Abstract

The use of two wavelengths to activate different photoreactions in a resin system has recently attracted much attention in the scientific community. Here, wavelength orthogonal photochemistry was used to spatially control the curing kinetics of the thiol-ene photopolymerization reaction. Antagonistic photochemical control is successfully applied to thiol-ene polymerization. In the investigated resin (pentaerythritol-tetrakis(3-mercaptopropionat); PETMP and triallyl-triazine-2,4,6(1H,3H,5H)-trione; TATO) system, radical curing is activated by a type II photoinitiator at 450 nm, while light at 365 nm is used to photorelease a base, resulting in an inhibition of the curing reaction. The antagonistic nature of these photoreactions is demonstrated in laser writing with minimum feature sizes below 0.5 µm as well as in grey scale patterning experiments. Spatially controlled inhibition and retardation of the thiol-ene curing reaction on a sub-micron scale have potential applications in advanced large area lithography, e.g. interference lithography.

Similar content being viewed by others

Introduction

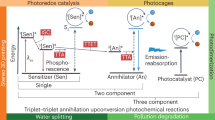

Light as a trigger for network formation has been widely used over the past decades due to its powerful advantages over other stimuli1. Using photochemical initiation, spatial and temporal control is readily achievable, explaining the increasing interest in photosensitive reactive systems2,3. Additional control over light-triggered reactions is provided through the concept of wavelength-selective activation, in which the responses exhibited by different chromophores can be influenced by the wavelength applied. As highlighted by various authors4,5, the integration of multiple wavelength-responsive reactions within a single material is key to unlocking the full potential of light-triggered reactions in photochemistry. In a recent article, Irshadeen et al. defined three types of two-color interactions—namely, synergistic, orthogonal, and antagonistic systems. Synergistic means that simultaneous illumination with at least two different wavelengths is required to activate the photoreaction. When photochemical chromophores behave orthogonally, they lead to different reactions that do not compete with each other. In antagonistic interactions, one wavelength initiates a reaction while the other wavelength quenches the reaction initiated by the first wavelength6,7.

The principle of antagonistic photochemistry has already been applied to Stimulated Emission Depletion (STED)-inspired lithography, allowing photopolymerization to be performed with feature sizes below 50 nm8,9. In addition, the group of Scott et al. reported on the use of antagonistic photochemistry to spatially suppress (meth)acrylate polymerization, enabling volumetric stereolithography10. More recently, Marco et al. introduced an elegant antagonistic system employing a monomer with photoswitchable reactivity. One color of light (625 nm) is used to deactivate said dienophile monomer—effectively suppressing polymerization—while another wavelength (365 nm) is able to switch the dienophile back to its active state. The authors demonstrated the

applicability of their system in spatially patterned films. However, the resolution reached did not exceed the millimeter-range, limiting the range of potential application at this state11.

Despite these examples of existing systems, to the best of our knowledge, antagonistic control of network formation has not been applied to precisely control reaction kinetics of radical mediated thiol-ene photopolymerization.

Thiol-ene chemistry has been the subject of extensive research for several years, which can be explained by the excellent biocompatibility and toughness of these networks compared to cured (meth)acrylates12. Whether Scott’s concept of selective termination of photopolymerization reactions by radical recombination can be applied to thiol-based chemistry is more than questionable due to the complex radical transfer reactions in such systems10. Recently, Thijssen et al. introduced radical inhibition of thiol-ene systems in volumetric 3D printing. Their approach uses a radical inhibitor to delay or hinder polymerization as long as unconsumed inhibitor molecules are present in the system, aiming at optimizing control over the required dose in volumetric printing13. However, since there is no trigger for the inhibiton (e.g., light or temperature), control over the system is limited.

In previous work, Bowman et al. showed that amines exert a retarding effect on the radical-mediated thiol-ene reaction14. Generally, thiol-ene reactions are deemed click-reactions, with high yields among other qualities15. In order to reach sufficient inhibition of the thiol-ene curing reaction, basic amines need to be introduced to the resin system. Those amines lead to deprotonation of the thiol, resulting in thiolate anions. Subsequently, a metastable disulfide anion species is formed as a result of interaction between thiyl radicals and thiolate anions. Consequently, the thiol-ene coupling reaction is inhibited due to the removal of the reacting thiyl radicals from the reaction. This effect occurs provided that the pKa of the thiol is lower than the pKa of the conjugated acid of the amine14.

Inspired by this study, in the current work the concept was advanced by using a photobase (PB) generator to enable the spatial release of an amine base. To realize the antagonistic control of the reaction kinetics in the used thiol-ene resin, wavelength orthogonality of the initiation and quenching reaction is required (Fig. 1).

