Abstract

Renewable electricity driven CO2 electroreduction into methane offers a sustainable route to mitigate our dependence on natural gas. However, this route is now limited by the unsatisfied efficiency and short durability, which originates from a kinetic disparity between water dissociation (WD) and proton-coupled electron transfer on existing catalysts. Herein, we harness the exceptional WD capability of the intermetallic electride (IE) materials for the electrocatalytic methanization from CO2. Combinative experimental and theoretical approaches strongly evidence a spontaneous WD on an IE LaCu0.67Si1.33 catalyst due to its unique electronic structure (strongly modified charge states, reversible lattice hydride ions and anionic electrons). Consequently, this catalyst exhibits improved methanization performance in alkaline flow cells, achieving a methane Faraday efficiency of 72% at −1.21 V versus the reversible hydrogen electrode (vs. RHE) and peak partial current density of 476.7 mA cm−2 at −1.52 V vs. RHE. Energetic calculations further establish the mechanistic link between WD and methanization processes on our catalyst, on which a lowered free energy barrier for the key *CO to *CHO transformation step is observed. This work sheds light on the pivotal role of WD and expands the repertoire of materials for efficient electrocatalytic methanization from CO2.

Similar content being viewed by others

Introduction

The renewable-electricity-powered electrochemical CO2 reduction (CO2RR) to methane is an appealing pathway to regenerate natural gas from carbon emissions1,2,3. Aiming to industrializing this pathway, vast efforts have been devoted to designing more efficient Cu-based catalysts with improved activity, selectivity, and stability4,5,6,7. Such catalyst design was mainly guided by the classic descriptor-based approach, in which the outcome of a catalyst is depicted by its binding strengthens to carbonaceous intermediates. For CO2RR, the binding energy of adsorbed carbon monoxide (COad) serves as a common and simple descriptor due to the universal scaling relation among all carbonaceous species8,9. Nevertheless, recent findings unravel other factors, in addition to carbonaceous adsorption, also depict the electrochemical methanization from CO210,11,12,13,14. In particular, promoting WD on a catalyst enhances the methanization because (1) CO2RR necessitates molecular water as hydrogen source15, (2) methane is a deeply hydrogenated product and involves the transfer of eight electrons and six hydrogens16, (3) The hydrogenation of COad to CHxOad (x = 1, 2, 3) is widely recognized as the rate-determining step along the methanization pathway17,18.

Established knowledge from the alkaline water electrocatalysis indicates the hydroxyl-favoring materials, e.g., metal hydroxide or oxides, could promote the rate of WD in alkaline/neutral environments19,20. Levering this knowledge, previous studies have designed electrocatalytic interfaces between CO2-active Cu-based components and hydroxyl-favoring components for CO2RR. Indeed, a positive link between the electrosynthesis of methane and WD was found and rationalized21. Though the effectiveness of these heterojunction approaches for methanization, the intrinsically multiphase catalysts encountered challenge of structural stability and thus performance sustainability during CO2RR22,23,24,25. In particular, metal hydroxides or oxides are apt to be reduced under negative bias and the co-presence of H2 (byproduct from CO2RR). This then desires a single-phase metallic alternative to the aforementioned multiphase catalysts for synchronizing WD and CO2 activation. Recently, on an emerging class of IE materials, we observed spontaneous WD when studying water-induced structural evolution26,27. Distinct from conventional alloys, IEs consist of transition metals with strongly modified charge states, reversible lattice hydride ions and anionic electrons, which facilitate the dissociation of small molecules, including H2O27, N228 and CO229 et al. This inspired us to design IE-based catalysts with balanced WD and CO2 activation.

In this work, we applied IE-based nanomaterials for CO2RR and reported a class of IE LaCu0.67Si1.33 catalyst for the electrochemical methanization. After verifying the structural features of IE using various characterizations, we systematically probed the WD behaviors of this IE catalyst using H2O-temperature-programmed surface reaction and energetic calculations, which confirmed a spontaneous WD on this IE surface. When tested in an alkaline flow cell, the IE LaCu0.67Si1.33 catalyst showed a methane Faradaic efficiency (FE) of 72% at a reduction potential of −1.21 V vs. RHE, along with a partial current density of 476.7 mA cm−2 at −1.52 V vs. RHE. In situ Fourier transform infrared spectroscopy observed that, compared to the Cu control, the IE LaCu0.67Si1.33 catalyst showed a strengthened atop-adsorbed CO and a lowered ratio of free and weakly hydrogen-bonded water. DFT calculations further showed the methanization pathway to be energetically more favorable on the IE LaCu0.67Si1.33 catalyst.

Results

Synthesis and characterizations of IE LaCu0.67Si1.33

We synthesized IE LaCu0.67Si1.33 catalysts using a sequential methodology that encompasses electric arc-melting followed by high-energy ball milling, which yields nanoparticles in size of hundreds of nanometers (Supplementary Figs. 1, 2). The X-ray diffraction (XRD) patterns of as-synthesized materials exhibit an alignment of diffraction peaks with the standard card of ICSD#103038 (Fig. 1a), signifying our successful synthesis of IE LaCu0.67Si1.33 with a hexagonal phase (adhering to the AlB2 structure, p6/mmm space group)30,31. Lattice fringes can be clearly visualized from the high-resolution transmission electron microscopy (HRTEM) image of IE LaCu0.67Si1.33, affirming its crystallinity nature (Fig. 1b). A selected-area electron diffraction pattern (inset) confirms the presence of the respective (101), (201), (2–10) plane of IE LaCu0.67Si1.33, which aligns perfectly with the XRD results. High angle annular dark field-scanning transmission electron microscopy (HAADF-STEM, Fig. 1c) image further provides intricate details on the atomic arrangement, while the accompanying energy-dispersive X-ray spectroscopy (EDX) elemental mappings illustrate the uniform distribution of La, Cu, and Si throughout the entire crystal domain (Fig. 1d and Supplementary Fig. 3).

a XRD patterns. b HRTEM image and the corresponding FFT patterns (inset) and c High-resolution HAADF-STEM image. d The corresponding EDS elemental mapping for La, Cu, and Si. e Unit cell structure of IE LaCu0.67Si1.33 (top and side views) along with the results of Bader charge analysis. f High-resolution Cu 2p XPS profiles of IE LaCu0.67Si1.33 and Cu samples. g XANES and h EXAFS spectra of Cu K-edge for Cu2O, CuO, Cu foil and IE LaCu0.67Si1.33. Source data are provided as a Source Data file.

