Abstract

Switchable control of adhesion is an important feature of many desired applications such as robotic manipulation, medical adhesives, and scalable microassembly. We present the study of the switchable dry adhesion of a shape memory polymer surface comprising nanotips which is based on not only overcoming but also exploiting the adhesion paradox, i.e., controlling surface roughness via the shape memory effect. Here, densely packed sharp nanotips causing an initial high surface roughness are flattened upon heating, pressing and cooling to provide a low surface roughness leading to a strong adhesion. However, the flattened nanotips restore their original shape upon reheating to cause a high surface roughness back resulting in a weak adhesion with the adhesion switchability of more than three orders of magnitude. These switchable adhesion capabilities are demonstrated in a variety of applications ranging from macro-scale robotic pick-and-place and fabric adhesives to deterministic micro-scale device-grade silicon platelet transfer and microLED assembly.

Similar content being viewed by others

Introduction

In recent years, rapid advancements in micro/nanofabrication have initiated an era where the fabrication and utilization of nano-sized objects and structures have become feasible. This progress, driven by the development of cutting-edge technologies capable of observing and fabricating structures at the nano level, has sparked intensive research into functional surfaces endowed with novel capabilities. Biomimetic engineering involving micro/nano structuring, drawing inspiration from nature’s designs such as gecko-inspired fibrillar adhesives1,2,3, octopus-inspired suckers4,5, and the lotus leaves-inspired superhydrophobic surfaces6,7, has emerged as a focal point. Concurrently, there is a notable emphasis on exploring the potential of micro/nano structures in enhancing the functionalities of smart materials like hydrogels8,9,10 and shape memory polymers (SMPs)11,12,13. Within this landscape, adhesive technologies stand out prominently, attracting significant attention due to their dual significance in academic inquiry and real-world economic value. Accordingly, switchable adhesion mechanisms employing smart materials have emerged, focusing on how to apply stimuli to modulate adhesive forces and control directional adhesion or detachment effectively14,15. Notably, research endeavors encompass a wide spectrum, ranging from the development of smart adhesives endowed with tailored functionalities to the exploration of transfer printing techniques8,13,16,17 for manipulating microobjects at the micro-scale and dry adhesive-based soft grippers18,19 and skin patches20 at the macro-scale. Nonetheless, challenges persist in achieving universal applicability across varying scales, necessitating further investigation to elucidate the adhesive mechanisms across different dimensions and thus unlock their full potential for real-world applications. In addition, exploring methods to modulate adhesion, such as completely eliminating adhesive forces using laser-driven strategies21,22,23,24,25 or mitigating them through structural surface design13,26,27,28,29, represents a significant challenge in achieving the desired adhesive performance.

Among various approaches, adhesives based on the SMP stand out for their remarkable capabilities, chiefly attributed to their distinctive ability to undergo a significant change in storage modulus in response to external stimuli30,31. This characteristic enables exceptional adhesion upon shape adaptation32, facilitating the application of switchable adhesion across diverse settings such as wet surfaces, underwater environments19,33, rough surfaces34,35, and across varying scales36,37. The adhesive strength of the SMP is based on van der Waals forces, and their switchable adhesion is realized through alterations in stiffness and the contact area with the adherend38. Building upon these characteristics, numerous studies have explored structured SMP surfaces, combining their inherent material properties with engineered surface architectures to enhance and expand the potential of switchable adhesion13,27,28,35,39,40. Linghu et al. 36 have shown the multiscale adhesion ability of the SMP by employing an SMP block to interlock multiscale objects, hold them in the SMP block, and subsequently release them through the shape recovery of the SMP. However, further elucidation is warranted regarding the adhesion mechanism necessary to achieve outstanding adhesion switchability across different scales, with challenges to surmount at each level. For instance, Fan et al. 37 demonstrated the feasibility of transfer printing across multiple scales using SMP; however, their approach did not establish a unified switchable adhesion mechanism applicable to both the macro- and micro-scales, as the adhesion mechanisms differ significantly between these scales. To develop a more versatile and practical multiscale switchable adhesive, it is essential to establish a unified adhesion mechanism capable of addressing objects across multiple scales. Overcoming the adhesion paradox induced by surface roughness, wherein van der Waals forces diminish significantly at the macro-scale34,41, emerges as a pivotal task to ensure adequate adhesion. In addition, at the micro/nano-scale where van der Waals forces reign supreme, mitigating these forces assumes paramount importance to achieve decent adhesion switchability42,43.

In this work, we have engineered a surface comprised of SMP nanotips and meticulously controlled its surface roughness to tackle the adhesion paradox at the macro-scale. Using the nanotipped SMP surface, we present an advancement of an adhesion mechanism capable of excellent switching adhesion at multiple scales, implementing the challenging deterministic pick-and-place of about 5 μm small objects, which is difficult to achieve using traditional self-assembly methods44 and other transfer printing methods26,45. The SMP surface, characterized by densely packed nanotips replicated in the silicon (Si) mold, which is formed via anisotropic wet etching, initially exhibits roughness attributed to these nanotips, resulting in weak adhesion to macro-scale objects. Similarly, its adhesion to microobjects is hindered by the limited contact area inherent in the nanotip structure13. However, through the application of pressure to the object and heating of the SMP surface, the remarkable surface adaptability of the SMP enables it to conform precisely to the object’s shape, thereby reducing roughness at the contact area25. Upon cooling below the glass transition temperature (Tg), this conformation is maintained, resulting in robust adhesion across both macro- and micro-scales. Unlike prior works relying on microstructured surfaces, which often require higher preload and exhibit limited adhesion adaptability across different scales, the densely packed nanotips in this study enable significantly lower asperity dimensions, resulting in greater compliance13,27,28. This increased compliance enhances surface adaptation, effectively reducing the required preload and extending adhesion performance across a wide range of scales. In contrast to previous microstructured surfaces that struggle to achieve both strong and switchable adhesion across macro and microobjects, the nanotipped SMP surface offers universal applicability while maintaining excellent adhesion switchability. Furthermore, its cost-effective and scalable fabrication process ensures practical deployment in various industrial applications. In the next section, we describe the mechanism elucidating how the nanotipped SMP surface achieves the remarkable adhesion switchability via surface roughness control, accompanied by corresponding finite element analysis and experimental results. Expanding on this mechanism, our work presents the advanced adhesive performance of the nanotipped SMP surface resulting from the excellent adhesion switchability across varying scales, from macro to micro. Finally, we demonstrate the robotic pick-and-place of diverse macro-scale objects and the transfer of microLEDs, highlighting the practical applications of the nanotipped SMP surface as a switchable adhesive in real-world contexts.

Results and discussion

Mechanism of switchable adhesion through controlling surface roughness of SMP

A thermally responsive epoxy SMP (Supplementary Fig. S1) has been utilized for the presented nanotipped SMP surface due to its excellent surface adaptability and significant changes in stiffness. This characteristic allows it to overcome the inherent trade-off between contact area and compliance. According to Eq. (1) 38, to achieve a higher adhesion force (\(F\)), both a larger contact area (\(A\)) and lower compliance (\(C\)) are necessary. Typically, achieving a larger contact area requires higher compliance, creating a dilemma for conventional elastomeric adhesives in attaining strong adhesion. However, SMP can drastically alter its stiffness through thermal response. When the SMP is soft, it can form a larger contact area, and by becoming stiffer, it achieves stronger adhesion. Thus, SMP offers both strong adhesion and switchable adhesion due to stiffness changes.

