Abstract

Soft mechanical sensors with high performance, mechanical robustness, and manufacturing reproducibility are crucial for robotics perception, but simultaneously satisfying these criteria is rarely achieved. Here, we suggest a magnetic crack-based piezoinductive sensor (MC-PIS) which exploits the strain modulation of magnetic flux in cracked ferrite films. The MC-PIS is insensitive to fatigue-induced crack propagation and environmental changes, showing same performance even when scratched in half or run over by a car. It can detect bidirectional bending with a precision of 0.01° from −200° to 327°, allowing for real-time reconstruction of dynamic shape changes of a flexible ribbon. We demonstrate an artificial finger recognizing surface topology and musical notes via vibrations, a crawling robot responding appropriately to external stimuli, a tree-planting gripper performing consecutive tasks from digging soil, removing stones, to placing trees. The MC-PIS opens a new paradigm to develop ultrasensitive yet highly robust sensors in real-world robotics applications.

Similar content being viewed by others

Introduction

Soft mechanical sensors that can detect strain, pressure, and/or bending curvature have wide applications, including artificial tactile skin for humanoids1,2, wearable activity monitoring3,4,5, perception of soft robotic motions6, medical instruments7, on-skin and implantable healthcare systems8,9, and human-machine interfaces10,11,12. Driven by increasing demands of soft mechanical sensors, remarkable progress has been made in materials, device structures, and fabrication processes13,14. For practical uses, however, it remains a great challenge to simultaneously meet the following requirements; signal reliability under repeated stimuli, mechanical robustness, long-term stability without fatigue, high sensitivity in a wide range of stimulation, simple structure, multimodality, fast data collection, and fabrication reproducibility. Piezoresistive and piezocapacitive soft mechanical sensors have won the majority due to their simple structure, high sensitivity, fast data acquisition as well as the strain-pressure multimodality when properly deconvoluted15,16,17. Unfortunately, soft piezoresistive sensors have limitations in terms of fabrication reproducibility and consistent performance, which become deteriorated as the sensitivity increases18,19. Soft piezocapacitive sensors are usually specialized for pressure sensing, but strain sensitivity is limited20,21. Although intrinsic deformability of ion gels has been explored for fabrication of ionic mechanical sensors on the basis of impedance change or capacitance change22,23, the sensors exhibit a sluggish response to dynamic stimulation24,25. Very recently, soft piezoinductive sensors have been suggested for noncontact movement recognition and excellent bending angle resolution26,27, but their resolutions for pressure and strain are relatively low. New approaches are required to simultaneously meet the above-mentioned requirements.

Electrically resistive cracks have been used to produce highly sensitive piezoresistive sensors, either in the ranges of very small tensile strain (ε) (ultrasensitive when ε ≤ 2%) by using metallic cracks28,29 or in the large strain ranges (ε > 10%) by using deformable composites30,31. Even though hierarchical crack structures have been introduced to bridge the two strain ranges32 and some progress has been made33,34,35, the resistive crack-based sensors often have the technological issues such as performance degradation, signal hysteresis, and large signal drift by fatigue during repeated operation. Those issues are attributed to the intrinsic characteristics of the ON-or-OFF electrical current by crack formation and the inevitable propagation of the cracks by fatigue (Supplementary Fig. 1). Unlike the electric current, the magnetic flux can pass through the air gap (with a low magnetic permeability, µr = 1) between magnetic domains (with a high magnetic permeability, µr > 100)36,37,38. This gradual change of the magnetic flux in through-thickness cracks may result in a gradient piezoinductive response of an inductive coil, hence making the sensor insensitive to crack configuration, crack-propagation related issues, and allowing high-precision detection in a small-to-large strain range. This air gap-modulated magnetic flux change has been used for sensing displacement in bulk industry systems39,40, however the concept has not been explored for soft electronics.

In this study, we present a deformable magnetic crack-based piezoinductive sensor (MC-PIS), which exploits the magnetic flux variation of a cracked ferrite film (CFF) and its resultant effect on the inductance of an electric coil placed below the ferrite film. This sensor shows ultrahigh mechanical robustness without fatigue behavior and achieves ultra-sensitivity in a small-to-large strain range for both compressive and tensile stimuli. The simple structure allows excellent fabrication reproducibility and fast data acquisition. By utilizing the intrinsic deconvolution for compression and extension, we demonstrate a soft robot which monitors its dynamic shape changes, obtains a height profile of microstructure patterns, detects an obstacle and moves over it, digs soil and plants a tree, and pretends dead or runs away accordingly to external stimuli.

Results

Strain modulated magnetic reluctance of the CFF

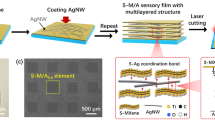

We used a commercial flexible ferrite film which consists of a 100 μm-thick ferrite film with a 50 μm-thick adhesive layer, a 30 μm-thick poly (ethylene terephthalate) (PET) film on top, and a 100 μm-thick backing paper. The ferrite film was cut into a strip (ex. 5 mm × 25 mm), and rolled on a cylindrical rod (diameter = 4 mm) to generate cracked flakes (Supplementary Fig. 2). After delaminating the backing paper, the CFF can be directly stuck on other substrate through the adhesive layer. Figure 1a shows scanning electron microscope (SEM) images of the non-cracked ferrite film, the CFF without strain (ε = 0%), and the uniaxially-stretched CFF at ε = 8%. The air-gap was variable depending on magnitude of the applied strain, and the relative magnetic flux gradually decreased with increasing air-gap (Supplementary Fig. 3 and Movie S1). Figure 1b exhibits the variation of the magnetic flux in the ferrite film as a function of the air-gap. The magnetic flux decreased considerably under tensile strain; B/B0 = 0.61 at ε = 0%, and B/B0 = 0.40 at ε = 3%. It is noteworthy that once the ferrite film was cracked that nearly null air-gap condition can be achieved under compression.

