Abstract

Silicon and its composites are key materials owing to their extensive use in the semiconductor industry. While the diamond-structured form dominates, other allotropes with superior properties at ambient conditions remain of interest. Toward this, Si46 clathrate type-I crystals containing alkali/alkaline-earth metals have been extensively studied, but the experimental observation of a guest-free Si46 structure has been challenging. Using advanced electron microscopy, we show experimental evidence of guest-free clathrate-I Si46 framework from Ba8-xSi46 under in situ heating. We reveal the stepwise Ba evacuation process, starting with loss of Ba1 from the smaller cages to form Ba6Si46, followed by removal of Ba2 in larger cages to reach Si46 that appears in the thin region of the nanocrystal with a thickness around 4-6 nm at 500 °C. Calculations give a quasi-direct bandgap of 1.89 eV and support the preferential evacuation of Ba1. The observation of this guest-free Si46 framework opens up possibilities for applications in high-speed transistors, optoelectronic devices or solar cell technologies.

Similar content being viewed by others

Introduction

Owing to its elemental abundance, low production cost and well-established production methods, silicon is one of the most important semiconductor materials for electronic devices. The most common form of Si is the diamond-type structure (d-Si), which is an indirect bandgap semiconductor with a bandgap of 1.17 eV1,2. This characteristic limits its potential applications in optoelectronic devices such as solar cells3,4, photosensitive devices5, lasers6,7 and light-emitting diodes (LEDs)8,9. Allotropes of carbon, which is the same group as silicon, such as diamond, graphene, carbon nanotubes, and the C60 family of fullerenes, all exhibit exceptionally high performances. Thus, there is significant interest in developing silicon allotropes with direct and wide bandgaps that are stable in ambient conditions for environmentally friendly optoelectronics devices based on well-established technical knowledge for Si.

Among the various allotropes of silicon, most metastable forms, such as R810 and T12-Si11, possess an indirect bandgap, while others, such as silicene12 and the BC8 phase10,13, exhibit semi-metallic properties2. In contrast, low-energy allotropes, particularly those with cage-like crystal structures, have been extensively studied and remain as a focal point of interest1,2,3,4,14,15,16. Numerous theoretical studies suggest that silicon’s empty framework structures could possess wide optical bandgaps, making them promising candidates for silicon-based optoelectronic devices. Previously reported examples, such as Si136 with a clathrate-II structure17,18 and Si24 (oC24)1, can be synthesised by removing sodium from the silicon cages. However, preparation of a pure Si46 framework in the clathrate-I structure is challenging. There are two kinds of cages in this structure, Si20 [512] and Si24 [51262], where each cage is generally filled with a guest metal atom. Experimental observations indicate that although metal atoms can be removed from the smaller cages, they remain stable in the larger cages19,20,21,22,23. Consequently, direct experimental observation of empty Si46 in the clathrate-I structure remains a demanding endeavour.

The binary Ba-Si clathrate-I compound, Ba8-xSi46, where x refers to Ba deficiency and depends on the synthesis conditions23, is of particular interest because it exhibits superconductivity and thermoelectric capability19,24,25. It was firstly prepared under high-pressure (above 2 GPa) and at high temperature (800 °C) by the reaction of BaSi2 and Si using a cubic multi-anvil press26. The structure of Ba8Si46 can be described as one where Ba atoms form a β-tungsten type structure (A-15 type: space group Pm-3n), and Ba1 takes 2a site and Ba2 takes 6d site. All Si atoms are tetrahedrally bonded to neighbouring Si atoms and form two types of cages, Si20 [512] and Si24 [51262], approximating a Voronoi polyhedron of Ba atoms (Fig. 1). It has been demonstrated that the number and location of Ba vacancies are of high interest, as they play a critical role in the electronic features, including superconductivity22,27.

a Model of the unit cell and the arrangement of the two different Si cages. b Projection along the [001] with Wyckoff positions. Different cages or Ba and Si atoms at different sites are indicated by different colours, as shown in the text in the figure. No change in the Si46-framework was observed, therefore, all Si atoms at three different sites are shown together in the same dark blue in subsequent figures.

Herein, starting from the pristine Ba8-xSi46 crystals, we have thoroughly studied the local fine structures of the Si-clathrate crystal, both in regard to the Si-framework and Ba deficiency (x), using a multimodal approach based on advanced scanning transmission electron microscopy (STEM) imaging techniques, which included annular dark field (ADF), annular bright field (ABF) and quantitative differential phase contrast (qDPC)28,29 imaging. The experiments were carried out at both room and high temperatures under in situ vacuum heating conditions. This enabled us to observe not only the vacancy of Ba1 in Si20 cages in the pristine crystal, but also the dynamic process of complete evacuation of Ba1 during the heating experiment. Subsequently, evacuation of Ba2 from Ba6Si46 to Si46 was clearly observed, particularly on very thin areas towards the crystal edge. Therefore, we could confirm the formation of a guest-free clathrate-I Si46 framework that is stable at ambient temperature. Electronic structure calculations suggested that the corresponding silicon allotrope Si46 has a quasi-direct bandgap of 1.89 eV. We also observed a Si26 [51263] cage in Si-clathrate I as a planar defect in the Si-framework. Importantly, we found that defects in the framework were healed under the heating conditions applied. The Si46 framework structure is formed from the basis of the 14-sided tetrakaidecahedra and 12-sided irregular dodecahedra used by Weaire and Phelan30 for the construction of an optimal division of space via minimisation of a curved surface wrapping polyhedral edges. This resulted in a surface area 0.3% better than the cubic structure based purely on 14-sided tetrakaidecahedra (such as the zeolite framework SOD) proposed by Lord Kelvin31 and serves as an additional indication of the importance of this structure.