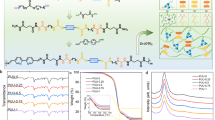

Despite these advantages, SMP retains a certain level of adhesion even in its highly compliant, rubbery state. For complete adhesion switchability, it is essential to reduce adhesion in the weakly adhering state or the adhesion-off state to near zero, akin to flipping a mechanical or electrical switch. One solution involves roughening the SMP surface with nanoscale structures that disrupt adhesion, thereby enabling excellent adhesion switchability by altering both stiffness and contact area. Figure 1a illustrates the process of fabricating a roughened SMP surface with nanoscale structures. Wet etching is performed on (100)-oriented bare Si using a solution of potassium hydroxide (KOH), deionized (DI) water, and isopropyl alcohol (IPA). This approach enables the cost-effective formation of numerous nanoscale pyramid tips on the large area Si surface without relying on advanced or costly micro/nanofabrication techniques (Supplementary Table S1). Since hard-polydimethylsiloxane (H-PDMS) is better suited for molding nanoscale features compared to conventional polydimethylsiloxane (PDMS), H-PDMS is then cast onto this roughened Si surface to create a negative mold (Detailed comparison between H-PDMS and PDMS is in SupplementaryFig. S2). The SMP precursor is poured into this negative mold, using soft lithography to produce an SMP surface densely populated with nanotips (for detailed fabrication steps, see Supplementary Fig. S3).

a The fabrication method of the nanotipped SMP surface and its application. (i) Schematic illustration of the fabrication process of the nanotipped SMP surface and switchable adhesion at multiple scales: (ii) at the macro-scale, (iii) at the micro-scale. b Comparison regarding the adhesion switchability among switchable adhesives at the multiple scales. (Macro: Switchable gecko adhesives48,49,50,51,52,53,54,55,56; Micro: Transfer printing stamps13,17,26,29,57,58,59,60,61,62,63). c Robotic arm capable of performing pick-and-place operations using the nanotipped SMP surface. d Transparent and flexible display featuring microLEDs transfer printed by the nanotipped SMP surface, attached to a glass vial with a radius of 1.3 cm.

The resulting nanotipped SMP surface exhibits on/off adhesion characteristics at both macro- (Fig. 1a ii) and micro-scales (Fig. 1a iii). Since SMP nanotips are a few hundreds of nanometers or smaller, on both scales, the nanotipped SMP surface with original roughness typically loses adhesion due to the adhesion paradox. However, when the nanotipped SMP surface adheres to an opposing surface with reduced roughness due to its shape fixing capability, the increased contact area results in strong adhesion. On the contrary, the shape recovery of SMP allows it to revert to its original rough surface, thereby losing adhesion. This shape memory behavior of the SMP nanotips is demonstrated in Supplementary Movie S1.

As shown in Fig. 1b, most research on switchable adhesion focuses on either the macro- or micro-scale. In contrast, the nanotipped SMP surface achieves extreme adhesion switchability across multiple scales. This capability of adhesion switchability across multiple scales is demonstrated through two applications: at the macro-scale, a robotic arm equipped with the nanotipped SMP surface successfully performs pick-and-place operations for various objects (Fig. 1c); at the micro-scale, the same surface enables the transfer printing of microobjects such as microLEDs (Fig. 1d).

Adhesion characteristics of roughness controllable SMP surface

To achieve optimal adhesion switchability, it is crucial to analyze the adhesion of SMP concerning surface roughness. Specifically, it is necessary to determine the level of surface roughness at which the SMP in its soft rubbery state exhibits near-zero adhesion and how much adhesion increases when the SMP transitions to a stiff glassy state with reduced surface roughness. Figure 2a demonstrates the surface roughness of Si surfaces increasing with higher KOH concentrations (Detailed measurement results are provided in Supplementary Figs. S4 and S5). These surfaces (15 mm × 15 mm × 0.7 mm) were replicated onto SMP using soft lithography. To measure the adhesion strength, a load cell and customized linear stage were employed, as illustrated in Fig. 2b i). The SMP surface was heated using Joule heating via an ITO-deposited glass slide and cooled naturally. Adhesion-off tests were conducted by heating the SMP surface above Tg as shown in Fig. 2b ii), while adhesion-on tests involved preloading the SMP surface above Tg and cooling it to transition from rubbery to glassy (R2G) state while maintaining preload, reducing surface roughness at the contact area and promoting strong adhesion, as illustrated in Fig. 2b iii).

a Surface roughness variation of bare Si (100) according to the weight percent of KOH in KOH wet etching. Scale bars: 10 μm. Data are presented as mean values with error bars indicating the minimum and maximum values. Five independent samples were measured for each condition. b Adhesion test method. (i) Adhesion test setup for the nanotipped SMP surface. (ii) The adhesion test procedure in the soft rubbery state. (iii) The adhesion test procedure in the R2G state. c Normalized contact area of the nanotipped SMP surface relative to the surface roughness. d Experimental results and FEA simulation results indicating a decrease in the rubbery state adhesion with increasing surface roughness of the SMP surface. Data are presented as mean values with error bars indicating the minimum and maximum values. Each condition was tested five times (n = 5). e FEA simulation result of adhesion of a nanotipped SMP surface with the surface roughness of about 200 nm in both rubbery and R2G state. f Adhesion switchability shown by comparing weak adhesion in the rubbery state due to its surface roughness and strong adhesion in the R2G state owing to conformality and drastically increased stiffness. g Comparison of adhesion switchability between the flat SMP surface and the nanotipped SMP surface upon varying retraction speed. Data are presented as mean values with error bars indicating the minimum and maximum values. For each condition, n = 5 independent measurements were conducted. h Adhesion repeatability test results on the nanotipped SMP surface.

To numerically investigate the mechanism of the adhesion switchability in relation to surface roughness, the true contact area of the nanotipped SMP surface with the adherend is further examined, as depicted in Fig. 2c. Detailed analysis of contact area variation on nanotipped SMP surfaces is in the Supplementary Information. The x-axis represents the position of the SMP surface, starting from the mean of each roughness profile. This position value is normalized by half the peak-to-peak distance of each roughness profile, with the starting point indicated as 0. The y-axis denotes the contact area of the SMP surface, normalized by its projected area. Surface roughness measurements were conducted using a 3D confocal scanning microscope. As the SMP surface moves from the mean roughness height towards detachment, the normalized contact area diminishes. Significantly, with increasing roughness upon increasing KOH concentration, the contact area decreases more rapidly. At the x-axis value of 0.5, indicating that the SMP surface has risen to 50% of half the peak-to-peak distance of its roughness profile from its mean roughness height, the contact area reduction is approximately 40% for cases with roughness from 1.0 wt.% to 10 wt.%, compared to only a 2% reduction for cases with roughness from 0.1 wt.% to 0.3 wt.%. This highlights that effective control of surface roughness can significantly reduce or maintain the contact area, thereby influencing the pull-off force, as described by Eq. (1), and it is supported by the theoretical contact mechanics analysis in the Supplementary Information. Furthermore, understanding how surface roughness experimentally impacts preload and pull-off force is critical for achieving effective control of surface roughness. Supplementary Fig. S6 provides detailed experimental results, illustrating the relationship between preload and pull-off force for different surface roughness levels, represented by varying KOH concentrations.

