Abstract

Ultrasound techniques are increasingly used to probe the internal dynamics of batteries to obtain cost-effective, real-time insights into electrochemical processes. However, prior studies have established only superficial correlations between ultrasound and electrochemical parameters, thus limiting the understanding of signal variations during cycling. In this study, the interpretability of these variations is improved by combining operando ultrasound measurements with synchrotron X-ray diffraction and nanodilatometry measurements during electrochemical cycling and relaxation. We show that at battery states of charge from 10% to 80%, ultrasound signals reflect primarily the change in the graphite electrode, particularly its elastic modulus during lithiation. At battery states of charge between 80% and 100%, the H2 → H3 phase transition in LiNi0.8Mn0.1Co0.1O2 affects the ultrasound signal. This multimodal approach enhances the understanding of how mechanical and structural battery dynamics influence ultrasound signals, thus marking a step forward in the interpretation of acoustic data in commercial cells via advanced synchrotron techniques.

Similar content being viewed by others

Introduction

Li-ion battery technology currently dominates the energy storage market but still suffers from limitations, notably high costs, low energy density, and safety issues. During ageing, the electrochemical performance of cells degrades due to various degradation reactions that cause serious safety issues, such as gas emission and thermal runaway1. These ageing processes are accelerated by additional external processes such as mechanical (vibration, compression, and penetration), thermal (high and low temperatures), and electrical (external short-circuit, overload, and overdischarge) processes2. Monitoring the state of charge (SoC) and state of health (SoH) of a battery during operation is of paramount importance for detecting premature battery failure. Once detected, the battery management system (BMS) can properly disconnect the cell from a stack to ensure user safety3. One approach for SoH estimation is to plot the differential curves dQ/dV and dV/dQ to observe the variations with cell ageing4,5,6. However, this method implies the presence of distinct electrochemical processes. Recent studies have used electrochemical impedance spectroscopy for ageing analysis by monitoring the frequency-dependent impedance of the cell7. Recently, optical fibers have been introduced to not only obtain mechanical insights for commercial cells8 but also probe the thermal distribution in cylindrical cells9. The internal strain in cylindrical cells has also been probed via strain gauge sensors, and a correlation with graphite swelling has been demonstrated10. The main issues with these sensors are their invasive nature and the possibility of modifying the local electrochemical behavior due to additional strain11. Therefore, the development and adaptation of noninvasive techniques for Li-ion batteries is crucial for further accelerating cell development and improving their operation.

Ultrasound technology, which is already used in many industries, such as nuclear12 and medical13 industries, has many advantages, such as low cost, high technology readiness level, and noninvasiveness. Ultrasound sensors could be implemented and used to study the electrochemical performance and degradation of batteries to provide additional information about their mechanical dynamics14. In the literature, researchers have used ultrasound techniques to investigate several parameters, such as the amount of gas emitted15, the degree of particle fracture that results from large volume changes (conversion or alloying materials) or from unusual anisotropic behavior (LiNixMnyCozO2 particle fractures)16, the wetting of the cell17, and the thermal runaway18. However, in all these cases, the ultrasound wave is drastically modified, and the detection of a change in the ultrasound signal begins after the processes have taken place, which causes the battery to fail and does not help ensure the safety of the user.

In 2019, Robinson et al.19 used an ultrasound technique to investigate a commercial cell (Samsung J5 smartphone battery composed of graphite||LiCoO2 electrodes) and demonstrated a relationship between the density evolution of the positive or negative electrode imposed by lithiation and delithiation processes and the time-of-flight (ToF) response. Having successfully evaluated the battery SoC as a function of the ToF signal, they demonstrated that shifts in the ToF signal can be used to locally probe the lithium content in the active material. Similarly, Zhao et al.20 used noncontact ultrasound-guided waves to probe and estimate the battery SoC and SoH of a commercial LiNi1-x-yMnyCoxO2-LiMn2O4- LiCoO2 blend vs. a commercial graphite cell. Irrespective of the wavelength used, the signal amplitude tended to increase as the SoC increased; conversely, the ToF signal tended to decrease. Recent works by Appleberry et al.15 and Zappen et al.18 investigated the ultrasound signal characteristics before and during cell thermal runaway induced by external heating. These studies suggest that ultrasound can be used to effectively predict thermal runaway events. Ultrasound can thus be applied to detect degradation processes, but to date, there is no clear understanding in the literature of the complex interactions of ultrasound with cell components. Despite current research in this area, a clear attribution of electrochemical effects to changes in ultrasound characteristics remains an open research question.

In 2023, Liu et al.21 decorrelated the influence of the battery SoC of the LiFePO4 (LFP) positive electrode from that of the graphite negative electrode via the ToF signal collected from an ultrasonic sensor. They demonstrated that the signal is dominated by the evolution of the electrode Young’s modulus, which shows that the latter can be influenced by the lithiation/delithiation processes. On the basis of their investigation, they concluded that in a full-cell LiFePO4 vs. graphite cell, most of the ultrasound signal comes from the graphite electrode. Following this type of investigation, Owen et al. demonstrated that the internal temperature of a cell could be determined via ultrasound measurements, as the temperature affects the Young’s modulus22.

In this study, we investigated a commercial LiNi0.8Mn0.1Co0.1O2 (NMC811) vs. graphite cell equipped with an ultrasound sensor while simultaneously monitoring the structural evolution within the cell via operando X-ray diffraction (XRD) at a large-scale facility (BM02 beamline at ESRF, Grenoble, France). To understand the signal monitored by the ultrasonic sensor, we studied the dynamics of lithiation/delithiation by using C/3 (124 mA.g−1 for graphite and 66.7 mA.g−1 for NMC811) with a relaxation protocol and performed a measurement close to thermodynamic equilibrium at the C/8 rate (46.5 mA.g−1 for graphite and 25 mA.g−1 for NMC811). The results obtained were further correlated with the mechanical and electrochemical processes via nanodilatometric measurements, with each electrode deconvolved. The evolution of the ultrasound signal was driven mainly by the evolution of the Young’s modulus of the graphite. By correlating the ToF evolution with the structural and electrochemical evolution, we demonstrated the sensitivity of ultrasound to the mechanism of lithium storage in both active materials.