a SEM images and magnetic flux density (B) of a ferrite strip with no cracks, and with cracks at 0% and 8% tensile strains (ε). b 2D simulation of B in the cracked ferrite film (CFF) strip with different air-gap. B was compared to those in a non-cracked ferrite film (B0) and in the air (Bair). c Schematic illustration of the CFF with the rigid flakes on the elastic substrate, and the resulting magnetic reluctance (Rm) modulation under tensile strain. d Schematic performance of the MC-PIS and the resistive crack-based sensor (RCS) under compressive and tensile strains. The MC-PIS is responsive to a wide range of compression and extension.

As illustrated in Fig. 1c, the CFF has a structure of rigid-flakes-on-elastic-substrate, in which these ferrite flakes are completely separated by randomly distributed through-thickness cracks. The ferrite flakes were random in size and shape (Supplementary Fig. 4). The average dimension of the flakes was 500 μm × 820 μm, and the average air-gap between the flakes was 6.7 μm at ε = 0% and 49.4 μm at ε = 8%. Figure 1calso presents two-dimensional simulation on magnetic flux (B) distributions in the CFF with a configuration extracted from a microscopic image, showing dynamic variation accordingly to the air-gaps under mechanical deformation. The principle of the magnetic circuit theory39 and details of the simulation results are provided in Supplementary Note 1. Since the ferrite flakes are rigid with very limited stretchability, when the CFF is stretched (or compressed), only air gaps between flakes vary with the applied strain, whereas the ferrite flakes only move apart from (/close to) each other (Supplementary Fig. 5). In addition, through-thickness cracking air-gaps and submillimeter rigid flakes make the CFF mechanically compliant to be compressed and stretched, and resilient to crack-propagation and fatigue. Benefiting from this structure and the magnetic induction mechanism, the MC-PIS can operate at a much wider strain range from compressive strain to tensile strain (−5% to 10%) and would only “saturate” at extreme conditions. Whereas cracked resistive sensors are insensitive to compressive strain and would completely disconnect and stop functioning above a small tensile strain (ε = ~2%). Figure 1d illustrates the distinct characteristics between the MC-PIS and a representative cracked metal film-based resistive sensor28. Comparison of strain sensing range, resolution, materials, fabrication technologies, and stability between the MC-PIS and some representative resistive crack sensors are summarized in Supplementary Table 1.

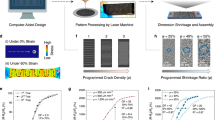

Robust yet highly precise bidirectional bending sensing

Flexible sensors that can detect bidirectional bending curvatures/angles are in high demand for proprioception and tactile sensing of robotics. A bidirectional bending sensor was fabricated by combining the CFF on a planar inductive coil (Fig. 2a and Movie S2). The soft planar coil was produced either by filling a microchannel in an elastomer substrate (Ecoflex 00–30) with stretchable liquid metal (eutectic In-Ga alloy) or by depositing a Cu trace pattern on a highly-flexible 20 μm-thick polyimide substrate. The two coils showed similar inductance responses for bending and twisting (Supplementary Fig. 6). The coil detected magnetic field changes resulting from the CFF, monitoring subtle compressive (inward bending) or tensile (outward bending) strains applied on the CFF. Figure 2b exhibits the inductance change while the sensor was bent from −327o to 327o, which correspond to ε = −2.85% to ε = 2.85%. The strain was calculated by assuming an offset thickness (100 µm) from the neutral plane. The inductance decreased monotonically from about -200o to 327o, and was not prominent at severe inward bending (< −200o) because the self-inductance decrease caused by coil bending canceled the inductance increase caused by compression of the CFF (Supplementary Fig. 7). The overall response of inductance to bending angle fell to a quadratic governing equation (solid line), L = -2.02 × 10-5 A2 – 9.78×10-3 A + 0.028 (where A is the angle in degree, L is the inductance in µH). The sensor showed identical inductance profile during bending and releasing processes without exhibiting any signal hysteresis (inset of Fig. 2b).

a Illustrations showing the working principle for bi-directional bending and camera images of the stretchable liquid metal coil and the flexible Cu planar coil. b Inductance variation of the MC-PIS at a bending angle from −327° to 327°. The inset emphasizes no hysteresis of inductance changes during a bending-releasing cycle. c Inductance variation of the MC-PIS during an incremental bending and releasing tests with a step of 1°. The inset shows inductance variation with a small bending angle change (0.01°), indicating the high precision detection limit of the MC-PIS. d Long-term stability of the sensor undergoes 50,000 bending-releasing cycles between 110° and 120°. e Negligible performance degradation of the MC-PIS while the CFF layer was half-scratched (1) and full-scratched (split the CFF in half) with a tweezer. f Inductance changes of the MC-PIS when it was heated from 27 °C to 70 °C, and submerged in water of different temperatures (20 °C, 82 °C, 2.8 °C). g Comparison of the MC-PIS with respect to the state-of-the-art bending sensors in aspects of detection resolution (data points/degree), bending angle range, and mechanical robustness.

