Abstract

The self-heating effect in wide bandgap semiconductor devices makes epitaxial Ga2O3 on diamond substrates crucial for thermal management. However, the lack of wafer-scale single-crystal diamond and severe lattice mismatch limit its industrial application. This study presents van der Waals β-Ga2O3 (VdW-β-Ga2O3) grown on high-thermal-conductivity polycrystalline diamond. VdW forces modify the coupling state between the single-crystal thin film and polycrystalline substrate. Tunable growth of (\(\bar{2}01\)) VdW-β-Ga2O3 is achieved by leveraging the mismatch between graphene and the oxygen surface densities of varying crystal orientations and their oxygen-partial-pressure dependence. The 350 nm thick, high-crystallinity films exhibit a smallest rocking curve FWHM value of 0.18° and a root mean square roughness of 6.71 nm. Graphene alleviated interfacial thermal expansion stress; β-Ga2O3/diamond interface exhibits an ultralow thermal boundary resistance of 2.82 m2·K/GW. Photodetectors exhibit a photo-to-dark current ratio of 106 and a responsivity of 210 A/W, confirming the strategy’s practicality and technological significance.

Similar content being viewed by others

Introduction

As a wide bandgap semiconductor, gallium oxide (Ga2O3) has attracted extensive research interest due to its rich material properties1,2, making it an ideal candidate for next-generation high-power electronic devices3 and ultraviolet optoelectronic applications4. The β-phase Ga2O3 exhibits a breakdown electric field 27 times higher than silicon and 2.4 times greater than GaN, demonstrating exceptional suitability for ultra-high voltage MOSFETs and Schottky diodes5. With a Baliga’s figure of merit (BFOM) 3000 times superior to silicon and 4 times better than GaN6, β-Ga2O3-based devices achieve significantly lower conduction loss and higher efficiency at equivalent voltage ratings. Owing to its outstanding properties including high breakdown field strength, low energy loss, excellent radiation hardness7, thermal stability8, and chemical stability9, β-Ga2O3 outperforms conventional wide-bandgap semiconductors by orders of magnitude in power electronics applications.

Despite the notable performance advantages of Ga2O3, it presents considerable drawbacks. One critical limitation is its relatively low thermal conductivity, approximately 10−30 W m⁻¹ K⁻¹, which is only one-sixth that of diamond10,11. This weakness poses considerable challenges for high-power semiconductor device materials. As miniaturization progresses and power levels rise, the reliability and stability of Ga2O3-based power devices encounter formidable challenges. For instance, the thermal accumulation effect rapidly intensifies with rising power density, leading to performance degradation and preventing the full utilization of Ga2O3’s high-power potential. Consequently, thermal management has emerged as one of the primary technical bottlenecks restricting the development and widespread application of Ga2O3-based power devices12,13. Enhancing thermal transport from the proximal junction heat region of Ga2O3-based devices is a promising solution. Diamond, with its ultra-high thermal conductivity, has gradually emerged as the preferred heat sink material for Ga2O3 devices14,15. Previous attempts to integrate Ga2O3 with diamond have employed low-temperature direct bonding16 and ion-cutting techniques17. However, these methods encounter challenges, including the formation of interfacial amorphous layers at high temperatures and irradiation-induced deep-level defects. Consequently, the epitaxial growth of Ga2O3 on diamond substrates has emerged as a promising research direction18,19. To date, researchers have successfully epitaxially grown β-Ga2O3 with a full width at half maximum (FWHM) between 3° and 4° on (111) single-crystal diamond substrates20 and κ-Ga2O3 on polycrystalline diamond substrates for photodetector applications21. However, notable challenges persist, including the lack of wafer-scale single-crystal diamond substrates and issues such as low crystallinity and high interfacial defects associated with conventional epitaxy. Virtually no progress has been achieved globally in the epitaxial growth of single-crystalline β-Ga2O3 on polycrystalline diamond substrates.

The core challenge associated with growing Ga2O3 on polycrystalline diamond substrates stems from the disordered orientation of diamond grains, making the mitigation of substrate influence critical22,23,24. Traditional epitaxy, which relies on covalent or ionic bonding, induces substantial stress, dislocations, and defects when lattice matching is poor—an issue exacerbated by the complex and asymmetric lattice structure of Ga2O3. In this work, we introduce the innovative concept of van der Waals β-Ga2O3 (VdW-β-Ga2O3), wherein materials are bound by weak VdW forces25,26,27,28,29. By employing a two-dimensional (2D) material as a lattice shielding layer, we achieve flexible control of interface coupling between the material and the substrate30,31,32,33. Using mist chemical vapor deposition (mist-CVD)34,35,36, we epitaxially grew highly oriented, pure-phase VdW-β-Ga2O3 films on polycrystalline diamond substrates. This non-vacuum method reduces energy costs via simple atomization/heating systems, using affordable, safe precursors without toxic byproducts. It enables scalable, large-area deposition and excels at low-temperature nucleation on inert surfaces (e.g., graphene/h-BN) through reactive intermediates (–OH/–COOH) from partially decomposed precursors, unlike MOCVD/MBE’s high-temperature/plasma requirements. Droplet-enhanced adsorption further aids uniform growth. Mist-CVD avoids wafer bonding’s interfacial defects/stress or amorphous layer risks. These advantages suit both lab and industrial use37.

