Abstract

Wearable electronic devices are gaining popularity, with textiles serving as a highly flexible platform. Organic electronic devices, known for their ultra-thin and flexible properties, are also attracting attention. This study presents a reliable fabrication method for textile-based organic light-emitting diodes (OLEDs) using a parylene-C planarization layer. The process creates a smooth surface with sub-nanometer roughness through a simple transfer and thermal annealing, forming a self-supporting planarization layer without immersion in water or chemicals. The parylene-C film enhances crystallinity and stiffness, ensuring mechanical stability. The fabricated OLEDs operate reliably under extreme deformations such as bending and wrinkling. Additionally, a 3×3 textile-based OLED array was demonstrated for display applications, and a scarf-based OLED verified its potential in fashion. This approach highlights the seamless integration of advanced electronics into textiles, offering promising applications across industries and marking a significant advancement in wearable display technology.

Similar content being viewed by others

Introduction

Recently, flexible and foldable devices have garnered significant attention, particularly in wearable technology for real-time communication between users and electronics1,2,3. Wearable technology initially began with smartwatches and glasses, progressed to devices using plastic substrates (e.g., Polyimide (PI), polyethylene terephthalate (PET)), and has now advanced to patches or bands that can be directly attached to the body4,5. These developments minimize user discomfort, enhance convenience and mobility, and enable real-time communication.

However, in the realm of advanced technology, wearable devices such as the Apple Watch and Google Glass offer a mechanical, attached feel, emphasizing the sensation of wearing a device. In contrast, among various wearable platforms, textiles are particularly advantageous due to their comfort and softness, allowing for imperceptible wear and potential applications in the biomedical and fashion industries6,7,8,9. The new concept of wearing technology integrates smart functionalities directly into textiles, creating multifunctional garments that are part of our everyday attire. This transition emphasizes the move from simply attaching technology to our bodies to seamlessly incorporating it into the textiles we wear, enhancing comfort and utility while maintaining the natural experience of wearing textiles.

Following this trend, research on various textile-based electronics, including sensors10,11, energy devices12,13,14, and displays15,16, is advancing, with particular emphasis on displays as mediums for information delivery. Currently, light-emitting diode (LED)3,17,18 or AC powder electroluminescent (ACEL)19,20,21 devices are fabricated on textile using techniques such as inkjet printing or screen printing, but their inherent thickness and rigidity make them unsuitable for wearable platforms, causing discomfort. Additionally, for ACELs, the high driving voltage (200–400 V) and low luminance (under 1000 cd/m2) limit their utility during daily wearable activities.

To address these issues, research has focused on OLEDs, which operate at low voltage, provide high luminance, and are ultra-thin, light, and flexible. Two approaches employing textile-based OLEDs have been investigated: (i) implementing devices on a single fiber, which is then woven into textiles (fiber type)22,23,24,25, and (ii) directly fabricating devices on the textile itself (textile type)6,7,9,16,26,27. While significant advancements have been made with regard to integrating devices into fiber types, challenges such as weaving, wiring, and encapsulation still remain. Conversely, the textile type, which involves directly fabricating devices on textiles, offers relative efficiency and ease, effectively making the textile itself a display. The attempt to form ultra-thin OLEDs directly on textiles has focused on overcoming the inherent roughness caused by the weave structure28. Initial methods used screen printing and thermal lamination for textile planarization, but these approaches resulted in thick layers that compromised the flexibility of the textile. Subsequent research has focused on developing thinner, stable planarization layers that maintain the flexibility of the textile, successfully achieving thinner thicknesses and demonstrating stable device operation16. However, most planarization methods employ solution processes, which can lead to uniformity and defect issues when fabricating large devices. Additionally, removing sacrificial layers by submerging the textile in water increases the fabrication time and introduces difficulties in integrating devices with varying processing methods and temperatures on a single substrate. Previous planarization layers are either thick or have high internal stress, leading to cracking under significant mechanical deformation. Because deformations in the plastic region directly impact the OLED on the planarization layer, the behavior in the elastic region is extremely important. Thus, planarization layer materials must be able to absorb significant energy in the elastic region to minimize deformation of the device.

In this study, parylene-C, which can be deposited at room temperature using chemical vapor deposition (CVD), is selected to overcome the aforementioned limitations. By utilizing this material, the planarization layer is initially deposited onto bare glass and is then transferred to the textile, replicating the flat surface of the glass. This method avoids the use of water or chemical agents, making the physical transfer process straightforward and significantly reducing the processing time. The crystallinity of parylene-C, a stress-free and semi-crystalline polymer material, is enhanced through thermal annealing, which improves its Young’s modulus and yield strength, enabling it to be used as a self-supporting planarization layer29,30,31,32. Parylene-C has been extensively studied as a substrate material for ultra-thin and flexible OLEDs33,34,35,36, particularly demonstrating its utility in bio and stretchable OLED applications due to its flexibility and stretchability. In contrast, this study employs parylene-C as a self-supporting planarization layer rather than as a direct substrate, addressing the unique challenges posed by textile substrates. Unlike conventional flexible substrates such as PET or PI, textiles exhibit inherent surface roughness and structural curvature, which significantly complicate stable device fabrication and operation. In this study, parylene-C is thermally annealed into a self-supporting structure, effectively addressing the challenges posed by the inherent roughness and curvature of textiles. This approach enables smooth and stable fabrication on textiles while preserving their inherent flexibility and mechanical characteristics. Furthermore, this research demonstrates stable device operation under typical textile deformation conditions, including bending and wrinkling. This approach demonstrates the adaptability of parylene-C for textile-based applications, particularly by addressing the unique challenges of fabricating OLEDs on textiles, which distinguishes it from previous studies focusing on its role as a substrate material.

In this study, a parylene-C self-supporting planarization layer is demonstrated to provide better resilience than previously used materials, forming a reliable planarization layer. Consequently, parylene-C planarization layers support stable OLED operation and also enhance the bending and wrinkling properties of the textile, making them suitable for wearing devices. Additionally, a 3 × 3 passive matrix (PM)-driving demonstration illustrates the potential for fashion displays and stable operation under significant wrinkling. This indicates the potential for textile expansion into various applications, such as fashion, automotive, and healthcare, demonstrating the feasibility and development possibilities for wearing displays.