Detection resolution for bending angle is high (Fig. 2c), precisely measuring 1o incremental bending angle changes (corresponding to ε = 0.008%) and successfully recognizing 0.01o bending angle changes (ε = 0.00008%, 0.8 µε). The sensitivity was 14.3 nH/o, with a root-mean-square noise of 0.05 nH (measured by a LDC1614 module at a bandwidth of 50 Hz, Supplementary Fig. 8), hence the theoretical sensing resolution for bending angle can be as small as 0.003°. Microscopic images of the crack configuration of the CFF were taken after the 1st, 10th, 100th, and 1000th bending cycle with bending test paused, respectively. No signal shift or visual cracks changes were observed even after 1000 cycles 0 ~ 180° bending test (Supplementary Fig. 9), which can be attributed to the through-thickness cracks structure of the CFF. Figure 2d shows bending angle measurement during 50,000 bending-releasing cycles between 120° and 110°, indicating ultrastable response during the 7 h test. We have tested the MC-PIS for both outward bending (0° ~ 180°) and inward bending (0° ~ −180°) of 5000 cycles. As show in Supplementary Fig. 10, the MC-PIS has ultrastable response for bending on both directions, corresponding to tensile strain and compressive strain on the CFF, respectively. Moreover, 6 MC-PISs were prepared to check the reliability in both precision detection and fabrication reproducibility (Supplementary Fig. 11). All the sensors showed identical signal profiles with only 0.58% maximum deviation. The sensor had no hysteresis at various velocities (Supplementary Fig. 12), indicating that the sensor demonstrates superior reliability in high-precision bending angle detection performance.

As the inductance represents the total magnetic field energy (spatial integral of the magnetic flux density) per unit current, the sensor was insensitive to additional crack propagation in the CFF or maintained the same sensing behavior under severe physical damages in the CFF (Fig. 2e and Supplementary Note 2). The sensor responded symmetrically to inward-outward bending motions (± 17o) (Test I). When the CFF was manually scratched off with an area of 1.5 mm × 5 mm, the inductance decreased, but the sensor maintained the same performance (Test II). Even when a scratch (5 mm in width) was made to completely divide the CFF in two halves, the sensor showed a similar response (Test III) (Supplementary Movie S3) with a sensitivity slightly decreased by 6% (Supplementary Fig. 13). Moreover, the sensor operated with the same performance while and after a car (1.8 ton) was run over it on the ground (Supplementary Movie S4). Even after 20 times run-over by a car, the sensor has same inductance to bending angle response curve with only 3% drop in sensitivity (Supplementary Fig 14). Such mechanical robustness is critical to real-world robotic applications. The MC-PIS is insensitive to environmental changes such as temperature and water. As shown in Fig. 2f, heating from 27 °C to 70 °C (blue line) increased the inductance only by 0.5%, which equals to a thermal drift coefficient of 0.011°/°C. When the MC-PIS was submerged in water of room temperature, it showed a negligible inductance change (0.008%). Submerging in hot water (82 °C) and cold water (2.8 °C) caused slight inductance increase (0.3%) and decrease (0.19%), respectively, due to the minimal effect of thermal drift. In addition, we have tested the MC-PIS’s response with a step motor running and stopping at a distance from 20 cm to 3 cm, no interference on the MC-PIS’s response was observed when the distance is larger than the dimension (4 cm × 4 cm) of the motor (Supplementary Fig. 15).

Figure 2g compares the performance of the MC-PIS with the state-of-the-art in the field of bending sensors in various aspects, such as detection angle range, angle resolution, and mechanical robustness (see also Supplementary Table 2). The MC-PIS is superior in detection range of the bending angle and the angle resolution (detection points/degree). In addition, the sensor endures direct physical damages in the sensing part without performance degradation, which is highly desirable for practical applications.

Recognition of dynamic shape changes of a flexible ribbon

Inspired by the elephant trunk (Fig. 3a) and the tentacles of the octopus, soft continuum robots have attracted extensive research in both robotics and biomedical fields41,42,43. Shape sensing (proprioception) of such continuum robots with “infinite” degrees of freedom (DOFs) has been a challenging task44,45. On the other hand, real-time recognition of dynamic shape changes is crucial for efficient closed-loop manipulation/navigation in biomedical engineering. We developed a sensorized flexible ribbon consisting of 16 MC-PIS units (Fig. 3b) to demonstrate its potential for real-time shape reconstruction of soft continuum robots or tubes. The connection leading lines between the 16 coils and the board had the serpentine structure to remove mechanical damage during handling (Supplementary Fig. 16). Same to the single MC-PIS, the inductances of the planar coils can reflect the local curvatures of the flexible ribbon as the local magnetic reluctance of the CFF changes with the bending-induced strain. Based on the piecewise-constant-curvature (PCC) model (Supplementary Note Fig. 2.3.1, Note 3), the shape curve of the ribbon can be divided into 16 segmented arcs with curvature/radius values extracted from the measured inductance variations from the 16 MC-PISs. Thus, the shape curve of the flexible ribbon bends at any shape can be obtained. The reconstructed curves of the flexible ribbon at four different bending postures shows a good match to the original images (Supplementary Note Fig. 2.3.2).

a Illustration of shape sensing of an elephant-inspired soft continuum robot. b Illustration and real images of the sensorized flexible ribbon. The ribbon contained 16 bi-directional bending sensor units. c Real-time reconstruction of the dynamically-changing shapes of the ribbon. (Top) Recorded raw data from the 16 MC-PIS units, (bottom left) a camera image showing that a glass rod was pushing and sliding along the ribbon to change the shape, (bottom right) the real-time reconstructed images of the ribbon with time intervals of 0.06 s, 0.17 s, and 0.61 s, respectively.