Results and discussion

The structure of as-synthesised Ba8-xSi46 was firstly solved by single-crystal X-ray diffraction (SCXRD) from a very small volume (2.5 × 2.0 × 1.1 μm3). A cubic cell, with space group Pm−3n and cell constant a = 10.3223(14) Å, was obtained in agreement with those previously reported26. Figure 1a shows the cage structure where Ba1, at the 2a position, sits at the centre of the Si20 cage 1 (light coral) and Ba2, at the 6d position, is at the centre of the Si24 cage 2 (blue). Different positions with multiplicities and Wyckoff letters are also marked in Fig. 1b, viewed along the [001]. The occupancies for Ba1 and Ba2 were refined to be 0.765 and 0.984, respectively, resulting in a chemical formula of Ba7.434Si46 (refined structure details: see Supplementary Tables 1–3). Electrical conductivity of this sample was measured as a function of specimen temperature, and the sample showed a clear transition to a superconductor at Tc = 7.6 K (Supplementary Fig. 1). This was compared with previously reported values with different Ba contents, showing that both the cell constant21 and Tc are closely related to the content of Ba (Supplementary Fig. 2).

Pristine structure at room temperature

Once the average structure was solved and the presence of Ba vacancies was confirmed, local information of the structure in general and on the Ba1 and Ba2 in particular was attempted through atomic resolution spherical aberration (Cs)-corrected STEM, including the analysis of their occupancies in the cages at different temperatures starting from the pristine structure. Figure 2 presents a set of ADF, ABF, and qDPC images of Ba7.434Si46 taken along the [001] direction. Each of the first three columns contains (i) low- and (ii) high- magnification images, (iii) the Fourier diffractograms (FDs) obtained from low-magnification images, and (iv) the intensity profiles along the three horizontal dotted lines in the low-magnification images and their averages. For the Ba8-xSi46 structure, there are three kinds of Ba positions when projected along the [001] direction (Supplementary Fig. 3); position 1 at a quarter of the cell edge overlapped with a Si atom (marked by a dashed red box), position 2 in between two position 1 with two neighbouring Si atoms (marked by a dashed yellow box) and position 3 in the centre surrounded by two circles of Si atoms (marked by a dashed blue box). Very high resolution up to 86 pm (ADF), 86 pm (ABF), and 80 pm (qDPC) was achieved in these images. Therefore, even the two neighbouring Si atoms of Ba1 at position 2 can be distinguished unambiguously in all images, where the projection distance between them is ca. 1.2 Å. This is not only present in the images (Fig. 2b, f, j) but also more straightforwardly in the intensity profiles (Fig. 2d, h, l). Individual peaks clearly show the position of the Ba1 atom and the two neighbouring Si atoms, as the grey dashed lines indicate. It is noted that two additional peaks can be observed in the ABF (Fig. 2h) and qDPC (Fig. 2l) profiles, in agreement with that there are five atom columns between two Ba2 at position 3 as marked by red dashed rectangle in Fig. 2m. This is because light elements could be imaged with better contrast in ABF and qDPC images, which is more favorable for observing Si atoms, compared to ADF images. Therefore, the inner circle Si atoms surrounding Ba at position 3 are also revealed in this case (Fig. 2n).

Low-magnification, high-magnification, Fourier diffractogram (FD) obtained from the low-magnification images, and intensity profiles along the three horizontal dotted lines in the low-magnification images in the corresponding colours and their averages in black of (a–d), ADF images, (e–h), ABF images and (i–l), qDPC images. m Projection view along [001] of structure model. n qDPC image incorporated with the structure mode showing that all atoms in the structure are revealed. o EELS mapping of Ba, Si and the overlaid result. Colour code in structure models: dark blue for Si, light coral for Ba1 and light blue for Ba2. Scale bar: 1 nm in (a, e, i), 0.5 nm in (b, f, j, o) and 5 nm−1 in (c, g, k).

Complementary chemical composition was studied by electron energy-loss spectroscopy (EELS) mapping and energy-dispersive spectroscopy (EDS) mapping, which were carried out in the thin area of the crystal (Fig. 2o and Supplementary Fig. 4–6). The EELS spectra integrated from a small region (red square) showed five distinct edges corresponding to Ba-M4,5, Ba-M2,3 edges and the Si-K from the framework (Supplementary Fig. 4). The resulting atomic resolution chemical mappings of Ba, Si and the overlay match very well with the structural model (Fig. 2o). All the Ba1, Ba2 and Si atoms could be well resolved, including the Si atoms that are partially overlapping with Ba2 at position 1 along the [001] direction, which could be hardly distinguished in the STEM images. Meanwhile, the signal intensity of Ba1 at different places also showed variations (Fig. 2o), indicating the deficiency of Ba1 at the 2a site. We also attempted to distinguish the valence states of Ba atoms at different positions via EELS spectra. However, owing to the limitation of the signal-to-noise ratio of pixels at the sub-Å level, the difference in the ratio of M4,5 edges at Ba1 and Ba2 sites integrated from a few pixels could barely be distinguished.

