Abstract

Realizing practical lithium–sulfur batteries with high energy density requires lean electrolyte design. However, under low electrolyte/sulfur (E/S) ratios, highly concentrated lithium polysulfides in the electrolyte phase limit cycling and capacity. Here, we report that a small amount of Lewis acidic calcium cation in the electrolyte addresses the problems of lean electrolyte lithium–sulfur batteries. Because of its Lewis acidity, Ca2+ readily converts lithium polysulfides into CaS and S8, preventing electrolyte jamming, polysulfide shuttle and Li corrosion. The in situ-formed CaS catalyzes the reduction reaction of lithium polysulfides. Ca2+ rejuvenates via electrochemical oxidation of CaS during charging, enabling a sustainable interconversion between Ca2+ and CaS during cycling. Li-S pouch cells with Ca2+ additive delivered an energy density of 493 Wh kg−1 (E/S of 2.4 μL mg−1) based on the total mass of the cell excluding external packaging, with 70% capacity retention at 220 cycle under 1 mA cm−2 discharge, and 346 Wh kg−1 (2.9 μL mg−1) with 77% capacity retention at 360 cycle under 1.0 C 2 mA cm−2 discharge. The judicious integration of lithium-sulfur and calcium-sulfur chemistries offers a handy but effective approach to overcome the long-lasting trade-off between energy density and cycling stability in the development of lithium–sulfur batteries.

Similar content being viewed by others

Introduction

With the growth of next-generation energy storage systems, lithium–sulfur batteries (LSBs) are among the most promising candidates1,2 owing to their high theoretical energy density, low cost3, environmental sustainability, and earth abundance of sulfur. However, lithium polysulfides (LiPSs), intermediates of the sulfur redox reaction (SRR), readily dissolve in the electrolyte and diffuse towards the lithium metal anode (LMA), causing self-discharge, LMA corrosion, and loss of active sulfur species. This phenomenon, known as polysulfide (PS) shuttle, is a major challenge to the commercial application of LSBs.

The challenge of the PS shuttle can effectively be addressed by employing sulfur hosts4,5,6 and catalysts7,8,9 in the sulfur cathode that capture LiPSs and facilitate their conversion to lithium sulfide (Li2S). These advanced cathodes, particularly when utilizing an excess amount of electrolyte (electrolyte/sulfur (E/S) ratio >5.0 μL mg−1), have demonstrated sustained positive performance over hundreds of cycles. However, LSBs with a high E/S ( > 5.0 μL mg−1) have failed to achieve energy densities exceeding 250 Wh kg−1 due to the large weight fraction of electrolytes, falling short of the requirements for replacing lithium-ion10. It is crucial to reduce the E/S ratio to less than 3.011 to achieve practical energy densities beyond 350 Wh kg−1. However, decreasing E/S ratio renders the advanced cathodes less effective than those with higher E/S.

Given the significant impact of E/S ratio on the chemistry of LSBs, careful consideration is required for electrolyte design. As E/S ratio decreases, LiPS concentration in the electrolyte increases, forming a PS-saturated environment that frequently leads to electrolyte gelation12. This hinders the transport of Li+ and PSs in the sulfur cathode and increases the PS concentration gradient. Thus, the PS-saturated environment hampers the SRR kinetics13, intensifies the PS shuttle, and exacerbates LMA corrosion, resulting in poor rate capability and cycling stability as demonstrated in Supplementary Fig. 1. In such a PS-saturated environment, electrocatalysts such as metal nitrides or metal oxides can undergo in situ-reconstruction into sulfides14,15,16,17, posing a challenge in maintaining their catalyst activity. These reactions deactivate the catalytic sites and promote the polymerization of 1,3-dioxolane (DOL)18, a commonly used electrolyte cosolvent, at the Lewis acidic site of the metal sulfides. Additionally, dead sulfur/Li2S2/Li2S precipitates may passivate the catalyst surfaces during extended operations19,20,21. Therefore, lean electrolyte LSB requires rejuvenation of the active catalytic sites upon cycling as well as tailoring the electrolyte to avoid the PS-saturated environment.

In this work, we report a handy yet effective electrolyte additive of Lewis acidic multivalent metal cations, which enables low E/S ratio operation. The electrolyte engineering is based on how the chemistry of sulfur batteries changes depending on the type of cation involved (Fig. 1a). Ca–S batteries22,23 (CSB) exhibit lower PS concentrations in the electrolytes during cell operation compared to LSB. However, these batteries suffer from slow redox kinetics of SRR in contrast to LSB. We discovered that the integration of LSB and CSB chemistry alleviates PS shuttle and facilitates SRR in LSB (Fig. 1b). A small dose of Ca2+ in the electrolyte effectively insolubilizes excess LiPSs via Lewis acid–base reaction, forming CaS catalyst at the sulfur cathode. The in situ-formed CaS catalyst accelerates SRR throughout the discharging process, and is oxidized to form Ca2+ in the electrolyte during charging. The regeneration of Ca2+ provides a means to rejuvenate the CaS catalyst deactivated by the covering of solid sulfur species, and lowers the PS concentration in the electrolyte during the subsequent discharge. Furthermore, the Ca2+ additive alters the Li+ solvation structure, driving the formation of a LiF-rich solid electrolyte interphase (SEI) and mitigating PS-induced Li corrosion. By synergistically enhancing the cathode and anode properties with Ca2+ additive, a pouch-type LSB delivered an energy density of 493 Wh kg−1 and stably operated for over 220 cycles. Another pouch cell with a higher E/S exhibited high cyclability of 360 cycles with an initial energy density of 346 Wh kg−1. These results highlight that even a small amount of Lewis acidic electrolyte additive can significantly enhance the stability and efficiency of LSBs under extreme electrolyte–starved conditions.

a Comparison of LSB, CSB, and LSB with Ca2+. LSB with conventional electrolytes shows moderate redox kinetics and significant PS shuttle due to a high PS solubility in the electrolyte. In contrast, CSB maintains a lower PS concentration in their electrolyte phase, thus leading to suppressed PS shuttle but slow redox kinetics. The introduction of Ca2+ in the LSB electrolyte effectively mitigates the PS shuttle as well as facilitates the sulfur redox reactions. b Design concept of Lewis acidic Ca2+ additive for lean electrolyte LSB. Under lean electrolyte conditions, the electrolyte becomes LiPS-saturated, hindering SRRs and aggravating the PS shuttle. The Ca2+ in the electrolyte functions as a PS-capturing additive, and the in situ-formed CaS as a catalyst for SRR. The interconversion between Ca2+ and CaS makes the dual functions sustainable during operation.