In the dynamic shape-changing experiments, the flexible ribbon’s top end was fixed (connected to the circuit board), and the bottom end was hung free (Supplementary Note Fig. 2.3.1a). The free end was pushed/pulled manually with hand and the left/right sides of the ribbon were pushed with a glass rod (Fig. 3c). Shape change of the ribbon was configured on the basis of the piecewise-constant-curvature model46,47. Details of the shape reconstruction model and the measurement setup are provided in Supplementary Note 3. The colored curves (top of Fig. 3c) exhibit the temporal raw data obtained from the 16 MC-PIS units. The bottom images exhibit the temporal shape changes of the ribbon at three selected periods with time intervals of 0.06 s, 0.17 s, and 0.61 s, respectively. The reconstructed ribbon shapes changing in real time were in excellent match to the real shapes of the ribbon (Supplementary Movie S5). This experiment demonstrated that the MC-PIS is highly sensitive, ultrastable, robust, mechanically durable and reliable for real-world robotics and biomedical applications.

Monitoring subtle vibrations and textures via a soft finger

Artificial soft finger with high sensitivity has attracted extensive interests for human-like touch perception by perceiving accurate posture and external subtle stimuli48. We fabricated a sensorized soft pneumatic finger by sticking a MC-PIS at the bottom surface of the finger actuator (Fig. 4a and Supplementary Fig. 17). The sensor provided inductance signals without delay when it bent upward and downward, and it immediately restored the reference signal when the bending was released. Owing to the no signal delay, it could detect the damping oscillations of the soft finger when it was plucked by the fingertip and shot with an air blow through a nozzle (Fig. 4b, Supplementary Movie S6). The damping oscillation signals showed that the soft finger has a self-resonance frequency of 8.09 Hz and a damping coefficient of 0.04, indicating the intrinsic dynamic properties of the soft finger.

a Design of the pneumatic artificial finger, and the inductance variation when the finger was actuated to bend upward and downward. b Damping oscillation of the inductance obtained with the artificial finger when the finger was plucked upwards with the fingertip (top) and pulsed downward with an air gun (bottom). c Finding the last-used position in a tape roll by sliding the artificial finger along the cylindrical surface. d Detection of the vibrations on a desk when mechanical pulse was applied on the desk with a hammer while the artificial finger was in contact with the desk. Comparison with the vibration detections when the artificial finger was in contact with a mouse pad and a silicone rubber pad placed on the desk. The bottom plot with tiny waves was extracted from the signal obtained on the silicone pad. e Detection of the subtle vibrations in the desk induced by the sound waves. A speaker was 5 cm apart to the desk plate. The artificial finger recognized different music notes (for instance, C1-Do, C1-So, and C2-Re).

The sensorized soft finger could recognize surface topologies of sub-mm features (Supplementary Fig. 18). Hence, it can be used for the takes requiring delicate hand sensation in daily life. We tested whether the soft fingertip could find the last-used location of a Scotch tape roll by moving along the surface of the tape (Fig. 4c). The overall inductance curve showed a smooth contact contour profile, increasing and decreasing while moving up and down along the tape roll. The artificial finger made a pulse-like signal when the soft finger touched the last-used location. The pulse-like signal was dependent on the relative position of the last-used location in the roll, creating prominent signal change when the last-used location was at the highest position of the roll.

Benefiting from its high sensitivity and fast response, the artificial finger could detect the subtle vibrations transmitted through the desk surface. In addition, when the artificial finger was placed on an object covering the desk and the vibrations were transmitted to it through the object, it was possible to distinguish the changes in the vibration mode according to the mechanical properties of the object (Fig. 4d). When an impact was applied on the desk with a small hammer, the artificial finger on the desk detected a single pulse and fast-decaying waves with a relaxation time (τ) of 6.1 ms. When the artificial finger was on a mouse pad made of rubber and fabric, it exhibited slowly-damping (τ = 34.4 ms) vibration signals. When a silicone rubber pad was placed on the desk, the damping waves exhibited a large relaxation time (τ = 55.5 ms) and an enhanced amplitude. Interestingly, all the damping profiles contained a sequence of tiny waves that could be extracted from the main waves (the bottom plot in Fig. 4d). The tiny waves are a higher-order vibration mode (~307 Hz) of the desk, not noise or signal artifact. The higher-order mode was magnified by insertion of the elastic rubber pad. This sensitivity to vibrations allowed the artificial fingers to distinguish the musical notes as the sound waves traveled through the desk (Fig. 4e). Several piano notes (C1-Do, C1-So, C2-Re) were played through a speaker placed 5 cm away from the desk. The frequency domain signals obtained by the fast Fourier transformation of the inductance signals clearly identified the main resonance frequency of the music notes which are 65 Hz, 110 Hz, and 166 Hz, respectively.