Results and discussion

Growth and fabrication of Van der Waals β-Ga2O3

The β-Ga2O3 crystal belongs to the hexagonal system and can be represented using a hexagonal close-packed model, where gallium ions occupy the centers of the hexagons and oxygen ions are positioned at the vertices. Graphene and h-BN form planar hexagonal honeycomb structures through sp² hybridization, which theoretically enables Ga2O3 epitaxy on polycrystalline substrates. To assess the feasibility of this epitaxy, we constructed atomic models of oxygen atoms and bulk Ga2O3 adsorbed onto monolayer (ML) graphene/diamond and monolayer hexagonal boron nitride (ML-h-BN)/diamond (Fig. 1a, c). The high adsorption energy displayed in Fig. 1b indicates effective nucleation induced by the 2D materials. Specifically, for the [100] orientation, the inclusion of 2D materials considerably increases the adsorption energy from −1.33 eV to −2.99 eV (graphene) and −3.09 eV (h-BN). A top-view analysis reveals that adsorption on hexagonal vacancies is more stable than that at grid-top positions. Figure 1d, e illustrate the adsorption energy trends of oxygen atoms and the Ga2O3 bulk material as a function of the number of graphene and h-BN layers, assuming a 3.5 Å interlayer spacing.

a Atomic structures of O atoms adsorbed on ML-graphene/diamond, ML-h-BN/diamond, diamond substrate visualized. The orientations of the diamond are [100], [110], and [111]. Both top and side views are provided. b Adsorption energies of oxygen atoms for the configurations depicted in (a). c Schematics illustrating the atomic structures of epitaxial Ga2O3 bulk material with ML-h-BN and Graphene as insertion layers. d Adsorption energy trends for epitaxial Ga2O3 and e O atoms as a function of the number of graphene and h-BN layers, with the number of insertion layers ranging from 1 to 6. Source data are provided as a Source Data file.

The data indicate that the adsorption energies of both oxygen atoms and Ga2O3 are maximized when a single insertion layer is used. As the number of graphene and h-BN layers increases, the binding energy drops and gradually stabilizes. This trend suggests that the interaction between the epitaxial material and the substrate weakens as the distance increases. This is because the weak VdW forces and distant atomic interactions cannot provide stronger binding. At this point, the VdW forces of the 2D materials dominate the epitaxial film behavior. Although polycrystalline substrates consist of randomly oriented grains, the interfacial adsorption energy is primarily determined by local atomic arrangements. Our experimental characterization confirms that most exposed grain surfaces match the model configuration, validating the representativeness of calculations. Furthermore, our computational predictions demonstrate that monolayer graphene/BN can significantly enhance adsorption energy, with improvements observed across various crystal orientations. Based on these findings, monolayer graphene was selected as the intercalation layer for the experiment.

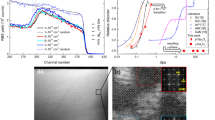

Transmission electron microscopy (TEM) was performed to examine the atomic arrangement of VdW-β-Ga2O3. The cross-sectional TEM image (Fig. 2a) clearly illustrates the interface distribution between VdW-β-Ga2O3, graphene, and polycrystalline diamond. VdW-β-Ga2O3 exhibits two distinct crystal orientations: (\(\bar{2}01\)) and (\(\bar{4}01\)), with (\(\bar{2}01\)) being the predominant one, characterized by a clearer and more orderly atomic arrangement. The High-resolution TEM (HR-TEM) images in Figs. 2b, c, along with the atomic structure schematics, reveal that the carbon atom spacing in the monolayer graphene is 0.492 nm, which closely matches the theoretical oxygen atom spacing of 0.496 nm in the (\(\bar{2}01\)) β-Ga2O3 orientation. In contrast, Fig. 2d indicates that the oxygen atom spacing in the (\(\bar{4}01\)) β-Ga2O3 orientation is 0.215 nm, explaining the preferential growth of Ga2O3 in the (\(\bar{2}01\)) orientation. The interplanar spacings measured at the cross-section are approximately 0.59 nm and 0.22 nm, respectively (Fig. 2d). The notable difference in atomic plane spacings is attributed to the island-like growth mode of the (\(\bar{2}01\))-oriented Ga2O3. During the transition from 3D island growth to 2D film coalescence, compression occurs, leading to extrusion of crystals at the coalescence sites along different directions. Figure 2e presents the top-view atomic structures of the (\(\bar{2}01\)) Ga2O3 and (001) graphene orientations. The oxygen atom spacings in the (\(\bar{2}01\)) orientation are 2.98 and 3.04 Å, while the carbon atom spacings in the (001) orientation of graphene is 2.46 and 2.84 Å. Using the formula Δa/a = (a1 – a2) / a1, the lattice mismatch coefficient between β-Ga2O3 and graphene is calculated to be as low as 4.9%. Given that the theoretical threshold for the lattice mismatch rate is 6%, this low mismatch ensures structural stability. These results confirm the successful epitaxial growth of VdW-β-Ga2O3 on graphene.

a High-magnification cross-sectional TEM image of the interface between VdW-β-Ga2O3, ML graphene, and poly-diamond. b HR-TEM images of the (\(\bar{2}01\)) β-Ga2O3 and c (\(\bar{4}01\)) β-Ga2O3 crystal orientations, with corresponding atomic structure schematics. d Crystal interface between the (\(\bar{2}01\)) β-Ga2O3 and (\(\bar{4}01\)) β-Ga2O3 orientations, including the measured interplanar spacings. e Top-view atomic structures of the (\(\bar{2}01\)) β-Ga2O3 orientation and (001) graphene.