Results

Fabrication and optimization of the textile platform

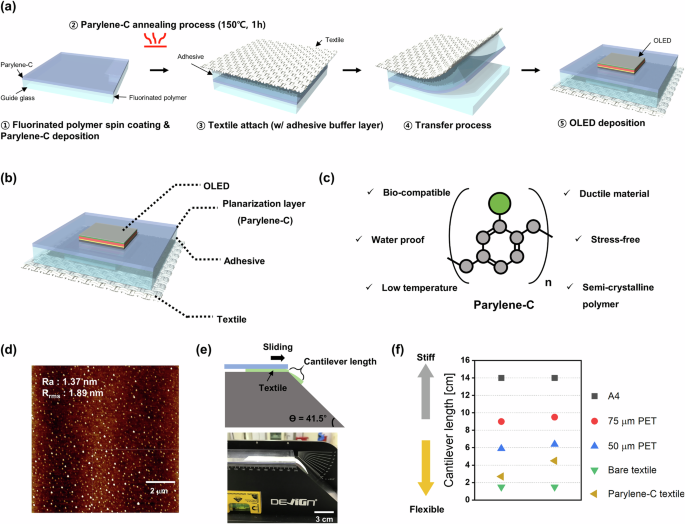

A textile substrate with a characteristic weave pattern exhibits roughness on the micron scale, which makes it difficult to operate OLEDs with thicknesses in the range of hundreds of nanometers27. Therefore, a simple transfer process was devised to planarize the roughness of the polyester textile to the nanometer scale, as shown in Fig. 1a.

a Fabrication procedure for the textile platform. b Schematic illustration of the textile-based OLED structures. c Parylene-C properties for the planarization layer. d Surface roughness of the textile platform measured by AFM. e Schematic diagram (top) and photograph (bottom) of the cantilever test (ASTM D:1388) demonstrating the flexibility of the textile platform. f Cantilever lengths of various substrates as measured by the cantilever test.

To create a smoother planarization layer, a surface-replicating method was employed to replicate a glass-like flat surface, as described in previous studies16. First, a fluorinated polymer was coated as a sacrificial layer to remove parylene-C more easily from the guide glass. Then, a parylene-C film with a thin thickness of 3 μm, intended for use as the planarization layer, was deposited using a chemical vapor deposition (CVD) process. The parylene-C planarization layer was easily removed and transferred from the guide glass due to the presence of the fluorinated polymer. The low surface energy of the fluorinated polymer allows for easy physical transfer without damaging other layers or the textile, providing a simple fabrication method that does not necessitate submerging the textile in water or the use of any chemical agents. In cases where high-temperature processes are required or the fabrication process is complex, making direct fabrication on textiles difficult, devices can be pre-fabricated on the guide glass/parylene-C and then transferred to the textile. This method is crucial for the future integration of many devices onto textiles.

Next, thermal annealing at 150 °C for 1 h was employed to increase the stiffness of the parylene-C. Thermal annealing is essential to obtain a flat surface, as the inherent low stiffness properties of parylene-C cause it to conform to the rough surface of the textile when transferred immediately after deposition. After annealing, the parylene-C intended for use as the planarization layer was attached to the textile as an adhesive and strain buffer layer. A Si-based elastomeric room temperature vulcanizing (RTV) material was utilized as the strain buffer layer through a spin-coating process16. This strain buffer layer can be naturally cured at room temperature, and due to its low 18 Shore A hardness, which is softer than a rubber band, the strain on the textile substrate caused by movement is reduced, thereby ensuring better flexibility16. Subsequently, after the adhesive layer cures at room temperature, the parylene-C is transferred to the textile to form a planarization layer. To protect the organic material from moisture and air, a bottom encapsulation structure was first applied. This bottom encapsulation consisted of a 30 nm Al2O3/ZnO nano-stratified structure deposited via an atomic layer deposition (ALD) process at 70 °C37. Next, the OLED was fabricated using a thermal evaporation process. Subsequently, a top encapsulation layer was deposited to further enhance device protection. The top encapsulation, similar to the bottom encapsulation, comprised an Al2O3/ZnO nano-stratified structure (30 nm) and a parylene-C layer (500 nm), ensuring protection for both the top and bottom of the device. This encapsulation structure effectively ensures comprehensive protection for both the top and bottom of the device, significantly enhancing the durability and environmental resistance of the textile-based OLED. The overall structure as shown in Fig.1b is composed of a commercially available 100% polyester type of textile, with a 19 μm adhesive and strain buffer layer and a 3 μm parylene-C planarization layer sequentially applied. Each layer thickness in this textile substrate was optimized based on experimental validation, theoretical analysis, and simulation results, as detailed in Supporting Note 1.1. This optimization process ensures the stability and mechanical compatibility of the textile-based OLED.

As shown in Fig. 1c, parylene-C has been implemented in various fields, such as micro-electromechanical systems (MEMS)38, sensors39, biomedical electronics31,40 and circuits, due to its diverse advantages. Additionally, the flexibility and biocompatibility required for textiles are provided by parylene-C, making it suitable as a planarization layer. Furthermore, its waterproof properties41 can provide an encapsulation42 effect for organic electronic devices vulnerable to water and oxygen.

Most importantly, parylene-C is a stress-free material and a semi-crystalline polymer with easily tunable mechanical properties, allowing its crystallinity and Young’s modulus to be easily enhanced through a thermal annealing process. Therefore, after annealing, parylene-C can maintain its structural integrity and function as a very thin but effective self-supporting planarization layer, even when transferred onto textile with a rough surface. The roughness of the fabricated planarization layer is shown in the atomic force microscopy (AFM) image in Fig. 1d, with Rrms (root-mean-square surface roughness) and Ra (average surface roughness) values measured at 1.89 nm and 1.37 nm, respectively. This demonstrated that a planarization layer can be easily and quickly implemented through the simple transfer process of the parylene-C layer, achieving a level of roughness that allows for the stable operation of very thin OLEDs.

Next, to assess the impact of the planarization layer on the flexibility of the textile, a simple cantilever test was conducted to measure the flexural rigidity of the textile. As illustrated in the schematic image in Fig. 1e, the cantilever test involved pulling the textile specimen along an inclined plane, at which point the length at which the specimen, driven by gravity, came into contact with the plane was measured. Higher flexibility is indicated by a shorter contact length, while greater stiffness is indicated by a longer contact length, as demonstrated by the results shown in Fig. 1f. To demonstrate the flexibility of the textile with parylene-C as the planarization layer, various substrates ranging from A4 paper to PET films with different thicknesses were measured and compared with untreated bare textiles. In the graph shown in Fig. 1f, instances where the planarization layer is on top of the textile are represented by the points on the left, and instances where the planarization layer is beneath the textile are represented by the points on the right. Despite the significantly greater thickness of the textile compared to other substrates such as PET or A4 paper, a much shorter cantilever length results from the inherent flexibility of the textile. It is also demonstrated that the planarization process maintains flexibility similar to that of the untreated bare textile. This confirms that the intrinsic flexibility of the textile was successfully preserved while implementing the planarization layer.

