EC) and diethyl carbonate (DEC) (volume ratio: 1:1). The electrode slurry was prepared by mixing active material, carbon black (Canrd Super P, 99%), carboxymethyl cellulose (CMC) sodium (Aladdin, 99.9% purity, molecular weight 180) and polymerized styrene butadiene rubber (SBR, Aladdin, 50% solid content, molecular weight 158) in mass ratios of 90:5:2:3 in deionized water and coated single-sided on the copper foil (purity 99.9% and thickness 9 μm) using a Doctor blade. The electrodes are disassembled into 10 mm discs using sheet punch. A 0.4 mm sodium foil was used as the counter electrode, and a glass fiber (Whatman GF/A CAT. NO. 1823−257, diameter 16 mm, thickness 260 μm, pore size 1.6 μm, porosity 40%) was used as the separator. All cells were assembled with ~1 mg cm−2 active material per cell inside an Agron-filled glovebox. The cell cases used were made of stainless steel. Forty microliters of electrolyte was added to each cell. The potentiostatic EIS measurement was conducted using an electrochemical workstation (Eco Chemie Autolab) in the frequency range 10 mHz–100 kHz with a PC signal amplitude of 10 mV. A total of 71 points were collected within the test frequency range. A quasi-stationary potential was applied for 600 s before carrying out the EIS measurement. The galvanostatic charge/discharge measurements were made on a Neware battery cycler (CT-4008T-5V20mA-164, Shenzhen, China) in the voltage range 0.005−2.5 V. The low-temperature performance testing was performed using cells containing an electrolyte of 1 M NaPF6 dissolved in diglyme. The batteries were placed in a thermostatic chamber that could change to different temperatures, while the galvanostatic charge/discharge measurements were performed using a the Neware battery cycler. The differential capacitance values at various potentials were determined through EIS measurements in a three-electrode system. Initially, the time constant was determined at the open circuit potential. Subsequently, the impedance data points corresponding to this time constant at different potentials were selected, and the differential capacitance was calculated using the following equation:

where Z″ is the imaginary component of impedance and f is AC frequency.

EQCM measurements

The quartz crystal microbalance (QCM) apparatus was Biolin’s Qsence-Analyzer. EQCM measurements were carried out using a three-electrode system with an Au quartz crystal resonator as the working electrode, a sodium plate as the counter electrode, and a sodium stick as the reference electrode. The electrode was cleaned in an aqueous solution containing H2O2 and H2SO4 (0.1 M) in the ratio of 1:3 followed by thorough rinsing with deionized water. After drying with nitrogen, the electrode slurry was sprayed uniformly on the electrode surface. The electrode slurry was prepared by mixing active material, carbon black, CMC sodium, and polymerized SBR in a mass ratio of 90:5:2:3 in deionized water. The electrode slurry needed to be diluted to 4 mg ml−1 to ensure that the electrode had a sufficiently low loading (200–300 μg cm−2) after spraying, in order to obtain a detectable change of electrode frequency.

Operando Raman

Operando Raman spectra were obtained on MicroRaman system (LabRAM HR spectrometer, Horiba) with an argon ion laser (532 nm). The electrodes were prepared by mixing the active materials, sodium-carboxymethylcellulose (CMC) and super P in mass ratios of 8:1:1 in deionized water, dropped and spread evenly on a stainless-steel wire mesh (300 mesh). The prepared electrodes were dried at 60 °C under vacuum for 12 h. A quartz window was fabricated on the top of a CR2032 coin cell with a hole for the laser to pass through and cut the cell off from air. Each spectrum was acquired for 60 s.

Operando XRD

Operando XRD patterns were obtained on a Rigaku D/Max 2500 PC diffractometer on CuKa radiation (λ = 1.54056 Å). A beryllium window was fabricated on the top of the operando electrochemical cell (Beijing Zhongke Wanyuan Technology Ltd) to allow X-rays to pass through. The electrodes were prepared by mixing the active materials, sodium-CMC and super P in mass ratios of 8:1:1 in deionized water, dropped and spread evenly on a stainless-steel wire mesh (300 mesh). The prepared electrodes were dried at 60 °C under vacuum for 12 h. The scan rate was 20 degrees per minute and set to continuous testing.

Theoretical calculation

All DFT calculations were carried out with the generalized gradient approximation using the Perdew–Burke–Ernzerhof parametrization67, as implemented in the Vienna ab-initio simulation package68. Projector-augmented wave potentials were employed to describe the interaction between ion cores and electrons. A vdW-DF functional with optimized exchange functionals for correlation part was selected to characterize the van der Waals interaction69,70. Adopting the supercell approach71, a vacuum layer larger than 10 Å was chosen to ensure the spurious interactions between structural images in periodic supercells negligible. All structures were fully optimized until the force on each atom was less than 0.01 eV/Å. The voltage is calculated as (n*ENa + Edef − Etot)/n, where ENa, Edef, and Etot are energies for bulk Na, defected graphene, and total energies for the adsorbed system, respective. n represents the number of Na adsorbed on defected graphene. The sequential energy difference is defined as Etot(n) − Etot(n − 1) − ENa.

