Abstract

Ethylene glycol is a monomer of the plastic polyethylene terephthalate (PET) and an environmental pollutant of increasing concern. Although it is generally accepted that bacteria use ethylene glycol as growth substrate, not all involved enzymes are well understood. Here, we show that Paracoccus denitrificans assimilates ethylene glycol solely via NAD-dependent alcohol and aldehyde dehydrogenases. Using comparative proteomics, we identify a gene cluster that is strongly expressed in the presence of ethylene glycol. We report the functional and structural characterization of EtgB and EtgA, key enzymes encoded by this etg gene cluster. We furthermore show that the transcriptional activator EtgR controls expression of the gene cluster. Adaptive laboratory evolution on ethylene glycol results in faster growth, enabled by increased production of EtgB and EtgA. Bioinformatic analysis reveals that the etg gene cluster is widely distributed among bacteria, suggesting a common role of NAD-dependent dehydrogenases in microbial ethylene glycol assimilation.

Similar content being viewed by others

Introduction

Polyethylene terephthalate (PET) is one of the most commonly used plastics, utilized in synthetic fibers, water containers, and food packaging. From the 1990s onward, the demand for PET, and therefore its production, increased exponentially. This increased usage of PET has resulted in a staggering accumulation of undegraded plastic waste. Nearly 80% of the 6.3 billion tons of plastic waste that had been generated as of 2015 were accumulated in landfills or the natural environment1. Moreover, the production of PET relies heavily on non-renewable fossil fuels, exacerbating environmental concerns over its widespread use2. In alignment with principles of environmental sustainability, the biotechnological upcycling of PET has recently emerged as a compelling solution3. Since the discovery of PETase, a hydrolase capable of depolymerizing this polyester4, enzymatic plastic breakdown is increasingly considered as a promising solution for managing PET waste. This enzyme and its improved derivatives, such as FAST-PETase5, Combi-PETase6, or HotPETase7, enable the breakdown of PET into bis(2-hydroxyethyl) terephthalate (BHET) and mono(2-hydroxyethyl) terephthalate (MHET). Subsequently, the enzyme MHETase is responsible for further degradation of MHET into ethylene glycol and terephthalic acid4. The metabolic capability of microorganisms to utilize these monomers of PET for growth has been explored in various biotechnological applications, especially in the context of bioremediation and bioconversion processes aimed at transforming plastic waste into useful products using genetically engineered bacteria8,9,10,11,12,13,14.

Ethylene glycol is a two-carbon alcohol with two hydroxy groups (Fig. 1). Besides being a PET monomer, ethylene glycol is also used in other polyester resins and fibers15 as well as antifreeze agents and solvents. In 2022, the annual production capacity of ethylene glycol amounted to 57 million tons. Recently, it has gained increased attention as a next-generation feedstock in microbial biotechnology16,17. This compound is assimilated aerobically or anaerobically by microorganisms as a source of carbon and energy18,19,20,21. Mycobacterium sp. converts ethylene glycol to acetaldehyde via a coenzyme B12-dependent diol dehydratase, followed by further conversion to acetate22. The acetogen Acetobacterium woodii also dehydrates ethylene glycol to acetaldehyde, which is subsequently disproportionated to ethanol and acetate23. But in the most common metabolic pathway for ethylene glycol assimilation, the alcohol is initially oxidized to glycolaldehyde by alcohol dehydrogenases18 (Fig. 1). In Pseudomonas putida JM37 and KT2440, the two pyrroloquinoline quinone (PQQ)-dependent enzymes PedE and PedH act as catalysts for this process24,25,26. In Rhodococcus jostii RHA1, mycofactocin (MFT) is the cofactor for the oxidation of ethylene glycol by an alcohol dehydrogenase27,28. However, PQQ- or MFT-dependent enzymes are limited to bacteria that possess the ability to synthesize the relevant cofactors; a large majority of bacteria only encode for nicotinamide adenine dinucleotide (NAD)-dependent alcohol dehydrogenases in their genomes. It is currently unclear to what extent NAD-dependent alcohol dehydrogenases enable efficient growth on ethylene glycol, since many characterized enzymes only exhibit poor kinetic parameters for the oxidation of this diol to glycolaldehyde (Supplementary Table 1). For example, the model bacterium Escherichia coli does not naturally grow on ethylene glycol; only an evolved strain with increased activity of the NADH-dependent lactaldehyde reductase FucO was capable of relatively slow growth (growth rate µ: 0.1 h−1) 29,30.

Many bacteria oxidize ethylene glycol to glycolaldehyde using alcohol dehydrogenases with NAD+, PQQ, or MFT as cofactor. Subsequently, glycolaldehyde is oxidized to glycolate and further to glyoxylate, which can enter central carbon metabolism via the glycerate pathway or the β-hydroxyaspartate cycle. In an alternative pathway, ethylene glycol is dehydrated to acetaldehyde, which is disproportionated into acetate and ethanol or converted into acetyl-CoA.

Glycolaldehyde is further oxidized to glycolate by NAD-dependent aldehyde dehydrogenases. Glycolate is converted into glyoxylate by glycolate oxidase18. Finally, glyoxylate enters central carbon metabolism via the glyoxylate shunt31 or dedicated pathways for net assimilation of glyoxylate (Fig. 1). To date, two net assimilation pathways for glyoxylate have been identified. The glycerate pathway is present in model bacteria, including E. coli and P. putida, and converts two molecules of glyoxylate into one molecule of 2-phosphoglycerate26,32,33. Notably, the reaction sequence of this metabolic route involves the release of carbon dioxide and is energetically inefficient. The second pathway for net glyoxylate assimilation was first discovered in the 1960s in the Alphaproteobacterium Paracoccus denitrificans34,35; however, the comprehensive characterization of the β-hydroxyaspartate cycle (BHAC) was only completed much later36. This cyclic pathway catalyzes the energetically efficient conversion of two molecules of glyoxylate into the four-carbon compound oxaloacetate without the release of carbon dioxide. Due to its favorable characteristics, the BHAC has been introduced into the model plant Arabidopsis thaliana as an alternative photorespiration pathway37 and into P. putida KT2440 as an alternative pathway for ethylene glycol assimilation. The P. putida strain engineered with the BHAC reached a growth rate of 0.24 h−1, which was further increased to 0.31 h−1 by adaptive laboratory evolution12. However, while the growth of P. denitrificans itself on ethylene glycol was recently demonstrated38, the involved catabolic enzymes have not been characterized experimentally.

In this work, we use comparative proteome analysis to identify a gene cluster in P. denitrificans that includes genes encoding for a transcriptional regulator (which we termed EtgR), an alcohol dehydrogenase (which we termed EtgB), and an aldehyde dehydrogenase (which we termed EtgA). Both dehydrogenases are NAD-dependent. We show that the alcohol dehydrogenase EtgB exhibits a relatively high affinity for ethylene glycol, while also catalyzing the oxidation of various other alcohols. The aldehyde dehydrogenase EtgA efficiently converts glycolaldehyde into glycolate, enabling the subsequent conversion of glycolate to glyoxylate, which then enters central carbon metabolism via the BHAC. The cryo-EM structures of EtgA and EtgB, determined at 3.1 and 3.0 Å resolution, respectively, provide a detailed insight into the active site of these enzymes and a starting point for structure-guided mutagenesis. Furthermore, we show that the transcriptional regulator EtgR functions as an activator of ethylene glycol assimilation, and that evolved P. denitrificans strains are capable of faster growth on ethylene glycol due to increased activity of EtgB and EtgA. Our investigation demonstrates that NAD-dependent dehydrogenases indeed enable efficient assimilation of ethylene glycol, and that similar gene clusters are widely distributed in bacteria. These findings elucidate key steps in the microbial transformation of ethylene glycol in the environment and pave the way for future applications of EtgB and EtgA in biocatalysis and PET upcycling.

Results

P. denitrificans can grow on ethylene glycol

To identify enzymes involved in ethylene glycol metabolism of P. denitrificans, we first tested its growth on minimal medium with this compound as the sole source of carbon and energy. The bacterium was growing on all tested concentrations of ethylene glycol, with an optimum growth rate at 400 mM (Fig. 2a). However, growth of P. denitrificans on 400 mM ethylene glycol was still considerably slower than on glycolate or glyoxylate (Fig. 2b). We observed an increased lag phase during growth on ethylene glycol, when compared to growth on glycolate or glyoxylate. The same phenotype was previously observed for P. putida JM37 and ascribed to the required induction of additional enzymes26.

a Growth rates of P. denitrificans on different concentrations of ethylene glycol. Data are the mean ± s.d. of n = 6 independently grown cultures. Results were compared using an unpaired t-test with Welch’s correction in GraphPad Prism 8.1.1. *: significantly different from growth rate with lower and higher concentrations of ethylene glycol (p-values in order of increasing ethylene glycol concentration: 0.0001; 0.0001; 0.017; 0.0009; 0.0001; 0.0001). b Growth curves of P. denitrificans on 60 mM glycolate (orange), 60 mM glyoxylate (purple), and 400 mM ethylene glycol (light red). Data are the mean ± s.d. of n = 6 independently grown cultures, with error bars shown in lighter colors. Source data are provided as a Source Data file.

