Abstract

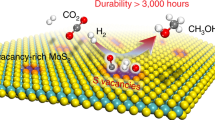

CO2 hydrogenation into methanol suffers from a huge obstacle of low methanol yield due to the leverage effect of CO2 conversion and methanol selectivity. Here, we report an In2O3-MnCO3 catalyst consisting of In2O3 covalently linked to MnCO3 for efficiently photothermal CO2 hydrogenation into methanol. Covalent linkage, the O atoms of In2O3 occupy the oxygen vacancies of MnCO3, enables the formation of In-O-Mn Lewis acid-base pairs at the In2O3-MnCO3 interface. Both light irradiations and heatings improve the electron excitations and transfers from In to O, promoting CO2 activation and methanol production. The In2O3-MnCO3 containing 30 mol.% In achieves 67.5% methanol selectivity and 13.5% CO2 conversion at 150 °C, 4.0 MPa, and 14400 mL·h−1·g−1 with a high stability for at least 500 h on stream. This study provides a serial In-Mn catalyst design and understanding of the molecular-level structure-mediated photothermal catalytic hydrogenation.

Similar content being viewed by others

Introduction

Large-scale, safe storage of H2 remains a considerable obstacle to a prosperous H2 economy. Chemical storage through the reaction of H2 with CO or CO2 is one of the important methods for safe H2 storage1,2, and between the two, CO2 is more attractive because of its easy storage, nonflammability, and safety3. Currently, catalysts have been developed to catalyze CO2 hydrogenation into methanol, such as In-based4,5,6,7,8,9,10,11, Zn-based12,13,14, and Cu-based catalysts15,16,17,18,19,20,21. However, these above catalysts require a reaction temperature of ≥250 °C to behave relatively well, which results in excess energy consumption. There are lots of low-grade heat sources (generally ≤150 °C) in the chemical plant, like low-pressure steam (100 ~ 150 °C). If the temperature for CO2 hydrogenation into methanol decreases to ≤150 °C, these low-grade heat sources can be coupled with the CO2-to-methanol process, apparently reserving the energy consumption.

CO2 activation is one of the critical steps limiting the decrease of CO2-to-methanol temperature. Actually, there is a leverage effect between high CO2 conversion and methanol selectivity. The critical problem is that lowering the temperature benefits methanol selectivity, but is against CO2 activation. Some researchers developed various methods to lower the CO2 activation temperature to realize efficient low-temperature CO2 hydrogenation into methanol. Chen et al. used ethanol as the CO2 activation agent to hydrogenate CO2 into methanol at 135 °C22, which achieved 4.7 × 10−4 s−1 methanol turnover frequency. Other researchers developed new catalysts for CO2 hydrogenation into methanol at low temperatures23,24,25,26,27. Although these above catalysts realized the low-temperature hydrogenation into methanol, they suffer from batch reactions or low methanol yield.

In recent years, photothermal catalysis has paid much attention to CO2 hydrogenation11,28,29, because light can excite electrons to activate chemical bonds of CO2 and promote hydrogenation reactions. However, the developed catalysts still require a temperature of ≥200 °C, and the methanol production rate is as low as ≤300 μmol·h−1·g−1.

In2O3 is not only an excellent catalyst for CO2 hydrogenation into methanol but also a good photocatalyst30. Both oxygen vacancies and photoelectrons on In2O3 can promote CO2 activations at low temperatures. To further decrease the temperature, one of the effective strategies is to reunite ZrO2 with In2O3 for the creation of efficiently interfacial CO2 activation sites5,6,12 and the increase of photoelectron concentrations, which promotes the photothermal low-temperature CO2 hydrogenation into methanol. The ZrO2 also interacted with In2O3 in the electron-transfer level, improving the electron density of In2O3, thus promoting H2 splitting and methanol production5,31. Exclude the ZrO2, few metal oxides have been reported to be reunited with In2O3.

Recently, metal carbonates were gradually used in the productions of various chemicals from catalytic hydrogenation32,33,34. For example, Kanan et al. used alkali oxide to create an oxide-carbonate interface to form carbonate or carboxylate intermediates from CO2 and then hydrogenation into chemicals at 320 °C and 0.25 MPa35. Yang et al. designed a Ru-metal carbonate interface to form active intermediates from CO2 and then hydrogenation into CH4 at 300 °C and 0.1 MPa36. In these above reports, metal/metal oxide-carbonate interfaces activated and converted CO2 in mild conditions36.

Inspired by the above idea, a different strategy to enhance the photothermal low-temperature CO2 hydrogenation activity of In2O3 is proposed, which reunites In2O3 with metal carbonate to promote CO2 activation. For this strategy to be successful, the metal sites in metal carbonate must possess a good affinity to CO2, which benefits the formation of active intermediates from CO2. MnCO3 is one of the typical metal carbonates for CO2 recycling from MnCO3 to MnO at a relatively lower temperature (≤300 °C), which benefits the formation of active carbon-based intermediates at low temperatures37. Here, we explore this strategy using a system consisting of In2O3 and MnCO3. A simple one-pot hydrothermal method was used, followed by in-situ synthesis, with the treatment in 23%vol. CO2/Ar and 200 °C, we constructed a catalyst of In2O3-MnCO3 composite, labeled as xIn-Mn, where x is the molar percentage of In, and evaluated their CO2 hydrogenation into methanol activities. Compared with the individual components, 30In-Mn exhibited 1.7 and 10.4 times higher methanol production rates than the pure In2O3 and MnCO3, respectively. The data could be explained by forming In-O-Mn Lewis acid-base pairs (LA-LB) due to the strong interactions between In2O3 and MnCO3.

Results

Characterizations of In2O3 and MnCO3 interactions

As shown in TEM and SEM images, MnCO3 presents nearly spherical particles with sizes of 0.5 ~ 2.5 μm (Fig. 1a and Supplementary Fig. 1a), while the In2O3 exhibits cubic particles with the range of 5 ~ 70 nm (Fig. 1b and Supplementary Fig. 1b). 30In-Mn shows irregular particles with the size as small as ~10 nm (Fig. 1c and Supplementary Fig. 1c). HRTEM images of the MnCO3 (Fig. 1d) show good crystallization with fringes of 0.29 nm corresponding to the MnCO3 (104) facet, while the 30In-Mn (Fig. 1e) mainly presents an amorphous surface with few crystalline areas.