The unit cell of IE LaCu0.67Si1.33 was meticulously constructed using density functional theory (DFT) calculations, synergistically enhanced by self-built machine learning-accelerated structural predictions27,32. This analysis reveals that La atomic layers are sandwiched between two-dimensional honeycomb planes formed by Cu and Si atoms, with an interlaminar distance of approximately 2.15 Å (Fig. 1e). Prior studies have postulated the presence of anionic electrons nestled within the interstitial spaces between the Cu/Si and La layers, thus lending credence to its nomination as ‘electride’33. Further corroborating this, Bader charge analysis of as-constructed IE LaCu0.67Si1.33 model underscores that Cu and Si atoms act as electron acceptors from La atoms, as evidenced by their respective charge states (Fig. 1e, La: 1.14 |e | ; Cu: −0.77 |e | ; Si: −0.47 |e | ). To gain deeper insights, we experimentally delved into the electronic structure of the synthesized IE LaCu0.67Si1.33 material.

The Cu LMM spectrum confirms Cu maintains its metallic state in the IE LaCu0.67Si1.33 sample (Supplementary Fig. 4). The high-resolution Cu 2p XPS spectra reveal a negative shift in the binding energy of IE LaCu0.67Si1.33 by approximately 0.14 eV compared to pure Cu nanoparticles, suggesting an enhanced electron density in the former (Fig. 1f). This observation is further reinforced by the Cu K-edge spectra of X-ray absorption near-edge structure (XANES) analysis, which displays a lower absorption threshold position and reduced intensity of the white-line peak for IE LaCu0.67Si1.33 material compared to Cu foil (Fig. 1g)34,35,36. The Fourier-transformed k2-weighted extended X-ray absorption fine-structure (EXAFS) spectrum displayed a weak peak around 2.2 Å (Fig. 1h). Combined with the EXAFS spectrum fitting results, the average Cu-Cu coordination number (CN) in IE LaCu0.67Si1.33 is 1.53, significantly lower than that of Cu foil (Supplementary Fig. 5 and Table S1). Having established the characteristic electride properties of IE LaCu0.67Si1.33, we move on to explore its behaviors towards WD.

WD on IE LaCu0.67Si1.33

First, we used DFT calculations to project energetics of WD on the constructed IE LaCu0.67Si1.33 model (Supplementary Fig. 6). Strikingly, our findings indicate a substantially lower stepwise barrier for the dissociation of *H2O into *H + *OH on the (101) surface of IE LaCu0.67Si1.33, which is the most exposed surface, at 0.33 eV, compared to the Cu(111) surface, which exhibits a barrier of 1.19 eV. Furthermore, this dissociation pathway was found to be more exergonic on the IE LaCu0.67Si1.33(101) surface (−1.33 eV), relative to the Cu(111) control (0.29 eV). These theoretical insights, from both thermodynamic and kinetic perspectives, strongly suggest that WD is preferentially facilitated on the surface of IE LaCu0.67Si1.33, even with the inclusion of solvation energies. (Fig. 2a and Supplementary Fig. 7).

To support the above calculations, H2O-temperature-programmed surface reaction (TPSR) tests were further carried out to track WD on various catalysts. Notably, on IE LaCu0.67Si1.33 sample, we first observed a desorption peak at around 84 °C (m/z = 18), which can be ascribed to the release of physically adsorbed H2O molecules (m/z = 18, Fig. 2b). Subsequently, we observed peaks corresponding to the desorption of H2 (m/z = 2) at about 340 and 540 °C. Given that water is the sole source for the adsorbed hydrogen in our test, the above observations indicate that, on the IE LaCu0.67Si1.33 surface, WD occurred below 84 °C at which temperature the molecular H2O desorbs from the surface. We also conducted TPSR tests on other control catalysts, including commercial Cu nanoparticles, home-made La3Cu2 and CuSi2 nanoparticles, and found both have a H2O desorption temperature close to 80 °C (Fig. 2b, Supplementary Figs. 8−10). Strikingly, we did not observe any peaks corresponding to H2 desorption on these materials within the 25–600 °C range tested, aligning with typical TPSR outcomes for conventional Cu-based alloys37. In addition, a prominent inelastic scattering background was observed on IE LaCu0.67Si1.33 in the neutron diffraction pattern based on elastic scattering, which is closely related to the presence of hydrogen-containing structure after dehydration treatment (Supplementary. 11). In short, combined results from TPSR tests, neutron diffraction pattern and energetic calculations enable us to conclude an exceptional WD capability of the IE LaCu0.67Si1.33 catalyst, potentially stemming from its distinctive electronic structure inherent to IE materials.

CO2RR performances

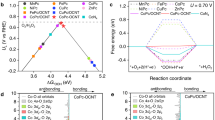

The electrolysis of CO2 on the IE LaCu0.67Si1.33 catalyst was carried out in a flow cell using 1 M KOH as the electrolyte. To benchmark the performance, commercial Cu nanoparticles (Supplementary Figs. 12, 13) were adopted, exhibiting comparable electrocatalytic activity and product distribution to previous reports, thereby validating our evaluating system38. Notably, the IE LaCu0.67Si1.33 catalyst distinguished itself from the commercial Cu nanoparticles by predominantly producing methane across all investigated current densities, ranging from 100 to 900 mA cm−2. Specifically, it reached a peak Faraday efficiency (FE) of 72% at −1.21 V vs. RHE, corresponding to a partial current density (jCH4) of 429.7 mA cm−2 (Fig. 3a). Furthermore, a high jCH4 of 476.7 mA cm−2 was achieved at −1.52 V vs. RHE (Fig. 3b), highlighting the exceptional performance of the IE LaCu0.67Si1.33 catalyst. We also noticed the IE LaCu0.67Si1.33 catalyst efficiently suppressed the generation of other liquid and gaseous products (Supplementary Fig. 14). Within the whole potential region, the total FE of C1 product on the IE LaCu0.67Si1.33 catalyst is higher than that on commercial Cu nanoparticles, which can be ascribed to a lower paired-Cu-site proportion on the former surface for C − C coupling, as evidenced by the fitting results from XAS analysis (Fig. 3c).

a The faradaic efficiencies (FE) for various products of IE LaCu0.67Si1.33 and corresponding cathode potentials (E – iR vs RHE; R = 3.49 ± 0.04) at different applied current densities, the error bars of FEs are calculated based on three independent measurements. b FE and partial current densities for CH4 of IE LaCu0.67Si1.33 and Cu as a function of cathodic currents. The error bars of FECH4 and jCH4 are calculated based on three independent measurements. c Comparison of the FE for various C1 products of IE LaCu0.67Si1.33 and Cu at different applied current densities. d CH4 FE of IE LaCu0.67Si1.33 and IC LaCu0.67Si1.33 at various current density. e Performance comparison regarding selectivity and productivity of CH4 on the IE LaCu0.67Si1.33 catalyst and prior reports in flow cells. f A continuous 10-h CO2 electrolysis using IE LaCu0.67Si1.33 catalyst under −100 mA cm−2. The CO2 flow rate was 20 sccm. 1 M KOH was used as the electrolyte. Source data are provided as a Source Data file. 13,45,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77.

