Abstract

High-entropy oxides (HEOs) are a class of promising materials with multielement tunability and untold scientific merits, yet the controllable preparation of nano-sized HEOs is notoriously difficult. Herein, we utilize the natural oxide layer on liquid gallium as an ideal substrate to facilitate the synthesis of thin HEO. Through experiments and density functional theory (DFT) calculations, it is found that Ga2O3 layer exhibits a strong affinity for metal ions and oxides, which not only enables it to anchor multiple metal ions and facilitate the formation of HEO, but also introduces a strain effect that can lower the free-energy barrier for oxygen evolution reaction (OER). It increases the exposed surface area and active sites of HEO, enhancing its reaction efficiency. As a result, the Ga2O3-supported thin HEO film (Mn0.65Fe0.59Co0.83Ni0.48Zn0.45O4) shows satisfactory OER performance compared with other control groups. This study exemplifies the potential of the liquid Ga2O3 layer as an affinity substrate for high-entropy material synthesis.

Similar content being viewed by others

Introduction

HEO is a promising material system for high-performance electrocatalysis, which shows unique properties including high-entropy effect, lattice distortion, sluggish diffusion and “cocktail” effect1,2. By incorporating five or more metal cations with equal or nearly-equal atomic ratios into a single phase and therefore elevating the entropy and lowering the energy of the whole system, its active sites can be turned easily, together with enhanced stability, catalytic activation, and species transportation3. The complex elemental configurations of HEOs can break through the limits of the primary element position in a volcano plot and enable better performance to be achieved4. Meanwhile, the lattice mismatch and internal strain significantly affect the d-band center, thereby effectively regulating the surface adsorption energy and activation barriers, enhancing catalytic reactivity5,6. In contrast to bulk HEOs, nano-sized and low-dimensional HEOs usually show special scale effects and surface characteristics. They are able to expose more active sites, establish faster mass transport pathways, exhibit higher stability in harsh conditions, and realize fine-tuning of catalytic activity7,8. The resulting regulability, efficiency and high activity could potentially replace traditional high-cost catalysts based on noble metals in the near future.

Because of the thermodynamic instability and phase separation caused by elemental immiscibility, however, the controlled synthesis and fine regulation of HEOs still remain formidable challenges, and most studies on low-dimensional HEOs require special equipment, harsh conditions, or cumbersome processes8,9,10,11,12,13. Accordingly, despite the proliferation of HEO-related research in the electrocatalysis field, few studies have mainly focused on the preparation technology of thin HEOs and their interaction with heterogeneous substrates. According to limited work in this field, the HEO has a great potential to serve as a protective layer to prevent the internal materials from surface reconstruction and structural damage during long-term electrochemical testing14.

Here, we utilize the gallium (Ga) oxide layer on liquid Ga for the synthesis of a thin HEO film. Ga is liquid at near room temperature and is forever covered by a self-limiting oxide layer, one of the most perfect planar materials with strong mechanical strength to overcome gravity and build surface structures15,16. Recently, the special properties of this oxide layer to prepare Ga-based high-quality film materials were exploited and harnessed17,18,19. In this work, we electroplate Ga to adhere to carbon paper (CP) fibers as droplets (Fig. 1a), which maintain a large surface area and avoid possible droplet coalescence caused by surface tension14. Moreover, solute molecules tend to be adsorbed on the surface to reduce surface energy20. It can therefore be used as a synthetic substrate to adsorb metal elements, which are transformed into an HEO during thermal treatment, while a liquid Ga core turns into solid Ga2O3 in the process to form heterostructural core-shell Ga2O3@HEO. Combining the experiments with density functional theory (DFT) calculations, it is found that Ga2O3 can greatly stabilize the HEO film by anchoring on the surface. The high-entropy effect of HEO brings satisfactory catalytic activity, while the Ga2O3-based core-shell structure can further enhance the internal strain of the surface HEO film, and thus, its electrocatalytic activity for OER can be further improved through the strain effect. As a result, the thin HEO film exhibits satisfactory OER performance as a non-noble metal electrocatalyst. It shows an overpotential of 408 mV at a current density of 100 mA cm−2 and a 43 mV dec−1 Tafel slope in 1 M KOH, with good stability. DFT calculations reveal that compared with CP-supported HEO, Ga2O3 regulated HEO film can decrease the activation barrier for the OER.

a Schematic illustration of the synthesis and application of carbon paper (CP)/Ga2O3@high-entropy oxide (HEO). Silver represents Ga; light blue, dark blue, green, purple, and blue-violet collectively represent Mn, Fe, Co, Ni, and Zn; yellow represents O; red represents H. b XRD patterns of CP/Ga2O3@HEO, CP/Ga2O3, CP/HEO, CP and PDF information of Ga2O3 and spinel Ni0.5Zn0.2Co0.3Fe2O4. c SEM images of CP/Ga2O3@HEO and histogram of particle size distribution. d Element line scan results of Ga2O3@HEO particle in Fig. 1e. e TEM image of Ga2O3@HEO particle. f Enlarged TEM image of the box area in Fig. 1e, which exhibits the lattice phase of HEO and the boundary between Ga2O3 and HEO. g, h SAED pattern of the core part and shell part of Ga2O3@HEO, respectively. Source data are provided as a Source Data file.

Results

Synthesis and characterizations

As illustrated in Fig. 1a, liquid Ga droplets were dispersed onto the surface of CP fibers by electroplating in a NaOH solution. NaOH temporarily removed the oxide layer of Ga (Ga2O3 + 2NaOH + 3H2O → 2NaGa(OH)4) and reduced the resistance of dispersing Ga into the solution21. The presence of NaGa(OH)4 has been confirmed by EDS mapping and the size changes of liquid Ga droplets in the NaOH solution (Supplementary Figs. 1 and 2). During electroplating, the positive and negative terminals were connected to the liquid Ga and CP, respectively. Under an electric field, liquid Ga was present as droplets (Supplementary Fig. 3), which were positively charged and obtained electrons on the negative electrode CP22. Meanwhile, the Ga droplets underwent electrochemical oxidation, generating an oxide layer on the surface22. The van der Waals force between the oxide layer and carbon enabled the droplets to adhere to the surface of the CP fibers and suppress aggregation15. After washing with ethanol and drying, the Ga-droplet-covered CP was immersed in a metal-nitrate mixed solution, and the metal ions tended to cover the surfaces of the Ga droplets to reduce the surface energy20. In this way, the surfaces of these Ga droplets served as surfaces advantageous for the adsorption of various metal sources, leading to the synthesis of multi-metal films. Finally, the CP was heated in a tube furnace. During this process, the metal ions adsorbed on the surface of Ga was transformed into thin HEO films, and the liquid Ga was oxidized to Ga2O3, ultimately forming core-shell structures attached to the surface of CP, which was used as an efficient OER electrocatalyst. By adjusting the voltage and time of the electroplating, the size of the Ga droplets and their distribution on the CP can be modified, thereby regulating the size and exposed surface area of the final core-shell structure (Supplementary Figs. 4 and 5) to optimize the electrocatalytic performance. The morphology of CP before electroplating can be observed in Supplementary Fig. 6. The detailed procedures can be referred to in the Methods section.