Next, we performed mass spectrometry-based whole-cell shotgun proteomics to analyze the proteome of P. denitrificans growing on either ethylene glycol or glyoxylate. With this approach, we aimed to identify the enzymes that are involved in ethylene glycol oxidation. We observed that the enzymes of the BHAC as well as several enzymes of the TCA cycle were downregulated on ethylene glycol, which is in line with the observed lower growth rate (Fig. 3). Notably, the P. denitrificans homologs of FucO and AldA, which catalyze the conversion of ethylene glycol to glycolate in an evolved strain of E. coli29,30,39, were not strongly upregulated (Supplementary Fig. 1). Instead, a gene cluster comprising a NAD-dependent aldehyde dehydrogenase (Gene ID: Pden_2366; Uniprot ID: A1B4L2), a NAD-dependent alcohol dehydrogenase (Pden_2367; A1B4L3), and a protein of unknown function (Pden_2368; A1B4L4) was strongly upregulated. We hypothesized that these enzymes might be involved in the conversion of ethylene glycol to glycolate and therefore termed these genes etgA, etgB, and etgC, respectively. Furthermore, the three subunits of glycolate oxidase and the transcriptional regulator GlcR, which acts as an activator for the glycolate oxidase gene cluster40, were strongly upregulated on ethylene glycol. This indicates that glycolate oxidase, and not glyoxylate reductase, as previously proposed38, is responsible for the oxidation of glycolate to glyoxylate.

a Analysis of the proteome of ethylene glycol-grown P. denitrificans compared to glyoxylate-grown P. denitrificans via mass spectrometry-based whole-cell shotgun proteomics. All proteins quantified by at least three unique peptides are shown, and the proteins involved in central carbon metabolism that showed the strongest decrease or increase in abundance are marked in red or blue in the volcano plot, respectively. b The log2 fold change of these proteins, sorted by locus name (in brackets). c The role of these up- and downregulated proteins in central carbon metabolism of P. denitrificans. Source data are provided as a Source Data file.

Moreover, the large subunit of PQQ-dependent methanol dehydrogenase (MxaF) was upregulated, together with several other proteins encoded by genes in the mxa gene cluster. We wondered whether this promiscuous enzyme41,42 might be involved in ethylene glycol assimilation. Therefore, we generated two P. denitrificans ΔmxaF strains, in which the gene was replaced with a kanamycin resistance cassette in either the same or the opposite direction of transcription to exclude any polar effects. As expected, these gene deletion strains were unable to grow on methanol (Supplementary Fig. 2a). However, their growth rate on different concentrations of ethylene glycol was not significantly different from the growth rate of the WT (Supplementary Fig. 2b). We therefore concluded that the PQQ-dependent methanol dehydrogenase is not involved in ethylene glycol assimilation in P. denitrificans. Finally, acetone carboxylase (AcxAB) was also strongly upregulated on ethylene glycol. The production of this enzyme is known to be induced by acetone and isopropanol43,44, while our results suggest that ethylene glycol or a downstream metabolite might also have an inducing effect in P. denitrificans.

Structural and functional characterization of EtgA and EtgB

Next, we investigated the potential involvement of the etg gene cluster in ethylene glycol assimilation. We hypothesized that the alcohol dehydrogenase EtgB can convert ethylene glycol into glycolaldehyde, which is subsequently further converted into glycolate by the aldehyde dehydrogenase EtgA. To test this hypothesis, we generated P. denitrificans ΔetgA and ΔetgB strains, in which the respective gene was replaced with a kanamycin resistance cassette in either the same or the opposite direction of transcription to exclude any polar effects. These gene deletion strains grew WT-like on succinate (Supplementary Fig. 3a), but their growth rate on different concentrations of ethylene glycol was significantly decreased compared to the growth rate of the WT (Supplementary Fig. 3b). We therefore concluded that EtgB and EtgA are the key enzymes for the conversion of ethylene glycol into glycolate in P. denitrificans. In the absence of one of these enzymes, other alcohol or aldehyde dehydrogenases might be able to catalyze the respective conversion with low efficiency, resulting in the observed decreased growth rates. To further investigate EtgB and EtgA, we produced both enzymes in E. coli and subsequently purified them.

We performed enzyme assays confirming that EtgB is indeed an alcohol dehydrogenase that utilizes NAD+ (NADH) as cofactor when converting alcohols to aldehydes (or vice versa). The kinetic parameters of EtgB with seven different substrates are listed in Table 1 (see also Supplementary Fig. 4). We found that this enzyme preferably accepts monoalcohols (ethanol, n-propanol, n-butanol) as substrates. No reaction was observed with methanol as substrate. The enzyme was found to catalyze the dehydrogenation of ethylene glycol, albeit with a kcat/Km value that is 300-fold lower than the kcat/Km for the conversion of ethanol. Nevertheless, when compared with NAD-dependent alcohol dehydrogenases characterized previously, EtgB shows favorable kinetic parameters with ethylene glycol as substrate (Supplementary Table 1). When produced in E. coli K-12, EtgB allowed growth on ethylene glycol (Supplementary Fig. 5). Furthermore, EtgB catalyzes the conversion of acetaldehyde to ethanol with an approximately 100-fold higher catalytic efficiency (kcat/Km) than the conversion of glycolaldehyde to ethylene glycol. To evaluate the suitability of the enzyme for in vitro biocatalysis, we also studied the effect of temperature and pH on the oxidation of ethylene glycol by EtgB. Among the tested conditions, the optimal pH for the reduction direction was 6, while the optimal pH for the oxidation direction was 10. Enzyme activity in the oxidation direction increased with increasing temperature, consistent with a relatively high unfolding temperature of 78 °C (Supplementary Fig. 6).

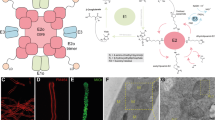

To investigate whether there are specific structural features that facilitate the conversion of ethylene glycol, we obtained the cryo-EM structure of EtgB at 3.0 Å resolution (PDB 9FLZ; Supplementary Fig. 7). The tetrameric EtgB is a class II zinc-dependent medium-chain alcohol dehydrogenase (Fig. 4a, b, Supplementary Table 2). It is structurally similar to previously characterized alcohol dehydrogenases from bacteria and yeast45,46,47,48 (Supplementary Table 3). Its active site contains a catalytic zinc ion and a proton-shuttling system including Thr44 and His47 (Fig. 4c), indicating that the reaction mechanism of EtgB runs analogous to other zinc-dependent alcohol dehydrogenases. In the active site of the structurally similar alcohol dehydrogenase from Pseudomonas aeruginosa (PDB 1LLU), the second hydroxyl group of ethylene glycol interferes with Thr46, which might explain why this diol is a poor substrate (kcat/Km < 23 M−1 s−1) for the enzyme (Fig. 4d, e)45. Therefore, we replaced the analogous Thr44 in EtgB with the smaller, isofunctional Ser to test for improved conversion of ethylene glycol and other diols. We also replaced His47 with Asn to probe the effect of this smaller amino acid on the active site and the proton-shuttling system. Finally, we created a Thr44Ser His47Asn double mutant to evaluate the combined effect of both substitutions. None of these mutations improved the catalytic efficiency for the dehydrogenation of ethylene glycol (Table 1). However, EtgB H47N and especially EtgB T44S H47N showed improved catalytic efficiency with propylene glycol as substrate (ca. three-fold and ca. five-fold improved compared to EtgB WT, respectively). Therefore, the re-design of the proton-shuttling system with smaller amino acids has a positive effect on the conversion of this bulky three-carbon diol substrate. We hypothesize that the mutations may have opened up the active site to better accommodate propylene glycol, while ethylene glycol might not be optimally positioned in the larger active site cavity of these mutant variants of EtgB.

a Cryo-EM map of EtgB with the four monomers shown in different colors. Fourth monomer is not visible in this view. b Left side: front view of the structure of EtgB shown in cartoon representation, with the four monomers shown in different colors. Zinc ions are shown in blue spheres. Green trapezium shows the view in (c) and (d). Right side: top view of EtgB, rotated 90° from front view. c Close up of the active site of EtgB with residues that line the cavity in yellow sticks. Zinc ion shown in blue sphere. d Active site of P. aeruginosa alcohol dehydrogenase45 in complex with NADH and ethylene glycol (EG). Active site residues, NADH and EG shown in sticks. Zinc ion shown in blue sphere. e Surface representation of the EtgB active site, with the NADH molecule from P. aeruginosa alcohol dehydrogenase modeled into the cavity.