To further inspect the correlation between the IE characteristic and CH4 selectivity, we crafted a LaCu0.67Si1.33 control sample, which exhibited relatively inferior crystallinity (denoted as IC LaCu0.67Si1.33) than the IE LaCu0.67Si1.33 sample. This was experimentally achieved by reducing the cycles of electric arc-melting while maintaining the same feeding ratio of La, Cu, and Si elements. In the XRD pattern of IC LaCu0.67Si1.33, the diffraction peaks observed were consistent with of the main diffraction peaks of IE LaCu0.67Si1.33, but some stray peaks were also observed (Supplementary Fig. 15). Less obvious lattice fringes, compared to the IE LaCu0.67Si1.33 catalyst, were observed in the TEM selected area of IC LaCu0.67Si1.33, corroborating the latter’s low crystallinity. EDX elemental mappings indicate that La, Cu, and Si are evenly distributed throughout the entire surveyed area (Supplementary Fig. 16). Next, H2O-TPSR analysis was performed on the IC LaCu0.67Si1.33 sample to probe its response to WD. The IC LaCu0.67Si1.33 sample exhibited a water desorption peak (m/z = 18) at 75 °C and two H2 desorption peak (m/z = 2) at 266 and 384 °C. Comparative integration of the H2 desorption peaks between the two samples revealed a 1.56-fold increase in peak area for IE LaCu0.67Si1.33, underscoring the pivotal role of the unique IE feature in enhancing WD on the IE LaCu0.67Si1.33 catalyst (Supplementary Fig. 17). It is worth noting that both the IC LaCu0.67Si1.33 and IE LaCu0.67Si1.33 samples were obtained by ball milling and exhibited comparable specific surface areas, thereby negating the influence of surface area effects (Supplementary Fig. 18 and Table S2). Notably, there are marked discrepancies in atomic configurations of active sites between IC and IE LaCu0.67Si1.33 surfaces. The disordered atomic arrangement in the IC model likely disrupts the anionic electron characteristics inherent in the crystalline lattice. This structural distortion results in diminished electron transfer capacity to adsorbed *CO species, as evidenced by the reduced electron transfer (1.23 |e | ) compared to the IE surface (1.70 |e | ). Consequently, the IC surface exhibits significantly weaker CO adsorption strength, with an adsorption energy of −1.49 eV versus −2.27 eV for the IE surface, highlighting the critical relationship between the IE characteristics and catalytic performance (Supplementary Fig. 19). Applying the IC LaCu0.67Si1.33 catalyst for CO2 electrolysis, we found a lower FE of methane than IE LaCu0.67Si1.33 across the whole investigated current densities (Fig. 3d and Supplementary Fig. 20). Consequently, the above structural and electrochemical results strongly suggest a correlation between the IE features, facilitated WD and enhanced CH4 selectivity on the IE LaCu0.67Si1.33 catalyst.

By comparing with prior representative methanization catalysts and home-made La3Cu2 and CuSi2 nanoparticles in flow cell setups under alkaline electrolyte, our IE LaCu0.67Si1.33 catalyst demonstrated significant advancements in both selectivity and partial current density (Fig. 3e, Supplementary Fig. 21−23). We also conducted an initial evaluation of structural stability of this new material as methanization electrocatalyst by operating the IE LaCu0.67Si1.33 catalyst in a flow cell for a continuous 10-h electrolysis at −100 mA cm−2. Throughout this duration, both the applied potential and the selectivity of CH4 remained stable, with minimal fluctuations observed (Fig. 3f). From the respective STEM images and XRD patterns of IE LaCu0.67Si1.33 catalyst before and after CO2 electrolysis, we observed negligible variations in either morphology or crystallinity, indicative of its structural integrity throughout the electrolysis process (Supplementary Fig. 24).

Mechanistic studies

In literature, the energetics of *CO has been widely used to project the electrocatalytic outcomes of CO2 into various mono-carbon or multi-carbon products39. Specifically, for the methanation of CO2, *CO undergoes an additional six hydrogenation steps, necessitating a robust methanization catalyst with substantial CO binding energy to hinder its undesirable desorption as a byproduct. Therefore, we initiated our mechanistic investigations by comparing the adsorption energies of *CO on the IE LaCu0.67Si1.33 and Cu surfaces using DFT calculations. CO has a significantly more negative adsorption energy on IE LaCu0.67Si1.33(101) than on Cu(111) (−2.27 vs. −1.02 eV), indicative of a more stable adsorption of *CO on the former (Fig. 4a). To validate these theoretical predictions, we employed low temperature CO-TPD experiments, which corroborated our DFT results by demonstrating that the IE LaCu0.67Si1.33 catalyst exhibits a higher CO desorption temperature than Cu nanoparticles (220 vs. 180 K). Moreover, the larger CO desorption peak area on the IE LaCu0.67Si1.33 surface, which is 2.6 times that of Cu nanoparticles, underscores the higher coverage of *CO on the former (Fig. 4b and Supplementary Fig. 25).

a Calculated adsorption energies of *CO on IE LaCu0.67Si1.33(101) and Cu(111) surfaces. b Low temperature CO-temperature program desorption curves over the IE LaCu0.67Si1.33 and Cu catalysts. Single of m/e = 28 is CO. c, d In situ ATR-SEIRAS spectra of IE LaCu0.67Si1.33 and Cu in CO2-saturated 0.5 M KHCO3 electrolyte at the applied potential of −0.1 to −1.9 V. e, f Deconvolution of the experimental O–H stretching vibration peak at −0.1 V and −1.9 V in IE LaCu0.67Si1.33 and Cu samples. Source data are provided as a Source Data file.

We further performed in situ attenuated total reflectance surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS) to probe the adsorption characteristics of CO during the reaction. On the IE LaCu0.67Si1.33, we observed a distinct signal in the range of 2038–2002 cm−1, attributed to linearly atop-adsorbed CO (*COatop). However, on the control Cu nanoparticles, in situ ATR-SEIRAS shows two prominent peaks for *COatop at 2040–2010 cm−1 and bridge-adsorbed CO (*CObridge) at 1897–1855 cm−1, respectively40. (Fig. 4c, d). Notably, the peak associated with the *COatop on Cu nanoparticles displays a blue-shift compared with that on the IE LaCu0.67Si1.33. This shift can be explained by the back-donation of electrons from the metal Cu atoms on the IE LaCu0.67Si1.33 surface, which enhances the filling of the 2π orbital of the CO molecule with electrons. This observation suggests the increased electronegativity of Cu atoms on the IE LaCu0.67Si1.33 surface, aligning with our calculations. The IE LaCu0.67Si1.33 exhibits a significantly higher COatop peak intensity compared to pure Cu across the entire potential window studied that can be attributed to the substantial difference in CO consumption between C2 and C1 product formation pathways where C2 production requires approximately twice the amount of CO compared to C1 products. Additionally, the presence of a second set of peaks on pure Cu nanoparticles at 1897–1855 cm−1 corresponds to *CObridge on adjacent Cu sites which related to the coupling behavior of *CO. The absence of such *CObridge on the IE LaCu0.67Si1.33 aligns with its tendency to favor C1 products and reinforces our EXAFS findings that this catalyst exhibits significantly lower Cu-Cu coordination numbers compared to pure Cu nanoparticles.