MC-PIS equipped soft intelligent crawling robot

Proprioception and tactile sensing play vital roles for living creatures to survive and thrive in complex environments6. For instance, worms or other insects have the capability to sense these stimuli from the environment and respond accordingly. Similarly, robots should explore and interact with their surroundings. We developed a soft crawling robot with embedded sensing/motion control for responding properly to external stimuli (Supplementary Fig. 19 and 20). The robot had two pneumatic bending modules (front and rear) with a MC-PIS unit in each module, and also contained an embedded control board and a color light emitting diode (LED) in the center (Fig. 5a). The MC-PIS can detect large bending deformation which provides precise bending motion monitoring (proprioception) for the soft crawling robot. As soft robots have low stiffness and deformable body, any external loading (stimuli) would introduce a local deformation which can be detect and recognized by the integrated MC-PIS. Figure 5b, c exhibit the sensing profiles from the front and rear bending modules for two survival scenarios (Supplementary Movie S7); (b) when the robot head was attacked the robot lay flat on the ground to ‘pretend dead’, and (c) when the rear part of the robot was attacked the robot switched to an ‘escaping mode’ by flashing the red light and ran away at its maximum speed (40 mm/s, operated at 4 Hz). The soft crawling robot could detect an obstacle when its forward movement The soft crawling robot could detect an obstacle when its forward movement was blocked (Fig. 5d and Supplementary Movie S8). The robot adopted its gait by the following steps (Fig. 5e): 1) lifting the front foot, 2) moving forward with small strides driven by the rear bending module in order to push the front foot and cross over the bar, 3) switching to normal gait and allow the middle part of the robot to cross the obstacle, and 4) lifting the rear foot and incrementally bending the front module to drag the rear foot and cross the obstacle. Unlike integrating large number of tactile sensors on the body of a soft robot, the above results demonstrate that tactile sensing of soft robots can be achieved in a simple and effective approach, by monitoring the subtle deformation which caused by external obstacles/loadings.

a Design and camera images of the responsive soft crawling robot. b Lying down and pretending ‘dead’ when the robot head was attacked. c Detecting a strike with a hammer at the rear part of the crawling robot, flashing the ‘escaping mode’ with red lighting, and running away at its maximum speed. d Recognition of an obstacle and adjustment of its locomotion gait to cross over it. e Inductive signals from the front and rear modules during the obstacle recognition and adaptive locomotion, inset: inductive signal of the front module at normal gait and when encountered an obstacle. f Camera images showing the robotic tree-planting and illustration of the soft fin-ray gripper with two integrated MC-PISs at the tip and root of the finger. g Tactile sensing signals during the consecutive tasks (digging a hole, removing a stone, plating a tree, and plowing and watering) while the robot was planting a small tree.

Smart robotic gripper for planting

Robotic farming is expected to be a prerequisite for the unmanned management of crops, the realization of automated urban farms, and scientific research and food production in space. We utilized the MC-PIS for a soft gripper that performs consecutive tasks required for planting a small tree in a soil tank (Fig. 5f and Supplementary Movie S9). Two MC-PISs were integrated on one finger of the gripper for distinctive perception of stimuli applied to the tip and root of the gripper (Supplementary Fig. 21). Tree-planting was begun with soil-digging; the gripper moved to dig in the soil, collected a small amount of soil, and released aside to make a hole in the middle of the soil tank. The inductance signals from the tip and root sensors exhibited clear difference (Fig. 5g), showing the details of soil-digging: poking into the soil (①), gripping the soil, lifting up the soil (②), moving aside and releasing the soil. If the gripper was pushed onto a stone (③), the tip sensor recognized it as an “abnormal item” from the abnormal signal amplitude, and the robot moved the stone to a corner of the soil tank (④). After finishing the hole-digging, the gripper grasped the trunk of the tree, moved down slowly to allow the roots of the plant to touch the soil (⑤), and pushed further to make the tree stand stable in the hole. The gripper plowed the soils to cover the roots of the tree (⑥), then press around the tree to solidify the soil (Supplementary Fig. 22). Finally, the gripper watered the tree and completed the tree-planting. This simple demonstration highlights the mechanical robustness of the MC-PIS in “harsh” conditions, showing excellent reliability and durability for practical robotic applications. By combing the precise and real-time tactile feedback using the MC-PIS with vision information and sophisticated motion planning of the robotic arm, the robot would be able complete much more complex tasks autonomously.

Discussion

In this work, we presented a magnetic crack-based piezoinductive sensor (MC-PIS) which is capable of bidirectional mechanical sensing for both proprioception and tactility. The sensor is ultrasensitive (0.01° angle resolution, equals to 0.8 µε strain), spanning a wide angle range from compression (−200°) to tension (327°). The key to the approach is the gradual decrease of the magnetic reluctance through the through-thickness cracks between ferromagnetic flakes. Hence, the soft sensor showed ultrastable response with no performance degradation even when scratched in half or run over by a car. Like other bulky inductive sensors that have been widely used in harsh industrial environment, the MC-PIS is insensitive to environmental changes like temperature, humanity, and dust. It can achieve the claimed performance in most application scenarios, not affected by running motors and machines. Although it should be noted that permanent magnets or large magnetic field changes could introduce errors as the relative permeability (µr) of the ferrite flakes might be changed. And nearby metal objects (within the distance of the coil dimension) should be avoided when implementing the MC-PIS in an application system as the induced eddy-current in metal would introduce errors in the inductance measurement as well. We demonstrated a flexible ribbon containing 16 MC-PIS units to perceive its real-time dynamic shape changes without training. We also fabricated a soft artificial finger with the MC-PISs to recognize delicate surface profiles and distinguish music notes transmitted from a speaker to the artificial finger through a solid surface. The MC-PISs were utilized in a soft crawling robot which responded to external attacks, and also used in a soft gripper performing the consecutive tasks required for planting a small tree. We believe that the MC-PIS represents a new paradigm for designing ultrasensitive yet robust mechanical sensors, realizing tactile intelligence in practical smart robots.