Numerical simulations using ABAQUS/Standard and experimental adhesion tests were also conducted to investigate the relationship between surface roughness and adhesion force in the rubbery and R2G states of SMP (sample size 15 mm × 15 mm × 0.7 mm). Detailed information about the simulation setup, parameters, and methodology is provided in the Supplementary Information. Figure 2d shows the adhesion force of nanotipped SMP surfaces in the rubbery state decreases with increasing surface roughness, with near-zero adhesion at root mean square (RMS) roughness (Rq) values above 200 nm (Detailed results of the adhesion test are shown in Supplementary Fig. S7). The result shows that the simulation and experimental values are consistent and show a significant decrease in adhesion force for Rq values above 200 nm, suggesting that an Rq value around 200 nm is optimal for the excellent adhesion switchability of a nanotipped SMP surface. The small deviation between simulation and experimental values might originate from the dimensional difference between the simulation (2D) and the experiment (3D), resulting in overestimation of contact area46. Fig. 2e illustrates the simulated adhesion force for the nanotipped SMP surface with an Rq of approximately 200 nm, highlighting substantial differences between the rubbery and R2G states. In the rubbery state, the work of adhesion is 0.2556 μJ, whereas in the R2G state, it increases dramatically to 34.2697 μJ, representing a 134-fold rise. During simulation, the stored energy in the rubbery state generates and recovers strain, thereby breaking adhesion and resulting in minimal tip contact with the opposing surface. In contrast, in the R2G state, the stored energy is locked, leading to temporary shape fixing with a larger contact area. This larger area and increased stiffness in the R2G state contribute to significantly higher work of adhesion.

Figure 2f presents the adhesion tests for the nanotipped SMP surface with Rq ~ 200 nm. The tests involved heating the SMP surface to 80 °C, applying a preload of 300 mN, and cooling it to various temperatures, 75, 60, 50, 35, and 25 °C. Pull-off force was measured at a retraction speed of 50 μm/sec. No significant adhesion occurred in the rubbery state above Tg, while in the R2G state, adhesion increased as the temperature decreased. Specifically, adhesion measured at 80 °C was 0.108 mN, and at 25 °C, it reached 483.036 mN, demonstrating over 1000-fold adhesion switchability. Figure 2g highlights the superior adhesion switchability of nanotipped SMP surfaces compared to flat SMP surfaces, with the latter showing only 12-fold switchability. Although both the flat and nanotipped SMP surfaces exhibit strong adhesion in the R2G state, there is a marked difference in their behavior when in the rubbery state. The flat SMP surface retains some adhesion due to its viscoelastic properties, resulting in increasing adhesion strength with higher retraction speeds. In contrast, the rough surface nanostructure of the nanotipped SMP surface prevents this increase in adhesion with retraction speed, allowing the adhesion energy to dissipate entirely (Detailed experimental results are shown in Supplementary Fig. S8). Figure 2h demonstrates the repeatability of adhesion of a nanotipped SMP surface. Even after more than 20 adhesion tests, there was no significant loss in adhesion strength or switchability, indicating reliable and consistent performance. In addition, throughout the 20 adhesion tests, there were no observable changes in the surface roughness or deformation in the geometry of the nanotipped SMP surface. Detailed explanations and supporting data are provided in Supplementary Fig. S9. The adhesion tests for both flat and nanotipped SMP surfaces are shown in Supplementary Movie S2 and S3, respectively.

Overcoming adhesion paradox through controlling SMP’s surface roughness at the macro-scale

Figure 3a demonstrates the switchable adhesion capability of the nanotipped SMP surface at the macro-scale. Typically, the inherent roughness of this surface, caused by numerous nanotips, results in weak adhesion due to the adhesion paradox, where increased surface roughness diminishes adhesive strength at the macro-scale. However, upon heating and pressing the nanotipped SMP surface against an adherend, followed by cooling, the shape fixing of SMP significantly reduces surface roughness, thereby increasing the contact area and resulting in strong adhesion. To revert to a state of weak adhesion, the surface roughness can be restored via shape recovery, returning the surface to its original rough state. Figure 3b provides a comparison between the surface profiles of the original nanotipped SMP surface (Rq = 227.1 nm) and the flattened SMP surface (Rq = 44.7 nm) using 3D optical profiling. The original nanotipped SMP surface exhibits high surface roughness, leading to loss of adhesion. In contrast, the flattened SMP surface shows a significantly reduced roughness, leading to a substantial increase in adhesion strength. Figure 3c presents a comparative analysis of the power spectral density (PSD) of surface roughness for both surfaces, calculated using an in-house MATLAB code (Detailed equations are in the Supplementary Information). The PSD plot shows the original nanotipped surface has a significantly higher magnitude across all wavevector (\({{{\bf{q}}}}\)) ranges compared to the flattened surface, indicating that the latter is considerably smoother.

a Schematic illustrations of the modulation of surface roughness on the nanotipped SMP surface, along with SEM images contrasting the original nanotipped SMP surface and its flattened surface, exhibiting reduced surface roughness. b 3D optical profiles of the nanotipped SMP surface and its flattened surface captured using a 3D confocal scanning microscope (Optelics hybrid C3, Lasertec, Japan) and (c) their roughness power spectra. d Optical microscopy image of a fabric and the nanotipped SMP surface adhering to the fabric (The character image is provided by POSTECH). e Switchable adhesion of the nanotipped SMP surface on the fabric (The character image is provided by POSTECH). f The nanotipped SMP surface adhering to a wet fabric. (i) Heat the nanotipped SMP surface above its Tg. (ii) Wet the fabric. (iii) Press the heated nanotipped SMP surface onto the wet fabric and cool it down. (iv) The nanotipped SMP surface adheres well even to the wet fabric (The character image is provided by POSTECH). g Adhesion switchability of the nanotipped SMP surface on various types of surfaces (Adhesion tests were conducted five times for each type of surface). Data are presented as mean values with error bars indicating the minimum and maximum values. h Easy self-release of the nanotipped SMP surface due to its extreme adhesion switchability. (i) Both the nanotipped SMP surface and the flat SMP surface strongly adhere to the glass beaker. (ii) Hot water is poured into the beaker. (iii) Only the nanotipped SMP surface can self-release.

Figure 3d-f demonstrate the switchable adhesion of the nanotipped SMP surface on typically non-adhesive fabrics. The optical microscopy in Fig. 3d shows the inherently rough surface of the fabric, which generally resists adhesion from typical dry adhesives. However, the high surface adaptability of the nanotipped SMP surface allows it to conform and shape fix to fabric structures smaller than 5 μm, as shown in Fig. 3e, resulting in strong R2G adhesion. The shape recovery then allows the surface to revert to its original rough state, enabling easy detachment without damaging the fabric21. Detailed explanations regarding the adhesion switchability of the flat SMP surface and the nanotipped SMP surface are provided in Supplementary Fig. S10. This switchable adhesion capability of the nanotipped SMP surface on fabric is detailed in Supplementary Movie S4. In addition, Fig. 3f illustrates that this adhesion switchability extends to even wet fabric surfaces22.

