Abstract

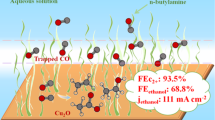

The distribution of anions within the Helmholtz plane features a determined effect on the reaction selectivity of CO2 electroreduction reaction (CO2RR). However, the conventional anions diffusion approach from the bulk electrolyte to the electrode-electrolyte interface is hampered by diffusive mass transfer resistance and electrostatic repulsion, resulting in difficulties in fast anions enrichment within the Helmholtz plane. Herein, Cu chelates are systematically screened, and a citrate-coordinated Cu chelate featuring rapid interfacial wettability reversal and minimum reconstruction potential is developed to enrich the citrate anion (CA) in the Helmholtz plane instead of in bulk solution and break the anions diffusion limits to achieve an internal inside to on-surface diffusion beyond the traditional external outside to above-surface diffusion. The enriched CA at the reaction interface is able to modulate the reaction pathway and accelerate C2H5OH electrosynthesis, in which a Faradaic efficiency of 55.3% and partial current density of 297 mA cm−2 for C2H5OH are achieved. This system opens an avenue to refine interfacial microenvironment by designing metal chelates for high-efficiency electrocatalysis.

Similar content being viewed by others

Introduction

Modulating the microenvironment of electrified Helmholtz plane at sub-nano scale and regulating the transport behavior of ions between the bulk electrolyte and the electrical double-layer (EDL) can significantly improve the electrochemical performance and alter the selectivity and activity of electrochemical reactions1,2,3,4, especially for star-level CO2 electroreduction reaction (CO2RR) with complex reaction pathways and products distribution over Copper (Cu)-based electrocatalysts5,6,7,8,9. The near-surface anions on the electrode surface can alter the structure of EDL, ionic interactions and the distribution of interfacial water, as well as stabilize reaction intermediates, thereby significantly regulate the activity and selectivity of CO2 electroreduction, verified by theoretical simulation and experiment10,11. Nevertheless, the regulation of the local chemical microenvironment in the Helmholtz plane is achieved by the concentration-driven migration of active electrolyte additives to the electrode surface12,13. This diffusion behavior from the bulk phase to the surface is affected and governed by Frumkin effects14, featuring the cross-scale, long-range, and time-consuming spatial & temporal characteristics (Fig. 1a). The diffusive mass transfer resistance together with electrostatic repulsion interaction impede the migration of anions from the bulk phase to the diffusion layer of cathode and further to the Helmholtz plane consisting of inner and outer Helmholtz layer (IHP and OHP) where CO2RR occurs. This long-range, outside to above-surface diffusion behavior across scales determines the significantly low anion concentration at the interface (Ci) than in the bulk phase (Cb), producing a spatially and temporally scale-limited slow response rate, leading to a suboptimal electrochemical performance. Thus, once the diffusion behavior is shifted to inside to on-surface, which is characterized by short diffusion distance and fast diffusion rate, it will be possible to break through the diffusion limitation and enrich the anions in the Helmholtz plane at the microscopic scale (Ci > Cb), which are highly essential for the optimization of CO2RR process.

a Outside to above-surface diffusion driven by the concentration difference in conventional system, which was achieved by migration of electrolyte additives from bulk solution to diffusion layer and further the Helmholtz plane, corresponding to a lower anion concentration in the Helmholtz plane compared to that in the bulk solution. b Inside to on-surface diffusion achieved by directly in-situ releasing anions from catalyst to the Helmholtz plane, which breaks diffusion limits and corresponds to an anion-enriched interfacial structure.

As a bran-new solution, the internal inside to on-surface diffusion behavior in the Helmholtz plane could shorten the anions diffusion pathway and time on spatial and temporal scales, correspondingly refraining the diffusive mass transfer resistance and creating the favored microenvironments to determine the selectivity of CO2RR, which are inaccessible for conventional external outside to above-surface diffusion approach (Fig. 1b). This inside to on-surface diffusion process can be ideally realized by in-situ releasing the anions from the unique chelate catalyst to the sub-nano Helmholtz plane. Specially, the chelate needs to be characterized by rapid reconfiguration and hydrophilic-to-hydrophobic interfacial wettability reversal to achieve anions enrichment at the Helmholtz plane and promote CO2RR process, being a major challenge. Once the hydrophilic chelate undergoes rapid reconstruction/phase transformation, the in-situ released anions will be fast enriched at the Helmholtz plane, where the optimized interfacial structure and reconfigured hydrophobic catalyst will be conducive to the favorable CO2RR dynamics as well as restricted hydrogen evolution reaction (HER) dynamics. This innovative strategy will simultaneously yet wholly optimize the reaction process in terms of both catalyst engineering and interface engineering.

Herein, a Cu chelate electrocatalyst was developed to realize the unique inside to on-surface diffusion beyond the traditional outside to above-surface diffusion, finally breaking the diffusion limits and enriching the anions in the Helmholtz plane to achieve a significant CO2-to-C2H5OH activity, which was never reported up to now. Among the comparatively screened a series of chelates, citrate-coordinated Cu chelate characterized by both rapid interfacial wettability reversal and minimum reconstruction potential, emerged as an ideal electrocatalyst to in-situ rapidly release citrate anion (CA) to the Helmholtz plane, thereby creating an anion-enriched sub-nano interface and governing the selectivity of the complicated CO2RR. Experimentally, the large-scale fabrication of the citrate-coordinated Cu chelate was carried out in a 5 L reactor, producing approximately 320 g in a single batch. The electrocatalyst after reconstruction, denoted as CA Cu, contained abundant metallic Cu that served as active sites as well as a unique Helmholtz plane enriched with CA, demonstrating a Faradaic efficiency (FE) and a partial current density (j) toward C2H5OH of 55.3% and 297 mA cm−2. In-situ spectroscopy techniques verified the intermolecular interactions between the CA and H2O and their positive influence for enhanced C–C coupling and synthesis of C2+ chemicals. Theoretical calculations revealed that the CA molecule adsorbed on the Cu catalyst surface weakened the Cu–O bond as well as stabilized the C–O bond in the *OC2H3 intermediate, thus turning the bond cleavage order and retaining the O atom in the intermediate, which facilitated the electrosynthesis of C2H5OH, an oxygen-containing chemical, correspondingly inhibited the production of C2H4, a non-oxygen-containing hydrocarbon chemical. Notably, a self-healing process was achieved by employing the asymmetric pulsed electrolysis, where the local microenvironment that varied with the reaction process was rebuilt and rejuvenated, creating a consecutively CA-enriched reaction condition in Helmholtz plane that enabled a continuous C2H5OH electrosynthesis. The carbon emission of C2H5OH production from CO2RR system was significantly lower than traditional coal-to-C2H5OH and biomass-to-C2H5OH ways, meanwhile the economic viability of C2H5OH electrosynthesis was demonstrated by techno-economic assessment (TEA) analysis.