Optimization of the parylene-C for planarization layer

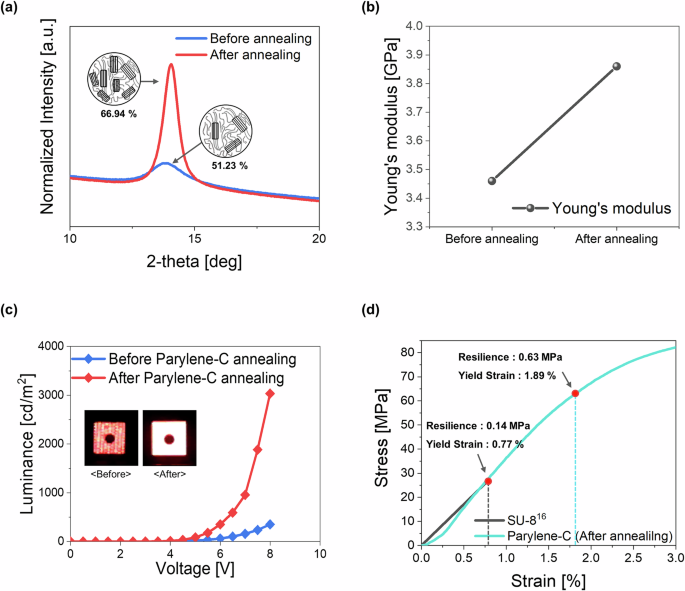

To ensure that ultra-thin and flexible OLEDs with thicknesses of hundreds of nanometers can operate stably on a textile substrate, a very thin self-supporting planarization layer was created to form a flat surface with sub-nanometer roughness and to prevent a collapse following the surface curves of the textile. Parylene-C is particularly noteworthy among various materials due to its biocompatibility, stress-free nature, and ease of property modification as a semi-crystalline polymer. The crystallinity and mechanical properties of parylene-C films can be altered through thermal annealing, making these films very convenient for achieving desired characteristics. Without the annealing process, parylene-C inherently has low stiffness. If used directly as a planarization layer without this process, it would conform to the surface curves of the textile, leading to instability and unreliable operation of ultra-thin OLEDs. To address this issue, a thin self-supporting planarization layer that does not collapse under the weave pattern was constructed. To ensure a stable self-supporting planarization layer for OLEDs, the crystallinity and Young’s modulus of parylene-C were enhanced through annealing. The annealing process, conducted at 150 °C for 1 hour, improved the crystallinity, as verified by an X-ray Diffraction (XRD) analysis. As shown in Fig. 2a, the annealed parylene-C films exhibit increased crystallinity due to relaxation and rearrangement in the amorphous regions of the polymer, resulting in higher peaks in the same direction. The crystallinity of each film was calculated for a quantitative comparison using the following equation43,44.

a Crystallinity measured by XRD. b Young’s modulus measured by the tensile test, comparing parylene-C films before and after thermal annealing. c Voltage (V)-luminance (L) graph of textile-based OLEDs before and after parylene-C film annealing for utilization as a planarization layer (inset: cell images of textile based-OLEDs). d Mechanical characteristics of the resilience and yield strain along the stress-strain curves of the parylene-C films measured in this study and in SU-8 films in a previous study16.

In this equation, \({A}_{C}\) represents the area under the crystalline peak, and \({A}_{A}\) represents the area under the amorphous region, calculated by integrating the area under the graph. The calculated crystallinity increased from 51.23% before annealing to 66.94% after 1 h of annealing at 150 °C. This increase in the crystallinity leads to higher tensile strength and greater overall stiffness. To verify the changes in the mechanical properties of parylene-C after annealing, tensile tests were conducted on samples before and after annealing at 150 °C for 1 h. (Supplementary Fig. 2a). The Young’s modulus was calculated by determining the slope of the linear region in the elastic range. The Young’s modulus of parylene-C before and after annealing were measured to be 3.46 GPa and 3.86 GPa, respectively (Fig. 2b). This indicates an ~11% increase in the Young’s modulus post-annealing, indicating an increase in the material’s stiffness and thus, enabling the construction of a self-supporting planarization layer that does not conform to the surface curves of the textile. When parylene-C was applied as a planarization layer without annealing, the deposited OLED followed the weaving pattern of the textile and did not operate stably, as shown in the inset of Fig. 2c. However, after annealing, the OLEDs exhibited stable operation. This demonstrates that the semi-crystalline properties of parylene-C, which are enhanced through annealing to improve the crystallinity and Young’s modulus, are effective. Thus, using annealed parylene-C films as a planarization layer provides stable support for textile-based OLEDs, as shown in Fig. 2c.

After confirming that a thin self-supporting planarization layer was successfully formed and enabled stable operation of OLEDs, an additional evaluation was conducted to investigate the mechanical properties and to determine whether it would withstand external mechanical deformations. Given that textiles often experience stress concentrations from body movements or external mechanical deformations, high resilience is required to prevent the planarization layer from breaking and impacting the devices fabricated on top of it. Therefore, it was compared with a SU-8 textile planarization layer used in previous studies16. Firstly, to evaluate the material’s capacity to absorb and release elastic strain energy within the elastic region, which indicates resilience45, the area under the stress-strain curve up to the yield stress was calculated using the following equation46.

To determine the yield strength (σy) and yield strain (εy), the intersecting point between the stress–strain curve and a line parallel to the slope of the linear region, starting at an offset of 0.2%47, was identified, as indicated by the red circles in Fig. 2d (Supplementary Fig. 2b). Additionally, for a comparison with the characteristics of the SU-8 planarization layer used in previous work16, the stress-strain curves measured in previous studies were plotted, as shown in Fig. 2d. The yield strength, yield strain and resilience of parylene-C after annealing were 65 MPa, 1.89%, and 0.63 MPa, respectively, which were ~2.5, 2.45, and 4.5 times higher than those of SU-8, which were 26 MPa, 0.77%, and 0.14 MPa, respectively. These measurements are summarized in Table 1. These results indicate that employing parylene-C instead of SU-8 as a textile planarization layer increases the resilience by ~4.5 times, enhancing the resistance to significant external deformations. This improvement ensures that the material does not easily degrade and maintains a balance between stiffness and reliability, as required for planarization layers, significantly enhancing robustness against bending and wrinkling. The detailed mechanical performance based on these results is explained in Figs. 4 and 5.

In summary, the 3 μm thin parylene-C, after the annealing process, enhanced its Young’s modulus and higher yield strength, thereby increasing the stiffness to create a self-supporting planarization layer that does not follow the roughness of the textile. Additionally, compared to the SU-8 planarization layer used in previous studies16, improved resilience was achieved, allowing the textile planarization layer to withstand various and severe mechanical deformations.

Electrical and optical performance of parylene-C planarization textile-based OLEDs

The textile substrate was fabricated and then used for the thermal deposition of top-emitting red OLEDs. The OLEDs with a micro-cavity effect were composed of several layers, with aluminum (Al) as a cathode, lithium quinolate (Liq) as an electron injection layer, bis(10-hydroxybenzo[h]quinolinato)beryllium (Bebq2) doped with Tris[1-phenylisoquinolinato-C2,N] iridium(III) (Ir(piq)3) at 8 wt% as the red-light-emitting layer, N,N’-bis(naphthalen-1-yl)-N,N’-bis(phenyl) benzidine (NPB) as the hole transport layer, molybdenum trioxide (MoO3) as the hole injection layer, and silver (Ag) as the anode.