Recent evidence verified the pivotal role of interfacial water in the electrocatalysis of HER and CO2RR41, which prompts us to investigate the interfacial water structures close to the IE LaCu0.67Si1.33 and Cu nanoparticles using ATR-SEIRAS. Our spectroscopic results revealed a broad vibrational band corresponding to V(O − H) stretching, spanning 3700 to 3000 cm−1 on both catalysts. This band is typically ascribed to diverse O − H stretching modes of water, encompassing signals from free water (H2O − F), strongly hydrogen-bonded water (H2O − S), and weakly hydrogen-bonded water (H2O − W), as corroborated by previous literature (Supplementary Fig. 26)42,43,44. Notably, as the potential increased, the proportions of H2O − F and H2O − W peaks on both IE LaCu0.67Si1.33 and Cu decreased, concurrent with the Stark effect. In principle, H2O − F and H2O − W are energetically easier to be dissociated for hydrogenation compared to H2O − S. It is therefore reasonable to deduce that a catalyst with strong water-dissociation capabilities should manifest a lower ratio of H2O − F and H2O − W peaks, as these species are expected to be consumed rapidly. Consistent with this rationale, the IE LaCu0.67Si1.33 catalyst exhibited a notably lower ratio of H2O − F and H2O − W peak areas compared to the control Cu nanoparticles, highlighting the superior water-dissociation properties of the former (Figure e, f and Supplementary Fig. 27). To quantify this difference, we compared the integration of the adsorption peaks at −0.1 V and −1.9 V, and found that the consumption of H2O − F and H2O − W peaks on IE LaCu0.67Si1.33 was approximately three times that on Cu nanoparticles, further confirming the exceptional WD capability of the IE LaCu0.67Si1.33 catalyst (Supplementary Fig. 28).

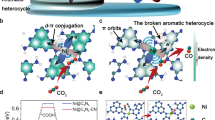

To theoretically rationalize the high CH4 selectivity of IE LaCu0.67Si1.33 catalyst, we carried out DFT calculations to investigate the methanogenesis pathways. After the adsorption of CO, the energy levels of CO protonation and C − C coupling determine the branching of C1 (e.g., CH4, CH3OH) vs. C2 (e.g., C2H4, C2H5OH) products. Therefore, we first compared the changes of Gibbs free energy for CO protonation and C − C coupling pathways (Fig. 5a). We found that the C − C coupling on the IE LaCu0.67Si1.33(101) surface is significantly energetically unfavorable compared to its protonation (0.68 vs. −0.66 eV), and *CO undergoes hydrogenation with a preference to form *CHO rather than *COH ( − 0.66 vs. 1.18 eV), even with a contribution of solvation (Supplementary Fig. 29). In contrast, although the protonation of *CO to *CHO is also energetically preferred on the Cu(111) surface, there is a small difference in energy between CO protonation and C − C coupling (0.82 vs. 1.32 eV). These calculated results are consistent with our ATR-SEIRAS observations. The charge density distributions were analyzed for both IE LaCu0.67Si1.33 and Cu surfaces with adsorbed *CHO by comparing the electron charge donation/acceptance status (Fig. 5b). After the adsorption of *CHO, the donation of electron charge can be observed on both IE LaCu0.67Si1.33(101) and Cu(111) surfaces, and the electron charge is accumulated between *CHO and surfaces. However, the electron density of the IE LaCu0.67Si1.33(101) surface, which is composed of transition metals with strongly changed charge states and anionic electrons, is stronger than that of Cu(111). Specifically, the IE LaCu0.67Si1.33 surface has more electrons that can be transferred to *CHO than the Cu surface (1.74 vs. 0.39 |e | ), which explains why the IE LaCu0.67Si1.33 surface can adsorb the key intermediate *CHO more stable than the Cu surface (−4.25 vs. −1.51 eV) to efficiently promote the CH4 selectivity.

a Hydrogenation and C − C coupling energies of *CO intermediate on IE LaCu0.67Si1.33(101) and Cu(111) surfaces. b Side view of charge-density differences of *CHO intermediate on IE LaCu0.67Si1.33(101) and Cu(111) surfaces. c Gibbs free energy diagram of two CO2-to-CH4 pathways on the IE LaCu0.67Si1.33(101) surface. Source data are provided as a Source Data file.

Figure 5c further provides the Gibbs free energy diagram for converting CO2 to CH4 on the IE LaCu0.67Si1.33 surface through the *CHO intermediate and possible hydrogenation routes according to previous literature45. The adsorption configurations of the related intermediates are given in Supplementary Fig. 30. The formation of *COOH and *CHO are exergonic on the IE LaCu0.67Si1.33 surface (−2.1 and −1.33 eV) but endergonic on the Cu surface (0.15 and 0.15 eV), which contributes to the higher CH4 selectivity of IE LaCu0.67Si1.33. The further hydrogenation products of *CHO can be *CH2O or *CHOH. By comparing the Gibbs free energies of these two pathways, we found that the hydrogenation of *CHO to *CH2O is more favored. The consecutive hydrogenation of the C end of *CH2O is strong exergonic, forming CH4. The effect of solvation energies on reaction free energies was benchmarked, proving that calculated results capture the correct trends (Supplementary Figs. 31, 32). We proposed that the CO2-to-CH4 conversion on the IE LaCu0.67Si1.33 surface follows: CO2 → *COOH → *CO → *CHO → *CH2O → *CH3O → CH4 (Supplementary Figs. 33, 34).

Discussion

In summary, we have reported a class of IE LaCu0.67Si1.33 catalyst with spontaneous WD for enhanced electrosynthesis of methane from CO2 reduction. Based on a series of physical characterizations and theoretical projections, we have unveiled the distinct electronic structures of IE LaCu0.67Si1.33 catalyst. The behaviors of WD on various catalysts were systematically investigated employing both experimental and calculational means, the results of which underscore a significantly enhanced WD on IE LaCu0.67Si1.33 over other control catalysts, including pure Cu and typical solid-solution alloys. We have evaluated this IE LaCu0.67Si1.33 catalyst for CO2 reduction in an alkaline flow cell, and achieved a remarkable methane Faraday efficiency of 72% at −1.21 V vs. RHE and the highest partial current density of 476.7 mA cm−2, along with an initial durability for 10 h. The coupling of in situ spectroscopies and DFT calculations pained an energetically favorable reaction pathway for the CO2-to-CH4 conversion on the IE LaCu0.67Si1.33 surface. This work demonstrates the spontaneous WD capability of IE materials as a promising catalyst platform for the electrochemical methanization of CO2 and potentially other H2O-involved renewable conversions.