Data availability

All data is available in the main text or the supplementary information. Source data are provided with this paper.

References

Xu, K. Charge-transfer” process at graphite/electrolyte interface and the solvation sheath structure of Li+ in nonaqueous electrolytes. J. Electrochem. Soc. 154, A162–A167 (2007).

Xu, K. & AvW, C. Li+-solvation/desolvation dictates interphasial processes on graphitic anode in Li ion cells. J. Mater. 27, 2327–2341 (2012).

Zhou, Y. et al. Real-time mass spectrometric characterization of the solid-electrolyte interphase of a lithium-ion battery. Nat. Nanotechnol. 15, 224–230 (2020).

Xu, K. Electrolytes and interphases in Li-ion batteries and beyond. Chem. Rev. 114, 11503–11618 (2014).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4417 (2004).

Zhu, Y., Chen, M., Li, Q., Yuan, C. & Wang, C. A porous biomass-derived anode for high-performance sodium-ion batteries. Carbon 129, 695–701 (2018).

Chu, Y. et al. Reconfiguring hard carbons with emerging sodium-ion batteries: a perspective. Adv. Mater. 35, 2212186 (2023).

Kamiyama, A. et al. MgO-template synthesis of extremely high capacity hard carbon for Na-Ion battery. Angew. Chem. Int Ed. 60, 5114–5120 (2021).

Meng, Q. et al. Tuning the closed pore structure of hard carbons with the highest Na storage capacity. ACS Energy Lett. 4, 2608–2612 (2019).

Zhang, S.-W. et al. Commercial carbon molecular sieves as a high performance anode for sodium-ion batteries. Energy Storage Mater. 3, 18–23 (2016).

Li, Q. et al. Sieving carbons promise practical anodes with extensible low-potential plateaus for sodium batteries. Natl. Sci. Rev. 9, nwac084 (2022).

Chen, H., Sun, N., Wang, Y., Soomro, R. A. & Xu, B. One stone two birds: pitch assisted microcrystalline regulation and defect engineering in coal-based carbon anodes for sodium-ion batteries. Energy Storage Mater. 56, 532–541 (2023).

Au, H. et al. A revised mechanistic model for sodium insertion in hard carbons. Energy Environ. Sci. 13, 3469–3479 (2020).

Yin, X. et al. Enabling fast Na+ transfer kinetics in the whole-voltage-region of hard-carbon anodes for ultrahigh-rate sodium storage. Adv. Mater. 34, e2109282 (2022).

Zheng, Y. et al. Superior electrochemical performance of sodium-ion full-cell using poplar wood derived hard carbon anode. Energy Storage Mater. 18, 269–279 (2019).

Jüntgen, H., Knoblauch, K. & Harder, K. Carbon molecular sieves: production from coal and application in gas separation. Fuel 60, 817–822 (1981).

Singh, A. & Koros, W. J. Significance of entropic selectivity for advanced gas separation membranes. Ind. Eng. Chem. Res. 35, 1231–1234 (1996).

Baker, R. W. & Lokhandwala, K. Natural gas processing with membranes: an overview. Ind. Eng. Chem. Res. 47, 2109–2121 (2008).

Largeot, C. et al. Relation between the ion size and pore size for an electric double-layer capacitor. J. Am. Chem. Soc. 130, 2730–2731 (2008).

Jurkiewicz, K. et al. Evolution of glassy carbon under heat treatment: correlation structure–mechanical properties. J. Mater. Sci. 53, 3509–3523 (2017).

Cui, H., Song, Y., Ren, D., Wang, L. & He, X. Electrocapillary boosting electrode wetting for high-energy lithium-ion batteries. Joule 8, 29–44 (2024).

Brunauer, S., Deming, L. S., Deming, W. E. & Teller, E. On a theory of the van der Waals adsorption of gases. J. Am. Chem. Soc. 62, 1723–1732 (1940).

Garrido, J., Solano, A. L., Martinez, J. M. & Sabio, M. M. Use of nitrogen vs. carbon dioxide in the characterization of activated carbons. Langmuir 3, 76–81 (1987).

Hu, X., Radosz, M., Cychosz, K. A. & Thommes, M. CO2-filling capacity and selectivity of carbon nanopores: synthesis, texture, and pore-size distribution from quenched-solid density functional theory (QSDFT). Environ. Sci. Technol. 45, 7068–7074 (2011).

Zhang, L. et al. DFT modeling of CO 2 and Ar low-pressure adsorption for accurate nanopore structure characterization in organic-rich shales. Fuel 204, 1–11 (2017).