Results and discussion

A schematic diagram of the experimental setup in Fig. 1a, where we can see the commercial cell (graphite||NMC811) paired with a US emitter receptor. The cell was placed on a custom sample holder23 developed by Lyonnard’s group (Fig. 1b), which enabled lateral scanning with the microbeam. The cycling protocol of the cell is displayed in Fig. 1c. Three cycles were performed: the first cycle at the C/3 rate to verify the cell behavior, the second cycle at the C/8 rate, and the last cycle via a technique similar to the galvanostatic intermittent titration technique (GITT) by using C/3-rate charging with 1 h pulses and 1 h relaxation steps.

a Schematic diagram of the operando scanning XRD setup and cell used for the study. The commercial cell was equipped with two ultrasound (US) transducers. A close-up schematic diagram of the battery assembly, which consists of graphite||NMC811 layers, is also shown. b Photograph of the commercial cell equipped with US transducers and placed on the beamline prior to investigation. c Electrochemical profile of the cell obtained during measurement at 25 °C between 2.7 and 4.2 V (P1: C/3 rate, P2: C/8 rate, and P3: GITT profile). The source data are provided as a Source data file.

Before starting the operando measurement, we checked that the ultrasound signal was not affected by temperature fluctuations in the hutch (see Note 1, Supporting Information) and that the measurement at the beamline was similar to that obtained in the laboratory (see Note 2, Supporting Information). We also checked that the cell did not suffer from X-ray damage (see Note 3, Supporting Information). Then, scalar quantities were extracted from the ultrasound signal, as mentioned in Note 4 (Supporting Information), especially the ToF, which is one of the most relevant parameters for ultrasound investigations in batteries. However, the interpretation of ToF evolution during cycling is far from trivial, as shown in Eq. (1). The ToF depends on constants such as the total mass and the section probed and on two variables: the thickness and the average effective elastic modulus (Young’s modulus) of the material being crossed by ultrasonic waves.

where m (kg) represents the mass probed, A (m2) represents the section, d (m) represents the thickness of the sample probed, Eeff (kg.m−1.s−2) represents the sample’s effective Young’s modulus, and ρ (kg.m−3) represents the average density of the sample. Both variables depend on the sample’s chemical composition and environmental conditions, i.e., temperature and pressure.

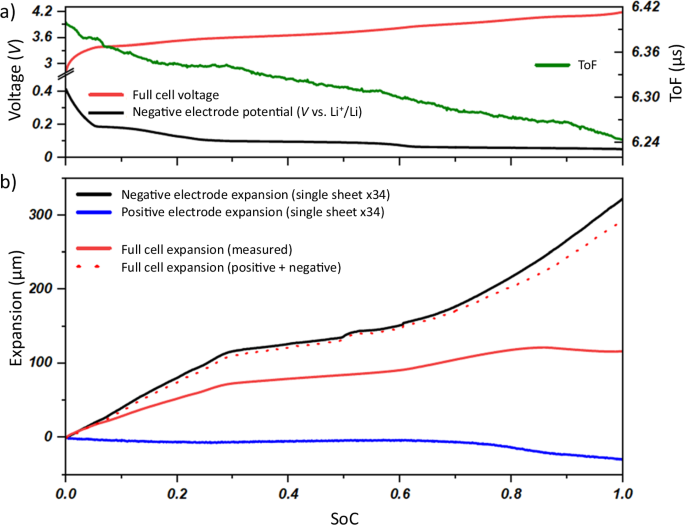

Figure 2a shows that the ToF decreased when the graphite||NMC811 cell was charged. On the basis of Eq. 1, this decrease could have been caused by an increase in the thickness probed (thickness of the full cell) or a decrease in the elastic properties. To determine which parameter was responsible for the changes in ToF, we needed to measure the cell’s thickness and how the effective elastic modulus (also called Young’s modulus) changed. Several studies have shown that the thickness of graphite||NMC811 cells increases by several tens of micrometers during charging24,25,26 (NMC delithiation and graphite lithiation). This increase in macroscopic thickness is caused by changes in the volume of the active materials at the electrode scale. For the graphite particles, the variations in lattice parameters are highly anisotropic and induce a large volume change along the c-axis of the crystal structure (which corresponds to the d-spacing of the graphene layers). This corresponds to a 14% increase in the c-axis thickness at 100% battery SoC. As a result, this expansion along the c-axis generates a unidirectional expansion at the electrode scale, thus increasing its thickness. From the volume changes at the lattice scale of graphite, on the basis of Schweidler et al.27, we estimated the expansion rate of the lattice volume with respect to the graphite SoC (x in LixC6). As an example, an expansion rate equal to 7 Å3/x was obtained for the LiC12 ⟷ LiC6 biphasic mechanism. The NMC particles are slightly more complex. During delithiation, NMC particles undergo an anisotropic variation in lattice parameters along the a-b-axis and c-axis, which results in an overall volume contraction (this process is reversible during lithiation; i.e., discharge). This volume contraction is very small for the H1 ⟷ H2 NMC phase transitions (estimated at −4 \({{{\text{\AA }}}}^{3}/x\), with x in Li(1-x)NMC28), whereas the last phase transition, H2 ⟷ H3, is responsible for a higher volumetric contraction of ca. −24 \({{{\text{\AA }}}}^{3}/x\), with x in Li(1−x)NMC28 at the lattice scale. With respect to the NMC electrode scale, the volume changes are not unidirectional but result in a 3D volume contraction. It is evident that, in the context of the H1 → H2 phase transition, the full-cell thickness is influenced predominantly by the graphite electrode volume change. Conversely, during the H2 → H3 phase transition, the NMC volume change at the electrode level contributes to the variation in the full cell thickness. These findings lead to the conclusion that the full-cell thickness expansion from 0% to 80% SoC is attributable to the expansion of the graphite electrode layers, and from 80% to 100% SoC, the NMC811 electrode slightly buffers the full-cell expansion.

a Full-cell voltage and negative electrode potential on the left axis and ToF evolution on the right axis. b Full-cell expansion measurements taken from ref. 26 and negative and positive electrode layer expansions estimated from nanodilatometry measurements. The full-cell and negative electrode data are horizontally aligned via the graphite-specific features of the DVA. All the measurements were performed at 25 °C at C/40 cycling rates between 2.7 and 4.2 V. The source data are provided as a Source data file.