X-ray diffraction (XRD) measurements were conducted for CP, Ga2O3 attached CP (CP/Ga2O3), HEO ((Mn, Fe, Co, Ni, Zn)3O4) attached CP (CP/HEO), and Ga2O3-supported HEO film-attached CP (CP/Ga2O3@HEO) to show the crystalline phases (Fig. 1b and Supplementary Fig. 7). Figure 1b is the enlarged view of Supplementary Fig. 7 from 30° to 88°, allowing for clearer observation of the Ga2O3 and HEO peaks by avoiding interference from the strong graphite carbon peak at 26.5°. Apart from the graphitic carbon, the other peaks in the XRD pattern of CP/Ga2O3 correspond to Ga2O3, and the other peaks in the XRD pattern of CP/HEO correspond to the cubic spinel structure. In CP/Ga2O3@HEO, except for the graphitic carbon, all peaks correspond to Ga2O3 and spinel HEO. The strongest peaks of Ga2O3 and spinel HEO are both located at around 35°, but that of spinel HEO is slightly shifted to a higher angle. As a result, in the XRD pattern of CP/Ga2O3@HEO, the peak located at 35.3° has an asymmetrical peak shape, wider on the right, comprising the strongest peaks of Ga2O3 and spinel HEO. As marked in the figure, the peak of CP/Ga2O3@HEO at 62.5°, which is attributable to spinel HEO, shifts to the left by 0.7° when compared with the peak of spinel HEO with the same elemental composition grown directly on CP. This is due to the tensile strain effect exerted by the Ga2O3 substrate on the HEO shell, causing an increase in its crystal plane spacing23,24. Furthermore, the peak of spinel HEO is broader in the XRD pattern of CP/Ga2O3@HEO than in that of CP/HEO, illustrating that a Ga2O3 layer can facilitate the formation of spinel HEO with a smaller size. Rietveld refinement results of XRD patterns of CP/Ga2O3@HEO and CP/HEO further confirm such an increase in crystal plane spacing and a decrease in HEO size, for the lattice parameter of CP/Ga2O3@HEO is 0.124 Å larger than CP/HEO and its particle size is 28.9% smaller than the latter (Supplementary Fig. 8 and Supplementary Table 1). The above results prove the successful preparation of CP/Ga2O3@HEO. The XRD patterns of other CP/Ga2O3@multimetal oxides and CP/Ga2O3@single-metal oxides were measured as control groups to compared to CP/Ga2O3@HEO and show the entropic stability effect (Supplementary Fig. 9). Based on the XRD patterns, all the multimetal oxides can be regarded as having a spinel crystal structure. Therefore, the chemical formulas are written according to the M₃O₄ stoichiometry.

The morphology and crystal structures were further characterized by scanning electron microscope (SEM) and high resolution transmission electron microscopy (HRTEM). The SEM image and histogram in Fig. 1c illustrate the distribution of liquid Ga droplets on the fiber of CP. Figures 1d, e shows the linear scanning profile and transmission electron microscopy (TEM) image of the particle of Ga2O3@HEO, with a spherical morphology, which is consistent with the SEM image. The linear scanning profile exhibits a core-shell structure, where the main metallic element inside the sphere is Ga, and the metallic elements in the outer shell of the sphere are Mn, Fe, Co, Ni, and Zn. These results can be attributed to the formation of a HEO film on the surface of the Ga oxide layer. This core-shell structure can be observed clearly in the enlarged Fig. 1f, which shows an obvious boundary between the Ga2O3 core and the HEO shell. The HEO shell is highly crystalline with an interplanar spacing of 0.49 nm, which corresponds to the (111) crystal plane, and is larger than the interplanar spacing provided by PDF 01-090-3514 (0.48 nm, spinel metal oxide). The HRTEM image of HEO formed directly on CP is exhibited in Supplementary Fig. 10. The HEO grown on the surface of CP exhibits a large block-like morphology with uneven particle sizes and significant agglomeration, in stark contrast to the HEO thin film grown on the Ga2O3 surface with uniform thickness. The HRTEM images of Ga2O3 on CP are shown in Supplementary Fig. 11. Figure 1g and h are the diffraction patterns of the core and shell part of Ga2O3@HEO, which correspond to monoclinic Ga oxide and spinel metal oxide.

The high-angle annular dark field (HAADF) and elemental mapping results in Fig. 2 confirm the universality of the method to prepare thin metal oxide films. The oxide layer of liquid Ga can serve as a substrate to synthesize a wide range of metal oxide films, including unary metal oxide films (Ni, Mn), binary metal oxide films (MnFe, FeNi), ternary metal oxide films (MnCoNi, FeCoNi), quaternary metal oxide films (MnFeCoNi, FeCoNiZn), and quinary metal oxide films (MnFeCoNiZn). The quinary metal oxide film is the HEO film mentioned above. The elemental mappings of these particles all show core-shell structures, where the element in the core is only Ga, while metal elements are evenly distributed in the shell without phase separation, forming a uniform thin film attached to the core. The thicknesses of the shells range from a few nanometers to several tens of nanometers, making them thin nanofilms. Oxygen can be found in both the core and shell. The mixed configuration entropy (ΔSmix) values of all the multimetal oxide films have been calculated by the following equation25,26:

where R represents the gas constant and xi is the molar concentration of each element. The values were calculated based on quantitative data of EDS in Supplementary Table 2, from which the composition of HEO is estimated as Mn0.65Fe0.59Co0.83Ni0.48Zn0.45O4, assuming a spinel M₃O₄ crystal structure. From unary metal oxides to quinary metal oxides, the values of configuration entropy gradually increase (the values of configuration entropy of unary metal oxides are zero). The mixed configuration entropy of quinary metal oxide film is 1.59 R, larger than the specific threshold of 1.5 R, making it a HEO film2. Furthermore, we prepared HEO films with different elemental compositions, all of which exhibited ΔSmix values greater than 1.5 R and uniform elemental distributions, further demonstrating the universality of this method for HEO synthesis (Supplementary Figs. 12 and 13, Supplementary Table 3). Figure 2 further confirms the successful syntheses of thin metal oxide films utilizing the liquid Ga oxide layer and the universality of the method.

HAADF-energy disperse spectroscopy (EDS) images of the Ga2O3@quinary metal oxide (HEO)(MnFeCoNiZn), Ga2O3@quaternary metal oxides (MnFeCoNi, FeCoNiZn), Ga2O3@ternary metal oxides (MnCoNi, FeCoNi), Ga2O3@binary metal oxides (MnFe, FeNi), and Ga2O3@unary metal oxides (Ni, Mn). All the scale bars are 100 nm. All the TEM samples are prepared by using powerful ultrasound to dislodge particles grown on CP. Light blue, dark blue, green, purple, and blue-violet collectively represent Mn, Fe, Co, Ni, and Zn; yellow represents O.

