Abstract

Active particles, which locally dissipate energy from their environment to function, are useful across disciplines given their dynamic and programmable behaviors. Altering particle shape or surface asymmetry has led to advancements in controlled locomotion or collective behavior for diverse applications such as microrobotics or biomedicine. However, making arbitrary active particles of precise shape and surface composition remains a significant challenge due to limitations in conventional fabrication methods. This paper introduces a fabrication technique that combines two-photon lithography with sacrificial stencil masking to deposit arbitrary metallic patches onto particles of any shape with a limit of resolution as low as 0.2 µm. Using this method, we demonstrate three varieties of active particles displaying nonconventional dynamics: electrokinetic active spheres with tunable three-dimensional motions, catalytic microdiscs with chiral axial spinning, and steric magnetic particles forming self-limiting microrobots. Overall, this high-resolution microstenciling technique offers a versatile strategy to create well-defined active particles and microrobots for numerous practical uses.

Similar content being viewed by others

Introduction

Active microparticles are heavily investigated for use in microrobotics1, biomedicine2, solute capture3, and functional materials fabrication4 due to their ability to harness energy from their environment to achieve higher-order assembly or locomotion. Various stimuli are used to control active particles such as external magnetic, electric, and acoustic fields as well as defined gradients of solute, temperature, or pH either in the environment or produced by the particle itself 5. No matter the system, active particles rely on anisotropy in their environment or encoded within the particle to function. While the shape of the particle can impart the necessary asymmetry to function6,7,8,9, another approach is to create surface asymmetries via compositionally distinct patches10,11. Janus particles, which display two halves of differing compositions, have been widely studied active agents and shown to enable linear propulsion due to their single asymmetrical axis12,13,14. Even with a fairly narrow range of mobility, Janus particles have proven useful in biosensing15, drug delivery16, transport through porous materials17, selective cargo transport18, and more. However, theoretical work has indicated that more complex surface patches lead to more sophisticated motions and functionalities due to additional axes of asymmetry19. On the multiple-particle level, researchers have clustered uniform or Janus microspheres, producing additional axes of asymmetry20,21,22. However, on the single-particle level, glancing angle deposition (GLAD) has enabled experimentalists to create particles with multiaxial asymmetry and begin to understand their more complex structure-function relationships. The Kretzschmar group first created arrays of particles displaying complex surface patches, dubbed ‘patchy particles’, by rotating the substrate relative to the direction of metal deposition, causing neighboring particles to shadow each other23. This fabrication strategy enabled the discovery of patchy particles that undergo directed assembly into percolated networks by dielectrophoresis24, patchy particles displaying helical trajectories in alternating current (AC) electric fields7,25, and particles with faster catalytic speeds by increased surface roughness26. Despite the numerous advances enabled by GLAD, a major challenge remains in creating particles with surface patches that are precise and uniform across batches. This capability remains inaccessible to GLAD because the structure of the patch is dictated by the deposition angle as well as the shape and orientation of neighboring particles, whereby the latter is difficult to control at the macroscale, limiting the potential complexity of patches and thus particle function.

To address this challenge, we introduce an approach to create precise patches on particles of arbitrary shape by combining two-photon lithography with stencil masking. As we show through three separate examples, the patch shape directly influences the motion or assembly of the particles. Specifically, we show that this method (i) enables control of trajectories at the single-particle level in electric and catalytic systems and (ii) is useful for guiding the assembly of structures that facilitate self-limited, reconfigurable magnetic microrobots. Due to the nature of this fabrication method, the shapes of the particles are also readily controlled across three dimensions, enabling use of this technology for applications in diverse areas such as micromanipulation, environmental remediation, and biomedicine.

Results

Fabrication of precise patchy particles

To increase the complexity of active particles, we adapted a sacrificial stencil masking approach that uses two-photon lithography (TPL) combined with physical vapor deposition (PVD) of various metals to fabricate particles with intricate surface and geometric asymmetries (Fig. 1). Our particles and stencils are fabricated from a single negative-tone photoresist, enabling cleaner development for sub-micron patch deposition than previous sacrificial stencil masking methods that use two resists, which we found led to a rougher, beaded surface (Supplementary Figs. 1,2)27. To do so, we engineered the stencils with long, pointed legs to minimize contact of the stencil with the substrate (Supplementary Fig. 3). Thus, the stencils have a smaller contact area with the substrate (i.e., typically <2.0 µm2) than that of the particles (i.e., typically >9.0 µm2), allowing the stencils to be selectively removed upon physical agitation in deionized (DI) water. We optimized the system to enable the precise spatial deposition of various metals to form complex surface patches on non-prismatic shapes, such as spheres, which are commonly studied in the active particle space. By depositing different metals, we show that the precise patchy particles (PPPs) can be used in several contexts, including electrokinetics, catalysis, and magnetics. Overall, this PPP fabrication method is customizable for the fabrication of arbitrarily shaped particles with precise surface patches that have feature sizes down to 200 nm.

a Particles and stencils are printed simultaneously using two-photon lithography. The material of choice is deposited, and the stencils are selectively removed by agitation to reveal precise patchy particles. Substrate is blue, resin is yellow, laser is red, metal is gold, particles fluoresce green. b Schematic illustration of PPP fabrication. Polymer resin is green, metal is black. c CU logo deposited onto a 10 µm diameter sphere. d Complex patch design with a smaller CU logo above a mountain range. Minimum feature size is ≈200 nm. In both cases, the patches comprise 10 nm chromium and 30 nm gold deposited using thermal evaporation. Images in (c, d) were taken using a mix of backscattering and secondary electron microscopy.

Fabrication workflow

To fabricate micron-sized patchy particles, we used two-photon polymerization to produce high-resolution particle-stencil arrays on a borosilicate substrate (Fig. 1a, b). We first washed a borosilicate substrate by rinsing with acetone and isopropyl alcohol (IPA) and drying with a nitrogen gun, before depositing a single drop of IP-L (a commercial, negative-tone TPL resin produced by Nanoscribe) on the surface. We left the resin to sit for 3 h to improve retention of the stencils during the development step. We then printed the particle-stencil arrays in the oil-immersion configuration (Supplementary Movie 1). We used a laser power of 27.5 mW to prevent the stencils from collapsing during printing; however, we found that laser power had to be optimized for each new stencil design and bottle of resin (Supplementary Fig. 4). Within each array, we spaced the particles at least 15 µm apart to allow for even metal coating and prevent the stencils from colliding with each other during the removal process. Directly following each print, the arrays were developed in room temperature SU-8 developer for 12 min and gently rinsed with IPA by spraying the edge of the substrate with a steady stream of IPA and letting it flow across the array.

