Abstract

H2S capture and valorization from polluted natural gas offer environmental and resource recovery benefits, but current approaches produce moderate-value sulfur with intensive carbon footprint. Herein, we develop an electrochemical deep oxidation method that converts H2S from polluted natural gas into value-added K2SO4 using in-situ cathodically generated H2O2. We first validate this concept using commercial H2O2 and then in-situ generated H2O2 in H-cell, revealing the importance of high H2O2 concentration for deep H2S oxidation, especially sluggish S2O32−-to-SO32− conversion. We then showcase its application potential in 4-cm2 and then 100-cm2 flow reactor with high interfacial H2O2 concentration and large current, with the latter achieving H2S removal (100,000 ppm to <15 ppm), >70% K2SO4 selectivity, and 100-h stable operation. Life-cycle assessment and techno-economic analysis confirm the strategy’s sustainability advantages and economic viability. We finally extend this method to produce a 1.4 wt% H2SO4 solution by modifying the flow reactor with a solid-electrolyte type.

Similar content being viewed by others

Introduction

Hydrogen sulfide (H2S) commonly exists in natural gas and crude oil reservoirs. It is a harmful gas, including threatening human health, endangering industrial processes (results in facility and pipeline corrosion during transportation, and catalyst deactivation during refinery process), and polluting environment through off-gases and wastewaters. In this context, H2S capture and valorization (H2S-CV) is of significant importance for protecting human, equipment, and environment from danger, as well as for producing valuable sulfur-involved chemicals.

As an important scenario, raw natural gas contains 1–10 vol% of H2S (corresponding to 10,000–100,000 ppm, Supplementary Table 1), calling for efficient H2S-CV technology. To date, H2S impurities are first captured using amine absorption, separating CH4 for downstream use, followed by distillation to regenerate H2S gas (Fig. 1a). Subsequently, the pure H2S gas is conventionally treated through the Claus process, in which 1/3 H2S is firstly oxidized to sulfur dioxide (SO2) by air in a combustion furnace, and then the remaining 2/3 H2S reacts with SO2 over Al2O3-based catalyst in Claus reactor to afford sulfur (S) as the final product1,2. This method features high H2S treatment capacity, accounting for more than 95% of total S production globally3. However, harsh reaction conditions (high temperature >900 °C) are necessary for the distillation and combustion step, resulting in a carbon-intensive process. In addition, complete reaction of H2S and SO2 cannot be achieved due to the thermodynamical equilibrium of the Claus reaction step4, resulting in the emissions of residual H2S and SO2 into atmosphere.

In recent years, renewable electricity powered electrochemical reaction has emerged as a promising approach for sustainable pollutants capture and chemicals production5, which can be operated under ambient conditions with ideally low carbon emission. Regarding H2S-CV, an electrochemical strategy based on anodic sulfion (S2−) oxidation reaction (ASOR, Fig. 1b) was previously reported, involving the oxidation of S2− to S at the anode6. Furthermore, advanced modulation strategies including sulfurization7,8, high-entropy alloying9, and carbon encapsulation10,11, were developed to improve the stability and sulfophobicity of anode materials, thereby mitigating the issue of sulfur passivation. The introduction of redox pairs with superior reaction kinetic, such as I−/I3− (ref. 12) and Fe2+/Fe3+ (ref. 4), are also efficient strategies to mediate the oxidation of H2S to S in the solution, by which sulfur deposition can be avoided. Additionally, the ASOR can couple with the hydrogen evolution reaction (HER) at the cathode to produce green hydrogen13,14. Nevertheless, the produced S shows a moderate price (110 $ per ton S), and it is not the end product on market but rather the feedstock for other chemicals production via additional oxidation reactions. For instance, oxidation of S to more valuable sulfates (500 $ per ton K2SO4) accounts for more than 90% of S consumption15. Moreover, when treating same quantities of H2S contaminants, the value-added from K2SO4 production remains much higher than S production, even after accounting for either the market price or production costs associated with KOH feedstock (Supplementary Fig. 1).

In this regard, it is attractive to develop an electrochemical strategy to directly transform H2S (ideally, using natural gas as the feedstock) into sulfates via deep oxidation at ambient conditions. This concept has been explored in the aerobic oxidation of sulfides at the anode, with successful production of sulfates16,17,18. However, sulfur deposition occurs at the same time, calling for advanced strategy to improve sulfide removal efficiency and sulfate selectivity. Typically, strong oxidant is required to achieve deep H2S oxidation, such as Cl2 or H2O2 (refs. 19,20), but the widespread applications are restricted by the formation of stoichiometric chlorine-containing waste or the use of expensive oxidant (i.e., H2O2). Alternatively, electrocatalytically generated H2O2 via two-electron oxygen reduction reaction (2e− ORR) serve as a promising oxidant, for it can be powered by renewable electricity and can be used on demand. Benefiting from the great progress of associated electrocatalysts design, especially the carbon-based one21,22, the development of in-situ generated H2O2 for oxidation reactions to produce value-added chemicals have been witnessed in a handful cases, including epoxidation of olefins23 and activation of N2 and CH4 (refs. 24,25.). Owing to the high oxidation efficiency of in-situ generated H2O2 and the sustainable nature of H2O2 electrosynthesis, there is plenty room for further exploration for other scenarios, not limited to the few applications shown above. For instance, the treatment of pollutant H2S is an important issue, and using in-situ generated H2O2 for its oxidation has not been reported. Therefore, we conceive to couple in-situ H2O2 generation at cathode with deep H2S oxidation to produce sulfates.

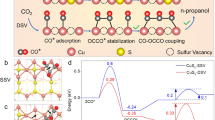

In this work, we report an electrochemical H2S oxidation reaction (EChem-SOR) for SO42− production from H2S-involved natural gas, via in-situ H2S oxidation by H2O2 generated from cathodic 2e− ORR (Fig. 1c). We first showed that H2S can be deeply oxidized into sulfate ions (SO42−) by commercial H2O2 solution via chemical oxidation reaction (Chem-SOR), and recognized the importance of high-concentration H2O2 for deep H2S oxidation. Then, we synthesized an oxidized carbon nanotube (OCNT) as an active 2e− ORR electrocatalyst for H2O2 generation, and demonstrated the feasibility of EChem-SOR in H-cell. During H2S conversion process, H2S was initially captured by an alkaline medium to form S2−, followed by stepwise oxidations to eventually produce SO42− by the in-situ generated H2O2 (in the form of HO2− in alkaline medium). We recognized that deep H2S oxidation was limited by the low H2O2 concentration, owing to low current and diluted solution in H-cell, leaving thiosulfate ions (S2O32−) an accumulated intermediate that is difficult to be further oxidized. To overcome this issue, we constructed a 4-cm2 flow reactor for continuous EChem-SOR at high currents, enabling high-concentration H2O2 over the cathodic interface and in the bulk solution, reaching an over 90% H2Scap and 90% K2SO4 selectivity. Furthermore, we scaled up the flow reactor to 100 cm2, showing the capacity to desulfurize real H2S-involved natural gas with stable operation for 100 h and efficiently convert H2S into K2SO4 at large-scale. By performing life-cycle assessment (LCA) and techno-economic analysis (TEA), we demonstrated that EChem-SOR strategy is potentially more sustainable for H2S treatment and K2SO4 production compared with industrial methods, and shows profitability for K2SO4 production. Furthermore, the EChem-SOR system can be extended to produce H2SO4 solution in a modified solid-electrolyte flow reactor.