Methods

Chemicals and materials

La, Cu and Si ingots (with a purity of 99.9%) were purchased from Cuibolin Instruments Ltd., Beijing. Commercial Cu nanoparticles (25 nm) were purchased from Sigma Aldrich. Gold chloride trihydrate (HAuCl4·3H2O, 99%), sodium hydroxide (NaOH, AR), potassium hydroxide (KOH, 85%), hydrofluoric acid (HF, 2%), ammonium fluoride (NH4F, AR), sodium thiosulfate (Na2S2O3, AR), sodium sulfite (Na2SO3, AR), sulfuric acid (H2SO4, 98%), ammonium chloride (NH4Cl, AR) and Acetone was purchased from Sinopharm group reagent Co. Ltd. The carbon paper-based gas diffusion layers (GDLs, Sigracet 28BC), anion-exchange membrane (AEM, Fumasep FAA-3-PK-130) and D520 NafionTM dispersion (5 wt%) were purchased from fuel cell store. Ultrapure Millipore water (resistivity 18.2 MΩcm) was used for all experiments. High purity CO2 gas (99.99%) was purchased from Tianjin liquefied gas Co. Ltd. All chemicals were purchased from commercial suppliers and used without further purification.

Synthesis of IE LaCu0.67Si1.33 catalyst

The IE LaCu0.67Si1.33 sample was synthesized through arc-melting stoichiometric ratios of La, Cu, and Si ingots in a water-cooled copper furnace under purified argon atmosphere (about −5 bar). To ensure phase purity, the arc-melting process was repeated eight times with intermediate flipping of the ingot. The resulting bulk material was manually ground into coarse powder using an agate mortar, followed by high-energy ball milling at 200 rpm for 20 h employing a ball-to-powder mass ratio of 20: 1 to achieve nanoparticle refinement. Wet milling with water was utilized during this size reduction process.

Synthesis of IC LaCu0.67Si1.33, La3Cu2 and CuSi2 catalysts

The IC LaCu0.67Si1.33 was prepared following identical procedures but with a single arc-melting cycle. Similarly, La3Cu2 and CuSi2 were synthesized using equivalent methodology, where respective elemental combinations (La + Cu or Cu + Si) were arc-melted in stoichiometric proportions under identical reactor conditions.

Characterizations

X-ray diffraction (XRD) patterns were obtained on a Bruker D2 Advance powder diffractometer with Cu-Kα radiation (λ = 1.54178 Å) at 30 kV and 10 mA. Imaging and elemental mapping were recorded on a field emission transmission electron microscope (TEM, JEOL ARM-200 F) equipped with a cold field emission gun and dual energy-dispersive X-ray detectors, operating at 200 kV accelerating voltage. The JEOL ARM200F microscope, equipped with an aberration corrector and dual energy-dispersive X-ray detectors, was used for high-resolution high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) imaging and corresponding elemental mapping. X-ray photoelectron spectroscopy (XPS) measurements were performed on a Thermo Scientific K-alpha system with an exciting source of Al Kα. The binding energy was calibrated using the extrinsic carbon C ls peak (284.6 eV). The textural properties of the samples were determined from N2-sorption isotherms recorded on a Micromeritics ASAP 2460 instrument at 77 K. The H2O-temperature-programmed surface reaction (TPSR) curves were recorded using a Micromeritics ChemiSorb 2920 instrument equipped with an online mass spectrometer. 300 mg of the sample was loaded into a U-tube, with He as the carrier gas (50 mL min−1), and heated to 600 °C for 2 h to remove surface residues. After cooling the sample to room temperature, water vapor was introduced over the catalyst surface via the He flow. The He flow was maintained at room temperature for 30 min to eliminate any excess H2O. Finally, TPSR measurements were conducted from 30 °C to 600 °C under helium at a heating rate of 10 °C min−1. For low-temperature CO-TPD, the sample was heated to 600 °C and held for 2 h in Ar atmosphere, followed by a switch to He gas at the same temperature for additional 30 min. After cooling to room temperature, the sample was further reduced to 150 K using liquid nitrogen circulation, and the carrier gas was switched back to the 5% CO-He mixture. Once the baseline stabilized, the data curve was recorded during heating from 150 K to 400 K at a rate of 20 K min−1. Powder neutron data were collected on the Multi-physics instrument at China Spallation Neutron Source (CSNS), Dongguan, China. Before testing, the sample IE LaCu0.67Si1.33 underwent a three-stage treatment process: First, it was thermally annealed at 600 °C for 2 h under continuous argon flow. Following cooling to ambient temperature, the atmosphere was switched to a water vapor-saturated argon flow (maintained for 1 h). Finally, the system was purged with pure argon and subjected to a secondary thermal treatment at 300 °C for 2 h to complete the processing. The sample (ca. 2 g) was loaded in vanadium alloy cans in the glove box. Then the powder neutron data were conducted by multiple bank detectors at room temperature.

Preparation of gas diffusion electrodes

A catalyst ink was prepared by ultrasonicating 8 mg of catalyst powder with 20 μL of Nafion solution (≈5 wt.%) in 1 mL ethanol for 1 h to achieve homogeneous dispersion. This ink was then uniformly spray-coated onto the microporous carbon layer of a 4 × 4 cm2 carbon paper substrate (Sigracet 28BC) using an airbrush system. The catalyst loading was controlled at approximately 0.35 mg cm2, as determined by gravimetric analysis of the substrate before and after coating. The coated electrode was trimmed to expose a 1 × 1 cm2 active area of catalytic layer. Finally, the prepared GDE was air-dried under ambient conditions for 12 h prior to electrochemical testing.

Electrochemical measurements

The CO2RR performance was evaluated at room temperature (25 ± 2 °C) and pressure (1.01 × 105 Pa) using a flow cell system, in which the anode and cathode chambers were separated by an ion-conducting anion exchange membrane (Fumasep FAA-3-PK-130). An electrochemical workstation (Autolab PGSTAT204) was configured as a three-electrode system with a constant current source. Anion exchange membrane (2.5 × 2.5 cm2) was soaked in 1 M KOH for 48 h and rinsed with deionized water before use. The catalyst loaded GDE served as the working electrode, while an Ag/AgCl electrode (with saturated KCl as the filling solution) and nickel foam were used as the reference and counter electrodes, respectively. All potentials in this experiment were calibrated to the potential relative to the reversible hydrogen electrode (RHE) based on the following equation after IR compensation:

The 80% iR compensation was performed for the electrolysis experiment at each potential, with the ohmic resistance determined through extrapolation of the high-frequency intercept in electrochemical impedance spectra. The Ag/AgCl reference electrode potential was calibrated against the reversible hydrogen electrode (RHE, Phychemi Co., Ltd.) in 1 M KOH electrolyte, yielding a stable value of 1.00 ± 0.01 V vs. RHE. The electrochemical measurements employed a freshly prepared 1 M KOH electrolyte (pH = 13.7 ± 0.2) that was utilized within 72 h of preparation. The electrolyte was stored in PTFE containers under ambient temperature conditions (25 ± 2 °C) between experimental sessions. For each electrolysis experiment, 10 mL electrolyte were dispensed into both the cathodic and anodic chambers of the flow cell system, each featuring a 1 cm3 working volume. Continuous electrolyte circulation was maintained through both electrode compartments using a peristaltic pump operating at a constant flow rate of 10 mL min–¹. The high-purity CO2 (99.99%) gas supply flow rate was regulated by a mass flow meter and passed through the gas chamber of the flow cell at a flow rate of 20 sccm. Use a stopwatch to time the volume flow rate of the outlet gas through the soap film. The outlet gas was collected in a gas sampling bag (100 mL) and quantitatively analyzed by gas chromatograph (Agilent 7890B). CH4 and C2H4 were detected by flame ionization detector (FID), and H2 and CO were detected by thermal conductivity detector (TCD). After the electrolysis, the cathode liquid phase product was analyzed by high performance liquid chromatography (HPLC). The gas and liquid phase products were calibrated by external standard method.

The Faradaic efficiencies (FE) of gas products can be calculated as below:

\({{FE}}_{x}=\frac{F\times {n}_{x}\times {V}_{{gas}}\times {c}_{x}}{i\times {V}_{m}}\)

Among them, \(F\) denotes the Faraday constant (96,485 C mol−1), \({n}_{x}\) denotes the number of electrons transferred for producing 1 mole of product \(x\), \({V}_{{\mbox{gas}}}\) is the gas flow rate at the flow cell outlet (sccm), \({c}_{x}\) represents the volume concentration of product \(x\) measured by gas chromatography, \(i\) is the total current, and \({V}_{m}\) is the molar volume (24.5 L mol−1; 298.15 K).

The FE of liquid products can be calculated as below:

\({{FE}}_{x}=\frac{F\times {n}_{x}\times {m}_{x}}{i\times t}\)

Where \({m}_{x}\) represents the amount of liquid products in moles, and \(t\) denotes the electrolysis time (s).

The partial current density for a given product was calculated as:

\({j}_{x}=\frac{i\times {{FE}}_{x}}{{electrode\; area}}\)

XAFS analysis

XAFS spectroscopic measurements of K-edges for Cu of IE LaCu0.67Si1.33 samples were conducted at the BL17B1 and BL20U beamlines in Shanghai Synchrotron Radiation Facility (SSRF). Spectra were collected in transmission mode using a Pilatus detector. For Cu K-edge measurements, Cu foil reference was scanned simultaneously with the sample for energy calibration. The acquired EXAFS data were processed according to the standard procedures using the Athena and Artemis software, parts of the Demeter package. Preprocessing of data included alignment, edge calibration, deglitching, normalization, background subtraction, and conversion of data into a chi file for data fitting; all this was done with Athena; EXAFS of the Cu was fitted to obtain the amplitude reduction factor S02.

Theoretical calculations

All calculations were performed using density functional theory (DFT) with the projector augmented wave (PAW)46,47 method and the Perdew-Burke-Ernzerhof generalized gradient approximation (GGA-PBE)48, as implemented in the Vienna Ab Initio Simulation Package (VASP)49,50. The cutoff energy was set to 400 eV after a series of tests. The Methfessel−Paxton51 method with σ = 0.2 eV was chosen as the smearing algorithm. The electronic self-consistent iteration and atomic forces were converged to within 10–5 eV and 0.03 eV Å–1, respectively. Grimme’s DFT-D352 approach was adopted to account for dispersion interactions. The optimized bulk lattice constants of IE LaCu0.67Si1.33 with (5 × 5 × 4) Monkhorst−Pack k-point grids53 are a = b = 8.20 Å and c = 12.87 Å. Convergence tests were performed with respect to the layer thickness and size of constrained layers according to the adsorption energy of *CO. Thus, the adsorption calculations on the IE LaCu0.67Si1.33(101) were performed using a ten-layer p(2 × 1) supercell (bottom five layers constrained) containing a vacuum region of 20 Å with (2 × 2 × 1) Monkhorst−Pack k-point grids. The adsorption calculations on the Cu(111) were performed using a six-layer p(4 × 4) supercell (bottom three layers constrained) containing a vacuum region of 20 Å with (3 × 3 × 1) Monkhorst−Pack k-point grids. The adsorption energy (\({E}_{{\mbox{ads}}}\)) of species X was calculated by \({E}_{{\mbox{ads}}}={E}_{{\mbox{X}}/{\mbox{slab}}}-{E}_{{\mbox{slab}}}-{E}_{{\mbox{X}}}\), where \({E}_{{\mbox{X}}}\), \({E}_{{\mbox{slab}}}\), and \({E}_{{\mbox{X}}}/{{\mbox{slab}}}\) are the total energy of the free adsorbate in gas phase, clean slab, and slab with the adsorbate, respectively. For reaction steps involving H+ and e−, the computational hydrogen electrode (CHE)54,55 model was used to calculate the Gibbs free energies changes. The thermal corrections to the Gibbs free energies were obtained using VASPKIT tool56. The transition state of a chemical reaction was located using the climbing image nudged elastic band method57. The electrochemical barriers were evaluated through the scheme developed by Akhade et al.58. For all calculations, the optimized structures are provided in Supplementary Data 1.

In situ IR measurements

In situ IR spectra were collected using a custom three-electrode H electrolytic cell on a Vertex70 (Bruker) spectrophotometer in an internal reflection configuration (Supplementary Fig. 35). Prior to testing, a polished silicon prism substrate was functionalized with a chemically deposited uniform gold film serving as the reflective working electrode. A catalyst ink was prepared by ultrasonically homogenizing 2 mg of catalyst powder with 500 μL ethanol and 10 μL Nafion solution (5 wt%), which was subsequently spray-coated onto the gold film to create a uniform catalytic layer. All electrochemical measurements were performed in CO2-saturated 0.5 M KHCO3 (pH = 7.4 \(\pm \,0.3\)) electrolyte, and CO2 was continuously bubbled onto the catalyst surface at a flow rate of 10 sccm. All spectra were absorption spectra collected at a resolution of 4 cm−1, and data were collected at different voltages.

Data availability

All data generated in this study are provided in the Supplementary Information/Source data file. Source data are provided in this paper. Source data are provided with this paper.

References

Gao, D. et al. Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat. Catal. 2, 198 (2019).

Lees, E. W. et al. Gas diffusion electrodes and membranes for CO2 reduction electrolysers. Nat. Rev. Mater. 7, 55 (2022).

Zhu, H. J. et al. Oxygen-tolerant CO2 electroreduction over covalent organic frameworks via photoswitching control oxygen passivation strategy. Nat. Commun. 15, 1479 (2024).

Fang, W. et al. Durable CO2 conversion in the proton-exchange membrane system. Nature 626, 86 (2024).