An advantage of ADF imaging is that the image contrast is proportional to Z(2-x) (x = 0.3-0.7), where Z is the atomic number of the elements; thus, a much higher contrast for Ba was observed than for Si, as shown in Fig. 2a. Further, the intensities are also related to the number of atoms along the incident direction, providing the possibility to analyse for Ba deficiency. In the ADF images, the intensity variations at different Ba positions suggest Ba deficiency exists, especially for the lower intensity at position 2, where the Ba has a lower occupancy of 0.765. However, this could also result from the inherent structure. Along the projection direction, there are two Ba2 in the atom column of position 3, while one Ba2 and two Si at position 1 and only one Ba1 at position 2 (Supplementary Fig. 3), which will naturally result in an intensity difference, that is, position 3 > position 1 > position 2. A similar phenomenon was also observed in the STEM images along [112] direction (Supplementary Fig. 7), where different atom contents also introduced contrast variations.

STEM observation of structural change under in situ heating

An accurate way to identify Ba deficiency is to compare the contrast (intensity) with the neighbouring atoms, where the crystal thickness is the same. Figure 3a corresponds to the ADF micrograph recorded along the [001] zone axis at room temperature, where the two areas marked by red and yellow dashed rectangles have been magnified and analysed. In these two images, the red and yellow arrows indicate an apparent discrepancy corresponding to the Ba1 located at position 2. By comparing the intensity line profiles, Supplementary Fig. 8, there is clear evidence of a lower intensity associated with the lower number of Ba atoms in these columns. No correlation was found between the discrepancy locations. This is consistent with the intuitive understanding that occupancy is a result of volume averaging. From this data, it can be concluded that Ba deficiencies distribute randomly at the Ba1 position in crystals, which means that some cage 1 (Si20) are empty.

Given that some studies have reported the structural change of Ba8-xSi46 at different temperatures by powder X-ray diffraction, which is an ensemble average over many crystallites, here we have focused on the local fine structure using Cs-corrected STEM at different temperatures with an in situ heating holder. Figure 3b, c exhibits the ADF images taken along the [001] direction at 300 and at 500 °C, respectively. Likewise at room temperature, no obvious structural change was found at 300 °C (Fig. 3b). The basic framework agrees with the Ba7.434Si46 structure and some deficiency of Ba1 at position 2 was observed, indicated by red and yellow arrows in Fig. 3b, bottom part. However, when the sample was heated up to 500 °C, Fig. 3c, a very different image was obtained; in this case, all Ba1 at the 2a sites disappeared. The structural transformation occurring at this temperature is different from the one previously reported at 500 °C at ambient pressure20, where no structural changes were identified, and at 527 °C under vacuum22, where only part of the Ba1 atoms were removed. This different behaviour may be attributed to the high-vacuum environment in the electron microscope, as the previous two reports already showed differences between vacuum and ambient pressure at similar temperatures. It must be remembered that at this temperature atoms appear larger and spatial resolution is decreased due to the strong thermal vibration.

To further corroborate this structural change, additional data were recorded along the most important orientation for a cubic crystal, i.e., the [110] direction (Supplementary Fig. 9). Owing to the severe movement of the crystal at high temperature, which is unfavourable for atomic imaging, the samples were cooled down to 400 °C. In addition, atomic images at room temperature before the heat treatment were also obtained for comparison (Supplementary Fig. 9a, b). These two images were collected both on thin and relatively thick regions to observe the influence of thickness. Both images show similar features: four Ba atoms are located at the corners of a rectangle, and three other Ba atoms sit inside the rectangle (as marked by the red box), among which the centre one is Ba1 at the 2a site, and others are Ba2 at the 6d site. Despite the rarity of Ba1 deficiency, as marked by the yellow arrow in the inset of Supplementary Fig. 9a and shown in the blue line profile (marked with the purple arrow), most areas of the image show three atomic columns within the rectangle, regardless of thickness. Compared to the images at room temperature, the annealed crystal exhibits obvious distinctions. Only two atomic columns are observed within all the rectangles; the centre one, Ba1 at the 2a site, is absent. This result is consistent with the previous assumption that after heating to 500 °C under a high-vacuum environment, Ba8-xSi46 exhibits a different behaviour: all Ba1 atoms at the 2a site are completely removed, but the basic clathrate structure does not change, resulting in the formula Ba6Si46 with a large x value of up to 2.

To catch the intermediate state of the Ba1 escape process during heat treatment, another sample was treated at 400 °C for 20 min and then cooled down to room temperature, followed by again heating up to 500 °C for the complete removal of Ba1. ADF images were taken at room temperature before any heating and after the two heating steps (Supplementary Fig. 10). Supplementary Fig. 10a corresponds to the initial state before any heat treatment, while Supplementary Fig. 10b shows the final state after 500 °C treatment, revealing a significant difference between the states associated with Ba1 removal. Instead of a bright spot in the middle with two tails, the signals of the neighbouring silicon atoms stand out, leaving a gap in the middle. In Supplementary Fig. 10c, which represents the intermediate state of the heat treatment, both types of contrast can be observed as marked by the green box (Ba1 present) and the red box (Ba1 removed). Furthermore, more regions show a vague contrast, as seen in the yellow box, indicating that Ba1 is partially evacuated upon heating. It should be noted that we didn’t observe the complete evacuation of Ba1, despite long-term heat treatment at 400 °C. Unfortunately, the position and orientation of the crystals changed so much that we could not obtain clear atomic imaging during the process of heating the sample from 400 to 500 °C. After readjusting the crystal orientation in a few minutes, we found that all Ba1 was absent. Thus, we believe this is mainly a thermodynamically driven process, as supported by the later theoretical calculations of the relative site stability.