To determine the optimal growth conditions for epitaxial VdW-β-Ga2O3 films, XRD and XPS characterization were performed. Figure 3a presents XRD scans of samples grown at various temperatures, revealing prominent diffraction peaks corresponding to the (\(\bar{2}01\)), (\(\bar{4}01\)), and (\(\bar{2}02\)) planes. The peak of the α-phase marked with black diamond, which occurs because the temperature of 700 °C remains relatively low and insufficient to meet the conditions for irreversible transformation of the metastable α-phase into the β-phase at higher temperatures. Additionally, sharp, zero-width peaks marked with blue diamonds were observed under 740 and 720 °C conditions, suggesting these “needle-like peaks” may represent instrumental noise or artifacts. Specifically, the peaks at (\(\bar{2}01\)), (\(\bar{4}02\)), and (\(\bar{6}03\)) indicate a consistent β-phase oriented along the <\(\bar{2}01\)> direction. Figure 3b presents an enlarged view of the XRD rocking curve for the (\(\bar{2}01\)) VdW-β-Ga2O3 reflection and its FWHM. The smallest rocking curve FWHM value of 0.18° occurs at 760 °C, where the 350 nm thick films (Supplementary Fig. 1) exhibit both the highest crystallinity and fewest interfacial defects. Figure 3c compares the XRD spectra at varying O2 flow rates. Our rigorous sample storage protocol ensures the temporal validity of the acquired data. (Supplementary Fig. 2) Peaks corresponding to other gallium compounds appear at 1000 sccm and 300 sccm, suggesting insufficient oxygen availability at low flow rates and incomplete precursor reactions at high flow rates. XPS characterization was conducted within the range of 0‒1300 eV. Figure 3d displays the O 1s signal peak at approximately 530.8 eV. Gaussian fitting identifies two components: a strong peak at 530.7 eV, corresponding to oxygen ions (OI) in the lattice, and a secondary peak at 531.7 eV, associated with oxygen vacancies (OII)38,39. The peak area ratio of OII/(OI + OII) provides an estimate of the relative oxygen vacancy density in the Ga2O3 film. The results indicate that oxygen vacancies decrease with increasing oxygen flow rate. This is primarily attributed to the higher oxygen partial pressure at higher O2 flow rates, which enhances the activity of lattice atoms in O2 and promotes the incorporation of oxygen atoms. Consequently, Ga‒O bond formation is strengthened, reducing the density of oxygen vacancies in the lattice.

a XRD spectra under different temperature conditions. b Amplified XRD rocking curve of the (\(\bar{2}01\)) VdW-β-Ga2O3 reflection (Inset: Trends of FWHM variations). c XRD spectra of VdW-β-Ga2O3 at various O2 flow rates. d XPS spectra of the O1s peak under different O2 flow rates. Source data are provided as a Source Data file.

Mechanism of tunable growth for (\(\bar{2}\)01) Van der Waals β-Ga2O3

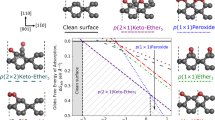

To illustrate the impact of growth conditions on crystal orientation, Fig. 4a presents the three primary orientations observed in the XRD spectra of Ga2O3 cross-sections. The (\(\bar{2}01\)) plane exhibits the highest oxygen atom density, whereas the other two planes, rotated by 23.2° and 22.7° along the X-axis, exhibit lower oxygen densities. This suggests that the O2 flow rate can influence the tilting of these planes. The lattice mismatch coefficients, calculated as Δa/a = |af – as|/as %, reveal that the (\(\bar{2}01\)) plane exhibits the best alignment with the substrate, with a mismatch of 4.9%, while the tilted planes display a mismatch of 7%. This is because the top view of the atomic arrangement in the (\(\bar{2}01\)) orientation forms a hexagonal pattern similar to that of planar graphene, which explains the preferred orientation observed in Fig. 3a. Collectively, these results indicate the influence of oxygen atom density and lattice mismatch on crystal growth orientation (Fig. 4b). The growth trend of β-Ga2O3 further suggests that as oxygen atom density decreases, the lattice mismatch coefficient increases, favoring the growth of the (\(\bar{2}01\)) crystal orientation. During the island-like growth of (\(\bar{2}01\))-oriented crystals, reduced oxygen atom contacts areas and lateral coalescence lead to slight tilting of the crystal planes (by 23.2° or 22.7°), shifting the orientations to (\(\bar{4}01\)) and (\(\bar{2}02\)). Figure 4b illustrates a schematic of the island-like growth and lateral coalescence of (\(\bar{2}01\))-oriented crystals, alongside a TEM cross-sectional image of the film. The distinct and orderly atomic arrangement in the (\(\bar{2}01\)) region confirms the validity of the oxygen-lattice co-modulation model.

a Schematic illustrating atoms at different crystal orientation cutting surface positions within the Ga2O3 crystal structure. b Influence of lattice mismatch (as and af represent the lattice constant of the substrate and epitaxial layer, respectively.) and oxygen atom density on the crystalline orientation growth trend. (Inset: schematic of the preferential growth of the (\(\bar{2}\)01) orientation and a TEM image.) Controlled growth of (\(\bar{2}\)01) orientation can be achieved with increasing oxygen partial pressure and decreasing lattice mismatch coefficient. c AFM surface morphology images at 740, 760, and 780 °C, showing the dependence of sample roughness on deposition temperature. (Source data are provided as a Source Data file.) d Regular and local magnified SEM images and corresponding schematics of samples grown at 600–800 °C. (This figure displays representative results from four independent experiments).

Due to the influence of this polycrystalline substrate, the wet-transferred graphene shows varying degrees of wrinkles with an RMS roughness of about 0.51 nm. The surface morphology of both diamond and graphene was characterized by AFM and SEM, as shown in Supplementary Fig. 3. Atomic force microscopy (AFM) images of the samples at varying temperatures are illustrated in Fig. 4c. The root mean square roughness initially decreases and then increases with temperature, explaining the periodic island-layer-island growth mode for the films. Combined with the TEM results and the schematic in Fig. 4d, these results suggest that at low temperatures, only a few hexagonal crystal grains adhere to the graphene surface. As the temperature increases, the grains coalesce into a smooth film, reducing surface roughness. Further temperature increases initiate a new growth cycle, causing the roughness to rise again. Distinct grain boundaries are observed at a growth temperature of 760 °C. These boundaries may be associated with defects present in the transferred graphene, the release of thermal stress after growth, or the gas flow rate during deposition. Therefore, selecting an appropriate carrier gas flow rate during growth is critical, as demonstrated in Supplementary Fig. 4.