To verify our hypothesis, a quantitative analysis between the full-cell expansion and the negative and positive layer expansion was performed to highlight the importance of the graphite in the volumetric changes. To do this, we disassembled the same commercial cell as the one brought to the synchrotron in an Ar-filled glovebox, washed the electrodes, carefully removed one side of the double-coated negative or positive electrodes, and mounted this single-sided coated electrode in a nanodilatometer to enable operando monitoring of the working electrode (graphite or NMC) expansion in a three-electrode setup (NMC or graphite as the counter electrode and Li metal as the reference electrode) (see Note 5, Supporting Information). In Fig. 2b, we compare the thickness evolution of the whole cell (measured with a constant pressure of 25 kPa) reported in the literature26 with the graphite and NMC811 electrode expansion measured by operando dilatometry as described above. Given that the full cell comprised 17 double-coated negative and positive electrodes, we applied a factor of 34 to the electrode expansion measured by nanodilatometry. As illustrated in Fig. 2b, the graphite electrode expansion largely exceeded the volume contraction of the NMC811 electrode. As a result, the extrapolated (experimental difference between the positive and negative electrode expansions) full-cell expansion strongly depends on the graphite electrode, with a slight effect from the NMC811 electrode, which buffers the global expansion above 80% SoC. By comparing the extrapolated full-cell expansion, for the dilatometric measurement with the full-cell expansion measurement of the commercial cell, we observe the effect of the cell manufacturing. Indeed, in the pouch cell, all the elements, such as separators, casings, and voids, that are voluntarily introduced in the assembly by the manufacturer buffer the global expansion. These observations support the abovementioned hypothesis that the full-cell thickness evolution upon charging mainly follows the evolution of the graphite negative electrode expansion.

The results obtained by substituting the abovementioned data into Eq. 1 suggest that the global thickness increase should result in a ToF increase during the charge of the cell, which is not the case.

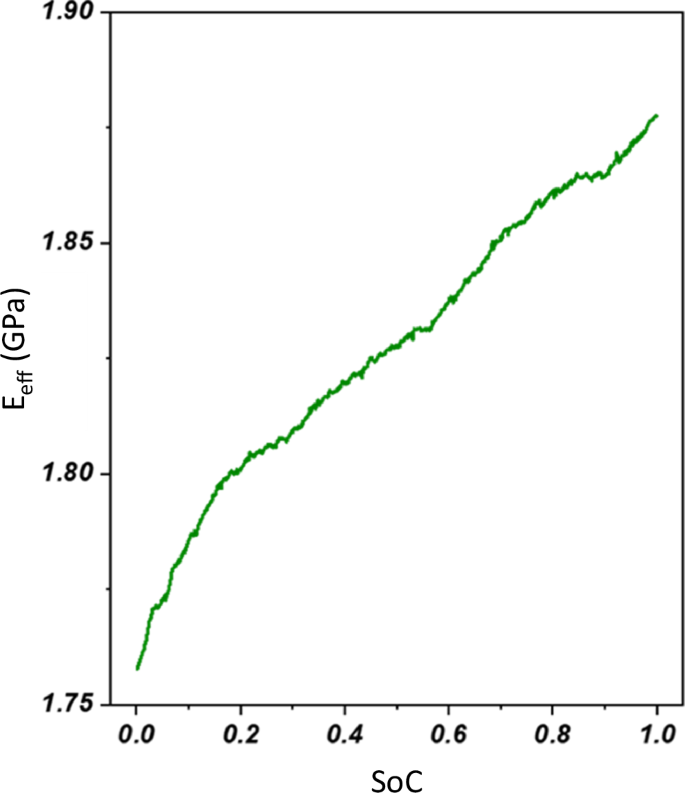

We subsequently examined the evolution of the Young’s modulus of the electrode materials (positive and negative) via literature data. DFT calculations, which were performed at the particle level29,30, demonstrated that the Young’s modulus values of graphite and NMC increase upon lithiation and decrease reversibly upon delithiation. Considering the full cell charge (graphite lithiation and NMC delithiation), the Young’s modulus of graphite increases, whereas for NMC, the Young’s modulus decreases. Following the trend identified via DFT calculations, we examined the order of magnitude of the Young’s modulus variations during charging for both materials. For NMC, a decrease of 50–60% was observed, whereas for graphite, an increase of 240% was obtained, thus indicating the dominance of graphite. To confirm this point, we conducted a numerical estimation of the average Young’s modulus of the full cell on the basis of the thickness evolution data (extracted from the full-cell expansion, Fig. 2b) and the ToF signal measured (Fig. 2a). Figure 3 shows an increase in the average elastic modulus of the full cell during charging, as previously deduced and in agreement with bending tests reported in the literature for both materials31,32.

The source data are provided as a Source data file.

In conclusion, the effective elastic modulus of the full cell is driven by the Young’s modulus of the negative electrode. Consequently, we observed an increase in the elastic modulus during charging. Furthermore, on the basis of Eq. (1), an increase in the average elastic modulus is consistent with the decrease in ToF observed during the charging process. However, the nonmonotonic evolution of ToF measurements indicates the presence of a complex correlation between the various cell components, with an additional correlation evident between both electrode materials.