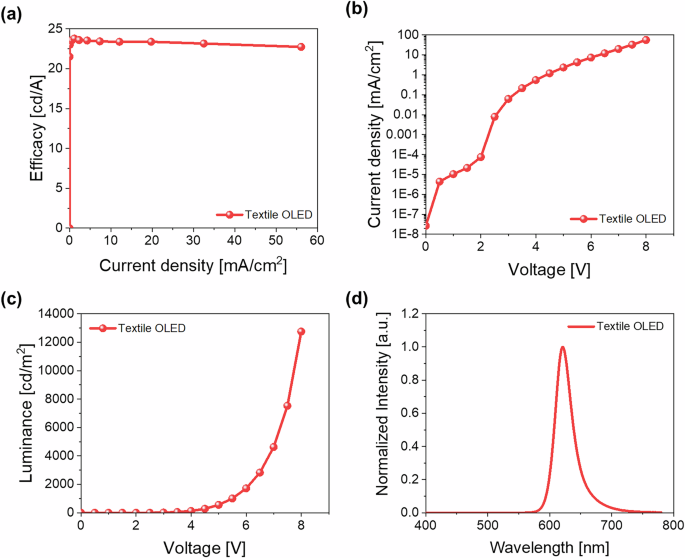

To confirm the light-emitting characteristics, Fig. 3 presents the optical and electrical properties of the optimized textile-based OLEDs with a device area of 9 mm². The micro-cavity structure was optimized using MATLAB-based Transfer Matrix Method (TMM) optical simulations to achieve a peak emission wavelength closely matching the photoluminescence (PL) peak (625 nm) of the dopant Ir(piq)₃. The optimization involved varying the thickness of the hole transport layer (NPB), and while the simulations predicted an optimal thickness of 63 nm, slight experimental deviations during fabrication resulted in the deposition of NPB at 62 nm. As shown in Fig. 3d, the fabricated textile-based OLED exhibited a peak emission wavelength of 623 nm. The optimized textile-based OLED demonstrated optimal performance, achieving a current efficiency of 23.8 cd/A and a maximum luminance of 12,748 cd/m² (Fig. 3a–c). Additionally, to evaluate the comparative performance, the optical and electrical characteristics of the textile-based OLEDs were compared with those of glass-based OLEDs. As shown in Supplementary Fig. 3, both devices exhibited similar optical and electrical properties, indicating that the parylene-C planarization layer effectively adapted to the rough textile surface and provided reliable device performance.

To protect the performance of the fabricated textile-based OLEDs from environmental factors, an encapsulation layer consisting of an Al₂O₃-ZnO nano-stratified layer (30 nm) and a parylene-C film (500 nm) was applied to the top surface of the device. Subsequently, the potential impact of the encapsulation layer on the optical properties of the OLEDs was thoroughly examined (Supplementary Fig. 4). The transmittance of the encapsulation layer slightly decreased compared to bare glass due to minor interference effects but maintained a relatively high level of 85–90% without significant oscillations (Supplementary Fig. 4a). Particularly, in the emission wavelength range of the red OLED (620–630 nm), the transmittance remained around 90%, ensuring that optical losses were negligible. The current density (J)-luminance (L) characteristics (Supplementary Fig. 4b) showed no significant differences in luminance between devices with encapsulation (w/ encapsulation) and without encapsulation (w/o encapsulation), confirming negligible impact on optical performance. Furthermore, angular dependency measurements revealed sub-Lambertian emission characteristics, caused by the cavity structure, rather than the typical Lambertian emission profile, with or without encapsulation having an insignificant influence on the angular characteristics (Supplementary Fig. 4c). This demonstrates that the encapsulation layer does not significantly degrade the optical performance while effectively supporting the stable operation of textile-based OLEDs under real-world application conditions.

To comprehensively evaluate the reliability of the encapsulated textile-based OLEDs, a series of tests were conducted under various environmental conditions (Supplementary Fig. 5). As shown in Supplementary Fig. 5a, the operating lifetime of the devices was measured under continuous wave operation in an ambient environment to assess their durability. The encapsulated OLEDs exhibited an operating lifetime more than five times longer compared to devices without encapsulation, demonstrating the significant effectiveness of the encapsulation structure in enhancing device stability. Following this, further testing was conducted under high-temperature and high-humidity conditions9 (30 °C, 90% RH (relative humidity)), as depicted in Supplementary Fig. 5b. The encapsulated OLEDs maintained 80% of their initial luminance over 160 h, whereas non-encapsulated devices exhibited rapid luminance degradation within the first 40 h, highlighting the critical role of encapsulation in preserving performance under harsh environmental conditions. Lastly, a water-storage test was conducted by immersing the OLEDs in water to evaluate their resistance to moisture and the performance of the encapsulation (Supplementary Fig. 5c). Devices without encapsulation failed immediately due to reactions between the organic layers and water. In contrast, encapsulated devices maintained 60% of their initial luminance for up to 120 h, thereby confirming the robust water and oxygen barrier properties provided by the encapsulation structure. These results collectively demonstrate that the encapsulation structure has negligible impact on the optical properties while effectively protecting the OLEDs from environmental challenges, ensuring their stability and performance under conditions such as prolonged exposure to moisture, ambient operation, and elevated humidity and temperature. This highlights the feasibility of the encapsulation structure for improving the reliability of textile-based OLEDs in real-world applications.