X-ray photoelectron spectroscopy (XPS) measurements were conducted to study the compositions and chemical states of the first few surface layers of CP/Ga2O3@HEO and CP/HEO (Supplementary Fig. 14). According to the high-resolution XPS spectra of Mn 2p, Fe 2p, Co 2p, Ni 2p, and Zn 2p, the chemical valence states of these elements equate with Mn2O3, NiFe2O4, Co3O4, NiFe2O4, ZnO, where NiFe2O4 has the same spinel structure as indicated by the PDF 01-090-3514, and other elements therefore partially replace Ni and Fe, altering their chemical states27,28. Among the metal elements constituting the thin HEO film on the Ga₂O₃ layer, Fe and Co exhibit higher valence states compared to other elements, which are considered to contribute to higher OER activity29,30,31. Other elements, such as Mn, play an indispensable role in maintaining their high valence states and high OER activity through alloying and synergistic effects31. The presence of multiple cations with different electronegativities and oxidizabilities facilitates the bonding of intermediates and subsequent oxidation steps during the OER process32. The surface chemical states of each element in the HEO film formed on Ga2O3 and those in the HEO formed on CP are the same, without obvious peak shift, which proves that different substrates do not affect the surface valence states of HEO. This demonstrates that the ligand effect between the HEO film and the underlying Ga2O3 substrate makes no change to the surface of the catalyst33. It should be noted that the XPS spectra of the 2p orbitals of transition metals often overlap with the Auger peaks. Such overlaps also occur in this work, making it difficult to perform elemental quantitative analysis of the HEO34,35. The surveys of CP/Ga2O3@HEO and CP/HEO also show the presence of each surface element. Besides, we measured the XPS of other CP/Ga2O3@metal oxides, which are compared with the XPS spectra of corresponding elements of CP/Ga2O3@HEO (Supplementary Figs. 15–22). For the CP/Ga2O3@quaternary metal oxides (MnFeCoNi, FeCoNiZn), CP/Ga2O3@ternary metal oxides (MnCoNi, FeCoNi), CP/Ga2O3@binary metal oxides (MnFe, FeNi), CP/Ga2O3@unary metal oxide (Mn), the chemical states of the corresponding elements are essentially the same, but compared to the HEO film, the peak positions are slightly shifted, which is due to the different elemental compositions towards different coordination environments of each element, further confirming that the elements are well mixed on their surfaces36. In CP/Ga2O3@unary metal oxide, Ni is present in the form of NiO, different from multimetal oxide films37. The different elemental compositions in metal oxides affect the chemical valence of each element, thereby influencing the overall electrocatalytic performance, which occurs on the catalysts’ surface.

Formation mechanism of HEO films using the Ga oxide layer

By using both DFT calculations and experimental methods, we studied the formation mechanism of HEO film on the Ga oxide layer and the way in which the Ga oxide layer stabilized and regulated the HEO film as a substrate. As shown in Supplementary Fig. 23a, b, the interfacial structures of HEO with Ga2O3 and graphite carbon were constructed, respectively. According to the calculation results, chemical bonds form on the interface between the Ga2O3 substrate and the HEO film, with a 2.3% lattice misfit, indicating that Ga2O3 not only has a strong affinity for HEO films, but also exerts a strain effect on HEO, a finding that corroborates the previous results. However, the conditions for HEO film on carbon substrate are dissimilar: after relaxation, HEO film tends to separate from the carbon substrate. This demonstrates that no chemical bonds can be established between carbon and HEO film, and HEO film cannot remain stably present on carbon. Supplementary Fig. 23c shows DFT calculations of the work of separation between the HEO film and Ga2O3/graphite carbon. The work of separation between HEO and Ga2O3 is 2.38 J/m2, and that between HEO and carbon is 0.03 J/m2, indicating that the bonding energy between HEO and Ga2O3 is higher. The work of separation between Ga₂O₃ and HEO, as well as that between CP and HEO, was also experimentally measured using TG, which similarly indicates that Ga₂O₃ and HEO exhibit stronger binding interactions (Supplementary Fig. 24). This can be observed even more clearly from the charge density difference images. In the 3D charge density difference images (Supplementary Fig. 23d, e and Supplementary Data 1, 2), we can see that the electrons are accumulated at the interface between HEO and Ga2O3, while the interface between HEO and carbon shows a dispersion distribution trend, with no electron accumulation. Analyzing the two-dimensional differential charge-density diagram of closely packed surfaces enables this trend to be observed more quantitatively (Supplementary Fig. 23f, g). All these results demonstrate that Ga2O3 can stabilize HEO as a substrate, creating favorable conditions for the growth of HEO films.

To more intuitively simulate and observe the adhesion of liquid Ga on conductive substrate, liquid Ga droplets were electroplated onto the TEM grid with a carbon substrate (Fig. 3a and Supplementary Fig. 25). Compared with Supplementary Fig. 3, the adhesion between Ga and the carbon substrate is stronger in the TEM samples prepared by electroplating. Electroplating allows positively charged Ga droplets to be fully captured by the negatively charged TEM grid, demonstrating that electroplating enables liquid Ga droplets to adhere firmly to the conductive substrate. To further demonstrate the affinity of the Ga oxide layer for multiple metal elements, the liquid Ga-attached TEM grid was wetted with a mixed-metal salt solution. The HAADF and elemental mapping results in Fig. 3b demonstrate that metal ions can be adsorbed uniformly on the surface of the oxide layer to reduce the surface energy19. This shows that the oxide layer of liquid Ga has a strong affinity for multiple metal ions, which lays the foundation for the subsequent formation of a thin HEO film. The TEM image of the electroplated and metal salt-wetted liquid Ga droplets is shown in Fig. 3c, d, and the enlarged view of the edge part reveals that the outer surface of the droplets is amorphous. After heating at 650 °C for 10 min, some indistinct lattices form on the surface of Ga oxide, and the outer surface is no longer completely amorphous, indicating that the HEO film is undergoing crystal growth (Fig. 3e, f). After heating at 650 °C for 30 min, a crystalline film forms on the surface of the substrate (Fig. 3g, h). Therefore, with the accumulation of heating time, a crystalline HEO film gradually forms. That is to say, the Ga oxide layer can adsorb metal elements and promote the growth of highly crystalline HEO films on its surface as a substrate. In addition, through electroplating, the precursor of the Ga2O3 substrate (liquid Ga droplets) can adhere tightly to the carbon surface, further enhancing the conductivity of the core-shell particles as electrocatalysts. An in-situ Raman measurement was also conducted on the salt-wetted Ga-electroplated CP with increasing temperature to reveal the formation mechanism of HEO on Ga2O3 substrate (Supplementary Fig. 26). With the increase in temperature, noticeable redshifts in the Raman characteristic bands of HEO were observed. This phenomenon is attributed to the increasingly tight bonding between HEO and the Ga₂O₃ substrate, where the tensile strain effect is exerted by Ga₂O₃ on HEO38,39. We also tried to synthesize HEO film on other substrates using similar methods (Supplementary Figs. 27–29). Metal oxide films formed on the surface of other substrates (TiO2, Al2O3, CuO), and their element distribution is uneven, with many areas of particle agglomerations. Uniform films covering the substrate surfaces are difficult to form. The quantitative data in HEO on different substrates also show very uneven element distribution (Supplementary Table 4–6). These results all indicate that the synthesis of HEO film has failed on these substrates. Through a series of comparative experiments, the particularity of the Ga oxide layer can be further verified.