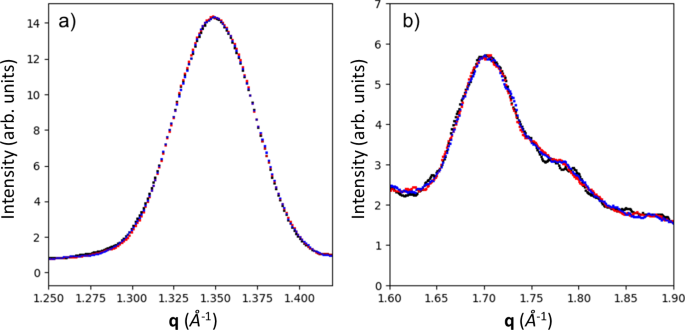

To deconvolve the ToF signal and attribute each process to a specific electrode phenomenon, we carried out a full structural investigation through operando XRD measurements while simultaneously collecting the ToF signal. From the diffraction patterns obtained, the evolution of the main NMC811 (003) Bragg reflection, as well as that of graphite (002), was followed, with both being properly separated in the q range. Using custom-made software for data correlation based on the MatPlotLib Python library33 and the LMFIT package34, we fitted both main reflections (the raw data are plotted in Note 7, Supporting Information) and obtained the average peak position to follow the structural changes through the evolution of the c-axis. The c-axis is of particular interest for graphite electrodes since the de/lithiation processes modify the interlayer d-spacing35. In the case of the NMC811 electrode, both the a-axis and c-axis evolve. However, as demonstrated by Quilty et al.36, the c-axis is the axis that evolves the most, especially during the H2‒H3 phase transition, which justifies the choice of this axis.

Although the structures of the positive and negative active materials in given states of lithiation can be separately accessed via XRD, and c-parameter variations can also be accessed, deconvolution between the positive electrode and the negative electrode reaction mechanisms is a challenging task. This is because, in a full cell, the electrochemical signatures of both electrodes are merged. To address this issue, operando nanodilatometric measurements were employed to deconvolve the electrochemical signatures of the two electrodes, thereby facilitating understanding of the global electrochemical signature and enabling the correlation of the volume change of one electrode at a time as a function of the voltage of the cell.

From the three-electrode setup, three potential differences can be measured:

where \({\varPhi }_{{{\rm{Gr}}}}\), \({\varPhi }_{{{\rm{NMC}}}}\) and \({\varPhi }_{{{\rm{Li}}}^\circ }\) represent the electronic potentials of graphite (WE), NMC811 (CE), and Li° (REF), respectively.

Equation (4) implies that the full-cell voltage (VFC) variations correspond to the sum of the variations in the voltage of the WE vs. Li° (VWE) and the CE vs. Li° (VCE) with respect to the full-cell capacity (QFC):

Since \({\varPhi }_{{{\rm{Li}}}^\circ }\) is assumed to be constant during the measurement for a C rate of C/40, we obtain Eq. (6):

We introduce weighting variables that quantify the effect of the electronic potential variation of one electrode (ωGr for the WE and ωNMC for the CE) on the full-cell voltage variation (Eq. 7).

On the basis of Eq. (7), we can “separate” mathematically the contribution of each electrode from the other electrode and thus “weight” their contributions; those functions are plotted in Fig. 4a.

a Weighting functions of the potential effects of the graphite and NMC electrodes on the full-cell voltage variation, supplemented by the main phase transitions observed at the top; b dt/dE curves of the graphite, NMC, and full cell with the full-cell voltage evolution. The data were obtained from nanodilatometric three-electrode setup measurements with a cycling rate of C/40 at 25 °C. The source data are provided as a Source data file.

Furthermore, the dt/dE (which is analogous to dQ/dV under a constant current process) evolution (Fig. 4b) offers insight into the underlying de/lithiation mechanism. In the case of the NMC811 material, lithium de/insertion occurs via a solid solution mechanism, with various lattice parameter changes inducing specific variations in the dt/dE representation. In the case of graphite, biphasic mechanisms result in peak generation, whereas solid solution mechanisms do not significantly impact the evolution of the curve. Notably, the three curves are linked through Eq. 8:

This representation enables us to assign each phenomenon to a specific electrode37. Region A of the charging cell (Fig. 4) displays a voltage variation imposed by the graphite electrode, as shown by the weighting function curve. However, in this region, no specific peak is observed in the dt/dE representation, as solid solution-like processes of lithiation/delithiation occur for both electrodes. In region B (Fig. 4), the full-cell voltage variation is attributed to the potential variation of both electrodes. However, the comparable shape of the peak observed for the full-cell and graphite curves in the bottom graph indicates that graphite undergoes its initial biphasic phase transition (stage IV, the formation of LiC36 from LiC7238), whereas NMC811 remains delithiated through the solid solution mechanism with no phase transition. A comparable observation can be made in region C (Fig. 4), where the apparent peak of the full-cell curve is attributed to the graphite stage III liquid-like transition. In region D (Fig. 4), two processes can be identified. The first of these (labeled D1) involves the graphite undergoing a stage II phase transition (LiC12 phase formation), and the hexagonal to monoclinic phase transition H1 → M of NMC811 (a common phase transition for the NMC811 compound family) occurs concurrently. The second subregion (D2) corresponds to the continuation of graphite stage II formation, while the specific phase transition of NMC811 is terminated. The final region E (Fig. 4) initially exhibits a local minimum, which can be attributed to the change in the biphasic mechanism of graphite from LiC12 formation to LiC6 formation (stage I). The NMC electrode subsequently undergoes the first monoclinic to second hexagonal phase transition M → H2 within the E1 subregion. The second characteristic peak in subregion E2 correlates with the second to third hexagonal transition H2 ⟷ H3, which involves the oxidation of Ni3+ and Co3+ to Ni4+ and Co4+, respectively39.