Images along the [112] direction were also taken at different states to compare the Ba1 removal process. As shown in Supplementary Fig. 11a, Ba1 atoms appear as a line of bright contrast, as marked by the yellow rectangle. With heat treatment, parts of this bright contrast disappear, indicating the loss of Ba1 (Supplementary Fig. 11b). Eventually, all Ba1 escape, leaving a blank line in Supplementary Fig. 11c. Combined with the observations along the [001] direction, it further proves that all Ba1 atoms are removed under this kind of heat treatment.

When analysing the intermediate state images, we also found that there is a surface dependence of Ba1 escaping at high temperature. As shown in Supplementary Fig. 12, which was taken at 400 °C during the intermediate state, different Ba1-containing regions were observed. Three representative areas were selected, with the thickness decreasing from (b) to (d). On the surface, the thinner area indicated by a yellow square, Ba1 was absent, indicating that all Ba1 escaped (Supplementary Fig. 12d). However, as the crystal becomes thicker, the orange and red squares, it can be observed that the Ba1 signal increased together with the thickness (Supplementary Fig. 12b, c). This would indicate that after this heating process, not all Ba1 would be evacuated, and the process would start from the surface of the crystal, maintaining the internal part with Ba1. This observation aligns well with the expected behaviour on evacuation.

Experimental observation of guest-free Si46 framework

In addition to the above observations for Ba1, the evacuation of Ba2, which is typically expected to remain stable in cage 2 (Si24), was also observed during the heating experiment. ADF images taken along the [001] direction at room temperature after the heat treatment showed the transition from a Ba2-only clathrate-I structure to a pure Si clathrate-I structure. After the heat treatment, all Ba1 in all parts of the crystal escaped from the structure, resulting in the Ba2-only clathrate-I structure, Ba6Si46, as marked by the orange square in Fig. 4a. However, an additional, distinct structure was observed at the crystal edge. The top part of the crystal, shown in Fig. 4a, b exhibits a perfect structure corresponding to Ba6Si46. In the central part, there is an interface between Ba6Si46 and the newly formed structure Ba6-ySi46 where y represents the deficiency of Ba2. In contrast, in the bottom region, Ba2 was completely removed, leaving the metal-free Si clathrate-I structure (Si46), as shown in Fig. 4a, d (yellow square), presenting a structure that has hitherto never been experimentally reported. An intensity profile of the image across the crystal centre to the edge region shows a very pronounced variation in the amount of Ba2 (Supplementary Fig. 13). Image simulations with varying Ba content and sample thickness were also conducted (Supplementary Fig. 14). At the same thickness, regions with different barium contents show significantly different contrast, where the experimental data matches better with that of 4–6 nm in thickness. It is noted that positions 1 and 3 as indicated in Supplementary Fig. 3 consist of only 4 and 8 Ba2 atoms at a thickness of 4 nm, respectively, in the projected direction for the fully occupied state. This finding suggests the possibility of further fine-tuning Ba content in Ba8–xSi46 with x larger than 2, and opens up the possibilities for synthesising Si allotropes such as Si46. At the same time, it also highlights the importance of in situ imaging for atomic material manufacturing and phase structure determination; for example, the structure of gas-phase Si cluster32,33,34 which is another important branch in the study of Si allotropes.

The image was taken along the [001] direction at room temperature after heat treatment, showing Ba2 deficiency at the crystal edge. a Overall view of the crystal edge, from top to bottom, showing the bulk of the crystal to the edge. b–d Three selected regions and corresponding structure model to the inset white box: (b) bulk part with all Ba1 escaped but Ba2 retained, (c) transition part with all Ba1 and Ba2 partially removed, (d) edge part with all Ba1 and Ba2 removed, leaving a guest-free Si46 framework. Colour code: dark blue for Si and light blue for Ba2. Scale bar: 2 nm.

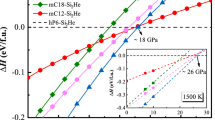

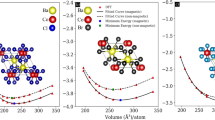

DFT calculations using different functionals revealed that the corresponding pure Si46 phase exhibits insulating behaviour and a quasi-direct bandgap with values of 1.27 eV (PBE) and 1.89 eV (HSE06) (Supplementary Figs. 15, 16), properties critical for optoelectronic applications due to the implied tunability of its bandgap via strain engineering. In contrast, Ba-doped phases (Ba6Si46 and Ba8Si46) exhibit metallic characteristics, with lattice parameters increasing systematically with Ba content, consistent with occupation of the cages causing expansion. Previous theoretical studies have classified Si46 with the clathrate-I structure as a stable, low-energy allotrope. In this work, it is experimentally confirmed that the guest-free clathrate-I Si46 framework remains stable at room temperature and under conditions ranging from low vacuum to ambient pressure. Although our calculations predict a smaller unit cell parameter for Si46 (10.16 Å) compared to the Ba6Si46 and Ba8Si46 structures (10.20 and 10.27 Å, respectively), experimental observations in the 4–6 nm-thick, 8 nm-wide thin region of the nanocrystal, where guest-free clathrate-I Si46 framework forms as an epitaxial-like film, showed no significant lattice parameter difference between Ba-rich and Ba-free regions. This suggests that slight deviations from predicted bulk values may arise from epitaxial growth constraints, aligning with the strain-responsive nature of its quasi-direct bandgap.