Results and discussion

Camphorquinone (CQ) (see Fig. 2a) was chosen as the radical photoinitiator (PI) because of its particularly low absorption at 365 nm and its ability to initiate polymerization in the 450 nm region. Due to its unique UV–Vis absorption characteristics (Fig. 2b), CQ is often used in dual wavelength reactive systems16. Recently, Hu et al. demonstrated rapid continuous 3D printing of acrylates using CQ as a PI with blue light while UV-activated butyl nitrite inhibits the radical chain growth locally17. CQ is a type II initiator that abstracts hydrogen from donor molecules (e.g., amines or thiols) during irradiation via a bimolecular mechanism18.

a Resin formulation with photoinitiator and photobase generator. b Absorption spectra of CQ and NPPOC-TMG versus the emission spectra of the light sources used. c Comparison of the photorheological behavior of the resin with and without prior photobase release. The gelpoint is marked through a dashed vertical line as the crossover of storage modulus (G’) and loss modulus (G’’).

Thiol monomers based on esters of mercaptopropionic acid, as the monomer used in the system at hand, show a pKa value in the range of 1019. Considering the pKa of aliphatic thiols as well as the UV absorption characteristics of CQ, 2-(2-nitrophenyl)-propyloxycarbonyl-1,1,3,3-tetramethylguanidine (NPPOC-TMG) was chosen as a strong latent amine base. It was synthesized according to a literature protocol and provides a pKa of 13.6 in its unprotected state20,21. The wavelength dependent response of the CQ and NPPOC-TMG was investigated in a stochiometric mixture of the monomers pentaerythritol-tetrakis(3-mercaptopropionat) PETMP and triallyl-triazine-2,4,6(1H,3H,5H)-trione (TATO, see Fig. 2a). Importantly, TATO shows hardly any homopolymerization and, due to the high electron density of the carbon double bond, is not susceptible to thiol anions making it inert to base catalyzed thiol-Michael reactions22,23,24.

Figure 3a shows the wavelength-dependent curing kinetics of the resin as determined by FTIR spectroscopy. Upon irradiation with visible light at 450 nm, the radical curing process is initiated, which is evidenced by the decreasing absorption of the C=C double bond (3080 cm⁻¹) and thiol groups (2570 cm⁻¹). The corresponding FTIR spectra are provided in Figures S3 and S4. Under these conditions, the photobase generator remains unaffected. When the formulation is subsequently exposed to UV light at 365 nm—triggering the deprotection of NPPOC-TMG and the release of TMG as a strongly basic amine—the thiol-ene curing rate drops drastically, approaching zero. This inhibition arises from the consumption of reactive thiyl radicals through the formation of a metastable disulfide radical anion species14. The release of TMG can be followed by the decrease of the C–N absorption band at 1530 cm⁻¹, which is formed during the photocleavage process25,26.

The data demonstrates both the wavelength orthogonal reaction response of the CQ and NPPOC-TMG as well as their antagonistic behavior in the PETMP-TATO system.

In order to evaluate the effect of CQ content on the curing rate of the system, resins were formulated with 2, 3, and 4 wt% of CQ. Curing was monitored through FTIR spectroscopy while illuminating with 450 nm. Figure S5a shows the thiol and ene conversion over time. As expected, conversion and reaction rate increase with higher CQ content. The resin’s maximum reactivity was achieved with 4 wt% CQ, therefore this concentration was selected for subsequent experiments. Additionally, the optimal concentration of photolatent base required for efficient inhibition was investigated by varying the NPPOC-TMG to thiol group ratio between 0.1, 0.2, and 0.4. All three resins underwent the same illumination regime: 450 nm for 10 min, followed by switching to 365 nm for one minute, then back to 450 nm. Figure S5b displays the thiol and ene conversion over time. As can be seen from the graph, the photobase content also influences the curing speed—the conversions in the system with a PB:SH ratio of 0.1 are much faster than in the other two systems. This effect also occurs before photobase activation, which is thought to be due to the latent basicity of the uncleaved photobase. It has been reported in literature that covalently bond photolatent tertiary amine bases exhibit a pKa above 727. Upon cleavage of NPPOC-TMG a drastic slowing down of the reaction speed is clearly seen even in the resin with the lowest photobase content. However, the slopes of the corresponding curves are still visibly higher than in the systems with 0.2 or 0.4 ratios of PB:SH. In both of these resins, the system’s response upon photobase activation is of similar effectiveness.