Following printing and development, we used thermal or electron-beam metal evaporation, two types of PVD, to uniformly cover the particle-stencil arrays with thin coatings of gold, platinum, or cobalt, depending on the application. During this process, transport of the vaporized metal is ballistic, traveling through the open areas of the stencil in nearly straight trajectories, thereby transferring the shape of the stencil opening onto the surface of the underlying particle with high fidelity. We deposited metals using deposition rates25,28 (1–2 Å s−1) and thicknesses12,29,30 (5–100 nm) typically used within the active particle field. Any material that can be deposited using some form of PVD can be adapted to this system. We note that other deposition techniques (e.g., sputter-coating) may be less ballistic, thus reducing the resolution of the patch but increasing the possible coverage area.

We removed the stencils from the particle arrays by physically agitating the substrates in DI water by vortexing (Supplementary Fig. 5) and were left with an array of precise patchy particles (Supplementary Fig. 6). The efficiency of stencil removal varied by the design of the stencil. For most successful prints, ≈86% of stencils were removed after vortexing while ≈94% of the particles remained attached. Finally, we removed and suspended the particles by depositing 10 µL of the suspension solution onto the array, scraping gently with a pipette tip, and then transferring the solution to a tube for storage or an experimental chamber (see Methods).

To demonstrate the precision of patch designs enabled by this PPP fabrication method, we printed two distinct patch shapes with micron to sub-micron features. The first print was the University of Colorado’s “CU” logo, which readily transferred onto 10 µm spherical particles (Fig. 1c). The second print was a smaller “CU” logo with an outline of a mountain ridge beneath it, which contains features as small as 0.2 µm (Fig. 1d). However, one might note that many active particles are <10 µm. Thus, we show that we can fabricate spherical patchy particles with a diameter as low as 3 µm (Supplementary Fig. 7) and non-patchy cubes and spheres with edge-lengths and diameters as low as 2 µm (Supplementary Fig. 8). A brief discussion of methods to further optimize print parameters for the fabrication of smaller structures accompanies these figures. Another benefit to printing smaller structures is that it decreases the print time. Since two-photon lithography is a volumetric printing method, it is more time-intensive than other more traditional photolithography methods, requiring ≈13.5 s to print a single 10 µm spherical particle and its associated stencil.

Resolution of patch deposition

To more rigorously characterize the resolution of the deposited patches, we printed a large rectangle with legs such that the distance between the underside of the stencil and the top of the substrate was approximately the same as that shown in Fig. 1 (≈2 µm; Fig. 2a). We deposited 10 nm of chromium as an adhesive layer and 30 nm of gold via electron-beam evaporation and removed the stencils by sonication for 15 s. Using backscattering electron microscopy (BSE), we imaged and characterized the deposited patches. We measured the resolution of the patches in three ways. First, we determined the line resolution of the patch, as defined by the minimum line width of patches after printing rectangular holes of decreasing width from 3.0 to 0.1 µm (note that the limit resolution of the Nanoscribe instrument is ≈0.2 µm)31. Second, we measured the radius of curvature resolution of the patch, as determined by printing circular holes of decreasing radii from 3.0 to 0.1 µm. Finally, we determined the overall limit of resolution of the patch by printing a triangular hole with an initial height of 2 µm that gradually decreases to a point (Fig. 2b).

a Resolution was tested by depositing 10 nm chromium and 30 nm gold via electron beam deposition through a stencil directly onto the borosilicate substrate after which the stencil was removed. Stencil design contains lines and circles of decreasing width and a gradually tapering triangle. Polymer resin is green, metal is black. b Diagram of resolution stencil with labeled dimensions for line width, circle radius and gradually tapering triangle. Boxes highlight lines analyzed in (e, f, h, i). c SEM images (taken in backscattering mode) comparing deposited metal through stencils fabricated at four different laser powers (LPs), 20, 22.5, 25 and 27.5 mW. d–i Measured values of stencil (d–f) and resulting metallic patch (g–i) line widths at different LPs. d, g Plots with measurements for all line widths. Boxes show line widths that were examined further in (e, f, h, i). e, f, h, i Plots comparing line widths 1.5 and 2.5 across laser powers. All error bars represent standard error of the mean. Statistics were calculated with a one-way ANOVA followed by multiple comparison results *P < 0.05, **P < 0.01 (N = 6 except for stencil LP 25 mW, 0.1 µm line where N = 3; patch LP 25 mW where N = 9 (1 µm line N = 3)). Source data are provided in the Source Data file.

To examine the effects of laser power on patch resolution, we printed four resolution stencil arrays with laser powers (LPs) of 20, 22.5, 25 and 27.5 mW (Fig. 2c). We chose this range empirically, as too low of a laser power (e.g., <20 mW) caused stencils to collapse (Supplementary Fig. 4). Alternatively, too high of a laser power (e.g., >27.5 mW) caused overexposure, decreasing the minimum feature size of the patches and deviating further from the original STL design. We measured the printed stencil hole and resulting deposited metallic patch dimensions for all LPs to assess the line resolution (Fig. 2d, g) and radius of curvature resolution (Supplementary Fig. 9). We found that when plotting the measured stencil hole and deposited metallic patch dimensions for each line and circle, the measured values for all LPs were less than the initial STL file designs for any line or circle above 0.2 µm, indicating there is some polymerization outside of the exposed region, likely due to radical diffusion32. Because the stencils are made from a negative-tone photopolymer, overexposure reduces the opening size and subsequently the deposited patch size. Additionally, when comparing the deposited metallic patches to the printed IP-L stencils, we found that the patches were also smaller than the stencils in all cases. We hypothesize that the thickness of the stencil and the gap between it and the underlying particle account for this discrepancy. We further hypothesize that more ballistic metal deposition procedures can minimize this discrepancy. We expect that if one could design a stencil that is thinner and closer to the particle, while ensuring the stencil is structurally sound (Supplementary Fig. 4) and can readily detach from the substrate (Supplementary Fig. 5), the dimensions of the deposited patch would be closer to the original STL design.

To compare laser powers, we plotted data from four representative features on each plot: 1.5 and 2.5 µm designed line widths (Fig. 2e, f, h, i) and 1.5 µm and 2.5 µm designed circle radii (Supplementary Fig. 9). We found that there was a clear decrease in the line width and circle radii of the printed stencils as LP increased, indicating that higher LPs lead to increased overexposure, causing the holes to shrink. We also found that patches deposited through stencils printed with LP 20 mW were significantly larger, and closer to the STL design, than all three higher LPs. We also studied the effects of voxel size, hatching orientation, and spacing between the stencil and the site of patch deposition (particle) on the patch resolution (Supplementary Figs. 10, 11). A description of the intrinsic tradeoff between hatch size and throughput of precise patchy particle fabrication accompanies these supporting figures.

We report the minimum resolution measurements from the LP 20 mW images because they had the closest feature sizes to the original STL designs. The smallest patches came from the 0.5 µm wide line and 0.5 µm circle radius designs, which resulted in deposited patches of 0.49 ± 0.01 µm (line width resolution) and 0.43 ± 0.01 µm (radius of curvature resolution). The overall minimum feature size, corresponding to the overall limit of resolution, was 0.19 ± 0.01 µm at the thinnest point along the triangle. However, the exact feature size is expected to vary with different deposition systems and conditions based on the type and directionality of deposition as well as the temperature and pressure at which materials are deposited.