Subsequently, we aimed to confirm that EtgA is responsible for the oxidation of glycolaldehyde to glycolate. It was shown previously that this enzyme converts acetaldehyde to acetate49. Enzyme assays revealed that EtgA readily oxidizes glycolaldehyde, albeit with a 2.5-fold lower catalytic efficiency than acetaldehyde (Table 1; Supplementary Fig. 4). We also obtained the cryo-EM structure of EtgA at 3.1 Å resolution (PDB 9FM9; Supplementary Fig. 8), with some density missing in one of the four monomers (Fig. 5a, b). This homotetrameric enzyme is made up of a ‘dimer-of-dimers’, where the main dimer interfaces show Gibbs free energy (ΔG) values of −31.2 kcal/mol, indicative of positive protein affinity (Supplementary Fig. 9). In contrast, the inter-dimer contacts show energetically unfavorable ΔG values of +2.3 and +4.5 kcal/mol, consistent with weak contacts between the ‘dimer-of-dimers’, resulting in flexibility and a weak definition of the cryo-EM map. EtgA is structurally similar to other bacterial aldehyde dehydrogenases50,51 (Supplementary Table 3) and has a canonical active site with catalytic Cys and Glu residues (Fig. 5c). The active site of EtgA is optimized for smaller aldehyde substrates, since Tyr464 takes the space that is occupied by Gly461 and the bulky product molecule indole-3 acetate (IAC) in the structurally similar aldehyde dehydrogenase of Pseudomonas syringae (PDB 5IUW; Fig. 5d) 50. When we introduced a Y464G mutation in EtgA, the resulting mutant enzyme did not catalyze the oxidation of acetaldehyde or glycolaldehyde anymore, supporting the hypothesis that the bulky tyrosine residue is key to the conversion of smaller aldehyde substrates.

a Left side: cryo-EM map of EtgA with the four monomers shown in different colors. The fourth monomer (light blue) is poorly visible in the cryo-EM map. Right side: same map rotated by 180° shows the absence of density for the fourth (light blue) monomer. b Front and top view of the structure of EtgA shown in cartoon representation, with the four monomers shown in different colors. The green star in the lower panel marks the location of the active site. c Close up of the active site of EtgA with residues that line the putative substrate-binding cavity in light pink sticks. d Active site of P. syringae aldehyde dehydrogenase50 in complex with NAD+ and indole-3 acetate (IAC). Active site residues, NAD+, and IAC are shown in magenta sticks. Note that Y464 in EtgA occupies the position of IAC in the P. syringae aldehyde dehydrogenase structure, where G461 is located at the same position.

EtgC is not involved in aerobic ethylene glycol assimilation

To complete our investigation of the etg gene cluster, we sought to investigate the role of EtgC, a small protein of unknown function (12.8 kDa). Phylogenetic analysis revealed that EtgC and its homologs constitute a clade that forms a sister group to iron-sulfur (Fe-S) cluster assembly proteins such as IscA and SufA from E. coli and ErpA from Haemophilus influenzae. Several ferredoxins—electron transfer proteins with Fe-S clusters—that are present in P. denitrificans are less closely related to EtgC (Supplementary Fig. 10). EtgC and its homologs have four conserved cysteines, which commonly serve to coordinate (nascent) Fe-S clusters in ferredoxins or Fe-S cluster assembly proteins52. Comparative analysis of the predicted structure of EtgC demonstrated similarity to the structures of ErpA, SufA, and IscA (Supplementary Table 3). It therefore seemed plausible that EtgC might also contain a Fe-S cluster. Next, we purified the heterologously produced protein and analyzed it via inductively coupled plasma optical emission spectroscopy (ICP-OES) to investigate the presence of iron atoms. Notably, this analysis revealed that neither iron nor cobalt, copper, manganese, or zinc were present in EtgC in stoichiometric amounts (Supplementary Table 4). We therefore concluded that EtgC either does not contain a Fe-S cluster, or that the Fe atom(s) were not properly inserted into the heterologously produced protein.

To investigate a possible role of EtgC in ethylene glycol assimilation, we generated two P. denitrificans ΔetgC strains, in which the gene was replaced with a kanamycin resistance cassette in either the same or the opposite direction of transcription to exclude any polar effects. The growth rate of these gene deletion strains was not significantly different from the growth rate of the WT on different concentrations of ethylene glycol (Supplementary Fig. 11a). We also compared the growth of the WT and ΔetgC strains in the absence of oxygen with nitrate as terminal electron acceptor. Growth of ΔetgC was slightly, but significantly, impaired under these conditions (Supplementary Fig. 11b, c). EtgC is therefore not involved in aerobic ethylene glycol assimilation, while its potential function in anaerobic ethylene glycol metabolism may deserve further investigation.

EtgR acts as activator of the etg gene cluster

The gene Pden_2365 (Uniprot ID: A1B4L1), adjacent to the etgABC gene cluster, is annotated as Fis family transcription factor. We hypothesized that this gene (henceforth called etgR) encodes for a regulator of the etg gene cluster. To test this hypothesis, we generated two gene deletion strains in which etgR was replaced with a kanamycin resistance cassette in either the same or the opposite direction of transcription. Growth assays on different carbon sources showed that ΔetgR grew on succinate just like the WT, but was unable to grow on ethylene glycol and barely grew on ethanol. Growth rates on other alcohols were decreased to a lesser degree (Fig. 6a). We therefore concluded that deletion of etgR abolishes expression of the etg gene cluster, indicating that EtgR acts as an activator. These results suggest that there are no suitable alternative enzymes for the oxidation of ethylene glycol in P. denitrificans, even though several other genes encoding for NAD-dependent alcohol dehydrogenases are present in its genome, and the PQQ-dependent alcohol dehydrogenase MxaF was upregulated on ethylene glycol. In contrast, there must be enzymes that mediate the oxidation of other alcohols, enabling decreased growth of ΔetgR.

a Growth rates of P. denitrificans WT and ΔetgR strains on succinate and different alcohols as sole sources of carbon and energy. n = 3 independent cultures per strain and carbon source. Results were compared using an unpaired t-test with Welch’s correction in GraphPad Prism 8.1.1. ns: not significantly different from WT; *: significantly different from WT (p-values for succinate: 0.2643, 0.4089; ethanol: 0.0008, 0.0007; n-propanol: 0.0032, 0.0054; n-butanol: 0.0285, 0.0237; ethylene glycol: 0.0017, 0.0017; propylene glycol: 0.0042, 0.0026; glycerol: 0.0143, 0.0194). b Growth and fluorescence (red) of P. denitrificans with pTE714-Petg on different carbon sources. Data are the mean ± s.d. of n = 3 independently grown cultures, with error bars shown in lighter colors. Growth and fluorescence of negative control strains are shown in Supplementary Fig. 15. Source data are provided as a Source Data file.

Next, we investigated under which conditions EtgR activates expression of the etg gene cluster. To this end, we created a promoter probe vector in which the gene encoding for mCherry is under the control of Petg, the putative promoter region of the etg gene cluster. Subsequently, we introduced this vector into P. denitrificans and grew the resulting promoter reporter strain on succinate and different alcohols. The Petg promoter reporter vector exhibited strong fluorescence on ethylene glycol, and to a lesser degree on ethanol and propylene glycol. Only low fluorescence was recorded on n-propanol, n-butanol, and glycerol (Fig. 6b). These results are consistent with the decreased growth rates of ΔetgR and suggest that different alcohols (or their downstream metabolites) interact to varying extents with the transcriptional regulator EtgR to activate the Petg promoter. Furthermore, we evaluated growth of the ΔetgR gene deletion strains with the promoter probe vector on minimal medium with 10 mM succinate and 60 mM ethylene glycol (Supplementary Fig. 12). Their limited growth suggests that only succinate was used for growth, and the low background fluorescence as well as the lack of additional fluorescence in the presence of ethylene glycol further confirm the characterization of EtgR as an activator.

Adaptive laboratory evolution of P. denitrificans on ethylene glycol results in faster growth due to increased production levels of EtgB and EtgA

Since P. denitrificans grows faster on glycolate than ethylene glycol (Fig. 2b), we hypothesized that growth rate on the diol is limited by either enzyme kinetic parameters or production levels of EtgB and/or EtgA. To investigate this hypothesis, we performed adaptive laboratory evolution by conducting ten controlled transfers of P. denitrificans on minimal medium containing 200 mM ethylene glycol. Subsequently, we isolated three evolved strains, which will henceforth be referred to as Evo 1, Evo 2, and Evo 3. Notably, these evolved strains exhibited significantly improved growth rates on ethylene glycol compared to the parental WT strain (Supplementary Fig. 13a). To understand the molecular basis of this phenotype, we characterized the three evolved strains via genome resequencing and proteome analysis. All evolved strains were found to have variants in their chromosomes (Table 2).

Interestingly, two evolved strains carry non-silent mutations in etgR, which might alter the expression level of the etgABC genes. The third evolved strain shows strongly increased coverage of a ~90,000 bp region including the etg gene cluster, suggesting that duplication of this chromosomal region might have occurred. Proteome analysis of the evolved strains revealed that the three enzymes EtgA, EtgB, and EtgC, and also the regulator EtgR, were upregulated more strongly, compared to P. denitrificans WT growing on ethylene glycol (Supplementary Fig. 1). In contrast, other alcohol and aldehyde dehydrogenases (MxaF, FucO, AldA) were not upregulated more strongly in the evolved strains, confirming that EtgB and EtgA are indeed the preferred enzymes for the conversion of ethylene glycol into glycolate. Mutations in the coding sequences of etgB or etgA were not observed in any of the evolved strains; therefore, the kinetic parameters of the encoded enzymes must be unchanged compared to the WT.

Next, we investigated the effect of the mutations on the expression of the etg gene cluster by implementing the Petg promoter reporter vector in the evolved strains. Like in the WT, fluorescence was strongly induced during growth on ethanol or ethylene glycol, but the level of fluorescence varied considerably between the WT and evolved strains (Supplementary Fig. 14), confirming that the mutations in etgR result in altered induction capabilities. As an additional line of evidence, we performed enzyme assays for EtgB and EtgA in cell-free extracts of the WT and evolved strains grown on either succinate or ethylene glycol. Enzyme activities of the alcohol or aldehyde dehydrogenases could not be measured in cell-free extracts of succinate-grown cells. However, strong enzyme activities of EtgB and EtgA were detectable in ethylene glycol-grown cells (Supplementary Fig. 13b, c). Notably, EtgB and/or EtgA enzyme activities in all evolved strains were consistently at least twofold higher than those in the WT. This supports the hypothesis that either mutated EtgR variants (in Evo 1 and 2) or gene duplications (in Evo 3) result in increased enzyme levels and therefore higher metabolic flux from ethylene glycol to glycolate, which directly results in increased growth rates of the evolved strains.