a Preparation and observation of a metal-nitrate mixed solution, wetted liquid Ga droplets attached TEM grid. b HAADF-EDS images of the liquid Ga droplet electroplated on a TEM grid after dropping a mixed metal salts solution. Scale bar is 0.5 μm. c, d TEM image of liquid Ga droplet after dropping mixed metal salts solution and enlarged view of the edge. The scale bars are 200 nm and 5 nm. e, f TEM image of Ga2O3@HEO after heating at 650 °C for 10 min and enlarged view of the edge. The scale bars are 100 nm and 5 nm. g, h TEM image of Ga2O3@HEO after heating at 650 °C for 30 min and enlarged view of the edge. d, f, h are the enlarged TEM images of the box area in (c, e, g), respectively. The scale bars are 100 nm and 5 nm.

Electrocatalytic performance and mechanism study

The OER electrocatalytic performance of CP/Ga2O3@HEO in alkaline solution was evaluated via a typical three-electrode system, and CP/Ga2O3, CP/HEO, commercial RuO2 were also tested under the same conditions for comparison (Fig. 4). The linear sweep voltammograms (LSV) in Fig. 4a shows that CP/Ga2O3@HEO has the lowest overpotential of 323 mV and 408 mV at both 10 mA cm−2 and 100 mA cm−2 (denoted as η10 and η100), superior to 497 mV η10 of CP/Ga2O3 (η100 is too high to measure), 424 mV η10 and 566 mV η100 of CP/HEO, and 332 mV η10 and 486 mV η100 of commercial RuO2. The comparison of the η10 and η100 values for CP/Ga2O3@HEO and different control groups are shown by the bar chart in Fig. 4c. Compared with CP/Ga2O3@HEO, the much higher overpotential of CP/HEO is reasonable. As discussed earlier, the HEO electrocatalyst grown directly on the CP surface exhibits a bulky morphology, as well as a tendency toward separation between the HEO and CP rather than tight chemical bonding. These issues reduce conductivity, affect mass transfer efficiency, and ultimately result in unsatisfactory electrocatalytic performance40. Previous studies also demonstrated that the distribution and morphology of HEO can make major changes to the OER reaction41,42. In addition, slight adjustments to the constituent elements of HEO can also affect its overall performance43. Moreover, CP/Ga2O3@HEO exhibits a low Tafel slope of 43 mV dec−1, much smaller than CP/Ga2O3 (86 mV dec−1), CP/HEO (83 mV dec−1), and commercial RuO2 (60 mV dec−1), suggesting that the reaction rate of CP/Ga2O3@HEO is the highest among all the tested samples (Fig. 4b). For CP/Ga2O3@HEO, electroplating makes the precursor of Ga2O3, i.e., liquid Ga droplets, bond closely to the surface of CP, and tight chemical bonding is established between Ga2O3 and HEO, so that they can play a synergistic effect together to maximize the conductivity and mass transport efficiency of the whole system. Furthermore, Ga2O3 substrates not only facilitates the formation of HEO thin films, but also influence their crystal lattice by providing internal tensile stress. The morphology greatly increases the exposed surface area and active sites of HEO for electrocatalytic reactions. All these factors greatly enhance the OER performance of CP/Ga2O3@HEO. The η10 and Tafel slope are also compared with that of other similar high-entropy oxides (Supplementary Table 7). The Nyquist plots of CP/Ga2O3@HEO, CP/Ga2O3 and CP/HEO were measured to evaluate the charge-transfer resistance (Rct) (Supplementary Fig. 30). The firm binding between the CP and the electroplated liquid Ga-derived Ga2O3 leads to the low Rct of CP/Ga2O3@HEO and CP/Ga2O3, in stark contrast to the much higher Rct of CP/HEO.

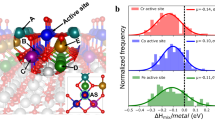

a, b Linear sweep voltammetry (LSV) curves and Tafel slopes of CP/Ga2O3@HEO, CP/Ga2O3, CP/HEO and RuO2 with a scan rate of 5 mV/s. c Overpotentials of CP/Ga2O3@HEO, CP/Ga2O3, CP/HEO and RuO2 at 10 and 100 mA cm−2. d Double layer capacitance (Cdl) of CP/Ga2O3@HEO, CP/Ga2O3, and CP/HEO. e Electrochemical active surface area (ECSA) and turnover frequency (TOF) at an overpotential of 350 mV of CP/Ga2O3@HEO, CP/Ga2O3, and CP/HEO. f OER free-energy landscape of CP/Ga2O3@HEO and CP/HEO. All the measurements were tested in 1.0 M KOH solution as the electrolyte (pH = 13.6 ± 0.2) at room temperature without iR correction. The catalyst loading varies depending on the parameters used for liquid gallium electroplating. Source data are provided as a Source Data file.

To calculate the electrochemical active surface area (ECSA) values of CP/Ga2O3@HEO, CP/Ga2O3, and CP/HEO, the electrochemical double-layer capacitance (Cdl) of these samples were measured (Fig. 4d and Supplementary Fig. 31)44. The Cdl values of CP/Ga2O3@HEO, CP/Ga2O3, and CP/HEO are 42.82, 11.71, and 27.56 mF cm-2. Based on Cdl, the ECSA values of the three are calculated to be 1070.50, 292.75, 689.00 cm2, respectively (Fig. 4e)45. The ECSA of CP/Ga2O3@HEO is higher than those of CP/Ga2O3 and CP/HEO, suggesting that the rational design of the catalyst can expose more active sites. The turnover frequency (TOF) values of the above three samples are also calculated to reveal their intrinsic activities (Fig. 4e)45. At a overpotential of 350 mV, the TOF values of CP/Ga2O3@HEO, CP/Ga2O3, and CP/HEO are 0.073, 0.0053, 0.0048 s-1, which confirms the best intrinsic activity of CP/Ga2O3@HEO for electrocatalytic OER, comparing with CP/Ga2O3 and CP/HEO.