Active patchy particles via PPP fabrication

After optimizing the fabrication of the precise patchy particles (Fig. 2 and Supplementary Fig. 9), we sought to demonstrate the usefulness of this method by making active particles with distinctive functional capabilities. We used external electric and magnetic fields, as well as local chemical gradients to show the effects of patch area, shape, and location, as well as particle shape, on the trajectories and assemblies of the precise patchy particles in each of these systems in a way that would be difficult to achieve using contemporary methods.

Electrokinetically powered patchy particles

Previous experimental and theoretical work showed that spherical particles can propel in AC electric fields by adding surface patches with different polarizabilities33. Janus particles, which have two distinct hemispheres with different surface polarizabilities, propel linearly due to their single axis of asymmetry12. When exposed to an AC electric field, the interface between the two hemispheres aligns with the electric field. This is due to an induced dipole within the particle rotating as it seeks the lowest energy orientation, aligning the polarizable region of the particle with the direction of the applied field to obtain a stable configuration in a process known as dielectrophoresis (DEP). Subsequently, the time-averaged asymmetric electro-osmotic flows originating from the asymmetric polarizability enables the particle to propel through induced charge electrophoresis (ICEP)34. Using GLAD23, Lee et al. fabricated particles with additional asymmetries via conductive surface patches, allowing the particles to produce additional components to its motion during ICEP, resulting in helical trajectories25. Using PPP fabrication, we show that distinct helical motions can be produced due to the ability to precisely change the shape of the deposited conductive patches.

To confirm that particles made by the PPP method propel as expected, we started by testing Janus particles fabricated using the same general two-photon process, but with no stencils. These particles were suspended in Milli-Q water and exposed to an AC electric field using a coplanar electrode chamber setup (Fig. 3a). As expected, the particles propelled linearly due to their Janus morphology (Fig. 3b, c). The speeds of the particles increased linearly with the square of the electric field strength, indicating the particles are propelling by ICEP (Fig. 3d)12. All electrokinetic trajectory images shown in Fig. 3 come from a corresponding video compilation (Supplementary Movie 2). The Janus particle trajectories likely deviate slightly from parallel to the electrode due to a combination of imperfections in the electrodes and particle fabrication, such as the need for a slight flattening of the sphere to maintain adhesion of the particle to the substrate during development and stencil removal.

a Coplanar electrode chamber created by two strips of gold separated on a clean glass slide. b Mechanism of ICEP. The gold side (black hemisphere) is more polarizable than the dielectric IP-L side (green hemisphere), inducing an asymmetric fluid flow across the particle, resulting in linear propulsion. c Trajectory of a 10 µm Janus particle fabricated using two-photon lithography and IP-L resin without a stencil. 10 nm chromium and 30 nm gold were deposited using electron-beam deposition. d Speed of TPL-fabricated Janus particles stimulated in 500, 750, 1000, 1250 V cm−1 electric fields at 4 kHz (N = 4, 7, 9, 2). Error bars represent standard error of the mean. e Fabrication mechanism for complex electrokinetic particles. Spherical particle is printed simultaneously beneath a round stencil. 10 nm chromium and 30 nm of gold are deposited through the stencil. The stencil is removed and a complex electrokinetically responsive particle remains. f, g Diagrams of particles showing offset between the axis of asymmetry of the patch and the alignment with the electric field. Movement of TPL-fabricated spheres with two different complex patches that produced distinct trajectories when exposed to an AC electric field: (f) teardrop and (g) propeller. Overlayed particle represents the initial starting position of the particle before the field was activated, determined from the circled point in each trajectory. The handedness of the trajectories is labeled as “R” or “L”. h–j Analysis of helix (h) radius, (i) pitch, and (j) angle from the field direction. First image shows how the measurement was acquired. Plot compares measured values for each patch type: teardrop (T) and propeller (P) (N = 5, 3). All error bars represent the standard error. Statistics were calculated with a two-sample t-test, n.s. not significant, *P < 0.05. Polymer resin is green, metal is black. Source data are provided in the Source Data file.

Using the full PPP fabrication method (Fig. 3e), we fabricated particles with two types of complex patches, a teardrop (Fig. 3f) and a propeller (Fig. 3g). We chose these patch shapes arbitrarily to generate distinct electrokinetic trajectories. We found that particles with teardrop-shaped patches propelled with a broad helical trajectory, displaying large pitches and a steep angle relative to the field direction. Alternatively, particles with propeller-shaped patches moved with a tight helical trajectory, displaying a more consistent helical course. While both helical trajectories had similar radii, the pitch and offset angle of the teardrop particles were roughly double that of the propeller particles (i.e. ≈225 µm and 45° compared to ≈105 µm and 25°, respectively; Fig. 3h–j). While understanding the exact relationship between patch shape and trajectory requires a systematic study of the combined effects of DEP and ICEP acting on these complex metallodielectric particles, we hypothesize the difference in trajectories is a consequence of additional axes of asymmetry due to the shapes of the patches generating multidirectional forces on the bodies of the particles as well as the strength of the dielectrophoretic alignment of the particles33. The offset of the axes of symmetry of the particles and dielectrophoretic alignment of the particles, as shown in the diagrams to the left of Fig. 3f, g, may contribute to the difference in helix angle. We ascribe the small variation in trajectory of particles of the same patch design to contributions from thermal noise and imperfections (beads) on the surfaces of the particles, as these particles were made using the two-resin fabrication method comprising both IP-L and SU-8 (Supplementary Fig. 1).

These findings suggest that the PPP fabrication method can be used to fine-tune the trajectories of metallodielectric particles in an AC electric field in a manner that is otherwise challenging to accomplish with contemporary patchy particle fabrication methods. Alternative trajectories realized through this PPP fabrication method could enable development of more complex electrokinetic active particles for applications like high-performance biosensing, environmental sample analysis and pollutant removal, or cargo delivery through geometrically confined environments. While these electrokinetic particles fall under the broadly studied category of surface-anisotropic spherical particles, we note that similar patches could be placed onto particles of anisotropic shape, which we reserve for future work.

Catalytic patchy particles

Catalytic active particles, those that self-propel due to a chemical reaction at their surface in the presence of a catalyst, are of significant interest for applications in drug delivery35 and environmental remediation36. Many of the early catalytic particles relied on platinum (Pt)-catalyzed decomposition of hydrogen peroxide into water and oxygen (2 H2O2 → O2 + 2 H2O)37,38,39. It is understood that the solute concentration gradients produced by the reaction on asymmetric particles propel the particle forward by self-diffusiophoresis30,40. However, there may be some contribution due to electrokinetic effects, which have been shown to contribute to the propulsion (and direction) of Pt-polystyrene catalytic active particles41,42. At the microscale, Janus rods and spheres have been shown to move quasi-linearly38,39. More recent studies have shown that the motion of self-propelled particles can be constrained to linear or circular trajectories by using more complex shapes like Ls or even tori with two patch orientations43,44. However, these studies do not provide a fabrication method to fully explore catalytic propulsion.