Thermal management and applications of thin films

To investigate the role of graphene in stress coupling between the thin film and the substrate, we conducted in situ temperature-dependent Raman measurements of β-Ga2O3 grown on different substrates. In principle, when β-Ga2O3 and the substrate exhibit similar interlayer coupling, the Raman frequency shift (Δω/ΔT) of β-Ga2O3 will be identical to that of the substrate owing to the equal compressive strain variation across both materials (Δε/ΔT). Figure 5a illustrates the temperature-dependent Raman spectra of β-Ga2O3 grown on ML-graphene/polycrystalline diamond. The high-frequency modes (at approximately 770‒500 cm⁻¹) display peaks at 752 cm−¹ and 751 cm−¹, corresponding to the stretching and bending of GaO4 tetrahedra. The mid-frequency modes (at approximately 480 to 310 cm−¹) exhibit peaks at 415, 344, and 453 cm−¹, attributed to the deformation of Ga2O6 octahedra. Finally, the low-frequency modes (below 200 cm−¹) present peaks at 188.3, 168, and 121 cm−¹, associated with the vibrational and translational modes of GaO4 tetrahedra and Ga2O6 octahedral chains in β-Ga2O340.

a Typical Raman spectra of β-Ga2O3 epitaxially grown on ML-graphene/polycrystalline diamond. b Local magnified Raman spectra. c Temperature-dependent Raman shift (Δω) of VdW-β-Ga2O3 on different substrate materials, extracted from in-situ Raman measurements. d Schematic of the photodetector structure and heat dissipation pathways. e Thermal conductivity of Ga₂O₃ films and interfacial thermal boundary resistance (TBReff) for sample1, 2 and 3. f Photocurrent and dark current of the photodetector under 0.795 mW/cm2 illumination. (Inset: optical microscope image of interdigitated electrodes). g Comparison of the PDCR and responsivity of this photodetector against the performance metrics of other devices during the same period. h Benchmark comparison of TBReff values across different interface engineering approaches. (GT Georgia Institute of Technology, SIMIT Shanghai Institute of Microsystem and Information Technology, SU Stanford University, NRL U. S. Naval Research Laboratory, PSU The Pennsylvania State University) Source data are provided as a Source Data file.

After temperature cycling, the Raman peaks return to their original positions at the same temperatures, confirming that the temperature cycling process is non-destructive. As the temperature increases from 0 °C to 200 °C, the Raman peaks exhibit a red shift. (Fig. 5b) During this temperature cycling process, the Δω values for various substrates change distinctly with temperature. Figure 5c compares the in-situ Raman spectra of β-Ga2O3 grown on various substrates as a function of temperature. The larger Δω/ΔT of β-Ga2O3 grown on the diamond substrate indicates a strong VdW coupling state and significant lattice stress release. This effect arises owing to the large thermal expansion coefficient difference between VdW-β-Ga2O3 and diamond. The largest Δω occurred for β-Ga2O3 on diamond at 100 °C, indicating the highest in-plane tensile stress, which was slightly alleviated by the graphene interlayer. The smaller Δω difference between sapphire and Si substrates (ΔωSi,100 °C = 2.418 cm−¹ vs ΔωSap,100 °C = 2.413 cm−¹) reflects their closer thermal expansion coefficients to β-Ga2O3.(Supplementary Fig. 5) When the temperature was increased to 200 °C, the Δω of β-Ga2O3 on polycrystalline diamond continued to rise to 10.8 cm−¹, yielding a calculated temperature coefficient of peak shift of approximately −0.05 cm⁻¹/K over the heating range. In contrast, β-Ga2O3 on both Si and sapphire substrates exhibited a smaller temperature coefficient of −0.024 cm−¹/K, which can be attributed to their relatively smaller thermal expansion coefficient mismatches. The slight blue shift observed at the final 0 °C measurement for β-Ga2O3 on Gra/Dia, Si, and Sapphire substrates is likely attributable to enhanced interfacial bonding strength induced by high-temperature treatment, which generates localized compressive stress and consequently increases phonon vibrational frequencies. These results highlight the effective role of graphene in stress release.

Here, we systematically measured the thermal conductivity of Ga2O3 films and the effective thermal boundary resistance (TBReff) at Ga2O3/Diamond interfaces using time-domain thermoreflectance (TDTR) for three samples: Sample 1(Graphene/poly-diamond, Gra/Dia), Sample 2(bare poly-diamond, Dia), and Sample 3(O2 plasma-treated Graphene/poly-diamond, P-Gra/Dia, 50 W for 30 s). All samples underwent identical β-Ga2O3 epitaxy conditions. As shown in Fig. 5e, Sample 2 exhibited the lowest effective thermal boundary resistance of 2.82 m2K/GW, while Sample 1 and Sample 3 showed higher values of 6.08 m2K/GW and 6.02 m2K/GW, respectively. This discrepancy arises from the limited phonon transport across vdW interfaces, governed by reduced actual contact area and weak adhesion energy. Although the plasma-treated graphene introduced sparse covalent bonds (marginally lowering TBReff), the random nucleation induced by nonuniform plasma treatment degraded film crystallinity, resulting in slightly lower Ga2O3 thermal conductivity. Consequently, the overall trend followed: TC(P-Gra/Dia) < TC(Gra/Dia) < TC(Dia). As demonstrated by Zheng et al., the thermal conductivity of Ga2O3 with specific orientations increases with thickness11. In our experiments, the (\(\bar{2}01\)) plane rocking curve showed a minimum FWHM of 0.18° for the 350-nm-thick film, corresponding to a thermal conductivity of 7.19 W/m·K. Furthermore, thinner films display more pronounced phonon boundary scattering (consistent with the Callaway model), leading to reduced effective thermal conductivity. As presented in Fig. 5h17,18,41,42,43,44,45,46, our results demonstrate a TBReff that is one order of magnitude lower than previous bonding and interlayer approaches, which is attributed to the ultraclean interface processing and optimized graphene transfer enabling atomically flat interfaces. This breakthrough fulfills the thermal management requirements for kW-class power devices.