Figure 3g tests the adhesion switchability of a 10 mm × 10 mm × 1 mm nanotipped SMP surface sample on various materials. In the rubbery state, negligible adhesion is observed across all materials, with results close to zero. In the R2G state, the nanotipped SMP surface exhibits strong adhesion, with over a 1000-fold increase in adhesion switchability on materials such as glass, acrylic, Si wafer, and wood (Details are in Supplementary Fig. S11). The results highlight the excellent adhesion switchability of the nanotipped SMP surface. Figure 3h compares the adhesion characteristics of nanotipped SMP and flat SMP surfaces. In the weak adhesion state, the nanotipped SMP surface achieves nearly zero adhesion, enabling easy self-release. When the SMP is below its Tg, both surface types can securely hold a glass beaker (Details are in Supplementary Fig. S12). However, upon heating each SMP surface above Tg by pouring 90 °C water into the beaker, the flat SMP surface, due to conformal contact, does not release easily even in the rubbery state. Conversely, the nanotipped SMP surface is easily released by itself from the beaker due to the restoration of the nanotips, resulting in minimal contact. The detailed experimental procedure is provided in Supplementary Movie S5.

Adhesion switchability of the nanotipped SMP surface for transfer printing at the micro-scale

Figure 4a illustrates the use of the nanotipped SMP surface in transfer printing technology to demonstrate micro-scale adhesion switchability. The process involves transferring a microobject from a donor substrate to a receiver substrate relying on the switchable adhesion of the nanotipped SMP surface. Figure 4b shows the microobject to be transfer printed, which is a 5 μm diameter Si platelet, called Si ink hereafter, anchored to photoresist. The detailed fabrication process of the Si ink is outlined in Supplementary Fig. S13. When the nanotipped SMP surface contacts with the Si ink in its rubbery state and subsequently cools down, the shape fixing significantly reduces the surface roughness at the contact area, resulting in strong adhesion, as illustrated in Fig. 4c. The inset is the SEM image of flattened nanotips captured after the forced removal of Si ink adhered to the nanotips. The shape recovery then restores the original rough surface, leading to weak adhesion and allowing the Si ink to be easily transferred. The nanotipped SMP surface, with its finely structured nanotips, exhibits low asperities, allowing strong adhesion to small microobjects, such as the 5 μm Si ink, with minimal preloading (Detailed experimental results in Supplementary Fig. S14). This feature ensures that the ink remains undamaged during the adhering process, underscoring the delicate yet robust capabilities of the nanotipped SMP surface for micro-scale applications. The detailed transfer printing process involves attaching the SMP surface to an ITO glass, heating it above Tg via Joule heating, and aligning it vertically with the Si ink under a microscope. Upon cooling below Tg, the strong adhesion (R2G state) enables the SMP surface to pick up the Si ink from the donor substrate. The process concludes with transferring and aligning the Si ink to the desired receiver substrate and heating the SMP surface above Tg to place the Si ink, with the restored nanotips for easy release. Figure 4d shows the successful transfer of 5 μm diameter Si inks onto the PDMS substrate to form the letters 3MNS. This extreme adhesion switchability also allows for the transfer printing of Si ink onto unconventional substrates, such as wood, leaves, and paper, as depicted in Fig. 4e.

a Schematic illustrations of a single microobject manipulation. (i) Pick-up scenario. (ii) Placing scenario. b Approximate size of 5 μm Si ink anchored by photoresist. c The small-sized nanotipped SMP surface picked up a single Si ink. The nanotipped SMP surface beneath the Si ink flattens to create a broad contact area, enabling strong adhesion to the Si ink. Scale bars: 5 μm. d Si inks were transfer printed one by one forming the letters 3MNS on a PDMS substrate. e SEM images of transfer printed Si inks on unconventional substrates: (i) wood, (ii) leaf, (iii) paper. f Schematic illustrations of large-scale transfer printing of microobjects. (i) Pick-up scenario. (ii) Placing scenario. g SEM image of Si inks on the nanotipped SMP surface. h The scalable transfer printing of 5 μm Si inks involves three stages, initially, the Si inks are positioned on a PDMS substrate. Subsequently, they are transferred onto the nanotipped SMP surface, and finally, they are placed onto the H-PDMS substrate. i Adhesion-on/off mode of nanotipped SMP surface for the 5 μm Si ink. j The parallel transfer printing process of 3D- shaped microobjects comprises three steps: firstly, SiO2 microspheres are arranged on the PDMS substrate, forming a Smile pattern. Secondly, the nanotipped SMP surface picks up all microspheres in parallel, and finally, they are precisely placed onto the H-PDMS substrate. k Adhesion-on/off mode of nanotipped SMP surface for the 3D-shaped microobject.

The scalability of this transfer printing technique is demonstrated by expanding the area of the nanotipped SMP surface to enable the simultaneous transfer of multiple microobjects. Figure 4f provides a schematic illustration of scalable transfer printing using an expanded nanotipped SMP surface. Figure 4g shows an SEM image of numerous Si inks accurately adhered to the nanotipped SMP surface. The scalable transfer printing follows the same detailed method described earlier. Figure 4h outlines the scalable transfer printing process of an array of 5 μm diameter Si inks. After heating the nanotipped SMP surface above Tg, it is precisely aligned and contacted with Si inks on a PDMS donor substrate. Upon cooling, the SMP surface picks up the Si inks due to its stronger adhesion compared to the PDMS. This process is further supported by the nanoscale dimensions of the nanotips, which are significantly smaller than Si inks. While the overall nanotipped SMP surfaces accommodates multiple Si inks at different positions, the applied preload remains sufficient across all inks, ensuring reliable adhesion. Due to the small size of the nanotips relative to the Si inks, their dimensions have minimal impact on the uniformity of the preload. Further details can be found in Supplementary Fig. S15. The process continues with the transfer of Si inks to an H-PDMS receiver substrate, facilitated by heating the SMP surface above Tg once again. These results demonstrate that, despite the donor substrate (PDMS) having relatively stronger adhesion than the receiver substrate (H-PDMS), the exceptional adhesion switchability of the nanotipped SMP surface enables successful transfer printing. Figure 4i provides SEM images illustrating the adhesion switchability of 5 μm Si ink on the nanotipped SMP surface. In the adhesion-on state, the surface roughness decreases and the Si ink becomes embedded. In the adhesion-off state, the restored nanotips cause Si ink to form a tip contact, reducing adhesion and allowing for easy release. Using the same mechanism, we successfully demonstrated scalable transfer printing of ultrathin Si3N4 inks with nanoscale thickness. Specifically, Si3N4 inks with a thickness of 200 nm and a length of 4 μm were picked up and transferred without damage, even under applied preload, thanks to the low asperities of the nanotipped SMP surface. The nanoscale thickness of the inks highlights the delicate nature of the materials, requiring precise and gentle handling during transfer. The shape recovery of the nanotips further enabled accurate placement of these ultrathin inks onto a PDMS receiver substrate. These results demonstrate the versatility and effectiveness of the nanotipped SMP surface for managing ultrathin, nanoscale materials. Detailed experimental results can be found in Supplementary Fig. S16.