During the heating process, Ba at different sites showed significant preferences. Thermodynamic analyses of Ba8Si46 further indicated that while 2a site Ba atoms (Ba1) face kinetic barriers for surface migration (requiring passage through the 6d site), their lower stability relative to 6d site Ba atoms (Ba2) drives preferential Ba1 evacuation at elevated temperatures, a trend reinforced by HSE06 calculations incorporating ionic relaxation (Supplementary Tables 4, 5). Collectively, these theoretical and experimental results bridge structural stability, lattice parameter behaviour, and Ba site energetics, providing a comprehensive mechanistic framework for understanding the electronic, structural, and dynamic properties of Si46-based materials across bulk and nanoscale regimes.

Planar defect and defect healing upon heating

In addition to the Ba1 deficiency observed at high temperatures, planar defects in the clathrate framework structure were also identified in the ADF images, Figs. 5a, b, taken along the [001] direction at 500 °C and [110] at 400 °C, respectively. As the images were taken at high temperatures, only Ba2 atoms were observed. Along the [001] direction, the image contrast in the left part can be considered as the translational extension of the unit marked by the white square, where four Ba2 occupy the vertices and another four Ba2 are located at the centre. However, the right part of the planar defect is shifted down by a half unit, and individual Ba atoms in the middle part are arranged in a zig-zag pattern (Fig. 5a). An antiphase region was observed in the image along the [110] direction. The unit marked by a white rectangle is composed of four Ba2 atoms at the vertices and two Ba2 atoms in the centre. The middle part of the defect region is shifted up by half a unit, and the right part shifted back (Fig. 5b). Efforts were made to elucidate the defect structure in these regions using a common model, the details can be found in the supplementary information (Supplementary Figs. 17–20). Since both sides of the planar defect region along the [110] direction have the same structure, only one side was considered during the model-building process. The result is shown in Supplementary Fig. 17, where the unit movement corresponds well with that shown in the ADF images along both directions, as marked by the white squares and rectangles. To present the defective structure clearly, boundary Ba atoms are shown in red to distinguish them from normal green ones. As this material is known for its typical clathrate structure, the defect structure is further presented in a cage style (Fig. 5c, d). Blue and pink cages correspond to the original Si24 and Si20 cages, while yellow and red represent the newly formed Si20 and Si26 cages around the planar defect region. It is noted that the images were taken after heating, thus Ba atoms are missing from both the original and newly formed Si20 cages.

Images observed along (a) the [001] direction and (b) the [110] direction. c Arrangement of different cages around the planar defect region viewed along different directions, and (d) comparison of different cages in different colours in this region. e ADF images showing defect region along the [110] direction taken at 400 °C. f Image of the same region but with the defect healed upon continuous heating. Scale bar: 2 nm.

An interesting defect-healing phenomenon is observed at 400 °C. As shown in Fig. 5e, an apparent defective region showing dark contrast appeared on the right side as marked by red dashed rectangle. After being kept at this temperature for a while, this region was restored to its original structure with all Ba1 removed (Fig. 5f). To exclude the effects of the electron beam, a control experiment was conducted at room temperature (Supplementary Fig. 21). The electron beam was focused on the region marked by the red box for 1 min before recording image, and destruction of the structure in this area was observed. This indicates that the heating, rather than the electron beam, is responsible for the defect healing at 400 °C. Based on this finding, it is proposed that annealing at a certain temperature might be a way to reduce planar defects in this sample, which should be critical for its application.

In summary, this study has detailed the local structure at the atomic level and at different evaporation stages of Ba in clathrate-I Ba8-xSi46. Refinement from SCXRD data revealed occupancies of 0.765 and 0.984 for Ba1 in the Si20 cage and Ba2 in the Si24 cage, respectively. Atomic STEM images were collected to image all Ba and Si atoms in the structure, as well as the deficiency of both Ba1 at the 2a site and Ba2 at the 6d site. In situ heating experiments show that no obvious changes occur at 300 °C, but Ba1 deficiency increases dramatically, and all Si20 cages are evacuated at 500 °C due to heating and ultra-high vacuum, resulting in the formula Ba6Si46, which differs from annealing at ambient or low pressure. Surface-dependent evacuation of Ba1 was observed during this heating process. Furthermore, the evacuation of Ba2 from the Si24 cage was also observed. The content of Ba2 can be fine-tuned, eventually resulting in the observation of a metal-free clathrate-I Si46 framework. Electronic structure calculations show that the corresponding Si46 phase is an insulator with a quasi-direct band gap of approximately 1.27 eV (PBE) and 1.87 eV (HSE06), while both Ba6Si46 and Ba8Si46 exhibit metallic band structures. The energy required to remove Ba1 from the Si20 [512] cage is significantly lower compared to the energy needed to remove Ba2 from the Si24 [51262] cage, indicating that Ba1 is easier to evacuate. In addition, a Si cage in clathrate-I, Si26 [51263], was observed at a planar defect in the heated sample. An interesting defect-healing phenomenon driven by heating was observed at 400 °C, suggesting a possible method to reduce planar defects in Ba8-xSi46 by annealing the crystals at certain temperatures. In general, this study presents clear experimental evidence of the guest-free clathrate-I Si46 framework, which shows great potential for optoelectronic devices. Our finding advances the investigation of Si allotropes that are stable in ambient conditions and the understanding of guest behaviour in Si clathrate-I structure, providing guidance for the rational atomic material manufacturing.