Results

Chemical oxidation of H2S using commercial H2O2

Prior to in-situ generated H2O2 via 2e− ORR for H2S oxidation, we first investigated if H2S can be deeply oxidized into SO42− by commercial H2O2 solution via Chem-SOR. As shown in the calculated Pourbaix diagram (Fig. 2a; see methods in Supplementary Note 1), H2S and its dissolved forms (HS− and S2−) can be converted into SO42− within a wide pH window. The conversion process may involve an intermediate sulfur in solid phase at pH below 8.4, whereas its formation can be avoided under highly alkaline conditions, leading to direct HS−/S2−-to- SO42− conversion. Additionally, the equilibrium potentials of H2S/HS−/S2−-to- SO42−, O2-to-OH− and H2O2/HO2−-to-OH− increase sequentially within the full pH window. This indicates that H2O2 shows the thermodynamical ability for deep oxidation of H2S to SO42−, and its oxidative ability exceeds that of O2.

a Pourbaix diagram of SO42− and S production from H2S in its various forms (H2S, HS−, or S2−) on the SHE (standard hydrogen electrode) scale. The dashed lines represent the reduction reactions of H2O2-to-H2O and O2-to-H2O, respectively, suggesting the thermodynamical ability of H2O2 for deep H2S oxidation, as well as stronger oxidizing capability than O2. H2Scap conversion (left in b), productivity of various oxidation products (right in b), and SO42− selectivity (c) at different H2O2 concentrations (0, 0.05, 0.1, 0.5, and 1 wt%) in 0.1 M KOH, with feeding 5% H2S/Ar at a flow rate of 20 ml min−1 for 2 h. The error bars represent the standard deviation of three independent measurements. Variation in the content of S2−, S2O32−, SO32−, and SO42− over time at H2O2 concentrations of 0.08 wt% (d), 0.4 wt% (e), and 1 wt% (f) in 0.1 M KOH. The amounts of NaHS and H2O2 were fixed at 1 mmol and 5 mmol, respectively. g Reaction pathway of H2O2-mediated H2S stepwise oxidation reactions under alkaline conditions.

Guided by the fundamental analysis, we evaluated the effect of H2O2 concentration on the H2S oxidation performance in an alkaline condition (0.1 M KOH), while the overall H2O2 amounts were increased accordingly. H2S/Ar mixing gas containing 5 vol% H2S was selected as the sulfur source (Ar was used as the diluted gas for safety concern, and H2S concentration mimics that in natural gas reservoirs). Since H2S was initially captured by alkaline solution and subsequently converted into products, H2S conversion calculation was based on the captured amount, which was defined as “H2Scap conversion”. As shown in Fig. 2b, H2Scap conversion was below 20% at <0.1 wt% H2O2 concentration and nearly 100% at 1 wt% H2O2 concentration, indicating that the oxidation rate of H2S can be significantly accelerated by increasing H2O2 concentration. The product distribution at different H2O2 concentrations (right in Fig. 2b) implies a stepwise oxidation of H2S to S2O32−, SO32−, and finally to SO42−. At low H2O2 concentrations (0.05 and 0.1 wt%), the primary products were S2O32− and SO32−, with only <25% SO42− selectivity (Fig. 2c). As the H2O2 concentration increased to 0.5 wt%, SO42− became the main oxidation product with >75% selectivity. When the H2O2 concentration further increased to 1 wt%, SO42− became the sole liquid-phase product, while solid S was also observed. These results preliminarily demonstrate deep oxidation of H2S to SO42− is viable by using commercially available H2O2 solution, and facilitated by high H2O2 concentration.

To more quantitatively study the dependance of product distribution and reactivity of different intermediates (S2−, S2O32−, SO32−) on H2O2 concentration. NaHS was utilized as the substrate to precisely control the introducing amount, considering that H2S is transformed to HS− and S2− when it is captured in an alkaline solution. We fixed the input amounts of NaHS (1 mmol) and H2O2 (5 mmol), while changed H2O2 concentration. As shown in Fig. 2d–f, S2O32− was accumulated at lower H2O2 concentration, suggesting that S2O32− oxidation is more sluggish compared to S2− and SO32−. As the H2O2 concentration increased, S2− consumption, S2O32− conversion and SO42− generation were greatly facilitated. Collectively, we proposed that H2S undergoes a stepwise oxidation pathway to SO42− in the presence of commercial H2O2 via Chem-SOR (Fig. 2g), and the reaction is limited by kinetically sluggish S2O32− oxidation. It is important to apply high-concentration H2O2 to facilitate deep H2S oxidation. In addition, the maintenance of strong alkaline condition is also critical for the above transformation, since solid-state S was generated under more acidic conditions (Supplementary Figs. 2 and 3), which may be related to the disproportionation reaction of the formed S2O32− in acidic conditions26.

EChem-SOR in H-cell

The above demonstration of H2S-to-SO42− conversion via Chem-SOR (that utilizes H2O2 as the oxidant) encourages us to develop an electrochemical strategy for H2S-to-SO42− conversion mediated by cathodically in-situ generated H2O2, the so-called EChem-SOR. The prerequisite for EChem-SOR is to prepare an efficient 2e− ORR catalyst for H2O2 electrosynthesis. Based on previous work27, we selected a well-established oxidized carbon nanotube (OCNT) as the electrocatalyst, by heat-treating pristine CNT with HNO3. The high-resolution transmission electron microscopy (HR-TEM) images and X-ray diffraction (XRD) patterns (Supplementary Fig. 4a–e) showed that OCNT retains the tubular and crystalline structure of CNT. Both the results of elemental analysis (EA) and X-ray photoelectron spectroscopy (XPS) revealed a higher oxygen content in OCNT (Supplementary Fig. 4f, g), indicating the successful introduction of oxygen-containing functional groups (OFGs) through HNO3 oxidation. Raman spectra results showed an increased ID/IG ratio for OCNT (Supplementary Fig. 5a), suggesting more defects or disordered structures were introduced into catalyst. Moreover, OCNT exhibited a higher ratio of C = O bond in high-resolution O 1 s XPS spectra, and a stronger signal of carboxyl groups (–COOH) in Fourier-transform infrared (FTIR) spectra (Supplementary Fig. 5b–d). These results suggest that more carboxyl groups are involved in the OFGs.

We then evaluated the 2e− ORR performance of OCNT and CNT using a rotating ring-disk electrode (RRDE) setup in a three-electrode system. RRDE LSV curves showed that the disk current density, ring current, and calculated H2O2 selectivity of OCNT are all higher than that of CNT (Supplementary Fig. 6a), indicating a superior 2e− ORR performance of OCNT. Moreover, the HNO3 treatment time was optimized to obtain an optimal OCNT, achieving a maximum H2O2 accumulated concentration of 0.12 wt% within 2 h at 0.2 V vs RHE in H-cell (Supplementary Fig. 6b–d), which is comparable to previously reported oxidized CNT electrocatalysts27,28,29. Furthermore, the in-situ FTIR spectra of OCNT and CNT at the open-circuit potential (OCP) and increasing potentials were collected (Supplementary Fig. 7). The results showed the peak intensity of OOH* intermediate gradually increases with the 2e− ORR overpotential, and OCNT exhibited a higher relative peak intensity and increased quickly with the potential. These prove that the more favorable formation of OOH* intermediate in OCNT compared to CNT, contributing the enhanced 2e− ORR performance.

Based on the high activity of OCNT for H2O2 electrosynthesis, we first investigated the feasibility of EChem-SOR route in a H-cell. The electrochemical setup contained two tandem parts (Fig. 3a and Supplementary Fig. 8), involving a H2S-capture tank (on the left) and a S2−-oxidation H-cell (on the right). For the H2S-capture unit, 5% H2S/Ar mixing gas was introduced into a catholyte reservoir containing 0.1 M KOH, where H2S was captured by the alkaline solution and dissociated to S2− ions via acid-base reaction. The dissociated S2− solution was then pumped into the cathodic chamber of H-cell. It is important to note that the H2S capture unit is important to the following S2−-oxidation unit (that is, electrolysis unit) to obtain a stable current-time (i-t) curve of 2e− ORR (Supplementary Fig. 9). If H2S/Ar was directly fed into H-cell without a H2S-capture tank, the current continuously decayed (Supplementary Fig. 10), owing to Ar expelled the dissolved O2 over the two-phase interface (between electrode and electrolyte) that hampered 2e− ORR. For the S2−-oxidation unit, the dissolved oxygen underwent 2e− ORR at the electrode-electrolyte interface, with the generated H2O2 participating in S2− oxidation. The electrode was fabricated by depositing OCNT electrocatalyst on a gas diffusion layer (OCNT/GDL) with an area of 1 cm2. Meanwhile, oxygen evolution reaction (OER) took place at a Pt foil counter electrode. We expected that the influent S2− ions would undergo deep oxidation process by H2O2 generated at cathode. The oxidation products (S2O32−, SO32− and SO42−) and unreacted S2− were then recirculated to the tank for further oxidation. As a result, H2S capture and conversion were operated in a batch manner.

a Schematic illustration of the electrochemical setup for EChem-SOR in H-cell separated by a bipolar membrane (BPM). H2Scap conversion (b), productivity of oxidation products (c), SO42− selectivity (d), and e−-to-sulfate efficiency (e) for CNT and OCNT without electrolysis or at different applied potentials, with feeding 5% H2S/Ar at a flow rate of 20 ml min−1 for 2 h. The error bars represent the standard deviation of three independent measurements.