Homologs of the etg genes are widely distributed among bacteria

Finally, we aimed to determine whether the etg genes—and therefore the ability to grow on ethylene glycol via NAD-dependent dehydrogenases—are present in other bacteria as well. Our search for EtgR/A/B/C revealed homologs of all four proteins in 3793 bacterial strains, which mostly belong to the classes Alpha- and Gammaproteobacteria, Actinomycetes, Bacilli, and Bacteroidia (Fig. 7a). Strains with homologs of all four proteins are distributed across the bacterial tree of life and also occur in other classes, for example Myxococcia and Acidobacteriae (Fig. 7b, Supplementary Data 1). The arrangement of the four genes as etgRABC is not conserved among this large number of strains (Supplementary Data 2), but there are many examples with an etgABC gene cluster adjacent to either etgR or a gene encoding for another transcriptional regulator. Other strains have a gene cluster consisting of only etgAC and either etgR or a gene encoding for another transcriptional regulator (Fig. 7c), with an etgB homolog located elsewhere in the genome (Supplementary Data 2). In summary, the etg genes, but not necessarily their arrangement as an etgRABC gene cluster, are widely distributed among bacteria and may play a common role in the microbial assimilation of ethylene glycol.

a Phylogenetic distribution of 3793 bacterial strains with homologs of EtgR, EtgA, EtgB, and EtgC in their genomes. b Genome-based phylogenetic tree of bacterial families; families containing strains with EtgR/A/B/C homologs are marked in red. The five bacterial classes named in (a) are highlighted. a, b Taxonomy is based on GTDB91,92 (release R95; https://gtdb.ecogenomic.org/). c Selected examples of etg gene clusters from diverse bacteria. Left: gene clusters with etgA, etgB, etgC, and etgR or another gene encoding for a transcriptional regulator; right: gene clusters with etgA, etgC, and etgR or another gene encoding for a transcriptional regulator. Pairwise identity of homologous proteins is denoted in shades of gray.

Discussion

Ethylene glycol is widely used as a monomer of PET, as a solvent, as an antifreeze agent, and as a next-generation feedstock in microbial biotechnology. Therefore, the investigation of ethylene glycol-converting enzymes and metabolic routes is highly relevant to develop efficient bioprocesses for the upcycling of this diol. Here we confirmed the ability of the soil bacterium P. denitrificans to grow on ethylene glycol as the sole source of carbon and energy. Using a comparative proteomics approach, we observed a notable upregulation in the expression of a gene cluster on ethylene glycol. Subsequently, we characterized this gene cluster, which includes etgR, etgA, etgB, and etgC, in detail. We showed that the NAD-dependent alcohol dehydrogenase EtgB catalyzes the conversion of ethylene glycol to glycolaldehyde with high efficiency in comparison to other alcohol dehydrogenases. Next, glycolaldehyde is further oxidized by the aldehyde dehydrogenase EtgA. The transcriptional regulator EtgR activates expression of the etg gene cluster in the presence of ethylene glycol and other alcohols. We furthermore demonstrate that increased enzyme activities of EtgB and EtgA result in faster growth of evolved strains on ethylene glycol, and that homologs of the etg genes are widely distributed among bacteria.

While the oxidation of ethylene glycol by PQQ- and MFT-dependent alcohol dehydrogenases was characterized previously, it was unclear whether NAD-dependent enzymes can also efficiently mediate this conversion. FucO from E. coli is NAD-dependent, but this iron-containing group III alcohol dehydrogenase53 mainly functions in the anaerobic reduction of lactaldehyde to propylene glycol39, and only mediates the oxidation of ethylene glycol in evolved strains of this model organism29. Gox0313 from Gluconobacter oxydans is NAD-dependent and oxidizes ethylene glycol in vitro54, but growth on this diol is rather mediated by a membrane-bound PQQ-dependent alcohol dehydrogenase55. While the PQQ-dependent methanol dehydrogenase of P. denitrificans is upregulated during growth on ethylene glycol, our work demonstrates that ΔmxaF strains still grow WT-like on ethylene glycol. In contrast, the growth rate of ΔetgB strains on ethylene glycol is strongly decreased. Therefore, EtgB represents an NAD-dependent alcohol dehydrogenase that naturally mediates the growth of its microbial host on ethylene glycol. The relatively good growth rate of P. denitrificans on ethylene glycol with only NAD-dependent enzymes can possibly be ascribed to high production of EtgB and a low Km of EtgA for glycolaldehyde. While the kinetic parameters of EtgB for ethylene glycol conversion are less favorable, they are still among the best reported so far. This makes this enzyme a promising candidate for in vitro biocatalysis, especially when combined with a suitable NAD+ regeneration system. Furthermore, it is likely that EtgB can be engineered to optimize its catalytic performance, based on the structural information reported in this study.

The heterologous production of PQQ-dependent enzymes is difficult, since they are often membrane-bound, localized in the periplasm, and might require the co-production of up to six enzymes for PQQ biosynthesis. Therefore, NAD-dependent dehydrogenases are frequently preferred in metabolic engineering approaches due to their localization in the cytosol and the ubiquity of NAD biosynthesis. Recently, the NAD-dependent alcohol dehydrogenases FucO and Gox0313 were applied to implement synthetic pathways for the conversion of ethylene glycol into 2,4-dihydroxybutyrate56 or aromatic amino acids11 in E. coli. EtgB is a promising enzyme for similar in vivo engineering projects in the future, especially since we demonstrated the growth of E. coli K-12 on ethylene glycol when equipped with EtgB. As an alternative to the heterologous expression of etgB in a host bacterium, P. denitrificans itself could be engineered for the production of value-added molecules from ethylene glycol, since genetic tools for this bacterium57,58 and its close relative Paracoccus pantotrophus59 are available. Besides applications of the enzymes EtgB and EtgA, the transcriptional regulator EtgR is a promising candidate for biosensor development. Future work should focus on its in vitro characterization, followed by the engineering of dynamic and robust sensor modules. A biosensor that rapidly responds to ethylene glycol will enable high-throughput screening of improved strains for both ethylene glycol production60,61,62 and PET degradation9,13,14.

In summary, our results provide comprehensive insights into the assimilation of ethylene glycol by P. denitrificans and demonstrate that NAD-dependent dehydrogenases enable efficient conversion of this diol. Therefore, this study paves the way toward applications of the involved proteins in biocatalysis and metabolic engineering for sustainable production with PET-derived ethylene glycol as feedstock.

Methods

Chemicals and reagents

Unless otherwise stated, all chemicals and reagents were acquired from Sigma-Aldrich (St. Louis, USA) or VWR International BV (Amsterdam, the Netherlands) and were of the highest purity available.

Strains, media and cultivation conditions

All strains used in this study are listed in Supplementary Table 5. Escherichia coli DH5α (for genetic work), ST1863 (for plasmid conjugation to P. denitrificans), BL21 AI (for protein production) and K-12 W3110 (for heterologous expression of etgB) were grown at 37 °C in lysogeny broth64.

Paracoccus denitrificans DSM 41365 and its derivatives were grown at 30 °C in lysogeny broth or in mineral salt medium with TE3-Zn trace elements66 supplemented with various carbon sources. To monitor growth, the OD600 of culture samples was determined on a photospectrometer (Merck Chemicals GmbH, Darmstadt, Germany).

Vector construction

All plasmids used in this study are listed in Supplementary Table 6. To create a plasmid for heterologous overexpression of etgC in E. coli, this gene (Pden_2368) was cloned into the standard expression vector pET16b. To this end, the gene was amplified from genomic DNA of P. denitrificans DSM 413 with the primers provided in Supplementary Table 7. The resulting PCR product was digested with suitable restriction endonucleases (Thermo Fisher Scientific, Waltham, USA) as given in Supplementary Table 7 and ligated into the expression vector pET16b that had been digested with the same enzymes to create a vector for heterologous production of EtgC. The genes encoding for EtgA (Pden_2366) and EtgB (Pden_2367) were cloned into pET16b using the same approach.

To create a plasmid for heterologous expression of etgB in E. coli, this gene (Pden_2367) was cloned into the expression vector pZ-ASS67. To this end, the gene was amplified from genomic DNA of P. denitrificans DSM 413 with the primers provided in Supplementary Table 7. Using Gibson assembly, the resulting PCR product was inserted into the backbone of pZ-ASS that had been amplified from the plasmid pZ-ASS with the primers provided in Supplementary Table 7 to create a vector for heterologous expression of etgB.

To create constructs for gene deletion in P. denitrificans, the upstream and downstream flanking regions of the genes to be deleted from P. denitrificans DSM 413 were cloned into the gene deletion vector pREDSIX58. To this end, the flanking regions were amplified from genomic DNA of P. denitrificans DSM 413 with the primers given in Supplementary Table 7. The resulting PCR products were used to perform Gibson assembly with the vector pREDSIX, which had been digested with MfeI. Subsequently, the resulting vector was digested with NdeI (or KpnI), and a kanamycin resistance cassette, which had been cut out of the vector pRGD-Kan with NdeI (or KpnI), was ligated into the cut site to generate the final vectors for gene deletion.