To comprehensively evaluate material performance, metals were deposited and etched onto the sample. Figure 5d illustrates the structure of the photodetector and its corresponding heat dissipation pathways. The basic parameters of the photodetector were subsequently measured. The dark current and photocurrent of the device were measured under bias voltages ranging from −3 V to 3 V, with a light power density of 0.795 mW/cm². Figure 5f illustrates the variation in the dark and photocurrents with voltage. Specifically, the dark current (Idark) is 5.83 × 10−6 μA, while the photocurrent (Ilight) is 7.92 μA, yielding a photo-dark current ratio (PDCR) of approximately six orders of magnitude. The inset displays an optical microscope image of the interdigitated electrodes, with an effective illuminated area of 6 × 10⁻⁴ cm². Using the formula for responsivity R = Iph/Pill, we obtain an R value of 210 A/W. Figure 5g47,48,49,50,51,52 compares the photodetector’s PDCR and responsivity with those of other devices recorded during the same period. The results indicate that the device demonstrates superior PDCR performance. Furthermore, under similar PDCR values, its higher responsivity confirms the practicality and high quality of the VdW-β-Ga2O3 film used in this study.

We further extracted the conductivity variations of the fabricated photodetector under high optical frequencies, as shown in Supplementary Fig. 6. The results demonstrate negligible conductivity changes with increasing light frequency, indicating efficient carrier extraction and well-passivated material defects/interface states that minimize the impact of slow recombination on high-frequency response. Although high-frequency illumination may induce localized Joule heating, the stable conductivity confirms effective thermal management in the device design, with no observable interface degradation due to temperature rise. Additionally, we measured the photocurrent response under 1 Hz optical pulse illumination over an extended duration of 2000 seconds. The device exhibits remarkable robustness and reproducibility, with response times of τ1 = 54 ms (rise) and τ2 = 4 ms (decay). Collectively, these results demonstrate outstanding long-term stability of the photodetector. The scalability of the proposed methodology for practical semiconductor applications is currently constrained by two key factors: The limited availability of large-area wafer-scale single-crystal diamond substrates, and challenges in maintaining monolayer graphene uniformity across full wafer dimensions. Overcoming these scalability bottlenecks represents a critical pathway for industrial implementation in future development.

In summary, this study proposes the innovative use of a 2D material interlayer to modify the coupling state between a single-crystal thin film and polycrystalline substrate, thereby improving the formation of the Ga2O3 nucleation layer. Adsorption Locator module calculations indicate that the 2D material interlayer enhances the nucleation probability of Ga2O3, facilitating the formation and growth of epitaxial films. Based on these computational findings, monolayer graphene—a cost-effective and stability material—was selected as the interlayer. Tunable growth of (\(\bar{2}01\)) VdW-β-Ga2O3 was achieved by controlling the lattice mismatch between graphene and the oxygen densities of different crystal orientations. The surface morphology evolution and growth mechanisms of the epitaxial Ga2O3 films were analyzed. The results reveal that Ga2O3 films exhibit an island growth mode, transitioning to a continuous film upon nucleation. The growth rate increases with the oxygen (O2) carrier gas flow rate, while the oxygen vacancy concentration decreases. The high-crystallinity films grown at 760 °C under 600 sccm O2 carrier gas exhibited the smallest rocking curve FWHM of 0.18° and an RMS roughness of 6.71 nm at 350 nm thickness. Temperature-dependent Raman measurements of β-Ga2O3 films on different substrates confirmed significant lattice thermal expansion stress release between β-Ga2O3 and the diamond substrate, enabled by the 2D interlayer. TDTR measurements reveal an ultralow TBReff of 2.82 m2K/GW at the β-Ga2O3/diamond interface, representing a one-order-of-magnitude reduction compared with state-of-the-art reported values. Finally, a photodetector was fabricated using the highly oriented pure-phase film. The device exhibited a high PDCR of 106 and a responsivity (R) of 210 A/W, surpassing similar metrics reported in recent studies. These results confirm the high quality, crystallinity, and uniformity of the material produced using the proposed method. This study overcomes the bottleneck of achieving direct epitaxial growth of Ga2O3 films on diamond substrates.

Methods

Graphene preparation and transfer

A 25-µm-thick Alfa Aesar copper foil was first subjected to electrochemical polishing. The polished foil was folded into a pouch of suitable size using tweezers and placed into a quartz boat. The quartz boat containing the foil pouch was positioned at the center of the heating zone within a tube furnace (Xiamen Xincheng CVD equipment). The system was maintained under a flow of 40 sccm CH4 and 40 sccm H2 for 40 min, followed by 10 sccm CH4 and 20 sccm H2 for 20 min, resulting in the formation of ML graphene fully encapsulated within the copper foil. Following CVD growth, we employed methyl methacrylate (MMA) as a transfer support layer. The copper substrate was etched using an ammonium persulfate ((NH4)2S2O8) solution, followed by multiple rinses with deionized water to completely remove residual etchant, thereby minimizing interfacial hydroxyl (-OH) group formation and its impact on material properties53. Prior to transferring graphene onto the polycrystalline diamond substrate, we performed ultrasonic cleaning of the diamond substrate using acetone, alcohol, and deionized water sequentially. Additionally, the substrate was immersed in dilute HF solution for five minutes to eliminate surface oxides, ensuring an atomically clean interface. We utilized polycrystalline diamond substrates from Element Six’s TM180 series. According to the manufacturer’s specifications (Element Six, Diamond Handbook 2024), these substrates demonstrate: Thermal conductivity >1800 W/m K at 300 K, Thermal conductivity >1500 W/m K at 425 K, Polished surface roughness (Ra) < 20 nm (Supplementary Table 1).