To further study the electrocatalytic mechanism, DFT calculations were conducted on the optimized structure of both CP/Ga2O3@HEO and CP/HEO as shown in Supplementary Fig. 23a, b. The most favorable configurations of OER intermediates with the lowest energies on the two catalysts are shown in Supplementary Figs. 32 and 33. The free energy changes are calculated based on the following four-step reactions:

and denoted as ΔG2, ΔG3, ΔG4, ΔG5. The overpotential of the whole OER reaction is determined by the step with the largest free energy change (η = (ΔG2, ΔG3, ΔG4, ΔG5)max/e− − 1.23 V). The free-energy landscape in Fig. 4f indicates that the OER rate-determining steps for both CP/Ga2O3@HEO and CP/HEO are (2), while the free-energy barrier of CP/Ga2O3@HEO is smaller than CP/HEO to some extent. The differences between the ΔG3 value of CP/Ga2O3@HEO and CP/HEO are consistent with the above OER test results. In addition to the free energy change, we also performed Climbing Image Nudged Elastic Band (CI-NEB) calculations from a kinetic perspective for the two key rate-determining steps, i.e., (3) and (4) (Supplementary Fig. 34). The results show that the reaction energy barrier of Ga₂O₃@HEO (2.90 eV) is slightly lower than that of CP/HEO (3.05 eV), indicating that HEO with a Ga₂O₃ substrate also has a kinetic advantage. From the above results, it can be deduced that the Ga2O3 substrate not only promotes the formation of thin HEO film and enhances its stability, but it also introduces a strain effect that results in lower reaction barriers and improved catalytic properties.

Furthermore, we also tested the electrocatalytic performance of other CP/Ga2O3@metal oxides (Supplementary Fig. 35). As the configuration entropy values of the metal oxides increase, a general trend of decreasing η10 and Tafel slope in the measured samples can be observed. In comparison to these control groups, CP/Ga2O3@HEO shows the best OER performance, with the smallest η10 and Tafel slope. This demonstrates that the high entropy effect can enhance the OER performance of the catalysts. In addition, the OER performance of CP/Ga2O3@HEO synthesized at varied electroplating voltages and times was measured to further study how different electroplating parameters affect the distribution of Ga precursors and ultimately impact their OER performance (Supplementary Figs. 36 and 37). CP/Ga2O3@HEO prepared from moderately and uniformly distributed liquid Ga precursors exhibits the best OER performance, comparing with other control groups. This stems from the fact that the substrate particles are too small and sparsely distributed, and the total area of the substrate is too small, causing a large amount of HEO to nucleate directly on CP, and preventing Ga2O3 from fully playing its role in synthesizing a uniform, stable HEO film with strain effects. When the substrate particles are too large or too aggregated, the specific surface area of Ga2O3 decreases, and there is a tendency toward Ostwald ripening between the particles, which is also detrimental to the performance of the HEO film in electrocatalysis. The precursors prepared with electroplating parameters of 8 V, 10 s exhibit the best OER performance, comparing with those prepared with different electroplating parameters. This further demonstrates the importance of Ga2O3 substrates in regulating the performance of composite CP/Ga2O3@HEO catalysts. The LSV curves before and after cycles were measured to test the stability of CP/Ga2O3@HEO (Supplementary Fig. 38). After 200 cycles, η10 and η100 of CP/Ga2O3@HEO increase by only 4 mV and 5 mV, respectively. It can be clearly observed that the LSV curves of the CP/Ga2O3@HEO before and after 200 cycles almost overlap each other, indicating the high stability of CP/Ga2O3@HEO. To evaluate its operation durability, the amperometric i-t curve was measured for 100 h, and the current density of CP/Ga2O3@HEO at a constant potential of 1.5 V decreased by 29% (Supplementary Fig. 39), and the leaching of elements in the electrolyte was studied by inductively coupled plasma mass spectrometry (ICP-MS), where the concentrations of Mn, Fe, Co, Ni, Zn were 0.12, 0.13, 0.10, 0.11, 0.10 mg/L. The XRD, XPS, and SEM after OER tests further show the stability of CP/Ga2O3@HEO catalyst (Supplementary Figs. 40–42).

Discussion

In this study, the oxide layer of liquid Ga is found to be an ideal substrate for preparing a thin HEO film. The deformability of the liquid phase allows it to be easily dispersed onto substrates to increase the surface area for supporting HEO film growth and enhancing the conductivity of the catalyst. Through experiments and DFT calculations, it is revealed that the affinity of the Ga oxide layer for different metal elements and multimetal oxides promotes the formation and stabilization of thin HEO films on its surface. Simultaneously, the Ga oxide substrate can exert a strain effect while establishing chemical bonding with the HEO. The synergistic interaction among the HEO film, Ga oxide, and CP enables it to function as an efficient electrocatalyst with a lower free-energy carrier. Consequently, compared with other control groups, CP/Ga2O3@HEO exhibits better OER performance as a non-noble electrocatalyst.

Methods

Reagents and materials

All chemicals were of analytical grade and were used without further purification. Gallium, Nafion solution, and CuO were purchased from Sigma-Aldrich. Mn(NO3)2·6H2O, Fe(NO3)3·9H2O, Co(NO3)2·6H2O, Ni(NO3)2·6H2O, Zn(NO3)2·6H2O, NaOH, TiO2, Al2O3, KOH, nitric acid, hydrochloric acid, and absolute ethyl alcohol were purchased from Fujifilm Wako Pure Chemical Co. Graphite electrodes were purchased from AS ONE, with 100% purity. Carbon paper was purchased from Toray. All chemical reagents used were of analytical grade.

Synthesis of CP/Ga

CP was soaked in a mixed solution of concentrated hydrochloric acid and concentrated nitric acid with a volume ratio of 3:1 for 24 h as pre-treatment. The acid-treated CP was then washed several times and dried. Subsequently, the CP was cut into rectangular pieces of a suitable size for electroplating. We used NaOH solution as an electroplating solution to remove the self-forming oxide layer of Ga. The NaOH solution was prepared by dissolving NaOH in deionized water and stirring until fully dissolved, to obtain a concentration of 0.5 M. The electrolyte can be stored at room temperature. We poured 10 mL electroplating solution and 1 mL liquid Ga into a beaker. The wire connected to the positive pole of the direct power supply was immersed in liquid Ga, while the CP, serving as the negative electrode, was immersed into the electroplating solution without contacting Ga. To compare the effects of different electroplating conditions on the size and distribution of the Ga droplets, as well as their influence on the electrocatalytic performance of the subsequently prepared catalysts, the voltage of the direct current power supply was initially set to 8 V. Electroplating was then carried out for 4, 7, 10, 13, and 16 s, respectively. Subsequently, the voltage was adjusted to 6, 7, 8, 9, and 10 V, and electroplating was performed for 10 s. This process yielded a series of CPs with varying Ga droplet sizes and distributions (Supplementary Figs. 4 and 5). The electroplating conditions of an 8 V voltage and 10 s duration were chosen as the most reasonable electroplating parameters. The CPs were washed and dried for the following steps. All the surfaces of the gallium droplets were covered by an oxide layer.