To further distinguish the components of these amorphous and crystalline areas, the ICP-OES, EDX mapping, and HAADF-STEM are conducted (Full names of characterizations in Supplementary Table 1). From ICP-OES measurements (Supplementary Table 2), the In and Mn contents are 26.9 and 73.1 mol.%, respectively. The EDX mapping shows that the 30In-Mn catalyst surface consists of 36.4 mol.% In and 63.6 mol.% Mn (Fig. 1f). Such a high concentration of In species does not exhibit In2O3 peaks in XRD patterns (Supplementary Fig. 2), suggesting that In species are most probably amorphous. An amorphous area over 30In-Mn shown in HRTEM and EDX images (Supplementary Fig. 3) presents In elemental distribution with very few Mn, indicating that the amorphous region consists of In species. Specific analysis of crystalline (light pink circle of Fig. 1g–i and Supplementary Fig. 4) and amorphous (light green circle of Fig. 1g–i and Supplementary Fig. 4) areas further support that the crystalline and amorphous regions consist of Mn and In species, respectively.

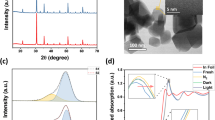

XRD patterns, Raman, and EPR spectra of xIn-Mn were undertaken to explore the above crystal change. XRD patterns (Fig. 2a) of MnCO3 and 30In-Mn only show diffraction peaks of MnCO3 (peak assignments in Supplementary Table 3 and 4). The intensity of MnCO3 peaks decreases with increasing In2O3 concentration for xIn-Mn. This indicates that the interaction between In2O3 and MnCO3 partially disrupts the crystal structures of MnCO3 but completely disrupts the crystal structures of In2O3, which is further confirmed by the slow-scanning XRD patterns (Supplementary Figs. 5 and 6).

a XRD patterns, (b) Raman spectra, and c room-temperature EPR spectra of MnCO3, 10In-Mn, 20In-Mn, 30In-Mn, 40In-Mn and In2O3; d Mn 2p, (e) In 3 d and f O 1 s XPS; g IR spectra of MnCO3, 30In-Mn and In2O3; h In-K edge EXAFS of 30In-Mn, In2O3 and In particles; i In-situ Mn-K edge EXAFS of 30In-Mn tested at room temperature after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and 100 °C, 150 °C and 200 °C.

Raman spectrum of In2O3 (Fig. 2b) shows several peaks corresponding to various In-O vibrations (Supplementary Table 5). It should be noted that the peaks at 126 and 297 cm−1 are attributed to the In-O vibrations within InO6 octahedra, and the peak at 357 cm−1 corresponds to the stretching vibrations of In-O-In, indicative of surface oxygen vacancies (InO6-X). Other catalysts present a sharp peak at 1084 cm−1 assigned to carbonate groups (Supplementary Table 6). With increasing In concentration from 0 to 40 mol.%, the peak at 1084 cm−1 decreases evidently, indicating that the carbonate groups in MnCO3 are destroyed after compounding and interacting with In2O3.

EPR spectra of In2O3 and MnCO3 at room temperature (Fig. 2c) exhibit a strong peak at g = 2.009, indicating a high concentration of oxygen vacancies6. However, this peak intensity decreases with the In2O3 concentration increasing, suggesting the decrease of oxygen vacancies. This phenomenon resulted from two aspects. On the one hand, the interaction between In2O3 and MnCO3 disrupts the crystal structures. On the other hand, O atoms in In2O3 occupy oxygen vacancies on MnCO3, or O atoms in MnCO3 occupy oxygen vacancies of In2O3.

Formations of In-O-Mn Lewis acid-base pairs

From analyzing the synthesis process of 30In-Mn (S10 in supporting information), it can be found that the In-O-Mn LA-LB is most probably formed during the CO2 pretreatment. To confirm the combination between In2O3 and MnCO3, XPS, IR, In K-edge EXAFS, and in-situ Mn K-edge EXAFS spectra were conducted. Mn 2p XPS of both MnCO3 and 30In-Mn (Fig. 2d) present Mn2+ and Mn3+ peaks as well as the shakeup peak of Mn2+ (Supplementary Table 7). It should be noted that the binding energies of Mn2+ in 30In-Mn are higher than the ones of MnCO3, suggesting the electron elimination around Mn2+. In 3 d XPS spectra of both In2O3 and 30In-Mn (Fig. 2e) show two peaks corresponding to In2+ and In3+. The binding energies of In2+ and In3+ for 30In-Mn are higher than the ones of In2O3, suggesting the electron elimination around In2+ and In3+. O 1 s XPS spectra of MnCO3, In2O3, and 30In-Mn (Fig. 2f) show three peaks attributing to the surface -OH, the MnCO3 or/and chemically adsorbed O, and the lattice O or/and metal carboxylate (Supplementary Table 7). It should be noted that binding energies of the latter two O species for 30In-Mn shift to lower values, indicating the higher electron density around O. All three XPS spectra indicate the possible formation of In-O-Mn LA-LB, which results from O atoms in In2O3 filling in oxygen vacancies in carbonates of MnCO3. Most likely, the O atoms in In2O3 occupy the Ov of MnCO3 and change In-O-In to In-O-Mn in In2O3, decreasing the electron density around In2+ and Mn2+ (the scheme shown in Supplementary Fig. 13). Moreover, such fillings may result in severe lattice distortions in In2O3, thus resulting in its crystal disruptions, consistent with the conclusions from section 2.1.

IR spectra of 30In-Mn (Fig. 2g) show similar peaks with MnCO3 (Supplementary Table 8), while a small new peak at 1156 cm−1, not observed in In2O3 and MnCO3 (Supplementary Table 8 and 9), appears for 30In-Mn, which is reported to be In-O-Mn linkage38. In K-edge EXAFS spectra (Fig. 2h and Supplementary Table 10) show that 30In-Mn presents a peak at ca. 2.01 Å, which is very near to the one of In-O distance in In2O3 (2.00 Å). Notably, the In-In bond is not observed in the 30In-Mn catalyst, confirming that O atoms of In2O3 occupy the oxygen vacancies on MnCO3 to form an In-O-Mn linkage. The peak at 2.01 Å should be attributed to the In-O-Mn linkage due to the slight increase of In-O distance compared to the In-O-In linkage. The radius of Mn atoms is smaller than the radius of In atoms, which results in the stretching of In-O bond, thus resulting in the longer In-O bond of In-O-Mn than the one of In-O-In. The results are consistent with the phenomenon in forming In-O-Zn or In-O-Zr linkage39,40 and DFT calculations (Supplementary Table 11).