Results

Screening of chelates

As a paradigm, initial hydrophilic Cu chelate featured a favorable contact with the electrolyte, allowing reasonable permeability of the H2O molecules, leading to the formation of an electrolyte-mediated conductive network for rapid reconstruction and reduction (Fig. 2a). Accompanying with the reconstruction of the Cu chelate, H2O will be repelled and retreated from the catalyst surface, while the anions were released and diffused from the inside to on-surface, and were as well as enriched in the Helmholtz plane, correspondingly resulting in formation of a reconstructed Cu and electrolyte-comediated continuous conductive network. This was also sensitive and dependent on the used metal-coordinated anions to a great degree. We had detailedly screened and compared a series of used ligands for copper chelates (Fig. 2b). Indeed, the interfacial wettability and onset reduction potential as descriptors can evaluate the rates of electrocatalysts reconstruction and anions release. For citrate-, gluconate-, acetate-, and tartrate-coordinated Cu chelates, the hydrophilicity was verified by contact angle measurements, in which the citrate-coordinated Cu chelate featured the strongest wettability with a H2O contact angle of 71°, corresponding to 78°, 83°, and 85° for the gluconate-, acetate-, and tartrate-coordinated Cu chelates (Fig. 2c). Furthermore, the H2O contact angles for oxalate-, acetylacetone-, phthalocyanine (Pc)-, and ethylene diamine tetraacetic acid (EDTA)-coordinated Cu chelates were all greater than 90° with a trend of Cu EDTA (130°) > CuPc (125°) > Cu acetylacetone (108°) > Cu oxalate (91°).

a Diagram of interfacial wettability reversal for hydrophilic-to-hydrophobic transformation accompanied by in-situ release of anion and changed continuously conductive network from electrolyte-mediated conductive network to reconstructed Cu and electrolyte-comediated continuous conductive network. b Scheme for structure of a series of anions for coordinating with Cu2+, containing acetate, oxalate, tartrate, acetylacetone, citrate, gluconate, EDTA, and Pc. c H2O contact angles and interfacial wettability of a series of Cu chelates. d First-cycled CV curves over a series of Cu chelates. Color code: grey (C), white (H), red (O), blue (N), orange (Cu).

Also, the onset reduction potential or reduction peak area of cyclic voltammetry (CV) activation test was correlated with the reconstruction rate of the Cu chelate. Among the results of first-cycled CV curves (Fig. 2d), the citrate-coordinated Cu chelate exhibited the minimum onset reduction potential of −0.74 V (vs. RHE, thereafter) as well as the maximal reduction peak area, indicating the fast reconstruction and metallic Cu formation. Although oxalate-, acetylacetone-, and acetate-coordinated Cu chelates expressed the onset reduction potentials close to citrate-coordinated Cu chelate (only 0.02 V higher), the smaller reduction peak areas were observed from CV curves, suggesting a more sluggish reconstruction process. Moreover, a more negative onset reduction potential of −0.95 V was exhibited for tartrate- and gluconate-coordinated Cu chelates as well as a potential of −1 V for EDTA- and Pc-coordinated Cu chelates, illustrating these Cu chelates were weakly activated and difficult to be reconstructed sufficiently, corresponding to slow release of anions to the sub-nano interface. In addition, after electrochemical reconstruction, the contact angle of citrate-coordinated Cu chelate was changed from 71° to 94°, verifying the in-situ hydrophilic-to-hydrophobic variation, which will be conducive to the subsequent CO2RR process (Supplementary Fig. 1). The in-situ Raman technique was employed to monitor the structure change during electrochemical reconstruction of citrate-coordinated Cu chelate, which was able to further determine the reconstruction rate of the chelate (Supplementary Fig. 2). The characteristic peak corresponding to the coordination of Cu and CA was located at 473 cm−1 under open circuit potential condition. The intensity of the characteristic peaks of Cu-CA coordination diminished with continuous applying of the negative potential, indicating that the citrate-coordinated Cu chelate underwent electrochemical reconstruction. After 270 s of reaction, the characteristic peak disappeared, indicating that the reconstruction was nearly completed, while the metallic Cu catalyst and a CA-enriched interface were formed. In consequence, among a series of Cu chelates, the citrate-coordinated Cu chelate, featured a relatively strong interfacial wettability, i.e. hydrophilicity, and minimum onset reduction potential compared with the other Cu chelates, emerged as the most desirable yet ideal electrocatalyst for achieving fast interfacial wettability reversal and in-situ release of anion to Helmholtz plane.

Preparation and characterization of catalysts

After screening the citrate-coordinated Cu chelate that enabled rapid interfacial wettability reversal and enrichment of anion in the Helmholtz plane, we further carried out a scale-up production of this unique catalyst in a 5 L reactor (Fig. 3a). Under the chelation of CA, Cu2+ was coordinated with carboxyl and hydroxyl groups to form chelate, and the generated chelate was gradually precipitated as the reaction temperature increased, and finally a single batch of 320 g of citrate-coordinated Cu chelate product was obtained after post-treatment (Supplementary Fig. 3, 3b). The structure of enlarged-batch citrate-coordinated Cu chelate was characterized by FT-IR spectroscopy (Fig. 3c). The absorbance peaks at 1602 and 1364 cm−1 were relevant to C = O, –COO stretching vibration from carboxyl group, while the peak at 1072 cm−1 was related to –OH bending vibration from hydroxyl group, verifying the successful scale-up synthesis of citrate-coordinated Cu chelate catalyst. The morphology characteristic of citrate-coordinated Cu chelate was characterized by scanning electron microscopy (SEM), showing a block structure with a smooth surface (Fig. 3d). Whereas after electrochemical activation and reconstruction, the CA Cu catalyst exhibited a rough surface morphology and a void-rich structure, as shown in Fig. 3e and Supplementary Fig. 4. Furthermore, the electrochemical active surface area (ECSA) of reconstructed CA Cu was evaluated based on the measurement of double-layer capacitance (Cdl). The CA Cu exhibited a larger Cdl (5.3 mF cm−2) compared to commercial Cu (2.1 mF cm−2), which implied that the CA Cu possessed more abundant active sites (Supplementary Fig. 5). Consequently, the CA Cu featured well-developed pore, high surface roughness characteristics and abundant active sites, which was conducive to promote the reactant diffusion and accelerate the reaction kinetics in the subsequent electrochemical process.

a The digital photograph of 5 L reactor for scale-up preparing of citrate-coordinated Cu chelate. b The digital photograph of a single batch of citrate-coordinated Cu chelate with a mass of 320 g. c FT-IR spectrum of enlarged-batch citrate-coordinated Cu chelate. d SEM image of citrate-coordinated Cu chelate. e SEM, f TEM, g HR-TEM images of electrochemically reconstructed CA Cu. h In-situ XRD patterns of citrate-coordinated Cu chelate in CO2-saturated 1 M KOH electrolyte. i CV curve collected in Ar-saturated 1 M KOH for CA Cu. a.u. arbitrary units.

Transmission electron microscopy (TEM) and high-resolution TEM (HR-TEM) images of reconstructed CA Cu exhibited the lattice distance of 0.21 and 0.18 nm, corresponding to Cu (111) and (200) crystal facets, (Fig. 3f, g)15,16. In-situ XRD technique was employed to further analyze and verify the evolution of crystalline structure for citrate-coordinated Cu chelate during electrochemical reconstruction (Fig. 3h, Supplementary Fig. 6). From the in-situ XRD patterns, new diffraction peaks located at 43° and 50° corresponding to the (111) and (200) planes related to Cu0 gradually appeared as the constant reduction proceeded17,18. The results revealed that central Cu2+ of citrate-coordinated Cu chelate was directly reduced to Cu0 during the electrochemical activation without the formation of Cu+ species. This direct conversion of Cu2+ to Cu0 also facilitated the rapid and complete release of the CA, creating a local microenvironment where CA was enriched in the Helmholtz plane. Furthermore, the surface structure of CA Cu was probed by hydroxide (OH−) adsorption technique, which was determined by analysis of CV curve collected in Ar-saturated electrolyte (Fig. 3i). The two adsorption peaks observed in CV curve at 0.33 and 0.47 V can be attributed to the OH− adsorption on Cu (100) and (111) surface12,19, respectively, which demonstrated that the Cu (100) and (111) structures were generated during the reconstruction process. Consequently, the released anions that enriched at sub-nano interface with the formation of rough & porous metallic Cu were favorable for the subsequent electrocatalytic reaction.