As shown in Fig. 3b, c, H2S oxidation took place with low reactivity in the absence of an applied potential, which can be attributed to the limited oxidative capability of O2 for deep H2S oxidation, as discussed in the Pourbaix diagram (Fig. 2a). By contrast, when cathodic potential was applied, H2Scap conversion and total productivity of three oxidation products (S2O32−, SO32− and SO42−) were largely promoted, demonstrating the feasibility of using in-situ generated H2O2 as the oxidant for H2S-to-SO42− conversion. In addition, OCNT exceeded CNT by showing higher H2Scap conversion and total productivity at various potentials. These results demonstrate that achieving higher activity for H2O2 electrosynthesis (by applying a more negative potential or utilizing a more active 2e− ORR electrocatalyst) is important for promoting H2S conversion.

Nevertheless, we recognized that the efficiency of deep H2S oxidation in H-cell requires substantial improvement, considering that H2Scap conversion was less than 45% (Fig. 3b) and SO42− selectivity was less than 25% (Fig. 3d) for both CNT and OCNT. In addition, an e−-to-sulfate efficiency (%) metric was defined to evaluate the utilization efficiency of electron for SO42− production. The calculation results showed that e−-to-sulfate efficiency in H-cell (for both CNT and OCNT) are less than 25% (Fig. 3e). We speculated that H2O2 concentration in H-cell may be insufficient, considering the limited current and H2O2 dilution in the bulk solution, calling for more advanced reaction system for EChem-SOR.

EChem-SOR in a 4-cm2 flow reactor

Based on H2O2-concentration dependence of H2S oxidation (in Chem-SOR) and the limited deep H2S oxidation in H-cell (in EChem-SOR), we deduce that the efficiency of EChem-SOR system in valorization of H2S to SO42− is significantly reliant on the enhancing H2O2 concentration. Therefore, we constructed a 4-cm2 flow reactor for EChem-SOR system (Supplementary Fig. 11), aiming at enhancing H2O2 concentration to further improve H2S oxidation performance.

The schematic of the flow reactor (Fig. 4a), the enlarged view of cathode chamber (Fig. 4b) and all the possible chemical and electrochemical reactions (Fig. 4c) are shown. The H2S-to-SO42− pathway is depicted below: (1) H2S/Ar mixing gas (20 ml min−1) and O2 (100 ml min−1) was together fed into the cathode side (Fig. 4b), migrated through GDL and reached the three-phase interface (between electrode, electrolyte, and gas). (2) O2 immediately underwent 2e− ORR over OCNT electrocatalyst (Eq. 1 in Fig. 4c), with the generation of high concentration of HO2− and OH− locally. Due to gaseous O2 was fed in this flow reactor, presumably showing higher efficiency than the use of water-dissolved O2 in aforementioned H-cell, the interference of co-feeding Ar can be neglected. (3) H2S was captured by the OH− generated at the interface and in the circulating electrolyte (1 M KOH), and was dissociated into S2− ions (Eq. 2). (4) Subsequently, the S2− ions were oxidized by in-situ generated HO2− to form SO42− (Eq. 3), which then flowed out as a K2SO4 solution. (5) Additionally, water dissociation reaction (Eq. 4) on bipolar membrane (BPM) and subsequent protonation reaction (Eq. 5) at cathodic side can prevent the S2− ions and oxidation products from migrating to anodic side, thus sulfur loss can be avoided (Supplementary Fig. 12). As a result, H2S capture and conversion can be operated in a continuous manner.

a Schematic illustration of the electrochemical setup for EChem-SOR in flow reactor separated by a BPM. The cathode is OCNT/GDL electrode with an electrode area of 4 cm2 and a catalyst loading of 1 mg cm−2. The anode is a Ti-based phase supported IrRu oxide (commercial IrRuOx/Ti) electrode. b Enlarged structural diagram and reaction pathway on the cathodic side. c Summary of electrochemical and chemical reactions occurring on the cathodic side and BPM. H2Scap conversion (d), productivity of oxidation products (e), SO42− selectivity (f), and e−-to-sulfate efficiency (g) for OCNT without electrolysis or at different applied currents, with feeding 5% H2S/Ar at a flow rate of 20 ml min−1 for 2 h. The error bars represent the standard deviation of three independent measurements.

The performance of H2O2 electrosynthesis over OCNT in flow reactor was first evaluated by only feeding O2 gas. The results showed that a high H2O2 FE over 90% was obtained under absolute current between 100 and 400 mA, with H2O2 productivity and accumulated concentration increasing with current (Supplementary Fig. 13a–c). Compared with preceding H-cell, the flow reactor delivered significantly higher H2O2 concentration over the same OCNT electrocatalyst (Supplementary Fig. 13d), with the maximum H2O2 concentration increasing from 0.12 wt% (in H-cell) to 0.98 wt% (in flow reactor). This performance is comparable to that reported in other electrochemical systems under similar experimental conditions (Supplementary Table 1), indicating a good H2O2 synthesis performance of the flow reactor system. Moreover, even under identical electrolysis conditions (current density: 50 mA cm−2, electrolyte volume: 50 ml, electrolysis time: 2 h), the flow reactor exhibited higher H2O2 concentration compared to the H-cell (Entry 1 and 2 in Supplementary Table 2). This enhancement correlates with both the enlarged electrode area and improved H2O2 FE in the flow reactor. Notably, the effect of FE on H2O2 concentration becomes more pronounced at elevated current densities (Entry 3 and 4 in Supplementary Table 2). This originates from the efficient O2 mass transport in flow reactor configuration, which enables maintenance of high H2O2 FE even at increased current densities.

Subsequently, the performance of in-situ H2O2 generation coupled with H2S oxidation was studied (Fig. 4d–g). In the absence of an applied current, the captured H2S can still be partially oxidized by O2, with over 70% being converted to S2O32− (Fig. 4d, e). Upon applying a constant current, H2Scap conversion as well as SO42− productivity and selectivity significantly increased. With continuous increase in applied current, the H2S-to-SO42− conversion was further enhanced, achieving a H2Scap conversion of 90%, a SO42− selectivity of 69%, and a maximum e−-to-sulfate efficiency of 80% under 200 mA. Moreover, compared to the H-cell, the flow reactor exhibited enhanced deep oxidation performance under the same constant-current density condition (Supplementary Fig. 14), which can be attributed to the higher H2O2 concentration in the bulk solution and at the cathode interface within the flow reactor system.

To verify the interfacial H2O2 concentration effect, two different H2S oxidation experiments were conducted (Supplementary Fig. 15a, b): (1) EChem-SOR method (that is integrated oxidation): Simultaneous 2e− ORR electrolysis and H2S oxidation by introducing O2 and H2S into the flow reactor during electrolysis; (2) Electrochemical-chemical tandem method: H2O2 is first electrochemically generated via 2e− ORR, followed by H2S oxidation using the resulting homogeneous H2O2 solution without applying electrolysis. The results show that the EChem-SOR method achieves superior H2S oxidation performance compared to the tandem method under all tested currents (Supplementary Fig. 15c). To eliminate potential H2O2 decomposition effects in tandem method, we also conducted additional short-duration tests, which confirmed the similar observed trend (Supplementary Fig. 15d). Moreover, the interfacial concentration advantage becomes more pronounced at lower flow rate of electrolyte (Supplementary Fig. 16). Furthermore, the COMSOL model were performed to visualize this concentration gradient (Supplementary Figs. 17 and 18), revealing that the H2O2 concentration near the electrode surface is much higher than in the bulk solution. Moreover, under elevated currents and reduced electrolyte flow rates, the interfacial H2O2 concentration was further enhanced (Supplementary Fig. 18f, l), which is consistent with the experimental observations. Specifically, the H2O2 concentration can reach up to 1.04 wt% within 10 μm from the electrode at 200 mA and 10 ml min−1 of electrolyte, which is more than 86 times higher than the bulk concentration (within 200 μm). These findings prove that a pronounced interfacial H2O2 concentration effect in flow reactor, making this system more suitable for scaled-up in-situ H2O2 applications.