In-situ Mn K-edge EXAFS spectra of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and 100 °C (Fig. 2i) present two peaks corresponding to Mn-O (2.07 Å) and Mn-C/Mn-Mn (2.93 Å) shell in MnCO3/MnO, respectively. The distance for Mn-O shell at 150 °C and 200 °C shifts to 1.97 and 1.90 Å, respectively. Both are shorter than those of MnCO3, Mn2O3, MnO, and MnO2, which are most probably attributed to the Mn-O shell in the In-O-Mn linkage due to the distortions of the MnCO3 lattice. It should be noted that the Mn-O distance of In-O-Mn linkage in 30In-Mn at 150 °C is longer than that at 200 °C, indicating that the bond is gradually stably formed with the temperature rising. It directly supports the formation of stable In-O-Mn linkage in 30In-Mn. The FT-EXAFS curves (Fig. 3a–c) reveal that the coordination numbers of Mn-O increase from 5.8 to 6.1 with the temperature rising from 100 °C to 200 °C (Supplementary Table 12 and 13), further supporting the conclusion that the In-O-Mn linkage is formed via the filling of oxygen vacancies on MnCO3 by O atoms of In2O3.

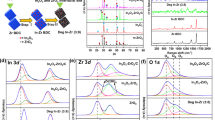

Wavelet-transformed spectra of Mn K-edge EXAFS of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and a 100 °C, (b) 150 °C and c 200 °C; d C 1 s XPS spectra of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and 100 °C, 150 °C, and 200 °C; e Mn K-edge XANES spectra of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and 100 °C, 150 °C and 200 °C; f In K-edge XANES spectra of 30In-Mn, In foil and In2O3; g Mn 2p and h In 3 d XPS spectra of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and 100 °C, 150 °C and 200 °C; i Differential charge calculations of 30In-Mn.

The formation of In-O-Mn linkage would adsorb CO2 to form carbonate and carboxylate in CO2 atmosphere. CO2-adsorbed IR and XPS spectra were conducted to confirm the carbonate and carboxylate formations. IR spectra of xIn-Mn in 23 vol.% CO2/Ar at 200 °C and 4.0 MPa (Supplementary Fig. 16) show two apparent peaks corresponding to carboxylate and one corresponding to carbonate. The C 1 s XPS of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa (Fig. 3d) shows three peaks at 289.4, 286.3, and 284.8 eV (adventitious C contamination) (Supplementary Table 7). These two former values are close to the reported ones of metal carboxylate41,42.

In-situ Mn K-edge XANES, In K-edge XANES spectra, in-situ XPS and DFT calculations were conducted to explore the formation of In-O-Mn LA-LB. In-situ Mn K-edge XANES spectra of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and 100 °C (Fig. 3e) present the absorption edge of 6543 eV, which is lower than the one at 150 °C and 200 °C (6546 eV) (Fig. 3e and Supplementary Fig. 17), indicating that the Mn tends to be more electron deficient at 150 °C and 200 °C. In K-edge XANES spectra of 30In-Mn (Fig. 3f) presents that the state of In species in the 30In-Mn are similar to the In2+ and In3+ of In2O3. Both indicate the electron transfer from Mn and In to O, suggesting the formation of In-O-Mn LA-LB.

The Mn 2p XPS of 30In-Mn after being pretreated in 23 vol.%CO2/Ar at 4.0 MPa and 100 °C (Fig. 3g) shows four peaks corresponding to Mn+ (640.8 eV), Mn2+ (641.9 eV), Mn3+ (644.0 eV) and shakeup satellite peak of Mn2+ (646.8 eV). The Mn2+ peak, being directly associated with In-O-Mn linkage, shifted to higher binding energies with the temperature rising to 150 °C and 200 °C, and the In for In 3 d XPS of 30In-Mn (Fig. 3h) also shifted to a higher binding energy at higher temperature, further supporting the formation of In-O-Mn LA-LB. Results of Mn 3 s XPS (Supplementary Fig. 18) also confirm the formation of In-O-Mn LA-LB. The change of ratios for the valences of Mn and In also supports the electron transfer from Mn and In to O (Supplementary Table 14 and 15). Calculations of charge density (Fig. 3i and Supplementary Fig. 19) show the increase of charge density around O and the decrease around Mn and In for 30In-Mn, further confirming the formation of In-O-Mn LA-LB.

Photothermal properties of In-O-Mn LA-LB

To explore the photothermal properties of catalysts, UV-vis DRS, UPS, PC, EIS, and PL spectra were conducted. UV-vis DRS and UPS spectra were used to estimate the electronic energies of conduction and valence bands of In2O3 and MnCO3 (Fig. 4a and Supplementary Fig. 20). The adsorption edge of In2O3 and MnCO3 were 457 and 1125 nm, respectively, indicating that the MnCO3 can adsorb the infrared light for temperature rising (Supplementary Fig. 21). The calculated band gap energy (Eg) of In2O3 and MnCO3 were 2.80 and 2.49 eV, respectively (Fig. 4b, calculation details in S25), similar to the reported values43. The upper onset and secondary onset energies in the UPS spectra for In2O3 were 15.23 and 2.47 eV, respectively (Fig. 4c). For MnCO3 14.71 and 1.37 eV, respectively (Fig. 4d). The estimated band positions for In2O3 and MnCO3 are shown in Fig. 4e (calculation details in S26), whose valence bands are 2.18 eV for In2O3 and 1.68 eV for MnCO3. In comparison with the XPS without photo irradiations, the binding energies of In shift to higher values, while the ones of O and Mn shift to lower values with photo irradiations, indicating the In-to-Mn electron transfer (Supplementary Fig. 22). The Z-scheme photocatalytic CO2 reduction process is proposed, as shown in Fig. 4f (detailed discussions in S28). The photoelectron of In2O3 migrates to the valence band of MnCO3, which results in the electron transfer from In2O3 to MnCO3 via In-O-Mn linkage under light irradiations. Such charge migration promotes the increase of the strength for LA-LB, which is beneficial to CO2 and NH3 adsorptions (Supplementary Figs. 24 and 25).

a UV-vis DRS of 30In-Mn, In2O3 and MnCO3; b (αhν)2 versus hν curve of MnCO3 and In2O3; UPS spectra of c MnCO3 and d In2O3; e scheme of band levels of MnCO3 and In2O3; f proposed Z-scheme charge flow pathway; g photocurrent transient curves of 30In-Mn, MnCO3 and In2O3 with typical on-off switches of light irradiation at a bias potential of 0 V vs. Ag/AgCl in 0.35 M Na2S + 0.25 M Na2SO3 aqueous solution; h EIS curves of 30In-Mn, MnCO3 and In2O3; i PL spectra of 30In-Mn, MnCO3 and In2O3.