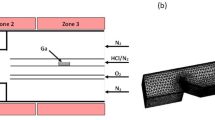

Mist-CVD epitaxial growth of Ga2O3

To determine the optimal conditions for the growth of β-Ga2O3 thin films on polycrystalline diamond substrates, various parameters, including temperature, carrier gas flow rate, precursor solution concentration, and HCl concentration, were investigated. A precursor solution (25–35 mL) was poured into a nebulizer, and the quartz boat loaded with graphene/diamond substrates was placed into the quartz tube. The temperature was raised to 700–800 °C under an Ar atmosphere at 2000 sccm. Once the target temperature was reached, the ultrasonic nebulizer (1.7 MHz) was activated, delivering droplets of the precursor solution onto the graphene/diamond substrates using O2 as the carrier gas (300–1000 sccm) and Ar as the diluting gas (3000 sccm) for 30–40 min. The optimal O2 flow rate was selected based on actual experimental data of material oxygen vacancies and comprehensive RMS values. The working principle utilizes the atomization characteristics of the ultrasonic nebulizer to convert the solution into small droplets, which are then transported into the heated reaction chamber by oxygen carrier gas. Due to the Leidenfrost effect, the droplets can float and migrate to the surface of the heated substrate. When droplets land on the high-temperature surface, the portion contacting the substrate vaporizes under heat, forming a vapor layer between them54. This layer prevents direct contact, and under the combined action of gravity and the vapor layer, the droplets remain suspended on the surface until complete vaporization, ultimately forming a thin film55. After the growth process, the heater was turned off, and the quartz boat was cooled to room temperature in an Ar atmosphere (1000 sccm) using a small fan. The samples were then removed, yielding graphene/diamond substrates coated with Ga2O3 films. The gallium precursor used was gallium acetylacetonate (C15H21O6Ga) with a purity >99.99%. The required mass of C15H21O6Ga was calculated based on the desired gallium concentration and dissolved in deionized water and concentrated hydrochloric acid to prepare the precursor solution. The concentration of this precursor solution was set between 0.02 mol/L and 0.08 mol/L, while the HCl concentration was adjusted between 1% and 10%. The concentrated hydrochloric acid was added to create acidic conditions to assist precursor dissolution in deionized water—otherwise the precursor solution cannot react completely.

Characterization techniques

The atomic-level structure of the films and their cross-sectional states were examined using TEM (FEI Talos F200S). The crystallographic orientation and alignment of the Ga2O3 films were determined through XRD (Rigaku Ultima IV), with a scanning angle (2θ) range of 10° to 70° and a step size of 0.02°. The surface morphology of the films was observed using SEM (Thermo Scientific Apreo 2C) combined with an energy dispersive spectrometer to analyze the elemental composition and distribution within the samples. XPS (Thermo Fisher Escalab Xi + ) was employed for both qualitative and quantitative analyses of surface elements, characterizing the elemental content on the film surface. AFM (Bruker Dimension R Icon TM) was conducted to characterize the surface topography of the samples in tapping mode, providing 2D and 3D morphological information and average roughness data. The interfacial coupling state between the material and substrate was characterized using temperature-dependent in-situ Raman spectroscopy (Horiba LabRAM HR Evolution), facilitating a comprehensive analysis of the crystal quality of the films. Supplemented our study with time-domain thermoreflectance (TDTR, Pioneer-ONE) measurements of both the thermal conductivity and thermal boundary resistance. For these tests, we deposited 100 nm Al films on all three samples via e-beam evaporation, with a pump beam spot radius of 12 μm (at 1/e2 intensity) and a probe beam spot radius of 4 μm (at 1/e2 intensity), using a 1 MHz modulation frequency at 25 °C. By fitting the measurement curves with theoretical models, we obtained the Ga2O3 thermal conductivity parameters and Ga2O3-diamond thermal boundary resistance values.

Adsorption energy calculation

All calculations were performed using the Adsorption Locator module in Materials Studio. The simulations were based on a forcefield approach, and the adsorption energies of oxygen atoms on diamond surfaces were calculated using a Monte Carlo method combined with Simulated Annealing to identify the most probable adsorption sites. The Universal force field was employed to describe interatomic interactions, including van der Waals and electrostatic terms, with a cutoff distance of 12.5 Å for interactions. To avoid periodic boundary artifacts, a vacuum layer of 30 Å was added perpendicular to the surface. The convergence tolerances for energy and force were set to 1.0 × 10-4 kcal/mol and 0.005 kcal/mol/Å, respectively. The displacement tolerance was set to 5.0 × 10−5 Å, and the maximum number of iterations was set to 500. The binding energies (Eb) of oxygen atoms on three different 2D insertion layers grown on diamond substrates oriented along [100], [110], and [111] were calculated. The value of Eb was estimated using Eb = Etotal − Eo − Eslab, where Etotal, Eo, and Eslab denote the total energy after adsorption, energy of the oxygen atom monomer, and energy of the substrate system, respectively.

Data availability

All data supporting the findings of this study are included within the paper and its Supplementary Information. All raw data generated in this study can be obtained from the corresponding author J.N. upon request and may be used for research purposes. Requests for access will typically be addressed within ten days. Source data are provided with this paper.

References

Zhang, Y. et al. MOCVD grown epitaxial β-Ga2O3 thin film with an electron mobility of 176 cm2/V s at room temperature. APL Mater. 7, 022506 (2019).

Gogova, D. et al. High crystalline quality homoepitaxial Si-doped β-Ga2O3 (010) layers with reduced structural anisotropy grown by hot-wall MOCVD. J. Vacuum Sci. Technol. A, 42, 022708 (2024).

Polyakov, A. et al. Electrical properties of α-Ga2O3 films grown by halide vapor phase epitaxy on sapphire with α-Cr2O3 buffers. J. Appl. Phys. 131, 215701 (2022).