Results

Performances of Li-S pouch cells with multivalent Lewis acidic cation additives

Lean electrolyte, pouch-type Li-S bi–cells with an E/S ratio of 3.5 μL mg−1 (Supplementary Table 1) were employed to assess the effectiveness of Lewis acidic calcium cation additives (Fig. 2a). A control electrolyte of 0.75 M lithium bis(fluorosulfonyl)imide (LiFSI) and 0.4 M lithium nitrate (LiNO3) in 1,2-dimethoxyethane (DME) was used. The control electrolyte exhibits enhanced cycling stability compared to the commonly used LiTFSI–DOL:DME electrolyte, due to its higher Li stability. We evaluated multi-stacked pouch cells, the configuration of which is illustrated in Supplementary Fig. 2a. Under an electrolyte-starved condition (E/S of 2.4 μL mg−1), the Ca-based pouch cell (high energy design) demonstrated an energy density of 493 Wh kg−1 (Fig. 2b; Supplementary Fig. 2b–d), marking the highest reported value for pouch-type Li–S batteries to date. This means that the same energy can be stored with half the number of batteries compared to conventional LIBs. Moreover, the addition of Ca(OTf)2 greatly enhanced the cycle life, lasting up to 220 cycles with a capacity retention of 70% even under the extremely lean electrolyte condition. We further implemented high–power applications at a challenging discharge rate of 1 C and an E/S ratio of 2.9 μL mg−1 (Fig. 2c; Supplementary Fig. 2e–g and 3). The corresponding cell (high power design) delivered a high initial gravimetric energy density of 346 Wh kg−1 and impressive cycling stability of 360 cycles with a capacity decay of merely 0.064% per cycle. The well-balanced energy density and cycling stability presented here are well-placed among those reported for Li–S pouch cells, as depicted in Supplementary Fig. 4 and Supplementary Table 2. Based on the above findings, the Ca2+ additive ensures an effective electrolyte design that enables lean-electrolyte LSBs with excellent cycling stability. The generality of Ca2+ and the influence of the OTf− anion on cell performance are profoundly addressed in Supplementary Fig. 5. The beneficial effects of Ca(OTf)2 additive can extend to various cell designs, including high-capacity cathodes, TFSI-DOL:DME electrolyte, and higher E/S ratios. This demonstrates the broad applicability and versatility of the electrolyte design concept.

a Pouch-type Li-S bi-cell (E/S = 3.5 μL mg−1) cycling with the control and Ca2+ additive-containing electrolytes. Blank circles represent coulombic efficiency. b High-Energy design Li–S stack cell with an E/S ratio of 2.4 μL mg−1 in the presence of Lewis acidic metal cation additives. Ca(OTf)2 additive shows stable cycling for over 200 cycles at 0.3 C. Configuration of a high-energy cell with 25 μm Li and sulfur loading of 2.26 mg cm–2. Blue blank squares represent the coulombic efficiency of the Ca cell. c High-Power design Li–S stack cell with an E/S ratio of 2.9 μL mg−1 in the presence of Lewis acidic metal cation additives. Ca(OTf)2 additive shows stable cycling for over 350 cycles at 1.0 C. Configuration of a high-power cell with 20 μm Li and sulfur loading of 1.81 mg cm–2. Blue blank squares represent the coulombic efficiency of the Ca cell. The experiment was conducted using three cells to confirm reproducibility.

PS-capturing effects of Lewis acidic metal ions

The improved cell performance with the Ca2+ additive is attributed to its interaction with PSs. Ca–S batteries22,23 exhibit lower PS concentration in the electrolytes during cell operation compared to LSBs due to the strong tendency to form an ionic Ca-S bond. In this context, we hypothesized that introducing multivalent metal cations with stronger Lewis acidity than Li+ would decrease LiPS concentration in the electrolytes. To demonstrate this, we investigated the correlation between LiPS concentration and the Lewis acidity of metal cations, which is strongly correlated with pKa values in H2O, according to Blakemore et al.24. The metal cations analyzed in this work (Li+, Sr2+, Ca2+, Mg2+, and Al3+) exhibited a descending order of pKa values25,26 (Li+ (13.8) > Sr2+ (13.2) > Ca2+ (12.6) > Mg2+ (11.2) > Al3+ (10.1)), implying a corresponding increase in Lewis acidity. To investigate whether Lewis acidic metal cations can suppress the dissolution of PS into the electrolyte during cell operation, we introduced these cations into the electrolyte and evaluated the relative PS concentration in lean electrolyte coin cells (E/S = 4 μL mg−1) using UV-vis spectra after discharging the cells to 2.1 V (Fig. 3a and Supplementary Fig. 6). Remarkably, the absorbance of S42−, which is the predominant PS species at 2.1 V during discharge27, decreased and its peak position shifted to a lower wavelength with the increasing Lewis acidity (Supplementary Fig. 7). The blue shift of the S42− peak indicates strong interaction of the cations with Lewis basic S42−, as per Hard Soft Acid–Base theory28. Accordingly, the PS concentration and the Lewis acidity (pKa value) of the multivalent metal cations were well correlated as shown in Fig. 3b. Although these multivalent metal cations effectively suppress PS solubility, these do not improve cell performance except Ca2+, likely attributed to the extremely low solubility of PSs28,29,30,31, gelation32, and/or precipitation observed in the corresponding electrolytes (Supplementary Fig. 8).

a UV-vis spectra of electrolytes from the coin cells (E/S = 4 μL mg−1) after being discharged to 2.1 V. b Correlation between the pKa value of the metal cation24 and the UV-vis absorbance at 425 nm (corresponding to S42−) in electrolytes containing Lewis acidic additives after discharge to 2.1 V. We conducted the test using four cells for each electrolyte to assess reproducibility. Error bars denote the standard deviation from measurements obtained from four independent coin cells. The data are presented as mean values ± standard deviation. c Coordination of Li+-S42− and fraction of Ca2+-complexed S42− as a function of Ca(OTf)2 concentration. d Illustration of the evolution of the solvation structure under lean electrolyte conditions.

To elucidate the mechanisms behind the reduced PS solubility, we conducted molecular dynamics (MD) simulations. The coordination number of Li+ with S42− is as high as 1.83 (Fig. 3c), signifying the formation of highly dissolved LiPS aggregates. These aggregates are driven by electrostatic interactions between Li+ and terminal sulfur atoms, with the Li+- S42− -Li+ length ranging from 9.50 to 2.93 Å (Supplementary Fig. 9a). This aggregation, particularly pronounced under lean electrolyte conditions, results in highly saturated LiPS clusters within the cathode structure. This observation is corroborated by small-angle X-ray scattering (SAXS) spectra30, where the peak scattering vector q ~ 1 Å is associated with the length of Li+- S42− -Li+. The SAXS spectra of the control catholyte demonstrate significant LiPS aggregation with dimensions ranging from 9.0 Å to 6.0 Å (Supplementary Fig. 9b). Notably, the shielding of Li+’s effective charge within these LiPS aggregates explains low DME coordination (Supplementary Fig. 9c) and high viscosity. With the increasing concentration of Ca2+, the coordination number of Li+ with S42− decreases, while the fraction of Ca2+-coordinated S42− to the total S42− increases (Fig. 3c). The changes in solvation microstructure with the Lewis acidic additive are visualized in Fig. 3d and Supplementary Fig. 9d, particularly focusing on the role of Ca2+ ions. Upon the addition of Ca(OTf)2, the hard Lewis acidic Ca2+ cations in the electrolyte weakened the interactions between PSs and Li+, thus mitigating the excessive dissolution of PSs. Furthermore, the suppressed interaction between Li+ and PSs enhanced the dissociation of Li+ by the solvent (Supplementary Fig. 9c). The result was consistent with the rightward shift of Li+-PS coordination peak in the scattering analysis of the Ca catholyte (Supplementary Fig. 9b), indicating decreased LiPS cluster sizes. This competitive dynamic between Ca2+ and Li+ for PSs mitigates the LiPS clustering.