Valorization of H2S in natural gas to K2SO4

The above promising results (over 90% H2Scap conversion and 90% SO42− selectivity) of EChem-SOR in 4-cm2 flow reactor encourages us to further evaluate its performance in desulfurization from H2S-involved natural gas (H2S/CH4), with the designed processing shown in Fig. 5a. To prevent potential operation risks and CH4 oxidation reaction induced by H2O2, as well as to separate CH4 from H2S for downstream utilization, the H2S/CH4 gas was first fed into a gas−liquid separator containing 1 M KOH solution, where H2S was captured in the form of S2− and the low-soluble CH4 was expelled upward. Benefiting from the high capture rate of base solutions for acid gas30,31, H2S can be almost completely absorbed by KOH solution (Supplementary Fig. 19).

a Schematic illustration of continuous H2S capture and K2SO4 production from a H2S-involved (100,000 ppm) natural gas via EChem-SOR system that enables nearly complete capture H2S and highly efficient K2SO4 production. The system comprises a simulated natural gas, a flow reactor, a gas-liquid separator filled with 1 M KOH, and a crystallizer. b A 100-h stability test of EChem-SOR system using 100-cm2 flow reactor at 5 A and 300 ml min−1 of 10 vol% H2S/CH4, with refreshing the catholyte daily for maintaining the alkaline environment to capture H2S. H2Scap conversion (left in c), H2S concentration in tail gas (right in c), K2SO4 selectivity (left in d), e−-to-sulfate efficiency (left in d), and accumulated K2SO4 mass (right in d) detected at different time points.

With the feed gas change from 5% H2S/Ar to 5% H2S/CH4, the H2S oxidation performance at the same current (400 mA) was maintained (Supplementary Fig. 20). And no CH4 oxidation products were detected in catholyte. These results indicate the generated H2O2 in EChem-SOR system is incapable of activating CH4, which is different from the recent reported systems where CH4 oxidation took place, which is owing to the utilization of acid conditions and the generation of oxygen radical species in their studies25,32. On the other hands, the effect of trace amounts of CO2 (1000 ppm), another prevalent impurity gas in raw natural gas, was also considered (Supplementary Fig. 21). The results indicate the system’s operation and H2S treatment performance were largely unaffected, while the introduced CO2 is almost completely converted into carbonate ions under alkaline environment of the system.

Moreover, the continuous H2S oxidation was preliminarily conducted using 4-cm2 flow reactor at 400 mA, showing that the EChem-SOR system maintained stable operation over a 40-hprolonged test, with cell voltage remained stable between 2.34 and 2.82 V (Supplementary Fig. 22a). Simultaneously, the products were analysis at intervals, achieving the stable H2Scap conversion (88–93%), SO42− selectivity (88–93%), and e−-to-sulfate efficiency (55–61%) throughout the duration of the experiment. The post-stability characterization confirmed the well-preserved structure of both the cathode (OCNT/GDL) and anode (IrRuOx/Ti) after continuous electrolysis (Supplementary Fig. 22b, e–g), with no notable transformation observed. And the post-OCNT/GDL retained >85% of its initial current density at 2 V while showing negligible decay (<3%) in H2O2 production performance (Supplementary Fig. 22c, d). This performance demonstrated the applicability of EChem-SOR system in H2S valorization.

Furthermore, to evaluate the performance of EChem-SOR system in application scenarios with other typical H2S concentration levels (Supplementary Table 2), the H2S concentration in feed gas was adjusted to 10,000 ppm and 100,000 ppm, respectively, while a flow rate of 20 ml min−1 was maintained. The results indicate that the system maintains high H2Scap conversion (>85%) and K2SO4 selectivity (>80%, Supplementary Fig. 23a), demonstrating its broad applicability. Furthermore, by increasing the H2S influx with higher H2S flow rate (>20 ml min−1, Supplementary Fig. 23b), K2SO4 production was promoted with higher e−-to-sulfate efficiency. However, both H2Scap conversion and K2SO4 selectivity showed gradual decreases, indicating that there were more unconverted S2− and accumulated S2O32−. This may be attributed to a mismatch between the limited generation rate of H2O2 and the required high oxidation rate of H2S under increased H2S influx, resulting in a decline in H2S processing capacity.

EChem-SOR in a 100-cm2 flow reactor

To increase the H2S processing capability (high ratio and high flow rate of H2S), the flow reactor was further scaled up by increasing electrode working area from 4 cm2 to 100 cm2 (Supplementary Fig. 24), with the aim of increasing H2O2 productivity to match high influx of H2S. Compared to the preceding 4-cm2 flow reactor, the 100-cm2 one showed obvious advantages for treating high flow rate of H2S/CH4 (>100 ml min−1; Supplementary Fig. 25). At a flow rate of 100 ml min−1, a superior performance was achieved at 3 A, with high H2Scap conversion (87%), K2SO4 productivity (1.7 g h−1), K2SO4 selectivity (73%), e−-to-sulfate efficiency (76%). At even higher flow rate of 300 ml min−1, the current is optimized to be 5 A, leading to high H2Scap conversion (93%), K2SO4 productivity (4.5 g h−1), K2SO4 selectivity (72%), and e−-to-sulfate efficiency (84%). These results reveal that a balance between the H2O2 production and H2S oxidation is achievable during scaling up (with higher electrode area) by balancing the applied current and flow rate of H2S/CH4.

We then evaluated stability of EChem-SOR system in the 100-cm2 flow reactor by employing continuous operation at 5 A for 100 h, with H2S/CH4 feeding at 300 ml min−1. During the operation, the cell voltage remained stable (between 2.52 and 2.94 V; Fig. 5b). According to the liquid products and tail gas analysis result at intervals (Fig. 5c, d), the reaction system showed efficient H2S capture (H2S concentration decrease from 100,000 ppm to <15 ppm, H2Scap conversion: >90%) and valorization (K2SO4 selectivity: 70%, e−-to-sulfate efficiency: 80%) abilities. At the end of the 100-h test, an accumulation of 397 g K2SO4 was produced, as confirmed by the XRD measurement result (Supplementary Fig. 26).

Collectively, by a series of engineering strategies (reactor design and gas feeding manner), we have demonstrated the capacity and stability of EChem-SOR system for effectively capturing H2S from natural gas and producing K2SO4 at large scale. As summarized in Table 1, the initial H-cell in Fig.3a featured a working electrode area of 1 cm2 and operated in batch manner. Due to the limited O2 mass transfer to the two-phase interface (electrode−electrolyte), the achievable current was relatively low (56 mA), resulting in a low H2O2 productivity and moderate H2S oxidation performance (H2Scap conversion: 45%, K2SO4 selectivity: 21%, e−-to-sulfate efficiency: 20%). To construct an efficient three-phase interface (electrode−electrolyte−gas), a 4-cm2 flow reactor with continuous operation manner and increased electrode area was employed in Fig.4a, enabling the formation of high concentration of H2O2 at the cathodic interface, thereby achieving higher H2S oxidation performance (H2Scap conversion: 98%, K2SO4 selectivity: 90%, e−-to-sulfate efficiency: 61%). Furthermore, for treating simulated natural gas with higher H2S influx, the flow reactor was scaled up to 100 cm2 and operated at higher current in Fig. 5a. Consequently, a superior H2S treatment capacity (flux up to 300 ml min−1), the maintained H2S oxidation performance (H2Scap conversion: 93%, K2SO4 selectivity: 72%, e−-to-sulfate efficiency: 84%), and larger-scale K2SO4 production (4.5 g h−1) were achieved. Even with normalized H2S influx per unit area (3 ml min−1 cm−2), the 100-cm2 flow reactor performed comparably to the 4-cm2 flow reactor and outperformed the H-cell (Supplementary Fig. 27). Additionally, long-term operation stability of 100 h was also achieved. These achievements highlight the versatility and potential of EChem-SOR system using flow reactor for future applications in natural gas desulfurization.