Electrolytic performance

CO2RR performance was measured in a three-compartment configured flow cell. FE values over CA Cu electrocatalyst were exhibited in Fig. 4a, and the typical 1H nuclear magnetic resonance (NMR) spectrum was exhibited in Supplementary Fig. 7. The highest FEC2H5OH was reached to 55.3% as well as the highest FEC2+ was 80.7% at −1.6 V, while the highest jC2H5OH and jC2+ of 297 and 473 mA cm−2, respectively, were displayed under the same conditions. To verify the role of CA for the reaction selectivity and activity and further illustrate the important yet positive roles of anion-enriched sub-nano interface created by inside to on-surface diffusion behavior, CO2RR measurements were carried out using commercial Cu as a catalyst and adding trace amounts of citric acid (1, 5 or 10 mM) to the electrolyte, wherein the concentration of K+ were remained. Notably, the pH and conductivity of electrolyte were nearly unaltered when adding micro-additive citric acid (Supplementary Fig. 8). The micromorphology and crystal structure of commercial Cu were characterized by TEM and XRD techniques, demonstrating the crystal structure was dominated by (111) and (200) facets (Supplementary Figs. 9, 10). The results of electrochemical performance for commercial Cu in electrolyte with/without CA were shown in Fig. 4b, c and Supplementary Figs. 11, 12. The FEs of 14.1% and 42.6% for C2H5OH and C2+ were exhibited on commercial Cu catalyst, as well as the jC2H5OH and jC2+ were 48 and 146 mA cm−2, respectively. When 1 mM citric acid was added into electrolyte, the poor selectivity (FEs of 15.2% and 42.6% for C2H5OH and C2+) and low activity (j of 54 and 152 mA cm−2 for C2H5OH and C2+) were still displayed, in which the overall CO2RR performance was nearly unchanged compared to that of commercial Cu in the electrolyte without CA. Surprisingly, the concentration of CA that was added to the electrolyte (1 mM) was far higher than the theoretical value for concentration of CA that was in-situ released to the electrolyte from adopted citrate-coordinated Cu catalyst, which was only near 0.07 mM. When the concentration of CA was further increased to 5 and 10 mM, some significant changes and improvements in performance of CO2RR on commercial Cu were observed, where FEC2H5OH reached 45.0% and 47.2%, and FEC2+ reached 70.0% and 74.3%. Similarly, the jC2H5OH and jC2+ increased to 172 and 248 mA cm−2 in electrolyte with 5 mM CA, as well as the jC2H5OH and jC2+ of 194 and 306 mA cm−2 in electrolyte with 10 mM CA. These results verified that the CA can indeed modulate the selectivity of CO2RR over Cu catalyst, but the required amount of CA as electrolyte additives was far higher than the dose of in-situ release from Cu chelate. Even two orders of magnitude higher concentrations of CA were added in the electrolyte, the CA was difficult to diffuse and enrich in the Helmholtz plane due to diffusion limitation and electrostatic repulsion, and it was difficult to achieve the positive effects of in-situ release approach. Moreover, to further demonstrate the intrinsic performance of CA Cu, the iR-corrected potential was also calculated and corresponding results was exhibited in Supplementary Fig. 13.

FEs of various products and j of C2H5OH and C2+ products under various applied potentials without iR compensation (internal resistance: 0.7 ± 0.2 Ω) over (a) CA Cu, (b) commercial Cu in electrolyte without CA, (c) commercial Cu in electrolyte with 1 mM CA. The error bars correspond to the standard deviation of three independent measurements. d The ratios of FEC2H5OH to FECH4, e FEC2+ to FECH4 under different applied potentials over CA Cu, and commercial Cu in electrolyte without and with 1, 5, 10 mM CA. f Comparison of CA Cu with advanced Cu electrocatalysts for C2H5OH electrosynthesis in terms of FE and j of C2H5OH.

To further verified the proposed inside to on-surface and outside to above-surface diffusion modes, electrochemical quartz crystal microbalance (EQCM), a sensitive weight detection instrument, was employed to monitor and record the changes in electrode mass during electrochemical process. As for citrate-coordinated Cu chelate and commercial Cu, the mass of the electrode increased significantly when a negative potential was applied. There was no obvious difference in the mass increase between the two samples, proved that the mass change corresponded to the adsorption of K+ from the electrolyte on the electrode surface (Supplementary Fig. 14a, 14b). During the kept negative potential, the mass of the electrode remained essentially stable, in which the citrate-coordinated Cu chelate was reconstructed. When the applied negative potential subsequently changed to the open-circuit potential state, the mass of the citrate-coordinated Cu chelate electrode decreased rapidly and more greatly than that of commercial Cu. Also, the mass change over citrate-coordinated Cu chelate from negative potential to open-circuit potential was higher than the state from the open-circuit to the negative potential applied. This demonstrated that from constant negative potential to open-circuit state, in addition to the K+, a small amount of CA also was desorbed from the interface. This result also reflected that the CA can be enriched in the Helmholtz plane through the inside to on-surface diffusion model. Also, the mass change of commercial Cu electrode in 1 M KOH electrolyte with 1 mM CA was similar to that in the case of the electrolyte without CA when the applied potential from open-circuit to negative condition (Supplementary Fig. 14b, 14c). This suggested that the mass change corresponding to CA adsorption from the electrolyte was low compared to that of K+ adsorption. And the CA was difficult to diffuse from the electrolyte to the electrode surface and enriched in the Helmholtz plane, i.e., the diffusion mode from outside to above-surface, which may be restricted by diffusive mass transfer resistance and electrostatic repulsion. Correspondingly, an undesirable localized microenvironment and an unsatisfactory electrocatalytic performance were presented over Cu catalyst in the electrolyte with 1 mM CA, and the overall performance of CO2RR was dramatically far inferior compared with that of CA Cu catalyst. Finally, such a unique inside to on-surface diffusion approach derived from CA-coordinated Cu chelate can distinctly yet positively affect the local microenvironment and create an anion-enriched sub-nano reaction interface, which was hardly achievable through conventional outside to above-surface diffusion approach. Consequently, a favorable condition for the electrosynthesis of C2H5OH and C2+ chemicals was created by in-situ released of CA from Cu chelate to sub-nano reaction interface, which significantly improved the selectivity and reactivity.

Additionally, the synthesis of C2+ products was competitive with the single-carbon product CH4, and the selectivity depended on whether the *CO intermediate underwent a C–C coupling to *OCCO* or a direct hydrogenation to *CHO intermediate. Consequently, once the direct hydrogenation of the *CO intermediate to CH4 production was inhibited, the C2+ products synthesis was correspondingly promoted. Electrochemical test results exhibited a FECH4 as high as 18.0% over commercial Cu catalyst (Fig. 4b), which suggested that the intense competitive reaction of CH4 production was received during the C2+ products formation, leading to a relatively poor selectivity of multi-carbon chemicals over Cu. Also, a nearly unchanged FECH4 of 17.8% was shown on commercial Cu in electrolyte with 1 mM CA (Fig. 4c). As a sharp contrast, the FEs of CH4 over a wide potential region from −1 to −1.8 V were decreased to 8.7% and 2.7% when the concentration of CA in electrolytes was raised to 5 and 10 mM (Supplementary Fig. 12), respectively, validating that the CA indeed can modulate the local microenvironment and produce the favorable conditions for C2+ generation and inhibition of competitive CH4 product. More astonishingly, the FECH4 only below 1% can be obtained over the proposed CA Cu catalyst, further confirming that the inside to on-surface diffusion approach derived from the intrinsic characteristics of CA Cu catalyst could enrich the anions at the sub-nano reaction interface more efficiently, giving a full effect to their modulation of reaction activity and selectivity. Correspondingly, the ratios of FEC2H5OH to FECH4 and FEC2+ to FECH4 at various applied potentials were calculated and shown in Fig. 4d, e, where the highest values of FEC2H5OH/FECH4 and FEC2+/FECH4 were 101 and 150 at −1.6 V, respectively, demonstrating the CO2RR selectivity was modulated by the in-situ release of anions from the chelate to the Helmholtz plane. This was completely different from and beyond the additive system. Upon comparison with recently reported Cu electrocatalysts for C2H5OH production, the reconstructed CA Cu electrocatalyst exhibited the extraordinary C2H5OH electrosynthesis in terms of FE and j (Fig. 4f, Supplementary Table 1)15,16,17,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36. In addition, to exclude the possibility of interference with the product selectivity caused by the convert of the CA into some new species under electrochemical conditions, correspondingly electrochemical performance was also tested on commercial Cu in electrolyte with 10 mM CA and without CO2 inlet. The 1H NMR spectrum of the electrolyte after reaction was collected and analyzed, where no liquid products (C2H5OH, n-propanol, CH3COO−, and HCOO−) were detected, verifying the CA was stable under electrochemical conditions (Supplementary Fig. 15).