Inhibition is not only dependent on the amount of photobase but also the illumination dose of the inhibition light source as shown in Fig. S5c. In this experiment illumination was first performed with 450 nm for 10 min before it was switched to 365 nm to activate the photo base. The 365 nm illumination dose was varied between 110 mJ cm−2, 440 mJ cm−2, and 1320 mJ cm−2. As the energy input for photobase generator cleavage is reduced, less base is released into the system, resulting in less efficient inhibition during subsequent illumination with 450 nm. This effect is most evident in the curves corresponding to the lowest inhibiting light dose of 110 mJ cm−², which shows a noticeably steeper slope in the normalized conversion profile. In contrast, the difference between the slopes for 440 mJ cm−² and 1320 mJ cm−² is significantly less pronounced, suggesting that even a dose of 440 mJ cm−² is sufficient to effectively suppress thiol–ene polymerization in very thin layers.

Furthermore, Fig. 3b shows that base-induced retardation of the reaction can be triggered at any stage of the curing process. It is worth noting that the introduction of these amines via cleavage of the photobase generator inevitably initiates the inhibition process, whether before or during activation of the radical photoinitiator.

The broad applicability of the inhibition strategy across various ene-monomer systems is demonstrated in Figure S6. Thiol and ene conversions were measured both without photobase activation and after activation of NPPOC-TMG by 365 nm light for 1 min, following an initial 10-min curing period under 450 nm illumination. After photobase cleavage, the illumination was switched back to 450 nm.

Figure S6a shows the inhibition behavior in a resin system containing a vinyl ester monomer. While overall conversions are higher compared to the allyl ether system shown in Fig. S6b, photobase activation significantly slows the polymerization in both cases—highlighting the method’s compatibility with different ene-types. Figure S6c presents results from a vinyl ether-based resin, where curing behavior was again responsive to photobase activation. Interestingly, this system exhibited a more pronounced increase in conversion after base release than the other monomers studied, suggesting less efficient inhibition control.

It should be noted that optimization of photobase and initiator concentrations, as well as modifications to the illumination protocol, are expected to further enhance inhibition performance across all systems.

To extend the scope, additional tests were conducted with thiol–acrylate and thiol–methacrylate resin formulations (Fig. S7). In these systems, however, photobase activation did not inhibit polymerization. In the methacrylate-based resin (Fig. S7a), the radical homopolymerization of methacrylate groups proceeded largely unaffected by the presence of the base. A slight increase in thiol conversion is likely due to a concurrent thiol–Michael addition, although radical polymerization appears to dominate. In contrast, the acrylate-based resin (Fig. S7b) showed the expected thiol–Michael reaction upon base release20, resulting in a rapid increase in both thiol and ene conversions.

In addition to curing kinetics, the influence of the photogenerated base on network formation was investigated by photorheology. Figure 2c shows the loss and storage moduli over time, with the gel point defined as the intersection of the two moduli (vertical dashed line). While the gel point is reached after an illumination dose of 140.4 J cm−2 at 450 nm, the resins pre-exposed to light of 365 nm show no gelation, confirming the inhibitory effect of the formed amine on network formation. The major advantage of this antagonistic approach is that the reactivity of the thiol-ene formulation can be tuned in a spatially resolved manner. To demonstrate this, a thin resin layer on a glass substrate was illuminated with 365 nm (7.84 J cm−2) through a cherry-shaped photomask. After removing the photomask, the irradiation was switched to 450 nm, illuminating the entire layer with 146.40 J cm−2. The solvent treatment showed that the area not previously covered by the photomask was completely soluble, indicating that no polymer network had formed in this area. Figure 3c shows the cured layer after washing with isopropanol.

Going a step beyond low-resolution mask lithography, the antagonistic nature of the two photoreactions has also been demonstrated in direct laser writing experiments. In this approach, two lasers were used – a curing continuous wave laser (λ = 435 nm) and a pulsed inhibition laser (λ = 355 nm, see Figure S8) Both lasers were laterally and axially aligned and focused on the photoresist. The writing speed was fixed to 20 µm/s; the power of curing the curing laser was chosen to be 20 µW and the power of inhibition laser was set to 0.42 µW. Figure 4a presents a SEM micrograph illustrating successful laser writing and inhibition. A structure consisting of 5 lines with 100 µm length is shown. In this experiment, the curing laser was continuously running, while the inhibition laser was switched on and off in a precisely controlled manner. Activating the inhibition laser while writing with 435 nm stopped curing completely, in a manner similar to STED lithography28, resulting in gaps in the written lines, confirming the antagonistic behavior of both photoreactions even at the microscale. Additionally, lateral feature sizes as a function of curing laser power and writing speed were analyzed to get a more thorough picture of ideal writing conditions. Figure S9 shows a SEM image of lines written with different writing speeds: 10, 20, 30, 40, and 50 µm/s. (columns from right to left) and power ranging from 8 to 40 µW (from top to bottom). Analyzed average lateral feature sizes and writing thresholds are presented in Fig. S10a and b respectively. In all cases, the line width increases linearly with rising laser power. Writing at 40 µm/s was possible above 30 µW, but at 50 µm/s, lines thinned and turned irregular below 39 µW. At 10 µm/s and higher powers writing produced irregular, oversized features due to excessive illumination doses. Linear writing thresholds were observed, indicating the expected one photon absorption process29.