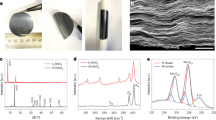

In situ formation and rejuvenation of CaS catalyst via the interconvertible transformation between Ca2+ and CaS

The PS complex bound to Ca2+ was probed to be energetically more stable compared to LiPS, regardless of the polysulfide species (Supplementary Fig. 10). Consequently, multiple PS molecules are captured around Ca2+ in the Ca electrolyte. These Ca2+-associated PSs undergo electrochemical reduction and chemical disproportionation to form CaS. The formation of CaS at the sulfur cathode during discharge was verified by the HAADF-STEM analysis with EDX mapping and SAED (Fig. 4a and Supplementary Fig. 11).

a HAADF-STEM image and corresponding element mapping of the CNF cathode after discharge of the Li-S/CNF cell to 2.1 V, scale bar: 200 nm. b Rate capability test for the Li–S coin cells (E/S ratio of 4 μL mg−1) with the control electrolyte and Ca electrolyte. c PITT measurements for the step-wise discharge from 2.4 V to 1.8 V for the Li–S cells (E/S ratio of 4 μL mg−1) with the control and Ca electrolyte. d DFT calculations of the adsorption strength on CaS or graphene surfaces for various LiPSs. Insets show the optimized configurations of LiPSs adsorbed on CaS. The yellow, green, and purple balls indicate the S, Ca, and Li atoms, respectively. e DFT calculations of the free energy diagram during the discharge process from S8 to Li2S on the surface of CaS and graphene. f ICP-MS analysis of the cathode and electrolyte at various states of charge. Error bars denote the standard deviation from measurements for cathodes obtained from independent coin cells. The data are presented as mean values ± standard deviation. g Linear sweep voltammetry profiles of the carbon paper electrode, Li2S-loaded carbon paper electrode, and CaS-loaded carbon paper electrode.

Additionally, we examined the supernatants and precipitates in Lewis acidic metal cation (0.1 M)-containing 0.2 M Li2S8 solution in DME (Supplementary Fig. 12). In contrast to the absence of precipitates in the additive-free and the LiOTf catholyte, precipitates were formed in the catholytes containing the multivalent cation additives (Supplementary Fig. 12a). The UV-vis absorption spectra of the supernatants (Supplementary Fig. 12b) indicate that the multivalent metal additives effectively reduce the PS concentration; absorbances at 425 nm and 617 nm, assigned to Li2S4 and LiS3•− respectively33, decreased in the order of increasing Lewis acidity. The X-ray diffraction (XRD) patterns and X-ray photoelectron spectroscopy (XPS) of the precipitates from the Al3+, Mg2+, Ca2+, and Sr2+ electrolytes (Supplementary Fig. 12c–e) reveal signals corresponding to metal sulfides and sulfur. This suggests the occurrence of chemical disproportionation of the associated PSs to metal sulfides and sulfur, typically represented for polysulfide species of S42− and the Ca electrolyte (1):

The disproportionation likely originates from the instability of PSs highly coordinated to Ca2+, as complexes formed between strong Lewis acids (multivalent metal cations) and weak Lewis bases (PSs) are thermodynamically unstable. The increased precipitation observed at higher PS concentration (Supplementary Fig. 13) supports this consideration.

CaS formation leads to a decrease of PS concentration in the electrolyte phase by not only consuming PS for the chemical disproportionation but also the adsorption of LiPS onto the CaS precipitates. The PS-adsorbing nature of CaS was evidenced by the decolorization of the PS-containing solution upon the addition of CaS powder (Supplementary Fig. 14). While electrolytes with extremely low PS solubility typically exhibit sluggish SRR kinetics owing to limited reactant supply and poor ionic conductivity34, the Ca electrolyte rather enhanced SRR, with much higher rate capability than the control (Fig. 4b).

We conducted potentiostatic intermittent titration technique (PITT) on lean electrolyte coin cells (E/S = 4; Fig. 4c and Supplementary Fig. 15). Throughout the potential region below 2.3 V, the Ca electrolyte exhibited higher cathodic currents, confirming that the Lewis acidic Ca2+ enhanced SRR kinetics under electrolyte-starved conditions. Furthermore, the CV curves of the Ca electrolyte cell showed higher cathodic peak current and cathodic peak potential, indicating enhanced cathode kinetics (Supplementary Fig. 16). Based on these results, we asserted that the Ca electrolyte improves the rate performance through two key factors: 1) the catalytic effect of polar CaS on the electrochemical conversion as demonstrated below, and 2) the suppression of immoderate PS dissolution through CaS formation, which will be discussed in the next section.

To investigate the catalytic effect of CaS, we calculated the binding energies of various PS species on graphene and CaS surfaces using density functional theory (DFT). For the calculation, the CaS surface was constructed based on the (220) crystal plane of in situ-formed CaS identified by the TEM analysis (Supplementary Fig. 11). Figure 4d compares the binding strengths of Li2Sn (n = 8, 6, 4, 2, and 1) on the CaS and graphene surfaces. The graphene surface exhibits a weak Van der Waals interaction, which lacks attractive forces, whereas the CaS surface shows electrostatic interaction with Li+ on its sulfur site and with Sn2− on its calcium site (Supplementary Fig. 17). The negative binding energies for the CaS surface (−2.81, −3.39, −2.88, −4.82 and −4.73 eV for Li2S8, Li2S6, Li2S4, Li2S2, and Li2S, respectively) indicate spontaneous binding of Li2Sn to the in situ-formed CaS phase. The relative free energy diagram for the entire discharge reaction from S8 to Li2S was thoroughly studied for the CaS and graphene surfaces (Fig. 4e). It is evident that the discharging process is thermodynamically more favorable on the CaS surface than on the graphene surface. Particularly, the successive reduction steps (Li2S4 → Li2S2 → Li2S), which are sluggish on carbon surfaces, exhibit a small energy barrier of less than 1 eV on the CaS surface, explaining its high catalytic ability.

Another important characteristic of CaS is its ability to rejuvenate the Ca2+ additive during charging. Previous studies on Ca-S batteries23,35 have shown that CaS is oxidized to CaSn and to S8 at approximately 2.35 and 2.47 V vs. Li/Li+, respectively. Since these oxidation voltages are within the operating voltage range of LSB, CaS is expected to undergo electrochemical decomposition during the charging process, rejuvenating Ca2+ to the electrolyte. To confirm this, we measured the Ca content in both the cathode and the electrolyte at various states of charge (SoC) using inductively coupled plasma-mass spectrometry (ICP-MS) (Fig. 4f). The Ca content at the cathode (indicative of the CaS content) increases during the course of discharge and decreases during the subsequent charge, indicating the oxidation of CaS to Ca2+. The Ca content in the electrolyte (indicative of the Ca2+ content) decreases during discharge and increases during the subsequent charge, supporting the CaS oxidation. This rejuvenation mechanism was consistently observed in the following cycles, as indicated by the lower CaS content at the cathode in the fully charged states compared to the fully discharged state (Supplementary Fig. 18a). Even after 30 cycles, the interconversion between Ca2+ and CaS was experimentally confirmed (Supplementary Fig. 18b, c). The rejuvenation of Ca2+ is highly meaningful as it enables sustainable regulation of the PS concentration in the electrolyte and refreshment of the CaS catalyst upon extended cycles.