Synthesis of CP/Ga2O3

CP/Ga2O3 was prepared by heating CP/Ga in a tube furnace in a 97% N2 and 3% O2 atmosphere. The temperature was raised to 650 °C within 30 min and maintained for 2 h. It was then cooled down to room temperature within 30 min to obtain CP/Ga2O3.

Synthesis of CP/HEO

A mixed solution of manganese nitrate, iron nitrate, cobalt nitrate, nickel nitrate, and zinc nitrate in ethanol was prepared, with a total concentration of 1 M. The acid-treated CP was then immersed in the mixed solution for 5 s and dried. Finally, the CP was heated in a tube furnace using the same heating process as preparing CP/Ga2O3 to obtain CP/HEO.

Synthesis of Ga2O3-supported metal oxide films-attached CPs

First, specific mixed-metal nitrate ethanol solutions with a total metal ion concentration of 1 M were prepared in advance according to the compositions of multielement metal oxide films. To prepare CP/Ga2O3@HEO, for example, a mixed ethanol solution of manganese nitrate, iron nitrate, cobalt nitrate, nickel nitrate, and zinc nitrate was necessary. CP/Ga was then immersed in a specific mixed-metal salt solution for 5 s and dried. The metal salt-attached CP/Ga samples were heated in a tube furnace using the same sintering parameters as above to obtain different CP/Ga2O3@metal oxide films.

Synthesis of Ga droplet and Ga2O3@HEO-attached TEM grid

We used NaOH solution as an electroplating solution and poured to 10 mL of the electroplating solution and 1 mL liquid Ga in a beaker. To avoid damage to the TEM grid, electroplating was first conducted using CP as a negative electrode before using the TEM grid, and a wire connected to liquid Ga was used as the positive electrode. The voltage of the direct current power supply was initially set to 8 V, and electroplating was then carried out for 20 s until the electroplating solution was full of liquid Ga droplets, whose color changed from transparent to turbid. The electroplating voltage was then changed to 4 V, and the negative electrode was changed to a copper TEM grid. The TEM grid was quickly immersed in the electroplating solution and removed. In this way, enough liquid Ga droplets can be captured on the TEM grid while the carbon support film was protected from being damaged by the high voltage. After washing with ethanol and dring, the mixed solution of manganese nitrate, iron nitrate, cobalt nitrate, nickel nitrate, and zinc nitrate with a total metal ion concentration of 1 M in ethanol was dropped onto the liquid Ga droplets attached to the TEM grid, so that the distribution and adsorbed state of metals on the Ga oxide layer could be measured.

Ga2O3@HEO samples after heating at 650 °C for different periods were prepared by a method similar to that of CP/Ga2O3@HEO, except that the heating time was changed to 10 and 30 min.

Synthesis of TiO2@HEO, Al2O3@HEO, and CuO@HEO

Powders of TiO2, Al2O3, and CuO were dispersed in ethanol by ultrasonication, and suspensions of the three were dropped on CP and dried, respectively. Then, the above-mentioned mixed-metal salt solutions were dropped onto the CP so that TiO2, Al2O3, and CuO were wetted by the mixed-metal salts. After drying, the CPs were heated at 650 °C for 2 h. For TEM characterization, the Ga2O3@HEO-attached CPs were shook off using strong ultrasound.

Characterization

PXRD patterns were measured with a Rigaku SmartLab powder diffractometer equipped with a Cu radiation source (λ = 0.15406 nm). The surface morphology of catalyst-loaded CP was observed with a ZEISS Gemini 560 scanning electron microscope. FE-STEM and HAADF-STEM were measured on a JEOL JEM-2100F with an acceleration voltage of 200 kV. TEM-EDS was performed using a JEOL JED-2300. Samples for transmission electron microscopy were prepared by stripping a minimal amount of catalyst particles attached to carbon paper through the use of intense ultrasonication. XPS spectra were conducted on a JEOL JPS-9100. The carbon peak at 284.7 eV was set as a reference for calibration. Direct observation of liquid Ga droplet was conducted by an optical microscope (OLYMPUS BX53). In-situ Raman spectroscopic measurement was performed by Horiba LabRAM HR Evolution. Thermogravimetry (TG) was performed with Rigaku 8120E2. The leaching of elements in the electrolyte during the electrocatalysis process was tested using inductively coupled plasma mass spectrometry (ICP-MS, Agilent 7800).

Electrochemical measurements

All the electrochemical measurements were conducted using a CHI 760EN electrochemical workstation (BAS Inc.) under ambient conditions, which used a three-electrode single-compartment cell system. The fabrication methods for the CP working electrodes of different control groups are described in the section above, which were then cut into a size of 0.15 cm² for electrocatalytic testing. The catalyst loading varies depending on the parameters used for liquid gallium electroplating. Detailed information is provided in Supplementary Figs. 4 and 5. The ink of RuO2 catalyst was prepared by mixing 4 mg of commercial RuO2 catalyst with 237.5 μL of deionized water, 712.5 μL of ethanol, and 5% Nafion (50 μL), followed by a 30 min ultrasonic dispersion process. Ten μL of ink was drop-cast onto a 3 mm-diameter glassy carbon electrode in two steps (5 μL each time). A graphite rod was used as the counter electrode, and a saturated calomel electrode (SCE, a saturated KCl) as a reference electrode. The data for all the electrochemical tests were obtained by an electrochemical workstation directly and collected for plotting. Before electrochemical tests, the SCE was calibrated in a saturated potassium chloride solution, which was used as the working electrode and a standard SCE was used as the reference to measure the open-circuit voltage between the two electrodes for no less than 1 h. Then, the theoretical values were determined using the Nernst equation with temperature correction applied. The reproducibility of the three measurements should be within ± 5 mV. We used 1.0 M KOH solution as the electrolyte (pH = 13.6 ± 0.2), which was prepared by adding 5.6 g of solid potassium hydroxide into 100 mL deionized water, stirring for at least 5 min, followed by argon purging. All potentials were calibrated versus the reversible hydrogen electrode (vs. RHE) using the following formula (6):

Polarization behavior was measured by linear sweep voltammetry (LSV) at 5 mV·s−1. The ECSA was measured by scanning the CV in a non-Faradaic region. Then, the ECSA was calculated using the following formula (7):

where Cdl is the double-layer capacitance measured from CV; C0 is the specific capacitance of a flat surface. The TOF values of the electrocatalysts are calculated using the following formula (8):

J is the current density at given overpotentials; A is the surface area of the electrode; F is the Faraday constant (96485 C mol−1); n is the mole number of active metals. At least three independent measurements were performed to determine the standard deviation.

Electrochemical impedance spectroscopy (EIS) measurements were conducted within a frequency range from 1 Hz to 106 Hz. The ohmic Rct values of CP/Ga2O3@HEO and CP/Ga2O3 are too low to be accurately fitted and quantified. The ohmic Rct values of CP/Ga2O3@HEO is fitted to be 0.55 ± 0.07 Ω. All the measurements were tested without iR correction.