Mechanical performance of parylene-C planarization textile-based OLEDs

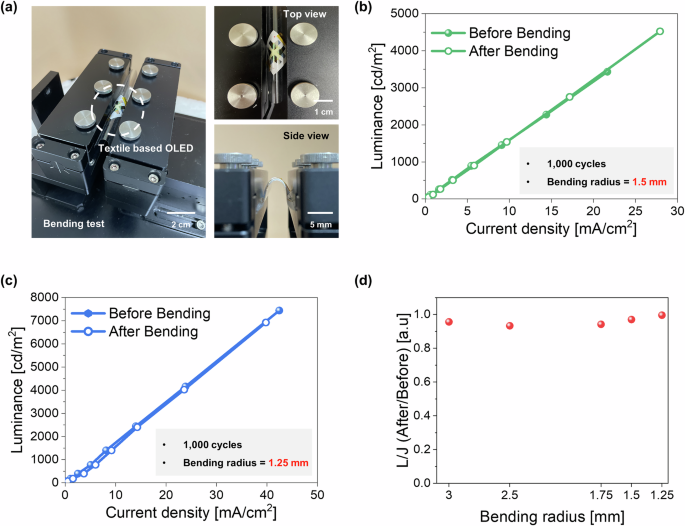

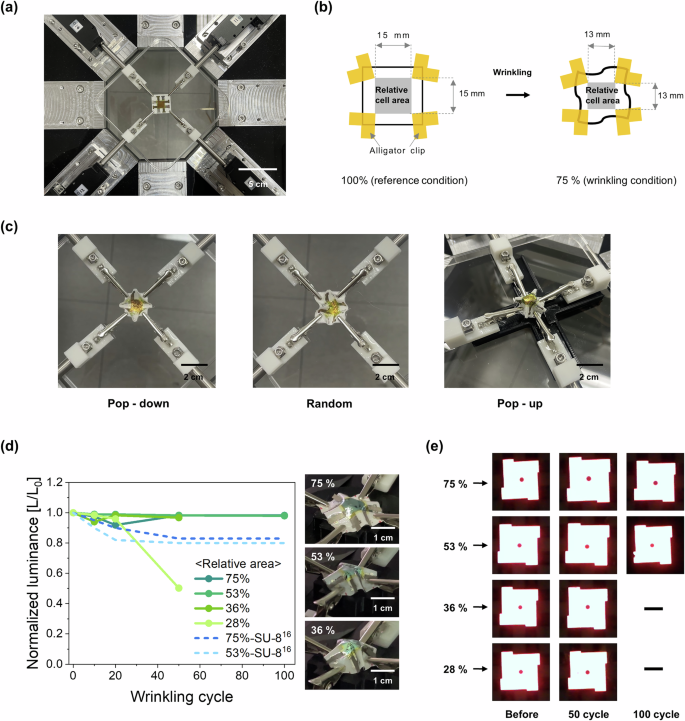

Textiles worn in everyday life have to withstand mechanical deformations such as bending or wrinkling. Therefore, to assess the mechanical reliability of textile-based OLEDs with a parylene-C planarization layer, bending and wrinkling tests were conducted, as shown in Fig. 4 and Fig. 5. The bending test, as shown in Fig. 4a, was implemented by clamping the parylene-C planarization textile-based OLEDs to a bending machine and varying the bending radius over 1000 cycles. Photographic images of the top and side views at a bending radius of 1.25 mm are also presented. The current density (J)-luminance (L) characteristics of the OLEDs before and after 1000 cycles at bending radii of 1.5 mm and 1.25 mm, respectively, indicated no performance degradation, as shown in Fig. 4b, c. Additionally, the bending radius was progressively reduced from 3 mm to 1.25 mm under increasingly harsh conditions, and the OLED characteristics were measured and expressed as the ratio of the luminance to the current density (L/J). The ratio of the luminance to the current density is represented as the slope in the current density-luminance graph in Fig. 4b, c. Identical values before and after bending indicate that the same degree of luminance is achieved at the same current input. Thus, it is confirmed that textile-based OLEDs with bending radii ranging from 3 mm to 1.25 mm exhibit minimal performance changes, thereby demonstrating high mechanical reliability. Additionally, the mechanical properties under multi-directional wrinkling, which can occur randomly due to daily movements, were evaluated (Fig. 5). For the wrinkling test, the devices were fabricated in a large size of 69 mm² to induce maximum deformation. As shown in Fig. 5a and supplementary Fig. 6, a multi-axis tensile test machine was used, with the corners of the textile clamped by alligator clips. The relative cell area was reduced by moving the clips toward the center. The detailed method, illustrated in Fig. 5b, involved starting with an initial cell area of 225 mm² set as 100% and progressively reducing the relative cell area due to wrinkling until it reached 28%. The wrinkled textile deformed into various shapes such as pop-down, random, and pop-up shapes, instead of uniformly bending (Fig. 5c). The wrinkling test was repeated 100 times, and the results are shown in Fig. 5d and Fig. 5e. After the wrinkling test, with the relative cell area decreased from 75% to 53%, no change in the luminance was observed after 100 cycles. However, for the SU-8 planarization layer utilized in previous studies16, as indicated by the dotted line, a slight initial decrease in the luminance was observed during wrinkling cycles, but it remained stable up to 100 cycles, with no measurements reported for more severe wrinkling. On the other hand, for the textile-based OLEDs using the parylene-C planarization layer, when the relative cell area decreased to 36%, the device maintained its performance for up to 50 cycles but ceased to operate after further repeated wrinkling. Moreover, at a relative cell area of 28%, the luminance decreased by more than 50% after 50 cycles and subsequently ceased to function. As depicted in the photographic images on the right in Fig. 5d, more significant deformations occurred as the relative cell area was decreased. Wrinkling induced a non-uniform strain distribution and concentrating high strain in localized areas, degrading the performance16. The emission images of OLEDs after each wrinkling cycle and at various relative areas are presented in Fig. 5e. These results validate that the enhanced resilience, as previously discussed, allows for greater deformation within the elastic region, thereby increasing the resistance to deformation. This confirms that textile-based OLEDs with a parylene-C planarization layer can maintain stable operation under extreme deformations, not only due to body movements and bending in everyday life but also under more severe mechanical deformations.

a Photographs (top and side view) of the textile-based OLEDs during repetitive bending with a 1.25 mm curvature radius. Current density (J)-luminance (L) graph according to a repetitive bending test of the textile-based OLEDs before and after bending under a bending radius of (b) 1.5 mm and (c) 1.25 mm, 1000 cycles, respectively. d Ratio of the luminance to the current density (the slope in the current density- luminance graph) at bending radii ranging from 3 mm to 1.25 mm.

a Photograph of the multi-axis tensile test machine used for the multi-directional wrinkling test. b Schematic image of the wrinkling test condition according to the relative cell area (reference condition: relative area 100% and wrinkling condition: relative area 75–28%). c Photograph of various wrinkled shapes (left: pop-down, middle: random, and right: pop-up). d Normalized luminance of the repetitive wrinkling cycle of parylene-C textile in this study (solid line) and SU-8 textile in a previous study (dotted line)16, the initial luminance: 1000 nit. e Photograph of a parylene-C textile-based OLED cell after wrinkling (relative area: 75, 53, 36 and 28%, wrinkling cycles: 0 (before), 50 and 100 cycles).

Additionally, the mechanical performance of textile-based OLEDs under stretching conditions, along with bending and wrinkling tests, was evaluated. As shown in Supplementary Fig. 7b, the device retained over 70% of its initial efficacy under a 4% stretching strain, despite a slight efficiency reduction attributed to current aggregation, while luminance remained stable. However, as shown in Supplementary Fig. 7a, cracks were observed under strains exceeding 5%, resulting in device failure. While the stretchability of the proposed device is currently limited, these results demonstrate that its performance exceeds the reported stretching limit (~1%) of conventional encapsulation technologies48. This suggests that the proposed technology provides relatively greater stretching tolerance, even with 100% polyester textiles that inherently lack significant stretchability. These findings indicate that, in its current form, the proposed textile OLED technology is more suitable for applications where flexibility and mechanical stability take precedence over stretchability, such as healthcare, wearable displays, and fashion devices. Furthermore, this study highlights the potential for future improvements in stretchability through techniques such as reactive ion etching (RIE)-based patterning of the planarization layer, paving the way for advanced stretchable OLED technologies.