Sustainability and economic evaluation of EChem-SOR

Based on the potential application of the developed EChem-SOR system in H2S capture and K2SO4 production, we performed a life-cycle assessment (LCA) to evaluate its sustainability (Supplementary Note 2). The model was illustrated (Supplementary Fig. 28), and the base case was according to the performance in 100-cm2 flow reactor, with the calculated various environmental implications being listed (Supplementary Table 3). The result showed that global warming potential (GWP) was the most notable environmental matric that was influenced by EChem-SOR system, which was contributed by electrochemical reaction, separation and H2S production processes. Specifically, the GWP of electrochemical reaction mainly originated from the electricity consumption thus is affected by different electricity sources (Supplementary Fig. 29a, b). The GWP of separation process is from the evaporation of water in crystallizer and evaporator, thus applying KOH electrolyte with higher concentration would reduce associated energy and thus GWP (Supplementary Fig. 29c, d). Moreover, the GWP contributed by H2S in the based case was assumed from its production process, whereas it can be reduced to zero in actual implementation by using waste H2S from natural gas (as demonstrated in the above study). Although the GWP values of base case during K2SO4 production and H2S removal are higher than those of industrial processes (shown by the dotted line in Fig. 6a, b and discussed in Supplementary Note 2), a more competitive target case with progressively reduced GWP values can be expected by a series of optimizations (Fig. 6a, b). The optimizations include utilizing renewable electricity powered by wind, increasing KOH concentration (to reduce water evaporation energy) and changing H2S resource to H2S-involved natural gas (H2S production process and associated energy would be excluded). As a result, the target case delivers a GWP value of 0.4 kg CO2e per kg K2SO4 and 2.7 kg CO2e per kg H2S, indicating that EChem-SOR system was potentially more sustainable than industrial K2SO4 production and H2S removal processes.

Roadmap to reducing GWP for K2SO4 production (a) and H2S removal (b) in the base case through progressive optimization of carbon emission-relevant parameters. c Sensitivity analysis of various single-variables (current density, e−-to-sulfate efficiency, electricity price and KOH price) on the production cost per kg K2SO4. The base point of relative change was chosen at a current density of 50 mA cm−2, e−-to-sulfate efficiency of 84%, electricity price of 0.03 $ kWh−1, KOH price of 0.38 $ kg−1. d A contour map for the total K2SO4 production costs in EChem-SOR system with respect to the different current densities and e−-to-sulfate efficiencies. The dotted line represents the breakeven line at current market price of 0.5 $ per kg K2SO4. The direction of the arrow represents the profitable region. All other parameters were fixed as the base point parameters in (c).

Subsequently, we conducted a techno-economic analysis (TEA) to assessed the economic viability of EChem-SOR system for K2SO4 production (Supplementary Note 3). The K2SO4 production costs include capital, operating, and material costs, in which current density, e−-to-sulfate efficiency, electricity price, and KOH price are the main factors (Supplementary Fig. 30). A single-variable sensitivity analysis of the above four factors on production costs were performed (Fig. 6c). The results showed that a reduction in current density and e−-to-sulfate efficiency, and substantial increases in electricity and KOH prices may lead to unprofitability. Furthermore, we calculated the total K2SO4 production cost at variable current density and e−-to-sulfate efficiency (Fig. 6d). The results revealed that higher current density coupled with improved e−-to-sulfate efficiency is vital for profitability of EChem-SOR system, since the H2O2 production rate and concentration are improved accordingly, thereby deep H2S oxidation to K2SO4 can be facilitated. Specifically, based on the high performance of EChem-SOR system in 100-cm2 flow reactor (with an e−-to-sulfate efficiency of 84% at 50 mA cm⁻2), we envisage a profit margin (with total production cost of 0.44 $ and market price of 0.5 $ per kg K2SO4) for K2SO4 production. Furthermore, we compared the economic viability of the EChem-SOR route with the current ASOR route, which can be coupled with cathodic H2 production (Supplementary Note 4). The results show that although the ASOR system achieves a lower S and H2 production cost (0.31 $ per kg S) compared to the EChem-SOR route, the AOR system reaches the profitability region only under higher current density and S Faradaic efficiency (Supplementary Fig. 31). This demonstrates that the promising profitability potential of the EChem-SOR system.

Extending EChem-SOR for H2SO4 solution production

Besides the above promising results for K2SO4 production from H2S by using in-situ generated H2O2, we conceived to expand the application of EChem-SOR system to produce other SO42−-involved valuable chemicals. Benefiting of the progress in solid-electrolyte (SE) flow reactor5,30,33, we sought to produce sulfuric acid (H2SO4) solution under electrolyte-free conditions, by introducing solid electrolyte into the middle layer and feeding pure H2O as a circulating solution in both middle SE layer and anodic chamber (Supplementary Fig. 32a). Notably, due to the weak absorption capacity of pure H2O for H2S, we are able to feed H2S/CH4 gas along with the circulated H2O into the middle SE layer (Supplementary Fig. 32b), which is conducive to H2S capture by OH− that was generated from 2e− ORR. The captured H2S were then oxidized to SO42− by HO2− that migrated from the cathodic interface, followed by combination with H+ that migrated from the anodic side to eventually yield outflowing H2SO4 solution (Fig. 7a).

a Schematic illustration of the reaction pathway in SE flow reactor for H2SO4 production. The SE flow reactor comprises an OCNT/DGL cathode, IrRuOx/Ti anode, anion exchange membrane (AEM), proton exchange membrane (PEM), and middle SE layer filled with H+-conducting ion exchange resin. b H2SO4 production and e−-to-sulfate efficiency of EChem-SOR system at 5 A with different H2S/CH4 flow rate. c Long-term stability test at 5 A and 60 ml min−1 of 10% H2S/CH4. After every 10-h electrolysis (50 h in total), the SE layer was chemically rinsed by Na2SO3 solution to remove deposited S without the need to disassemble the reactor (for 2 h, without applying a current). The right axis represents the corresponding H2SO4 concentration and e−-to-sulfate efficiency in each electrolysis period.

We first examined the H2SO4 production performance at 5 A and different H2S/CH4 flow rates. As the flow rate increased, the H2SO4 production and e−-to-sulfate efficiency improved but with reducing trend (Fig. 7b). This suggests the amount of H2S captured by OH− slowly reached its maximum under this condition. Notably, S2O32− was not detected in all the tests, even at lower currents but only SO42− (Supplementary Fig. 33a, b). Under such conditions, we expected S2O32− might be accumulated. Note that the middle circulation solution became acidic and sulfur deposition was observed in the middle SE layer (Supplementary Fig. 33c, d). Therefore, we speculated that the intermediate S2O32− was not only oxidized to SO42−, but also underwent a disproportionation reaction in the presence of H+ with the formation of sulfur (Fig. 7a). To address the potential impact of sulfur deposition on system operation, we rinsed the middle SE chamber of the reactor with Na2SO3 solution (without applying a current) every 10 h of electrolysis (Supplementary Fig. 34). This approach utilizes the comproportionation reaction between Na2SO3 and sulfur to generate Na2S2O3 (SO32− + S → S2O32−), effectively removing deposited sulfur, which extends the system’s operating time without the need to disassemble the reactor. Note that the recovered S2O32− was not included in the final H2SO4 calculation. As a result, the EChem-SOR system achieved stable operation for over 50 h in total at 5 A and 60 ml min−1 of 10% H2S/CH4 (Fig. 7c), with efficient H2SO4 production (1.4 wt% concentration and 30% e−-to-sulfate efficiency), demonstrating its potential for long-term H2SO4 solution production.

Discussion

Overall, we developed an electrochemical method for simultaneous removal of high-concentration H2S from natural gas and production of value-added K2SO4 or H2SO4, via coupling cathodic in-situ H2O2 generation and deep H2S oxidation.

We performed a progressive study to demonstrate the above concept: (1) Showing the ability of deep H2S oxidation to SO42− using commercially available H2O2 via Chem-SOR; (2) Preliminarily demonstrating the feasibility of EChem-SOR in a H-cell; (3) Designing a 4-cm2 flow reactor with three-phase interface to generate interfacial high-concentration H2O2, showing over 90% H2Scap conversion and 90% K2SO4 selectivity; (4) Scaling up the flow reactor to 100 cm2 with stable IrRuOx/Ti anode, achieving efficient H2S capture (from 100,000 to below 15 ppm), large-scale K2SO4 production (72% selectivity and high productivity of 4.5 g h−1) and good stability (100 h); (5) Demonstrating the sustainability (in terms of environmental implications and carbon emission intensity) and profitability (in terms of K2SO4 production) of EChem-SOR system; (6) Extending the product of H2S conversion to H2SO4 in a solid-electrolyte-based flow reactor, with the stable production of 1.4 wt% H2SO4 solution in each electrolysis cycle.