In order to analyze and elucidate the effects of anions diffusion by inside to on-surface behavior on the cations (mainly K+) diffusion, in-situ electrochemical impedance spectroscopy (EIS) was adopted to detect the impedance variations during the electrochemical reconstruction and the release of CA from citrate-coordinated Cu chelate. When applying a constant potential, the resistance in high-frequency region in the EIS displayed a gradual increase. When the potential was applied for a period time, the resistance nearly no longer changed (Supplementary Fig. 16a). While at the low-frequency region, the relationship between the Z′ (real part) and w−1/2 (w: angular frequency) reflected the impedance of ion diffusion, and a larger slope of the curve after fitting (σ: Warburg coefficient) was presented, indicative of the larger ion diffusion resistance. As shown in Supplementary Fig. 16b, the ion diffusion resistance increased significantly during the initial stage of electrochemical reconstruction and then remained stable. This suggested that the diffusion of K+ from the electrolyte to the interface was impeded by CA released from the catalyst to the electrode-electrolyte interface, which may be contributed to the competitive yet relative co-motion of the CA and K+, as well as the steric-hindrance effects.

Revealing the effects of enriched CA on CO2RR mechanism

Since the anions released by in-situ electrochemical reconstruction of chelate allowed anions enrichment at the Helmholtz plane and the modulation of reaction selectivity, advanced in-situ FT-IR, a strong and powerful instrument for detecting the key reaction intermediates, was employed to further reveal the CA-dominated mechanisms that favored the C2+ production37. To avoid the effects of structural features of electrocatalysts on the results and further accurately analyze the effect of CA on selectivity, the commercial Cu as the stationary catalyst was used and the changes for the reaction intermediates were also investigated in the electrolyte with 10 mM and without CA. From the in-situ FT-IR results (Fig. 5a, b), except the H2O absorption peak located at 1570 cm−1 was clearly observed, the *CO intermediate intensity in the 2040-2100 cm−1 related to CO adsorption on Cu0 site gradually increased as the reaction proceeded38,39. The obvious differences for the absorbance peaks in the range of 1200 to 1600 wavenumbers were presented due to the presence of CA, indicating that the CA at the sub-nano reaction interface profoundly affected the adsorption strength and further conversion of reaction intermediates and governed the CO2RR mechanism. Specifically, for the system without CA, the *OCCOH, *OC2H5 intermediates corresponding to the synthesis of C2+ products and C2H5OH located at 1210 and 1350 cm−1 as well as the *CHO and *OCH3 intermediates associated with the formation of CH4 at 1480 and 1410 cm−1 were clearly detected40,41,42. Differently, in the presence of CA, the *OCCOH and *OC2H5 were extraordinarily stronger in the intensities and dramatically easier than the formation of *CHO and *OCH3 intermediates for the formation of CH4, distinctly illustrating that the C2H5OH and C2+ products were favorably formed over the developed catalyst. In consequence, the CA dominated and had a determined effect on the change in CO2RR selectivity on Cu catalyst, in which the key *CO intermediate was stabilized, resulting in a favored C–C coupling kinetics and restricted directed *CO hydrogenation process, ultimately promoted the C2+ product formation and inhibited the methanation (Fig. 5c).

In-situ FT-IR spectra of commercial Cu under CO2RR in electrolyte (a) without CA, (b) with CA. a.u. arbitrary units. c Schematic of CO2RR mechanism and pathway for various single-/multi-carbon products. d ∆G diagram of C–C coupling on Cu(100) and Cu(100)-CA. e COHP analysis of C–O bonding interaction in *OC2H3 intermediate on Cu(100) (left) and Cu(100)-CA (right). f COHP analysis of Cu–O bonding interaction in *OC2H3 intermediate on Cu(100) (left) and Cu(100)-CA (right). g Diagram of CA-dominated CO2-to-C2H5OH conversion mechanism over Cu catalyst. Gibbs free energy diagram of *OC2H3 to C2H4 or C2H5OH over (h) Cu(100), (i) Cu(100)-CA. j The atomic structure of C–C coupling and C2H4/C2H5OH formation states on Cu(100)-CA. Color code: grey (C), white (H), red (O), orange (Cu).

After decoupling the role of CA on the selectivity of CO2RR, the interaction of CA at the Helmholtz plane with H2O molecules and H2O dissociation process were further real-time investigated and analyzed by a highly surface sensitive in-situ Raman technique43,44. At the 3000-3800 cm−1 position of the Raman spectra, the O–H stretching vibration can be decomposed into three types according to Gaussian fitting (Supplementary Fig. 17)45,46. Revealed by existing findings43,47, K+ in the electrolyte was more likely to be specifically adsorbed on the electrode surface. The K+-coordinated water (denoted as K+ H2O) will continuously supply H2O to electrode surface as well as accelerated the HER kinetics, which was more significantly yet effectively for HER than the other two structural types of H2O (2-, 4-coordinated H-bond water, which were denoted as 2-HB H2O and 4-HB H2O). The in-situ Raman spectra results exhibited that the proportions of K+ H2O over Cu catalyst increased from 6.6% to 12.3% as the potential decreased from 0 to −1 V in the electrolyte without CA, as well as an increase from 6.8% to 10.7% in the electrolyte with CA was presented (Supplementary Fig. 18). Compared with that of the electrolyte without CA, the proportion of K+ H2O increased slowly along with changed potential on Cu electrode in the electrolyte with CA to some degree, implying a restricted HER rate, which may be due to the enhanced interaction of CA and H2O molecules at the reaction interface. In addition, due to the Stark effect, the vibrational wavenumber of the O–H bonding decreased as the increase of the electric field (Supplementary Fig. 19). In comparison, the smaller Stark effect over Cu catalyst in the electrolyte with CA indicated that the reorientation of H2O was slower, as well as the longer distance of Cu–H bond48, illustrating H2O was far away from the catalyst surface in the presence of CA (Supplementary Fig. 20). Consequently, an ordered/stable H-bond network derived from the strong intermolecular interaction of CA with H2O molecules governed a restricted H2O adsorption and activation processes, further inhibited the HER kinetics.