Almaev, A. et al. Solar-blind ultraviolet detectors based on high-quality HVPE α-Ga2O3 films with giant responsivity. IEEE Sens. J. 23, 19245–19255 (2023).

Wang, C. et al. Proposal and Simulation of β-Ga2O3 Hetero-Junction Schottky Diodes With Low Work-Function Anode and High Breakdown Voltage. IEEE J. Electron Devices Soc. 13, 334–342 (2025).

Zhang, J. et al. Ultra-wide bandgap semiconductor Ga2O3 power diodes. Nat. Commun. 13, 3900 (2022).

Titov, A. I. et al. Comparative study of radiation tolerance of GaN and Ga2O3 polymorphs. Vacuum 200, 111005 (2022).

Togashi, R. et al. Thermal stability of β-Ga2O3 in mixed flows of H2 and N2. Jpn. J. Appl. Phys. 54, 041102 (2015).

Kang, H. Y., Kang, H., Lee, E., Lee, G. R. & Chung, R. B. K. Sn-induced phase stabilization and enhanced thermal stability of κ-Ga2O3 grown by mist chemical vapor deposition. ACS omega 6, 31292–31298 (2021).

Anaya, J. et al. Control of the in-plane thermal conductivity of ultra-thin nanocrystalline diamond films through the grain and grain boundary properties. Acta Mater. 103, 141–152 (2016).

Cheng, Z. et al. Thermal conductance across β-Ga2O3-diamond van der Waals heterogeneous interfaces. APL Mater. 7, 031118 (2019).

Zhou, H., Maize, K., Qiu, G., Shakouri, A. & Ye, P. D. β-Ga2O3 on insulator field-effect transistors with drain currents exceeding 1.5 A/mm and their self-heating effect. Appl. Phys. Lett. 111, 092102 (2017).

Yuan, C. et al. Modeling and analysis for thermal management in gallium oxide field-effect transistors. J. Appl. Phys. 127, 154502 (2020).

Cheng, Z. et al. Integration of polycrystalline Ga2O3 on diamond for thermal management. Appl. Phys. Lett. 116, 062105 (2020).

Tadjer, M. J. et al. Raman Thermography of β-Ga2O3 Nanomembrane FETs on Diamond. Electrochem. Soc. Meet. Abstr. 235, 1270 (2019).

Matsumae, T. et al. Low-temperature direct bonding of β-Ga2O3 and diamond substrates under atmospheric conditions. Appl. Phys. Lett. 116, 141602 (2020).

Xu, W. et al. Thermal transport properties of β-Ga2O3 thin films on Si and SiC substrates fabricated by an ion-cutting process. ACS Appl. Electron. Mater. 6, 1710–1717 (2024).

Malakoutian, M. et al. Polycrystalline diamond growth on β-Ga2O3 for thermal management. Appl. Phys. Express 14, 055502 (2021).

Li, K. et al. Solar-blind position-sensitive detectors fabricated from β-Ga2O3/polycrystalline diamond heterojunctions. Phys. Status Solidi RRL 15, 2100347 (2021).

Kusaba, T. et al. Heteroepitaxial growth of β-Ga2O3 thin films on single crystalline diamond (111) substrates by radio frequency magnetron sputtering. Appl. Phys. Express 16, 105503 (2023).

Girolami, M. et al. Structural and photoelectronic properties of κ-Ga2O3 thin films grown on polycrystalline diamond substrates. Materials 17, 519 (2024).

Wang, W. H. et al. Recent progress on controlling dislocation density and behavior during heteroepitaxial single crystal diamond growth. N. Carbon Mater. 36, 1034–1045 (2021).

Koma, A. Van der Waals epitaxy for highly lattice-mismatched systems. J. Cryst. Growth 201, 236–241 (1999).

Ghosh, R., Basak, D. & Fujihara, S. Effect of substrate-induced strain on the structural, electrical, and optical properties of polycrystalline ZnO thin films. J. Appl. Phys. 96, 2689–2692 (2004).

Min, J. H. et al. Toward large-scale Ga2O3 membranes via quasi-Van Der Waals epitaxy on epitaxial graphene layers. ACS Appl. Mater. Interfaces 13, 13410–13418 (2021).

Ryu, H. et al. Two-dimensional material templates for van der Waals epitaxy, remote epitaxy, and intercalation growth. Appl. Phys. Rev. 9, 031305 (2022).

Arata, Y., Nishinaka, H., Tahara, D. & Yoshimoto, M. Van der Waals epitaxy of ferroelectric ε-gallium oxide thin film on flexible synthetic mica. Jpn. J. Appl. Phys. 59, 025503 (2020).

Castellanos-Gomez, A. et al. Van der Waals heterostructures. Nat. Rev. Methods Prim. 2, 58 (2022).

Liu, Z. et al. Two-dimensional material-assisted remote epitaxy and van der Waals epitaxy: a review. Natl Sci. Open 2, 20220068 (2023).

Zhao, C. et al. Novel III-V semiconductor epitaxy for optoelectronic devices through two-dimensional materials. Prog. Quantum Electron. 76, 100313 (2021).

Gbadamasi, S. et al. Interface chemistry of two-dimensional heterostructures–fundamentals to applications. Chem. Soc. Rev. 50, 4684–4729 (2021).

Kim, J. et al. Principle of direct van der Waals epitaxy of single-crystalline films on epitaxial graphene. Nat. Commun. 5, 4836 (2014).

Nishinaka, H., Nagaoka, T., Kajita, Y. & Yoshimoto, M. Rapid homoepitaxial growth of (010) β-Ga2O3 thin films via mist chemical vapor deposition. Mater. Sci. Semicond. Process. 128, 105732 (2021).

Xu, Y. et al. Ultrahigh-performance solar-blind photodetectors based on high quality heteroepitaxial single crystalline β-Ga2O3 film grown by vacuumfree, low-cost mist chemical vapor deposition. Adv. Mater. Technol. 6, 2001296 (2021).