We conducted linear sweep voltammetry (LSV) of a carbon paper electrode incorporating chunky36, commercial Li2S, and CaS powders to verify CaS oxidation in LSBs (Fig. 4g and Supplementary Fig. 19a–d). Upon anodic scanning up to 4 V vs. Li/Li+, the blank carbon paper electrode showed anodic currents originating from the oxidation of DME, whereas the Li2S electrode exhibited an oxidative peak at 3.87 V, which corresponds to the decomposition of highly crystalline Li2S particles. Interestingly, the CaS electrode exhibited oxidation peaks at 3.42, 3.63, and 3.75 V, which were significantly lower than those of the Li2S electrode. This indicates easier decomposition of CaS than Li2S. The three peaks may be associated with the oxidation of CaS, CaSn, and Li2Sn. When the CaS and Li2S cells were charged to 4.0 V and subsequently discharged (Supplementary Fig. 19e), both cells exhibited two discharge plateaus as conventional LSBs. This indicates the formation of S8 due to the oxidation of CaS during charging, supporting the rejuvenation of the Ca2+ additive from Reaction (2).

Experimental and simulation analyses provide conclusive evidence of the interconversion between the Ca2+ additive and catalytic CaS. The rejuvenation of Ca2+ takes advantage of the lower thermodynamic redox potential of CaS oxidation than Li2S delithiation. The PSs released into the electrolyte phase through the electrochemical oxidation of CaS undergo disproportionation reactions with unreacted Li2S, facilitating charge kinetics (Supplementary Fig. 15) and diminishing the delithiation overpotential (Supplementary Fig. 20). Unlike cathode catalysts embedded during electrode preparation, the interconvertible CaS catalysts avoid passivation of the active sites by dead sulfur or Li2S; even in the case of passivation, it can be rejuvenated in the form of Ca2+ during charging.

Effects of the reduced PS concentration on sulfur redox chemistry under lean electrolyte conditions

In conventional LiTFSI–DOL:DME electrolytes, PS gelation often occurs at low E/S ratios, causing a significant decrease in ionic conductivity13. As a result of the Lewis acid–base interaction between Ca2+ and PS anions, the problems caused by highly concentrated PSs in the electrolyte, such as PS shuttle and slow transport of Li+ and PSs, can be mitigated in the presence of Ca2+ additive. To explore the physicochemical attributes in a PS-saturated environment of the control and Ca electrolytes, we added 1.6 M Li2S4 to the electrolytes (equivalent to the E/S ratio of 5), and measured their viscosity and ionic conductivity. As shown in Fig. 5a, with the addition of the Ca2+ additive, the viscosity was reduced by 70%, and the ionic conductivity was enhanced by 30%.

a Viscosity and ionic conductivity of the 1.6 M Li2S4 (corresponding to E/S = 5 μL mg−1)–containing control and Ca electrolytes. The data are presented as mean values from the measurements for each cathode. Error bars denote the standard deviation from the measurements for each cathode. b Evolution of ohmic resistance during 0.1 C discharging. c The galvanostatic intermittent titration technique discharge profile and cell polarization during 0.1 C discharge for the Li–S cells with the control and Ca electrolytes. The empty triangle symbols correspond to the equilibrium potentials. d Self-discharge behavior of the charged Li–S cells with the control and Ca electrolytes under OCV conditions after 15 cycles. e Shuttle current measurement of Li–S cells with the control and Ca electrolytes.

We traced the ohmic resistance (Rohm) of the Li–S cells with the control and Ca electrolytes during discharge at 0.1 C using electrochemical impedance spectroscopy (EIS) analysis (Fig. 5b and Supplementary Fig. 21a–d). The Ca electrolyte exhibited a lower Rohm than the control electrolyte throughout the whole depth of discharge (DoD). In the control electrolyte, the PS concentration reached its maximum at 30% DoD37, resulting in the highest Rohm. At the specific DoD, the Rohm reduction effect of Ca2+ additive was more pronounced. Galvanostatic intermittent titration technique (GITT) analysis (Fig. 5c) showed that the Ca electrolyte exhibited markedly lower overpotentials during the conversions from Li2S6 to Li2S4 and from Li2S4 to Li2S. A combined analysis of Rohm and GITT (Supplementary Fig. 21e–h) revealed a reduction in ohmic, interfacial, and charge-transfer polarization in the Ca electrolyte throughout the discharge process. These results collectively suggest that the Ca electrolyte promotes SRR by facilitating Li+ migration and its delivery to the cathode.

The Ca electrolyte can mitigate PS shuttle by reducing the PS concentration in the electrolyte phase. The beaker cells containing the control and Ca electrolytes visually display the suppression of PS dissolution in the Ca electrolyte (Supplementary Movie); in the absence of the Ca2+ additive, the electrolyte phase rapidly turned red upon galvanostatic discharge due to the dissolution of PSs, whereas the Ca electrolyte phase changed color more slowly due to the reduced PS solubility and PS adsorption on CaS. The degree of PS shuttle can be assessed by self-discharge test, which monitors the open-circuit voltage (OCV) of a fully charged Li–S cell (E/S ratio of 4 μL mg−1) during storage and measures the discharge capacity retention afterward. Figure 5d illustrates the progressive decrease in OCV of the control cell due to the chemical reduction of PSs at the LMA, while the Ca electrolyte exhibits slower OCV fading, indicating a suppressed PS shuttle. Additionally, the capacity loss during 200 h storage was only 10% for the Ca electrolyte, in contrast to that for the control electrolyte (20%) (Supplementary Fig. 22). We measured shuttle current by holding the cell voltage at 2.35 V for the control and Ca electrolytes. At E/S of 7 μL mg−1, the control and Ca electrolytes exhibited shuttle currents of 3.4 and 2.4 μA cm−2, respectively (Supplementary Fig. 23). Decreasing the E/S ratio to 4 μL mg−1 resulted in an increase of shuttle current by 1.4 μA cm−2 for the control electrolyte but by merely 0.5 μA cm−2 for the Ca electrolyte (Fig. 5e). The above analysis demonstrates that the Ca electrolyte with low PS solubility prevents electrolyte gelation, enhances Li+ mobility, and suppresses PS shuttle. The advantageous electrolyte properties are combined with the catalytic effect of CaS phase, enabling low E/S operation.

Enhanced lithium stability by manipulating the PS solvation

The modified PS-dissolving ability of the Ca electrolyte dictates Li metal corrosion and stability. Short-chain PSs, such as S42−, tend to strongly bind to Li+ in the control electrolyte (Supplementary Fig. 24). Thus, a decrease in the PS concentration by the Ca2+ additive can alter the structure of Li+ solvation shell, affecting not only bulk electrolyte properties but also SEI formation38. To understand how the PS-capturing effect of Ca2+ additive influences Li+ solvation structure, MD analysis was conducted on the electrolytes, taking into account the reduced PS saturation concentration at an E/S ratio of 5 μL mg−1 (Supplementary Fig. 25). Due to the stronger attraction of S42− with Ca2+ compared to that with Li+, the addition of Ca2+ decreases average coordination number of S42− in the Li+ solvate from 1.73 to 1.05, and increases the coordination number of FSI− anion from 0.26 to 0.46 (Fig. 6a and Supplementary Fig. 26). Moreover, the Ca2+ addition increased the anion/PS ratio in the Li+ solvation sheath from 0.15/1.0 to 0.44/1.0 (Fig. 6b). In parallel, Raman spectroscopy confirms the strengthened Li+–FSI− coordination while the LiPS signal intensity decreases (Supplementary Fig. 27).