Methods

Preparation and characterization of CFFs

A flexible sintered ferrite film (WE-FSFS 354001, 0.1 mm thick, µr = 230, Würth Elektronik, Germany) was cut to the desired dimension by using scissors. The non-cracked ferrite sample was rolled on a cylindrical acrylic rod (D = 4 mm, unless otherwise specified) to generate the cracks. The ferrite layer was broken into hundreds of small flakes during the rolling process but remained in place because the elastic adhesive held them together as the CFF. The backing paper at the bottom side of the CFF was readily removed. Optical microscopic images of the CFF were taken to extract the crack configuration and used to analyze the dimensions of these ferrite flakes. In-situ tensile test under scanning electron microscope (SEM) was performed to quantify the variation of the air-gap between the flakes at different tensile strains.

Preparation of the bidirectional bending sensors

We prepared the CFF slightly larger than the planar coil. The induction coil for sensing was composed of two planar coils overlapped and connected at the center of the coils (Supplementary Fig. 23). After the backing paper of the CFF was removed, the CFF was slowly stacked on top of a planar coil, starting from one side edge to the other side, avoiding buckling or air bubbles. The CFF was trimmed along the edges of the planar coil by using scissors. Finally, the two ends of the coil were connected to an LCR meter (LCR 8210, GWINSTEK, China) for measurement.

Static characterization of the bending sensor

Acrylic tubes and rods with specified diameters of 7 mm, 8 mm, 9 mm, 10 mm, 11 mm, 12 mm, 13 mm, 14 mm, 16 mm, 18 mm, 20 mm, 22 mm, 25 mm, 28 mm, 32 mm, 35 mm, 40 mm, 45 mm, 50 mm, 60 mm, 80 mm, 100 mm, 120 mm, 150 mm, 200 mm, and 300 mm (equal to a bending angle from 327.4° to 7.6°) and flat acrylic plates (0°) were cut into suitable lengths for performing static bending characterization. The MC-PIS samples were rolled firmly on a cylindrical surface (or flat surface) with two sides fixed by polyimide tape (Supplementary Fig. 24). The inductance was measured at 200 kHz with the LCR meter. After the inductance measurement, the MC-PIS sample was peeled off and stuck to the surface of the other acrylic tubes for next measurements. For each tube, the sensor was tested for positive bending angles (outwards bending) and then for negative bending angles (inwards bending).

Dynamic bending experiments

Dynamic bending testing of the MC-PIS was performed by controlling the position of a motorized linear stage (M-404.6PD, Physik Instrument, Germany) to adjust the distance between the two side edges of the flexible MC-PIS (Supplementary Fig. 25). Two side edges of the flexible sensor were connected to the rigid acrylic plates (1.72 mm) with a thin polyimide tape (20 µm) which acted as flexure hinges to allow gradual bending between the edges of the sensor and the acrylic plate. The MC-PIS was pre-bent to a small angle to guide the bending in one direction. The maximum bending angle tested in this study was 180° where the sensor was curved to a semi-cylinder surface. A customized program (LabView, National Instruments, USA) was developed to control the movement of the linear stage and to record inductance values from the LCR meter.

Preparation of the sensorized flexible ribbon

The flexible coil array (1 × 16 array) was stuck on a PET substrate (0.3 mm thick, 20 mm wide) by using a double-sided tape (Supplementary Fig. 16). Each coil unit had dimensions of 15 mm × 10 mm and had 16 turns. The inductance sensor was composed of double layers of the coil. Four CFF strips with a dimension of 68 mm × 12 mm were prepared by rolling them on the acrylic rod of 4 mm in diameter, and then stacked on the surface of the coil array. Each CFF strip covered 4 coils. Traces near the flexible printed circuit (FPC) connector was designed with the serpentine structure to avoid fatigue during repeated cyclic bending tests. A customized 4-channel inductance to digital converting chip (LDC1614, Texas instruments, USA) was used to measure the inductance and communicated with a microcontroller (NI myRIO 1900, National Instruments, USA) through the I2C protocol to a computer to save and display the results (Supplementary Fig. 26). A customized circuit board consisting of 4 LDC1614 chips was designed to achieve simultaneous inductance measurements of 16 sensing units. A multiplexer was used to switch the I2C communication bus between the four LDC1614 chips.

Fabrication of the sensorized finger and crawling robot

A soft pneumatic finger (SPA) was designed based on the classic PneuNet structure to produce bending deformations under positive pressure. The casting mold (outer case part) of the SPA was 3D printed (Raise 3D, China) with tough polylactic acid (PLA), whereas the sacrificial inner supporting mold (air chamber part) was printed with a water-soluble filament, polyvinyl alcohol (PVA). The elastomeric body of the soft finger was cast in the assembled mold with DragonSkin 20 A (Smooth-On, USA). After curing, the elastomeric body with the supporting PVA was removed from the PLA case, and submerged in water for 48 h to completely dissolve the PVA part. Then, a silicone tube (Dout = 2 mm, Din = 1 mm) was inserted into the hole to connect the air chamber and sealed with Sil-Poxy (Smooth-On, USA). A MC-PIS (15 mm × 30 mm) was prepared and then stuck at the bottom surface of the soft finger. The soft smart crawling robot was designed and fabricated with the same methods. The crawling robot has two pneumatic bending modules. Each module had a 3D-printed feet which had anisotropic friction mounted at its end to produce directional movement by repeated bending movements. Two MC-PISs were integrated at the bottom of each bending module to monitor the bending deformation.