a SEM image of a laser-written structure consisting of five lines, illustrating controlled inhibition of polymerization. The curing laser was on continuously for all five lines whereas the inhibition laser was off while writing the first line (topmost), turned on one, two, and three times while writing the second, third, and fourth lines, respectively, and was continuously on during writing of the fifth line. Colored lines correspond to the laser paths (blue for the curing laser λ = 435 nm, pink for the inhibition laser λ = 355 nm). The dots visible on the left side of the fifth line correspond to a short deactivation of the inhibition laser in order to mark the position of the laser path. b Greyscale experiment—height profile of the obtained structure. c Dose-dependent variation in the depth of the formed valleys.

Laser writing was used to systematically investigate photobase diffusion and the resulting spatial and temporal limits on the applicability of the system. The experimental setup involved a three-step writing sequence: first, a reference line was written using a 435 nm laser. At a defined lateral distance—varied throughout the experiments—a second line was exposed to 355 nm light to release the photobase. Subsequently, a third line was inscribed with the 435 nm laser.

Using SEM imaging (see Fig. S11 for an example), all line sets were analyzed by measuring the width of each line and noting whether the third line was still visible. The difference in line width between the first and the second line served as a measure for inhibition: higher photobase presence in the exposed area reduces polymerization efficiency, resulting in narrower lines. The absence of the third line suggested significant photobase diffusion—here polymerization was inhibited completely.

To further evaluate diffusion behavior, both the lateral distance between the second and the third line, and the delay times between these exposure steps (ranging from 1 to 11 s), were varied. The results, presented in Figure S12, plot the relative change in line width against time delay and spatial separation (6–17 µm). These changes directly reflect inhibition efficiency and, by extension, the diffusion behavior of the photobase. As shown in the heat map, the effective diffusion radius at a delay time of one second is approximately 9 µm, with longer delay times leading to increased diffusion.

In this context, Forman et al. deemed the diffusivity of the inhibitor as the limiting factor in terms of resolution30. The degree of photobase diffusion observed limits the suitability of the investigated resin system for high-resolution techniques such as STED lithography. However, it is well suited for single-step illumination lithography techniques, such as interference lithography31, which are less affected by the diffusion properties of photoinitiators or inhibitors. Increasing resin viscosity up to solid state, e.g., in photo-resists, potentially improves the obtainable resolutions by limiting base diffusion.

In addition to spatial control, this approach also enables precise adjustment of the reaction kinetics by the amount of photogenerated base. Since the introduction of the base into the resin is triggered photochemically, the intensity of the inhibition can be varied by changing the illumination dose. This concept was applied to gray scale experiments as shown in Fig. 4b, c.

In this approach, 3 rectangles (4 mm × 10 mm) were inscribed with 365 nm with increasing dose (288 mJ cm-2 to 1440 mJ cm−2) within defined resin layer and then exposed to 460 nm with a dose of 1050 J cm-2 over the complete area. Due to the differences in the inhibition, i.e., reaction kinetics, a structure with different heights was obtained.

The storage stability of the resin was assessed by tracking its viscosity over time. As illustrated in Figure S13, the viscosity increased from 505.9 mPa s to 1058.9 m Pa s within 10 days—an effect attributed to dark reactions, a well-documented phenomenon in thiol–ene systems32. Adding a phosphoric acid stabilizer—as introduced by P. Esfandiari et al.—has been shown to effectively alleviate this issue and increase storage stability33.

To further investigate the impact of non-activated photobase on resin reactivity, curing kinetics were measured for formulations with and without a photobase generator (see Fig. S14a, b). The results clearly show that the mere presence of the photobase reduces both the polymerization rate and the maximum conversion, likely due to the inherent basicity of the protected base26.

While the reactivity of the photobase-free resin remained stable over time, the formulation containing the photobase exhibited a gradual decline in curing rate during storage. This suggests that slow, unintended cleavage of the photobase may occur over time, adversely affecting the polymerization behavior. Although this cleavage does not pose an issue for the applications presented therein, a strategy to mitigate the cleavage over time could be the addition of small amounts of acid—analogous to cationic polymerization systems, were small amounts of base are added for stabilization reasons34.