a Coordination number profiles for Li+−S (the sulfur atom in S42−) and Li+−O (the oxygen atom in FSI− anion) for the control and Ca electrolytes, assuming complete dissolution of sulfur into electrolyte at E/S ratio of 5 μL mg−1. b Scheme of the Li+ solvate for the control and Ca electrolytes. c ToF–SIMS three-dimensional render images of the LMAs (represented by Li2−) in the coin cells (E/S = 4 μL mg−1) with the control and Ca electrolytes. d Cryo-TEM images of the LMAs in the 0.2 M Li2S8 containing-control electrolyte (left) and the 0.2 M Li2S8 containing-Ca electrolyte (right). The scale bars are 300 nm. e LSV of the Li-Ni half cells with the 0.2 M Li2S8-containing control and Ca electrolytes under cathodic scan at 0.5 mV s−1. f Plot of the CE at the second cycle for the Li-Ni half cells with the 1.6 M Li2S4 (corresponding to E/S = 5 μL mg−1) containing the control and Ca electrolytes as a function of calendar ageing time. The data are presented as mean values ± standard deviation. Error bars denote the standard deviation from the measurements for each cathode.

The increased involvement of FSI− anion in the Li+ solvate is known to promote the formation of anion–derived SEI39. We investigated the chemical structure of the SEI formed on LMA using three-dimensional reconstructions of Time–of–Flight Secondary Ion Mass Spectrometry (ToF–SIMS) depth profiles (Fig. 6c). The decomposition products of LiFSI, LiPS, and DME are identified by LiF2−, LiS−, and C2H3O− secondary ions, respectively40,41. Compared to the control electrolyte, the SEI formed in the Ca electrolyte features a stronger LiF2− signal and weaker C2H3O− signal, indicating the formation of LiF-enriched SEI42. Additionally, the SEI comprised a significantly weaker LiS− signal, which represents a lower Li2S or Li2S2 contents43, aligning with the suppressed PS shuttle. The XPS analysis of the cycled Li metal electrodes showed an increase in the F atomic content by more than fivefold with the Ca2+ additive (Supplementary Fig. 28), further verifying the formation of LiF-enriched SEI. This enrichment reduces Li adatom surface diffusion barrier and improves electron insulation44, increasing the reversibility of the Li metal anode (Supplementary Fig. 29).

The SEI structure was further verified using cryo-transmission electron microscopy (cryo-TEM), as shown in Fig. 6d. The SEI formed with the Ca catholyte exhibits an average thickness of 36.5 nm (Supplementary Fig. 30), which is 40% that of the control electrolyte (58.2 nm), fostering a shortened Li+ diffusion path. Also, much evenly distributed SEI thickness in the Ca electrolyte results in more uniform Li+ flux and Li deposition45 (Supplementary Fig. 31).

To investigate the cathodic decomposition of the electrolyte components, including PSs, we evaluated the LSV for the Li–Ni half-cells with 1.6 M Li2S4-containing control and Ca electrolytes under cathodic scan (Fig. 6e). The Ca catholyte exhibits lower cathodic currents from the cathodic decomposition of LiPS, FSI−, and DME46 than the control catholyte. These results suggest that the stable passivation layer derived from the Ca2+ additive reduces electrolyte consumption47.

PSs, which are extremely corrosive to Li, are not completely consumed in the electrolyte phase, even after full discharge or charge. Therefore, calendar aging causes LMA corrosion by PSs, resulting in the loss of active LMA. To quantitatively investigate the storage effect, we measured the CE of the Li–Ni half-cells by varying the storage period between the charging and discharging steps at the second cycle48. The PS-free control electrolyte exhibits nearly invariant CE values above 90% with increasing the storage time up to seven days (Supplementary Fig. 32). Conversely, the 1.6 M Li2S4-containing control electrolyte experiences much lower CE values and gradual CE decreases with increasing storage time due to chemical corrosion by PS (Fig. 6f). However, the 1.6 M Li2S4-containing Ca electrolyte shows significantly higher CE values and a slower CE reduction with storage time, suggesting that the Ca electrolyte forms a robust self-passivating LiF-rich SEI that blocks further Li corrosion.

Discussion

In this work, we demonstrated that Lewis acidic Ca2+ additive enables lean electrolyte and high energy density LSBs. A small amount of Ca2+ in the electrolyte forms CaS on the sulfur cathode while lowering PS concentration in the electrolyte phase. The CaS readily adsorbs LiPSs and catalyzes SRR. During charging, CaS decomposes and rejuvenates Ca2+ in the electrolyte phase, fostering sustainable catalytic effects in subsequent cycling. By decreasing the participation of PSs and increasing the participation of FSI− in the Li+ solvate, Ca2+ additive drives LiF-enriched SEI formation, effectively mitigating electrolyte decomposition and PS shuttle. Benefiting from the positive impacts of Ca2+ and CaS, a Li–S pouch cell with our electrolyte delivers a high energy density of 346 Wh kg−1 under a fast discharging rate of 1 C, sustaining 360 stable cycles with capacity decay of only 0.064% per cycle. At a lower E/S ratio, our electrolyte also enables an exceptional energy density of 493 Wh kg−1. Our electrolyte design with Lewis acidic multivalent cation demonstrates an academic strategy to simultaneously address the critical challenges in the practical application of LSBs (including slow cathode kinetics, PS shuttle, and low Li metal reversibility). We expect that the design principles will drive electrolyte advancements across diverse battery technologies, addressing challenges as additive depletion and catalyst deactivation.

Methods

Electrolyte characterization

In the argon-filled glovebox, the control electrolyte was prepared by dissolving 0.75 M LiFSI (provided from LG Energy Solution Ltd.) and 0.4 M LiNO3 (Sigma-Aldrich, 99.999%) in DME (Sigma-Aldrich). Electrolytes denoted as Al, Mg, Ca, Sr, and Li were prepared by dissolving 0.05 M of Al(OTf)3(Sigma-Aldrich, 99.9%), Mg(OTf)2 (Sigma-Aldrich, 97%), Ca(OTf)2 (Alfa Aesar,), Sr(TFSI)2 (Alfa Aesar), and Li(OTf) (Tokyo Chemical Industry, >98.0%) into the control electrolyte. Sr(TFSI)2 was used as Sr(OTf)2 was not available to purchase. LiTFSI and DOL (anhydrous, 99.5%) were purchased from 3 M and Sigma-Aldrich, respectively.

Different concentrations of LiPS solution were generated by stirring and heating stoichiometric amounts of S8 (Sigma-Aldrich) and Li2S (Sigma-Aldrich, 99.98%) in the electrolyte solution.