DFT calculations were carried out to further understand the contribution of CA in the CO2RR process, especially the effects of C–C coupling and hydrocarbon or oxygenated multi-carbon chemicals selectivity. Thermodynamically, Cu(100) facet was conducive to C–C coupling, which was verified by previous work49,50. Consequently, we constructed a Cu(100) catalyst model with and without a CA molecule adsorbed on the surface (denoted as Cu(100)-CA and Cu(100), Supplementary Data1). *CO was a key intermediate in the synthesis of multi-carbon chemicals, and C–C coupling step following the reduction of CO2 to CO was usually regarded as the rate-determining step51,52. Therefore, the Gibbs free energy (∆G) of the C–C coupling step corresponding to form the key OC**CO intermediate was calculated, where the value of ∆G on Cu(100)-CA was 0.51 eV, significantly lower than that on the Cu(100) (1.75 eV) (Fig. 5d). This illustrated that the CA molecule was able to enhance the *CO stability indeed, thereby increasing the chances of C–C coupling. It was well known that the generation of C2H4 was thermodynamically more favorable compared to C2H5OH16. According to the reaction mechanism of C2H4 or C2H5OH formation, the further reaction of the *OC2H3 intermediate from the hydrogenation of OC**CO intermediate was crucial in determining the mechanism for the synthesis of C2 products, in which the direct deoxygenation of *OC2H3 intermediate led to C2H4 formation, whereas the retention of C–O bond in *OC2H3 intermediate shifted towards the synthesis of C2H5OH. Consequently, the affinity of the Cu catalyst toward oxygen in *OC2H3 will have an effect on the interaction intensity of Cu with adsorbed *OC2H3 intermediate, i.e., the strength of Cu–O (*OC2H3) bond, and correspondingly changed the stability of C–O bond of *OC2H3 intermediate. Accordingly, this determined the cleavage versus preservation of C–O bond, resulting in the synthesis of hydrocarbon versus oxygenated products. The interaction of Cu with adsorbed *OC2H3 intermediate and C–O internal bond strength of *OC2H3 on Cu(100) and Cu(100)-CA were investigated by the crystal orbital Hamilton populations (COHP). The COHP results and the integrated overlap populations up to Fermi level (ICOHP) of C–O and Cu–O bonds on Cu(100) and Cu(100)-CA were shown in Fig. 5e, f. According to the ICOHP theory, more negative ICOHP value represented stronger bond strength53,54. With CA, the strength of C–O bond was strong, while the Cu–O interaction was weak. In brief, the adsorbed CA molecule weakened the interaction between Cu and O atoms, stabilizing the C–O bond within the *OC2H3 and allowing O atom to be retained, thus promoting the formation of oxygen-containing C2H5OH. The electroreduction pathway from CO2 to C2H5OH and corresponding change in selectivity by CA molecule were shown in Fig. 5g. Further, the ∆G of each step from *OC2H3 to C2H4 and C2H5OH on Cu(100) and Cu(100)-CA were calculated and shown in Fig. 5h, i, corresponding model structure of reaction intermediates were also shown in Fig. 5j and Supplementary Fig. 21–23. The ∆G of C2H4 formation (−0.43 eV) on bare Cu(100) was lower than the formation of *OC2H4 (0.14 eV), verifying the cleavage of C–O bond was more favorable than Cu–O bond, resulting in the formation of C2H4 instead of C2H5OH. On the surface of Cu(100)-CA, the ∆G of C2H4 formation exhibited major uphill to −0.24 eV, whereas the ∆G of *OC2H4 formation was downhill to −0.75 eV, thus switching the selectivity from C2H4 to C2H5OH. Consequently, the presence of CA molecule affected the adsorption strength of *OC2H3 over Cu surface and its internal C–O bond, switching the bond cleavage order and the CO2RR pathway, thus resulting in the impressive C2H5OH selectivity.

Continuous enrichment of CA by pulsed electrolysis strategy

A proposed inside to on-surface diffusion approach can well enrich the anions in the Helmholtz plane indeed and manipulate the interface microenvironment. To deeply intensify this process and alleviate the gradual diffusion of CA into the bulk electrolyte due to electrostatic repulsion during long-term operation, we innovatively employed an asymmetric pulsed electrolysis method to rebuild and rejuvenate the local chemical microenvironment, sufficiently enriching and continuously maintaining the CA in the Helmholtz plane. At the same time, in order to avoid the overhigh positive potential during pulse electrolysis affecting the structure and morphology of the Cu catalyst, a specific asymmetric pulse electrolysis procedure was designed, i.e., −1.6 V for 15 min, then rapidly switching to 0.1 V for 5 min (Fig. 6a, Supplementary Fig. 24). This continuous dynamic potential switching strategy significantly improved the stability of the reaction system, allowing the continuous and stable electrosynthesis of C2H5OH for up to 40 h. As a sharp comparison, the FEC2H5OH was significantly decreased to less than 40% after 5 h reaction in a constant static electrolysis (Fig. 6b). By carrying out the asymmetric pulse electrolysis, the decay rate of FEC2H5OH decreased dramatically (Fig. 6c). Also, the XRD patterns of CA Cu after applying constant and pulse electrolysis processes illustrated that the valence structure of the catalyst remained unchanged (Fig. 6d). Furthermore, we verified this asymmetric pulsed electrolysis strategy of re-enriching CA to the electrode-electrolyte interface by NMR technique. The presence of CA was barely detectable in the electrolyte after 7000 s test, then the concentration of CA reached 0.02 mM after 17000 s, and further the concentration of CA reached 0.05 mM after 50000 s (Supplementary Fig. 25, Fig. 6e). Whereas when a continuous pulsed electrolysis was employed, a relatively low CA concentration in the electrolyte was emerged (near 0.01 mM, Fig. 6f) from the 1H NMR spectrum, suggesting that the CA was continuously enriched in the Helmholtz plane. This result suggested that the CA enriched in the Helmholtz plane, which was achieved by the unique inside to on-surface diffusion approach, can be consistently maintained by the innovative asymmetric pulsed electrolysis strategy, further facilitated the efficient and continuous electrosynthesis of value-added C2H5OH product.

a Schematic diagram showing the dynamic asymmetric pulse electrolysis (−1.6 V, 15 min; 0.1 V, 5 min) to achieve a stable CA-enriched microenvironment for C2H5OH electrosynthesis. Color code: grey (C), white (H), red (O), orange (Cu). b Stability tests of CA Cu and the corresponding FEC2H5OH with pulsed and constant potential. c FEC2H5OH decay rate on CA Cu under constant and pulse electrolysis, where pulsed electrolysis reduced the decay rate by a factor of 6 compared to constant electrolysis. d XRD patterns of CA Cu after constant and pulsed electrolysis processes. 1H NMR spectra of electrolyte during CO2RR (e) applied in the constant potential after 50000 s, (f) applied in the pulsed potential after 100000 s. a.u. arbitrary units. g CO2 emission values of coal-to-C2H5OH, biomass-to-C2H5OH and electrochemical CO2-to-C2H5OH ways. h The fraction of operation cost of CO2 electrolysis for C2H5OH production. i TEA analysis results of CO2 electrolysis under current result and optimistic scenario.

CO2 emission and TEA of CO2RR process

After verifying that the unique inside to on-surface diffusion approach can achieve an efficient and stable C2H5OH electrosynthesis, we further validated the potential of this approach for the scale-up production of C2H5OH in a large-area (25 cm2) membrane electrode assembly (MEA) electrolyzer, where a high FEC2H5OH and CO2 conversion rate of 45.2% and 12% as well as an energy efficiency (EE) of 16.6% were achieved under an industrial current of 5 A (Supplementary Fig. 26, 27). Also, we investigated CO2 emission reduction and performed TEA based on the tested electrochemical performance data to evaluate the environmental impact and economic feasibility of this industrial CO2RR-to-C2H5OH conversion55,56,57,58. Here, distillation was employed for the separation of C2H5OH produced by CO2RR, which was due to the fact that the distillation was commonly commercial way of separation and purification for alcohols. Calculations suggested that one ton (t) of C2H5OH produced by CO2 electrolysis using renewable wind energy as the driving force emitted 1.2 t of CO2 accordingly, which substantially lower than that of conventional coal-to-C2H5OH and biomass-to-C2H5OH approaches with emission values of 7.6 and 3.9 tCO2/tC2H5OH, respectively (Fig. 6g, Supplementary Note 1, Supplementary Table 2)59. Additionally, under current TEA analysis, the system of CO2 electrolysis for C2H5OH production was economically feasible (Supplementary Note 2). We analyzed the cost of C2H5OH production from CO2 electrolysis, where electricity was the largest contributor to the cost, accounting for 54.8%. In addition, product separation costs, including pressure swing adsorption (PSA) for gas-phase products and distillation for liquid-phase products, was 3.9% and 2.9%, respectively. Considering the high cost of electricity and gas separation parts, an optimization scenario was envisaged whereby low cell voltage (2.5 V) and high CO2 conversion rate (20%) could be achieved in the future. Accordingly, the TEA analysis verified that if the overall cell voltage and CO2 conversion rate can be further optimized, the overall cost can be significantly reduced, where the operation cost can be reduced to 82% of the original cost, the capital cost can reduce by 13%, the annual profit can be increased by 133%, and the payback period can be reduced from the original 8.6 years to 3.2 years (Fig. 6i, Supplementary Table 3). In conclusion, there is an attractive potential for the advanced electrochemical CO2-to-C2H5OH system driven by renewable energy sources to meet carbon neutrality and also provides an important guideline for the economic feasibility of large-scale CO2 electrolysis projects in the future.