Now that we have gained a better understanding of the electrochemical response of a full cell (graphite||NMC811), we establish a correlation between the ToF signal and the electrochemical processes of NMC811 and graphite, as well as their structural evolution, which has been obtained via operando XRD. Figure 5a, c shows the evolution of the peak position from the (002) Bragg reflection of graphite and the (003) Bragg reflection of NMC811, respectively. Figure 5b shows the evolution of dt/dE from the full-cell voltage variation obtained at C/8, which is correlated with ToF evolution. As with the dilatometric data, we divided the obtained correlated ToF-XRD data into the five same regions of interest, beginning with the cell discharge (graphite delithiation and NMC811 lithiation). Notably, the potential boundaries are slightly shifted between Figs. 4 and 5 due to the high separator resistance employed in the nanodilatometric measurements. In region E2’, a significant variation in the ToF signal was observed, which was correlated with the peak attributed to the H3 ⟷ H2 transition of NMC811. This resulted in a notable change in the lattice volume of NMC811, which was estimated at 4% by Quilty et al.36 and is the most important variation in volume among all the transitions of NMC811. In the remaining region E’, which spans from 4.1 V–3.8 V, a linear increase in the ToF signal was observed, which may be attributable to the disappearance of the LiC6 phase. No obvious changes in the slope of the ToF signal were observed when NMC811 underwent the H2 ⟷ M phase transition (E1’ subregion). A change in the slope of the ToF signal was observed in the D2’ region in comparison to the E1’ region, which was correlated with the change in the biphasic mechanism of graphite (from LiC6 to LiC12). When NMC811 underwent the M → H1 phase transition in subregion D1’, the slope intensity of the ToF signal increased. In the third region (C’), a period of pseudoplateau in the ToF signal was correlated with the liquid-like stage III of graphite. In this potential range, the exchange of charges is minimal, thus resulting in negligible variation in the global Young’s modulus of the cell. With respect to the B’ region, again, a distinctive slope in the ToF increase was discernible, which was correlated with stage IV of graphite disappearance. For the final region of interest (A’), a plateau-like feature was identified in the ToF signal, which was correlated with the minimal amount of lithium stored via a solid solution-like mechanism in both materials.

a Variations in the peak position of graphite, the characteristic biphasic mechanism observed for LiC6 formation, and other biphasic mechanisms are not visible because of the numerous layers probed; b dt/dE curve and ToF evolution with cell voltage; and c variations in the peak position of NMC related to lattice parameter changes depending on the cell voltage. The source data are provided as a Source data file.

Regarding the previous discussion, we observed that the ToF signal was driven mainly by the evolution of the Young’s modulus of graphite, which led to a decrease in ToF during charging of the cell and an increase in ToF during discharging. By deconvolving all the electrochemical processes, we also demonstrated that most of the modulations in ToF were correlated with structural changes in the two electrode materials. We observed that, in general, the ToF changes depend linearly on the potential in the selected regions, with varying positive or negative slopes that might reflect a correlation between specific phase transitions and ultrasound properties. This effect could be further investigated in simplified systems to identify quantitative relationships between ToF and electrochemical processes, which is beyond the scope of this study.

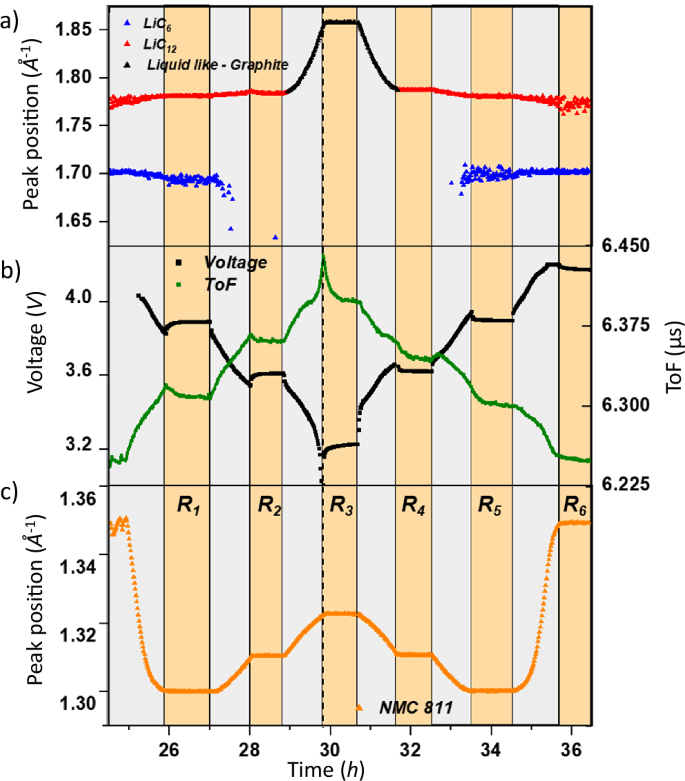

Furthermore, a technique similar to GITT was employed to elucidate the influence of structure relaxation on the ToF signal. This electrochemical characterization is a widely used technique in the field of batteries40 and consists of the application of regular pulses of low-intensity current. A long resting period is then left between those pulses to allow the cell to relax and the electrode material to reach a state of quasi-equilibrium. The lithium concentrations are subsequently equilibrated in the cell, which leads to homogeneous lithium distribution throughout the electrode volume. In this instance, a current pulse equivalent to the C/3 rate was selected with the objective of generating heterogeneities in the cell, thereby facilitating understanding of the sensitivity of the ultrasound technique.