To create a reporter plasmid for P. denitrificans, the intergenic region between etgR/etgA (Pden_2365/Pden_2366) was cloned into the promoter probe vector pTE71440. The region was amplified from genomic DNA of P. denitrificans DSM 413 with the primers provided in Supplementary Table 7. The resulting PCR product was digested with suitable restriction endonucleases (Thermo Fisher Scientific, Waltham, USA) as given in Supplementary Table 7 and ligated into likewise digested pTE714. Successful cloning of all desired constructs was verified by Sanger sequencing (Macrogen, Amsterdam, the Netherlands).

Production and purification of recombinant proteins

For heterologous overproduction of EtgA, EtgB, and EtgC, the corresponding plasmid encoding for the respective protein was first transformed into chemically competent E. coli BL21 AI cells. The cells were then grown on LB agar plates containing 100 µg mL−1 ampicillin at 37 °C overnight. A starter culture in selective LB medium was inoculated from a single colony on the next day and left to grow overnight at 37 °C in a shaking incubator at 180 rpm. The starter culture was used on the next day to inoculate a production culture in selective TB medium in a 1:100 dilution. The production culture was grown at 37 °C in a shaking incubator at 180 rpm to an OD600 of 0.5 to 0.7, induced with 0.5 mM IPTG and 0.2% L-arabinose and subsequently grown overnight at 18 °C in a shaking incubator at 180 rpm. Cells were harvested at 6000 × g for 15 min at 4 °C, and cell pellets were stored at −20 °C until purification of enzymes.

Cell pellets were resuspended in twice their volume of buffer A (EtgA/EtgB: 300 mM sodium chloride, 25 mM potassium phosphate pH 8.0, 15 mM imidazole, 1 mM β-mercaptoethanol, and one tablet of SIGMAFAST™ protease inhibitor cocktail, EDTA-free, per L; EtgC: identical, but pH 8.5). The cell suspension was treated with a Sonopuls GM200 sonicator (BANDELIN electronic GmbH & Co. KG, Berlin, Germany) at an amplitude of 35% in order to lyse the cells and subsequently centrifuged at 50,000 × g and 4 °C for 1 h. The filtered supernatant (0.45 µm filter; Sarstedt, Nümbrecht, Germany) was loaded onto a Ni-NTA column (Cytiva, Medemblik, the Netherlands) connected to an ÄKTA Start FPLC system (Cytiva, Medemblik, the Netherlands), which had previously been equilibrated with 5 column volumes of buffer A. The column was washed with 20 column volumes of buffer A and 5 column volumes of 85% buffer A and 15% buffer B, and the His-tagged protein was eluted with buffer B (buffer A with 500 mM imidazole). The eluate was desalted using PD-10 desalting columns (Cytiva, Medemblik, the Netherlands) and buffer C (EtgA/EtgB: 100 mM sodium chloride, 25 mM potassium phosphate pH 8.0, 1 mM DTT; EtgC: identical, but pH 8.5). Purified proteins in buffer C were subsequently used for downstream experiments.

Before structure determination, affinity purification was followed by purification on a size exclusion column (Superdex 200 Increase 10/300 GL; Cytiva, Medemblik, the Netherlands) connected to an ÄKTA Pure system (Cytiva, Medemblik, the Netherlands) using buffer C. 500 µL concentrated protein solution was injected, and flow was kept constant at 0.75 mL min−1. Elution fractions containing pure protein were determined via SDS-PAGE analysis68 on 12.5% gels.

Enzyme activity assays

For all enzyme assays, the reduction of NAD+ or oxidation of NADH was followed at 340 nm on a Cary 60 UV-Vis photospectrometer (Agilent, Santa Clara, USA) in quartz cuvettes with a path length of 1 mm (Hellma Optik, Jena, Germany).

The enzyme assays to determine the kinetic parameters of EtgB with different alcohols or aldehydes as substrates were performed at 30 °C in a total volume of 300 µL. The reaction mixture contained 100 mM glycine-NaOH buffer pH 10, 2.4 mM NAD+, different amounts of the respective substrates, and 120 nM EtgB in the alcohol oxidation assays and 100 mM potassium phosphate buffer pH 7.5, 0.2 mM NADH, different amounts of the respective substrates, and 60 nM EtgB in the aldehyde reduction assays. The enzyme assays to determine the kinetic parameters of EtgA with different aldehydes as substrates were performed at 30 °C in a total volume of 300 µL. The reaction mixture contained 100 mM potassium phosphate buffer pH 7.5, 2.4 mM NAD+, different amounts of the respective substrates, and 69 nM EtgA.

Enzyme activity assays in P. denitrificans cell-free extracts

P. denitrificans cultures were collected during mid-exponential phase (OD600 of 0.5–0.7), resuspended in ice-cold 100 mM potassium phosphate buffer (pH 7.2), and lysed by sonication. Cell debris was separated by centrifugation at 35,000 × g and 4 °C for 1 h. Total protein concentrations of the resulting cell-free extracts were determined by Bradford assay69 using bovine serum albumin as standard. The assays for the activity of EtgA and EtgB were performed as described above.

Protein thermal stability measurement

For the purified proteins EtgA, EtgB, and EtgC, the thermal stability was measured using a Tycho NT.6 instrument (NanoTemper Technologies GmbH, Munich, Germany). A constant heating rate of 30 °C per minute was applied to the samples, heating from 35 °C to 95 °C.

Electron microscopy data collection

Cryo-electron microscopy data was collected on a Titan Krios operating at 300 kV (Thermo Fisher Scientific, Eindhoven, the Netherlands) equipped with a BioQuantum energy filter using a slit width of 20 eV and K3 direct electron detector (Gatan, Inc, Pleasanton, CA, USA) at the Netherlands Centre for Electron Nanoscopy (NeCEN). Movies were recorded with EPU software (Thermo Fisher Scientific) operating in electron counting mode and using aberration free image shift (AFIS) at a nominal magnification of 105.000 x (0.836 Å/pixel). The defocus range was set from −0.8 to −2.2 µm and the total accumulated dose to 50 electrons/Å2 (1 e/Å2 per frame).

Electron microscopy data processing

Cryo-electron microscopy data were processed using RELION-5.070. Movies were motion corrected and dose-weighted using MotionCor271 and CTF estimated using CTFFIND-4. Particles were identified with Topaz72 using the standard pre-trained neural network. After extraction, particles were submitted to several rounds of 2D classification, ab-initio model generation and 3D classification. Final 3D reconstructions were obtained after two iterative rounds of 3D refinement, CTF refinement (beam-tilt and aberration correction, anisotropic magnification estimation, and per-particle defocus and per-micrograph astigmatism correction) and Bayesian polishing. The final reconstruction was sharpened and locally filtered using RELION post-processing and yielded a final average resolution of 3.0 Å for EtgB and 3.1 Å for EtgA.

Model building and refinement

Models for monomeric EtgA and EtgB were derived from AlphaFold 273 and superimposed onto the crystal structures of tetrameric Pseudomonas syringae aldehyde dehydrogenase50 (PDB code 5IUW) or tetrameric Pseudomonas aeruginosa alcohol dehydrogenase45 (PDB code 1LLU), respectively. Models were manually adjusted in Coot74 and refined in Phenix75. Figures were prepared using ChimeraX76 and PyMOL77. Interface energy values were calculated using the EBI PISA server78 (https://www.ebi.ac.uk/pdbe/pisa).

Metal content determination of EtgC

Inductively coupled plasma optical emission spectroscopy (ICP-OES) was used for the metal content quantification of EtgC. 0.715 mg of purified EtgC was dissolved in 0.5 mL trace metal grade concentrated nitric acid overnight at room temperature, followed by boiling for 2 h at 70 °C. Samples were diluted to a final volume of 8.5 mL in double-distilled water. Sample analysis was conducted using a 720/725 ICP-OES device (Agilent, Santa Clara, USA), with the following wavelengths used for metal determination: iron (λ = 238.204 nm), cobalt (λ = 228.615 nm), copper (λ = 327.395 nm), manganese (λ = 257.610 nm) and zinc (λ = 213.857 nm). The device was operated with ICP Expert v4.1.0 software (Agilent, Santa Clara, USA), and an ICP multi-element standard solution IV (Merck Chemicals GmbH, Darmstadt, Germany) was used as the standard for the quantification of the metals.

Genetic modification of P. denitrificans

Transfer of replicative plasmids into P. denitrificans was performed via conjugation using E. coli ST18 as the donor strain. As described previously36, E. coli ST18 containing the plasmid to be conjugated was grown on LB agar plates containing 100 µg mL−1 ampicillin, 50 µg mL−1 kanamycin and 50 µg mL−1 aminolevulinic acid at 37 °C overnight. A culture in selective LB medium was inoculated the next day and left to grow overnight at 37 °C. The culture was diluted the next morning to an OD600 of 0.1. A culture of P. denitrificans DSM 413 in LB medium was inoculated from a glycerol stock and grown at 30 °C. ST18 cultures were collected at an OD600 of around 0.7, and the P. denitrificans culture was collected at an OD600 of about 1.3. All cell pellets were washed once with sterile 10 mM MgSO4 and resuspended to an OD600 of approximately 10 in sterile 10 mM MgSO4. Suspensions of ST18 cells and P. denitrificans cells were mixed in a 2:1 ratio and spotted on minimal medium agar plates without any carbon source. Plates were incubated at 30 °C overnight. The next morning, spots were removed from the plates, resuspended in LB medium and plated on selective LB agar plates. Selection of conjugants was performed at 30 °C on LB plates containing 1 µg mL−1 tetracycline. Successful transfer of plasmids into P. denitrificans was verified by colony PCR.