Methods

Materials

The sample Ba8-xSi46 with clathrate-I structure was prepared using high-pressure, high-temperature conditions of 3 GPa at 800 °C26.

STEM imaging and simulation

Bulk sample was crushed into fine powder then dispersed in ethanol and a few drops of the suspension were placed onto ultrathin carbon-coated copper grids for STEM imaging. STEM images were collected at 300 kV on JEM-ARM300F microscope (JEOL) equipped with a cold FEG and double Cs correctors. After routine Cs-correction procedure, it can offer high resolution for STEM imaging better than 80 pm.

For the in situ heating and imaging experiment, the nanocrystals of Ba7.434Si46 were placed onto Fusion Thermal E-chips and heated using the Fusion Select system (Protochips). The silicon nitride membrane on the E-chip was around 40 nm thick, which enabled atomic resolution imaging under heating conditions. Since the crystal tends to drift significantly during the heating process, we did not follow a fixed heating-holding-observation procedure. However, the vacuum level in the electron microscope remained constant throughout the experiment. In general, we used a faster heating rate in the initial stage—for example, 20 °C s−1 from room temperature to 300 °C. At higher temperatures, the rate was reduced to 0.2–0.5 °C s−1 to minimise sample drift caused by rapid heating. During cooling, we applied a rate of 0.5–2 °C s−1. The dwell times at different temperatures ranged from 5 to 20 min, depending on factors such as the need to observe different regions of the crystal and adjustments for crystal position and orientation. The convergence semi-angle is 16 mrad for images in Fig. 2 and Supplementary Fig. 7, and 24 mrad for others. The collection angle is 27–110 mrad for all ADF images, 5.9–12 mrad for ABF images.

Image simulations were performed using QSTEM software35,36 with the same convergence angle and collection angle as in the experiments. Thermal vibration was considered on the basis of the effect of thermal diffuse scattering (TDS). Before the image simulation, a structure model with different Ba content was built first. All Ba1 were removed from the model, and there are three different regions in this model that is all Ba2 retained, half Ba2 retained and no Ba2 retained. Then images under different sample thickness were simulated to compare with the experimental results.

Electronic structure calculations

To help characterise the differences and similarities between the Si46, Ba6Si46 and Ba8Si46 structures, calculations based on density functional theory were performed on the bulk structures. PBE37 density functional calculations were performed using the Quantum Espresso programme (version 7.2) and the SSSP PBE Precision v1.3.0 pseudopotentials38 for Si39 and Ba40. The following parameters were used for all calculations unless otherwise specified; relevant cutoffs for the electronic structure calculation were 35 Ry for the kinetic energy cutoff and 140 Ry for the charge density, as recommended for in the SSSP library, Methfessel-Paxton41 smearing with a smearing width of 0.01 Ry, and a 6 × 6 × 6 Monkhorst-Pack42 k-point grid sampling for the Brillouin zone. A conservative number of additional (empty) bands were added, yielding 184, 244, and 264 bands each for Si46, Ba6Si46, and Ba8Si46, respectively. For each of these structures, starting with the experimentally determined Ba8Si46 lattice parameter of 10.327 Å, a full cell relaxation was performed, and the band structure was subsequently calculated.

To obtain a more accurate estimate of the band gap of pure Si46, a screened hybrid functional calculation using HSE0643 with largely the same settings was performed, with the following modification and additional settings; 80 Ry cutoff for the kinetic energy cutoff and 640.0 Ry for the charge density, Optimised Norm-Conserving Vanderbilt pseudopotentials44 for Ba and Si and use of the Adaptively Compressed Exchange45 operator (ACE) with 1 × 1 × 1 the three-dimensional sampling mesh in k-space.

To approximate the difference in thermodynamic stability between the two Ba sites, fixed-cell optimisations of the Ba8Si46 structure were performed for the removal of each site, as well as for the addition of each Ba site individually to the pure silicon lattice (using the Ba8Si46 optimised lattice parameter for removal and the Si46 lattice parameter for addition). The calculation using a hybrid functional HSE06 with energy evaluation used the optimised cells but allowed ion positions to relax.

Single-crystal X-ray diffraction

Bulk sample was crushed, a small piece (2.5 × 2.0 × 1.1 μm3) was picked up for nano-SCXRD using Rigaku SynergyCustom system equipped with a rotating anode generator (FR-X) and a hybrid photon counting detector (HyPiz-6000HE) at room temperature in order to reduce the influence of inhomogeneity in large crystals. It was measured using Cu Kα radiation (λ = 1.54184 Å). The diffraction data were processed using CrysAlisPro46. The structure was solved and refined by SHELXT47 and SHELXL48 implemented in Olex249.