Jiang, M. et al. Review on strategies for improving the added value and expanding the scope of CO2 electroreduction products. Chem. Soc. Rev. 53, 5149 (2024).

Ross, M. B. et al. Designing materials for electrochemical carbon dioxide recycling. Nat. Catal. 2, 648 (2019).

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610 (2019).

Sun, X. et al. Advancing electrocatalytic reactions through mapping key intermediates to active sites via descriptors. Chem. Soc. Rev. 53, 7392 (2024).

Seh, Z. et al. Combining theory and experiment in electrocatalysis: Insights into materials design. Science 355, eaad4998 (2017).

Jiao, J. et al. Constructing asymmetric double-atomic sites for synergistic catalysis of electrochemical CO2 reduction. Nat. Commun. 14, 6164 (2023).

Chen, J. et al. Promoting CO2 electroreduction kinetics on atomically dispersed monovalent ZnI sites by rationally engineering proton-feeding centers. Angew. Chem. Int. Ed. 61, e202111683 (2022).

Jiao, J. et al. Copper atom-pair catalyst anchored on alloy nanowires for selective and efficient electrochemical reduction of CO2. Nat. Chem. 11, 222 (2019).

Chen, S. et al. Engineering water molecules activation center on multisite electrocatalysts for enhanced CO2 methanation. J. Am. Chem. Soc. 144, 12807 (2022).

Li, Y. et al. Promoting CO2 methanation via ligand-stabilized metal oxide clusters as hydrogen-donating motifs. Nat. Commun. 11, 6190 (2020).

Ma, M. et al. Local reaction environment for selective electroreduction of carbon monoxide. Energy Environ. Sci. 15, 2470 (2022).

Sa, Y. et al. Catalyst–electrolyte interface chemistry for electrochemical CO2 reduction. Chem. Soc. Rev. 49, 6632 (2020).

Liu, X. et al. Understanding trends in electrochemical carbon dioxide reduction rates. Nat. Commun. 8, 15438 (2017).

Zhi, X., Vasileff, A., Zheng, Y., Jiao, Y. & Qiao, S. Role of oxygen-bound reaction intermediates in selective electrochemical CO2 reduction. Energy Environ. Sci. 14, 3912 (2021).

Dinh, C. T. et al. Multi-site electrocatalysts for hydrogen evolution in neutral media by destabilization of water molecules. Nat. Energy 4, 107 (2019).

Subbaraman, R. et al. Trends in activity for the water electrolyser reactions on 3d M(Ni,Co,Fe,Mn) hydr(oxy)oxide catalysts. Nat. Mater. 11, 550 (2012).

Luo, M. et al. Hydroxide promotes carbon dioxide electroreduction to ethanol on copper via tuning of adsorbed hydrogen. Nat. Commun. 10, 5814 (2019).

Zhang, Q. et al. Atomic dynamics of electrified solid–liquid interfaces in liquid-cell TEM. Nature 630, 643 (2024).

Yang, Y. et al. Operando studies reveal active Cu nanograins for CO2 electroreduction. Nature 614, 262 (2023).

Amirbeigiarab, R. et al. Atomic-scale surface restructuring of copper electrodes under CO2 electroreduction conditions. Nat. Catal. 6, 837 (2023).

Vavra, J. et al. Solution-based Cu+ transient species mediate the reconstruction of copper electrocatalysts for CO2 reduction. Nat. Catal. 7, 89 (2024).

Sun, Y. et al. The facile dissociation of carbon–oxygen bonds in CO2 and CO on the surface of LaCoSiHx intermetallic compound. Angew. Chem. Int. Ed. 133, 25742 (2021).

Sun, Y. et al. Water-induced structural evolution of LaTMSi ternary intermetallic electrides. Chem. Mater. 35, 1972 (2023).

Gong, Y. et al. Ternary intermetallic LaCoSi as a catalyst for N2 activation. Nat. Catal. 1, 178 (2018).

Gong, Y. et al. Unique catalytic mechanism for Ru-loaded ternary intermetallic electrides for ammonia synthesis. J. Am. Chem. Soc. 144, 8683 (2022).

Lu, Y. et al. Synthesis of rare-earth-based metallic electride nanoparticles and their catalytic applications to selective hydrogenation and ammonia synthesis. ACS Catal. 8, 11054 (2018).

Hosono, H. & Kitano, M. Advances in materials and applications of inorganic electrides. Chem. Rev. 121, 3121 (2021).

Yuan, X. et al. Crystal structure prediction approach to explore the iron carbide phases: novel crystal structures and unexpected magnetic properties. J. Phys. Chem. C. 124, 17244 (2020).

Ye, T. et al. Copper-based intermetallic electride catalyst for chemoselective hydrogenation reactions. J. Am. Chem. Soc. 139, 17089 (2017).

Wu, H. et al. Selective and energy-efficient electrosynthesis of ethylene from CO2 by tuning the valence of Cu catalysts through aryl diazonium functionalization. Nat. Energy 9, 422 (2024).

Fu, W. et al. Photoinduced loading of electron-rich Cu single atoms by moderate coordination for hydrogen evolution. Nat. Commun. 13, 5496 (2022).

Wan, B. et al. BaCu, a two-dimensional electride with Cu anions. J. Am. Chem. Soc. 146, 17508 (2024).

Zhang, Z. et al. The most active Cu facet for low-temperature water gas shift reaction. Nat. Commun. 8, 488 (2017).

Fan, L. et al. Proton sponge promotion of electrochemical CO2 reduction to multi-carbon products. Joule 6, 205 (2022).

Gao, W. et al. Experimental evidence of distinct sites for CO2-to-CO and CO conversion on Cu in the electrochemical CO2 reduction reaction. Nat. Catal. 6, 885 (2023).

Delmo, E. P. et al. In situ infrared spectroscopic evidence of enhanced electrochemical CO2 reduction and C−C coupling on oxide-derived copper. J. Am. Chem. Soc. 146, 1935 (2024).

Li, P. et al. Hydrogen bond network connectivity in the electric double layer dominates the kinetic pH effect in hydrogen electrocatalysis on Pt. Nat. Catal. 5, 900 (2022).

Gomes, R. J. et al. Modulating water hydrogen bonding within a non-aqueous environment controls its reactivity in electrochemical transformations. Nat. Catal. 7, 689 (2024).

Mi, Z., Wang, T., Xiao, L., Wang, G. & Zhuang, L. Catalytic peculiarity of alkali metal cation-free electrode/ polyelectrolyte interfaces toward CO2 reduction. J. Am. Chem. Soc. 146, 17377 (2024).

Zhu, Z. et al. Covalent organic framework ionomer steering the CO2 electroreduction pathway on Cu at industrial-grade current density. J. Am. Chem. Soc. 146, 1572 (2024).

Zhao, J. et al. Modulation of *CHxO adsorption to facilitate electrocatalytic reduction of CO2 to CH4 over Cu-based catalysts. J. Am. Chem. Soc. 145, 6622 (2023).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758 (1999).