Discussion

In summary, we presented a short-range yet inside to on-surface diffusion approach to regulate the transport behavior of anions at the microscopic scale and alter the selectivity and activity of electrochemical reactions via the developed Cu chelate catalysts, far surpassing conventional outside to above-surface approach. This can greatly break the diffusion limits in Helmholtz plane and create a continuously CA-enriched sub-nano interface, which was far beyond the conventional system achieved by adding the additives in the electrolyte. This led to the efficient electrosynthesis of C2H5OH along with high C2+ yield rate. The easily scalable CA Cu catalyst achieved an expressive FEC2H5OH of 55.3% and a jC2H5OH of 297 mA cm−2, respectively. In-situ FT-IR and Raman spectra verified that the CA can stabilize the H-bond network of H2O, as well as promote C2H5OH electrosynthesis. The CA weakened the interaction between Cu and O atoms, stabilized the C–O bond within the adsorbed *OC2H3, thereby changing the selectivity of CO2RR on Cu from C2H4 to C2H5OH, confirmed by DFT calculations. Also, in order to continuously enrich the CA at the interface, we proposed an asymmetric pulse electrolysis strategy to rejuvenate the local chemical microenvironment and achieve the continuous CA enrichment in Helmholtz plane by periodically applying an anodic potential without changing the valence structure of the Cu catalyst, resulting in stable C2H5OH electrosynthesis at industrial current density. CO2 emission reduction analysis indicated the electrochemical C2H5OH production can reduce emissions by 84% and 69% compared to traditional coal-to-C2H5OH and biomass-to-C2H5OH ways, respectively. Also, the scale-up C2H5OH electrosynthesis in large-area (25 cm2) MEA with industrial large current of 5 A and TEA analysis illustrated the electrochemical C2H5OH production was economically viable. This work deepened the understanding of electrode-electrolyte interfacial chemistry, broke the ions diffusion limits through the simple design of a Cu chelate catalyst, enabled the enrichment of anions in Helmholtz plane and efficient CO2 electroreduction to oxygenated chemicals, which also guided the efficient utilization of CO2 and the large-scale synthesis of economic-viable & value-added chemicals in the future.

Methods

Materials and chemicals

The gas diffusion electrode (YLS-30T), Nickel (Ni) foam, and the titanium (Ti) felt loaded with IrO2 were purchased from Suzhou Sinero Technology. The GDE (Sigracet 38BC) was purchased from SGL Carbon. Anion exchange membranes were purchased from Fumatech (Fuma, FAA-PK-130), and Dioxide Materials (Sustainion X37-50 grade 60). Commercial Cu was purchased from Guangzhou Metal Metallurgy Co., Ltd.

Preparation of citrate-coordinated Cu chelate

Citrate-coordinated Cu chelate was prepared by liquid-phase precipitation method in a 5 L reactor. First, 1.2 mol anhydrous copper sulfate was dissolved in 2 L deionized water to form the uniform solution. Then, 1 M sodium citrate solution (1.25 L) was added to copper sulfate solution with constant stirring at 70 °C for 30 min. Eventually, the precipitate was filtered by suction with deionized water and then dried in a vacuum oven at 50 °C.

Materials characterization

SEM was performed on HITACHI SU8220, TEM was conducted using FEI TF30 microscope. The interfacial wettability was conducted on contact angle measurement (KINO, SL150E). The FT-IR spectra were collected on a Bruker INVENIO-R spectrometer.

In-situ Raman measurement

In-situ Raman was performed using a spectro-electrochemical cell to detect the cathode. The catalyst was supported on the glassy electrode (loading mass of 1 mg cm−2). The Pt wire and Ag/AgCl served as counter and reference electrodes, respectively, while the CO2-saturated 1 M KOH with and without CA as the electrolytes. The Raman spectroscope (LabRAM HR Evolution) was configuration with an 50X objective len and a 532 nm Raman laser for spectra acquisition. Raman signals were collected in the wavenumber range of 50-4000 cm−1 during electrolysis for 30 s at each applied potential.

In-situ XRD measurement

In-situ XRD was measured with SmartLab equipped with a D/teX Ultra250 detector using Cu Kα radiation (λ = 1.5406 Å). Single-compartment cell including a liquid inlet port and a liquid outlet port was used as a reactor. The citrate-coordinated Cu chelate coated carbon paper was used as the working electrode, prepared CO2-saturated 1 M KOH solution as the electrolyte while cycling through the electrochemical cell at a rate of 5 mL min−1. Platinum wire and Ag/AgCl were used as counter electrode and reference electrode, respectively. The applied potential was set as −1 V vs. RHE.

In-situ FT-IR measurement

In situ FT-IR was conducted with time-resolved FT-IR spectrometer (Bruker INVENIO-R). The commercial Cu catalyst was loaded in Pt disk electrode (loading mass of 1 mg cm−2) as the working electrode. The counter and reference electrodes used were the Pt wire and Ag/AgCl, respectively, while the CO2-saturated 1 M KOH with and without CA as the electrolytes. The applied potential was set as −1 V vs. RHE. Spectra were collected with a resolution of 4 cm−1 in the wavenumber range of 400-3800 cm−1 and recorded by the OPUS software.

Electrochemical measurements

The ECSA measurement was based on the CV tests at different scan rates (20, 40, 60, 80, 100 mV s−1) in the range of 0.1 to 0.2 V vs. RHE. The OH− electrosorption measurement was employed by CV tests in Ar-saturated 1 M KOH electrolyte in the range of 0 to 0.8 V vs. RHE, where different Cu facets exhibited distinctive adsorption peaks on the CV curves.

The EQCM was performed on an SRS QCM equipment at open-circuit potential and −0.8 V vs. RHE in 1 M KOH electrolyte. In situ EIS was performed using a EnergyLab instrument over the frequency range of 100 kHz to 0.03 Hz at −0.8 V vs. RHE in 1 M KOH electrolyte with an amplitude voltage of 10 mV.

For CO2RR in a flow cell, a three-electrode compartment was employed consisting with an anion exchange membrane (Fuma, FAA-PK-130), Ni foam anode and catalyst-deposited GDE cathode. The catalyst and acetylene black with a mass ratio of 2:1 was dispersed in a mixed solvent consisting of isopropanol (1 mL) and Nafion binder (100 µL) under ultrasonication for 30 min to achieve a homogenous ink. The solution was dropped on the GDE (YLS 30 T) as cathode (active area of 1 cm2, loading mass of 2 mg cm−2). The high-purity CO2 gas was injected into cathode at 15 mL min−1. 1 M KOH solution was used as anode and cathode electrolytes and pumped at 5 mL min−1. Before electrochemical performance tests, the electrocatalyst was activated via CV measurement until the current density was basically unchanged. The data was collected and recorded by the Corrtest CS310M electrochemical workstation (Wuhan Corrtest Instrument, China) and the CHI 1140 C electrochemical workstation (Shanghai ChenHua, China). The measured electrolyte resistance was 0.7 ± 0.2 Ω. The potential was converted to RHE based on the Nernst equation:

The iR-corrected potentials were all recorded with 100 % iR compensation and calculated by the equation:

For MEA measurement, the electrochemical signal was provided and recorded by a DC power supply (WYG-30V200A) without iR corrected. The preparation of the cathode electrode was similar to that in the flow cell, the catalyst ink was pipetted onto the GDL (Sigracet 38BC), with an effective area of 5 × 5 cm2. The anode electrode was a Ti felt loaded with IrO2 with a loading mass of 1 mg cm−2 and an anion exchange membrane (Sustainion X37-50 grade 60) was placed between cathode and anode. Additionally, 1 M KOH was pumped to anode at 50 mL min−1 and dry CO2 was transported to cathode with 80 mL min−1. The test was carried out at room temperature (25 °C).