The PPP fabrication method enables creation of well-defined non-spherical particles with control over patch placement. Thus, we fabricated disc-shaped particles with a cutout wedge. One design had a patch on one interior face of the wedge (Fig. 4a) while the other had a patch on the outside of the particle, opposite of the wedge (Fig. 4b). Similar to previous studies, we utilized the catalytic reaction of platinum and H2O2 to propel the complex patchy particles (Fig. 4c). The effects of patch placement are evident in the trajectories shown in Fig. 4d, e where the interior patch results in circular trajectories while backside patch results in semi-linear trajectories. Because the interior patch extends radially from the center axis of the discs, they rotate around that axis when exposed to H2O2. Alternatively, because the backside patch is on the outside, and symmetrically placed opposite of the wedge, they move quasi-linearly. To quantitatively characterize the differences between trajectories, we evaluated the angular speed and net linear speed of the catalytic particles. A representative image sequence, used to measure the rotation for each type of particle, shows the particle propulsion and orientation over time (Fig. 4f). Comparisons of the angular speed for each particle type in Fig. 4g show that the interior patch induces an angular speed more than twice that of the backside patch. We used an overlay of the trajectory of each particle, produced in ImageJ, to measure the net displacement of the particles in each video (Fig. 4h). For particles containing an interior patch, we only included those that completed a full rotation about their own axis for consistency. We then normalized the measurements by the length of the video to acquire the net linear speed for each particle. As expected, the semi-linear trajectories of the backside patches result in a much higher net linear speed, nearly 8.5 times that of the circular trajectories displayed by particles with interior patches (Fig. 4i). All catalytic trajectory images shown in Fig. 4 come from a corresponding video compilation (Supplementary Movie 3). While other catalytic particle designs have induced circular trajectories43 and even rotation around a central axis in one case at larger scales (i.e., 150 µm)45, this is the first example of catalytic active particles that rotate around their own central axis at this size scale (i.e., ≈10 µm). Further, flexibility of the PPP fabrication method enabled fabrication of two particles with distinct motions just by changing the initial print design, rather than modifying the fabrication process for each. The interior patch design, in particular, would be challenging to achieve with contemporary fabrication methods. By taking advantage of other designs, materials and catalytic reactions, this PPP fabrication method could enable the development of more complex catalytic particles to enhance drug delivery and environmental remediation, but also to be used in other areas such as industrial processes, fluid mixing, or self-assembly.

a, b Fabrication schemes for preparing complex catalytic particles. Disc-shaped particles with a missing wedge printed simultaneously beneath a rectangular stencil. 10 nm platinum is deposited through the stencil. The stencil is removed, and a complex catalytically responsive particle remains. Particles have (a) interior and (b) backside patches. c Catalytic chamber created by a silicone spacer (red) affixed to a glass slide (gray). Hydrogen peroxide and catalytic particles are combined in a separate tube before being transferred into the chamber. Inset shows the reaction that induces propulsion. d, e Plots showing trajectories for particles with (d) interior and (e) backside patches. f Sequential image captures of catalytic particles as they rotate and translate in a 0.5 vol.% H2O2 solution (time shown is in min:s). Square insets show overlay of captures. g Plot comparing the angular speeds of particles with each patch type: interior, outside (N = 10, 14). h Overlays of particle trajectories used to measure the linear displacement of particles over time. i Plot comparing the net linear speed of particles with each patch type: interior, outside (N = 8, 14). Statistics were calculated with a two-sample t-test, ***P < 0.001 All error bars represent the standard error. Polymer resin is green, metal is black. Source data are provided in the Source Data file.

Magnetically reconfigurable microrobots from patchy particles

Single patchy particles are useful in many cases, but as designs become more complex, the fabrication timescales increase. Further, once fabricated, their designs are often static and thus require additional iterations of fabrication to create particles with different functionalities. To mitigate this, it is possible to fabricate simpler subunits and assemble them into more complex structures. Magnetic assemblies have proven useful for this purpose by creating complex and reconfigurable active particle systems, or so-called microrobots. Previous work has shown that polymeric microcubes, with one face coated in a patch of cobalt, will assemble linearly in a uniform magnetic field46. When these microcubes assemble into a structure where their cobalt patches are on the same side of the particles, a hinge is formed, and the structure folds when the external magnetic field is removed due to residual dipolar interactions between neighboring patches. One disadvantage of magnetically directed assembly of patchy particles is that the assembly process is not self-limiting (i.e., the magnetic particle chains continue to grow in a concentration-dependent manner)47. Thus, magnetically reconfigurable microrobots made using this approach are difficult to control.

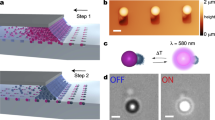

To create self-limiting magnetic microrobots, as another proof-of-concept illustration of the PPP fabrication method, we designed L-shaped particles with a rectangular cobalt patch deposited along the inner, long side of each L-shape (Fig. 5a). This patchy particle design restricts the assembly of particles into dimers when in the presence of a uniform magnetic field, whereby the short arm of the L-shape provides steric hinderance to surrounding particles and prevents assemblies from fully closing and reaching an irreversible energetic minimum. Prior to being magnetized, the patchy particles are randomly oriented along the bottom of the chamber. Once they are exposed to a uniform magnetic field produced by a pair of electromagnetic coils (100 G for the studies shown here), the cobalt patches become magnetized, and magnetic torque causes the particles to align such that their longest magnetic axis is parallel to the external field direction. Subsequently, nearby particles assemble with one another into dimers (Fig. 5b, c). Two types of particle assemblies formed, those that are reconfigurable (Fig. 5d) and those that are not (Fig. 5e). When the two assembled L-shaped particles have patches on the same side (reflectional symmetry), they are reconfigurable. The assemblies remain linearly outstretched when an external magnetic field is applied, as field-dipole interactions dominate. When the external magnetic field is removed, dipole-dipole interactions dominate, driving the constituent particles to reconfigure to minimize their dipolar interaction energy46. Alternatively, when particles assemble with patches on the opposite side (rotational symmetry), they are not reconfigurable, presumably due to a slight overlap in the magnetic films arresting their ability to reconfigure. In the case where the L-shaped particles assembled with reflectional symmetry, cycling the field on and off caused the assemblies to open and close repeatedly (Fig. 5f). All magnetic assembly images shown in Fig. 5 come from a corresponding video (Supplementary Movie 4). Recent studies have shown that certain drugs can be loaded into the polymeric network of the particles during printing with TPL48,49. Enabling microrobots to deliver these drugs requires careful design consideration because reciprocal motions, such as the actuation of a symmetric, single-hinged structure like the dimer above, prevents swimming at low Reynolds numbers in Newtonian fluids. However, by taking advantage of the nonlinear rheology of non-Newtonian fluids and applying time-asymmetric magnetic fields, reconfigurable assemblies have the potential to swim in non-Newtonian biological fluids, such as mucus, until they reach their destination in the body50. Similarly, while other cell gripping capabilities exist, magnetic grippers have been shown to enable the simultaneous manipulation and transport of cells46,51. Optimization of the magnetic patchy particle design could improve the assembly and performance of these microrobots to enable their use in applications such as drug delivery or cell manipulation.