Figure 4j extends this transfer printing capability to 3D microobjects, demonstrating scalable transfer printing of SiO2 microspheres. Initially, a small area nanotipped SMP surface shown in Fig. 4c transfers individual SiO2 microspheres to form a smiley face pattern on the PDMS donor substrate (the nanotipped SMP surface is detailed in Supplementary Fig. S17). Subsequently, a large area nanotipped SMP surface picks up these microspheres in a single operation and successfully transfer prints them onto H-PDMS. Figure 4k shows SEM images of SiO2 microspheres illustrating the adhesion-on/off states. In the adhesion-on state, the microspheres are fully embedded and adhered, while in the adhesion-off state, the restored nanotips facilitate easy detachment. In addition, Supplementary Movie S6 provides a demonstration of simple, hand-operated transfer printing of a 300 μm × 300 μm Si array, confirming the straightforward applicability of switchable adhesion. These results demonstrate the capability of nanotipped SMP surfaces to perform mass transfer of both 2D and 3D microobjects, highlighting their practical application as micro-scale adhesives, particularly for the transfer printing process.

Practical use of nanotipped SMP surface at the macro-scale with dry adhesive based-soft gripper

To evaluate the practical application of the nanotipped SMP surface at the macro-scale, we integrated it with a six-axis robotic arm (Panda, Franka Emika Co., Germany) to function as a soft gripper. A mounting module was designed to attach the nanotipped SMP surface to the robotic arm, utilizing a thermoelectric Peltier device for rapid heating and cooling. Figure 5a shows the Peltier module mounted on the robotic arm for robotic manipulation. The nanotipped SMP surface is affixed to the Peltier module with silicone paste. For stable operation, the opposite side of the Peltier module is equipped with an aluminum fin acting as a heat sink and fans for cooling. The Peltier module is controlled by an H-bridge circuit with power MOSFETs to switch between heating and cooling quickly. The direction of current flow through the Peltier module, determined by MOSFET switches, dictates its heating and cooling states. Figure 5b illustrates the schematic of how heating and cooling occur in the Peltier module within the H-bridge circuit.

a A Peltier module, used to heat and cool the nanotipped SMP surface, is mounted on the end effector of the robotic arm. b An H-bridge circuit is employed to control the heating and cooling functions of the Peltier module. (i) Cooling mode. (ii) Heating mode. c The pick-and-place process using the robotic arm consists of: (i) picking up the object, (ii) placing the object at the desired location. d SEM images of the nanotipped SMP surface on the Peltier module demonstrate the adhesion switchability during the pick-and-place of a paper. e The manipulation of various objects using the robotic arm with the nanotipped SMP surface includes: (i) glass slide, (ii) stainless sheet, (iii) wood board, (iv) A4 paper, (v) glass vial, (vi) plastic spoon, (vii) egg, (viii) integrated circuit.

Utilizing the adhesion control of the nanotipped SMP surface through the Peltier module, we conducted pick-and-place operations with objects of various shapes and weights. Figure 5c demonstrates the process of using the nanotipped SMP surface-equipped soft gripper to pick and place a single sheet of A4 paper from a stack to a desired location. The SMP is heated above Tg using the Peltier module and then contacted with the A4 paper. To achieve strong adhesion, the Peltier module quickly cools the SMP below Tg by reversing the current direction. Despite the rough surface of the A4 paper, the nanotipped SMP surface adapts to it, allowing the paper to be picked up without disturbing the remaining sheets in the stack. The robotic arm then moves to the target location, where the SMP is reheated above Tg using the Peltier module, enabling the paper to be placed with minimal adhesion, facilitating easy release. The detailed pick-and-place of the A4 paper using the nanotipped SMP surface is shown in Supplementary Movie S7.

Traditional grippers often struggle to handle thin objects, but the soft gripper demonstrated in this experiment can manipulate lightweight and thin objects, such as paper, without disruption. Figure 5d presents SEM images of the nanotipped SMP surface in adhesion-on and -off states with A4 paper. When the SMP surface adapts to the paper’s surface in its R2G state, it achieves strong adhesion. Upon reheating and reversing to its original nanotipped form, the surface loses adhesion almost entirely, enabling easy release of the paper.

Figure 5e demonstrates the soft gripper picking up various objects using the adhesive properties of the nanotipped SMP surface. Figure 5e (i–iv) shows the gripper picking up flat objects, including a smooth glass slide, a stainless sheet, a wood board, and A4 paper, all with strong adhesion despite their surface roughness. The process of the nanotipped SMP surface transitioning from a non-adhesive rubbery state to a strong adhesive R2G state, and then being heated above Tg for easy or self-release of the wood board, is shown in Supplementary Movie S8. Figure 5e (v–viii) demonstrates the soft gripper’s ability to pick up curved objects of various materials, showing how the nanotipped SMP surface adapts to the curvature and achieves strong adhesion in the R2G state. The pick-and-place process for a glass vial, including self-release after pickup, is detailed in Supplementary Movie S9. The capabilities of the soft gripper equipped with the nanotipped SMP surface allow for the versatile pick-and-place of objects with various materials, surface roughness, and shapes. Notably, it excels in handling thin and lightweight objects without damage, addressing a common limitation of traditional grippers by relying solely on adhesion switching.

Practical use of nanotipped SMP surface at the micro-scale with transparent/flexible microLED display

To assess the applicability of the nanotipped SMP surface in microfabrication, a transparent and flexible microLED display was fabricated by transferring commercial microLED chips using the nanotipped SMP surface. Figure 6a provides a schematic illustration of the transfer printing setup. For this process, a 300 μm × 300 μm × 300 μm SMP surface with densely distributed nanotips was fabricated and attached on an ITO glass, which could be heated above the SMP’s Tg. A carrier tape serving as the donor substrate for the microLEDs, was fixed through a vacuum chuck below the nanotipped SMP surface on an ITO glass and manipulated using an xyz stage. The alignment between the nanotipped SMP surface and the microLEDs was performed under a microscope by moving the donor substrate in the xy directions, with the contact and release of the microLEDs achieved by moving in the z-direction.

a Setup for microLED transfer printing using the nanotipped SMP surface. b Process of picking up a microLED from carrier tape using the nanotipped SMP surface. c Process of placing the microLED onto a PDMS substrate using the nanotipped SMP surface. d F-d curve of microLED for various adhesives. e Inspection of the transfer printed microLED on the PDMS substrate. f Comparison of the I–V curves of the microLED between on donor state and on receiver state. g Optical images of a transparent and flexible microLED display, showcasing the letter P pattern.

Figures 6b, c show microscope images of the pickup and placement processes, respectively. During pickup, the heated nanotipped SMP surface was aligned with a single microLED chip, brought into contact, and then cooled below Tg before being gently lifted to detach the microLED from the carrier tape. For placement, the SMP surface with the attached microLED was aligned with the PDMS receiver substrate, heated above Tg, and the nanotips were restored, enabling easy release of the microLED.

Figure 6d presents force-displacement (F-d) curves showing the adhesion of a single microLED chip against relevant adhesives including PDMS, carrier tape, nanotipped SMP surfaces in the R2G state and in the rubbery state (the detailed adhesion test procedure is outlined in Supplementary Fig. S18 and Supplementary Movie S10). The results indicate that the rubbery state nanotipped SMP surface exhibits almost no adhesion on the microLED, while the R2G state nanotipped SMP surface has the strongest adhesion. In contrast to the viscoelastic properties of carrier tape, the R2G state nanotipped SMP surface, although showing a smaller work of adhesion based on the area under the F-d curve, demonstrates much stronger adhesion, effectively removing the microLED from the carrier tape. In its rubbery state, the SMP surface exhibits viscoelastic properties, but due to the reduced adhesion of the nanotips, almost no work of adhesion occurs, allowing for the easy release of microLEDs onto the PDMS substrate.