The gas products from CO2RR were analyzed by adopting an online Agilent 8860 gas chromatograph. The liquid products were quantified by 1H NMR spectroscopy (AVANCE NEO 600 M, Bruker), DMSO was used as an internal standard. As for flow cell, the catholyte and anolyte after CO2RR were collected and analyzed to determine the concentration of the liquid products. For MEA electrolyzer, the liquid products entrained by the cathode gas was collected by condensation, and the condensational solution at the cathode and anolyte were analyzed.

The FE of product is calculated using the following equation:

F is Faraday constant (96485 C mol−1), n is the mole of product, Z is the quantity of transferred electrons for each product, Q is total transfer charge.

The CO2 conversion rate calculation was following equation:

Where uCO2 was the CO2 flow rate at the inlet of MEA (mmol h−1), Rproducts was the formation rate of CO2RR products including CO, HCOO−, CH4, CH3COO−, C2H5OH, C2H4, and n-Propanol. The specific Rproduct for each CO2RR product was calculated as follow:

where Z was number of electrons required for different products (Z = 2 for CO and HCOO−, 8 for CH4 and CH3COO−, 12 for C2H5OH and C2H4, and 18 for n-Propanol), F was Faradaic constant (96485 C mol−1), t was the reaction time (h), and Qtotal was the recorded total charge during the reaction (C).

The EE was determined using:

where E0C2H5OH referred to the thermodynamic potential for CO2 conversion into C2H5OH, which was 0.09 V vs. RHE, and Ecell was the total cell voltage.

DFT calculations

Vienna ab initio simulation package (VASP)60 was used to carry out the spin-polarized DFT calculations61,62. Pseudopotentials built by the projector-augmented wave (PAW) method and Perdew−Burke−Ernzerh (PBE)63 exchange-correlation function within the Van der Waals (vdW) correction exploited by Grimme (DFT + D3)64. Similar calculated parameters had been performed in Previous works65,66. We constructed a three layer 5 × 5 Cu(100) surface, and for modeling real aqueous solution conditions, 14 H2O molecules were randomly placed above the Cu(100) catalyst surface, and added a CA molecule above the catalyst surface to simulate the catalyst-electrolyte interface that formed by electrochemical reconfiguration of citrate-coordinated Cu chelate. We set a 20 Å vacuum space in the perpendicular direction. The Gibbs free energies were calculated by the VASPKIT tool at a temperature of 298.15 K using the formula:

where EDFT represented the electronic energy calculated by DFT, and S and EZPE represented the entropy contribution and zero-point energy67.

Data availability

Additional data related to this study are available from the corresponding authors on reasonable request. Source data are provided with this paper.

References

Li, F. et al. Molecular tuning of CO2-to-ethylene conversion. Nature 577, 509–513 (2020).

García de Arquer, F. Pelayo. et al. CO2 electrolysis to multicarbon products at activities greater than 1 A cm−2. Science 367, 661–666 (2020).

Sa, Y. J. et al. Catalyst-electrolyte interface chemistry for electrochemical CO2 reduction. Chem. Soc. Rev. 49, 6632–6665 (2020).

Jin, B., Gao, J., Zhang, Y. & Shao, M. Deprotonated of layered double hydroxides during electrocatalytic water oxidation for multi‐cations intercalation. Smart Molecules 2, e20230026 (2024).

Tan, X. et al. Recent advance in innovative strategies for CO2 electroreduction reaction. Energy Environ. Sci. 14, 765–780 (2021).

Gu, J. et al. Modulating electric field distribution by alkali cations for CO2 electroreduction in strongly acidic medium. Nat. Catal. 5, 268–276 (2022).

Yang, Y. et al. Operando studies reveal active Cu nanograins for CO2 electroreduction. Nature 614, 262–269 (2023).

Jin, J. et al. Constrained C2 adsorbate orientation enables CO-to-acetate electroreduction. Nature 617, 724–729 (2023).

Chen, J. et al. Selective and stable CO2 electroreduction at high rates via control of local H2O/CO2 ratio. Nat. Commun. 15, 5893 (2024).

Yoo, J. M., Ingenmey, J., Salanne, M. & Lukatskaya, M. R. Anion effect in electrochemical CO2 reduction: from spectators to orchestrators. J. Am. Chem. Soc. 146, 31768–31777 (2024).

Tan, X. et al. Robust O-Pd-Cl catalyst-electrolyte interfaces enhance CO tolerance of Pd/C catalyst for stable CO2 electroreduction. Nano Energy 104, 107957 (2022).

Han, Z. et al. Steering surface reconstruction of copper with electrolyte additives for CO2 electroreduction. Nat. Commun. 13, 3158 (2022).

Zeng, M. et al. Reaction environment regulation for electrocatalytic CO2 reduction in acids. Angew. Chem. Int. Ed. 63, e202404574 (2024).

Zhu, X., Huang, J. & Eikerling, M. Hierarchical modeling of the local reaction environment in electrocatalysis. Acc. Chem. Res. 57, 2080–2092 (2024).

Sang, J. et al. A reconstructed Cu2P2O7 catalyst for selective CO2 electroreduction to multicarbon products. Angew. Chem. Int. Ed. 61, e202114238 (2022).

Bi, J. et al. Construction of 3D copper-chitosan-gas diffusion layer electrode for highly efficient CO2 electrolysis to C2+ alcohols. Nat. Commun. 14, 2823 (2023).

Lin, Y. et al. Tunable CO2 electroreduction to ethanol and ethylene with controllable interfacial wettability. Nat. Commun. 14, 3575 (2023).

Zhu, C. et al. Ampere-level CO2 reduction to multicarbon products over a copper gas penetration electrode. Energy Environ. Sci. 15, 5391–5404 (2022).

Zhong, D. et al. Coupling of Cu(100) and (110) facets promotes carbon dioxide conversion to hydrocarbons and alcohols. Angew. Chem. Int. Ed. 60, 4879–4885 (2021).

Lv, Z. et al. Improving CO2‐to‐C2 conversion of atomic CuFONC electrocatalysts through F, O‐codrived optimization of local coordination environment. Adv. Energy Mater. 14, 2400057 (2024).

Kim, C. et al. Cu/Cu2O interconnected porous aerogel catalyst for highly productive electrosynthesis of ethanol from CO2. Adv. Funct. Mater. 31, 2102142 (2021).

Meng, X. et al. Steering C–C coupling by hollow Cu2O@C/N nanoreactors for highly efficient electroreduction of CO2 to C2+ products. Adv. Funct. Mater. 34, 2312719 (2024).

Chen, C. et al. Highly efficient electroreduction of CO2 to C2+ alcohols on heterogeneous dual active sites. Angew. Chem. Int. Ed. 59, 16459–16464 (2020).

Zang, Y. et al. Selective CO2 electroreduction to ethanol over a carbon-coated CuOx catalyst. Angew. Chem. Int. Ed. 61, e202209629 (2022).

Zhang, X. Y. et al. Direct OC-CHO coupling towards highly C2+ products selective electroreduction over stable Cu0/Cu2+ interface. Nat. Commun. 14, 7681 (2023).

Zhang, G. et al. Efficient CO2 electroreduction on facet-selective copper films with high conversion rate. Nat. Commun. 12, 5745 (2021).

Kim, J. et al. Vitamin C-induced CO2 capture enables high-rate ethylene production in CO2 electroreduction. Nat. Commun. 15, 192 (2024).

Liang, Y. et al. Stabilizing copper sites in coordination polymers toward efficient electrochemical C-C coupling. Nat. Commun. 14, 474 (2023).

Zhang, X. et al. Selective and high current CO2 electro-reduction to multicarbon products in near-neutral KCl electrolytes. J. Am. Chem. Soc. 143, 3245–3255 (2021).