Saurel, D. et al. A SAXS outlook on disordered carbonaceous materials for electrochemical energy storage. Energy Storage Mater. 21, 162–173 (2019).

Lu, Z. et al. Consummating ion desolvation in hard carbon anodes for reversible sodium storage. Nat. Commun. 15, 3497 (2024).

Luo, W. et al. Low-surface-area hard carbon anode for Na-ion batteries via graphene oxide as a dehydration agent. ACS Appl. Mater. Interfaces 7, 2626–2631 (2015).

Zhang, E. et al. Unraveling the capacitive charge storage mechanism of nitrogen-doped porous carbons by EQCM and ssNMR. J. Am. Chem. Soc. 144, 14217–14225 (2022).

Wu, Y. C. et al. Electrochemical characterization of single layer graphene/electrolyte interface: effect of solvent on the interfacial capacitance. Angew. Chem. Int, Ed. 60, 13317–13322 (2021).

Wang, Z.-F. et al. Effect of N-doping-derived solvent adsorption on electrochemical double layer structure and performance of porous carbon. J. Energy Chem. 80, 120–127 (2023).

Takada, K. et al. Unusual passivation ability of superconcentrated electrolytes toward hard carbon negative electrodes in sodium-ion batteries. ACS Appl. Mater. Interfaces 9, 33802–33809 (2017).

Cheng, F. et al. Electrolyte salts for sodium-ion batteries: NaPF6 or NaClO4. ACS Nano 17, 18608–18615 (2023).

Yamada, Y. et al. Unusual stability of acetonitrile-based superconcentrated electrolytes for fast-charging lithium-ion batteries. J. Am. Chem. Soc. 136, 5039–5046 (2014).

Wang, Y. et al. Weak solvent–solvent interaction enables high stability of battery electrolyte. ACS Energy Lett. 8, 1477–1484 (2023).

Ellis, L. D. et al. A new method for determining the concentration of electrolyte components in lithium-ion cells, using fourier transform infrared spectroscopy and machine learning. J. Electrochem. Soc. 165, A256–A262 (2018).

Meyer, L., Kinder, C. & Porter, J. Using machine learning and infrared spectroscopy to quantify species concentrations in battery electrolytes. J. Electrochem. Soc. 170, 100521 (2023).

Meyer, L., Curran, D., Brow, R., Santhanagopalan, S. & Porter, J. Operando measurements of electrolyte li-ion concentration during fast charging with FTIR/ATR. J. Electrochem. Soc. 168, 090502 (2021).

Liu, X. et al. Structural disorder determines capacitance in nanoporous carbons. Science 384, 321–325 (2024).

Lyu, D. et al. Understanding sorption of aqueous electrolytes in porous carbon by NMR spectroscopy. J. Am. Chem. Soc. 146, 9897–9910 (2024).

Luo, H. et al. Revealing the dynamic evolution of electrolyte configuration on the cathode-electrolyte interface by visualizing (De)solvation processes. Angew. Chem. Int. Ed. 63, e202412214 (2024).

Hu, L. et al. Restructuring electrolyte solvation by a versatile diluent toward beyond 99.9% coulombic efficiency of sodium plating/stripping at ultralow temperatures. Adv. Mater. 36, e2312161 (2024).

Liu, M. et al. Interfacial-catalysis-enabled layered and inorganic-rich sei on hard carbon anodes in ester electrolytes for sodium-ion batteries. Adv. Mater. 35, e2300002 (2023).

Yan, G. et al. A new electrolyte formulation for securing high temperature cycling and storage performances of Na ion batteries. Adv. Energy Mater. 9, 1901431 (2019).

Lu, Z. et al. Step-by-step desolvation enables high-rate and ultra-stable sodium storage in hard carbon anodes. Proc. Natl. Acad. Sci. USA 119, e2210203119 (2022).

Yan, C. et al. Regulating the inner helmholtz plane for stable solid electrolyte interphase on lithium metal anodes. J. Am. Chem. Soc. 141, 9422–9429 (2019).

Kitsu Iglesias, L. et al. Revealing the sodium storage mechanisms in hard carbon pores. Adv. Energy Mater. 13, 2302171 (2023).

Zhang, J. et al. Achieving superb sodium storage performance on carbon anodes through an ether-derived solid electrolyte interphase. Energy Environ. Sci. 10, 370–376 (2017).

Deng, L. et al. Self-optimizing weak solvation effects achieving faster low-temperature charge transfer kinetics for high-voltage Na3V2(PO4)2F3 cathode. Energy Storage Mater. 44, 82–92 (2022).

Zhao, S. & Huang, F. Weakly solvating few-layer-carbon interface toward high initial coulombic efficiency and cyclability hard carbon anodes. ACS Nano 18, 1733–1743 (2024).