Transfer of gene deletion plasmids into P. denitrificans was performed in the same way. Selection of conjugants was performed at 30 °C on LB agar plates containing 25 µg mL−1 kanamycin. The respective gene deletion was verified by colony PCR and DNA sequencing and the deletion strain was propagated in selective LB medium.

High-throughput growth and fluorescence assays with P. denitrificans and E. coli

Cultures of P. denitrificans DSM 413 WT and its derivatives were pre-grown at 30 °C in LB medium containing 25 µg mL−1 kanamycin or 1 µg mL−1 tetracycline, when appropriate. Cells were harvested, washed once with minimal medium containing no carbon source and used to inoculate growth cultures of 180 µL minimal medium containing an appropriate carbon source as well as 25 µg mL−1 kanamycin or 1 µg mL−1 tetracycline, when appropriate. Growth and fluorescence in 96-well plates (Thermo Fisher Scientific, Waltham, USA) were monitored at 30 °C at 600 nm in a Tecan Infinite M200Pro plate reader (Tecan, Männedorf, Switzerland). Fluorescence of mCherry was measured at an emission wavelength of 610 nm after excitation at 575 nm, with a fixed gain of 100.

Cultures of E. coli K-12 W3110 and its derivatives were pre-grown at 37 °C in LB medium containing 50 µg mL−1 streptomycin, when appropriate. Cells were harvested, washed once with M9 minimal medium containing no carbon source and used to inoculate growth cultures of 180 µL M9 minimal medium containing an appropriate carbon source as well as 50 µg mL−1 streptomycin, when appropriate. Growth in 96-well plates (Thermo Fisher Scientific, Waltham, USA) was monitored at 37 °C at 600 nm in a Tecan Infinite M200Pro plate reader (Tecan, Männedorf, Switzerland).

Anaerobic growth of P. denitrificans

P. denitrificans WT and ΔetgC were grown in sealed vials anaerobically at 30 °C under an argon atmosphere (Air Liquide Deutschland GmbH, Düsseldorf, Germany) in minimal medium containing 30 mM ethylene glycol and 120 mM KNO3. Precultures were grown for 24 h before OD600 was measured. P. denitrificans main cultures were inoculated to an OD600 of 0.05, and OD600 was monitored for 7 days. Growth was monitored by extracting 150 µL of culture with an argon-flushed needle, and OD600 was measured in a 96-well plate (Sarstedt AG & Co. KG, Nümbrecht, Germany) using a Tecan Infinite M Nano+ (Tecan, Männedorf, Switzerland). The growth of four independent cultures was monitored.

Whole-cell shotgun proteomics

To acquire the proteome of P. denitrificans growing on different carbon sources, 30 mL cultures were grown to mid-exponential phase (OD600 ∼ 0.4) in minimal medium supplemented with 60 mM glyoxylate or 60 mM ethylene glycol. Four replicate cultures were grown for each carbon source. Main cultures were inoculated from precultures grown in the same medium in a 1:1000 dilution. Cultures were harvested by centrifugation at 4000 × g and 4 °C for 15 min. Supernatant was discarded, and pellets were washed in 40 mL phosphate-buffered saline (PBS; 137 mM NaCl, 2.7 mM KCl, 10 mM Na2HPO4, 1.8 mM KH2PO4, pH 7.4). After washing, cell pellets were resuspended in 1 mL PBS, transferred into Eppendorf tubes, and centrifuged one more time as described above. Cell pellets in Eppendorf tubes were snap-frozen in liquid nitrogen and stored at −80 °C until they were used for the preparation of samples for LC-MS analysis and label-free quantification.

For protein extraction, bacterial cell pellets were resuspended in 4% sodium dodecyl sulfate (SDS) and lysed by heating (95 °C, 15 min) and sonication (amplitude: 30%, 2 min; Hielscher Ultrasonics GmbH, Teltow, Germany). Reduction was performed for 15 min at 90 °C in the presence of 5 mM tris(2-carboxyethyl)phosphine followed by alkylation using 10 mM iodoacetamide at 25 °C for 30 min. The protein concentration in each sample was determined using the BCA protein assay kit (Thermo Fisher Scientific, Waltham, USA) following the manufacturer’s instructions. Protein cleanup and tryptic digest were performed using the SP3 protocol79 with minor modifications regarding protein digestion temperature and solid phase extraction of peptides. SP3 beads were obtained from GE Healthcare (Chicago, USA). 1 µg trypsin (Promega, Fitchburg, USA) was used to digest 50 μg of total solubilized protein from each sample. Tryptic digest was performed overnight at 30 °C. Subsequently, all protein digests were desalted using C18 microspin columns (Harvard Apparatus, Holliston, USA) according to the manufacturer’s instructions.

LC-MS/MS analysis of protein digests was performed on a Q-Exactive Plus mass spectrometer connected to an electrospray ion source (Thermo Fisher Scientific, Waltham, USA). Peptide separation was carried out using an Ultimate 3000 nanoLC-system (Thermo Fisher Scientific, Waltham, USA), equipped with an in-house packed C18 resin column (Magic C18 AQ 2.4 µm; Dr. Maisch, Ammerbuch-Entringen, Germany). The peptides were first loaded onto a C18 precolumn (preconcentration set-up) and then eluted in backflush mode with a gradient from 94% solvent A (99.85% ddH2O, 0.15% formic acid) and 6% solvent B (99.85% acetonitrile, 0.15% formic acid) to 25% solvent B over 87 min, continued with 25% to 35% of solvent B for an additional 33 min. The flow rate was set to 300 nL/min. The data acquisition mode for the initial LFQ study was set to obtain one high-resolution MS scan at a resolution of 60,000 (m/z 200) with scanning range from 375 to 1500 m/z, followed by MS/MS scans of the 10 most intense ions. To increase the efficiency of MS/MS shots, the charged state screening modus was adjusted to exclude unassigned and singly charged ions. The dynamic exclusion duration was set to 30 s. The ion accumulation time was set to 50 ms (both MS and MS/MS). The automatic gain control (AGC) was set to 3 × 106 for MS survey scans and 1 × 105 for MS/MS scans. Label-free quantification was performed using Progenesis QI (version 2.0). MS raw files were imported into Progenesis, and the output data (MS/MS spectra) were exported in mgf format. MS/MS spectra were then searched using MASCOT (version 2.5) against a database of the predicted proteome from P. denitrificans downloaded from the UniProt database (www.uniprot.org; download date 01/26/2017), containing 386 common contaminant/background proteins that were manually added. The following search parameters were used: full tryptic specificity required (cleavage after lysine or arginine residues); two missed cleavages allowed; carbamidomethylation (C) set as a fixed modification; and oxidation (M) set as a variable modification. The mass tolerance was set to 10 ppm for precursor ions and 0.02 Da for fragment ions for high-energy collision dissociation (HCD). Results from the database search were imported back to Progenesis, mapping peptide identifications to MS1 features. The peak heights of all MS1 features annotated with the same peptide sequence were summed, and protein abundance was calculated per LC-MS run. Next, the data obtained from Progenesis were evaluated using the SafeQuant R-package version 2.2.280.

Computational analysis of etg gene cluster variants

Homologs of EtgR/A/B/C were identified in other bacterial genomes via searching for the PFAM identifiers PF00171, PF00107, PF05610, and PF02954 in AnnoTree81 with a cutoff E value of 1e-10. The lists of identified bacterial strains and homologous proteins are provided in Supplementary Data 1 and 2. The phylogenetic tree shown in Fig. 7b was downloaded from AnnoTree and annotated in Adobe Illustrator 2021. To generate Fig. 7c, sequences of selected etg gene clusters (given in Supplementary Data 3 and 4) were downloaded from the NCBI Nucleotide database (https://www.ncbi.nlm.nih.gov/nuccore), followed by alignment and visualization using CAGECAT/clinker82,83 (https://cagecat.bioinformatics.nl/tools/clinker) and annotation in Adobe Illustrator 2021.

Computational analysis of etgC homologs

Homologs of EtgC were identified in other bacterial genomes via BLAST84 searching and via searching for the PFAM identifier PF05610 in AnnoTree81 with a cutoff E value of 1e-10. To generate the phylogenetic tree shown in Supplementary Fig. 10a, sequences of EtgC homologs and related proteins (given in Supplementary Data 5) were downloaded from the NCBI Protein database (https://www.ncbi.nlm.nih.gov/protein/) and aligned using MUSCLE85. A maximum likelihood phylogenetic tree of the aligned sequences was calculated with MEGA X86 using the Le-Gascuel model87 with 100 bootstraps. The resulting tree was visualized using iTOL88.

The alignment of amino acid sequences shown in Supplementary Fig. 10b was generated using MUSCLE and colored with Jalview89. Sequences used for the alignment are given in Supplementary Data 6. The superimposition of protein structures shown in Supplementary Fig. 10c was generated using Foldseek90.

Visualization and statistical analysis

Data were evaluated and visualized using GraphPad Prism 8.1.1., and results were compared using an unpaired t-test with Welch’s correction in GraphPad Prism 8.1.1.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

Genome sequencing data of evolved P. denitrificans isolates are available in the NCBI SRA database under accession PRJNA1126100. Mass spectrometry proteomics data are available at ProteomeXchange under accession PXD060720. Cryo-EM maps for EtgA and EtgB are deposited in the EMDB under codes EMD-50550 and EMD-50545. Atomic coordinates of EtgA and EtgB are deposited in the PDB under 9FM9 and 9FLZ. Source data are provided with this paper.

References

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, e1700782 (2017).