UV–vis spectroscopy (GENESYS 10S, Thermo Scientific) was used to determine the relative PS solubility for the electrolytes. Immediately after discharging the coin cells with E/S ratio of 4 to 2.1 V, the coin cell components, including the spacer, electrodes, and separator, were gently washed with 2 mL of DME to wash off the dissolved polysulfides, particularly from the porous cathode and separator. The washed solution was filtered using a syringe filter with a pore size of 0.22 μm. The solution was then diluted tenfold with the control electrolyte, which served as the baseline for UV-Vis spectroscopy. All measurements were conducted using four independently prepared cells to confirm reproducibility. Supernatants of 0.2 M Li2S8 catholytes were also diluted by a factor of 200 and were analyzed using a 10 mm high precision cell (Hellma Analytics). A conductivity meter (LAQUA twin, Horiba Scientific) was used to measure the ionic conductivity of the electrolytes. To mimic the polysulfide-saturated environment, 1.6 M Li2S4 (equivalent to the E/S ratio of 5) was added to the Control electrolyte and Ca electrolyte, and the solutions were stirred for 72 h at 25 °C. The catholytes were then rested for 24 h to achieve equilibrium and filtered through a syringe filter with a pore size of 0.22 μm to obtain the saturated solution. The viscosity of the catholytes was measured using a viscometer (LVDV-2 + P CP, BROOKFIELD) at 25 °C for 1 min. To ensure accurate viscosity measurements for solutions with significantly different viscosities (7 cP vs. 2 cP), the torque values were maintained within the optimal range (60–90%) by adjusting the rotational speed. For the Control catholyte, the rotational speed was set to 30–40 RPM with a corresponding shear rate of 225–300 s−1. For the Ca catholyte, the rotational speed was adjusted to 90–95 RPM, with a shear rate of 675–721.5 s−1. These adjustments ensured reliable viscosity readings while minimizing instrument-related errors.

Sulfur electrode preparation and materials characterization

For the preparation of the cathode, a CNT/S composite (75 wt% Sulfur) and the binder mixture (carboxymethyl cellulose)/poly(acrylic acid)/styrene-butadiene rubber binder = 3/1/4 by weight) were homogenized with a weight ratio of 96:4 in deionized water. The CNT/S composite was prepared by impregnating molten sulfur into a CNT micro-ball via melt-diffusion at 120 °C. Afterward, the resulting slurry was cast on the Al foil, followed by drying at 80 °C. For coin-type and pouch-type bi-cell, single-side-coated cathodes were fabricated at sulfur loadings of 3.8 and 2.25 mg cm−2, respectively. For high-energy and high-power pouch cells, double side-coated cathodes were prepared at sulfur loadings of 2.26 and 1.81 mg cm−2, respectively. CaS (Alfa Aesar) and Li2S (Sigma-Aldrich) were loaded onto the carbon paper by dispersing 0.1 M of each material in DME and drop-casting the resulting dispersion onto the carbon paper electrode, which was maintained at 80 °C on a hot plate. SEM (Magellan 400, FEI Co.) was used to examine the Li deposition morphologies under various PS concentrations and the electrode morphologies after full cell cycling. Samples for ICP-MS (Agilent ICP-MS 7900 and 7700S) measurements were prepared by washing coin cells with different SoCs with 3 mL DME, then the washed solution and the cathode were extracted. XRD (Cu K-α, Rigaku), XPS (Al K-α, Thermo VG Scientific), TEM (Talos F200X), and Cryo-TEM (Thermo Fisher Scientific) were performed at the KAIST Analysis Center for Research Advancement (KARA). All XPS spectra were calibrated to the C 1 s sp2 hybridization signal at 248.5 eV. XPS and ToF–SIMS (ION-TOF) were performed to observe depth profiles of Li electrodes after a SEI formation cycle at 0.05 C discharge and 0.05 C charge. Samples for Raman spectroscopy were prepared by filling a sample vial, then were tightly sealed. Spectra were recorded using a dispersive Raman spectrometer (ARAMIS, JY Horiba), and sample excitation was carried out at 514 nm.

Electrochemical analyses

For electrochemical analysis, a 2032-type coin cell assembled in an Ar-filled glovebox was used. A galvanostatic charge and discharge test was performed with a WBC300L (Wonatech) automatic battery cycler. Before the galvanostatic cycling test, Li–S cells were subjected to pre-cycling at 0.05 C (i.e., 83.6 mAh g−1) for 2 cycles and 0.1 C (167.2 mAh g−1) for 2 cycles and were cycled between 1.8 and 2.7 V. Li foil (40 µm, Honjo Metal) with a size of Ø 16 mm and a Celgard 2400 monolayer polypropylene (PP) membrane (Ø 18 mm) were used for Li–S coin cells. The GITT experiments consist of a series of pulse currents at 0.1 C for 0.1 h, each followed by a 0.4 h open-circuit period. The open-circuit relaxation time should be long enough that the voltage fluctuation is within a 10 mV range. The OCV curves of the Li–S cells were constructed by connecting the voltage points after each relaxation period. For the discharge PITT test, Li–S cells were discharged from 2.4 V to 1.8 V at an interval of 0.02 V and a cutoff current density of 0.05 mA cm−2. For the charge PITT evaluation, the coin cells were first galvanostatically discharged to 1.8 V at 0.05 C. For the measurement of PS shuttling current of Li–S cells, cells were firstly pre-cycled at 0.05 C for three cycles, then galvanostatically discharged to 1.8 V, and then charged until 2.35 V. Finally, the shuttle current was determined by potentiostatic mode at 2.35 V. Cyclic voltammetry tests of Li–S coin cells were performed under E/S ratio of 7 μL mgs−1 and 4 μL mg−1. LSV of Li-Carbon paper cells were scanned from OCV to 4.0 V at a scan rate of 0.1 mV s−1. Beaker cells were discharged at 0.1 C. For the Li-Ni half-cell test, Li foil (150 µm, Honjo Metal) with a size of Ø 12 mm and nickel foil with a size of Ø 16 mm were installed in the coin cell. A Celgard 2400 monolayer PP membrane (Ø 18 mm) was inserted between the electrodes as a separator, and a predetermined volume of electrolytes (30 µL for aging test, 50 µL for cycle performance of Li-Ni cell) was added to the cell. The Li-Ni half cells were operated in a 0.5 mA cm−2/1 mA h cm−2 condition to test the reversibility of the Li metal electrode. For the coulombic efficiency test of Li-Ni half cells, 3 mAh cm−2 of Li was deposited and stripped to 1.0 V, followed by deposition of 3 mAh cm−2 on Ni as Li reservoir. Then, 0.3 mAh cm−2 of Li was stripped and deposited for ten cycles. The remaining Li was stripped, where the average CE corresponds to the ratio of total stripping capacity to total deposited capacity. Potentiostatic electrolyte decomposition tests were conducted using identical 2032-type coin cell setups with 20 μL of 0.2 M Li2S8 catholyte Li-Ni cells and a VSP potentiostat system (Biologic) at a scan rate of 0.5 mV s−1. EIS was conducted at a frequency range from 1 MHz to 0.1 Hz using a Solartron 1470E (Solartron Analytical). Galvanostatic signal with quasi-stationary current and amplitude of 0.2 mA, where the number of data points is per decade of frequency.

Assembly and assessment of pouch cell

The pouch-type bi-cell cells were fabricated for the comparison of Li–S battery performance with the Lewis acidic metal additives. The Cu foil and sulfur cathode (5 cm × 3 cm in dimension) were welded with Ni and Al tabs, each, using an ultrasonic welder. The electrodes and separators were assembled and packed with an aluminum pouch bag in an Ar-filled glovebox. 236.25 μL (E/S = 3.5 μL mg−1) of each electrolyte was injected into the cell, and the fabricated pouch cells were vacuum-sealed. Finally, the cells were uniaxially pressurized with pressure jigs under a clamping torque of 30 kgf cm, corresponding to 0.6 MPa.