The photocurrent transient responses for In2O3, MnCO3 and 30In-Mn at different temperatures are shown in Fig. 4g and Supplementary Fig. 26. The photocurrent responses decrease in the following order: 30In-Mn > In2O3 > MnCO3, and the ones for all three catalysts increase with the temperature rising. EIS of 30In-Mn (Fig. 4h and Supplementary Fig. 27) exhibited lower impedance than In2O3 and MnCO3, and the impedance of all three catalysts decreased with the temperature rising. It indicates that formations of In-O-Mn LA-LB and temperature rising benefit the photo-generated electron-hole pairs and the electron transfer, which may play a significant role in the photothermal CO2 reduction. PL spectra of 30In-Mn (Fig. 4i and Supplementary Fig. 28) displayed a quenched PL emission signal in contrast to In2O3 and MnCO3, signifying the suppressed recombination of the charge carriers for 30In-Mn. TRPL decay of 30In-Mn (Supplementary Fig. 29) shows both a longer fast decay lifetime (τ1 = 30.2 ns) and slow decay lifetime (τ2 = 882.5 ns) than that of MnCO3 (τ1 = 0.85 ns, τ2 = 611.7 ns), supporting its better electron-hole separations.

Photothermal performances

H2-TPR profile of MnCO3 (Fig. 5a) shows only one peak at 407 °C, and the MS profiles at m/z = 44 for the exhausted gas (Supplementary Fig. 30) exhibit only one peak at 414 °C, indicating that the MnCO3 decomposes in H2 atmosphere at ~ 410 °C. In2O3 presents two peaks assigned to the reduction of surface O (267 °C) and bulk lattice O (≥500 °C). 30In-Mn shows two peaks corresponding to MnCO3 decomposition (407 °C) and In-O-Mn linkage reduction (662 °C).

a H2-TPR profiles of 30In-Mn, In2O3 and MnCO3; b In-situ DTG analysis of 30In-Mn at different CO2 pressures; c In-situ XRD patterns of 30In-Mn at different temperatures under 0.92 MPa CO2 and 3.08 MPa H2; In-situ Raman spectra of d 30In-Mn and e MnCO3 at different temperatures under 0.92 MPa CO2 and 3.08 MPa H2; f Mass spectrum of products from CO2 hydrogenation over 30In-Mn; Catalytic performances of g 30In-Mn, (h) MnCO3 and i In2O3.

The in-situ DTG analysis of 30In-Mn (Fig. 5b) shows that the initially decomposed temperature increases from 290 to 360 °C with the CO2 pressure increasing from 1.0 to 30.0 KPa. In this study, the partial pressure of CO2 was 0.92 MPa. Thus, the 30In-Mn would not be decomposed at ≤360 °C, consistent with the results of differential heat flow (Supplementary Fig. 31). In-situ XRD of 30In-Mn (Fig. 5c) shows characteristic peaks of MnCO3 at 100 – 400 °C, and a very small peak of MnO is appeared at 400 °C, suggesting its thermal stability at ≤400 °C. In2O3 presents good thermal stability (Supplementary Fig. 32). In comparison, MnCO3 shows thermal stability at ≤350 °C (Supplementary Fig. 33). In-situ Raman spectra of both MnCO3 and 30In-Mn (Fig. 5d and e) show a main peak (1084 cm−1) at ≤ 400 °C without new peaks, further confirming the stability of both catalysts.

The formation of In-O-Mn LA-LB and excellent photothermal electron transfers will promote the CO2 hydrogenation into methanol. The optimal In2O3 concentration of xIn-Mn was identified from preliminary experiments (Supplementary Fig. 34), and 30In-Mn presents the best performance. MS of condensed liquid productions (Fig. 5f) shows H2O and methanol.

Photothermal catalytic performances of MnCO3, In2O3 and 30In-Mn were shown in Fig. 5g–i and Supplementary Figs. 35–S36. In all tests, the carbon balance was better than 98% with an uncertainty of ≤1.0% (Supplementary Table 16). The CO2 conversion under the same test conditions was the highest for 30In-Mn, reaching above 13.9% at 170 °C, and the lowest for MnCO3. With temperatures ranging from 100 to 170 °C, the methanol selectivity decreases from 80.3 to 63.7%. The optimal methanol yield reaches 13.5 mmol·g−1·h−1 at 150 °C (Fig. 6a and Supplementary Fig. 35). The methanol selectivity is 67.5% in this condition (Fig. 5g). The thermodynamic curves of CO2 hydrogenation into methanol (Supplementary Fig. 38) exhibits the methanol yield of 14.3 mmol·g−1·h−1 at 150 °C. The MnCO3 achieves the lowest methanol selectivity (≤27.1%) in the temperature range. The 30In-Mn was stable. Tested at 150 °C, it maintained its activity and product selectivity for over 500 h (Fig. 6b). The maximum methanol yield without heatings and light irradiations (Supplementary Fig. 39) for 30In-Mn is 1.23 and 1.88 mmol·g−1·h−1, respectively, which are 10.9 and 7.2 times lower than the ones in photothermal conditions. Moreover, the surface area-based methanol production rate 30In-Mn is also higher than In2O3 and MnCO3 (Supplementary Table 17 and Supplementary Fig. 40). This indicates that heating and light irradiations are important in CO2 hydrogenation into methanol. The methanol production rate achieved with 30In-Mn compares favorably with literature results for other catalysts, as shown in Supplementary Table 18 and Supplementary Fig. 41.

To illustrate the close relationship between In-O-Mn LA-LB and methanol productions, CO2-adsorption IR spectra quantified the number of In-O-Mn LA-LB. CO2-adsorption IR spectra (Supplementary Figs. 16 and 42) show that the peak area of carboxylate, directly associated with the number of In-O-Mn LA-LB, presents a linear relationship with methanol production rate. Moreover, the peak area for In-O-Mn linkage also presents a good linear relationship with the methanol production rate (Supplementary Fig. 43). It indicates that In-O-Mn LA-LB is mainly responsible for methanol production.