Figure 6e shows functional testing of the microLED after transfer printing onto a PDMS substrate, with a source/measurement unit connected to a probe station. Figure 6f compares the IV curves of the microLED on both the donor and receiver substrates, demonstrating no significant performance difference after transfer printing. Finally, as shown in Fig. 6g, microLEDs are successfully transferred in the shape of the letter P onto the PDMS substrate via the nanotipped SMP surface and metal interconnections were formed to create a transparent and flexible microLED display (Detailed fabrication process provided in Supplementary Fig. S19, and the flexibility of the microLED display fabricated using this method is detailed in Supplementary Fig. S20).

In summary, the nanotipped SMP surface exhibits extreme adhesion switchability through the manipulation of surface roughness at both macro- and micro-scales, facilitated by the shape fixing and shape recovery effects of SMP. The SMP surface, densely populated with nanotips, is fabricated using KOH wet etching and soft lithography, resulting in surface roughness ranging from nano to sub-micron scales. The adhesion characteristic with respect to surface roughness was analyzed numerically and experimentally. It was found that the nanotipped SMP surface with an Rq value exceeding 200 nm shows negligible adhesion in the rubbery state, while achieving over a 1000-fold increase in adhesion in the R2G state. Based on this analysis, the nanotipped SMP surface demonstrates strong adhesion on macro-scale surfaces, such as fabric, which are challenging for conventional dry adhesives. In the R2G state, it provides strong adhesion, while in the rubbery state, it can be removed without damage. To demonstrate its practical application, the nanotipped SMP surface was integrated into a soft gripper for pick-and-place operations of various macro-scale objects. This application showed that the nanotipped SMP surface could easily handle thin and lightweight objects without damage, overcoming the limitations of traditional grippers. At the micro-scale, the nanotipped SMP surface enabled individual as well as scalable transfer printing of 5 μm diameter Si platelets, demonstrating controllable adhesion even at the micro-scale through the deformation and restoration of nanotips. In addition, it facilitated the transfer printing of not only simple 2D microobjects like Si ink but also complex 3D microobjects, enhancing the yield and scalability of transfer printing technologies. These properties of the nanotipped SMP surface were further applied to practical micro-scale applications, such as transfer printing microLEDs onto flexible substrates, contributing to the development of flexible displays. These results indicate that the nanotipped SMP surface offers a switchable adhesive solution, providing an essential contribution to pick-and-place and transfer printing technologies regardless of the scale involved.

Methods

SMP materials

The epoxy-based SMP used in this study was created by mixing EPON 826 (a diglycidyl ether of bisphenol A epoxy monomer; Sigma-Aldrich, USA), E1075 (poly(bisphenol A-co-epichlorohydrin); Sigma-Aldrich, USA), and Jeffamine D230 (poly(propylene glycol)bis(2-aminopropyl); Sigma-Aldrich, USA) in a weight ratio of 1:0.94:0.83747. To get rid of any crystals, EPON 826 was first pre-treated by heating it to 120 °C for 10 min. After that, E1075 and EPON 826 were mixed together and heated for 30 min to 120 °C in a glass vial. Subsequently, Jeffamine D230, at room temperature, was added to the epoxy mixture. The resulting mixture (SMP precursor) was poured on a polydimethylsiloxane (PDMS; Sylgard 184, Dow Corning Corp., USA) or a hard-polydimethylsiloxane (H-PDMS 1180c; Dowchem, Korea) negative mold placed on a hot plate and degassed for 2 min. Finally, the SMP precursor was cured at 120 °C for 1 h.

Fabrication of nanotipped SMP surfaces

To fabricate the master mold for the nanotipped SMP surface, bare Si (100) was subjected to KOH (potassium hydroxide, 95 % purity; DaemyungChem, Korea) wet etching. The KOH wet solution consisted of KOH pellets, DI water, and IPA, with IPA comprising 20 % of the total volume. The KOH pellets were added based on a weight percent relative to the total solution weight. To achieve surfaces with the Rq value of 200 nm or higher, the solution was prepared with 1 % KOH by weight and 20 % IPA by volume, and etching was conducted at 70 °C for 20 min. The etched Si surface was then coated with silane (Trichloro(1H,1H,2H,2H-perfluorooctyl)silane, 97% purity; Sigma-Aldrich, USA) to facilitate easy release from H-PDMS. Following this, H-PDMS precursor was poured over the Si surface, degassed, and cured at 120 °C for 20 min. The SMP precursor was then poured into the H-PDMS negative mold and cured at 150 °C for 10 min. Upon demolding from the negative mold, the nanotipped SMP surface was completed.

Adhesion tests

The adhesion tests for the nanotipped SMP surface were conducted separately for the rubbery state and the R2G state. The adhesion test setup consists of a glass hemisphere probe equipped with a load cell (GS0-25; Transducer Techniques, USA), which can move vertically via a mechanical stage (VT-80 Linear Stage; Physik Instrumente, Germany). The nanotipped SMP surface is attached to an ITO-deposited glass slide (Omniscience, Korea). To measure adhesion in the rubbery state, the nanotipped SMP surface is first heated above its Tg. The probe is then brought into contact with the surface at a specified preload and allowed to dwell for 10 s before being retracted at a controlled speed. For the R2G state adhesion measurement, the process begins similarly with the surface being heated above Tg and contacted with the probe at a specified preload. However, the heating is then stopped by cutting off the current to the ITO, allowing the surface to cool below Tg through natural convection before retracting the probe. After each test, the probe was cleaned with a lens-cleaning tissue to ensure the accuracy of subsequent measurements.

H-bridge circuit control

The H-bridge circuit comprises four power MOSFET switches (IRF3205S; Infineon, Germany), each controlled by an individual H-bridge driver (IR2104; Infineon, Germany) to prevent H-bridge short circuits. An Arduino UNO board was utilized as the controller for the H-bridge circuit. Each switch turns ON when a 5 V voltage is applied and turns off when the voltage is removed. A Peltier element (TEC1-12706; HB Electronic Components, China) is connected to the H-bridge circuit. By turning on the MOSFET switches to allow current to flow in the forward direction through the Peltier element, the nanotipped SMP surface is cooled. Conversely, by enabling current to flow in the reverse direction, the SMP surface is heated.

Fabrication of Si ink array

Si ink array was created using silicon-on-insulator (SOI) wafers (KST World Corp., Japan), as shown in Supplementary Fig. S13. After patterning a photoresist layer (AZ GXR 601; Az Electronic Materials Korea Ltd., Korea) and deep reactive ion etching (Multiplex Lite ASE-SR; STS, UK) of the exposed Si layer, the form of the Si inks was determined. Wet etching with HF (hydrofluoric acid, 49 % concentration; Sigma-Aldrich, USA) was employed to remove the buried oxide layer (SiO2) and form an undercut trench beneath the borders of the patterned Si inks. After that, photoresist was once more applied to the wafers, and photoresist anchors were patterned on the Si inks. Following a further HF etching process, the Si inks were ready for retrieval since they were suspended with photoresist anchors to the Si wafer underneath.