a Fabrication scheme for making complex magnetic patchy particles. An L-shaped particle is printed beneath a rectangular stencil. 10 nm chromium and 100 nm of cobalt are deposited through the stencil. The stencil is removed, and the patchy magnetic particle remains. b Uniform magnetic field set-up created by a pair of electromagnetic coils. c When a uniform magnetic field is applied (100 G), particles align parallel to the field and nearby particles assemble. When the external field is removed, assemblies with particles on the same side of the metal film reconfigure. d Two L-shaped particles that assembled with reflectional symmetry such that the patches are on the same side and the structure is reconfigurable as the external field cycles on and off. e Two L-shaped particles that assembled with rotational symmetry such that the patches are on opposite sides and the structure does not reconfigure. f Plot indicating the angle between two particles in a reconfigurable assembly (specifically the microrobot shown in (d) as the external magnetic field toggles on and off). Source data are provided in the Source Data file.

Discussion

This paper describes a versatile method to fabricate precise patchy particles using two-photon lithography, stencil masking, and physical vapor deposition. We show that the stencil mask can accommodate various two-dimensional designs with a limit of resolution as low as 0.2 µm to control the shape of metallic patches deposited onto the particles. The stencils are selectively removed, producing arrays of well-defined patchy particles that can be removed and used for various applications in active particles and microrobotics. It should be noted that the patch location is limited to the upper hemisphere of the particle using this method. However, it may be possible to expand this range using less directional vapor deposition methods, such as sputtering, with stencils that have a curvature that more closely resembles that of the underlying particle.

We showed that by using different metals (i.e., gold, platinum, and cobalt), we could create active particles for propulsion by different mechanisms (i.e., electrokinetics, catalysis, and magnetics) all from the same base fabrication method. For each type of particle, we demonstrated how the PPP method could be used to expand active particle functionality through the creation of particles with more complex, precise and repeatable, geometries and patches. With the electrokinetic particles, we showed that by changing the patch design on an otherwise symmetric spherical particle, we can create distinct helical trajectories. With the catalytic discs, we demonstrated that we can also change the particle shape to deposit patches that either extend radially from the particle center and induce rotation about the central axis of the particle or are on the backside of the particle inducing linear motion, just by changing the printed design. And finally, with magnetic L-shaped particles, we were able to control the magnetic assembly of particles into dimeric structures with limited variation in morphology for more consistent reconfiguration within a large population. We note that after stencil removal, additional fabrication steps using GLAD and particle stamping could allow for additional metals to be deposited in precise locations on a single particle to create particles that respond to multiple different stimuli, eliciting greater control of active particles52,53.

While we focus on the use of one or two photo-resins, we note this approach can use other photocurable materials. Active particles rely on a variety of materials to improve or enable their function. Other photo-resins that could benefit from this PPP fabrication include those that respond to acoustic fields48,54, light55, temperature56, or pH gradients49. The performance of new types of active particles and microrobots made using this PPP method may be extended by using a broader range of base materials. Already, numerous custom photoresins have been used with two-photon lithography57,58. Additionally, the use of other patch materials with PVD could give rise to other functionalities beyond what is shown here59. Applications in the healthcare or environmental remediation fields likely would benefit from active particles made of biodegradable materials, while conductive materials might be beneficial for applications in batteries or solar cells. Last, while we focused on the use of stencil masking for active particle fabrication, this method could lend itself to other fields. Other areas such as microelectromechanical systems (MEMs), microoptics60, microfluidics61, and self-assembled24 materials may benefit from the adoption of the PPP fabrication method.

Methods

Two-photon lithography

Particle and stencil arrays were printed using the Nanoscribe Photonic Professional GT2. STL designs were created using Blender and converted to print files using DeScribe (Nanoscribe software). Prints were completed using Nanowrite. Particles were printed using the standard oil-immersion (ZEISS - Immersol 518 F) configuration with the 63x objective. The standard recipe for IP-L (Nanoscribe) was generally followed except for optimization of the laser power, which ranged from 20–27.5 mW, but was reoptimized with each new bottle of resist and each stencil design (Supplementary Fig. 4). The Nanoscribe system is calibrated to deliver 50 mW at PowerScaling 1 and LaserPower 100. Due to the competing balance of needing to retain particles and remove stencils, optimization was performed to ensure that stencils remained adhered during particle development but were easily shaken off during stencil removal (Supplementary Figs. 5, 6). Drop-casting the photoresin at least 3 h prior to printing enables sufficient solvent evaporation for stencils to remain adhered during development (Supplementary Fig. 12). Instead of the 3 h dropcast, the standard development procedure (12 min in SU-8 developer (Kayaku) and 3 min in IPA) can also be modified such that particles remain in IPA until they are transferred to a critical point drier (Leica EM CPD300), which eliminates stresses on the stencils during IPA evaporation (Supplementary Fig. 13). Additional methods can be found in the SI for optimization that can be used when modifying the PPP fabrication method for alternative designs, materials, or applications. Specifically, these include using IP-Dip2 resin, changing the interface finding settings during TPL printing, and heating the developer solution (Supplementary Figs. 14, 15).

Stencil removal

Stencils were removed by placing the developed substrates in a suspension of DI water in either a glass scintillation vial or cell-staining jar (Supplementary Fig. 5). Stencils were vortexed using a VWR Vortex-Genie 2. The necessary vortex strength varied across stencil designs, but stencils were optimally removed between a vortex level of 5–8 after a period of 3–5 min. The removal time was optimized by first vortexing for 3 min on a vortex level of 5, inspecting stencil detachment by optical microscopy, and repeating for longer durations or higher vortex intensities as needed.

Particle and stencil fabrication

-

i)

Complex patchy particle fabrication (CU and CU Mountain): Spherical particles from Fig. 1 were printed as 10 µm diameter spheres with the corresponding stencils and were coated with 10 nm Cr and 30 nm Au using thermal evaporation. After stencil removal, particles were removed from the substrate by depositing 10 µL of DI water onto the printed array, scraping with a pipette tip, transferring the suspended particles to an Eppendorf tube, and diluting to a concentration of 30 particles µL−1 of DI water. For images of STL designs and the corresponding files, refer to Supplementary Fig. 16 and STL files 1 and 2 (Supplementary Data).