The Arrhenius plots (Fig. 6c and Supplementary Table 19) show that two-stage Arrhenius plots were obtained for dark conditions, while only one plot is appeared for light irradiation conditions. For dark conditions and 130 ~ 160 °C, the plots exhibit the activation energy of 173.56 kJ·mol−1, while it presents 48.74 kJ·mol−1 at 160 ~ 200 °C. One of the critical steps limiting the decrease of CO2-to-methanol temperature is CO2 activation16,19,20. The low temperature makes activating CO2 over In-O-Mn LA-LB difficult under dark conditions. The plots exhibit the activation energy of 34.93 kJ·mol−1 for light irradiation conditions, similar to the one from dark conditions at high temperatures. This indicates that they evolved a very similar reaction mechanism. It suggests that light irradiations promote performance via activating CO2 over In-O-Mn LA-LB.

To confirm that the detected carbon and hydrogen are mainly from the reaction and not from MnCO3 or other sources, 13CO2 and D2 labeled experiments and 13C-NMR are performed (details in S50 ~ S51). The data are collected after being pretreated in 13CO2 atmosphere. All these characterizations indicate that methanol’s carbon and hydrogenation source were exclusively from CO2 and H2, respectively.

Both In2O3 and MnCO3 showed similar trends in methanol selectivity with 30In-Mn, but they presented smaller CO2 conversion and lower methanol selectivity than the one of 30In-Mn in all reaction temperature ranges. The tested CO2 conversion and methanol selectivity of 30In-Mn are compared with the ones of fitted CO2 conversion and methanol selectivity from In2O3 and MnCO3 (Fig. 6d) and the ones of admixed In2O3/MnCO3 containing 30 mol.% In (Supplementary Fig. 47). The fitted values and activities from admixed catalysts are much lower than those of the tested 30In-Mn. This supports the conclusion that strong interactions between In2O3 and MnCO3 promote the activations of CO2 and H2, thus benefitting the CO2 hydrogenation into methanol.

To explore the adsorptions and activations of H2, H2-TPD profiles and H2-D2 experiments were conducted. MS at m/z = 2 profiles from H2-TPD of MnCO3 present two peaks at ≤300 °C corresponding to the physically adsorbed H2. In2O3 presents two peaks corresponding to the physically adsorbed H2 (139 °C) and splitting H (335 °C), indicating that the In2O3 is critical for the H2 activation. 30In-Mn shows only one splitting H peak at 352 °C. Results of quantitative analysis (Supplementary Fig. 48) show that the In2O3, MnCO3, and 30In-Mn, respectively, exhibit the H2 desorption of 0.32, 0.60, and 1.81 mmol·g−1cat. H2-D2 experiments (Fig. 6e and Supplementary Fig. 49) show that the In2O3 produces a much larger HD (m/z = 3) than MnCO3, supporting the critical role of H2 adsorptions and activations over In2O3. 30In-Mn produces the largest amount of HD (Fig. 7a), indicating the promotion of H2 adsorptions and activations by In-O-Mn LA-LB formations. Li et al. reported that H2 activation and migration are essential to limiting CO2 hydrogenation into methanol44,45.

To explore the adsorptions and activations of CO2, CO2-TPD profiles were conducted by TPD equipment linking with MS (Fig. 7b). MnCO3 exhibits four peaks corresponding to physically adsorbed CO2 (142 °C), chemically adsorbed CO2 (335 °C) and decomposition of MnCO3 (MnCO3→MnO+CO2) (416 and 535 °C). In2O3 shows only a wide peak corresponding to the chemically adsorbed CO2 (431 °C). 30In-Mn presents three peaks attributing to the physically adsorbed CO2 (151 °C), chemically adsorbed CO2 (352 °C) and MnCO3 decomposition (416 °C). It can be observed from CO2 adsorption profiles (Supplementary Fig. 50) that the adsorption capacity for chemically adsorbed CO2 is the largest for 30In-Mn and the smallest for In2O3. Results of temporal analysis of CO2 (Supplementary Fig. 51) show that the CO2 adsorption rate at 150 °C decreases with the following order: 30In-Mn > In2O3 > MnCO3.

To further confirm the critical role in CO2 adsorption and activation over In-O-Mn LA-LB, in-situ IR and C 1 s XPS in CO2 atmosphere are conducted. In-situ IR spectra of In2O3 (Supplementary Fig. 52) show small \({{{\rm{CO}}}}_{3}^{2-}\) peaks. MnCO3 (Fig. 7c) presents several peaks corresponding to \({{{\rm{CO}}}}_{3}^{2-}\), Mn-O-C linkage, and Mn-O (Peak assignments in Supplementary Table 20). 30In-Mn presents similar peaks with MnCO3 (Fig. 7d), while two new peaks at 1607 and 1409 cm−1 corresponding to vibrations of carboxylate are observed, whose peaks are consistent with the ones of HCOOH over 30In-Mn (Supplementary Fig. 53). This results from the formation of In-O-Mn linkage, which leads to the different vibrations of C-O in O = C-O groups in carboxylate.

C 1 s XPS (Supplementary Fig. 54) of In2O3 and MnCO3 after being pretreated in 0.92 MPa CO2 atmosphere exhibited three peaks corresponding to mixtures of carbonate and bicarbonate (289.0 ~ 289.2 eV), adsorbed CO (286.1 eV) and adventitious carbon contamination (284.9 eV) (peak assignments in Supplementary Table 21). It should be noted that the peak of adsorbed CO over In2O3 and MnCO3 has been disappeared, and a new peak of carboxylate (286.5 eV) is appeared for 30In-Mn. It indicates that the adsorbed CO is from the CO2 decomposition over oxygen vacancies, and In-O-Mn LA-LB is beneficial for the carboxylate formation after interactions between In2O3 and MnCO3, consistent with the results of in-situ IR spectra.