Aurbach, D. & Zaban, A. The application of EQCM to the study of the electrochemical behavior of propylene carbonate solutions. J. Electroanal. Chem. 393, 43–53 (1995).

Xiao, J. et al. Understanding and applying coulombic efficiency in lithium metal batteries. Nat. Energy 5, 561–568 (2020).

Cai, W. et al. A review on energy chemistry of fast-charging anodes. Chem. Soc. Rev. 49, 3806–3833 (2020).

Chmiola, J. et al. Anomalous increase in carbon capacitance at pore sizes less than 1 nanometer. Science 313, 1760–1763 (2006).

Pan, S. et al. Integrating SEI into layered conductive polymer coatings for ultrastable silicon anodes. Adv. Mater. 34, e2203617 (2022).

Zheng, X. et al. Knocking down the kinetic barriers towards fast-charging and low-temperature sodium metal batteries. Energy Environ. Sci. 14, 4936–4947 (2021).

Zhou, J. et al. Low-temperature and high-rate sodium metal batteries enabled by electrolyte chemistry. Energy Storage Mater. 50, 47–54 (2022).

Morikawa, Y., Nishimura, S., Hashimoto, R., Ohnuma, M. & Yamada, A. Mechanism of sodium storage in hard carbon: an x‐ray scattering analysis. Adv. Energy Mater. 10, 1903176 (2019).

Stratford, J. M. et al. Correlating local structure and sodium storage in hard carbon anodes: insights from pair distribution function analysis and solid-state NMR. J. Am. Chem. Soc. 143, 14274–14286 (2021).

Sun, D. et al. Engineering the trap effect of residual oxygen atoms and defects in hard carbon anode towards high initial Coulombic efficiency. Nano Energy 64, 103937 (2019).

Hardwick, L. J. et al. In situ Raman spectroscopy of insertion electrodes for lithium-ion batteries and supercapacitors: first cycle effects. J. Phys. Chem. Solids 69, 1232–1237 (2008).

Li, Q. et al. Discrete graphitic crystallites promise high rate ion intercalation for KC8 formation in potassium ion batteries. Adv. Energy Mater. 12, 2201574 (2022).

Zhong, X. et al. High-performance sodium-ion batteries based on nitrogen-doped mesoporous carbon spheres with ultrathin nanosheets. ACS Appl. Mater. Interfaces 11, 2970–2977 (2019).

Li, Y. et al. Origin of fast charging in hard carbon anodes. Nat. Energy 9, 134–142 (2024).

Wang, Y. et al. Releasing free radicals in precursor triggers the formation of closed pores in hard carbon for sodium‐ion batteries. Adv. Mater. 36, 2401249 (2024).

Deringer, V. L. et al. Towards an atomistic understanding of disordered carbon electrode materials. Chem. Commun. 54, 5988–5991 (2018).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Klimeš, J., Bowler, D. R. & Michaelides, A. Van der Waals density functionals applied to solids. Phys. Rev. B 83, 195131 (2011).

Dion, M., Rydberg, H., Schroder, E., Langreth, D. C. & Lundqvist, B. I. Van der Waals density functional for general geometries. Phys. Rev. Lett. 92, 246401 (2004).

Ihm, J., Zunger, A. & Cohen, M. L. Momentum-space formalism for the total energy of solids. J. Phys. C Solid State Phys. 12, 4409–4422 (1979).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 52202278, 22379109 and U23B2077), Young Elite Scientists Sponsorship Program by CAST (No. 2022QNRC001), the National Industry-Education Integration Platform of Energy Storage, the Haihe Laboratory of Sustainable Chemical Transformations, the Fundamental Research Funds for the Central Universities, and Collaborative Innovation Center of Chemical Science and Engineering (Tianjin).

Author information

Authors and Affiliations

Contributions

Q.-H. Y. and J. Z. conceived the idea. Y. Z., S.-W. Z., and H. X. synthesized carbon electrode materials. Y. Z., Y. C., T. C., and D. Q. conducted the material characterizations, electrochemical tests, and mechanistic characterizations. S.-W. Z. and X. Z. conducted the theoretical calculations. Y. J. performed all TEM tests. G. Z. and Z. P. contributed to NMR testing and analysis. D.-W. W., Y. T., F. K., and W. L. jointly supervised the research. Y. Z., S.-W. Z., J. Z., and Q.-H. Y. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Y., Zhang, SW., Chu, Y. et al. Redefining closed pores in carbons by solvation structures for enhanced sodium storage. Nat Commun 16, 3634 (2025). https://doi.org/10.1038/s41467-025-59022-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-59022-8

This article is cited by

-

Comprehensive Understanding of Closed Pores in Hard Carbon Anode for High-Energy Sodium-Ion Batteries

Nano-Micro Letters (2025)