Robotic tree planting

A fin-ray gripper with two adaptive “fingers” (WHEELTEC, China) was used as a versatile end-effector to handle the diverse tasks during robotic-tree planting. The tasks included grasping soils and stones, digging holes in the soil, grasping the tree, plowing the soils, and pressing the soils. Two MC-PISs were prepared and placed on one of the adaptive fingers to monitor the tactile signals; one at the tip and the other at the root of the finger (Supplementary Fig. 20). The sensorized adaptive fin-ray gripper was mounted on a six-axis robotic arm (AUBO i3, China) with a payload of 3 kg. The six-axis robotic arm carries the sensorized fin-ray gripper to perform the consecutive tasks to complete all steps during robotic tree planting. Motion planning and manipulation control of the robotic arm to perform these tasks were realized via the imitation learning mode of the robotic control panel. For the sensorized fin-ray gripper, a step motor was used to drive the screws and the linkages to produce the rotational movements of two fingers to close and open. The two MC-PISs provided tactile signals for the various tasks during the tree-planting demonstration, showing no output drift or performance degradation after repeated contacts and wears with soil and stones.

Data availability

All relevant data generated in this study are provided in the Supplementary Information/Source Data file. The data that support the findings of this study are available in Figshare with the identifier https://doi.org/10.6084/m9.figshare.29036288. Source data are provided with this paper.

References

Cutkosky, M. R. & Provancher, W. Force and tactile sensing. Springer Handbook of Robotics, 717-736 (2016).

Bartolozzi, C., Natale, L., Nori, F. & Metta, G. Robots with a sense of touch. Nat. Mater. 15, 921–925 (2016).

Yang, J. C. et al. Electronic skin: recent progress and future prospects for skin-attachable devices for health monitoring, robotics, and prosthetics. Adv. Mater. 31, 1904765 (2019).

Amjadi, M., Kyung, K. U., Park, I. & Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: a review. Adv. Funct. Mater. 26, 1678–1698 (2016).

Ling, Y. et al. Disruptive, soft, wearable sensors. Adv. Mater. 32, 1904664 (2020).

Wang, H., Totaro, M. & Beccai, L. Toward perceptive soft robots: progress and challenges. Adv. Sci. 5, 1800541 (2018).

Tiwana, M. I., Redmond, S. J. & Lovell, N. H. A review of tactile sensing technologies with applications in biomedical engineering. Sens. Actuators A: phys. 179, 17–31 (2012).

Boutry, C. M. et al. Biodegradable and flexible arterial-pulse sensor for the wireless monitoring of blood flow. Nat. Biomed. Eng. 3, 47–57 (2019).

Chung, H. U. et al. Binodal, wireless epidermal electronic systems with in-sensor analytics for neonatal intensive care. Science 363, eaau0780 (2019).

Xu, J. et al. Recent progress of tactile and force sensors for human-machine interaction. Sensors 23, 1868 (2023).

Yin, R., Wang, D., Zhao, S., Lou, Z. & Shen, G. Wearable sensors-enabled human-machine interaction systems: from design to application. Adv. Funct. Mater. 31, 2008936 (2021).

Mintchev, S., Salerno, M., Cherpillod, A., Scaduto, S. & Paik, J. A portable three-degrees-of-freedom force feedback origami robot for human-robot interactions. Nat. Mach. Intell. 1, 584–593 (2019).

Luo, Y. et al. Technology roadmap for flexible sensors. ACS Nano 17, 5211–5295 (2023).

Kim, T. Y., Suh, W. & Jeong, U. Approaches to deformable physical sensors: electronic versus iontronic. Mater. Sci. Eng.: R: Rep. 146, 100640 (2021).

Boutry, C. M. et al. A stretchable and biodegradable strain and pressure sensor for orthopaedic application. Nat. Electron. 1, 314–321 (2018).

Oh, J. et al. Pressure insensitive strain sensor with facile solution-based process for tactile sensing applications. ACS Nano 12, 7546–7553 (2018).

Yang, J. C. et al. Microstructured porous pyramid-based ultrahigh sensitive pressure sensor insensitive to strain and temperature. ACS Appl. Mater. Interfaces 11, 19472–19480 (2019).

Nguyen, T. et al. Advances in ultrasensitive piezoresistive sensors: from conventional to flexible and stretchable applications. Mater. Horiz. 8, 2123–2150 (2021).

Zheng, Q., Lee, J. -h, Shen, X., Chen, X. & Kim, J.-K. Graphene-based wearable piezoresistive physical sensors. Mater. Today 36, 158–179 (2020).

Nur, R. et al. A highly sensitive capacitive-type strain sensor using wrinkled ultrathin gold films. Nano Lett. 18, 5610–5617 (2018).

Cuthbert, T. J., Hannigan, B. C., Roberjot, P., Shokurov, A. V. & Menon, C. HACS: helical auxetic yarn capacitive strain sensors with sensitivity beyond the theoretical limit. Adv. Mater. 35, 2209321 (2023).

You, I. et al. Artificial multimodal receptors based on ion relaxation dynamics. Science 370, 961–965 (2020).

Chang, Y. et al. First decade of interfacial iontronic sensing: from droplet sensors to artificial skins. Adv. Mater. 33, 2003464 (2021).

Zhao, C. et al. Ionic flexible sensors: mechanisms, materials, structures, and applications. Adv. Funct. Mater. 32, 2110417 (2022).