Photothermally catalytic mechanisms

The possible mechanisms are proposed as shown in Supplementary Fig. 55. Changes in the adsorbed species in a flow of reactants without and with light irradiations are monitored by in-situ IR spectra at different temperatures and 4.0 MPa of 23 vol.%CO2/H2, and the results are shown in Fig. 7a~g. 30In-Mn with photo irradiations (Fig. 8a) shows almost no peaks at 50 °C. At 100 °C, peaks corresponding to \({{{\rm{CO}}}}_{3}^{2-}\) and Mn-O of MnCO3 are observed (peak assignments in Supplementary Table 22), suggesting that the CO2 reacts with Mn sites to form carbonates even in the H2 atmosphere. Simultaneously, COO* peaks appear at 100 °C, and their intensity increases with the temperature rising, being consistent with the one of \({{{\rm{CO}}}}_{3}^{2-}\). It indicates that the CO2 adsorption on 30In-Mn forms \({{{\rm{CO}}}}_{3}^{2-}\) and COO* simultaneously. Some previous literature reported the conversion of \({{{\rm{CO}}}}_{3}^{2-}\) into COO*35,37. In-situ transient IR spectra of 30In-Mn with CO2 pretreatment and H2 pretreatment are conducted, and the results are shown in Supplementary Fig. 56. It can be obtained that the COO* is formed after H2 introduction, suggesting that the carbonate can be partially converted into COO* with the help of H2. At 120 °C, C-H and C-O vibrations of CH3O* are observed, suggesting the formation of methanol (standard IR spectra in Supplementary Fig. 57). Their intensity first increases with the temperature rising to 160 °C and then remains unchanged, almost consistent with the change of COO* and methanol activities. This indicates that methanol is mostly formed from COO*.

In-situ IR spectra of a 30In-Mn, (b) MnCO3, and c In2O3 in 23vol.% CO2/H2 atmosphere at 4.0 MPa with photo irradiations; In-situ IR spectra of d 30In-Mn, (e) MnCO3 and f In2O3 in 23vol.% CO2/H2 atmosphere at 4.0 MPa without photo irradiations; g In-situ C 1 s XPS of 30In-Mn after being pretreated in 23vol.% CO2/H2 atmosphere at 4.0 MPa and 100 °C and 150 °C; h DFT calculations for CO2 adsorption over MnCO3 and 30In-Mn.

MnCO3 presents similar peaks with the ones of 30In-Mn (Fig. 8b). However, peaks corresponding to COO* and CH3O* disappeared. It further confirms that interactions between In2O3 and MnCO3 will form In-O-Mn LA-LB and COO*, which is very critical for CH3O* formation. For In2O3, the peaks corresponding to carbonate, CO*, and C-O are observed, but with lower intensity, confirming the low activity (Fig. 8c).

In-situ IR spectra without photo irradiations are conducted in Fig. 8d–f to investigate the effect of light irradiations. For 30In-Mn, those peaks similar to the ones under light irradiations, including carbonate, COO*, CH3O*, CO*, C = O, and Mn-O, are observed at higher temperatures, indicating that the photo promotes the CO2-to-methanol at lower temperatures but does not alter the reaction pathway, consistent with results from activation energy. For MnCO3 and In2O3, similar peaks are observed but with lower intensity in comparison with the ones under photo irradiations.

In-situ C 1 s XPS were conducted of 30In-Mn after being pretreated in 23 vol.% CO2/H2 atmosphere at 4.0 MPa and 100 °C and 150 °C to clarify the reaction pathway for CO2 hydrogenation into methanol (Fig. 8g). The peak at 284.2 eV was assigned to adventitious C contamination. Several peaks corresponding to COO*/HCOO*, CH2O*, CH3O*, and carbonate/bicarbonate were observed for both 100 °C and 150 °C. Combining with the results of in-situ IR, it could be induced that the CO2 firstly adsorbed on the catalyst surface to form carbonate/bicarbonate and the COO*/HCOO*, which would be further hydrogenated into CH2O* and CH3O*. The formation of carbonate/bicarbonate results from the surface -OH or oxygen vacancies, and the formation of COO*/HCOO* is from the In-O-Mn LA-LB. It should be noted that the CH3O* concentration in 30In-Mn is lower than that in MnCO3, which suggests the easier desorption of CH3O* from catalysts to form methanol.

To explain and understand the evolution of CO2 into methanol on the 30In-Mn, DFT calculations were performed to illustrate the generation of methanol over In-O-Mn LA-LB. As shown in Fig. 8h, the adsorption energy of CO2 on In-O-Mn LA-LB (−0.31 eV) is easier than on MnCO3 (−1.80 eV), indicating that the CO2 prefers to be adsorbed on In-O-Mn LA-LB, which is consistent with the results of in-situ IR. After adsorption on In-O-Mn LA-LB, CO2 is converted into COO* intermediates, which is further hydrogenated into CO* and H2O (Supplementary Fig. 45). CO* tends to be further hydrogenated into *OCH, which is further converted into *OCH2, *OCH3 and methanol (Supplementary Fig. 45). Thus, the catalytic mechanism was clear.

Discussion

xIn-Mn catalysts prepared by the in-situ synthesis method in 23 vol.%CO2/Ar at 4.0 MPa can photothermally hydrogenate CO2 into methanol with the production rate of 13.5 mmol·g−1·h−1, which compares well with the state-of-art catalysts in the open literature. The O atoms in In2O3 occupied the oxygen vacancies in MnCO3, resulting in the formation of In-O-Mn linkage, thus promoting the in-situ generation of In-O-Mn LA-LB at the In2O3-MnCO3 interface. The formation of In-O-Mn linkage and In-O-Mn LA-LB benefit the electron transfer from In and Mn to CO2 activation into carboxylate under photothermal conditions, respectively. The carboxylate can be further hydrogenated into methanol. The strategy of fabricating metal oxide - metal carbonate interface active sites by taking advantage of the unique combination of metal oxides and metal carbonate reported here is expected to shed light on developing new seriously highly selective catalysts for photothermal CO2 hydrogenation reactions.

Methods

Catalyst preparations

A series of xIn2O3-MnCO3 catalysts, denoted as xIn-Mn, where x denotes the molar percentage of In, were prepared by the hydrothermal method followed by the in-situ synthesis method. Typically, 1.808 g of In(NO3)3·3H2O (Macklin reagent, ≥99.99%) and 4.500 g of Mn(CH3COO)2·4H2O (Adamas reagent, ≥99.99%) were dissolved in 150 mL distilled water. 4.954 g of Na2CO3 (Energy Chemical reagent, ≥99.50%) was dissolved into the above solution under stirring. After stirring for 1 h, the solution was transferred into the hydrothermal vessel, which was reacted at 180 °C for 24 h under stirring. The precipitations were treated by filtration and vacuum drying at 60 °C for 24 h, and calcining at 400 °C for 6 h in Ar atmosphere. The 30In-Mn was obtained by the in-situ synthesis in 23 vol.%CO2/Ar atmosphere with flow rate of 24 mL·min−1 at 4.0 MPa and 200 °C for 6 h, and the scheme of the in-situ synthesis equipment is shown in Supplementary Fig. 59. For samples containing different molar percentages of In, different weights of In(NO3)3·3H2O were used (Supplementary Table 23). In2O3 was prepared with the above method without adding Mn(CH3COO)2·4H2O. MnCO3 was prepared with the above method without adding In(NO3)3·3H2O. Admixed catalysts containing different contents of In2O3 and MnCO3 were also prepared, referred as xIn2O3/MnCO3 where x denotes the molar percentage of In.