Narancic, T. & O’Connor, K. E. Microbial biotechnology addressing the plastic waste disaster. Microb. Biotechnol. 10, 1232–1235 (2017).

Wierckx, N. et al. Plastic waste as a novel substrate for industrial biotechnology. Microb. Biotechnol. 8, 900–903 (2015).

Yoshida, S. et al. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science 351, 1196–1199 (2016).

Lu, H. et al. Machine learning-aided engineering of hydrolases for PET depolymerization. Nature 604, 662–667 (2022).

Joho, Y. et al. Enhancing PET degrading enzymes: a combinatory approach. Chembiochem 25, e202400084 (2024).

Bell, E. L. et al. Directed evolution of an efficient and thermostable PET depolymerase. Nat. Catal. 5, 673–681 (2022).

Sullivan, K. P. et al. Mixed plastics waste valorization through tandem chemical oxidation and biological funneling. Science 378, 207–211 (2022).

Tiso, T. et al. Towards bio-upcycling of polyethylene terephthalate. Metab. Eng. 66, 167–178 (2021).

Franden, M. A. et al. Engineering Pseudomonas putida KT2440 for efficient ethylene glycol utilization. Metab. Eng. 48, 197–207 (2018).

Panda, S. et al. Engineering Escherichia coli to produce aromatic chemicals from ethylene glycol. Metab. Eng. 79, 38–48 (2023).

Schada von Borzyskowski, L. et al. Implementation of the beta-hydroxyaspartate cycle increases growth performance of Pseudomonas putida on the PET monomer ethylene glycol. Metab. Eng. 76, 97–109 (2023).

Werner, A. Z. et al. Tandem chemical deconstruction and biological upcycling of poly(ethylene terephthalate) to β-ketoadipic acid by Pseudomonas putida KT2440. Metab. Eng. 67, 250–261 (2021).

Valenzuela-Ortega, M., Suitor, J. T., White, M. F. M., Hinchcliffe, T. & Wallace, S. Microbial upcycling of waste PET to adipic acid. ACS Cent. Sci. 9, 2057–2063 (2023).

Yue, H., Zhao, Y., Ma, X. & Gong, J. Ethylene glycol: properties, synthesis, and applications. Chem. Soc. Rev. 41, 4218–4244 (2012).

Wagner, N., Wen, L., Frazão, C. J. R. & Walther, T. Next-generation feedstocks methanol and ethylene glycol and their potential in industrial biotechnology. Biotechnol. Adv. 69, 108276 (2023).

Shimizu, T. & Inui, M. Novel aspects of ethylene glycol catabolism. Appl. Microbiol. Biotechnol. 108, 369 (2024).

Caskey, W. H. & Taber, W. A. Oxidation of ethylene glycol by a salt-requiring bacterium. Appl. Environ. Microbiol. 42, 180–183 (1981).

Carnegie, D. & Ramsay, J. A. Anaerobic ethylene glycol degradation by microorganisms in poplar and willow rhizospheres. Biodegradation 20, 551–558 (2009).

Child, J. & Willetts, A. Microbial metabolism of aliphatic glycols: bacterial metabolism of ethylene glycol. Biochim. Biophys. Acta 538, 316–327 (1978).

Willetts, A. Bacterial metabolism of ethylene glycol. Biochim. Biophys. Acta 677, 194–199 (1981).

Wiegant, W. M. & De Bont, J. A. M. A new route for ethylene glycol metabolism in Mycobacterium E44. Microbiology 120, 325–331 (1980).

Trifunović, D., Schuchmann, K. & Müller, V. Ethylene glycol metabolism in the acetogen Acetobacterium woodii. J. Bacteriol. 198, 1058–1065 (2016).

Li, W.-J. et al. Laboratory evolution reveals the metabolic and regulatory basis of ethylene glycol metabolism by Pseudomonas putida KT2440. Environ. Microbiol. 21, 3669–3682 (2019).

Wehrmann, M., Billard, P., Martin-Meriadec, A., Zegeye, A. & Klebensberger, J. Functional role of lanthanides in enzymatic activity and transcriptional regulation of pyrroloquinoline quinone-dependent alcohol dehydrogenases in Pseudomonas putida KT2440. mBio 8, e00570-17 (2017).

Mückschel, B. et al. Ethylene glycol metabolism by Pseudomonas putida. Appl. Environ. Microbiol. 78, 8531–8539 (2012).

Shimizu, T., Suzuki, K. & Inui, M. A mycofactocin-associated dehydrogenase is essential for ethylene glycol metabolism by Rhodococcus jostii RHA1. Appl. Microbiol. Biotechnol. 108, 58 (2024).

Roccor, R., Wolf, M. E., Liu, J. & Eltis, L. D. The catabolism of ethylene glycol by Rhodococcus jostii RHA1 and its dependence on mycofactocin. Appl. Environ. Microbiol. 90, e00416-24 (2024).

Boronat, A., Caballero, E. & Aguilar, J. Experimental evolution of a metabolic pathway for ethylene glycol utilization by Escherichia coli. J. Bacteriol. 153, 134–139 (1983).

Caballero, E., Baldomá, L., Ros, J., Boronat, A. & Aguilar, J. Identification of lactaldehyde dehydrogenase and glycolaldehyde dehydrogenase as functions of the same protein in Escherichia coli. J. Biol. Chem. 258, 7788–7792 (1983).

Kornberg, H. L. & Krebs, H. A. Synthesis of cell constituents from C2-units by a modified tricarboxylic acid cycle. Nature 179, 988–991 (1957).

Gupta, N. K. & Vennesland, B. Glyoxylate carboligase of Escherichia coli: a flavoprotein. J. Biol. Chem. 239, 3787–3789 (1964).

Kaplun, A. et al. Glyoxylate carboligase lacks the canonical active site glutamate of thiamine-dependent enzymes. Nat. Chem. Biol. 4, 113–118 (2008).

Kornberg, H. L. & Morris, J. G. β-Hydroxyaspartate pathway: a new route for biosyntheses from glyoxylate. Nature 197, 456–457 (1963).

Kornberg, H. L. & Morris, J. G. The utilization of glycollate by Micrococcus denitrificans: the β-hydroxyaspartate pathway. Biochem. J. 95, 577–586 (1965).

Schada von Borzyskowski, L. et al. Marine proteobacteria metabolize glycolate via the β-hydroxyaspartate cycle. Nature 575, 500–504 (2019).

Roell, M.-S. et al. A synthetic C4 shuttle via the β-hydroxyaspartate cycle in C3 plants. Proc. Natl. Acad. Sci. USA 118, e2022307118 (2021).

Bordel, S., Martín-González, D., Börner, T., Muñoz, R. & Santos-Beneit, F. Genome-scale metabolic model of the versatile bacterium Paracoccus denitrificans Pd1222. mSystems 9, e01077–e01023 (2024).

Chen, Y. M., Zhu, Y. & Lin, E. C. NAD-linked aldehyde dehydrogenase for aerobic utilization of L-fucose and L-rhamnose by Escherichia coli. J. Bacteriol. 169, 3289–3294 (1987).

Schada von Borzyskowski, L. et al. Multiple levels of transcriptional regulation control glycolate metabolism in Paracoccus denitrificans. mBio 15, e01524 (2024).

Kim, H. G. & Kim, S. W. Purification and characterization of a methanol dehydrogenase derived from Methylomicrobium sp. HG-1 cultivated using a compulsory circulation diffusion system. Biotechnol. Bioprocess Eng. 11, 134–139 (2006).

Grosse, S., Voigt, C., Wendlandt, K.-D. & Kleber, H.-P. Purification and properties of methanol dehydrogenase from Methylosinus sp. WI 14. J. Basic Microbiol. 38, 189–196 (1998).

Clark, D. D. & Ensign, S. A. Evidence for an inducible nucleotide-dependent acetone carboxylase in Rhodococcus rhodochrous B276. J. Bacteriol. 181, 2752–2758 (1999).

Sluis, M. K. & Ensign, S. A. Purification and characterization of acetone carboxylase from Xanthobacter strain Py2. Proc. Natl. Acad. Sci. USA 94, 8456–8461 (1997).

Levin, I., Meiri, G., Peretz, M., Burstein, Y. & Frolow, F. The ternary complex of Pseudomonas aeruginosa alcohol dehydrogenase with NADH and ethylene glycol. Protein Sci. 13, 1547–1556 (2004).

Guntupalli, S. R., Li, Z., Chang, L., Plapp, B. V. & Subramanian, R. Cryo-electron microscopy structures of yeast alcohol dehydrogenase. Biochemistry 60, 663–677 (2021).

Contente, M. L. et al. Uncommon overoxidative catalytic activity in a new halo-tolerant alcohol dehydrogenase. ChemCatChem 12, 5679–5685 (2020).

Petratos, K. et al. Structure and dynamics of a thermostable alcohol dehydrogenase from the antarctic psychrophile Moraxella sp. TAE123. ACS Omega 5, 14523–14534 (2020).

Felux, A.-K., Denger, K., Weiss, M., Cook, A. M. & Schleheck, D. Paracoccus denitrificans PD1222 utilizes hypotaurine via transamination followed by spontaneous desulfination to yield acetaldehyde and, finally, acetate for growth. J. Bacteriol. 195, 2921–2930 (2013).

McClerklin, S. A. et al. Indole-3-acetaldehyde dehydrogenase-dependent auxin synthesis contributes to virulence of Pseudomonas syringae strain DC3000. PLoS Pathog. 14, e1006811 (2018).