Parameter setting of DFT calculations

All calculations were conducted using the DFT code - Vienna ab-initio simulation package (VASP)46 with periodic conditions and the plane-wave basis sets32. The interactions between electron ions were handled by the method of the projector-augmented wave theory46,47,48. The generalized gradient approximation method (GGA) was utilized to describe the exchange-correlation energy49,50. The cut-off energy was set to 500 eV. K-points obtained by the Monkhorst-Pack method51 were set to 2 × 8 × 4 for bulk Ga2O3, 5 × 5 × 5 for bulk HEO, and 2 × 2 × 1 for all the slabs and interfaces. The vacuum layer was 10 Å in thickness. The energy changes and the maximum stress converge to 1.0 × 10-5 eV/atom and 0.01 eV/A, respectively. The climbing image nudged elastic band (CI-NEB) method is employed to obtain the transition state and energy barrier for different pathways. Three images between the initial and final configurations are inserted and relaxed until the maximum residual force falls below 0.03 eV/Å.

Calculation of lattice mismatch

The lattice mismatch was calculated using Bramfitt’s two-dimensional lattice mismatch theory52. According to this theory, the lattice mismatch of the Ga₂O₃/HEO interface can be determined using the following formula (9)52,53:

\({(hkl)}_{{{{\rm{H}}}}}\) and \({(hkl)}_{{{{\rm{G}}}}}\) are low-index lattice planes of HEO and Ga₂O₃ phase, respectively; \({[uvw]}_{{{{\rm{H}}}}}\) and \({[uvw]}_{{{{\rm{G}}}}}\) are low-index crystal orientations in \({(hkl)}_{{{{\rm{H}}}}}\) and \({(hkl)}_{{{{\rm{G}}}}}\), respectively; \({d}_{{[uvw]}_{{{{\rm{H}}}}}}\) and \({d}_{{[uvw]}_{G}}\) are the interatomic spacing along \({[uvw]}_{{{{\rm{H}}}}}\) and \({[uvw]}_{{{{\rm{G}}}}}\); θ is the angle between the \({[uvw]}_{{{{\rm{H}}}}}\) and \({[uvw]}_{{{{\rm{G}}}}}\).

Calculation of work of separation of different interfaces

The work of separation Wsep is closely related to interface characteristics, which can be used to estimate the bonding strength of the interface54,55. Wsep is defined as the reversible work to separate an interface into two free surfaces, as calculated via the following formula (10)54,55,56:

\({E}_{1/2}\) is the total energy of the interface; A is the interface area; \({E}_{1}\) is the laminate energy of Ga2O3 or the graphite slab, correspondingly; \({E}_{2}\) is the laminate energy of the HEO slab.

Data availability

Source data are provided in this paper.

References

Chang, X. J., Zeng, M. Q., Liu, K. L. & Fu, L. Phase engineering of high-entropy alloys. Adv. Mater. 32, e1907226 (2020).

Ma, Y. J. et al. High-entropy energy materials: challenges and new opportunities. Energ. Environ. Sci. 14, 2883–2905 (2021).

Sun, Y. F. & Dai, S. High-entropy materials for catalysis: A new frontier. Sci. Adv. 7, eabg1600 (2021).

Li, H. N. et al. Nano high-entropy materials: synthesis strategies and catalytic applications. Small Struct. 1, https://doi.org/10.1002/sstr.202000033 (2020).

Jalan, V. & Taylor, E. J. Importance of interatomic spacing in catalytic reduction of oxygen in phosphoric-acid. J. Electrochem. Soc. 130, 2299–2301 (1983).

Hou, Z. Q. et al. Lattice-strain engineering for heterogenous electrocatalytic oxygen evolution reaction. Adv. Mater. 35, e2209876 (2023).

Li, H. D. et al. Fast site-to-site electron transfer of high-entropy alloy nanocatalyst driving redox electrocatalysis. Nat. Commun. 11, 5437 (2020).

Yao, Y. G. et al. High-entropy nanoparticles: synthesis-structure-property relationships and data-driven discovery. Science 376, 151 (2022).

Zhan, C. H. et al. Medium/high-entropy amalgamated core/Shell nanoplate achieves efficient formic acid catalysis for direct formic acid fuel cell. Angew. Chem. Int. Ed. 62, e202213783 (2023).

Patel, R. K. et al. Thickness dependent OER electrocatalysis of epitaxial thin film of high entropy oxide. Appl. Phys. Rev. 10, 031407 (2023).

Wang, T. Y. et al. The controlled large-area synthesis of two dimensional metals. Mater. Today 36, 30–39 (2020).

Yin, H., Yang, R. S., Wang, S. H. & Jin, K. X. Manipulation of 2DEG at double-doped high-entropy heterointerfaces. Nanoscale 14, 9771–9780 (2022).

Li, W., Liu, P. & Liaw, P. K. Microstructures and properties of high-entropy alloy films and coatings: a review. Mater. Res. Lett. 6, 199–229 (2018).

Zhao, C. et al. Suppressing strain propagation in ultrahigh-Ni cathodes during fast charging via epitaxial entropy-assisted coating. Nat. Energy 9, 345–356 (2024).

Daeneke, T. et al. Liquid metals: fundamentals and applications in chemistry. Chem. Soc. Rev. 47, 4073–4111 (2018).

Lin, Y. L., Genzer, J. & Dickey, M. D. Attributes, fabrication, and applications of gallium-based liquid metal particles. Adv. Sci. 7, https://doi.org/10.1002/advs.202000192 (2020).

Zavabeti, A. et al. A liquid metal reaction environment for the room-temperature synthesis of atomically thin metal oxides. Science 358, 332–335 (2017).

Carey, B. J. et al. Wafer-scale two-dimensional semiconductors from printed oxide skin of liquid metals. Nat. Commun. 8, 14482 (2017).

Syed, N. et al. Printing two-dimensional gallium phosphate out of liquid metal. Nat. Commun. 9, 3618 (2018).

Ding, Y. R., Zeng, M. Q. & Fu, L. Surface chemistry of gallium-based liquid metals. Matter 3, 1477–1506 (2020).

Hoshyargar, F., Crawford, J. & O’Mullane, A. P. Galvanic replacement of the liquid metal galinstan. J. Am. Chem. Soc. 139, 1464–1471 (2017).

Hu, L., Wang, L., Ding, Y. J., Zhan, S. H. & Liu, J. Manipulation of liquid metals on a graphite surface. Adv. Mater. 28, 9210 (2016).

Göransson, D. J. O. et al. Measurements of strain and bandgap of coherently epitaxially grown wurtzite InAsP-InP core-Shell nanowires. Nano Lett. 19, 2674–2681 (2019).

Kim, D., Shcherbakov-Wu, W., Ha, S. K., Lee, W. S. & Tisdale, W. A. Uniaxial strain engineering via core position control in CdSe/CdS core/shell nanorods and their optical response. ACS Nano 16, 14713–14722 (2022).