The multi-stacked pouch cells with high energy design (E/S = 2.9 μL mg−1) and high power design (E/S = 2.4 μL mg−1) were provided by LG Energy Solution Ltd. The following equations were used to calculate the energy densities of the multi-stacked pouch cells.

Eg is the gravimetric energy density, Careal is the areal capacity (0.704 Ah for high energy cell and 0.450 Ah for high power cell), V is the nominal cell voltage (2.134 V for high energy cell and 2.14 V for high power cell), Mtotal is the total mass of the cell components shown in Supplementary Fig. 4, excluding the package. For the high-power design pouch stack cells, 0.5 M LiFSI–5 wt% LiNO3–DME: Bis(2,2,2-trifluoroethyl) ether (4:1 v/v) was used as control electrolyte, and 0.5 M LiFSI–5 wt% LiNO3–DME: 1,3,5-Trioxane (4:1 v/v) for high-energy design pouch stack cells. High-power design pouch stack cells were performed on three independent cells. LiFSI, LiNO3, and DME were purchased from Chunbo, Bis(2,2,2-trifluoroethyl) ether was purchased from Solvay, and 1,3,5-Trioxane was purchased from Sigma-Aldrich. Cosolvents were added to the control electrolyte to improve the performance of the anode, but not in the electrolyte used in the other types of cells. The concentration of Ca(OTf)2 was 0.1 M for the pouch stack cells and 0.05 M for the other types of cells, unless otherwise specified. All cells were cycled under 25 °C.

Computational methods

DFT calculations were performed using the DMol3 package in Material Studio (Accelrys Inc.). These calculations involved generalized gradient approximation (GGA) method with the Perdew-Burke-Ernzerhof (PBE) functional, along with a double numerical plus polarization (DNP+) basis set, to optimize molecular geometries and determine binding energies. An orbital cutoff of 4.0 Å was selected, and the COSMO model was utilized to mimic the conditions of the DME solvent. The binding energy and relative free energies of calcium sulfide and graphene with LiPSs were calculated using the Gaussian smearing width of 0.05 eV. Vacuum slabs of 10 Å height were set for CaS and graphene surfaces, and each surface exhibited a dimension of length and width >10 Å. The binding energies were calculated on the most exposed (220) surface of the catalyst, which was confirmed by TEM. LiPSs were placed on the surfaces to obtain the most spontaneous structure, and their binding energy (Eb) to the surface is calculated by Eq. (3):

where ELi2Sn+Surface, ESurface, and ELi2Sn correspond to the energies of LiPSs-surface adsorption complex, CaS or graphene surface, and LiPSs. Relative free energy for discharge reaction from S8 to Li2S at the surface of CaS and graphene was calculated from the thermodynamic energy differences of reaction (4–8):

Atomistic MD simulations were performed using the Forcite package in Material Studio software. Simulation cells were constructed with electrolyte molar ratios including 1.6 M Li2S4, which corresponds to the concentration when sulfur is all dissolved at E/S ratio of 5 μL mg−1 and sulfur loading of 3.8 mg cm−2. The COMPASS III force field was assigned to all molecules. The constructed cells were equilibrated at a 1 atm, 298 K condition in an NPT ensemble during 1 ns for Li+ coordination analysis. A Nose thermostat and Berndensen barostat with an integration time step of 1 fs were used to equilibrate the simulation cells under constant temperature and pressure. The cells were equilibrated at the same temperature by 1 ns of NVT ensemble simulation, then 5 ns simulation was followed to obtain the coordination chemistry among the molecules through the radial distribution function.

Data availability

The authors declare that all data supporting the findings of this study are available within the paper and its Supplementary Information and Source Data File. The main source data in this work has been uploaded to “Source data”. Computational data are available in the Harvard Dataverse at https://doi.org/10.7910/DVN/4MRMYM. Any additional information can be requested from the corresponding authors. Source data are provided with this paper.

References

Cheon, S.-E. et al. Rechargeable lithium sulfur battery: I. structural change of sulfur cathode during discharge and charge. J. Electrochem. Soc. 150, A796 (2003).

Cheon, S.-E. et al. Rechargeable lithium sulfur battery: II. rate capability and cycle characteristics. J. Electrochem. Soc. 150, A800 (2003).

Chung, W. J. et al. The use of elemental sulfur as an alternative feedstock for polymeric materials. Nat. Chem. 5, 518–524 (2013).

Manthiram, A., Fu, Y., Chung, S.-H., Zu, C. & Su, Y.-S. Rechargeable lithium–sulfur batteries. Chem. Rev. 114, 11751–11787 (2014).

Liang, J., Sun, Z.-H., Li, F. & Cheng, H.-M. Carbon materials for Li–S batteries: Functional evolution and performance improvement. Energy Storage Mater. 2, 76–106 (2016).

Li, Z. N. et al. Lithiated metallic molybdenum disulfide nanosheets for high-performance lithium-sulfur batteries. Nat. Energy 8, 84–93 (2023).

Pang, Q., Liang, X., Kwok, C. Y. & Nazar, L. F. Advances in lithium–sulfur batteries based on multifunctional cathodes and electrolytes. Nat. Energy 1, 16132 (2016).

Hua, W. X. et al. Optimizing the p charge of S in p-block metal sulfides for sulfur reduction electrocatalysis. Nat. Catal. 6, 174–184 (2023).

Zhong, Y. et al. Identification and catalysis of the potential-limiting step in lithium-sulfur batteries. J. Am. Chem. Soc. 145, 7390–7396 (2023).

Zerrin, T. et al. An overlooked parameter in Li-S batteries: the impact of electrolyte-to-sulfur ratio on capacity fading. Nano Energy 104, 107913 (2022).

Zhou, G. M., Chen, H. & Cui, Y. Formulating energy density for designing practical lithium-sulfur batteries. Nat. Energy 7, 312–319 (2022).

Fan, F. Y. & Chiang, Y. M. Electrodeposition kinetics in Li-S batteries: effects of low electrolyte/sulfur ratios and deposition surface composition. J. Electrochem. Soc. 164, A917–A922 (2017).

Wang, L. et al. Ultralean electrolyte Li-S battery by avoiding gelation catastrophe. ACS Appl. Mater. Interfaces 14, 46457–46470 (2022).

Sun, M. et al. Rational understanding of the catalytic mechanism of molybdenum carbide in polysulfide conversion in lithium–sulfur batteries. J. Mater. Chem. A. 8, 11818–11823 (2020).

Zeng, P. et al. In situ non-topotactic reconstruction-induced synergistic active centers for polysulfide cascade catalysis. Adv. Funct. Mater. 33, 2214770 (2023).

Deng, Q., Dong, X., Shen, P. K. & Zhu, J. Li–S chemistry of manganese phosphides nanoparticles with optimized phase. Adv. Sci. 10, 2207470 (2023).

Peng, L. et al. Surface reconstruction on Ni2P@CC to form an ultrathin layer of Ni(OH)2 for enhancing the capture and catalytic conversion of polysulfides in lithium–sulfur batteries. J. Mater. Chem. A. 11, 3504–3513 (2023).

Li, X.-Y. et al. Surface gelation on disulfide electrocatalysts in lithium–sulfur batteries. Angew. Chem. Int. Ed. 61, e202114671 (2022).