As illustrated in Fig. 6, the ToF signal is sensitive to the relaxation processes that occur within the cell, as evidenced by the fluctuations observed during the resting periods (R1–R6 in Fig. 6) of the cell. Several parameters may contribute to the relaxation processes. Here, we tried to identify the parameter that has a dominant effect on this relaxation. First, the temperature change induced by cycling at the C/3 rate could generate the local heating that the cell needs to dissipate and could affect the ToF signal. On the basis of the results of previous experiments conducted in the laboratory with similar commercial batteries, an estimated dependency of 26 ns/K was derived. Considering most of the relaxation phases (except R3, which exhibits greater relaxation), the ToF signal showed an average decrease of 12 ns, which corresponded to a temperature decrease of ~0.5 K. Additional temperature measurements indicate that the surface temperature of the cell decreased by 0.1 K to 0.3 K during R1 and R2 and by ~1 K during R3. The discrepancy between the temperature change inferred from ultrasound and the surface temperature can be attributed to the fact that ultrasound probes the internal structure of a cell. Moreover, the Young’s modulus of graphite, which was identified as the dominant factor that influences the overall evolution of the ToF signal upon cycling, may also be sensitive to relaxation processes due to the local inhomogeneous reaction imposed by the C/3 rate. To investigate this, particular attention was given to the diffraction patterns of NMC811 and the evolution of graphite during relaxation periods (see Note 8, Supporting Information), specifically the final relaxation period related to the high SoC of the cell, which corresponds to the transition from LiC12 to LiC6. Figure 7 shows the XRD patterns of the two electrodes during R6 relaxation, which involved the H3 phase of NMC811 and a mixture of LiC12 (~1.78 Å−1) and LiC6 (~1.70 Å−1) graphite phases. No discernible shift in the peak position for NMC811 was observed, thus leading to the conclusion that NMC811 did not undergo a relaxation process at the C/3 rate. For the graphite, no alterations in the intensity or shape (constant FWHM) of the LiC6 peak are discernible, and the slight variations in the LiC12 contribution are noise-related, which indicates a constant structural state during the relaxation process. Notably, however, the numerous layers probed in the battery induce large diffraction peaks, which may make the detection of small variations in the local SoC of both electrode materials challenging in the present through-plane-averaged XRD setup. Therefore, ruling out the possibility of a relaxation in the Young’s modulus, which would affect the ToF, is not possible. Nevertheless, our observations demonstrate that the Young’s modulus is not the primary factor that influences ToF relaxation. Additionally, mechanical relaxation of the electrode, which results from changes in the electrode volume, may also affect the ToF signal. The binder signal has thus far been undetectable because of its very small contribution (less than 2 wt.% in each electrode). In the present case, temperature relaxation due to ohmic relaxation contributes to ToF relaxation. However, excluding a contribution from mechanical relaxation, which may be derived from the electrode binder or the separator, is not possible.

a Peak position evolution of the (002) graphite Bragg reflection, b Cell voltage and ToF variations with time, and c Peak position evolution of the (003) NMC811 Bragg reflection obtained by fitting. Cycling was performed at C/3 at 25 °C between 2.7 and 4.2 V. The source data are provided as a Source data file.

Ultrasound techniques could be used in BMSs to assess the state of health of batteries. However, the correlation of ultrasound signals with specific phenomena remains a challenge. Following an in-depth investigation into the correlations between ultrasound time-of-flight signals and electrochemical responses and structural evolution, as obtained through operando XRD measurements, the time-of-flight signal was demonstrated to be dominated by the graphite negative electrode, with a particular focus on the evolution of its Young’s modulus during cycling. By performing an operando dilatometric measurement in a three-electrode configuration on identical materials, we were able to accurately deconvolve the evolution of NMC811 from that of graphite. This approach enabled the identification of a comprehensive correlation between the observed variation in ToF and the structural and electrochemical changes that occur upon charge and discharge, with each electrode material being deconvolved. At high voltage, where the phase transitions in both electrode materials have the most detrimental effect on long-term cycling, we demonstrated the sensitivity of the ultrasonic sensor to structural changes, such as the H2 to H3 phase transition of the NMC811 electrode, which is known to generate significant stress on the particles. Quantitative links between the specific slopes observed in ToF variation and the structural changes in electrode materials could be further established by performing repeated and reproducible experiments, including dedicated model systems or half-cell measurements. Further measurements should be carried out to gain a deeper understanding of the ultrasound approach under harsh conditions (low and high temperatures, high current, and aged cells). Multiprobe characterizations should be used to correlate ultrasound signals with gas generation, structural evolution, morphological evolution, etc. In this study, the potential value of integrating ultrasound sensors into BMSs to monitor structural changes and provide a reliable state of health evaluation through ultrasound modulation quantification has been demonstrated.

Methods

Experimental setup

The cell used for this study was an industrial KOKAM® pouch cell of 11.6 Ah. It is a multilayer liquid electrolyte cell with the following chemical composition graphite||LiNi0.8Mn0.1Co0.1O2 (product number: SLPB065070180).

Ultrasound sensor

On the surface of the cell, piezoelectric ceramic elements (manufactured from the PIC255 material by PI Ceramic, with dimensions L × B × T of 10 × 10 × 2 mm and a resonance frequency of 1 MHz) were glued at the centers of both sides. Special care was taken to place the elements directly opposite each other. At the synchrotron, an Olympus Epoch 650 was used to excite one of the piezoceramic elements with a single pulse (500 µs duration) and read out the other element’s delayed response. During additional measurements outside the beam, custom hardware was used to excite and read out the piezoceramic elements. The custom hardware further enabled excitation by a rectangular wave (1 MHz frequency) in contrast to a single pulse.

Cycling protocol

The cell was cycled at the synchrotron beamline as follows: In a thermoregulated hutch at ~25 °C without a pressure appliance, the cell was first discharged and charged at the C/3 rate, followed by one cycle at the C/8 rate, and the last cycle was performed via a GITT-like protocol with a cycling rate of C/3 and then paused for 1 h. The cut-off voltages were 2.7–4.2 V. The C rate in this study was defined as a specific current of 1C = 372 mA.g−1 for graphite and 200 mA.g−1 for NMC811.