Xu, F. et al. Oxygen-Bridged Cu Binuclear Sites for Efficient Electrocatalytic CO2 Reduction to Ethanol at Ultralow Overpotential. J. Am. Chem. Soc. 146, 9365–9374 (2024).

Feng, J. et al. Modulating adsorbed hydrogen drives electrochemical CO2-to-C2 products. Nat. Commun. 14, 4615 (2023).

Chen, C. et al. Oxidation of metallic Cu by supercritical CO2 and control synthesis of amorphous nano-metal catalysts for CO2 electroreduction. Nat. Commun. 14, 1092 (2023).

Su, X. et al. Complementary operando spectroscopy identification of in-situ generated metastable charge-asymmetry Cu2-CuN3 clusters for CO2 reduction to ethanol. Nat. Commun. 13, 1322 (2022).

Yang, P. P. et al. Protecting copper oxidation state via intermediate confinement for selective CO2 electroreduction to C2+ fuels. J. Am. Chem. Soc. 142, 6400–6408 (2020).

Yao, K. et al. Mechanistic insights into OC–COH coupling in CO2 electroreduction on fragmented copper. J. Am. Chem. Soc. 144, 14005–14011 (2022).

Fu, W. et al. Preserving molecular tuning for enhanced electrocatalytic CO2‐to‐ethanol conversion. Angew. Chem. Int. Ed. 63, e202407992 (2024).

Zhang, Y. et al. Ni/N-modulated biomass pyrolysis to make carbon-based catalysts for electrochemical CO2-to-CO conversion. Nano Energy 126, 109658 (2024).

Yuan, X. et al. Controllable Cu0‐Cu+ sites for electrocatalytic reduction of carbon dioxide. Angew. Chem. Int. Ed. 60, 15344–15347 (2021).

Cheng, J. et al. Proton Shuttling by Polyaniline of High Brønsted Basicity for Improved Electrocatalytic Ethylene Production from CO2. Angew. Chem. Int. Ed. 62, e202312113 (2023).

Ding, L. et al. Over 70 % Faradaic Efficiency for CO2 Electroreduction to Ethanol Enabled by Potassium Dopant-Tuned Interaction between Copper Sites and Intermediates. Angew. Chem. Int. Ed. 61, e202209268 (2022).

Zhao, J. et al. Modulation of *CHxO adsorption to facilitate electrocatalytic reduction of CO2 to CH4 over Cu-based catalysts. J. Am. Chem. Soc. 145, 6622–6627 (2023).

Li, J. et al. Twin Heterostructure Engineering and Facet Effect Boosts Efficient Reduction CO2-to-Ethanol at Low Potential on Cu2O@Cu2S Catalysts. ACS Catal 14, 3266–3277 (2024).

Wang, Y.-H. et al. In situ Raman Spectroscopy Reveals the Structure and Dissociation of Interfacial Water. Nature 600, 81–85 (2021).

Li, W. et al. Beyond leverage in activity and stability toward CO2 electroreduction to formate over a bismuth catalyst. ACS Catal 14, 8050–8061 (2024).

Liu, Z. et al. Interfacial water tuning by intermolecular spacing for stable CO2 electroreduction to C2+ products. Angew. Chem. Int. Ed. 62, e202309319 (2023).

Zhong, W. et al. Mitigating cathodic dissolution through interfacial water masking to enhance the longevity of aqueous zinc–ion batteries. Energy Environ. Sci. 17, 2059–2068 (2024).

Liu, H. et al. Observation on microenvironment changes of dynamic catalysts in acidic CO2 reduction. J. Am. Chem. Soc. 146, 5333–5342 (2024).

Wang, Y. et al. Strong Hydrogen-Bonded Interfacial Water Inhibiting Hydrogen Evolution Kinetics to Promote Electrochemical CO2 Reduction to C2+. ACS Catal 14, 3457–3465 (2024).

Pang, Y. et al. Efficient electrocatalytic conversion of carbon monoxide to propanol using fragmented copper. Nat. Catal. 2, 251–258 (2019).

De Gregorio, G. L. et al. Facet-dependent selectivity of Cu catalysts in electrochemical CO2 reduction at commercially viable current densities. ACS Catal 10, 4854–4862 (2020).

Chen, L. et al. Energy-efficient CO2 conversion to multicarbon products at high rates on CuGa bimetallic catalyst. Nat. Commun. 15, 7053 (2024).

Li, P. et al. Manipulation of oxygen species on an antimony-modified copper surface to tune the product selectivity in CO2 electroreduction. J. Am. Chem. Soc. 146, 26525–26533 (2024).

Tan, X. et al. Stabilizing copper by a reconstruction-resistant atomic Cu-O-Si interface for electrochemical CO2 reduction. J. Am. Chem. Soc. 145, 8656–8664 (2023).

Lin, L. et al. A highly CO-tolerant atomically dispersed Pt catalyst for chemoselective hydrogenation. Nat. Nanotechnol. 14, 354–361 (2019).

Jouny, M., Luc, W. & Jiao, F. General techno-economic analysis of CO2 electrolysis systems. Ind. Eng. Chem. Res. 57, 2165–2177 (2018).

Shin, H., Hansen, K. U. & Jiao, F. Techno-economic assessment of low-temperature carbon dioxide electrolysis. Nat. Sustain. 4, 911–919 (2021).

Li, H. et al. CO Electrolysis to Multicarbon Products over Grain Boundary-Rich Cu Nanoparticles in Membrane Electrode Assembly Electrolyzers. Nat. Commun. 15, 4603 (2024).

Fan, L. et al. Selective production of ethylene glycol at high rate via cascade catalysis. Nat. Catal. 6, 585–595 (2023).

Li, J. & Cheng, W. Comparison of life-cycle energy consumption, carbon emissions and economic costs of coal to ethanol and bioethanol. Appl. Energ. 277, 115574 (2020).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G. & Hafner, J. Ab-Initio molecular-dynamics simulation of the liquid-metal amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Kresse, G. & Hafner, J. Ab Initio Hellmann-Feynman Molecular Dynamics for Liquid Metals. J. Non-Cryst. Solids 156, 956–960 (1993).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Methfessel, M. & Paxton, A. T. High-Precision Sampling for Brillouin-Zone Integration in Metals. Phys. Rev. B 40, 3616–3621 (1989).

Tan, X. et al. Toward an understanding of the enhanced CO2 electroreduction in NaCl electrolyte over CoPc molecule‐implanted graphitic carbon nitride catalyst. Adv. Energy Mater. 11, 2100075 (2021).

Li, W. et al. Metal-free polyphthalocyanine with implanted built-in electric field enabling high-efficiency CO2 electroreduction. Chem. Mater. 36, 1602–1611 (2024).

Wang, V., Xu, N., Liu, J. C., Tang, G. & Geng, W. T. VASPKIT: a user-friendly interface facilitating high-throughput computing and analysis using VASP code. Comput. Phys. Commun. 267, 108033 (2021).

Acknowledgements

This work was partly supported by the National Natural Science Foundation of China (NSFC, No. U24B20198, C.Y.), the Fundamental Research Funds for the Central Universities (DUT23LAB612, C.Y.), the National Key Research and Development Program of China (Grant No. 2022YFB4101602, C.Y.), LiaoNing Revitalization Talents Program (XLYC2202003, C.Y.).

Author information

Authors and Affiliations

Contributions

J.Q. and C.Y. supervised and revised the manuscript. W.L. conceived the concept and carried out the experiments. W.L. conducted the electrochemical measurements and characterizations. W.L., J.Q. and C.Y. co-wrote the paper. W.L., X.S. and W.Y. performed the DFT calculations. W.L., Y.Z., X.T., W.L. and Y.Y. discussed and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Lei Wang, Wenlei Zhu, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, W., Yu, C., Song, X. et al. A chelate to break diffusion limits on Helmholtz plane for CO2 electroreduction to ethanol. Nat Commun 16, 8390 (2025). https://doi.org/10.1038/s41467-025-63009-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63009-w