Takane, H. et al. Prospects of mist CVD for fabrication of β-Ga2O3 MESFETs on β-Ga2O3 (010) substrates. Appl. Phys. Express 16, 081004 (2023).

Mondal, A. K. et al. Heteroepitaxial growth of an ultrathin β-Ga2O3 film on a sapphire substrate using mist CVD with fluid flow modeling. ACS omega 7, 41236–41245 (2022).

Li, Z. et al. Single crystalline β-Ga2O3 homoepitaxial films grown by MOCVD. Vacuum 178, 109440 (2020).

Li, X. et al. Atomic layer deposition of Ga2O3/ZnO composite films for high-performance forming-free resistive switching memory. ACS Appl. Mater. Interfaces 12, 30538–30547 (2020).

Zhu, R., Liang, H., Hu, S., Wang, Y. & Mei, Z. Amorphous-Ga2O3 optoelectronic synapses with ultra-low energy consumption. Adv. Electron. Mater. 8, 2100741 (2022).

Rao, R. et al. Blueshifted Raman scattering and its correlation with the [110] growth direction in gallium oxide nanowires. J. Appl. Phys. 98, 094312 (2005).

Zhao, T. et al. First demonstration of wafer-level arrayed β-Ga2O3 thin films and MOSFETs on diamond by transfer printing technology. IEEE International Electron Devices Meeting, 1-4 (IEEE, 2024).

Nepal, N. et al. Heteroepitaxial growth of β-Ga2O3 films on SiC via molecular beam epitaxy. J. Vac. Sci. Technol. A 38, 063406 (2020).

Cheng, Z. et al. Thermal conductance across β-Ga2O3-diamond van der Waals heterogeneous interfaces. Apl. Mater. 7, 031118 (2019).

Cheng, Z. et al. Thermal transport across ion-cut monocrystalline β-Ga2O3 thin films and bonded β-Ga2O3-SiC interfaces. ACS Appl. Mater. Interfaces 12, 44943–44951 (2020).

Song, Y. et al. Ga2O3-on-SiC composite wafer for thermal management of ultrawide bandgap electronics. ACS Appl. Mater. Interfaces 13, 40817–40829 (2021).

Vaca, D. et al. Thermal conductivity of β-Ga2O3 thin films grown by molecular beam epitaxy. ITherm, 1011–1016. (IEEE, 2020).

Hou, X. et al. Ultrahigh-performance solar-blind photodetector based on α-phase-dominated Ga2O3 film with record low dark current of 81 fA. IEEE Electron Device Lett. 40, 1483 (2019).

Chen, K. et al. Photoelectrochemical self-powered solar-blind photodetectors based on Ga2O3 nanorod array/electrolyte solid/liquid heterojunctions with a large separation interface of photogenerated carriers. ACS Appl. Nano Mater. 2, 6169 (2019).

Xu, Y. et al. Solar blind deep ultraviolet β-Ga2O3 photodetectors grown on sapphire by the Mist-CVD method. Opt Mater. Express 8, 2941–2947 (2018).

Alema, F. et al. Solar blind photodetector based on epitaxial zinc doped Ga2O3 thin film. Phys. Status Solidi (a) 214, 1600688 (2017).

Qin, Y. et al. Metal–semiconductor–metal ε-Ga2O3 solar-blind photodetectors with a record-high responsivity rejection ratio and their gain mechanism. Acs Photonics 7, 812–820 (2020).

Guo, X. C. et al. β-Ga2O3/p-Si heterojunction solar-blind ultraviolet photodetector with enhanced photoelectric responsivity. J. Alloy. Compd. 660, 136–140 (2016).

Shen, X. et al. MMA-enabled ultraclean graphene transfer for fast-response graphene/GaN ultraviolet photodetectors. Carbon 169, 92–98 (2020).

Xu, Y. et al. Depletion-Mode β-Ga2O3 MOSFETs Grown by nonvacuum, cost-effective mist-CVD method on Fe-doped GaN substrates. IEEE Trans. Electron Devices 69, 1196–1199 (2022).

Zhang, Z. et al. High-quality crystalline NiO/β-Ga2O3 p–n heterojunctions grown by the low-cost and vacuum-free mist-CVD for device applications. Sci. China Mater. 67, 1646–1653 (2024).

Acknowledgements

J.N. acknowledges support from the General Program of Natural Science Foundation of China (Grant No: 62274134) and the National Key Research and Development Program (Grant Nos: 2023YFB3609900 and 2021YFA0716400); J.C.Z. acknowledges support from the National Science Foundation for Distinguished Young Scholars (Grant No: 62525402) and the National Science Foundation for Innovative Research Groups (Grant No: 62421005); J.N. acknowledges support from Key R&D Project in Xi’an City (Grant No: 2023JH-ZCGJ-0013); Aerospace Institute 771 Innovation Fund (Grant No:771CX2023007); The Natural Science Basic Research Program of Shaanxi Province (Grant No. 2025SYS-SYSZD-084).

Author information

Authors and Affiliations

Contributions

Z.C.Y. carried out the experiment, including grew the material and analyzed physicochemical characterization results. Z.C.Y., J.N. and D.W. designed the figures. Z.C.Y., H.D.W. and J.N. wrote the manuscript. Y.F.C., X.M.D., X.B.Z. and Y.N.Z. were involved in a discussion about device preparation and growth mechanism. J.C.Z. and Y.H. supervised the complete work. All authors discussed the results and remarked on the manuscript at all stages.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Daniela Gogova who co-reviewed with Asadollah Bafekry; Si-Young Bae, and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ning, J., Yang, Z., Wu, H. et al. Van der Waals β-Ga2O3 thin films on polycrystalline diamond substrates. Nat Commun 16, 8144 (2025). https://doi.org/10.1038/s41467-025-63666-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-63666-x