-

ii)

Resolution stencil fabrication: Resolution stencils from Fig. 2 were printed with TPL and coated with 10 nm Cr and 30 nm Au using electron-beam evaporation. Stencils were removed by sonication in DI water for 15 s. For images of STL designs and the corresponding file, refer to Supplementary Fig. 17 and STL file 3 (Supplementary Data).

-

iii)

Electrokinetic particle fabrication: Electrokinetic particles from Fig. 3 were printed as 10 µm diameter spheres with their corresponding stencils and were coated with 10 nm Cr and 30 nm Au using electron-beam metal deposition. After stencil removal, particles were removed by depositing 10 µL of Milli-Q water onto the printed array, scraping with a pipette tip, transferring the suspended particles to an Eppendorf tube, and diluting to a concentration of 28.5 particles µL−1 of Milli-Q water. For images of STL designs and the corresponding files, refer to Supplementary Fig. 18 and STL files 4–6 (Supplementary Data).

-

iv)

Catalytic particle fabrication: Catalytic particles from Fig. 4 were printed as 10 µm diameter discoidal particles of 2 µm thickness, having wedge-shaped cutouts, along with corresponding stencils and were coated with 10 nm Pt using electron-beam evaporation. After stencil removal, particles were removed by depositing 10 µL of 0.01 vol.% Tween 20 in DI water onto the printed array, scraping with a pipette tip, transferring the suspended particles to an Eppendorf tube, and diluting to a concentration of 6 particles µL−1 of 0.01 vol.% Tween 20 in DI water. For images of STL designs and the corresponding files, refer to Supplementary Fig. 19 and STL files 7 and 8 (Supplementary Data).

-

v)

Magnetic particle fabrication: Magnetic patchy particles from Fig. 5 were printed as 12 µm long L-shaped particles of 3 µm thickness with their corresponding stencils and were coated with 10 nm Cr and 100 nm Co using electron-beam metal deposition. After stencil removal, particles were removed by depositing 10 µL of 0.1 vol.% Tween 20 in DI water onto the printed array, scraping with a pipette tip, transferring the suspended particles into an Eppendorf tube, and diluting to a concentration of 325 particles µL−1 of 0.1 vol.% Tween 20 in DI water. For images of STL designs and the corresponding file, refer to Supplementary Fig. 20 and STL file 9 (Supplementary Data).

Metal evaporation

-

i)

Thermal evaporation: Initial patchy particle optimization was performed using a CVC SC-300 thermal evaporator, due to ease of accessibility. Cr was deposited from a heated rod, followed by Au deposition from pellets. Both metals were deposited at ≈2 Å s−1. The substrate holder plate was not rotatable in this system, resulting in minor batch-to-batch variability.

-

ii)

Electron-beam evaporation: Electron-beam evaporation (e-beam) was used for all metal deposition procedures described in this study except for the initial fabrication optimization work. Au was deposited on an Edwards Auto 306 instrument. Cr was first deposited as an adhesion layer, followed by Au. Co and Pt were deposited on an Angstrom Engineering EvoVac instrument. Again, Cr was first deposited as an adhesion layer, followed by Co or Pt. All metals were deposited at ≈1 Å s−1. Substrate plates did rotate in both electron-beam deposition systems, resulting in consistent patch transfers across batches.

Coplanar electrokinetic particle setup

Electrokinetic chambers were fabricated by depositing 30 nm Cr and 100 nm Au onto a borosilicate glass slide. Two separate electrodes were defined by placing a ≈ 2.1 mm strip of Kapton tape down the long axis of the microscope slide, prior to metal deposition, that was later removed. The chambers were coated with polyethylene glycol silane (Laysan Bio—mPEG-silane) (see next section for details) to reduce particle-surface interactions. A piece of copper tape (3 M) was attached to each electrode to serve as leads. A chamber was formed by drawing a small square spanning across the two electrodes with a hydrophobic pen (Vector Laboratories—ImmEdge Pen). Two strips of polytetrafluoroethylene (PTFE) tape were placed on either side of the hydrophobic boundary, perpendicular to the electrodes. 5 µL of particle sample (≈28 particles µL−1 Milli-Q water) was pipetted into the chamber before being enclosed with a coverslip. Leads were connected to an Agilent 33210 A function generator and a TEGAM 2340 Amplifier (50x) to produce fields of 500–1250 V cm−1 at frequencies of 1–5 kHz.

PEG-silane slide coating

To minimize interactions between the hydrophobic IP-L particles and hydrophilic borosilicate slides, we coated the electrokinetic chambers with mPEG-silane (2 kg mol−1). A glass petri dish, filled with silica desiccant beads and covered by an eyelet lid, was completely dried in an oven at 90 °C. Concurrently, 1/8 inch silicone molds and electrode slides were soaked in acetone at room temperature for 5 min. Silicone molds were placed on each electrode, then placed into the petri dish and dried for another 10 min at 90 °C. The molds were then filled with (15 w/w% mPEG-silane in dimethyl sulfoxide) and placed back into the petri dish for a 15 min incubation at 90 °C. Finally, the molds were removed, and the electrodes were rinsed with DI water and dried with nitrogen.

Catalytic particle setup

Particles were suspended in DI water with 0.01 vol.% Tween 20 (Sigma-Aldrich) (≈6 particles µL−1). 30 µL of the particle solution and H2O2 (Fisher Chemical) were mixed in an Eppendorf (resulting in a final concentration of 0.5 vol.% H2O2). 9 µL of the solution was then transferred into a SecureSeal Imaging Spacer (Grace Bio-Labs) on a glass slide and enclosed with a coverslip.

Magnetic particle setup

A uniform magnetic field was formed by providing a direct current (DC) electric field to a pair of electromagnetic coils (4.8 cm diameter), separated by 5 cm. Coils were connected to a Tuffiom Power Supply (30 V/5 A TF-K305D) to create a field strength of 100 G. 9 µL of the particle sample (≈325 particles µL−1 0.1 vol.% Tween 20 in DI water) was pipetted into a silicone chamber placed at the center of a glass slide, before being enclosed with a coverslip.

Imaging

All optical images were taken on a Keyence VHX-7000 microscope or Zeiss AxioVert A1 microscope. Scanning electron microscope (SEM) images were taken using the Hitachi TM-4000 Plus II with EDS tabletop SEM. Due to the non-continuous nature of our metal coatings over the entire stencil or particle surface, we used the low vacuum charge reduction mode at 10 kV. Images were predominately taken using the BSE mode to increase the contrast between metallic and polymeric regions. However, when labeled, some images were taken using a combination of backscattering and secondary electron modes (MIX) to obtain additional topographical information.

Particle tracking and image analysis

All images and videos were analyzed using FIJI-ImageJ (Version 2.16.0/1.54p). Image measurements were taken using the line or angle tools. Overlays were created using the Z-project function. Particle tracking, used for Janus particle speed analysis and to create the catalytic trajectory plots, was completed using the MTrack2 Plugin. Stencil height analysis (Supplementary Fig. 11) was taken by (a) measuring the area by first thresholding to focus on patches, then using the ‘analyze particles’ function, and (b) measuring the Kurtosis by again thresholding and then using the FeatureJ: Statistics Plugin.