Shortall, K., Djeghader, A., Magner, E. & Soulimane, T. Insights inTo Aldehyde Dehydrogenase Enzymes: A Structural Perspective. Front. Mol. Biosci. 8, 659550 (2021).

Fontecave, M. & Ollagnier-de-Choudens, S. Iron–sulfur cluster biosynthesis in bacteria: mechanisms of cluster assembly and transfer. Arch. Biochem. Biophys. 474, 226–237 (2008).

Montella, C. et al. Crystal structure of an iron-dependent group III dehydrogenase that interconverts L-lactaldehyde and 1,2-propanediol in Escherichia coli. J. Bacteriol. 187, 4957–4966 (2005).

Zhang, X., Zhang, B., Lin, J. & Wei, D. Oxidation of ethylene glycol to glycolaldehyde using a highly selective alcohol dehydrogenase from Gluconobacter oxydans. J. Mol. Catal. B Enzym.112, 69–75 (2015).

Wei, L.-J. et al. Functions of membrane-bound alcohol dehydrogenase and aldehyde dehydrogenase in the bio-oxidation of alcohols in Gluconobacter oxydans DSM 2003. Biotechnol. Bioprocess Eng. 17, 1156–1164 (2012).

Frazão, C. J. R., Wagner, N., Rabe, K. & Walther, T. Construction of a synthetic metabolic pathway for biosynthesis of 2,4-dihydroxybutyric acid from ethylene glycol. Nat. Commun. 14, 1931 (2023).

Schada von Borzyskowski, L., Remus-Emsermann, M., Weishaupt, R., Vorholt, J. A. & Erb, T. J. A set of versatile brick vectors and promoters for the assembly, expression, and integration of synthetic operons in Methylobacterium extorquens AM1 and other alphaproteobacteria. ACS Synth. Biol. 4, 430–443 (2015).

Ledermann, R., Strebel, S., Kampik, C. & Fischer, H. M. Versatile vectors for efficient mutagenesis of Bradyrhizobium diazoefficiens and other alphaproteobacteria. Appl. Environ. Microbiol. 82, 2791–2799 (2016).

Pal, U. et al. A genetic toolbox to empower Paracoccus pantotrophus DSM 2944 as a metabolically versatile SynBio chassis. Micro. Cell Fact. 23, 53 (2024).

Bourgade, B., Humphreys, C. M., Millard, J., Minton, N. P. & Islam, M. A. Design, analysis, and implementation of a novel biochemical pathway for ethylene glycol production in Clostridium autoethanogenum. ACS Synth. Biol. 11, 1790–1800 (2022).

Zhang, Z. et al. Ethylene glycol and glycolic acid production from xylonic acid by Enterobacter cloacae. Microb. Cell Fact. 19, 89 (2020).

Chen, Z., Huang, J., Wu, Y. & Liu, D. Metabolic engineering of Corynebacterium glutamicum for the de novo production of ethylene glycol from glucose. Metab. Eng. 33, 12–18 (2016).

Thoma, S. & Schobert, M. An improved Escherichia coli donor strain for diparental mating. FEMS Microbiol. Lett. 294, 127–132 (2009).

Bertani, G. Studies on lysogenesis I. J. Bacteriol. 62, 293–300 (1951).

Beijerinck, M. W. & Minkman, D. C. J. Bildung und verbrauch von stickoxydul durch bakterien. Zentralbl Bakteriol. Naturwiss 25, 30–63 (1910).

Hahnke, S. M., Moosmann, P., Erb, T. J. & Strous, M. An improved medium for the anaerobic growth of Paracoccus denitrificans Pd1222. Front. Microbiol. 5, 18 (2014).

Wenk, S., Yishai, O., Lindner, S. N. & Bar-Even, A. An engineering approach for rewiring microbial metabolism in Methods in Enzymology (ed. Scrutton, N.) Ch. 12 (Academic, 2018).

Laemmli, U. K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227, 680–685 (1970).

Bradford, M. M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72, 248–254 (1976).

Zivanov, J. et al. A Bayesian approach to single-particle electron cryo-tomography in RELION-4.0. eLife 11, e83724 (2022).

Zheng, S. Q. et al. MotionCor2: anisotropic correction of beam-induced motion for improved cryo-electron microscopy. Nat. Methods 14, 331–332 (2017).

Bepler, T. et al. Positive-unlabeled convolutional neural networks for particle picking in cryo-electron micrographs. Nat. Methods 16, 1153–1160 (2019).

Jumper, J. et al. Highly accurate protein structure prediction with AlphaFold. Nature 596, 583–589 (2021).

Emsley, P., Lohkamp, B., Scott, W. G. & Cowtan, K. Features and development of Coot. Acta Crystallogr. D 66, 486–501 (2010).

Liebschner, D. et al. Macromolecular structure determination using X-rays, neutrons and electrons: recent developments in Phenix. Acta Crystallogr. D 75, 861–877 (2019).

Meng, E. C. et al. UCSF ChimeraX: tools for structure building and analysis. Protein Sci. 32, e4792 (2023).

The PyMOL Molecular Graphics System, Version 2.0 (Schrödinger, LLC; 2024).

Krissinel, E. & Henrick, K. Inference of macromolecular assemblies from crystalline state. J. Mol. Biol. 372, 774–797 (2007).

Moggridge, S., Sorensen, P. H., Morin, G. B. & Hughes, C. S. Extending the compatibility of the SP3 paramagnetic bead processing approach for proteomics. J. Proteome Res. 17, 1730–1740 (2018).

Glatter, T. et al. Large-scale quantitative assessment of different in-solution protein digestion protocols reveals superior cleavage efficiency of tandem Lys-C/trypsin proteolysis over trypsin digestion. J. Proteome Res. 11, 5145–5156 (2012).

Mendler, K. et al. AnnoTree: visualization and exploration of a functionally annotated microbial tree of life. Nucleic Acids Res. 47, 4442–4448 (2019).

van den Belt, M. et al. CAGECAT: the CompArative GEne Cluster Analysis Toolbox for rapid search and visualisation of homologous gene clusters. BMC Bioinformatics 24, 181 (2023).

Gilchrist, C. L. M. & Chooi, Y.-H. clinker & clustermap.js: automatic generation of gene cluster comparison figures. Bioinformatics 37, 2473–2475 (2021).

Altschul, S. F., Gish, W., Miller, W., Myers, E. W. & Lipman, D. J. Basic local alignment search tool. J. Mol. Biol. 215, 403–410 (1990).

Edgar, R. C. MUSCLE: multiple sequence alignment with high accuracy and high throughput. Nucleic Acids Res. 32, 1792–1797 (2004).

Kumar, S., Stecher, G., Li, M., Knyaz, C. & Tamura, K. MEGA X: molecular evolutionary genetics analysis across computing platforms. Mol. Biol. Evol. 35, 1547–1549 (2018).

Le, S. Q. & Gascuel, O. An improved general amino acid replacement matrix. Mol. Biol. Evol. 25, 1307–1320 (2008).

Letunic, I. & Bork, P. Interactive Tree Of Life (iTOL) v5: an online tool for phylogenetic tree display and annotation. Nucleic Acids Res. 49, W293–W296 (2021).

Waterhouse, A. M., Procter, J. B., Martin, D. M. A., Clamp, M. & Barton, G. J. Jalview Version 2—a multiple sequence alignment editor and analysis workbench. Bioinformatics 25, 1189–1191 (2009).

van Kempen, M. et al. Fast and accurate protein structure search with Foldseek. Nat. Biotechnol. 42, 243–246 (2024).

Parks, D. H. et al. GTDB: an ongoing census of bacterial and archaeal diversity through a phylogenetically consistent, rank normalized and complete genome-based taxonomy. Nucleic Acids Res. 50, D785–D794 (2022).

Parks, D. H. et al. A standardized bacterial taxonomy based on genome phylogeny substantially revises the tree of life. Nat. Biotechnol. 36, 996–1004 (2018).

Acknowledgements

We thank the staff members at the Netherlands Center for Electron Nanoscopy (NeCEN) for their help with data collection. This study was funded by Leiden University, a stipend of the Chinese Scholarship Council (grant CSC202207720003 to M.R.), and the German Research Foundation (DFG grant 446841743 to J.G.R.). T.G., J.G.R., and H.A. are grateful for the generous support of the Max Planck Society. M.H.L. was supported by a Bontius Stichting grant (BS182). Access to NeCEN was supported by the Netherlands Electron Microscopy Infrastructure (NEMI), project 184.034.014 of the National Roadmap for Large-Scale Research Infrastructure of the Dutch Research Council (NWO).

Author information

Authors and Affiliations

Contributions

M.R.: data acquisition, data analysis, figure design, writing. D.L.: data acquisition, data analysis. H.A.: data acquisition, data analysis. W.E.M.N.: data acquisition, data analysis, figure design. E.H.A.: data acquisition, data analysis. T.G.: data acquisition, data analysis. J.H.d.W.: data analysis, supervision. J.G.R.: data analysis, supervision, funding. M.H.L.: data analysis, figure design, supervision, funding. L.S.v.B.: conceptualization, data acquisition, data analysis, figure design, writing, supervision, funding.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Lindsay Eltis, Zongchao Jia and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ren, M., Li, D., Addison, H. et al. NAD-dependent dehydrogenases enable efficient growth of Paracoccus denitrificans on the PET monomer ethylene glycol. Nat Commun 16, 5845 (2025). https://doi.org/10.1038/s41467-025-61056-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-61056-x