In summary, an antagonistically behaving photoactivated system to control thiol-ene reaction kinetics was successfully demonstrated. A dual wavelength approach was realized to locally inhibit the thiol-ene curing reaction. While curing was initiated at 450 nm, the reaction can be stopped at 365 nm. Several types of ene monomers were shown to successfully undergo photobase induced inhibition. The photochemically induced inhibition on the macroscopic scale was shown by contact lithography, while laser writing experiments demonstrated the antagonistic character of the resin on the micrometer scale. In addition to spatial control, this approach also offers the possibility of tuning the kinetics of the thiol-ene photoreaction, which was demonstrated in gray-scale experiments. This approach holds great potential for large area patterning such as interference lithography31, where illumination is done in a singular step as opposed to laser scanning lithography. Additionally, the authors are working on utilizing the inhibition strategy for thiol-ene resins in continuous 3D-printing. Inhibiting curing locally with a second wavelength (365 nm) enables the introduction of a so-called “dead zone”—similar to continuous printing approaches for acrylate-based resins35. Specifically, coupling the inhibition wavelength into a waveguide at the bottom of a vat photopolymerization 3D-printer could reduce adhesion to the surface through the formation of an inhibition layer.

Methods

Materials

All chemicals were used as received without further purification. Pentaerythritol tetrakis(3-mercaptopropionate) (PETMP) was donated from Bruno Bock GmbH (Marschacht, Germany). All other chemicals were purchased from Sigma-Aldrich (St. Louis, USA).

Light sources

For kinetics measurements (FTIR and photo-rheology) and masking experiments a LED Control 5S from Opsytec Dr. Gröbel (Germany) was used with different UV-LEDs (365 nm and 450 nm). The emission spectra and intensities of the used light sources were determined with an Ocean Optics (USA) Ocean Insight STS-UV Miniature Spectrometer. For data processing, Spectragryph optical spectroscopy software (version v1.2.16.1.) was used.

Resin preparation

PETMP (37.67 mol%) and 1,3,5-triallyl-1,3,5-triazin-2,4,6-(1H,3H,5H)-trione (TATO, 50.23 mol%) were added into a brown glass vial in stoichiometric amounts. Pyrogallol (0.1 wt%), camphorquinone (CQ, 4 wt%) and 2-(2-nitrophenyl)-propyloxycarbonyl-1,1,3,3-tetramethylguanidine (NPPOC-TMG, 3.6 wt%) were added to the liquid resin and stirred on a magnetic stirrer at room temperature until all solid components were dissolved. When investigating the influence of the content of CQ and NPPOC-TMG, the respective ratios were varied—2–4 wt% of CQ and 0.1–0.4 ratios of PB:SH groups. To study different ene monomers, divinyl adipate, diethylene glycol divinyl ether, 1,4-butanediol diacrylate and 1,4-butanediol dimethacrylate were used in resins at a stoichiometric ratio to the thiol groups. For masking and grayscale experiments 0.05 wt% avobenzone was added to improve the resolution.

Synthesis of NPPOC-TMG

The synthesis of NPPOC-TMG was done according to literature protocol1. 2-(2-Nitrophenyl)propyl chloroformate (NPPOC, 3.71 mmol) was dissolved in 20 ml of DCM, while TMG (6.31 mmol) was dissolved in 50 ml of DCM. The solution of NPPOC was added to the TMG solution dropwise over the course of 10 min. The reaction mixture was stirred at room temperature for 8 h. Subsequently, the mixture was washed with brine three times and then once with DCM. After drying over sodium sulfate, solvent was removed on a rotary evaporator. Figure S1 and Fig. S2 show the corresponding NMR spectra of the obtained compound.

1H-NMR (400 MHz, chloroform-d): δ 7.75–7.68 (m, 1H), 7.61–7.45 (m, 2H), 7.39–7.22 (m, 1H), 4.26 (d, J = 6.8 Hz, 2H), 3.83–3.60 (m, 1H), 2.80 (s, 12H), 1.34 (d, J = 7.2 Hz, 3H)

13 C NMR (101 MHz, chloroform-d): δ 165.95, 159.93, 159.93, 150.29, 138.26, 132.49, 128.47, 126.94, 124.04, 68.42, 67.71, 50.74, 39.73, 36.34, 33.84, 18.52, 17.56.

NMR-spectroscopy

For characterization of the synthesized compound 1H-NMR and 13C-NMR spectra were recorded with a Varian 400-NMR spectrometer. Data analysis was done with MestReNova version 14.2.0.

UV–Vis–spectroscopy

UV–Vis spectra of CQ (concentration = 3 mmol/l) and NPPOC-TMG (concentration = 0.05 mmol/l) were recorded in acetonitrile with a Varian Cary 50 UV–Vis spectrophotometer (Agilent Technologies Inc, Santa Clara, USA; software: CaryWinUV Scan version 3.00(182)).