XRD acquisition and integration

The XRD measurements were performed on the BM02-D2AM French CRG beamline at the ESRF. The beam energy was set to 25 keV with a beam size of 100 × 100 µm². The detector was a Cegitek innovation detector, with Si hybrid pixel technology and a pixel size of 130 µm². The detector was mounted just after the sample to measure a large Q range. The 2D images were integrated via the pyFAI library41 after the geometry was calibrated by using LaB6 samples. All integrations were corrected to mitigate the effects of the flat detector geometrical distortion and incoming beam intensity.

XRD treatment

From the raw diffraction patterns obtained, specific ranges of q (Å−1) were selected to isolate the peaks of interest (1.2–1.45 Å−1 for 003 NMC Bragg reflection and 1.6–1.95 Å−1 for 002 graphite Bragg reflection). Each diffractogram was fitted via the Python LMFIT library34 with a pseudo-Voigt model, and the peak position was then extracted. Other metrics, such as the FWHM and amplitude, were extracted but not relevant because of the high broadness of the peaks. Simpler metrics, such as the mass center of the diffractograms, were extracted via weighted averaging of the peak mean positions.

Dilatometric measurement

Nanodilatometric measurements were performed with the EL-CELL ECD-3 nanodilatometric setup presented in Note 5 (Supporting Information) in a thermoregulated oven @25 °C ± 0.1. The dilatometer enabled measurements in a three-electrode setup, with one electrode to be probed via dilatometry. Here, graphite or NMC811 was used as the working electrode and probed via dilatometry (measurement of the one-dimensional expansion along the electrode thickness). NMC811 or graphite was used as the counter electrode, and metallic lithium was used as the reference electrode. The assembly included a T-frit as a separator, which was wetted by ~500 µL of LP30 as the electrolyte, and an additional Whatman was placed between the T-frit and the counter electrode. The dilatometer was assembled in an Ar-filled glovebox with less than 1 ppm O2 and H2O, and cycling was then performed in a thermoregulated enclosure at 25 °C.

Data availability

The analysis generated in this study is provided in the Source data file. The raw X-ray data that support the findings of this study are available in ESRF with the identifier https://doi.org/10.15151/ESRF-DC-2210520775. Analyzed data for all figures are provided in the Source data Files. Source data are provided with this paper.

References

Feng, X., Ren, D., He, X. & Ouyang, M. Mitigating thermal runaway of lithium-ion batteries. Joule 4, 743–770 (2020).

Liu, K. et al. Transfer learning for battery smarter state estimation and ageing prognostics: recent progress, challenges, and prospects. Adv. Appl. Energy 9, 100117 (2023).

Chen, M., Ma, G., Liu, W., Zeng, N. & Luo, X. An overview of data-driven battery health estimation technology for battery management system. Neurocomputing 532, 152–169 (2023).

Berecibar, M. et al. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 56, 572–587 (2016).

Zhou, W., Lu, Q. & Zheng, Y. Review on the selection of health indicator for lithium ion batteries. Machines 10, 512 (2022).

Li, X., Yuan, C., Li, X. & Wang, Z. State of health estimation for Li-ion battery using incremental capacity analysis and Gaussian process regression. Energy 190, 116467 (2020).

Eddahech, A., Briat, O., Bertrand, N., Delétage, J. Y. & Vinassa, J. M. Behavior and state-of-health monitoring of Li-ion batteries using impedance spectroscopy and recurrent neural networks. Int. J. Electr. Power Energy Syst. 42, 487–494 (2012).

Ge, X. et al. Revealing the electrochemical-mechanical correspondence between electrode films and 20 Ah prismatic Li-ion batteries via optical fiber monitoring. Chem. Eng. J. 488, 150895 (2024).

Guo, Z. et al. Global thermal image of cylindrical 21700 Li-ion batteries with distributed optical fibre sensor. J. Power Sources 592, 233980 (2024).

Zhu, S. et al. In operando measuring circumferential internal strain of 18650 Li-ion batteries by thin film strain gauge sensors. J. Power Sources 516, 230669 (2021).

Lyonnard, S. et al. Revealing how internal sensors in a smart battery impact the local graphite lithiation mechanism. Nat. Commun. 15, 10258 (2024).

Juengert, A. et al. Advanced ultrasonic techniques for nondestructive testing of austenitic and dissimilar welds in nuclear facilities. AIP Conf. Proc. 1949, 110002 (2018).

Colchester, R. J. et al. Broadband miniature optical ultrasound probe for high resolution vascular tissue imaging. Biomed. Opt. Express 6, 1502–1511 (2015).

Ladpli, P., Liu, C., Kopsaftopoulos, F. & Chang, F. K. Estimating lithium-ion battery state of charge and health with ultrasonic guided waves using an efficient matching pursuit technique. In Proc. 2018 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific) 1–5 (IEEE, 2018).

Appleberry, M. C. et al. Avoiding thermal runaway in lithium-ion batteries using ultrasound detection of early failure mechanisms. J. Power Sources 535, 231423 (2022).

Ohzuku, T., Tomura, H. & Sawai, K. Monitoring of particle fracture by acoustic emission during charge and discharge of Li/MnO2 cells. J. Electrochem. Soc. 144, 3496–3500 (1997).

Deng, Z. et al. Ultrasonic scanning to observe wetting and “unwetting” in Li-ion pouch cells. Joule 4, 2017–2029 (2020).

Zappen, H., Fuchs, G., Gitis, A. & Sauer, D. In-operando impedance spectroscopy and ultrasonic measurements during high-temperature abuse experiments on lithium-ion batteries. Batteries 6, 25 (2020).

Robinson, J. B. et al. Spatially resolved ultrasound diagnostics of Li-ion battery electrodes. Phys. Chem. Chem. Phys. 21, 6354–6361 (2019).

Zhao, G., Liu, Y., Liu, G., Jiang, S. & Hao, W. State-of-charge and state-of-health estimation for lithium-ion battery using the direct wave signals of guided wave. J. Energy Storage 39, 102657 (2021).