Demonstration of textile-based OLEDs

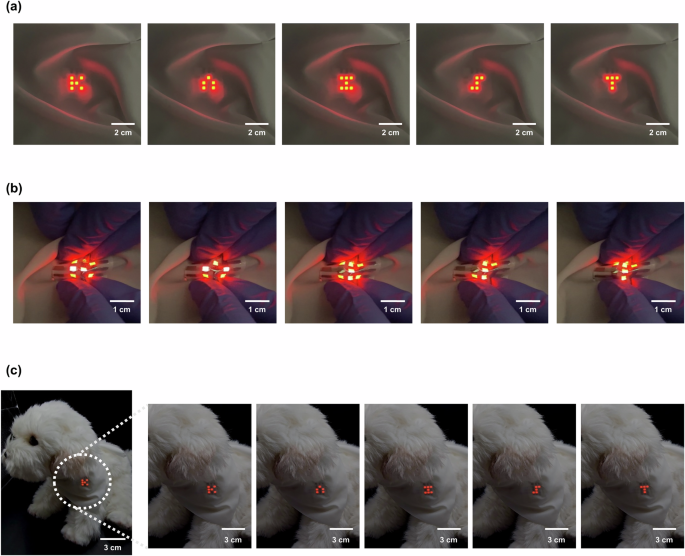

In this study, textile-based OLEDs were fabricated directly onto textile with a parylene-C planarization layer using a top-emission structure. These OLEDs can be utilized in two configurations. First, as shown in Supplementary Fig. 8a, light is emitted directly into the air, resulting in clear and bright emission, although the wiring lines and electrodes remain exposed due to the deposition process. Second, as depicted in Supplementary Fig. 8b, a sandwich structure is employed where an additional bare textile is placed over the pre-fabricated textile-based OLED, allowing the light to pass through the textile. This configuration conceals the wiring lines and electrodes but may cause light diffusion or an intensity reduction. Both modes were demonstrated in this study. To demonstrate an actual textile-OLED display, a 3 × 3 textile-based OLED array was arranged to display the letters “KAIST,” as shown in Fig. 6. A microcontroller unit (MCU, Arduino Uno) was connected to the textile-based OLED to enable passive matrix control, and the device was driven using a line-scanning method at 5 V. In Fig. 6a, a sandwich structure was created by adding a bare textile layer on top of the fabricated textile-based OLED to prevent exposure of the electrodes and wiring lines. This structure ensures a very neat appearance by completely concealing the wiring, although some light diffusion was observed due to the light passing through the textile. In contrast, the light from the OLEDs was emitted directly without an additional textile layer in Fig. 6b, similar to the structure shown in supplementary Fig. 8a, demonstrating stable operation even when the textile was wrinkled beyond natural folds (supplementary Movie S1). Lastly, a dog’s scarf was used to demonstrate the potential for practical applications in fashion displays (Fig. 6c, supplementary Movie S2). The scarf was placed around the neck of a stuffed dog, displaying desired text via passive matrix driving, similar to that shown in Fig. 6a, b. This textile display can present a range of information such as names, the weather, and the time, confirming its capability as a true wearing display that operates stably even under extreme wrinkling without causing discomfort.

The proposed textile-based OLED technology is not only suitable for fashion displays but also shows great potential for other practical applications. For instance, it can be applied to wearable healthcare devices and phototherapy. By replacing conventional heavy and rigid point light sources, lightweight, flexible, and comfortable textile-based OLED masks have been demonstrated as an ideal solution for phototherapy49. These masks emit specific wavelengths of light, offering promising results for skincare and treatment while ensuring user comfort and accessibility. Moreover, the proposed OLED technology holds significant potential in the field of healthcare. Devices measuring biometric data such as heart rate and oxygen saturation can be integrated with textile-based displays to provide real-time feedback directly on the textile. This integration represents a user-friendly platform that combines convenience with efficiency, paving the way for advanced wearable healthcare systems. Additionally, the fabrication method proposed in this study supports scalability for large-area displays. As shown in Supplementary Fig. 9, OLEDs exceeding 4225 mm² were successfully fabricated using laboratory-scale deposition equipment, demonstrating stable operation. These results indicate that the textile substrate possesses high flatness and mechanical stability even under bending conditions. This scalability suggests the potential for industrial-scale production using advanced deposition systems, enabling broader applications in large-area displays.

To further validate the practicality of the proposed textile-based OLEDs, thermal performance was evaluated under various luminance conditions (Supplementary Fig. 10). PM-driving was conducted at 5 V with a 3 × 3 OLED array, and additional thermal evaluations were performed across a wide range of luminance levels to simulate practical usage scenarios. Operating temperatures were assessed at typical luminance levels (300–500 nit), outdoor visibility levels (1000 nit), and maximum luminance (5000 nit). The corresponding operating voltages were 4.5 V, 5 V, 5.5 V, and 7 V, respectively. Using a thermal imaging camera (FOTRIC, 228GRD), temperature changes were measured under continuous driving operation. The results showed that temperatures stabilized within 5 min under all conditions. Specifically, at 300–500 nit, the temperature increased by less than 1 °C (Supplementary Fig. 10a, Supplementary Fig. 10b). At 1000 nit, the temperature rose by ~3 °C, stabilizing at 21.5 °C (Supplementary Fig. 10c). At the maximum luminance of 5000 nit, the temperature reached 35 °C (Supplementary Fig. 10d), which remains below the 40 °C threshold for low-temperature burns during skin contact. These results confirm that the textile-based OLED maintains stable thermal performance even at high luminance levels, ensuring user safety. In conclusion, the proposed textile-based OLED technology demonstrates versatility across various fields such as fashion, healthcare, and phototherapy. Its stable operation under wearable conditions, scalability for industrial-scale applications, and demonstrated safety at high luminance levels underline the potential of this technology to revolutionize wearable electronics and enable innovative solutions in various domains.

Discussion

In summary, an advanced and highly reliable textile display that utilizes a parylene-C planarization layer has been demonstrated, which has both biocompatible and semi-crystalline polymer properties. First, thermal annealing of the parylene-C layer increases its crystallinity due to relaxation and rearrangement in the amorphous regions of the polymer. This process enhances the stiffness of parylene-C, enabling its use as a thin self-supporting planarization layer that does not collapse according to the weave pattern of the textile surface. Additionally, it has been shown that a physically smooth surface with sub-nanometer roughness can be created through a simple transfer process, without immersion in water or the use of chemical substances. The fabricated textile-based OLEDs exhibited stable operation, with luminance of 12,748 cd/m2 and current efficiency of 23.8 cd/A, demonstrating their suitability for use in wearing display applications. Furthermore, relatively high resilience was achieved, defined as the maximum energy that can be absorbed per unit volume in the elastic region. This resilience allows the OLEDs to withstand extreme mechanical deformations including bending and multi-directional wrinkling similar to real movement in everyday life. Consequently, this study demonstrates that by using parylene-C as a planarization layer, a balance is achieved between enhanced stiffness due to thermal annealing and the material’s inherent resilience, allowing the successful fabrication of textile-based OLEDs that operate stably and withstand extreme deformations. In addition, this study presents a comparative analysis with previously reported textile-based display technologies, as shown in Supplementary Table 1, and demonstrates superior performance in various aspects. These include the implementation of an ultra-thin 3 μm planarization layer while simultaneously achieving high mechanical stability and large-area operation. This development suggests the potential application of textile-based electronic devices across various industries, particularly in the fashion, automotive, and biomedical fields. The successful demonstration of innovative wearing displays highlights the feasibility of integrating advanced technologies into textiles, potentially heralding a new era of true wearing devices.