FTIR-spectroscopy

Curing kinetics of the resin were measured between two CaF2 platelets on a VERTEX 70 FTIR spectrometer from Bruker (USA) in transmission mode. Spectra were recorded from 4000 cm−1 to 800 cm−1 with a resolution of 4 cm−1 and a total of 16 scans. Measurements were taken of the unilluminated sample and after stepwise illumination with 450 nm (4 cm, 22 mW cm−2) and 365 nm (3 cm, 43.5 mW cm−2). SpectraGryph optical spectroscopy software (version v1.2.16.1.) was used for baseline correction of the spectra as well as normalizing (area of CO-peak, 1655–1790 cm−1) them. The CO2 absorption bands were removed manually to improve clarity of the shown spectra. Integration of the absorption bands of the C=C double bond (3055–3110 cm−1), the thiol (2530–2605 cm−1) and the bond between 1513 and 1550 cm−1, relating to the cleavage of the photobase, was used to follow the respective curing reactions.

Photo-rheology

Photo-rheology measurements were performed on an Anton Paar (Austria) Modular Compact Rheometer 102 with a parallel-plate measuring system (diameter = 25 mm) with a constant gap of 0.1 mm. The resin was illuminated from below through a quartz plate with LED light sources (450 nm and 365 nm, LED Control 5S, see Light sources) at 25 °C.

Viscosity measurements

Stability of the formulation was investigated through viscosity measurements over the course of several days using a Physica MCR 501 rheometer (Anton Paar, Austria) with plate-plate geometry. The plate diameter was 25 mm with a gap distance of 0.1 mm at 25 °C. The viscosity was measured during a frequency sweep from 1 to 300 s−1 with intervals of 3 s−1. The measurement of each point was conducted within a minute, and the average value was taken as a viscosity value at the exact shear rate.

Masking experiments

Masking experiments were performed between a fluorinated ethylene propylene film and a glass slide. During illumination with 365 nm (7.84 J cm−2) the mask was placed on top of the film and removed before curing the whole film with 450 nm (146.40 J cm−2). After curing, the film on the glass slide was washed with isopropanol.

Laser writing experiments

For laser writing experiments, a custom-built optical setup incorporating two laser sources was used. The curing laser was a multimode continuous-wave (CW) laser diode, (λ = 435 nm, Laser Tree, China). To expand the beam diameter, the laser output was coupled into a telescopic system consisting of an entrance achromatic lens (AC254-050-A-ML, f = 50.0 mm; Thorlabs, USA) and a collimating bi-convex lens (LB1676-A, f = 100.0 mm; Thorlabs, USA), resulting in a beam expansion factor of 2. To extract the fundamental transverse electromagnetic mode (TEM₀₀), a 15 µm pinhole (900PH-15, Newport, USA) was placed at the focal plane of the entrance lens. The inhibition laser was a pulsed, diode-pumped, passively Q-switched solid-state laser (1Q 355-2, CryLaS GmbH, Germany; λ = 355 nm, pulse width = 1 ns, repetition rate = 10 kHz). This beam was also expanded using a telescopic system composed of a plano-convex entrance lens (LA1986-A, f = 125.0 mm; Thorlabs, USA) and a collimating lens (LA1509-A, f = 150.0 mm; Thorlabs, USA), resulting in a moderate increase in beam diameter. No pinhole was used. The expansion was configured such that the beam slightly underfilled the back aperture of the objective lens, thereby increasing the effective voxel size in the focal plane. Figure S5 shows the full emission spectra of both lasers. Both beams were focused and co-aligned onto the sample plane using a 100× oil immersion objective lens (NA = 1.46, alpha-Plan Apochromat; Zeiss, Oberkochen, Germany). Laser powers were measured at the back aperture of the objective using a LaserPoint Plus2power meter with an PD-50-D9-UV-photodiode sensor (Vimodrone, Italy). Sample positioning and scanning were performed using a three-axis piezo stage (P-562.3CD, Physik Instrumente PI, Germany) offering bidirectional positioning accuracy of 2 nm in x/y and 4 nm in z, with a travel range of 200 µm along each axis. Unless stated otherwise, the sample scan velocity was set to 20 µm/s. After writing, samples were washed with ethanol and acetone to remove any unpolymerized resin.

Scanning electron microscopy (SEM) analysis was carried out using a Tescan Clara system (Brno, Czech Republic). To improve electrical conductivity and image resolution, samples were coated with a thin layer of gold using a Cressington 108 sputter coater (Cressington Scientific Instruments, Watford, UK) prior examination. The SEM was utilized in Ultra High Resolution and Depth mode, operating either the Everhart Thornley Detector or the Axial Beam Detector, depending on the imaging requirements. Parameters such as working distance, electron beam current, and accelerating voltage were carefully optimized for each specimen to obtain high resolution images at print magnifications of 400× and 1000×, corresponding to fields of view of 318 µm and 127 µm respectively.