Fabrication process of transparent/flexible microLED display

MicroLED chips (LA HB11HP1; Light Avenue, USA) are transferred from carrier tape onto a PDMS substrate in a letter P patterned tranches using the nanotipped SMP surface. After transfer printing, the microLEDs in the PDMS trenches are planarized by spin-coating a thin layer of PDMS precursor, which is then cured in an oven at 65 °C for 3 h. To expose the microLEDs’ top surface for electrode formation, a pressure sensitive adhesive (scotch magic tape; 3 M, USA) is applied to the PDMS surface, selectively removing the PDMS layer covering the microLEDs and revealing the P and N poles. Ni/Au electrodes are subsequently formed on the exposed microLED array through sputtering (Q300D; Quorum Technologies, UK), followed by patterning a positive photoresist (AZ P4620; AZ Electronic Materials Korea Ltd., Korea) on top of the metal layer. After sequential etching of the Au and Ni layers, the photoresist is removed with acetone, resulting in the proper formation of metal electrodes on the microLED array. The functional testing of the fabricated microLED display was conducted with a source/measurement unit (B2902B; Keysight, USA) connected to a probe station (APX-6B; WIT, Korea).

Data availability

All data used and generated in this study are available in the article and Supplementary Information. All data related to this study are available from the corresponding author upon request.

References

Murphy, M. P., Kim, S. & Sitti, M. Enhanced adhesion by gecko-inspired hierarchical fibrillar adhesives. ACS Appl. Mater. Interfaces 1, 849–855 (2009).

Mengüç, Y., Yang, S. Y., Kim, S., Rogers, J. A. & Sitti, M. Gecko-inspired controllable adhesive structures applied to micromanipulation. Adv. Funct. Mater. 22, 1246–1254 (2012).

Kim, J.-K. et al. Enhanced flexible mold lifetime for roll-to-roll scaled-up manufacturing of adhesive complex microstructures. Adv. Mater. 35, 2207257 (2023).

Baik, S. et al. A wet-tolerant adhesive patch inspired by protuberances in suction cups of octopi. Nature 546, 396–400 (2017).

Lee, J. et al. Artificial Octopus-Limb-Like adhesive patches for cupping-driven transdermal delivery with nanoscale control of stratum corneum. ACS Nano 18, 5311–5321 (2024).

Park, J. K., Yang, Z. & Kim, S. Black silicon/elastomer composite surface with switchable wettability and adhesion between lotus and rose petal effects by mechanical strain. ACS Appl. Mater. Interfaces 9, 33333–33340 (2017).

Ghasemlou, M. et al. Robust and eco-friendly superhydrophobic starch nanohybrid materials with engineered lotus leaf mimetic multiscale hierarchical structures. ACS Appl. Mater. Interfaces 13, 36558–36573 (2021).

Wu, H. et al. Transfer printing of metallic microstructures on adhesion-promoting hydrogel substrates. Adv. Mater. 27, 3398–3404 (2015).

Shi, Y., Ilic, O., Atwater, H. A. & Greer, J. R. All-day fresh water harvesting by microstructured hydrogel membranes. Nat. Commun. 12, 2797 (2021).

Loebel, C. et al. Microstructured hydrogels to guide self-assembly and function of lung alveolospheres. Adv. Mater. 34, 2202992 (2022).

Cheng, Z. et al. Superwetting shape memory microstructure: Smart wetting control and practical application. Adv. Mater. 33, 2001718 (2021).

Yang, G. et al. Thermal-triggered “On–Off” switchable triboelectric nanogenerator based on two-way shape memory polymer. Adv. Funct. Mater. 33, 2214001 (2023).

Kim, J., Son, C., Lee, S. & Kim, S. A single microtip shape memory polymer surface with reversible dry adhesion for transfer printing. Adv. Mater. Technol. 9, 2301468 (2024).

Tan, Y. L. et al. Adhesion evolution: Designing smart polymeric adhesive systems with on-demand reversible switchability. ACS Nano 18, 24682–24704 (2024).

Croll, A. B., Hosseini, N. & Bartlett, M. D. Switchable adhesives for multifunctional interfaces. Adv. Mater. Technol. 4, 1900193 (2019).

Zhang, S. et al. Hydrogel-enabled transfer-printing of conducting polymer films for soft organic bioelectronics. Adv. Funct. Mater. 30, 1906016 (2020).

Kim, S., Liu, N. & Shestopalov, A. A. Contact printing of multilayered thin films with shape memory polymers. ACS Nano 16, 6134–6144 (2022).

Roh, Y. et al. Vital signal sensing and manipulation of a microscale organ with a multifunctional soft gripper. Sci. Robot. 6, eabi6774 (2021).

Son, C., Jeong, S., Lee, S., Ferreira, P. M. & Kim, S. Tunable adhesion of shape memory polymer dry adhesive soft robotic gripper via stiffness control. Robotics 12, 59 (2023).

Jung, H., Kim, M. K., Lee, J. Y., Choi, S. W. & Kim, J. Adhesive hydrogel patch with enhanced strength and adhesiveness to skin for transdermal drug delivery. Adv. Funct. Mater. 30, 2004407 (2020).

Saeidpourazar, R. et al. Laser-driven micro transfer placement of prefabricated microstructures. J. Microelectromechanical Syst. 21, 1049–1058 (2012).

Chen, F. et al. Laser-driven hierarchical “gas-needles” for programmable and high-precision proximity transfer printing of microchips. Sci. Adv. 9, eadk0244 (2023).

Li, C., Luo, H., Lin, X., Zhang, S. & Song, J. Laser-driven noncontact bubble transfer printing via a hydrogel composite stamp. Proc. Natl. Acad. Sci. USA 121, e2318739121 (2024).

Li, C. et al. Laser-induced adhesives with excellent adhesion enhancement and reduction capabilities for transfer printing of microchips. Sci. Adv. 10, eads9226 (2024).

Luo, H., Li, C., Wang, S., Zhang, S. & Song, J. Switchable adhesive based on shape memory polymer with micropillars of different heights for laser-driven noncontact transfer printing. ACS Appl. Mater. Interfaces 16, 9443–9452 (2024).

Wang, C. et al. Programmable and scalable transfer printing with high reliability and efficiency for flexible inorganic electronics. Sci. Adv. 6, eabb2393 (2020).

Eisenhaure, J. D. et al. The use of shape memory polymers for MEMS assembly. J. Microelectromechanical Syst. 25, 69–77 (2016).

Eisenhaure, J. D., Xie, T., Varghese, S. & Kim, S. Microstructured shape memory polymer surfaces with reversible dry adhesion. ACS Appl. Mater. Interfaces 5, 7714–7717 (2013).

Kim, S. et al. Microstructured elastomeric surfaces with reversible adhesion and examples of their use in deterministic assembly by transfer printing. Proc. Nat.l Acad. Sci. USA 107, 17095–17100 (2010).

Xie, T. Tunable polymer multi-shape memory effect. Nature 464, 267–270 (2010).

Michal, B. T., Spencer, E. J. & Rowan, S. J. Stimuli-responsive reversible two-level adhesion from a structurally dynamic shape-memory polymer. ACS Appl. Mater. Interfaces 8, 11041–11049 (2016).