Catalyst characterizations

Catalysts were characterized by X-Ray Diffractions (XRD), Raman Spectra, Infrared Spectra (IR), Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES), Scanning Electron Microscopy (SEM), High-Resolution Transmission Electron Microscopy (HRTEM) with Energy Dispersive X-Ray Spectroscopy (EDX), Electron Spin-Resonance Spectroscopy (EPR), Extended X-Ray Absorption Fine Structure (EXAFS), X-Ray Photoelectron Spectroscopy (XPS), in-situ XPS, Ultraviolet Photo-Electron Spectroscopy (UPS), in-situ EXAFs, in-situ XRD, in-situ Raman, High-pressure TGA analysis, H2 Temperature-Programmed Reduction (H2-TPR), H2 Temperature-Programmed Desorption (H2-TPD), CO2 Temperature-Programmed Desorption (CO2-TPD), H2-D2 exchange experiments, in-situ IR and Density Functional Calculations (DFT). More information about the catalyst characterizations is given in supporting information S69.

Activity tests

The performance of the prepared catalysts in the CO2 hydrogenation was evaluated using a fixed-bed reactor with light irradiations as shown in Supplementary Fig. 60. Briefly, 0.1 g of catalysts were firstly loaded into the reactor. A flowing 24 mL·min−1 with 23 vol.% CO2/Ar mixtures was introduced into the reactor at the pressure of 4.0 MPa, and the temperature remained at 200 °C for 2 h. After activating the catalysts, the temperature and pressure were decreased to the reaction temperature and pressure, respectively. The gases were changed to 23 vol.% CO2/H2 with a flow of 24 mL·min−1, and the performances started to record. The products were analyzed by an online gas chromatograph equipped with two packed columns and capillary columns. For more information about the catalyst characterizations, see S65 in the supporting information.

Data availability

Source data are provided with this paper.

References

Kattel, S., Ramírez Pedro, J., Chen Jingguang, G., Rodriguez José, A. & Liu, P. Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts. Science 355, 1296–1299 (2017).

Zhao, H. et al. The role of Cu1-O3 species in single-atom Cu/ZrO2 catalyst for CO2 hydrogenation. Nat. Catal. 5, 818–831 (2022).

Ye, R. et al. Design of catalysts for selective CO2 hydrogenation. Nat. Synth. 4, 288–302 (2025).

Jiang, X. et al. A combined experimental and DFT study of H2O effect on In2O3/ZrO2 catalyst for CO2 hydrogenation to methanol. J. Catal. 383, 283–296 (2020).

Yang, C. et al. Strong electronic oxide–support interaction over In2O3/ZrO2 for highly selective CO2 hydrogenation to methanol. J. Am. Chem. Soc. 142, 19523–19531 (2020).

Pinheiro Araújo, T. et al. Flame-made ternary Pd-In2O3-ZrO2 catalyst with enhanced oxygen vacancy generation for CO2 hydrogenation to methanol. Nat. Comm. 13, 5610 (2022).

Wang, J. et al. CO2 hydrogenation to methanol over In2O3-based catalysts: from mechanism to catalyst development. ACS Catal 11, 1406–1423 (2021).

Frei, M. S. et al. Nanostructure of nickel-promoted indium oxide catalysts drives selectivity in CO2 hydrogenation. Nat. Comm. 12, 1960 (2021).

Ye, J., Liu, C. & Ge, Q. DFT study of CO2 adsorption and hydrogenation on the In2O3 surface. ACS Catal 116, 7817–7825 (2012).

Frei, M. S. et al. Atomic-scale engineering of indium oxide promotion by palladium for methanol production via CO2 hydrogenation. Nat. Comm. 10, 3377 (2019).

Zhang, Z. et al. New black indium oxide—tandem photothermal CO2-H2 methanol selective catalyst. Nat. Comm. 13, 1512 (2022).

Wang, J. et al. A highly selective and stable ZnO-ZrO2 solid solution catalyst for CO2 hydrogenation to methanol. Sci. Adv. 3, e1701290 (2017).

Wang, Y. et al. Exploring the ternary interactions in Cu-ZnO-ZrO2 catalysts for efficient CO2 hydrogenation to methanol. Nat. Comm. 10, 1166 (2019).

Zhang, J. et al. Neighboring Zn-Zr sites in a metal–organic framework for CO2 hydrogenation. J. Am. Chem. Soc. 143, 8829–8837 (2021).

Kattel, S., Yan, B., Yang, Y., Chen, J. G. & Liu, P. Optimizing binding energies of key intermediates for CO2 hydrogenation to methanol over oxide-supported copper. J. Am. Chem. Soc. 138, 12440–12450 (2016).

Zhou, H. et al. Engineering the Cu/Mo2CTx (MXene) interface to drive CO2 hydrogenation to methanol. Nat. Catal. 4, 860–871 (2021).

Mitsuka, Y. et al. Fabrication of integrated copper-based nanoparticles/amorphous metal-organic framework by a facile spray-drying method: highly enhanced CO2 hydrogenation activity for methanol synthesis. Angew. Chem. Int. Ed. 60, 22283–22288 (2021).

Larmier, K. et al. CO2-to-methanol hydrogenation on zirconia-supported copper nanoparticles: reaction intermediates and the role of the metal–support interface. Angew. Chem. Int. Ed. 56, 2318–2323 (2017).

Ling, L.-L., Yang, W., Yan, P., Wang, M. & Jiang, H.-L. Light-assisted CO2 hydrogenation over Pd3Cu@UiO-66 promoted by active sites in close proximity. Angew. Chem. Int. Ed. 61, e202116396 (2022).

Ye, J., Liu, C., Mei, D. & Ge, Q. Active oxygen vacancy site for methanol synthesis from CO2 hydrogenation on In2O3(110): A DFT study. ACS Catal 6, 1296–1306 (2013).

Wu, C. et al. Inverse ZrO2/Cu as a highly efficient methanol synthesis catalyst from CO2 hydrogenation. Nat. Com. 11, 5767 (2020).