For evaluation of lateral line width (for writing speed and diffusion experiments), line width was measured in 5 different places over the length of the line and averaged using ImageJ (open source) software.

Greyscale experiments

A custom-built printer (Luxinergy GmbH, Austria) with two different light sources (365 nm and 460 nm) was used to create the structured layer that was analyzed in the gray scale experiments. First, three stripes (4 mm × 10 mm) were illuminated with 365 nm with varying intensity (288 mJ cm−2, 864 mJ cm−2, 1440 mJ cm−2). After that, the whole sample (20 mm × 10 mm) was illuminated with 450 nm to cure the layer (1050 J cm−2). For measuring the height profile of the sample, a Keyence (Japan) laser confocal microscope VKX 1100 was used with 20× magnification. 30 pictures were stitched in X direction to create a picture over the length of the sample.

Data availability

The source data generated in this study have been deposited in the Zenodo database https://doi.org/10.5281/zenodo.16752061. All other data are available from the corresponding author upon request.

References

Yagci, Y., Jockusch, S. & Turro, N. J. Photoinitiated polymerization: advances, challenges, and opportunities. Macromolecules 43, 6245–6260 (2010).

Blasco E., Wegener M., Barner-Kowollik C. Photochemically driven polymeric network formation: synthesis and applications. Adv. Mater. 29. https://doi.org/10.1002/adma.201604005 (2017).

Aubert, S., Bezagu, M., Spivey, A. C. & Arseniyadis, S. Spatial and temporal control of chemical processes. Nat. Rev. Chem. 3, 706–722 (2019).

Lu, P. et al. Wavelength-selective light-matter interactions in polymer science. Matter 4, 2172–2229 (2021).

Zhang, X., Xi, W., Huang, S., Long, K. & Bowman, C. N. Wavelength-selective sequential polymer network formation controlled with a two-color responsive initiation system. Macromolecules 50, 5652–5660 (2017).

Irshadeen, I. M. et al. Action plots in action: in-depth insights into photochemical reactivity. J. Am. Chem. Soc. 143, 21113–21126 (2021).

Hobich, J., Blasco, E., Wegener, M., Mutlu, H. & Barner-Kowollik, C. Synergistic, orthogonal, and antagonistic photochemistry for light-induced 3D printing. Macromol. Chem. Phys. 224, 1–10 (2023).

Fischer, J., Von Freymann, G. & Wegener, M. The materials challenge in diffraction-unlimited dired-laser-writing optical lithography. Adv. Mater. 22, 3578–3582 (2010).

Müller P. et al. STED-inspired laser lithography based on photoswitchable spirothiopyran moieties. Chem. Mater. 1966–1972 (2019).

Beer et al. Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Sci. Adv. 5, 1–8 (2019).

Marco, A. et al. Antagonistic two-color control of polymer network formation. Adv. Funct. Mater. 2415431, 1–9 (2025).

Hoyle, C. E., Lee, T. Y. & Roper, T. Thiol-enes: chemistry of the past with promise for the future. J. Polym. Sci. Part A Polym. Chem. 42, 5301–5338 (2004).

Thijssen Q., Ortega A. J., Vieira R. P., Van Vlierberghe S. Radical inhibition in tomographic volumetric 3D printing for thiol-ene photoresists: from photorheology to printability. React. Funct. Polym. 205 (2024).

Love, D. M. et al. Amine induced retardation of the radical-mediated thiol−ene reaction via the formation of metastable disulfide radical anions. J. Org. Chem. 83, 2912–2919 (2018).

Hoyle, C. E. & Bowman, C. N. Thiol-ene click chemistry. Angew. Chem. - Int Ed. 49, 1540–1573 (2010).

Scott, T. F., Kowalski, B. A., Sullivan, A. C., Bowman, C. N. & McLeod, R. R. Two-color single-photon photoinitiation and photoinhibition for subdiffraction photolithography. Science 324, 913–917 (2009).

Hu, M., Cheng, H. & Feng, Y. Rapid continuous 3D printing via orthogonal dual-color photoinitiation and photoinhibition. 3D Print. Addit. Manuf. 11, 476–484 (2024).

Pérez-Mondragón, A. A., Cuevas-Suárez, C. E., González-López, J. A., Trejo-Carbajal, N. & Herrera-González, A. M. Evaluation of new coinitiators of camphorquinone useful in the radical photopolymerization of dental monomers. J. Photochem. Photobiol. A Chem. 403, 112844 (2020).

Bernasconi, C. F. & Killion, R. B. High intrinsic rate constant and large imbalances in the thiolate ion addition to substituted α-nitrostilbenes. J. Am. Chem. Soc. 110, 7506–7512 (1988).