We envision that this system may show broad opportunity for the treatment of other sulfur-containing industrial waste gases and waters. Moreover, more application scenarios for in-situ H2O2 utilization are expected to expand in the future. Through development of highly efficient catalysts, innovative reactor design and optimization of reaction systems, more sustainable and economic route for sulfur-containing wastes valorization are expected.

Methods

Chemicals

All chemicals were used as purchased without further purification. Deionized water was used throughout the experiments. Potassium hydroxide (KOH, 99.99%) and sodium hydroxide (NaOH, 97%) were purchased from Macklin Reagent Co. Ltd (Shanghai, China). Hydrogen peroxide (H2O2, 30 wt%), concentrated nitric acid (HNO3, 68 wt%), concentrated sulfuric acid (H2SO4, 98 wt%) were TongGuang Fine Chemicals Co. Ltd (Beijing, China). Sodium sulfate (Na2SO4, 99%), sodium sulfite (Na2SO3, 98%), sodium thiosulfate (Na2S2O3, 99%), sodium hydrosulfide (NaHS, 70%), cerium sulfate (Ce(SO4)2, 99%), N, N-dimethyl-p-phenylenediamine dihydrochloride (C8H12N2·2HCl, 96%) and ammonium iron sulfate dodecahydrate (NH4Fe(SO4)2·12H2O, 99.95%) were purchased from Aladdin Reagent Co. Ltd (Shanghai, China). Carbon nanotube (CNT, 99%) and Nafion solution (5 wt%) were purchased from Sigma-Aldrich Chemical Reagent Co. Ltd (Shanghai, China). Binary mixture of hydrogen sulfide and argon (5% H2S/Ar), binary mixture of hydrogen sulfide and methane (5% H2S/CH4 and 10% H2S/CH4) and oxygen (O2, 99.999%) were purchased Air Liquide Co. Ltd (Tianjin, China). Gas diffusion layer (GDL, YLS-30T), bipolar membrane (FBM-PK), anion exchange membrane (FAA-3-50) and proton exchange membrane (Nafion 117) were purchased from Shengernuo Co. Ltd. (Suzhou, China). Solid electrolyte (Amberlite IR-120, hydrogen form) was purchased from Alfa Aesar Co. Ltd. (Shanghai, China).

Synthesis of OCNT

OCNT was prepared by heat treating pristine CNT with HNO3 solution. Typically, 0.1 g of pristine CNT was added to 100 ml of 13 M HNO3 solution. The mixed solution was heated to 80 °C in an oil bath and stirred for 12 h under reflux condensation. After cooling to room temperature, the solution was centrifuged and washed with water until the supernatant became neutral. The precipitate was then dried in an oven at 60 °C overnight to obtain OCNT electrocatalyst. HNO3-6h and HNO3-24h were prepared following the same procedure as OCNT, except that the heat treatment time were changed to 6 and 24 h, respectively.

Preparation of electrodes

To maintain consistency between the tests conducted in H-cell and flow cell, and to avoid introducing additional variables that could affect the electrochemical synthesis of H2O2, the same substrate (i.e., GDL) was utilized to support OCNT. For preparation of OCNT/GDL electrode with different working area (1, 4, and 100 cm2), typically, a catalyst ink with a concentration of 2 mg ml−1 was first prepared through mixing electrocatalyst, ethanol, and Nafion solution. The ink was sonicated for 1 h to obtain a homogeneous mixture and then spray-coated onto the GDL using an ultrasonic spraying system (SCP101, Shengernuo Co. Ltd., Suzhou, China). After drying, the OCNT/GDL electrode with a catalyst loading of 1 mg cm−2 was obtained. The RRDE-loaded electrocatalysts were prepared by dropping 13 µl of catalyst ink with a concentration of 2 mg ml−1 onto the disk electrode (0.247 cm2) of RRDE, and then drying at room temperature, resulting in a catalyst loading of 0.1 mg cm−2.

Materials characterization

Scanning electron microscopy (SEM) images were obtained by ApreoC microscopy. High-resolution transmission electron microscopy (HR-TEM) images were obtained by FEI Tecnai F20 microscopy. X-ray diffraction (XRD) patterns were recorded on Bruker D8-Focus using Cu Kα radiation in the range from 10° to 60° at 40 kV and 40 mA. Raman spectroscopy was recorded on the confocal Raman microscopy (HORIBA LabRAM HR Evolution) with signals excited by 532 nm (50 mW) laser. Elemental analysis (EA) was performed on the Unicube Elemental Analyzer from Elementar, Germany. X-ray photoelectron spectroscopy (XPS) spectra were performed on on ESCALAB Xi+ photoelectron spectrometer. Fourier transform infrared spectroscopy (FT-IR) spectra were recorded on Vertex 70 FT-IR Spectrometer. In-situ FTIR spectra were collected on a TENSOR II FT-IR (NETZSCH GERAETEBAU GMBH). The experiments were conducted in 0.1 M KOH solution with O2 introduced into the custom built three-electrode PTFE cell, with OCNT/GDL or CNT/GDL coated ZnSe prism as the working electrode, Pt wire as the counter electrode and Hg/HgO as the reference electrode. Each spectrum was collected with an acquisition time of 100 s at a potential interval of 100 mV from OCP or 0.9 V vs RHE.

Electrochemical 2e− ORR measurements and H2O2 production

The 2e− ORR performance of electrocatalysts were measured using a rotating ring-disk electrode (RRDE) in a three-electrode system. The RRDE-loaded electrocatalyst, graphitic rod and Hg/HgO electrode were used as the working electrode, counter electrode and reference electrode, respectively. All the potentials measured against Hg/HgO (EHg/HgO) were converted to the reversible hydrogen electrode (ERHE) scale in this work using ERHE = EHg/HgO + 0.0591 × pH + 0.098 V. Unless otherwise specified, all curves are reported without iR compensation. The solution resistance was determined by electrochemical impedance spectroscopy technique at open circuit potential in a frequency range from 105 to 1 Hz with a perturbation of 5 mV. The linear scan voltammetry (LSV) curve was measured from 1 to 0.2 V vs RHE at 10 mV s−1 and 1600 rpm in O2-saturated electrolyte, while the ring potential of RRDE was fixed at 1.23 V vs RHE. The H2O2 partial current density (jH2O2) and selectivity (%) were calculated as follows:

where iring is the measured ring current, idisk is the measured disk current, Sdisk is the area of disk electrode (0.247 cm2), and N is collection efficiency (37%).

The electrochemical H2O2 production in H-cell was performed using chronoamperometry with a CS1350 electrochemical analyzer (CS Instruments, Inc.,Wuhan). OCNT/GDL (1 cm2), Pt foil and Hg/HgO electrode were used as the working electrode, counter electrode and reference electrode, respectively. The working and counter chambers were both filled with 0.1 M KOH solution and separated by a BPM. 100 ml min−1 of O2 was continuously bubbled into the working chamber. The electrochemical H2O2 production in flow reactor was performed using chronopotentiometry. OCNT/GDL (4 cm2) and IrRuOx/Ti (4 cm2) electrode were used as the cathode and anode, respectively. The cathodic and anodic chamber were separated by a BPM. 1 M KOH solution was circulated in both chambers at a rate of 10 ml min−1.

The H2O2 concentration was measured by Ce(SO4)2 titration method based on the colorimetric reaction between Ce4+ and H2O2. After electrolysis, 50 µl of catholyte was mixed with 10 ml 0.5 mM Ce4+ solution. The Ce4+ concentration can be detected by ultraviolet-visible spectrophotometer (UV-Vis, UV-3600, Shimadzu) at 318 nm (Supplementary Fig. 35). The H2O2 FE, productivity and accumulated concentration can be calculated according the following equations:

where NH2O2 is the electron transfer number of 2e− ORR, F is the Faraday constant, CH2O2 is the measured concentration of H2O2, V is the volume of catholyte, Q is total charge through electrolysis, t is the electrolysis time, MH2O2 is the molar mass of H2O2, and ρH2O2 is the density of H2O2 solution at room temperature.