Chen, Y., Choi, S., Thompson, L. T. & Low-temperature, C. O. 2 hydrogenation to liquid products via a heterogeneous cascade catalytic system. ACS Catal 5, 1717–1725 (2015).

Yang, T. et al. Coordination tailoring of Cu single sites on C3N4 realizes selective CO2 hydrogenation at low temperature. Nat. Comm. 12, 6022 (2021).

Mosrati, J. et al. Low-temperature hydrogenation of CO2 to methanol in water on ZnO-supported CuAu nanoalloys. Angew. Chem. Int. Ed. 62, e202311340 (2023).

Sugiyama, H., Miyazaki, M., Sasase, M., Kitano, M. & Hosono, H. Room-temperature CO2 hydrogenation to methanol over air-stable hcp-PdMo intermetallic catalyst. J. Am. Chem. Soc. 145, 9410–9416 (2023).

Hu, J. et al. Sulfur vacancy-rich MoS2 as a catalyst for the hydrogenation of CO2 to methanol. Nat. Catal. 4, 242–250 (2021).

Wang, L., Yi, Y., Guo, H. & Tu, X. Atmospheric pressure and room temperature synthesis of methanol through plasma-catalytic hydrogenation of CO2. ACS Catal 8, 90–100 (2018).

Han, X. et al. Photothermal CO2 hydrogenation to CO on CeO2 catalyst via redox mechanism. Chem. Eng. J. 510, 161609 (2025).

Li, L. et al. Operando spectroscopic studies on redox mechanism for CO2 hydrogenation to CO on In2O3 catalysts. J. Catal. 439, 115762 (2024).

Wang, S., Guan, B. Y. & Lou, X. W. D. Construction of ZnIn2S4–In2O3 hierarchical tubular heterostructures for efficient CO2 photoreduction. J. Am. Chem. Soc. 140, 5037–5040 (2018).

Zhang, X. et al. Support effect and surface reconstruction in In2O3/m-ZrO2 catalyzed CO2 hydrogenation. ACS Catal 12, 3868–3880 (2022).

Lux, S., Baldauf-Sommerbauer, G. & Siebenhofer, M. Hydrogenation of inorganic metal carbonates: a review on its potential for carbon dioxide utilization and emission reduction. ChemSusChem 11, 3357–3375 (2018).

Coufourier, S. et al. Hydrogenation of CO2, hydrogenocarbonate, and carbonate to formate in water using phosphine free bifunctional iron complexes. ACS Catal 10, 2108–2116 (2020).

Kumar, A., Janes, T., Espinosa-Jalapa, N. A. & Milstein, D. Manganese catalyzed hydrogenation of organic carbonates to methanol and alcohols. Angew. Chem. Int. Ed. 57, 12076–12080 (2018).

Banerjee, A. & Kanan, M. W. Carbonate-promoted hydrogenation of carbon dioxide to multicarbon carboxylates. ACS Cent. Sci. 4, 606–613 (2018).

Luo, L. et al. Synergy of Pd atoms and oxygen vacancies on In2O3 for methane conversion under visible light. Nat. Comm. 13, 2930 (2022).

Zubar, V. et al. Hydrogenation of CO2-derived carbonates and polycarbonates to methanol and diols by metal–ligand cooperative manganese catalysis. Angew. Chem. Int. Ed. 57, 13439–13443 (2018).

Stowell, C. A., Wiacek, R. J., Saunders, A. E. & Korgel, B. A. Synthesis and characterization of dilute magnetic semiconductor manganese-doped indium arsenide nanocrystals. Nano Lett. 3, 1441–1447 (2003).

Utsuno, F. et al. A structural study of amorphous In2O3–ZnO films by grazing incidence X-ray scattering (GIXS) with synchrotron radiation. Thin Solid Films 516, 5818–5821 (2008).

Pinheiro Araujo, T. et al., Reaction‐induced metal‐metal oxide interactions in Pd‑In2O3/ZrO2 catalysts drive selective and stable CO2 hydrogenation to methanol. Angew. Chem. Int. Ed. 62, e202306563 (2023).

Chenakin, S. P., Alekseev, S. A. & Kruse, N. X-ray photoelectron spectroscopy and diffuse reflectance infrared fourier transform spectroscopy insight into the pathways of manganese oxalate thermal decomposition to MnO and MnCO3. Inorg. Chem. 61, 12106–12117 (2022).

Liu, Y., Zhang, P., Zhan, J. & Liu, L. Heat treatment of MnCO3: an easy way to obtain efficient and stable MnO2 for humid O3 decomposition. Appl. Surf. Sci. 463, 374–385 (2019).

Astam, A. & İnanç, C. T. Hydrothermal synthesis of MnCO3 thin film and its conversion to Mn-oxides by annealing in different atmospheres. J. Mater. Sci. Mater. El. 34, 2078 (2023).

Tang, C. et al. Insights into the selectivity determinant and rate-determining step of CO2 hydrogenation to methanol. J. Phys. Chem. C 126, 10399–10407 (2022).

Sha, F. et al. The promoting role of Ga in ZnZrOx solid solution catalyst for CO2 hydrogenation to methanol. J. Catal. 404, 383–392 (2021).

Acknowledgements

J. D., S. X., and Y.M.Z. are grateful for the financial support of the National Natural Science Foundation of China (22378203), the Natural Science Foundation of Jiangsu Province (BK20240188), Suzhou Science and Technology Plan Project (ST202202), Top-notch Academic Programs Project of Jiangsu Higher Education Institutions. Q.Z. recognizes the support to the National Natural Science Foundation of China (22478193). M.F. acknowledges the funding provided by National Science Foundation (NSF 1903627). R.Y. acknowledges the funding provided by Natural Science Foundation of Jiangxi Province for Distinguished Young Scholars (20232ACB213001).

Author information

Authors and Affiliations

Contributions

J.D., M.F., S.Z., and Q.Z. designed experiments, J.D., A.H., X.S., Y.M.Z., and F.Z. performed experiments, J.D., Y.F., Y.L.Z., and R.Y. analyzed data, J.D. wrote the manuscript with the help from M.F., S.Z., and Q.Z.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ding, J., Shang, X., Zhou, Y. et al. In-situ synthesis of interfacial In-O-Mn lewis acid-base pairs for low-temperature photothermal CO2 hydrogenation to methanol. Nat Commun 16, 7804 (2025). https://doi.org/10.1038/s41467-025-61851-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-61851-6