T c measurement

Electrical resistance of single crystals was measured on a polished fresh surface by the standard four-terminal method in the physical property measurement system (PPMS-14T) from Quantum Design.

EDS and EELS analysis

EDS was collected on a JEOL dual SDD system (100 mm2*2). EELS data were collected on a Gatan 965 GIF Quantum ER spectrometer equipped with both a US1000FTXP detector and a retractable direct electron detector (K2).

Data availability

The data supporting the findings of this study are available from the corresponding authors upon request. Source data are provided in this paper.

References

Kim, D. K., Stefanoski, S., Kurakevych, O. O. & Strobel, T. A. Synthesis of an open-framework allotrope of silicon. Nat. Mater. 14, 169–173 (2015).

Guo, Y., Wang, Q., Kawazoe, Y. & Jena, P. A new silicon phase with direct band gap and novel optoelectronic properties. Sci. Rep. 5, 14342 (2015).

Iwasaki, S. et al. A novel technique for controlling anisotropic ion diffusion: bulk single-crystalline metallic silicon clathrate. Adv. Mater. 34, 2106754 (2022).

Botti, S., Flores-Livas, J. A., Amsler, M., Goedecker, S. & Marques, M. A. L. Low-energy silicon allotropes with strong absorption in the visible for photovoltaic applications. Phys. Rev. B 86, 121204–12120 (2012).

Wang, G. et al. Two dimensional materials based photodetectors. Infrared Phys. Technol. 88, 149–173 (2018).

Watanabe, K., Taniguchi, T. & Kanda, H. Direct-bandgap properties and evidence for ultraviolet lasing of hexagonal boron nitride single crystal. Nat. Mater. 3, 404–409 (2004).

Wirths, S. et al. Lasing in direct-bandgap GeSn alloy grown on Si. Nat. Photon. 9, 88–92 (2015).

Ng, W. L. et al. An efficient room-temperature silicon-based light-emitting diode. Nature 410, 192–194 (2001).

Fadaly, E. M. T. et al. Direct-bandgap emission from hexagonal Ge and SiGe alloys. Nature 580, 205–209 (2020).

Malone, B. D., Sau, J. D. & Cohen, M. L. Ab initio survey of the electronic structure of tetrahedrally bonded phases of silicon. Phys. Rev. B 78, 035210 (2008).

Zhao, Z. et al. Tetragonal allotrope of group 14 elements. J. Am. Chem. Soc. 134, 12362–12365 (2012).

Cahangirov, S., Topsakal, M., Aktürk, E., Şahin, H. & Ciraci, S. Two-and one-dimensional honeycomb structures of silicon and germanium. Phys. Rev. Lett. 102, 236804 (2009).

Besson, J., Mokhtari, E., Gonzalez, J. & Weill, G. Electrical properties of semimetallic silicon III and semiconductive silicon IV at ambient pressure. Phys. Rev. Lett. 59, 473 (1987).

Kasper, J. S., Hagenmuller, P., Pouchard, M. & Cros, C. Clathrate structure of silicon Na8Si46 and NaxSi136 (x <11). Science 150, 1713–1714 (1965).

Munetoh, S., Moriguchi, K., Kamei, K., Shintani, A. & Motooka, T. Epitaxial growth of a low-density framework form of crystalline silicon: a molecular-dynamics study. Phys. Rev. Lett. 86, 4879–4882 (2001).

Guloy, A. M. et al. A guest-free germanium clathrate. Nature 443, 320–323 (2006).

Gryko, J. et al. Low-density framework form of crystalline silicon with a wide optical band gap. Phys. Rev. B 62, R7707 (2000).

Ammar, A. et al. On the clathrate form of elemental silicon, Si136: preparation and characterisation of NaxSi136 (x→ 0). Solid State Sci. 6, 393–400 (2004).

Liang, Y. et al. Synthesis of the clathrate-I phase Ba8− x Si46 via redox reactions. Inorg. Chem. 50, 4523–4528 (2011).

Liang, Y., Böhme, B., Vasylechko, L., Baitinger, M. & Grin, Y. In situ investigation of the thermal decomposition of clathrate-I Ba6. 2Si46. J. Phys. Chem. Solid 74, 225–228 (2013).

Castillo, R. et al. The clathrate Ba8–xSi46 revisited: preparation routes, electrical and thermal transport properties. Z. Anorg. Allg. Chem. 641, 206–213 (2015).

Fukuoka, H., Kiyoto, J. & Yamanaka, S. Superconductivity of metal deficient silicon clathrate compounds, Ba8-x Si46 (0<x≤ 1.4). Inorg. Chem. 42, 2933–2937 (2003).

Fukuoka, H., Kiyoto, J. & Yamanaka, S. Synthesis and superconductivity of barium deficient type I silicon clathrate compounds, Ba8− xSi46. J. Phys. Chem. Solid 65, 333–336 (2004).

Tanigaki, K. et al. Mechanism of superconductivity in the polyhedral-network compound Ba8Si46. Nat. Mater. 2, 653–655 (2003).

Yamanaka, S. Silicon clathrates and carbon analogs: high pressure synthesis, structure, and superconductivity. Dalton Trans. 39, 1901–1915 (2010).

Yamanaka, S., Enishi, E., Fukuoka, H. & Yasukawa, M. High-pressure synthesis of a new silicon clathrate superconductor, Ba8Si46. Inorg. Chem. 39, 56–58 (2000).