Chemical oxidation of H2S to SO4 2−

The chemical H2S oxidation reaction was conducted by using prepared H2O2 solution to oxidize the captured H2S. Typically, 50 ml of 0.1 M KOH solution was first prepared for the capture of H2S gas, a certain volume (0–1.5 ml) of commercial H2O2 solution (30 wt%) was then added to the KOH solution to obtain defined-concentration H2O2 solutions (0–1 wt%). Subsequently, 5% H2S/Ar mixing gas was fed into the above solution with a flow rate of 20 ml min−1, and the tail gas was absorbed using a 3 M NaOH solution. After aeration for 2 h, the unreacted S2− in the solution were detected through the methylene blue spectrophotometric method using UV-Vis spectrophotometer, and the liquid oxidation products (S2O32−, SO32− and SO42−) of H2S were analyzed through an ion chromatography (IC, ICS-5000, Thermo Fisher Scientific) equipped with a conductivity detector (CD). The quantitative methods are provided in the later section. The solid oxidation product (S) of H2S was collected by centrifuging and drying the post-reaction solution, and its content was determined by weighing.

Electrochemical oxidation of H2S to K2SO4

The electrochemical H2S oxidation to produce K2SO4 was carried out by utilizing in-situ generated H2O2 at cathode to oxidize the captured H2S in KOH electrolyte. The electrolysis in H-cell and flow reactor were performed with a CS1350 electrochemical analyzer (CS Instruments, Inc., Wuhan). For the experiments in H-cell, 50 ml of 0.1 M KOH solution was circulated between the H2S-capture tank and the cathode chamber at a flow rate of 10 ml min−1. The anode chamber contained 30 ml of 0.1 M KOH solution, separated from the cathode chamber by a BPM. OCNT/GDL (1 cm2), Pt foil and Hg/HgO electrode were used as the working electrode, counter electrode and reference electrode, respectively. During electrolysis, the chronoamperometry test was performed at a constant potential. Meanwhile, O2 was fed into the cathode chamber and 5% H2S/Ar was fed into the H2S-capture tank, with the tail gas being absorbed by a 3 M NaOH solution. After electrolysis, the unreacted S2− and oxidation products were detected using UV-Vis and ion chromatography, respectively.

For the experiments performed in a 4-cm2 flow reactor, OCNT/GDL (4 cm2) and commercial IrRuOx/Ti (4 cm2) electrode were used as the cathode and anode, respectively. The cathode and anode chamber were separated by a BPM, with 50 ml of 1 M KOH solution circulating on each side at a flow rate 10 ml min−1. During electrolysis, the chronopotentiometry test was performed at a constant current. O2 and H2S/Ar were together fed into the cathode chamber, part of the mixing gas passed through the GDL to participate in the reaction, while the remaining gas was recirculated into the KOH circulation solution for residual H2S capture. After electrolysis, the unreacted S2− and oxidation products were detected using UV-Vis and ion chromatography, respectively.

For the experiments performed in a 100-cm2 flow reactor, a commercial IrRuOx/Ti electrode was used as the anode and the electrode working area was enlarged to 100 cm2. To simulate the treatment of H2S-involved natural gas using EChem-SOR system, 5% H2S/CH4 or 10% H2S/CH4 was as the gas source to replace 5% H2S/Ar. For high flux H2S/CH4 (>100 ml min−1), H2S/CH4 was first fed into a 500 ml of 1 M KOH solution for H2S capture and then along with the circulation solution for subsequent reactions in cathode chamber.

For the long-term operation of EChem-SOR system in flow reactor, the electrolysis process followed the aforementioned flow reactor procedure. Additionally, the cathodic KOH circulation solution was refreshed daily for maintaining the alkaline environment to capture H2S. An additional gas bag was connected to the end of KOH reservoir to collect the tail gas, and the H2S concentration in tail gas was measured via a gas chromatograph (GC, SOE−131, Shimadzu) equipped with a flame photometric detector (FPD). After the long-term operation, the catholyte was collected and K2SO4 product was obtained through rotary evaporation and crystallization.

Electrochemical oxidation of H2S to H2SO4 in solid-electrolyte flow reactor

The electrochemical H2S oxidation to produce H2SO4 solution was carried out in a SE flow reactor. The SE flow reactor includes a 100 cm2 OCNT/DGL cathode, 100 cm2 commercial IrRuOx/Ti anode, anion exchange membrane (AEM), proton exchange membrane (PEM), and middle SE layer filled with H+-conducting ion exchange resin. The middle SE layer and the anode chamber were circulated by 500 ml of deionized water at a flow rate of 1 ml min−1 and 10 ml min−1, respectively. During electrolysis, the chronopotentiometry test was performed at a constant current. O2 was fed into the cathode chamber. 10% H2S/CH4 was first mixed with the circulating water, both were then circulated in the middle layer.

Sulfur-containing compounds quantification

The concentration of S²⁻ ions in the solution can be determined by the methylene blue spectrophotometric method34,35. Typically, after electrolysis, 30 μl of catholyte was added to a sample tube containing 10 ml of 0.25 M NaOH solution, leading to all sulfide ions (HS⁻) dissociate into S²⁻ in a strongly alkaline environment (pH > 13). Next, 5 ml of 0.01 M C8H12N2·2HCl solution in 4 M H2SO4 was slowly added along the wall of the sample tube. After capping and shaking, 0.5 ml of 0.2 M NH4Fe(SO4)2·12H2O solution in 0.2 M H2SO4 was slowly added along the tube wall. Then, 20 mL of deoxygenated deionized water was added, and the mixture was shaken well. After standing for a moment, the solution turned blue. Finally, the absorbance of the test solution was measured at a wavelength of 665 nm using UV-Vis spectrophotometer. The concentration of S²⁻ in the solution can be determined according to the standard curve. To obtain the standard curve, 10 sets of NaHS solutions in 0.1 M KOH with known concentrations (ranging from 0.3 to 16.7 mM) were first prepared. The test solutions were then prepared according to the above procedure, and the standard curve was plotted by linearly fitting the absorbance values of the test solutions at a wavelength of 665 nm (Supplementary Fig. 36).

The liquid oxidation products (S2O32−, SO32− and SO42−) of H2S were detected using ion chromatography equipped with a conductivity detector and AS11-HC column. The mobile phase was 100 mM NaOH solution with a flow rate of 0.38 ml min−1. Typically, after electrolysis, 20 µl of catholyte was collected and diluted with 1000 µl of deionized water, and then 10 µl of the diluted solution was subjected to ion chromatography analysis. The concentrations of three oxidation products can be determined according to the calibration curves of known concentration samples (Supplementary Figs. 37–39).

Calculation of productivity, H2Scap conversion and e−-to-sulfate efficiency

The productivity of various oxidation products was calculated according the following equations:

where CSO42−, CSO32− and CS2O32− are the concentration of SO42−, SO32− and S2O32− measured under electrolysis, respectively. mS is the mass of S obtained by weighing, MS is the molar mass of S, V is the volume of catholyte, t is the electrolysis time.

The H2Scap conversion (%) was calculated according the following equation:

where CS2− is the concentration of S2− measured by the methylene blue spectrophotometric method.

To describe the electron utilization efficiency for SO42− production, we define the e−-to-sulfate efficiency (%) as follows:

where CSO42−0, CSO32−0, CS2O32−0, and CS2−0 is the concentration of SO42−, SO32−, S2O32−, and S2−, respectively, which is measured under the condition of only O2 feeding, without performing electrolysis. NS2− (8) is the electron transfer number from S2− to SO42−, NS2O32− (4) is the electron transfer number from S2O32− to SO42−, NSO32− (2) is the electron transfer number from SO32− to SO42−. RS2O32− is the ratio of S2O32− among all sulfur species under the condition of only O2 feeding, without performing electrolysis. RSO32− is the ratio of SO32− among all sulfur species under the condition of only O2 feeding, without performing electrolysis.

It is important to note that the concentrations of the three oxidation products (SO42−, SO32− and S2O32−) produced from O2-assisted H2S oxidation are dynamically changing during the electrolysis process, leading to the contribution of O2 to the H2S oxidation reaction cannot be precisely excluded. Therefore, the calculated e−-to-sulfate efficiency based on the equation may deviate from the actual situation. Nevertheless, this still allows for an objective comparison of electron utilization efficiency for different reactors.