Xiong, Y., Han, J., Wang, Y., Wang, Z. L. & Sun, Q. Emerging iontronic sensing: materials, mechanisms, and applications. Research https://doi.org/10.34133/2022/9867378 (2022).

Wang, H. et al. Folding and bending planar coils for highly precise soft angle sensing. Adv. Mater. Technol. 5, 2000659 (2020).

Veerapandian, S. et al. Two-terminal deformable induction array sensor capable of recognizing non-contact dynamic motions of various objects. Adv. Funct. Mater. 34, 2305776 (2024).

Kang, D. et al. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 516, 222–226 (2014).

Yang, T. et al. Structural engineering of gold thin films with channel cracks for ultrasensitive strain sensing. Mater. Horiz. 3, 248–255 (2016).

Amjadi, M., Turan, M., Clementson, C. P. & Sitti, M. Parallel microcracks-based ultrasensitive and highly stretchable strain sensors. ACS Appl. Mater. Interfaces 8, 5618–5626 (2016).

Li, S. et al. Bioinspired robot skin with mechanically gated electron channels for sliding tactile perception. Sci. Adv. 8, eade0720 (2022).

Zhou, R. et al. Hierarchical synergistic structure for high resolution strain sensor with wide working range. Small 19, 2301544 (2023).

Cho, C. et al. Strain-resilient electrical functionality in thin-film metal electrodes using two-dimensional interlayers. Nat. Electron. 4, 126–133 (2021).

Wang, S. et al. Network cracks-based wearable strain sensors for subtle and large strain detection of human motions. J. Mater. Chem. C. 6, 5140–5147 (2018).

Na, H. R. et al. Vertical graphene on flexible substrate, overcoming limits of crack-based resistive strain sensors. npj Flex. Electron. 6, 2 (2022).

Spaldin, N. A. Magnetic materials: fundamentals and applications (Cambridge University Press, 2010).

Xu, H. et al. A simple calculation method for center magnetic flux density of a magnetic core electromagnet with a wide air gap. IEEE Trans. Appl. Supercond. 32, 1–6 (2022).

Nie, B. et al. Textile-based wireless pressure sensor array for human-interactive sensing. Adv. Funct. Mater. 29, 1808786 (2019).

Sivadasan, K. Analysis of self-sensing active magnetic bearings working on inductance measurement principle. IEEE Trans. Magn. 32, 329–334 (1996).

Lemarquand, V. A new bi-directional inductive force sensor. IEEE Trans. Magn. 34, 1333–1335 (1998).

Zhang, J. et al. A preprogrammable continuum robot inspired by elephant trunk for dexterous manipulation. Soft Robot. 10, 636–646 (2023).

Burgner-Kahrs, J., Rucker, D. C. & Choset, H. Continuum robots for medical applications: a survey. IEEE trans. Robot. 31, 1261–1280 (2015).

Xie, Z. et al. Octopus-inspired sensorized soft arm for environmental interaction. Sci. Robot. 8, eadh7852 (2023).

Van Meerbeek, I., De Sa, C. & Shepherd, R. Soft optoelectronic sensory foams with proprioception. Sci. Robot. 3, eaau2489 (2018).

Hu, D., Giorgio-Serchi, F., Zhang, S. & Yang, Y. Stretchable e-skin and transformer enable high-resolution morphological reconstruction for soft robots. Nat. Mach. Intell. 5, 261–272 (2023).

Xie, Z. et al. A proprioceptive soft tentacle gripper based on crosswise stretchable sensors. IEEE/ASME Trans. Mechatron. 25, 1841–1850 (2020).

Della Santina, C., Bicchi, A. & Rus, D. On an improved state parametrization for soft robots with piecewise constant curvature and its use in model-based control. IEEE Robot. Autom. Lett. 5, 1001–1008 (2020).

Wang, Y. et al. Toward human-like touch sense via a bioinspired soft finger with self-decoupled bending and force sensing. Cell Rep. Phys. Sci. 5, 102225 (2024).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NO. 52275579, H. Wang), the Talent Introduction Program of Chinese Academy of Sciences (H. Wang), and a starting grant from the University of Science and Technology of China (H. Wang).

Author information

Authors and Affiliations

Contributions

Y. P., Z. W., U. J., and H. Wang conceived the work and designed the experiments. Y. P., Z. W., and H. Wu carried out the fabrication and characterization of CFF and MC-PIS samples. H. Wu analysed the microscopic images of the CFF samples. Z. W., Z. F., and H. Wang conducted the theoretical analysis and simulations. Y. P., H. Wu, J. L., X. C., and Y. W. carried out the demonstrations of shape reconstruction, soft artificial finger, smart responsive crawling robot, and the robotic tree planting. H. Wu., J. L., S. Z., and Z. F. contributed to the data analysis, experiments design, figure illustration, and paper preparation. Y. P., U. J., and H. Wang wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

A Chinese innovation patent (CN 202311395900.6) based on the sensor technology described in this article has been filled by the University of Science and Technology of China, which is granted by the China National Intellectual Property Administration. Authors H. Wang, Y. P., Z. W. and H. Wu are inventors of this granted patent. The other authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Youfan Hu, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Peng, Y., Wang, Z., Wu, H. et al. Magnetic crack-based piezoinductive mechanical sensors: way to extreme robustness and ultra-sensitivity. Nat Commun 16, 6370 (2025). https://doi.org/10.1038/s41467-025-61784-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-61784-0