Fan, F. Y., Carter, W. C. & Chiang, Y. M. Mechanism and kinetics of Li2S precipitation in lithium-sulfur batteries. Adv. Mater. 27, 5203–5209 (2015).

Yuan, H. et al. Conductive and catalytic triple-phase interfaces enabling uniform nucleation in high-rate lithium–sulfur batteries. Adv. Energy Mater. 9, 1802768 (2019).

Ye, H. et al. Enhanced polysulfide conversion catalysis in lithium-sulfur batteries with surface cleaning electrolyte additives. Chem. Eng. J. 410, 128284 (2021).

Zhou, D. et al. Multi-ion strategy toward highly durable calcium/sodium-sulfur hybrid battery. Nano Lett. 21, 3548–3556 (2021).

Yu, X. W., Boyer, M. J., Hwang, G. S. & Manthiram, A. Toward a reversible calcium-sulfur battery with a lithium-ion mediation approach. Adv. Energy. Mater. 9 (2019).

Kumar, A. & Blakemore, J. D. On the use of aqueous metal-aqua pK(a) values as a descriptor of Lewis acidity. Inorg. Chem. 60, 1107–1115 (2021).

Hawkes, S. J. All positive ions give acid solutions in water. J. Chem. Educ. 73, 516 (1996).

Perrin, D. D. In Ionisation Constants of Inorganic Acids and Bases in Aqueous Solution (2nd Edn.) (ed. Perrin, D. D) 1–138 (Pergamon, 1982).

Sadd, M. et al. Visualization of dissolution-precipitation processes in lithium–sulfur batteries. Adv. Energy Mater. 12, 2103126 (2022).

Li, X.-Y. et al. Kinetic evaluation on lithium polysulfide in weakly solvating electrolyte toward practical lithium–sulfur batteries. J. Am. Chem. Soc. 146, 14754–14764 (2024).

Li, Z. et al. Correlating polysulfide solvation structure with electrode kinetics towards long-cycling lithium–sulfur batteries. Angew. Chem. Int. Ed. 62, e202309968 (2023).

Gao, X. et al. Electrolytes with moderate lithium polysulfide solubility for high-performance long-calendar-life lithium–sulfur batteries. Proc. Natl. Acad. Sci. 120, e2301260120 (2023).

Kim, I. et al. Moderately solvating electrolyte with fluorinated cosolvents for lean-electrolyte Li–S batteries. Adv. Energy Mater. 15, 2403828 (2025).

Chen, Y. et al. Aluminum corrosion chemistry in high-voltage lithium metal batteries with lifsi-based ether electrolytes. ACS Appl. Mater. Interfaces 16, 47581–47589 (2024).

Zou, Q. & Lu, Y. C. Solvent-dictated lithium sulfur redox reactions: an operando uv-vis spectroscopic study. J. Phys. Chem. Lett. 7, 1518–1525 (2016).

Liu, Y. T. et al. Electrolyte solutions design for lithium-sulfur batteries. Joule 5, 2323–2364 (2021).

Li, Z. et al. Rechargeable calcium-sulfur batteries enabled by an efficient borate-based electrolyte. Small 16, e2001806 (2020).

Li, M. et al. In situ localized polysulfide injector for the activation of bulk lithium sulfide. J. Am. Chem. Soc. 143, 2185–2189 (2021).

Mistry, A. N. & Mukherjee, P. P. Electrolyte transport evolution dynamics in lithium-sulfur batteries. J. Phys. Chem. C. 122, 18329–18335 (2018).

Yao, Y. X. et al. Regulating interfacial chemistry in lithium-ion batteries by a weakly solvating electrolyte*. Angew. Chem. Int. Ed. 60, 4090–4097 (2021).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Nanda, S. & Manthiram, A. Lithium degradation in lithium-sulfur batteries: insights into inventory depletion and interphasial evolution with cycling. Energy Environ. Sci. 13, 2501–2514 (2020).

Kim, J. et al. Designing fluorine-free electrolytes for stable sodium metal anodes and high-power seawater batteries via SEI reconstruction. Energy Environ. Sci. 15, 4109–4118 (2022).

Kim, J. et al. Concurrent electrode–electrolyte interfaces engineering via nano-Si3N4 additive for high-rate, high-voltage lithium metal batteries. Energy Environ. Sci. 18, 3148–3159 (2025).

Yan, C. et al. Lithium metal protection through in-situ formed solid electrolyte interphase in lithium-sulfur batteries: The role of polysulfides on lithium anode. J. Power Sources 327, 212–220 (2016).

Li, F. et al. Gradient Solid Electrolyte Interphase and Lithium-Ion Solvation Regulated by Bisfluoroacetamide for Stable Lithium Metal Batteries. Angew. Chem. Int. Ed. 60, 6600–6608 (2021).

Zhang, Q.-K. et al. Homogeneous and mechanically stable solid–electrolyte interphase enabled by trioxane-modulated electrolytes for lithium metal batteries. Nat. Energy 8, 725–735 (2023).

Shin, W. & Manthiram, A. A Facile Potential Hold Method for Fostering an Inorganic Solid-Electrolyte Interphase for Anode-Free Lithium-Metal Batteries. Angew. Chem. Int. Ed. 61, e202115909 (2022).

Wu, Z. H. et al. Growing single-crystalline seeds on lithiophobic substrates to enable fast-charging lithium-metal batteries. Nat. Energy 8, p340–350 (2023).

Boyle, D. T. et al. Corrosion of lithium metal anodes during calendar ageing and its microscopic origins. Nat. Energy 6, 487–494 (2021).

Acknowledgements

We express gratitude to S.-H. Park, C. H. Lee, for their support and comments on the research. This work was supported by LG Energy Solution-KAIST Frontier Research Laboratory (2023). H.-T.K. acknowledges support by the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT (MSIT) (RS-2023-00261543) and the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT (MSIT) (RS-2024-00455177). Some of the battery measurement parts were supported at the LGES R&D campus.

Author information

Authors and Affiliations

Contributions

H.C. and J.J. contributed equally. H.C., J.J., and H.-T.K. conceived the idea and directed the project. H.C. designed and carried out the series of experiments involved in the study, including SEM/TEM analyses, battery tests, electrochemical measurements, and UV-vis experiments. H.C., J.J., and J.H. conducted the DFT/MD simulations. H.C., I.K., and S.K. contributed to battery tests for optimizing the cycle performance. H.C. and J.K. contributed to analyzing the ICP-MS and cryo-TEM data. J.J., C.H.L., H.K., and W.O. contributed to the pouch cell design. J.L. assisted with the interpretation of results. All authors discussed and analyzed the data. H.C. and H.-T.K. co-wrote and revised the manuscript, and H.-T.K. supervised the work.

Corresponding author

Ethics declarations

Competing interests

H.-T.K., H.C., and J.J. declare that this work has been filed for a KR Provisional Patent Application (No. 10-2024-0044901). The remaining authors declare no competing interests.

Inclusion & ethics statement

This research aligns with the Inclusion & ethical guidelines embraced by Nature Communications.

Peer review

Peer review information

Nature Communications thanks Quanquan Pang, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cho, H., Jung, J., Kim, I. et al. Interconvertible and rejuvenated Lewis acidic electrolyte additive for lean electrolyte lithium sulfur batteries. Nat Commun 16, 6805 (2025). https://doi.org/10.1038/s41467-025-62169-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62169-z