COMSOL simulation of H2O2 concentration distribution

The COMSOL simulation was conducted by coupling electrochemistry and fluid flow modules. A two-dimensional axisymmetric model was adopted to simulate the flow cell, with dimensions matching the experimental setup (electrode width: 20 mm, channel height: 1.5 mm). Various currents were applied to the working electrode, while the inlet electrolyte flow rate was set to 0.5–10 ml min−1 with fully developed laminar flow. Initial H2O2 concentration was set to zero throughout the domain. The numerical model solves the following governing equations while accounting for both diffusion and convection effects:

Where ji is the applied current, ci is the H2O2 concentration, Ri and Si are the source items, μ is the velocity field, that is obtained by solving the Navier-Stokes equation.

Data availability

The data generated in this study are provided in the Source Data file. All data supporting the findings of this study are available within the paper and its Supplementary information or from the corresponding author upon request. Source data are provided with this paper.

References

Zhang, X., Tang, Y., Qu, S., Da, J. & Hao, Z. H2S-selective catalytic oxidation: catalysts and processes. ACS Catal. 5, 1053–1067 (2015).

Pieplu, A., Saur, O., Lavalley, J. C., Legendre, O. & Nedez, C. Claus catalysis and H2S selective oxidation. Catal. Rev. Sci. Eng. 40, 409–450 (1998).

Final Background document for sulfur recovery. 1, 42, United States Environmental Protection Agency. https://www.epa.gov/chief (1992).

Wang, Z. et al. Hydrogen sulfide splitting into hydrogen and sulfur through off-field electrocatalysis. Environ. Sci. Technol. 58, 10515–10523 (2024).

Zhu, P. et al. Continuous carbon capture in an electrochemical solid-electrolyte reactor. Nature 618, 959–966 (2023).

Kim, K. & Lee, C. Recent progress in electrochemical hydrogen sulfide splitting: strategies for enabling sulfur-tolerant anodic reactions. Chem. Eng. J. 469, 143861 (2023).

Zhang, S. et al. Sulfophobic and vacancy design enables self‐cleaning electrodes for efficient desulfurization and concurrent hydrogen evolution with low energy consumption. Adv. Funct. Mater. 31, 2101922 (2021).

Yu, Z., Deng, Z., Li, Y. & Wang X. Advances in electrocatalyst design and mechanism for sulfide oxidation reaction in hydrogen sulfide splitting. Adv. Funct. Mater. 34, 2403435 (2024).

Pei, Y. et al. High-entropy sulfide catalyst boosts energy-saving electrochemical sulfion upgrading to thiosulfate coupled with hydrogen production. Angew. Chem. Int. Ed. 63, e202411977 (2024).

Zhang, M. et al. Highly effective and durable integrated-chainmail electrode for H2 production through H2S electrolysis. Angew. Chem. Int. Ed. 64, e202502032 (2025).

Zhang, M. et al. Highly efficient H2 production from H2S via a robust graphene-encapsulated metal catalyst. Energy Environ. Sci. 13, 119–126 (2020).

Cui, H. et al. Highly-efficient natural gas desulfurization and simultaneous H2O2 synthesis based on the electrochemical coupling reaction strategy. J. Hazard. Mater. 463, 132823 (2024).

Li, T. et al. Energy-saving hydrogen production by seawater electrolysis coupling tip-enhanced electric field promoted electrocatalytic sulfion oxidation. Nat. Commun. 15, 6173 (2024).

Zhu, Y. et al. Screened d-p orbital hybridization in turing structure of confined nickel for sulfion oxidation accelerated hydrogen production. Angew. Chem. Int. Ed. 64, e202419572 (2024).

Sulfur statistics and information. U.S. Geological Survey (2022).

Shao, X., Huang, Y., Wood, R. M. & Tarpeh, W. A. Electrochemical sulfate production from sulfide-containing wastewaters and integration with electrochemical nitrogen recovery. J. Hazard. Mater. 466, 133527 (2024).

Shao, X., Johnson, S. R. & Tarpeh, W. A. Quantifying and characterizing sulfide oxidation to inform operation of electrochemical sulfur recovery from wastewater. ACS ES&T Eng 2, 807–818 (2022).

Kim, K. & Han, J.-I. Performance of direct alkaline sulfide fuel cell without sulfur deposition on anode. Int. J. Hydrogen Energy 39, 7142–7146 (2014).

Pikaar, I., Rozendal, R. A., Yuan, Z., Keller, J. & Rabaey, K. Electrochemical sulfide removal from synthetic and real domestic wastewater at high current densities. Water Res 45, 2281–2289 (2011).

Zhang, L. et al. Chemical and biological technologies for hydrogen sulfide emission control in sewer systems: a review. Water Res. 42, 1–12 (2008).

Siahrostami, S. H2O2 electrosynthesis and emerging applications, challenges, and opportunities: a computational perspective. Chem Catal. 3, 100568 (2023).

Lee, B.-H. et al. Supramolecular tuning of supported metal phthalocyanine catalysts for hydrogen peroxide electrosynthesis. Nat. Catal. 6, 234–243 (2023).

Dong, K. et al. Epoxidation of olefins enabled by an electro-organic system. Green Chem. 24, 8264–8269 (2022).

Chen, S. et al. Direct electroconversion of air to nitric acid under mild conditions. Nat. Synth. 3, 76–84 (2023).

Kim, J. et al. Electro-assisted methane oxidation to formic acid via in-situ cathodically generated H2O2 under ambient conditions. Nat. Commun. 14, 4704 (2023).

Davis, R. E. Displacement reactions at the sulfur atom. I. an interpretation of the decomposition of acidified thiosulfate. J. Am. Chem. Soc. 80, 3565–3569 (1958).

Lu, Z. et al. High-efficiency oxygen reduction to hydrogen peroxide catalysed by oxidized carbon materials. Nat. Catal. 1, 156–162 (2018).

Fan, L. et al. Selective production of ethylene glycol at high rate via cascade catalysis. Nat. Catal. 6, 585–595 (2023).

She, F. et al. Curvature-dependent electrochemical hydrogen peroxide synthesis performance of oxidized carbon nanotubes. ACS Catal. 14, 10928–10938 (2024).

Zhang, X., Fang, Z., Zhu, P., Xia, Y. & Wang, H. Electrochemical regeneration of high-purity CO2 from (bi)carbonates in a porous solid electrolyte reactor for efficient carbon capture. Nat. Energy 10, 55–65 (2024).

Sanz-Pérez, E. S., Murdock, C. R., Didas, S. A. & Jones, C. W. Direct capture of CO2 from ambient air. Chem. Rev. 116, 11840–11876 (2016).

Song, Y. et al. High-pressure electro-Fenton driving CH4 conversion by O2 at room temperature. J. Am. Chem. Soc. 146, 5834–5842 (2024).

Xia, C. et al. Continuous production of pure liquid fuel solutions via electrocatalytic CO2 reduction using solid-electrolyte devices. Nat. Energy 4, 776–785 (2019).

Guenther, E. A., Johnson, K. S. & Coale, K. H. Direct ultraviolet spectrophotometric determination of total sulfide and iodide in natural waters. Anal. Chem. 73, 3481–3487 (2001).

Water quality-determination of sulfide-methylene blue spectrophotometric method. HJ 1226-2021, Ministry of Ecology and Environment of the People's Republic of China. https://www.mee.gov.cn (2021).

Acknowledgements

H.D. acknowledges the support from the National Key R&D Program of China (2023YFA1507400), the National Natural Science Foundation of China (Grant No. 22325805, 22441010), Beijing Natural Science Foundation (Grant No. JQ22003), the Haihe Laboratory of Sustainable Chemical Transformations (24HHWCSS00007) and Tsinghua University Dushi Program.

Author information

Authors and Affiliations

Contributions

H.D. conceived the idea, supervised the project and revised the manuscript. H.Z. designed and supervised the experiments. C.Z. performed all experiments and data analysis, and drafted the manuscript. A.L. and B.Y. assisted with the materials synthesis, materials characterization and electrochemical measurements. X.L. assisted with the flow reactor tests and techno-economic analysis. YB.L., K.K. and Q.S. assisted with the energy consumption calculations and contributed to the discussion of experiment data. S.L. assisted with life-cycle assessment calculations. YQ.L. and Z.Y. assisted with the solid-electrolyte flow reactor tests. All authors reviewed and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yuqin Zou, Xiaoqing Huang and Kwiyong Kim for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, C., Li, AZ., Yuan, BJ. et al. Electrochemical valorization of H2S in natural gas to sulfate under mild conditions. Nat Commun 16, 7175 (2025). https://doi.org/10.1038/s41467-025-62445-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62445-y