Angyal S. J. & Warburton W. K. The basic strengths of methylated guanidines. J. Chem. Soc. 2492–2494 (1951).

Zhang, X. et al. O-Nitrobenzyl-based photobase generators: efficient photoinitiators for visible-light induced thiol-michael addition photopolymerization. ACS Macro Lett. 7, 852–857 (2018).

Shen, P., Moghaddam, S. Z., Huang, Q. & Daugaard, A. E. Hard-soft thiol-ene materials without interfacial weakness. Mater. Today Commun. 21, 100657 (2019).

Lu, H., Carioscia, J. A., Stansbury, J. W. & Bowman, C. N. Investigations of step-growth thiol-ene polymerizations for novel dental restoratives. Dent. Mater. 21, 1129–1136 (2005).

Ganabady, K. et al. High-throughput screening of thiol—ene click chemistries for bone adhesive polymers. ACS Appl Mater. Interfaces 15, 50908–50915 (2023).

Socrates G. Infrared and Raman Characteristic Group Frequencies, 3rd edn. (John Wiley & Sons, Ltd, 2001).

Parker F. S. (1971) Applications of Infrared Spectroscopy in Biochemistry, Biology, and Medicine, 1st edn. (Springer, 1971).

Reisinger, D., Dietliker, K., Sangermano, M. & Schlögl, S. Streamlined concept towards spatially resolved photoactivation of dynamic transesterification in vitrimeric polymers by applying thermally stable photolatent bases. Polym. Chem. 13, 1169–1176 (2022).

Wollhofen, R., Katzmann, J., Hrelescu, C., Jacak, J. & Klar, T. A. 120 nm resolution and 55 nm structure size in STED-lithography. Opt. Express 21, 10831 (2013).

Yu H., Ding H., Zhang Q., Gu Z., Gu M. Three-dimensional direct laser writing of PEGda hydrogel microstructures with low threshold power using a green laser beam. Light Adv. Manuf. 2, 31 (2021).

Forman, D. L., Cole, M. C. & McLeod, R. R. Radical diffusion limits to photoinhibited superresolution lithography. Phys. Chem. Chem. Phys. 15, 14862–14867 (2013).

Lu, C. & Lipson, R. H. Interference lithography: a powerful tool for fabricating periodic structures. Laser Photonics Rev. 580, 568–580 (2010).

Cramer, N. B. & Bowman, C. N. Kinetics of thiol-ene and thiol-acrylate photopolymerizations with real-time Fourier transform infrared. J. Polym. Sci. Part A Polym. Chem. 39, 3311–3319 (2001).

Esfandiari, P. et al. Efficient stabilization of thiol-ene formulations in radical photopolymerization. J. Polym. Sci. Part A Polym. Chem. 51, 4261–4266 (2013).

Yoshida, T., Kanazawa, A., Kanaoka, S. & Aoshima, S. Instant living cationic polymerization using SnCl4/EtAlCl 2 with a weak lewis base: ultrafast polymerization in seconds. J. Polym. Sci. Part A Polym. Chem. 43, 4288–4291 (2005).

Tumbleston J. R. et al. Continuous liquid interface production of 3D objects. Sciencexpress 1–7 (2015).

Acknowledgements

Part of the research was carried out within the COMET-Module project” Repairtecture” (project-no.: 904927) at the Polymer Competence Center Leoben GmbH (PCCL, Austria) within the framework of the COMET-program of the Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology and the Federal Ministry of Labour and Economy. Funding was provided by the Austrian Government and the State Governments of Styria and Upper Austria. We would like to thank the Austrian Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology and the Austrian Research Promotion Agency (FFG) for funding the “3DFit4Wear” project as part of the Production of the Future program line (project no. 891254) and the “Fast3DCast 2.0” project as part of the BRIDGE program line (project no. 891107). Part of the research was carried out within the Austrian Science Fund (FWF) program line Principal Investigator Projects within the project PAT3523723.

Author information

Authors and Affiliations

Contributions

R.J.H., D.S., G.G., S.M.M., and L.H. performed experimental work, Data analysis was done by R.J.H. and D.S.; T.G.: and S.S. conceptualized the work. R.J.H. wrote the original draft. T.A.K. and J.J. contributed to the discussion of the study. T.G.: supervised the work. All authors critically reviewed and edited the manuscript and were involved in scientific discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Kailong Jin, Hatice Mutlu, and the other, anonymous, reviewer for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Höller, R.J., Sivun, D., Gvindzhiliia, G. et al. Spatial control of curing kinetics in thiol-ene-systems through antagonistic photoreactions. Nat Commun 16, 8487 (2025). https://doi.org/10.1038/s41467-025-63407-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63407-0