Methods

Fabrication of the textile platform

First, a 10 cm × 10 cm guide glass was rinsed in deionized water, after which sacrificial, planarization, and adhesive layers were sequentially deposited on it. Then, the textile was directly attached to the adhesive-coated side and cured, followed by the removal of the planarization layer from the guide glass to fabricate the textile platform. The sacrificial layer, Novec™ 1700 Electronic Grade Coating by 3 M™, was spin-coated at 2000 rpm for 30 s and cured at 100 °C for 3 min. Next, a 3 μm parylene-C film was deposited through CVD equipment and annealed at 150 °C for 1 h to enhance the crystallinity. Finally, the adhesive layer, a Si-based elastomeric room-temperature vulcanizing (RTV) layer, was spin-coated at 4000 rpm for 60 s to a thickness of ~19 μm, and was then attached to a 100% polyester textile. Subsequently, applying uniform pressure with a force of 10 N, the assembly was cured at room temperature for over 5 h after easily removing parylene-C from the guide glass to produce the textile platform.

Measurement of parylene-C characteristics

Tensile tests were conducted to evaluate the mechanical properties of parylene-C in accordance with ASTM D3039 using a universal tensile machine (Sciencetown Inc). A fluorinated polymer was initially coated onto a 13 cm × 13 cm bare glass substrate, and a 17 μm thick parylene-C layer was then deposited via CVD. To compare the effects of annealing, one sample was treated with thermal annealing at 150 °C for 1 h, while another sample was left unannealed. Each parylene-C film was cut into 11 cm × 1 cm strips, removed from the glass, and clamped at the edges with ~0.5 cm fixed in a jig. The samples were subjected to tensile testing at a rate of 10 mm/min, measuring the distance and force applied by the load cell. These measurements were then converted into strain and stress values. Additionally, to verify the enhancement in the crystallinity through annealing, the crystal structure and size of the parylene-C films were measured using a high-resolution powder X-ray diffractometer (SmartLab, RIGAKU Inc.) with the Theta-2theta method.

OLED fabrication and measurement

Both the glass and textile utilized an inverted structure, and top-emission OLEDs were thermally evaporated. The structure of the red-colored OLEDs consisted of Al (100 nm), Liq (1 nm), Bebq2 doped with Ir(piq)3 at 8 wt% (70 nm), NPB (62 nm), MoO3 (5 nm), and Ag (30 nm). Additionally, OLED devices were fabricated in sizes of either 9 mm² or 69 mm² depending on the situation. All devices were encapsulated with an Al2O3/ZnO nano-stratified structure using the atomic layer deposition (ALD) process at 70 °C. Also, the current density–voltage–luminance (J–V–L) characteristics of the OLEDs were measured using a source measurement unit (Keithley 2400) and a spectro-radiometer (CS2000, Konica Minolta Inc.).

Cantilever test

The cantilever test is a simple method for measuring the flexural rigidity of textiles. The textile is manufactured in a form that is relatively wider than it is tall, with one end fixed and the other end left free. The length at which the textile touches an inclined surface is measured to determine its flexural rigidity. The cantilever tests were conducted according to the international standard, American Society for Testing and Materials (ASTM D:1388).

Bending and wrinkling test

A bending test machine (Sciencetown Inc.) was utilized to evaluate the flexibility through specific bending radii and repetitive bending. Additionally, a multi-axis tensile test machine was employed for wrinkling tests, which was constructed in our laboratory using an L12-30F-6 micro linear actuator controlled by Arduino. As detailed in Fig. 5b, the motor moved diagonally in the center direction by \(\sqrt{2}\) for each horizontal and vertical length reduction of 1 mm, progressively reducing the relative cell area.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Mishra, S. et al. Soft, wireless periocular wearable electronics for real-time detection of eye vergence in a virtual reality toward mobile eye therapies. Sci. Adv. 6, 1–11 (2020).

Kwon, S. et al. Recent progress of fiber shaped lighting devices for smart display applications—a fibertronic perspective. Adv. Mater. 32, 1–25 (2020).

Shi, X. et al. Large-area display textiles integrated with functional systems. Nature 591, 240–245 (2021).

Yokota, T. et al. Ultraflexible organic photonic skin. Sci. Adv. 2, 1–8 (2016).

Jeon, Y. et al. Sandwich-structure transferable free-form OLEDs for wearable and disposable skin wound photomedicine. Light Sci. Appl. 8, 114 (2019).

Choi, S. et al. Wearable photomedicine for neonatal jaundice treatment using blue organic light-emitting diodes (OLEDs): toward textile-based wearable phototherapeutics. Adv. Sci. 9, 1–10 (2022).

Lee, J. et al. RGB-color textile-based flexible and transparent OLEDs considering aesthetics. Adv. Mater. Interfaces 10, (2023).

Hwang, Y. H. et al. Organic light-emitting fibers and fabrics for truly wearable smart displays: Recent progress and future opportunities. J. Soc. Inf. Disp. 30, 727–747 (2022).

Jeong, S. Y. et al. Foldable and washable textile-based OLEDs with a multi-functional near-room-temperature encapsulation layer for smart e-textiles. npj Flex. Electron. 5, 1–9 (2021).

Cochrane, C., Koncar, V., Lewandowski, M. & Dufour, C. Design and development of a flexible strain sensor. Sensors 7, 473–492 (2007).

Trung, T. Q. et al. Freestanding, fiber-based, wearable temperature sensor with tunable thermal index for healthcare monitoring. Adv. Healthc. Mater. 7, 1–9 (2018).

Lv, J. et al. Sweat-based wearable energy harvesting-storage hybrid textile devices. Energy Environ. Sci. 11, 3431–3442 (2018).

Huang, Q., Wang, D. & Zheng, Z. Textile-based electrochemical energy storage devices. Adv. Energy Mater. 6, 1–28 (2016).

Jeong, E. G., Jeon, Y., Cho, S. H. & Choi, K. C. Textile-based washable polymer solar cells for optoelectronic modules: Toward self-powered smart clothing. Energy Environ. Sci. 12, 1878–1889 (2019).

Hwang, Y. H. et al. High-performance and reliable white organic light-emitting fibers for truly wearable textile displays. Adv. Sci. 9, 1–10 (2022).

Choi, S. et al. Multi-directionally wrinkle-able textile OLEDs for clothing-type displays. npj Flex. Electron. 4, 1–9 (2020).

Cherenack, K., & Van Pieterson, L. Smart textiles: challenges and opportunities. J. Appl. Phys. 112, 091301 (2012).

Parkova, I. & Viļumsone, A. Functional and aesthetic design of woven electro-textile fabrics. J. Text. Apparel Technol. Manag. 8, 3 (2013).