Son, C. & Kim, S. Dual adaptation of a flexible shape memory polymer adhesive. ACS Appl. Mater. Interfaces 13, 27656–27662 (2021).

Park, J. K., Eisenhaure, J. D. & Kim, S. Reversible underwater dry adhesion of a shape memory polymer. Adv. Mater. Interfaces 6, 1801542 (2019).

Linghu, C. et al. Overcoming the adhesion paradox and switchability conflict on rough surfaces with shape-memory polymers. Proc. Natl. Acad. Sci. USA 120, e2221049120 (2023).

Lee, S. H., Song, H. W., Park, H. J. & Kwak, M. K. Surface adaptable and adhesion controllable dry adhesive with shape memory polymer. Macromol. Rapid Commun. 43, 2200012 (2022).

Linghu, C. et al. Universal SMP gripper with massive and selective capabilities for multiscaled, arbitrarily shaped objects. Sci. Adv. 6, eaay5120 (2020).

Fan, F., Chen, L., Zhou, Y. & Duan, H. Multiscale transfer printing via shape memory polymer with high adhesion and modulus switchability. ACS Appl. Mater. Interfaces 16, 26824–26832 (2024).

Bartlett, M. D. et al. Looking beyond fibrillar features to scale Gecko-like adhesion. Adv. Mater. 24, 1078–1083 (2012).

Seo, J., Eisenhaure, J. & Kim, S. Micro-wedge array surface of a shape memory polymer as a reversible dry adhesive. Extrem. Mech. Lett. 9, 207–214 (2016).

Kim, S. et al. Modulation of interfacial adhesion using semicrystalline shape-memory polymers. Langmuir 38, 3607–3616 (2022).

Tiwari, A., Wang, J. & Persson, B. N. J. Adhesion paradox: Why adhesion is usually not observed for macroscopic solids. Phys. Rev. E 102, 042803 (2020).

Rabinovich, Y. I., Adler, J. J., Ata, A., Singh, R. K. & Moudgil, B. M. Adhesion between nanoscale rough surfaces: II. Measurement and comparison with theory. J. Colloid Interface Sci. 232, 17–24 (2000).

Ramakrishna, S. N., Clasohm, L. Y., Rao, A. & Spencer, N. D. Controlling adhesion force by means of nanoscale surface roughness. Langmuir 27, 9972–9978 (2011).

Lee, D. et al. Fluidic self-assembly for MicroLED displays by controlled viscosity. Nature 619, 755–760 (2023).

Park, S. H. et al. Universal selective transfer printing via micro-vacuum force. Nat. Commun. 14, 7744 (2023).

Wlanis, T. et al. Cu-SiO2 hybrid bonding simulation including surface roughness and viscoplastic material modeling: A critical comparison of 2D and 3D modeling approach. Microelectron. Reliab. 86, 1–9 (2018).

Eisenhaure, J. & Kim, S. High-strain shape memory polymers as practical dry adhesives. Int. J. Adhes. Adhes. 81, 74–78 (2018).

Bae, W.-G., Kim, D. & Suh, K.-Y. Instantly switchable adhesion of bridged fibrillar adhesive via gecko-inspired detachment mechanism and its application to a transportation system. Nanoscale 5, 11876–11884 (2013).

Song, S. & Sitti, M. Soft grippers using micro-fibrillar adhesives for transfer printing. Adv. Mater. 26, 4901–4906 (2014).

Purtov, J., Frensemeier, M. & Kroner, E. Switchable adhesion in vacuum using bio-inspired dry adhesives. ACS Appl. Mater. Interfaces 7, 24127–24135 (2015).

Tao, D. et al. Controllable anisotropic dry adhesion in vacuum: Gecko inspired wedged surface fabricated with ultraprecision diamond cutting. Adv. Funct. Mater. 27, 1606576 (2017).

Jin, K. et al. Biomimetic bidirectional switchable adhesive inspired by the gecko. Adv. Funct. Mater. 24, 574–579 (2014).

Shahsavan, H., Salili, S. M., Jákli, A. & Zhao, B. Thermally active liquid crystal network gripper mimicking the self-peeling of Gecko Toe Pads. Adv. Mater. 29, 1604021 (2017).

Wang, Y. et al. Switchable dry adhesion with step-like micropillars and controllable interfacial contact. ACS Appl. Mater. Interfaces 8, 10029–10037 (2016).

Zhou, M. et al. Controllable interfacial adhesion applied to transfer light and fragile objects by using Gecko Inspired mushroom-shaped pillar surface. ACS Appl. Mater. Interfaces 5, 10137–10144 (2013).

Kizilkan, E., Strueben, J., Staubitz, A. & Gorb, S. N. Bioinspired photocontrollable microstructured transport device. Sci. Robot. 2, eaak9454 (2017).

Lee, H. et al. Octopus-inspired smart adhesive pads for transfer printing of semiconducting nanomembranes. Adv. Mater. 28, 7457–7465 (2016).

Kim, S. et al. Enhanced adhesion with pedestal-shaped elastomeric stamps for transfer printing. Appl. Phys. Lett. 100, 171909 (2012).

Yang, S. Y. et al. Elastomer surfaces with directionally dependent adhesion strength and their use in transfer printing with continuous roll-to-roll applications. Adv. Mater. 24, 2117–2122 (2012).

Carlson, A. et al. Active, programmable elastomeric surfaces with tunable adhesion for deterministic assembly by transfer printing. Adv. Funct. Mater. 22, 4476–4484 (2012).

Carlson, A. et al. Shear-enhanced adhesiveless transfer printing for use in deterministic materials assembly. Appl. Phys. Lett. 98, 264104 (2011).

Eisenhaure, J. D. et al. The use of shape memory polymers for microassembly by transferprinting. J. Microelectromechanical Syst. 23, 1012–1014 (2014).

Luo, H., Wang, S., Wang, C., Linghu, C. & Song, J. Thermal controlled tunable adhesive for deterministic assembly by transfer printing. Adv. Funct. Mater. 31, 2010297 (2021).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (2022R1A2C3006420).

Author information

Authors and Affiliations

Contributions

J.K. (Junhyung Kim) and S.K. (Seok Kim) conceived the idea. J.K. (Junhyung Kim), S.K. (Seungbeom Kim), J.K. (Jeong Hyeon Kim), C.S. and Y.L. conducted experimental studies. N.K. and T.Y. performed the theoretical and computational analysis. J.K. (Junhyung Kim) wrote the manuscript. All authors read and revised the manuscript. S.K. (Seok Kim), N.K., H.L., and K.K. supervised the work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kim, J., Kim, S., Yun, T. et al. Shape memory polymer surfaces with controllable roughness for multiscale switchable dry adhesion. Nat Commun 16, 4954 (2025). https://doi.org/10.1038/s41467-025-60220-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-60220-7

This article is cited by

-

Gradient-graphene-enabled directional photothermal regulation for self-aligned laser transfer printing

Light: Science & Applications (2026)

-

Composition-Engineered Shape Memory Polymer Stamps for Robust Micro-Transfer Printing of µLEDs

Electronic Materials Letters (2026)

-

Recent advances in transfer printing of inorganic thin films for flexible hybrid systems

Micro and Nano Systems Letters (2025)