George, E. P., Raabe, D. & Ritchie, R. O. High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019).

Kang, Y. et al. Mesoporous multimetallic nanospheres with exposed highly entropic alloy sites. Nat. Commun. 14, 4182 (2023).

Biesinger, M. C., Lau, L. W. M., Gerson, A. R. & Smart, R. S. C. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Sc, Ti, V, Cu and Zn. Appl. Surf. Sci. 257, 887–898 (2010).

Biesinger, M. C. et al. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl. Surf. Sci. 257, 2717–2730 (2011).

Li, N., Hadt, R. G., Hayes, D., Chen, L. X. & Nocera, D. G. Detection of high-valent iron species in alloyed oxidic cobaltates for catalysing the oxygen evolution reaction. Nat. Commun. 12, https://doi.org/10.1038/s41467-021-24453-6 (2021).

Zhu, Y. M. et al. Improving the activity for oxygen evolution reaction by tailoring oxygen defects in double perovskite oxides. Adv. Funct. Mater. 29, https://doi.org/10.1002/adfm.201901783 (2019).

Abdelhafiz, A., Wang, B., Harutyunyan, A. R. & Li, J. Carbothermal shock synthesis of high entropy oxide catalysts: dynamic structural and chemical reconstruction boosting the catalytic activity and stability toward oxygen evolution reaction. Adv. Energy Mater. 12, 2200742 (2022).

Kante, M. V. et al. A high-entropy oxide as high-activity electrocatalyst for water oxidation. ACS Nano 17, 5329–5339 (2023).

Li, M. G. et al. Exclusive strain effect boosts overall water splitting in PdCu/Ir core/shell nanocrystals. Angew. Chem. Int. Ed. 60, 8243–8250 (2021).

Einert, M. et al. Sol-gel-derived ordered mesoporous high entropy spinel ferrites and assessment of their photoelectrochemical and electrocatalytic water splitting performance. Small 19, 2205412 (2023).

Huang, P.-C., Chu, P.-C., Yang, T.-J., Wang, J.-Z. & Lin, W.-C. Investigation of the corrosion behavior of AlCoCrFeNi high-entropy alloy in 0.5 M sulfuric acid solution using hard and soft X-ray photoelectron spectroscopy. Appl. Surf. Sci. 648, 158942 (2024).

Liu, Q., Cong, H. J. & Deng, H. X. Deciphering the spatial arrangement of metals and correlation to reactivity in multivariate metal-organic frameworks. J. Am. Chem. Soc. 138, 13822–13825 (2016).

Biesinger, M. C., Payne, B. P., Lau, L. W. M., Gerson, A. & Smart, R. S. C. X-ray photoelectron spectroscopic chemical state quantification of mixed nickel metal, oxide and hydroxide systems. Surf. Interface Anal. 41, 324–332 (2009).

Süess, M. J. et al. Analysis of enhanced light emission from highly strained germanium microbridges. Nat. Photonics 7, 466–472 (2013).

Li, H. et al. Optoelectronic crystal of artificial atoms in strain-textured molybdenum disulphide. Nat. Commun. 6, 7381 (2015).

Lyu, S. L. et al. Exceptional catalytic activity of oxygen evolution reaction via two-dimensional graphene multilayer confined metal-organic frameworks. Nat. Commun. 13, 6171 (2022).

Triolo, C. et al. Evaluation of electrospun spinel-type high-entropy (Cr0.2Mn0.2Fe0.2Co0.2Ni0.2)3O4, (Cr0.2Mn0.2Fe0.2Co0.2Zn0.2)3O4 and (Cr0.2Mn0.2Fe0.2Ni0.2Zn0.2)3O4 oxide nanofibers as electrocatalysts for oxygen evolution in alkaline medium. Energy Adv. 2, 667–678 (2023).

Tian, X. F. et al. Rapid, self-sacrificing template synthesis of two dimensional high-entropy oxides toward high-performance oxygen evolution. J. Mater. Chem. A 12, 3276–3282 (2024).

Stenzel, D. et al. High-entropy spinel-structure oxides as oxygen evolution reaction electrocatalyst. Front. Energy Res. 10, https://doi.org/10.3389/fenrg.2022.942314 (2022).

Anantharaj, S., Karthik, P. E. & Noda, S. The significance of properly reporting turnover frequency in electrocatalysis research. Angew. Chem. Int. Ed. 60, 23051–23067 (2021).

Kibsgaard, J. & Jaramillo, T. F. Molybdenum phosphosulfide: an active, acid-stable, earth-abundant catalyst for the hydrogen evolution reaction. Angew. Chem. Int. Ed. 53, 14433–14437 (2014).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Troullier, N. & Martins, J. L. Efficient pseudopotentials for plane-wave calculations. Phys. Rev. B 43, 1993–2006 (1991).

Monkhorst, H. J. & Pack, J. D. Special points for brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Bramfitt, B. L. The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metall. Trans. 1, 1987–1995 (1970).

Jin, H. X. et al. First-principles theoretical and experimental studies of effects of ruthenium on precipitation behavior of μ phase and μ/matrix interface stability in Ni-based single crystal superalloys. Intermetallics 113, 106556 (2019).

Dudiy, S. V. & Lundqvist, B. I. Wetting of TiC and TiN by metals. Phys. Rev. B 69, https://doi.org/10.1103/PhysRevB.69.125421 (2004).

Jin, H. X. et al. Atomistic mechanism of phase transformation between topologically close-packed complex intermetallics. Nat. Commun. 13, 2487 (2022).

Liu, L. M., Wang, S. Q. & Ye, H. Q. First-principles study of polar Al/TiN(111) interfaces. Acta Mater. 52, 3681–3688 (2004).

Acknowledgements

This research was supported by the JST-ERATO Yamauchi Materials Space-Tectonics Project (JPMJER2003, Y. Y. and Y. S.) and the Japan Society for the Promotion of Science (JSPS Kakenhi No. 24F24036, W. Z., JSPS Kakenhi No. 22F22348, H. J.). This work was the result of using research equipment (SmartLab, JEM-2100F, JED-2300, JPS-9100) shared in the MEXT Project for promoting public utilization of advanced research infrastructure (Program for supporting construction of core facilities) Grant Number JPMXS0440500024.

Author information

Authors and Affiliations

Contributions

Y.S. and Y.Y. supervised the research. W. Z. and H.J. wrote the paper. W.Z. designed the experiments and performed the experimental studies, as well as characterization analysis. H.J. performed the theoretical calculations and relevant analysis. W.Z., H.J., Y.S., Y.Y., Y.G., Y.C., J.Q., and J.Z. discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

Authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Ben Breitung, Marcus Einert, Ugur Unal, and the other anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, W., Jin, H., Guo, Y. et al. A universal approach for thin high-entropy oxides regulated by Ga2O3 layers for oxygen evolution reaction. Nat Commun 16, 6667 (2025). https://doi.org/10.1038/s41467-025-60399-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-60399-9