Moriguchi, K., Yonemura, M., Shintani, A. & Yamanaka, S. Electronic structures of Na8Si46 and Ba8Si46. Phys. Rev. B 61, 9859 (2000).

Shibata, N. et al. Differential phase-contrast microscopy at atomic resolution. Nat. Phys. 8, 611 (2012).

Ishizuka, A., Oka, M., Seki, T., Shibata, N. & Ishizuka, K. Boundary-artifact-free determination of potential distribution from differential phase contrast signals. Microscopy 66, 397 (2017).

Weaire, D. & Phelan, R. A counter-example to Kelvin’s conjecture on minimal surfaces. Philos. Mag. Lett. 69, 107–110 (1994).

Thompson, W. On the division of space with minimal partitioned area. Philos. Mag. 25, 503–514 (1887).

Ho, K. M. et al. Structures of medium-sized silicon clusters. Nature 392, 582–585 (1998).

Hudgins, R. R., Imai, M., Jarrold, M. F. & Dugourd, P. High-resolution ion mobility measurements for silicon cluster anions and cations. J. Chem. Phys. 111, 7865–7870 (1999).

Haertelt, M. et al. Gas-phase structures of neutral silicon clusters. J. Chem. Phys. 136, 064301 (2012).

STEM: Quantitative TEM/STEM Simulations https://www.physik.hu-berlin.de/en/sem/software/software_qstem.

Koch, C. T. PhD thesis. Determination of Core Structure Periodicity and point defect Density Along dislocations. (2002).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 78, 3865 (1997).

Prandini, G., Marrazzo, A., Castelli, I. E., Mounet, N. & Marzari, N. Precision and efficiency in solid-state pseudopotential calculations. Npj Comput. Mater. 4, 72 (2018).

Corso, A. D. Pseudopotentials periodic table: From H to Pu. Comp. Mater. Sci. 95, 337–350 (2014).

Hamann, D. R. Optimized norm-conserving Vanderbilt pseudopotentials. Phys. Rev. B 88, 085117 (2013).

Methfessel, M. & Paxton, A. T. High-precision sampling for Brillouin-zone integration in metals. Phys. Rev. B 40, 3616 (1989).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Janesko, B. G., Henderson, T. M. & Scuseria, G. E. Screened hybrid density functionals for solid-state chemistry and physics. Phys. Chem. Chem. Phys. 11, 443–454 (2009).

Schlipf, M. & Gygi, F. Optimization algorithm for the generation of ONCV pseudopotentials. Comput. Phys. Commun. 196, 36–44 (2015).

Lin, L. Adaptively compressed exchange operator. J. Chem. Theory Comput. 12, 2242–2249 (2016).

Matsumoto, T. et al. “What is This?” A structure analysis tool for rapid and automated solution of small molecule structures. J. Chem. Crystallogr. 51, 438–450 (2021).

Sheldrick, G. M. SHELXT–Integrated space-group and crystal-structure determination. Acta Cryst. A71, 3–8 (2015).

Sheldrick, G. M. Crystal structure refinement with SHELXL. Acta Cryst. C71, 3–8 (2015).

Dolomanov, O. V., Bourhis, L. J., Gildea, R. J., Howard, J. A. K. & Puschmann, H. OLEX2: A complete structure solution, refinement and analysis program. J. Appl. Cryst. 42, 339–341 (2009).

Acknowledgements

The work was supported by the Centre for High-Resolution Electron Microscopy (CħEM), ShanghaiTech University (EM02161943) and Shanghai Key Laboratory of High-resolution Electron Microscopy. A.M. acknowledges the Spanish Ministry of Science (RYC2018-024561-I, CNS2023-144346 and CEX2023-001286-S funded by MICIU/AEI /10.13039/501100011033) and the Aragon government (E13_23R). P.S. and J.D.G. thank the Australian Research Council for funding, as well as the Pawsey Supercomputing Centre and National Computational Infrastructure for computing resources. S.Y., H.F. and O.T. thank CREST, JST, Japan for funding. We thank Prof. Yanhang Ma, ShanghaiTech University, and Prof. Sven Lidin, Lund University, for scientific discussion, and Prof. Gunnar von Heijne, Stockholm University, for scientific support to CħEM.

Author information

Authors and Affiliations

Contributions

O.T. conceived this project, and Y.Z. and Q.Z. designed the studies. Y.Z. and Q.Z. performed the electron microscopy experiments, Y.Z. analysed the STEM images, performed the image simulation and model building, Q.Z. analysed the EELS data, A.M. conducted the qDPC imaging. P.R.S. and J.D.G. conducted the DFT calculation and analysis with comments from M.W.A. T.M. conducted the SCXRD experiment. J.L. conducted the Tc measurement. H.F. and S.Y. prepared the sample. Y.Z. Q.Z. and O.T. prepared the first version of the manuscript, and all authors contributed to the final version.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

peer review

Peer review information

Nature Communications thanks Alexandre Courac and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhou, Y., Zhang, Q., Mayoral, A. et al. Observation of a guest-free Si46 clathrate-I framework from Ba8-xSi46 upon in situ vacuum heating. Nat Commun 16, 9238 (2025). https://doi.org/10.1038/s41467-025-64277-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-64277-2