Statistical analysis

All statistical analyses were completed in MATLAB or Excel. Excel was used to find standard error, which was used for all error bars in this paper. MATLAB was used to complete analysis of variance (ANOVA) tests and t-tests for significance. For t-tests, we used the two-sample t-test (ttest2(x,y) in MATLAB). We used the standard one-way ANOVA (anova1(x)) when groups were the same size. When groups were different in size, we used an unbalanced one-way ANOVA (anova1(x,group) in MATLAB). When significance between groups was found, we completed a multicomparison test (multcompare(stats) in MATLAB) to determine which pairings were significant. All p-values, F-values, t-values, and degrees of freedom are reported in Supplementary Tables 1–10.

Data availability

The data that support the findings of this study are available from the corresponding author upon request. STL files are provided as Supplementary Data. Source data are provided in this paper. Source data are provided with this paper.

References

Yang, T., Tasci, T. O., Neeves, K. B., Wu, N. & Marr, D. W. M. Magnetic microlassos for reversible cargo capture, transport, and release. Langmuir 33, 5932–5937 (2017).

Anker, J. N. & Kopelman, R. Magnetically modulated optical nanoprobes. Appl. Phys. Lett. 82, 1102–1104 (2003).

Soler, L., Magdanz, V., Fomin, V. M., Sanchez, S. & Schmidt, O. G. Self-propelled micromotors for cleaning polluted water. ACS Nano 7, 9611–9620 (2013).

Moran, S. E., Bruss, I. R., Schönhöfer, P. W. A. & Glotzer, S. C. Particle anisotropy tunes emergent behavior in active colloidal systems. Soft Matter 18, 1044–1053 (2022).

Bishop, K. J. M., Biswal, S. L. & Bharti, B. Active colloids as models, materials, and machines. Annu. Rev. Chem. Biomol. Eng. 14, 1–30 (2023).

Shields, C. W. IV et al. Supercolloidal spinners: complex active particles for electrically powered and switchable rotation. Adv. Funct. Mater. 28, 1803465 (2018).

Lee, J. G., Al Harraq, A., Bishop, K. J. M. & Bharti, B. Fabrication and electric field-driven active propulsion of patchy microellipsoids. J. Phys. Chem. B 125, 4232–4240 (2021).

Sabrina, S. et al. Shape-directed microspinners powered by ultrasound. ACS Nano 12, 2939–2947 (2018).

Brooks, A. M., Sabrina, S. & Bishop, K. J. M. Shape-directed dynamics of active colloids powered by induced-charge electrophoresis. Proc. Natl Acad. Sci. USA 115, E1090–E1099 (2018).

Gong, Z., Hueckel, T., Yi, G.-R. & Sacanna, S. Patchy particles made by colloidal fusion. Nature 550, 234–238 (2017).

Kim, A. et al. Symmetry-breaking in patch formation on triangular gold nanoparticles by asymmetric polymer grafting. Nat. Commun. 13, 6774 (2022).

Gangwal, S., Cayre, O. J., Bazant, M. Z. & Velev, O. D. Induced-charge electrophoresis of metallodielectric particles. Phys. Rev. Lett. 100, 058302 (2008).

Takei, H. & Shimizu, N. Gradient sensitive microscopic probes prepared by gold evaporation and chemisorption on latex spheres. Langmuir 13, 1865–1868 (1997).

Wang, W., Duan, W., Sen, A. & Mallouk, T. E. Catalytically powered dynamic assembly of rod-shaped nanomotors and passive tracer particles. Proc. Natl Acad. Sci. USA 110, 17744–17749 (2013).

Thome, C. P., Hoertdoerfer, W. S., Bendorf, J. R., Lee, J. G. & Shields, C. W. IV Electrokinetic active particles for motion-based biomolecule detection. Nano Lett. 23, 2379–2387 (2023).

Alapan, Y., Bozuyuk, U., Erkoc, P., Karacakol, A. C. & Sitti, M. Multifunctional surface microrollers for targeted cargo delivery in physiological blood flow. Sci. Robot. 5, eaba5726 (2020).

Wu, H., Greydanus, B. & Schwartz, D. K. Mechanisms of transport enhancement for self-propelled nanoswimmers in a porous matrix. Proc. Natl Acad. Sci. USA118, e2101807118 (2021).

Boymelgreen, A. M., Balli, T., Miloh, T. & Yossifon, G. Active colloids as mobile microelectrodes for unified label-free selective cargo transport. Nat. Commun. 9, 760 (2018).

Lisicki, M., Reigh, S. Y. & Lauga, E. Autophoretic motion in three dimensions. Soft Matter 14, 3304–3314 (2018).

Lee, J. G. et al. Magnetically locked Janus particle clusters with orientation-dependent motion in AC electric fields. Nanoscale 15, 16268–16276 (2023).

Ma, F., Yang, X., Zhao, H. & Wu, N. Inducing propulsion of colloidal dimers by breaking the symmetry in electrohydrodynamic flow. Phys. Rev. Lett. 115, 208302 (2015).

Nourhani, A., Brown, D., Pletzer, N. & Gibbs, J. G. Engineering contactless particle–particle interactions in active microswimmers. Adv. Mater. 29, 1703910 (2017).

Pawar, A. B. & Kretzschmar, I. Patchy particles by glancing angle deposition. Langmuir 24, 355–358 (2008).

Gangwal, S., Pawar, A., Kretzschmar, I. & Velev, D. O. Programmed assembly of metallodielectric patchy particles in external AC electric fields. Soft Matter 6, 1413–1418 (2010).

Lee, J. G., Brooks, A. M., Shelton, W. A., Bishop, K. J. M. & Bharti, B. Directed propulsion of spherical particles along three dimensional helical trajectories. Nat. Commun. 10, 2575 (2019).

Choudhury, U., Soler, L., Gibbs, J. G., Sanchez, S. & Fischer, P. Surface roughness-induced speed increase for active Janus micromotors. Chem. Commun. 51, 8660–8663 (2015).

Puce, S. et al. 3D-microfabrication by two-photon polymerization of an integrated sacrificial stencil mask. Micro Nano Eng. 2, 70–75 (2019).

Kurt J. Lesker Company. Gold Au Evaporation Process Notes. https://www.lesker.com/newweb/deposition_materials/deposition-materials-notes.cfm?pgid=au1 (2025).

Hu, X. et al. Magnetic soft micromachines made of linked microactuator networks. Sci. Adv. 7, eabe8436 (2021).

Wang, S. & Wu, N. Selecting the swimming mechanisms of colloidal particles: bubble propulsion versus self-diffusiophoresis. Langmuir 30, 3477–3486 (2014).

Specifications. NanoGuide. https://support.nanoscribe.com/hc/en-gb/articles/360006826534-Specifications (2024).