Perdew, J., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15 (1996).

Methfessel, M. & Paxton, A. T. High-precision sampling for Brillouin-zone integration in metals. Phys. Rev. B 40, 3616 (1989).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886 (2004).

Rossmeisl, J. et al. Electrolysis of water on oxide surfaces. J. Electroanal. Chem. 607, 83 (2007).

Wang, V. et al. Vaspkit: A user-friendly interface facilitating high-throughput computing and analysis using vasp code. Comput. Phys. Commun. 267, 108033 (2021).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901 (2000).

Akhade, S. A. et al. A simple method to approximate electrode potential-dependent activation energies using density functional theory. Catal. Today 288, 63 (2017).

Dai, Y. et al. Manipulating local coordination of copper single atom catalyst enables efficient CO2-to-CH4 conversion. Nat. Commun. 14, 3382 (2023).

Tan, X. et al. Stabilizing copper by a reconstruction-resistant atomic Cu–O–Si interface for electrochemical CO2 reduction. J. Am. Chem. Soc. 145, 8656 (2023).

Zhou, X. et al. R Stabilizing Cu2+ ions by solid solutions to promote CO2 electroreduction to methane. J. Am. Chem. Soc. 144, 2079 (2022).

Chen, S. et al. Highly selective carbon dioxide electroreduction on structure-evolved copper perovskite oxide toward methane production. ACS Catal. 10, 4640 (2020).

Chen, S. et al. MOF encapsulating N-heterocyclic carbene-ligated copper single-atom site catalyst towards efficient methane electrosynthesis. Angew. Chem. Int. Ed. 134, e202114450 (2022).

Han, Z. et al. Steering surface reconstruction of copper with electrolyte additives for CO2 electroreduction. Nat. Commun. 13, 3158 (2022).

Liu, J. et al. Switching between C2+ products and CH4 in CO2 electrolysis by tuning the composition and structure of rare-earth/copper catalysts. J. Am. Chem. Soc. 145, 23037 (2023).

Wang, R. et al. Partial coordination-perturbed Bi-copper sites for selective electroreduction of CO2 to hydrocarbons. Angew. Chem. Int. Ed. 60, 19829 (2021).

Liu, K. et al. Unraveling and tuning the linear correlation between CH4 and C2 production rates in CO2 electroreduction. Sci. Bull. 67, 1042 (2022).

Xia, C. et al. Highly selective electrocatalytic CO2 conversion to tailored products through precise regulation of hydrogenation and C–C coupling. J. Am. Chem. Soc. 146, 20530 (2024).

Chen, S. et al. Lewis acid site-promoted single-atomic Cu catalyzes electrochemical CO2 methanation. Nano Lett. 21, 7325 (2021).

Zhang, L. et al. Enhanced cuprophilic interactions in crystalline catalysts facilitate the highly selective electroreduction of CO2 to CH4. J. Am. Chem. Soc. 143, 3808 (2021).

Jiang, Y. et al. Pushing the performance limit of Cu/CeO2 Catalyst in CO2 electroreduction: A cluster model study for loading single atoms. ACS Nano 17, 2620 (2023).

Zhang, Y. et al. Coordination environment dependent selectivity of single-site-Cu enriched crystalline porous catalysts in CO2 reduction to CH4. Nat. Commun. 12, 6390 (2021).

Pan, F. et al. N and OH-immobilized Cu3 clusters in situ reconstructed from single-metal sites for efficient CO2 electromethanation in bicontinuous mesochannels. J. Am. Chem. Soc. 146, 1423 (2024).

Xiong, L. et al. Geometric modulation of local CO Flux in Ag@Cu2O nanoreactors for steering the CO2RR pathway toward high-efficacy methane production. Adv. Mater. 33, 2101741 (2021).

Zhang, Y. et al. Tailoring coordination microenvironment of Cu(I) in metal–organic frameworks for enhancing electroreduction of CO2 to CH4. Adv. Funct. Mater. 32, 2203677 (2022).

Jeon, H. S. et al. Selectivity control of Cu nanocrystals in a gas-fed flow cell through CO2 pulsed electroreduction. J. Am. Chem. Soc. 143, 7578 (2021).

Jiao, J. et al. Steering the reaction pathway of CO2 electroreduction by tuningthe coordination number of copper catalysts. J. Am. Chem. Soc. 146, 15917 (2024).

Acknowledgements

This research is financial supported by the Ministry of Science and Technology of China (Grant No. 2022YFA1604100[X.W.]), the National Science Fund for Distinguished Young Scholars of China (Grant No. 22225206[X.W.]), the CAS Project for Young Scientists in Basic Research (YSBR-005[X.W.]), the Key Research Program of Frontier Sciences CAS (ZDBS-LY-7007[X.W.]), the Major Research Plan of the National Natural Science Foundation of China (92045303[X.W.]), the Informatization Plan of Chinese Academy of Sciences (Grant No. CAS-WX2021SF0110[X.W.]), the National Natural Science Foundation of China (Grant No. 22372188[X.W.]), the Ministry of Science and Technology of China (Grant No. 2022YFA1604100[F.W.]), the Innovation Foundation of the Institute of Coal Chemistry, Chinese Academy of Sciences (SCJC-HN-2023-14[F.W.]), and Synfuels China Co., Ltd. We gratefully acknowledge Y. J. Jiang, Y. L. Bai, and Z. G. Lv at Synfuels China Co., Ltd. for assistance in performing GC, H2O-TPSR, and XPS analysis, respectively. The authors also acknowledge H. C. Chen and W. Yin for assistance with the neutron powder diffraction experiments performed at the Multi-Physics Instrument (MPI) of the China Spallation Neutron Source (CSNS) in Dongguan, China; W. T. Zheng (State Key Laboratory of Coal Conversion, CAS) and the staff of the BL17B and BL20U1 beamlines in Shanghai Advanced Research Institute, Chinese Academy of Sciences, for their technical support in XAFS data collection and analysis. X. C. Liu (State Key Laboratory of Coal Conversion, CAS) for help with theoretical calculations.

Author information

Authors and Affiliations

Contributions

L.Z. designed and performed the experiments, and wrote the manuscript. H.M. performed the DFT calculations. Y.S. provided guidance on catalyst preparation and performed the XAS tests. Y.Z. assisted in the analysis of the in-situ IR data. H.D. and Y.W. provided help with the testing of the CO2RR. M.L. F.W. and X.W. conceived the idea and supervised the project. All authors discussed, commented on, and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yuan-Biao Huang, Min Kuang, Adithya Polasa, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, L., Ma, H., Sun, Y. et al. Spontaneous water dissociation on intermetallic electride LaCu0.67Si1.33 enhances electrochemical methanization of CO2. Nat Commun 16, 5039 (2025). https://doi.org/10.1038/s41467-025-60353-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-60353-9