Liu, X. et al. Decoupling of the anode and cathode ultrasonic responses to the state of charge of a lithium-ion battery. Phys. Chem. Chem. Phys. 25, 21730–21735 (2023).

Owen, R. E. et al. Operando ultrasonic monitoring of lithium-ion battery temperature and behaviour at different cycling rates and under drive cycle conditions. J. Electrochem. Soc. 169, 040563 (2022).

Berhaut, C. L. et al. Prelithiation of silicon/graphite composite anodes: benefits and mechanisms for long-lasting Li-Ion batteries. Energy Storage Mater. 29, 190–197 (2020).

Aufschläger, A. et al. High precision measurement of reversible swelling and electrochemical performance of flexibly compressed 5 Ah NMC622/graphite lithium-ion pouch cells. J. Energy Storage 59, 106483 (2023).

Mohtat, P., Lee, S., Sulzer, V., Siegel, J. B. & Stefanopoulou, A. G. Differential expansion and voltage model for Li-ion batteries at practical charging rates. J. Electrochem. Soc. 167, 110561 (2020).

Laufen, H. et al. Correlation between voltage, strain, and impedance as a function of pressure of a Nickel-rich NMC lithium-ion pouch cell. Adv. Mater. Technol. 9, 2301965 (2024).

Schweidler, S. et al. Volume changes of graphite anodes revisited: A combined operando X-ray diffraction and in situ pressure analysis study. J. Phys. Chem. C122, 8829–8835 (2018).

Quilty, C. D. et al. Multimodal electrochemistry coupled microcalorimetric and X-ray probing of the capacity fade mechanisms of Nickel rich NMC—progress and outlook. Phys. Chem. Chem. Phys. 24, 11471–11485 (2022).

Davies, G. et al. State of charge and state of health estimation using electrochemical acoustic time of flight analysis. J. Electrochem. Soc. 164, A2746–A2755 (2017).

He, X., Ding, X. & Xu, R. Anisotropic mechanical properties of LiNi Mn Co1O2 cathodes for Li-ion batteries: a first-principles theoretical study. Acta Mater. 267, 119751 (2024).

Gupta, P., Üçel, İB., Gudmundson, P. & Olsson, E. Characterization of the constitutive behavior of a cathode active layer in lithium-ion batteries using a bending test method. Exp. Mech. 60, 847–860 (2020).

Üçel, İB., Gupta, P. & Gudmundson, P. Experimental determination of the constitutive properties of a graphite anode layer in lithium-ion batteries using a bending test method. J. Energy Storage 46, 103845 (2022).

The Matplotlib Development Team. Matplotlib: visualization with Python. Zenodo, https://doi.org/10.5281/zenodo.592536 (2024).

Newville, M. et al. Ingargiola, LMFIT: non-linear least-square minimization and curve-fitting for Python. Zenodo, https://doi.org/10.5281/ZENODO.11813 (2014).

Dahn, J. R. Phase diagram of LixC6. Phys. Rev. B 44, 9170–9177 (1991).

Quilty, C. D. et al. Marschilok, probing sources of capacity fade in LiNi0.6Mn0.2Co0.2O2 (NMC622): an operando XRD study of Li/NMC622 batteries during extended cycling. J. Phys. Chem. C124, 8119–8128 (2020).

Busà, C., Belekoukia, M. & Loveridge, M. J. The effects of ambient storage conditions on the structural and electrochemical properties of NMC-811 cathodes for Li-ion batteries. Electrochim. Acta 366, 137358 (2021).

Levi, M. D. & Aurbach, D. Simultaneous measurements and modeling of the electrochemical impedance and the cyclic voltammetric characteristics of graphite electrodes doped with lithium. J. Phys. Chem. B 101, 4630–4640 (1997).

Liu, S. et al. Origin of phase separation in Ni-rich layered oxide cathode materials during electrochemical cycling. Chem. Mater. 35, 8857–8871 (2023).

Dees, D. W., Kawauchi, S., Abraham, D. P. & Prakash, J. Analysis of the galvanostatic intermittent titration technique (GITT) as applied to a lithium-ion porous electrode. J. Power Sources 189, 263–268 (2009).

Kieffer, J., Valls, V., Blanc, N. & Hennig, C. New tools for calibrating diffraction setups. J. Synchrotron Radiat. 27, 558–566 (2020).

Acknowledgements

Beamtime at the ESRF was granted within the Battery Pilot Hub MA4929 “Multiscale multitechnique investigations of Li-ion batteries: Towards a European battery hub.” We thank Dr. Samuel Tardif for his kind help at the beamline and the Region Auvergne-Rhône-Alpes (Pack Ambition Recherche 2021—Projet IsoBATT) for the financial support of Corentin Renais’s thesis. The authors are grateful for the financial support provided by the Federal Ministry of Education and Research as part of the research cluster Batterienutzungskonzepte through the projects MADAM4Life (grant number 03XP0327C) and NUbase (grant number 03XP0322C). Open access funding was enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

Corentin Renais: writing—original draft, data treatment and acquisition, and visualization/correlation; Benjamin Mercier-Guyon: writing—original draft, data treatment and acquisition, and visualization/correlation; David Wasylowski: experimental design and acquisition, simulation, and review; Morian Sonnet: experimental design and acquisition, simulation, and review; Phillip Dechent: experimental design; Maxime Servajon: data treatment and software optimization; Nils Blanc: beamline management and experimental acquisition; Sandrine Lyonnard: experimental design, data acquisition, and review; Dirk Uwe Sauer: experimental design and review; Claire Villevieille: experimental design, data treatment and acquisition, supervision of the writing and review of the original draft, and supervision of the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Xiaonan Shan and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Renais, C., Mercier-Guyon, B., Wasylowski, D. et al. Exploring electrochemical dynamics in graphite||LiNi0.8Mn0.1Co0.1O2 cells via operando ultrasound and multiprobe approaches. Nat Commun 16, 7774 (2025). https://doi.org/10.1038/s41467-025-62935-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62935-z