Higgins, C. I., Killgore, J. P., DelRio, F. W., Bryant, S. J. & McLeod, R. R. Photo-tunable hydrogel mechanical heterogeneity informed by predictive transport kinetics model. Soft Matter 16, 4131–4141 (2020).

Squires, T. M. & Bazant, M. Z. Breaking symmetries in induced-charge electro-osmosis and electrophoresis. J. Fluid Mech. 560, 65–101 (2006).

Bazant, M. Z. & Squires, T. M. Induced-charge electrokinetic phenomena: theory and microfluidic applications. Phys. Rev. Lett. 92, 066101 (2004).

Esteban-Fernández de Ávila, B. et al. Micromotor-enabled active drug delivery for in vivo treatment of stomach infection. Nat. Commun. 8, 272 (2017).

Campuzano, S. et al. Bacterial isolation by lectin-modified microengines. Nano Lett. 12, 396–401 (2012).

Ismagilov, R. F., Schwartz, A., Bowden, N. & Whitesides, G. M. Autonomous movement and self-assembly. Angew. Chem. Int. Ed. 41, 652–654 (2002).

Howse, J. R. et al. Self-motile colloidal particles: from directed propulsion to random walk. Phys. Rev. Lett. 99, 048102 (2007).

Paxton, W. F. et al. Catalytic nanomotors: autonomous movement of striped nanorods. J. Am. Chem. Soc. 126, 13424–13431 (2004).

Moran, J. L. & Posner, J. D. Phoretic self-propulsion. Annu. Rev. Fluid Mech. 49, 511–540 (2017).

Brown, A. & Poon, W. Ionic effects in self-propelled Pt-coated Janus swimmers. Soft Matter 10, 4016–4027 (2014).

Ebbens, S. et al. Electrokinetic effects in catalytic platinum-insulator Janus swimmers. EPL 106, 58003 (2014).

Kümmel, F. et al. Circular motion of asymmetric self-propelling particles. Phys. Rev. Lett. 110, 198302 (2013).

Baker, R. D. et al. Shape-programmed 3D printed swimming microtori for the transport of passive and active agents. Nat. Commun. 10, 4932 (2019).

Catchmark, J. M., Subramanian, S. & Sen, A. Directed rotational motion of microscale objects using interfacial tension gradients continually generated via catalytic reactions. Small 1, 202–206 (2005).

Han, K. et al. Sequence-encoded colloidal origami and microbot assemblies from patchy magnetic cubes. Sci. Adv. 3, e1701108 (2017).

Shields IV, C. W. et al. Field-directed assembly of patchy anisotropic microparticles with defined shape. Soft Matter 9, 9219–9229 (2013).

Lee, J. G. et al. Bubble-based microrobots with rapid circular motions for epithelial pinning and drug delivery. Small 19, 2300409 (2023).

Xin, C. et al. Environmentally adaptive shape-morphing microrobots for localized cancer cell treatment. ACS Nano 15, 18048–18059 (2021).

Han, K., Shields, C. W. IV, Bharti, B., Arratia, P. E. & Velev, O. D. Active reversible swimming of magnetically assembled “microscallops” in non-newtonian fluids. Langmuir 36, 7148–7154 (2020).

Breger, J. C. et al. Self-folding thermo-magnetically responsive soft microgrippers. ACS Appl. Mater. Interfaces 7, 3398–3405 (2015).

Pawar, A. B. & Kretzschmar, I. Multifunctional patchy particles by glancing angle deposition. Langmuir 25, 9057–9063 (2009).

Sanchez, S., Solovev, A. A., Schulze, S. & Schmidt, O. G. Controlled manipulation of multiple cells using catalytic microbots. Chem. Commun. 47, 698–700 (2010).

Thome, C. P. et al. Acoustic pipette and biofunctional elastomeric microparticle system for rapid picomolar-level biomolecule detection in whole blood. Sci. Adv. 10, eado9018 (2024).

Tahmid Shahriar, S., Feltman, C., Machler, S. & Tanjeem, N. Modulating photothermocapillary interactions for logic operations at the air–water interface. Soft Matter 20, 1689–1693 (2024).

Bae, J., Na, J.-H., Santangelo, C. D. & Hayward, R. C. Edge-defined metric buckling of temperature-responsive hydrogel ribbons and rings. Polymer 55, 5908–5914 (2014).

Nelson, B. R. et al. Multifunctional dithiolane monomers for multi-scale, recyclable light-driven additive manufacturing. Polym. Chem. 16, 2108–2116 (2025).

Dayan, C. B. et al. 3D printing of elastomeric bioinspired complex adhesive microstructures. Adv. Mater. 33, 2103826 (2021).

Chen, C., Ding, S. & Wang, J. Materials consideration for the design, fabrication and operation of microscale robots. Nat. Rev. Mater. 9, 159–172 (2024).

Wang, H. et al. Two-photon polymerization lithography for optics and photonics: fundamentals, materials, technologies, and applications. Adv. Funct. Mater. 33, 2214211 (2023).

Studer, V., Pépin, A., Chen, Y. & Ajdari, A. An integrated AC electrokinetic pump in a microfluidic loop for fast and tunable flow control. Analyst 129, 944–949 (2004).

Acknowledgements

The authors thank the Colorado Shared Instrumentation in Nanofabrication and Characterization (COSINC) facility for use of the clean room and instrumentation as well as the clean room manager, Dylan Bartusiak for many helpful discussions. The majority of fabrication, and characterization of it, was performed at COSINC-FAB and COSINC-CHR, CU Boulder (RRID:SCR_018985). The authors also thank Arkava Ganguly for helpful discussions about catalytic active particles. This work was primarily funded by the Pew Biomedical Scholars Program. K.M.K. acknowledges support from a National Science Foundation (NSF) Graduate Research Fellowship (DGE 2040434). A.K. acknowledges support from the Summer Program for Undergraduate Research (SPUR) at the University of Colorado Boulder. Additional support from the NSF to C.W.S. (CBET 2143419) is acknowledged. C.W.S. is a Pew Scholar in the Biomedical Sciences, supported by the Pew Charitable Trusts. C.W.S. thanks the Packard Foundation for their support of this project. Many of the figures, and all of the print designs in this article were made using Blender.

Author information

Authors and Affiliations

Contributions

K.M.K., Z.A.C., and A.K. performed experiments and completed analysis. Paper predominately written by K.M.K. with support from Z.A.C. All authors contributed to conceptualization, writing, reviewing, and editing. Supervised by C.W.S.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kreienbrink, K.M., Cruse, Z.A., Kumari, A. et al. Precise surface patches on active particles of arbitrary shape through microstenciling. Nat Commun 16, 6062 (2025). https://doi.org/10.1038/s41467-025-61218-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-61218-x

This article is cited by

-

Shape-morphing active particles with invertible effective polarizability for configurable locomotion and steering

Nature Communications (2026)

-

Ion stencils used for synthesis of patchy nanoparticles

Nature (2025)