Hu, B. et al. Textile-based flexible electroluminescent devices. Adv. Funct. Mater. 21, 305–311 (2011).

Hu, B. et al. CNT/conducting polymer composite conductors impart high flexibility to textile electroluminescent devices. J. Mater. Chem. 22, 1598–1605 (2012).

Wu, Y., Mechael, S. S., Chen, Y. & Carmichael, T. B. Solution deposition of conformal gold coatings on knitted fabric for e-textiles and electroluminescent clothing. Adv. Mater. Technol. 3, 1–7 (2018).

Hwang, Y. H. et al. Bright-multicolor, highly efficient, and addressable phosphorescent organic light-emitting fibers: toward wearable textile information displays. Adv. Funct. Mater. 31, 1–10 (2021).

Kong, S. U. et al. Anode-patterned monorail-structure fiber-based organic light-emitting diodes with long lifetime and high performance for truly wearable displays. Adv. Opt. Mater. 11, 1–9 (2023).

Song, Y. J. et al. Fibertronic organic light-emitting diodes toward fully addressable, environmentally robust, wearable displays. ACS Nano 14, 1133–1140 (2020).

Kwon, S. et al. Weavable and highly efficient organic light-emitting fibers for wearable electronics: a scalable, low-temperature process. Nano Lett. 18, 347–356 (2018).

Kim, J. S. & Song, C. K. Textile display with AMOLED using a stacked-pixel structure on a polyethylene terephthalate fabric substrate. Materials12, 2000 (2019).

Choi, S. et al. Highly flexible and efficient fabric-based organic light-emitting devices for clothing-shaped wearable displays. Sci. Rep. 7, 1–8 (2017).

Kim, W. et al. Soft fabric-based flexible organic light-emitting diodes. Org. Electron. 14, 3007–3013 (2013).

Jackson, N. et al. Crystallinity and mechanical effects from annealing Parylene thin films. Thin Solid Films 603, 371–376 (2016).

Kim, B. J., Chen, B., Gupta, M. & Meng, E. Formation of three-dimensional Parylene C structures via thermoforming. J. Micromech. Microeng. 24, 065003 (2014).

Golda-Cepa, M., Engvall, K., Hakkarainen, M. & Kotarba, A. Recent progress on parylene C polymer for biomedical applications: a review. Prog. Org. Coat. 140, 105493 (2020).

Hsu, J. M., Rieth, L., Kammer, S., Orthner, M. & Solzbacher, F. Effect of thermal and deposition processes on surface morphology, crystallinity, and adhesion of Parylene-C. Sens. Mater. 20, 87–102 (2008).

Keum, C. et al. A substrateless, flexible, and water-resistant organic light-emitting diode. Nat. Commun. 11, 1–9 (2020).

Lee, D. et al. Stretchable OLEDs based on a hidden active area for high fill factor and resolution compensation. Nat. Commun. 15, 1–13 (2024).

Jean, J., Wang, A. & Bulović, V. In situ vapor-deposited parylene substrates for ultra-thin, lightweight organic solar cells. Org. Electron. 31, 120–126 (2016).

Sim, J. H., Chae, H., Kim, S. B. & Yoo, S. Simple and practical methods for utilizing parylene C film based on vertical deposition and laser patterning. Sci. Rep. 12, 1–8 (2022).

Jeong, E. G., Han, Y. C., Im, H. G., Bae, B. S. & Choi, K. C. Highly reliable hybrid nano-stratified moisture barrier for encapsulating flexible OLEDs. Org. Electron. 33, 150–155 (2016).

Ortigoza-Diaz, J. et al. Techniques and considerations in the microfabrication of parylene c microelectromechanical systems. Micromachines 9, 422 (2018).

Lecomte, A., Degache, A., Descamps, E., Dahan, L. & Bergaud, C. In vitro and in vivo biostability assessment of chronically-implanted Parylene C neural sensors. Sens. Actuators B Chem 251, 1001–1008 (2017).

Lecomte, A. et al. Deep plasma etching of Parylene C patterns for biomedical applications. Microelectron. Eng. 177, 70–73 (2017).

Song, Q. et al. A new method for polydimethylsiloxane (PDMS) microfluidic chips to maintain vacuum-driven power using Parylene C. Sens. Actuators B Chem. 256, 1122–1130 (2018).

Wu, J. et al. Efficient multi-barrier thin film encapsulation of OLED using alternating Al2O3 and polymer layers. RSC Adv. 8, 5721–5727 (2018).

Vinodhini, P. A. et al. FTIR, XRD and DSC studies of nanochitosan, cellulose acetate and polyethylene glycol blend ultrafiltration membranes. Int. J. Biol. Macromol. 104, 1721–1729 (2017).

Doumeng, M. et al. A comparative study of the crystallinity of polyetheretherketone by using density, DSC, XRD, and Raman spectroscopy techniques. Polym. Test. 93, (2021).

Guha, S. Quantification of inherent energy resilience of process systems pertaining to a gas sweetening unit. Int. J. Ind. Chem. 11, 71–90 (2020).

Huda, Z. Mechanical Behavior of Materials. Fundamentals, Analysis, and Calculations (Springer, 2022).

Faridmehr, I. et al. Correlation between engineering stress-strain and true stress-strain curve. Am. J. Civ. Eng. Archit. 2, 53–59 (2014).

Zhang, Y. et al. Stretchable PDMS encapsulation via SiO2 doping and atomic layer infiltration for flexible displays. Adv. Mater. Interfaces 9, 1–9 (2022).

Lee, J. et al. Analytic modeling and validation of strain in textile-based OLEDs for advanced textile display technologies. npj Flex. Electron. 8, 1–14 (2024).

Acknowledgements

This work was supported by the Technology Innovation Program (20018379, Development of high-reliability light-emitting fiber-based woven wearable displays) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea). This work was supported by the Technology Innovation Program (20017569, Development of substrate materials that can be stretched more than 50% for stretchable displays) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea). This work was supported by BK21 FOUR (Connected AI Education & Research Program for Industry and Society Innovation, KAIST EE, No. 4120200113769).

Author information

Authors and Affiliations

Contributions

K.C.C. supervised the manuscript. H.-E.C. optimized and analyzed the characteristics of the planarization layer and textile-based OLEDs. M.J.K. and J.C. characterized the textile's mechanical properties through tensile testing and XRD analysis. J.A. fabricated the textile-based OLEDs. Y.N., S.C. and S.Y.J. assisted with the optimization of the textile substrate. H.-E.C. participated in the preparation of the manuscript. All authors discussed the experimental results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cho, HE., Kim, M.J., Chang, J. et al. Advanced textile-based OLEDs utilizing parylene-C planarization for enhanced flexibility and stability in true wearing displays. npj Flex Electron 9, 36 (2025). https://doi.org/10.1038/s41528-025-00413-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41528-025-00413-8

This article is cited by

-

Wearable textile-based phototherapy platform with customized NIR OLEDs toward non-invasive hair loss treatment

Nature Communications (2026)